Submitted:

12 August 2023

Posted:

14 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

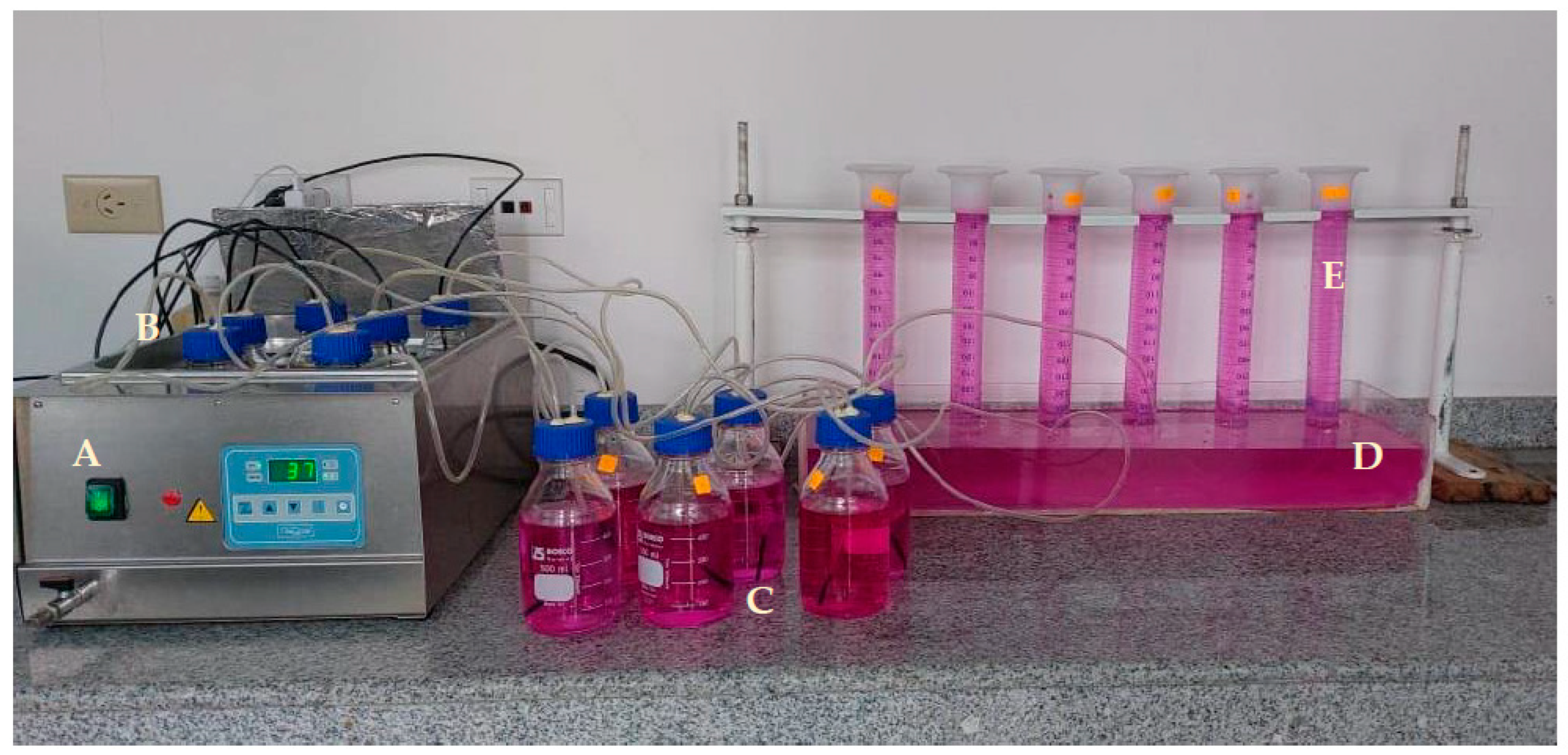

2. Materials and Methods

2.1. Raw materials used

2.2. Physico-chemical characterisation

2.3. Experimental procedure

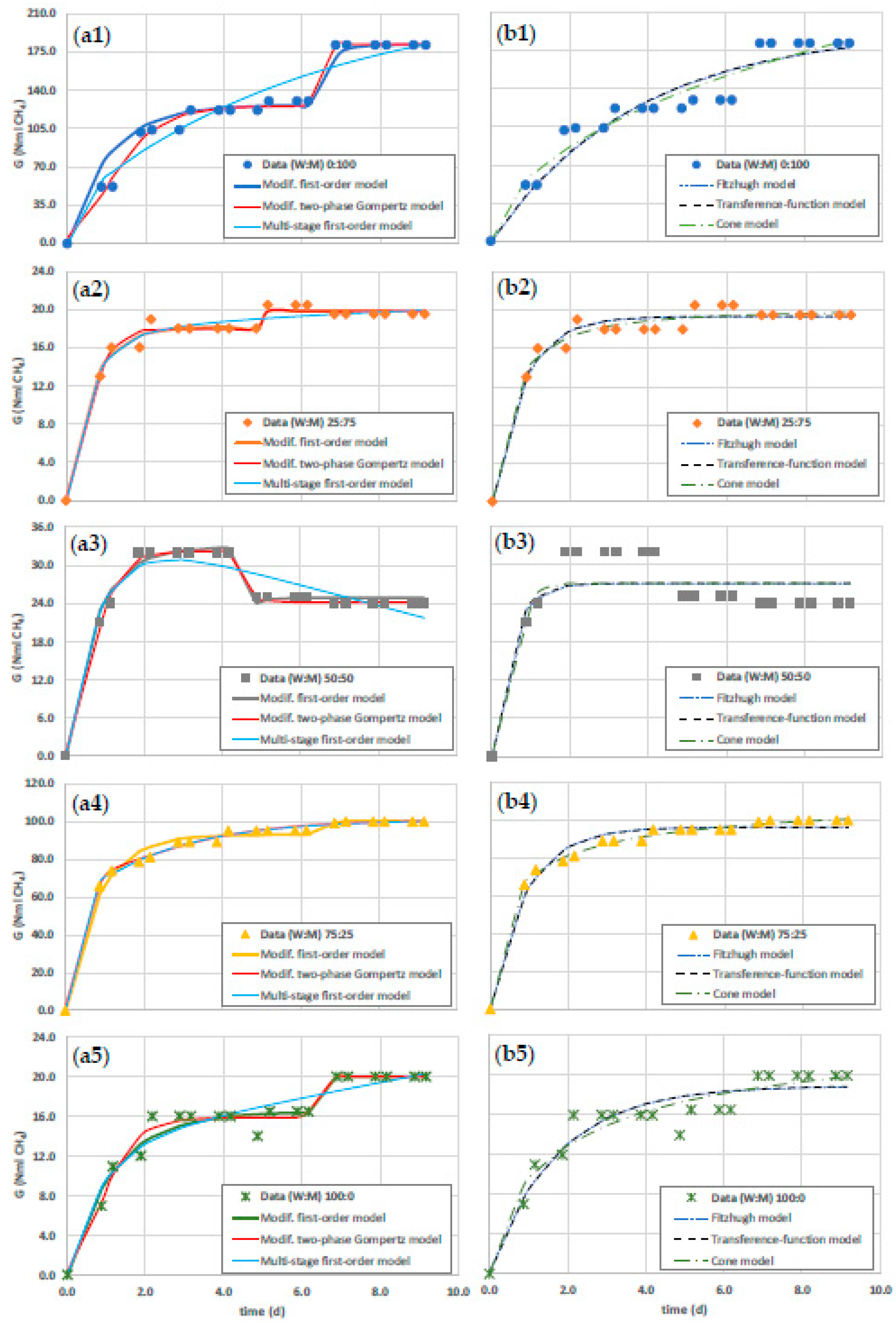

2.4. Kinetic model for the anaerobic co-digestion mixes of whey and molasses

2.5. Statistical Comparison of Models

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Araújo, R.G.; Chavez-Santoscoy, R.A.; Parra-Saldívar, R.; Melchor-Martínez, E.M.; Iqbal, H.M.N. Agro-food systems and environment: Sustaining the unsustainable. Curr. Opin. Environ. Sci. Heal. 2023, 31. [Google Scholar] [CrossRef]

- Peralta, A. Eficiencia en la producción lechera. In Proceedings of the VIII Foro del Sector Lechero Ecuatoriano. Estrategias para mejorar el consumo de lácteos en la población.; Centro de la Industria Láctea (CIL): Quito, 2017; p. 20. [Google Scholar]

- Pais Chanfrau, J.M.; Núñez Pérez, J.; Lara Fiallos, M. V; Rivera Intriago, L.M.; Abril Porras, V.H.; Cuaran Guerrero, M.J.; Trujillo Toledo, L.E. Milk whey-from a problematic byproduct to a source of valuable products. Prensa Med. Argent 2017, 103, 1. [Google Scholar]

- Sánches, A.; Vayas, T.; Mayorga, F.; Freire, C. Sector Azucarero del Ecuador. Obs. Econ. y Soc. Tunguragua 2018. [Google Scholar]

- Alghoul, O.; El-Hassan, Z.; Ramadan, M.; Olabi, A.G. Experimental investigation on the production of biogas from waste food. Energy Sources, Part A Recover. Util. Environ. Eff. 2019, 41. [Google Scholar] [CrossRef]

- López González, L.M.; Pereda Reyes, I.; Romero Romero, O. Anaerobic co-digestion of sugarcane press mud with vinasse on methane yield. Waste Manag. 2017, 68. [Google Scholar] [CrossRef] [PubMed]

- Zeller, V.; Lavigne, C.; D’Ans, P.; Towa, E.; Achten, W.M.J. Assessing the environmental performance for more local and more circular biowaste management options at city-region level. Sci. Total Environ. 2020, 745. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174. [Google Scholar] [CrossRef]

- Rao, P.V.; Baral, S.S.; Dey, R.; Mutnuri, S. Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew. Sustain. Energy Rev. 2010. [Google Scholar] [CrossRef]

- Rice, E.; Baird, R.; Eaton, A.; Clesceri, L. Standard Methods for the Examination of Water and Wastewater. Stand. Methods 2012. [Google Scholar]

- Pagés Díaz, J.; Pereda Reyes, I.; Lundin, M.; Sárvári Horváth, I. Co-digestion of different waste mixtures from agro-industrial activities: Kinetic evaluation and synergetic effects. Bioresour. Technol. 2011, 102. [Google Scholar] [CrossRef] [PubMed]

- Montesdeoca-Pichucho, N.B.; Garibaldi-Alcívar, K.; Baquerizo-Crespo, R.J.; Gómez-Salcedo, Y.; Pérez-Ones, O.; Pereda-Reyes, I. Synergistic and antagonistic effects in anaerobic co-digestion. Analysis of the methane yield kinetics. Rev. Fac. Ing. Univ. Antioquia 2022. [Google Scholar] [CrossRef]

- Gomes, C.S.; Strangfeld, M.; Meyer, M. Diauxie studies in biogas production from gelatin and adaptation of the modified gompertz model: Two-phase gompertz model. Appl. Sci. 2021, 11. [Google Scholar] [CrossRef]

- Lima, D.R.S.; Adarme, O.F.H.; Baêta, B.E.L.; Gurgel, L.V.A.; de Aquino, S.F. Influence of different thermal pretreatments and inoculum selection on the biomethanation of sugarcane bagasse by solid-state anaerobic digestion: A kinetic analysis. Ind. Crops Prod. 2018, 111. [Google Scholar] [CrossRef]

- Pitt, R.E.; Cross, T.L.; Pell, A.N.; Schofield, P.; Doane, P.H. Use of in vitro gas production models in ruminal kinetics. Math. Biosci. 1999, 159. [Google Scholar] [CrossRef] [PubMed]

- Venkateshkumar, R.; Shanmugam, S.; Veerappan, A. Anaerobic co-digestion of cow dung and cotton seed hull with different blend ratio: experimental and kinetic study. Biomass Convers. Biorefinery 2022, 12. [Google Scholar] [CrossRef]

- Jhunjhunwala, U.; Padhi, S.K.; Pattanaik, L.; Sharma, D.; Kumar, A.; Chaudhary, P.; Saxena, V. Anaerobic co-digestion of food waste and waste activated sludge for methane production: Evaluation of optimum ratio, microbial analysis, and kinetic modeling. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Redzwan, G.; Banks, C. The use of a specific function to estimate maximum methane production in a batch-fed anaerobic reactor. J. Chem. Technol. Biotechnol. 2004, 79. [Google Scholar] [CrossRef]

- Groot, J.C.J.; Cone, J.W.; Williams, B.A.; Debersaques, F.M.A.; Lantinga, E.A. Multiphasic analysis of gas production kinetics for in vitro fermentation of ruminant feeds. Anim. Feed Sci. Technol. 1996, 64, 77–89. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Fox, R.L.; Ratner, M.W. Nonlinear optimization using the generalized reduced gradient method. RAIRO Oper. Res. 1974, 8, 73–103. [Google Scholar] [CrossRef]

- Morais, N.W.S.; Coelho, M.M.H.; de Oliveira, M.G.; Mourão, J.M.M.; Pereira, E.L.; dos Santos, A.B. Kinetic Study of Methanization Process Through Mathematical Modeling in Biochemical Methane Potential Assays from Four Different Inoculants. Water. Air. Soil Pollut. 2021, 232. [Google Scholar] [CrossRef]

- Akaike, H. A New Look at the Statistical Model Identification. IEEE Trans. Automat. Contr. 1974, 19. [Google Scholar] [CrossRef]

- Chai, A.; Wong, Y.S.; Ong, S.A.; Lutpi, N.A.; Sam, S.T.; Kee, W.C.; Eng, K.M. Kinetic model discrimination on the biogas production in thermophilic co-digestion of sugarcane vinasse and water hyacinth. Environ. Sci. Pollut. Res. 2022, 29. [Google Scholar] [CrossRef] [PubMed]

- Roubinek, O.K.; Wilinska-Lisowska, A.; Jasinska, M.; Chmielewski, A.G.; Czerwionka, K. Production of Biogas from Distillation Residue as a Waste Material from the Distillery Industry in Poland. Energies 2023, 16. [Google Scholar] [CrossRef]

- AL-Huqail, A.A.; Kumar, V.; Kumar, R.; Eid, E.M.; Taher, M.A.; Adelodun, B.; Abou Fayssal, S.; Mioč, B.; Držaić, V.; Goala, M.; et al. Sustainable Valorization of Four Types of Fruit Peel Waste for Biogas Recovery and Use of Digestate for Radish (Raphanus sativus L. cv. Pusa Himani) Cultivation. Sustain. 2022, 14. [Google Scholar] [CrossRef]

- Hassan, M.; Anwar, M.; Sarup Singh, R.; Zhao, C.; Mehryar, E. Co-digestion of chicken manure with goose manure and thermo-oxidative-treated wheat straw in CSTR: co-digestion synergistics and OLR optimization through kinetic modeling. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Khatun, M.L.; Nime, J.; Nandi, R.; Alam, M.M.; Saha, C.K. Co-digestion of poultry droppings and banana waste for maximizing biogas production in Bangladesh. Fuel 2023, 346. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements. opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas. methods. instructions or products referred to in the content. |

| Models | Parameters | Mix (W:M) | ||||

| 0:100 | 25:75 | 50:50 | 75:25 | 100:0 | ||

| Modif. first-order (f = 5) Equation (2) |

Gm1, Nml CH4 | 127.00 | 18.21 | 32.90 | 92.86 | 16.47 |

| k01, d-1 | 0.95 | 1.55 | 1.37 | 1.25 | 0.86 | |

| Gm2, Nml CH4 | 182.00 | 19.83 | 24.90 | 100.00 | 20.00 | |

| k02, d-1 | 3.92 | 32.18 | 4.72 | 12.53 | 12.65 | |

| td, d | 6.17 | 4.80 | 4.17 | 6.51 | 6.21 | |

| R², - | 0.949 | 0.983 | 0.979 | 0.986 | 0.966 | |

| NRMSE, % | 5.59% | 2.84% | 3.17% | 2.62% | 4.48% | |

| AICC, - | 102.75 | -5.95 | 15.12 | 51.24 | 10.44 | |

| Modif. two-phase Gompertz (f = 6) Equation (3) |

Gm1, Nml CH4 | 125.71 | 1.90 | 32.30 | 66.89 | 15.90 |

| Rm1, Nml CH4·d-1 | 59.39 | 35.66 | 28.95 | 159.11 | 10.80 | |

| λ1, d | 0.13 | 4.88 | 0.16 | 0.39 | 0.20 | |

| Gm2, Nml CH4 | 56.31 | 17.94 | -8.02 | 33.45 | 4.10 | |

| Rm2, Nml CH4·d-1 | 251.23 | 20.22 | -13.43 | 6.90 | 18.10 | |

| λ2, d | 6.16 | 0.18 | 4.20 | 0.00 | 6.14 | |

| R², - | 0.990 | 0.983 | 0.993 | 0.995 | 0.975 | |

| NRMSE, % | 2.66% | 2.81% | 1.86% | 1.48% | 3.85% | |

| AICC, - | 78.94 | -2.02 | -0.68 | 33.90 | 9.11 | |

| Multi-stage first-order (f = 5) Equation (4) |

Gm1, Nml CH4 | 193.22 | 3.99 | 36.66 | 47.91 | 49.88 |

| k01, d-1 | 0.16 | 0.15 | 1.20 | 0.42 | 0.02 | |

| Gm2, Nml CH4 | 1.10 | 10.22 | 1013.16 | 25.60 | 6.38 | |

| k02, d-1 | 3.50 | 1.67 | 0.00 | 6.37 | 1.13 | |

| Gm12, Nml CH4 | 32.5 | 6.70 | 1144.77 | 27.5 | 6.4 | |

| R², - | 0.926 | 0.968 | 0.921 | 0.996 | 0.932 | |

| NRMSE, % | 7.15% | 3.84% | 5.88% | 1.46% | 6.22% | |

| AICC, - | 112.11 | 5.56 | 38.63 | 28.88 | 22.91 | |

| Fitzhugh (f = 3) Equation (5) |

Gm, Nml CH4 | 194.38 | 19.29 | 27.14 | 96.39 | 18.89 |

| k0, d-1 | 0.16 | 0.99 | 1.79 | 1.09 | 0.48 | |

| n, - | 1.65 | 1.28 | 1.19 | 0.99 | 1.21 | |

| R², - | 0.915 | 0.960 | 0.667 | 0.971 | 0.898 | |

| NRMSE, % | 8.09% | 4.33% | 10.93% | 3.83% | 7.75% | |

| AICC, - | 109.80 | 3.05 | 55.18 | 58.63 | 24.25 | |

| Transference function (f = 3) Equation (6) |

Gm, Nml CH4 | 194.40 | 19.30 | 27.14 | 96.39 | 18.89 |

| Rm, Nml CH4·d-1 | 52.63 | 24.47 | 58.03 | 104.96 | 10.99 | |

| λ, d | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| R², - | 0.915 | 0.960 | 0.672 | 0.971 | 0.898 | |

| NRMSE, % | 8.09% | 4.33% | 10.93% | 3.83% | 7.75% | |

| AICC, - | 109.80 | 3.05 | 55.18 | 58.63 | 24.25 | |

| Cone (f = 3) Equation (7) |

Gm, Nml CH4 | 746.80 | 20.24 | 27.18 | 116.36 | 26.06 |

| k, d-1 | 0.02 | 2.00 | 1.40 | 1.76 | 0.48 | |

| n, - | 0.61 | 1.26 | 5.78 | 0.67 | 0.77 | |

| R², - | 0.933 | 0.968 | 0.688 | 0.996 | 0.919 | |

| NRMSE, % | 6.91% | 3.85% | 10.72% | 1.42% | 6.81% | |

| AICC, - | 103.79 | -1.40 | 54.44 | 20.93 | 19.32 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).