Submitted:

09 August 2023

Posted:

10 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Theoretical Method

2.1. Thermodynamic Potential and Electromechanical Properties of Epitaxial Thin Films

2.2. Electrocaloric Effect Temperature Change

3. Results and Analysis

4. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Seidel, J.; Li, J. Multiferroics under the Tip: Probing Magnetoelectric Coupling at the Nanoscale. National Science Review 2019, 6, 626–628. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Huang, B.; Wei, L.; Yan, F.; Huang, X.; Li, Y.; Xie, S.; Pan, K.; Liu, Y.; Li, J. Resolving Fine Electromechanical Structure of Collagen Fibrils via Sequential Excitation Piezoresponse Force Microscopy. Nanotechnology 2019, 30, 205703. [Google Scholar] [CrossRef] [PubMed]

- Martin, L.W.; Rappe, A.M. Thin-Film Ferroelectric Materials and Their Applications. Nat Rev Mater 2016, 2, 16087. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J. Multiferroics: Looking Back and Going Forward. Sci. China Technol. Sci. 2020, 63, 2735–2736. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V Nanogenerator for Mechanical Energy Harvesting Using PZT Nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef]

- Zhu, Q.; Pan, K.; Xie, S.; Liu, Y.; Li, J. Nanomechanics of Multiferroic Composite Nanofibers via Local Excitation Piezoresponse Force Microscopy. Journal of the Mechanics and Physics of Solids 2019, 126, 76–86. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K,Na)NbO3 -Based Lead-Free Piezoceramics: Fundamental Aspects, Processing Technologies, and Remaining Challenges. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Carl, K.; Härdtl, K.H. On the Origin of the Maximum in the Electromechanical Activity in Pb(ZrxTi1−x)O3 Ceramies near the Morphotropic Phase Boundary. Phys. Stat. Sol. (a) 1971, 8, 87–98. [Google Scholar] [CrossRef]

- Auciello, O.; Gifford, K.D.; Lichtenwalner, D.J.; Dat, R.; Al-Shareef, H.N.; Bellur, Kashyap. R.; Kincon, A.I. A Review of Composition-Structure-Property Relationships for PZT-Based Heterostructure Capacitors. Integrated Ferroelectrics 1995, 6, 173–187. [Google Scholar] [CrossRef]

- Pandey, D.; Singh, A.K.; Baik, S. Stability of Ferroic Phases in the Highly Piezoelectric Pb(ZrxTi1−x)O3 Ceramics. Acta Crystallogr A Found Crystallogr 2008, 64, 192–203. [Google Scholar] [CrossRef]

- Wang, K.; Malič, B.; Wu, J. Shifting the Phase Boundary: Potassium Sodium Niobate Derivates. MRS Bull. 2018, 43, 607–611. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Zhu, J. Potassium–Sodium Niobate Lead-Free Piezoelectric Materials: Past, Present, and Future of Phase Boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Gu, H.; Hu, Y.; Yang, K.; Hu, M.; Zhou, D.; Guan, J. Synthesis, Growth Mechanism and Optical Properties of (K,Na)NbO3 Nanostructures. CrystEngComm 2010, 12, 3157. [Google Scholar] [CrossRef]

- Meng, X.; Wang, W.; Ke, H.; Rao, J.; Jia, D.; Zhou, Y. Synthesis, Piezoelectric Property and Domain Behaviour of the Vertically Aligned K1−xNax NbO3 Nanowire with a Morphotropic Phase Boundary. J. Mater. Chem. C 2017, 5, 747–753. [Google Scholar] [CrossRef]

- Jin, W.; Wang, Z.; Li, M.; He, Y.; Hu, X.; Li, L.; Gao, Y.; Hu, Y.; Gu, H.; Wang, X. Evolution of the Composition, Structure, and Piezoelectric Performance of (K1-xNax)NbO3 Nanorod Arrays with Hydrothermal Reaction Time. Appl. Phys. Lett. 2018, 112, 142904. [Google Scholar] [CrossRef]

- Esin, A.A.; Alikin, D.O.; Turygin, A.P.; Abramov, A.S.; Hreščak, J.; Walker, J.; Rojac, T.; Bencan, A.; Malic, B.; Kholkin, A.L.; et al. Dielectric Relaxation and Charged Domain Walls in (K,Na)NbO3 -Based Ferroelectric Ceramics. Journal of Applied Physics 2017, 121, 074101. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant Piezoelectricity in Potassium–Sodium Niobate Lead-Free Ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef]

- Ge, W.; Li, J.; Viehland, D.; Chang, Y.; Messing, G.L. Electric-Field-Dependent Phase Volume Fractions and Enhanced Piezoelectricity near the Polymorphic Phase Boundary of (K0.5Na0.5)1−xLixNbO3 Textured Ceramics. Phys. Rev. B 2011, 83, 224110. [Google Scholar] [CrossRef]

- Tan, Z.; Xing, J.; Peng, Y.; Zhang, Q.; Zhu, J. Polarization Rotation Boosts Strong Piezoelectric Response in the Lead-Free Perovskite Ferroelectric K0.5Na0.5NbO3. Phys. Rev. B 2021, 104, 014104. [Google Scholar] [CrossRef]

- Seog, H.J.; Ullah, A.; Ahn, C.W.; Kim, I.W.; Lee, S.Y.; Park, J.; Lee, H.J.; Won, S.S.; Kim, S.H. Recent Progress in Potassium Sodium Niobate Lead-Free Thin Films. J. Korean Phys. Soc. 2018, 72, 1467–1483. [Google Scholar] [CrossRef]

- von Helden, L.; Bogula, L.; Janolin, P.E.; Hanke, M.; Breuer, T.; Schmidbauer, M.; Ganschow, S.; Schwarzkopf, J. Huge Impact of Compressive Strain on Phase Transition Temperatures in Epitaxial Ferroelectric KxNa1−xNbO3 Thin Films. Appl. Phys. Lett. 2019, 114, 232905. [Google Scholar] [CrossRef]

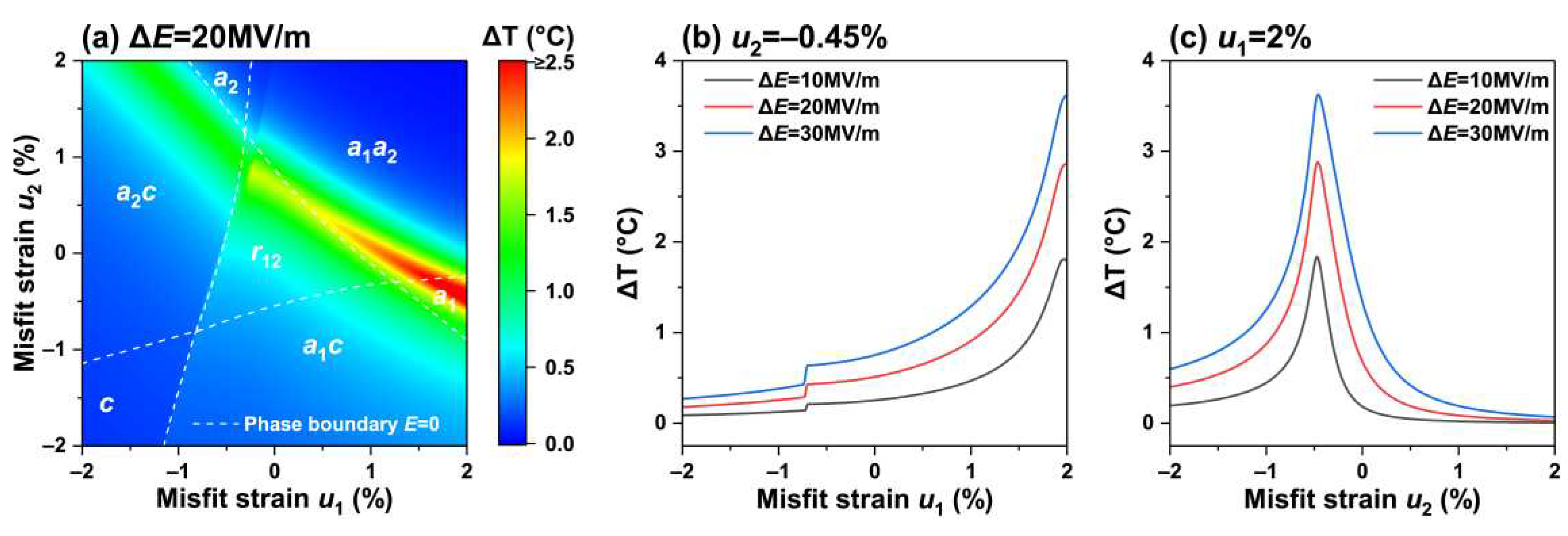

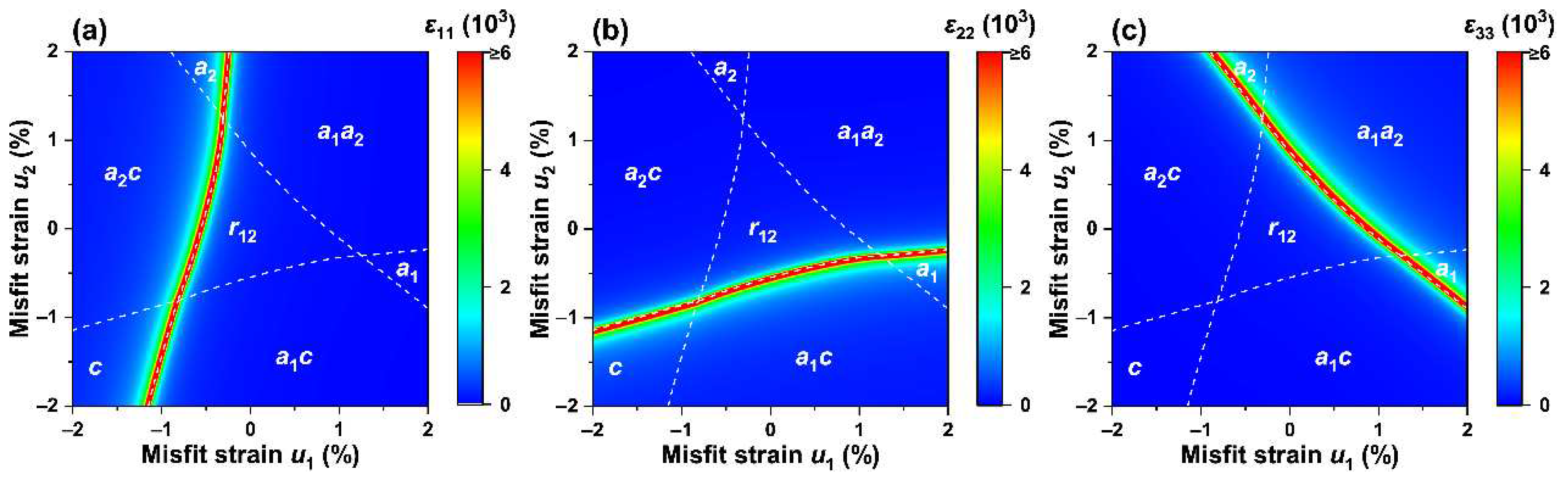

- Shan, D.L.; Lei, C.H.; Cai, Y.C.; Pan, K.; Liu, Y.Y. Mechanical Control of Electrocaloric Response in Epitaxial Ferroelectric Thin Films. International Journal of Solids and Structures 2021, 216, 59–67. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Vasudevan, R.K.; Pan, K.; Xie, S.H.; Liang, W.I.; Kumar, A.; Jesse, S.; Chen, Y.C.; Chu, Y.H.; Nagarajan, V.; et al. Controlling Magnetoelectric Coupling by Nanoscale Phase Transformation in Strain Engineered Bismuth Ferrite. Nanoscale 2012, 4, 3175. [Google Scholar] [CrossRef]

- Wang, J.J.; Su, Y.J.; Wang, B.; Ouyang, J.; Ren, Y.H.; Chen, L.Q. Strain Engineering of Dischargeable Energy Density of Ferroelectric Thin-Film Capacitors. Nano Energy 2020, 72, 104665. [Google Scholar] [CrossRef]

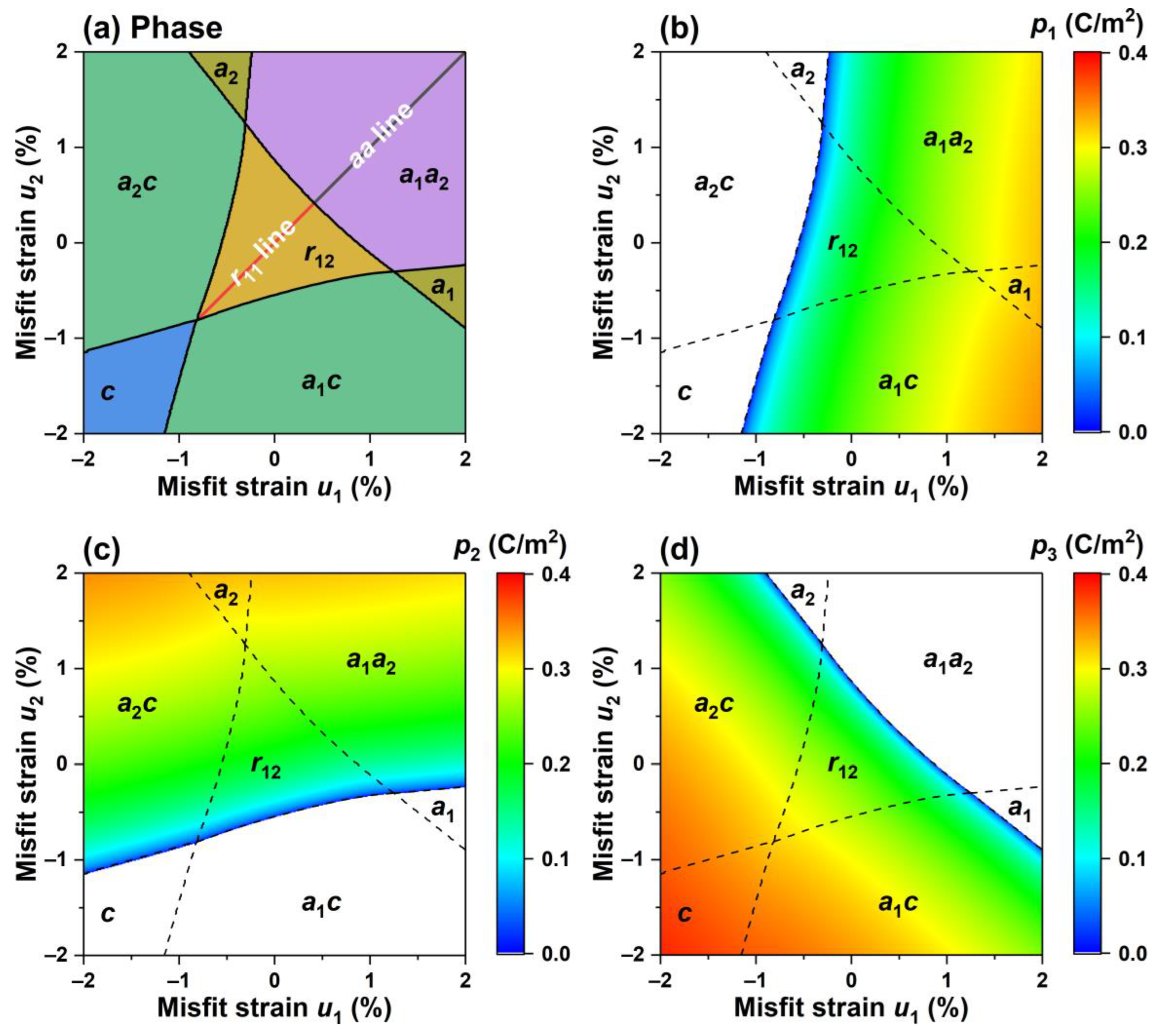

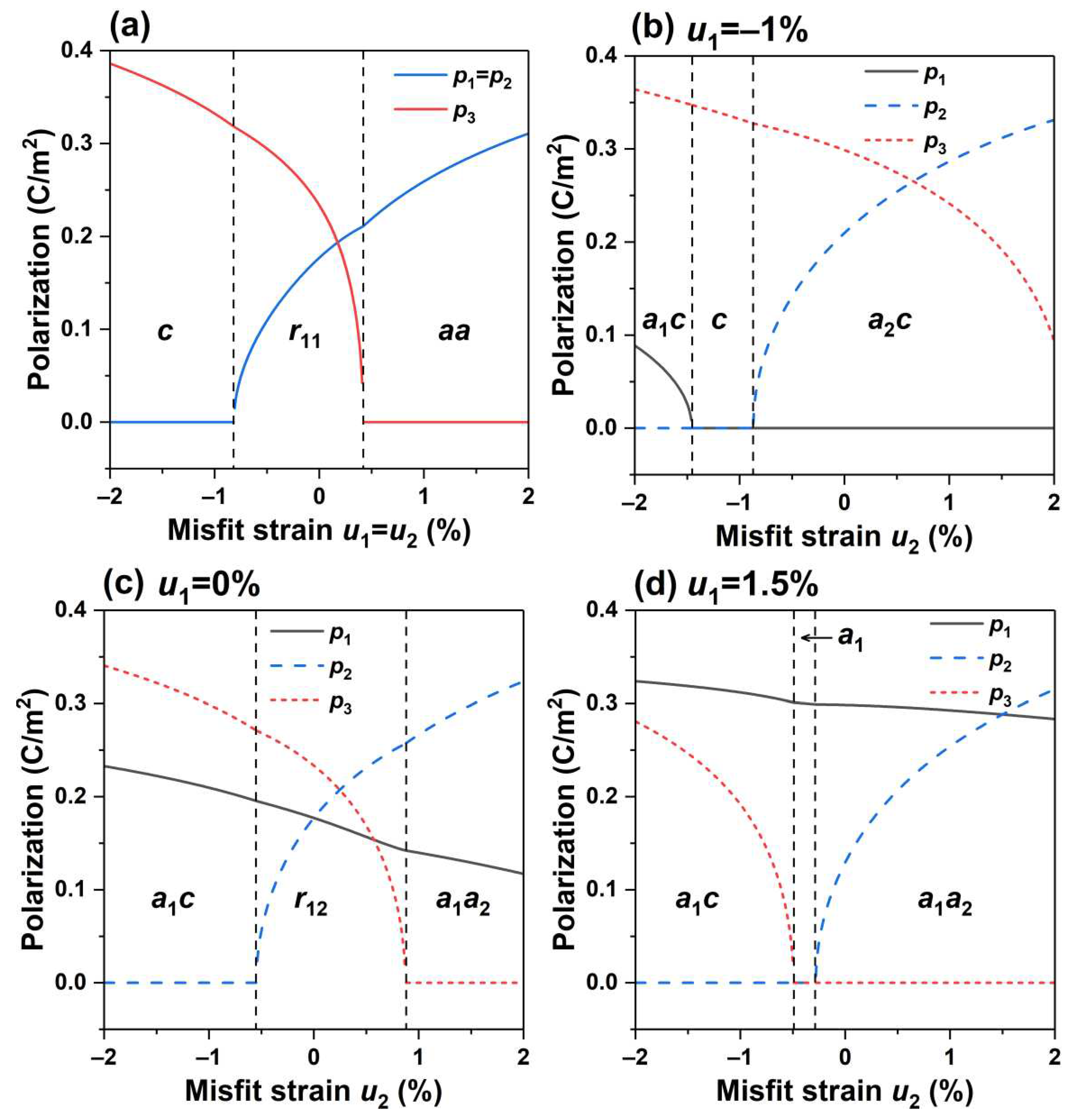

- Liu, D.; Bai, G.; Gao, C. Phase Diagrams Classification Based on Machine Learning and Phenomenological Investigation of Physical Properties in K1 −xNaxNbO3 Thin Films. Journal of Applied Physics 2020, 127, 154101. [Google Scholar] [CrossRef]

- Zhou, M.J.; Wang, J.J.; Chen, L.Q.; Nan, C.W. Strain, Temperature, and Electric-Field Effects on the Phase Transition and Piezoelectric Responses of K 0.5Na0.5NbO3 Thin Films. Journal of Applied Physics 2018, 123, 154106. [Google Scholar] [CrossRef]

- Pohlmann, H.; Wang, J.J.; Wang, B.; Chen, L.Q. A Thermodynamic Potential and the Temperature-Composition Phase Diagram for Single-Crystalline K 1-xNaxNbO3(0≤ x ≤ 0.5). Appl. Phys. Lett. 2017, 110, 102906. [Google Scholar] [CrossRef]

- Peng, J.; Shan, D.; Liu, Y.; Pan, K.; Lei, C.; He, N.; Zhang, Z.; Yang, Q. A Thermodynamic Potential for Barium Zirconate Titanate Solid Solutions. npj Comput Mater 2018, 4, 66. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Zhu, Z.X.; Li, J.F.; Li, J.Y. Misfit Strain Modulated Phase Structures of Epitaxial Pb(Zr1−xTix)O3 Thin Films: The Effect of Substrate and Film Thickness. Mechanics of Materials 2010, 42, 816–826. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Zembilgotov, A.G.; Tagantsev, A.K. Effect of Mechanical Boundary Conditions on Phase Diagrams of Epitaxial Ferroelectric Thin Films. Phys. Rev. Lett. 1998, 80, 1988–1991. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Li, J.Y. Shear-Driven Morphotropic Phase Boundary in Epitaxial Ferroelectric Thin Films. Phys. Rev. B 2011, 84, 132104. [Google Scholar] [CrossRef]

- Haun, M.J.; Furman, E.; Jang, S.J.; Cross, L.E. Thermodynamic Theory of the Lead Zirconate-Titanate Solid Solution System, Part I: Phenomenology. Ferroelectrics 1989, 99, 13–25. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Yang, L.; Li, J.Y. Strain-Engineered Orthorhombic-Rhombohedral Phase Boundary in Epitaxial Bismuth Ferrite Films. Journal of Applied Physics 2013, 113, 183524. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Kukhar, V.G.; Kohlstedt, H.; Waser, R. Phase Diagrams and Physical Properties of Single-Domain Epitaxial Pb(Zr1−xTix)O3 Thin Films. Phys. Rev. B 2003, 67, 054107. [Google Scholar] [CrossRef]

- Tomeno, I.; Tsunoda, Y.; Oka, K.; Matsuura, M.; Nishi, M. Lattice Dynamics of Cubic NaNbO3 : An Inelastic Neutron Scattering Study. Phys. Rev. B 2009, 80, 104101. [Google Scholar] [CrossRef]

- Liang, L.; Li, Y.L.; Chen, L.Q.; Hu, S.Y.; Lu, G.H. A Thermodynamic Free Energy Function for Potassium Niobate. Applied Physics Letters 2009, 94, 072904. [Google Scholar] [CrossRef]

- Barman, A.; Kar-Narayan, S.; Mukherjee, D. Caloric Effects in Perovskite Oxides. Adv. Mater. Interfaces 2019, 6, 1900291. [Google Scholar] [CrossRef]

- Shan, D.; Pan, K.; Liu, Y.; Li, J. High Fidelity Direct Measurement of Local Electrocaloric Effect by Scanning Thermal Microscopy. Nano Energy 2020, 67, 104203. [Google Scholar] [CrossRef]

- Pirc, R.; Kutnjak, Z.; Blinc, R.; Zhang, Q.M. Electrocaloric Effect in Relaxor Ferroelectrics. Journal of Applied Physics 2011, 110, 074113. [Google Scholar] [CrossRef]

- He, N.; Li, Q.; Lei, C.; Pan, J.; Shan, D.; Pan, K.; Liu, Y. Electrocaloric Response Modulated by Misfit Strain in Different Oriented Epitaxial Ferroelectric Thin Films. International Journal of Solids and Structures 2022, 252, 111808. [Google Scholar] [CrossRef]

- Shan, D.; Cai, Y.; Lei, C.; Peng, J.; He, N.; Pan, K.; Liu, Y.; Li, J. Electric-Field-Driven Coexistence of Positive and Negative Electrocaloric Effects near Room Temperature for High-Efficiency Two-Stage Cooling. Appl. Phys. Lett. 2021, 118, 122905. [Google Scholar] [CrossRef]

- Lei, C.H.; Liu, Y. Correlations between Local Electrocaloric Effect and Domains in Ferroelectric Crystals. Appl. Phys. Lett. 2022, 121, 102902. [Google Scholar] [CrossRef]

- Luo, J.; Sun, W.; Zhou, Z.; Lee, H.Y.; Wang, K.; Zhu, F.; Bai, Y.; Wang, Z.J.; Li, J.-F. Monoclinic (K,Na)NbO3 Ferroelectric Phase in Epitaxial Films. Adv. Electron. Mater. 2017, 3, 1700226. [Google Scholar] [CrossRef]

| Coeff | Values | Units |

|---|---|---|

| Phase | Polarization |

|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).