Submitted:

14 July 2023

Posted:

18 July 2023

You are already at the latest version

Abstract

Keywords:

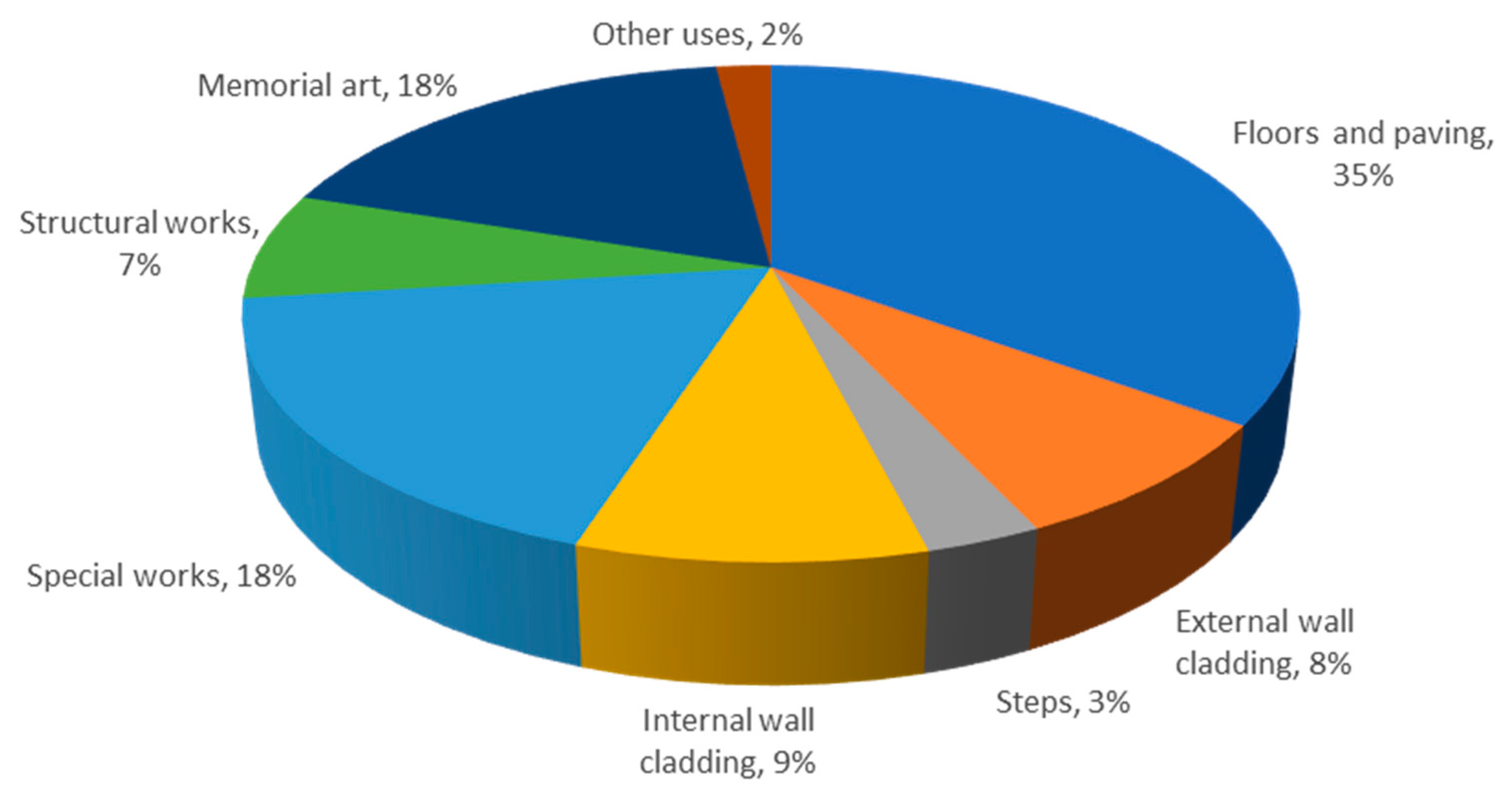

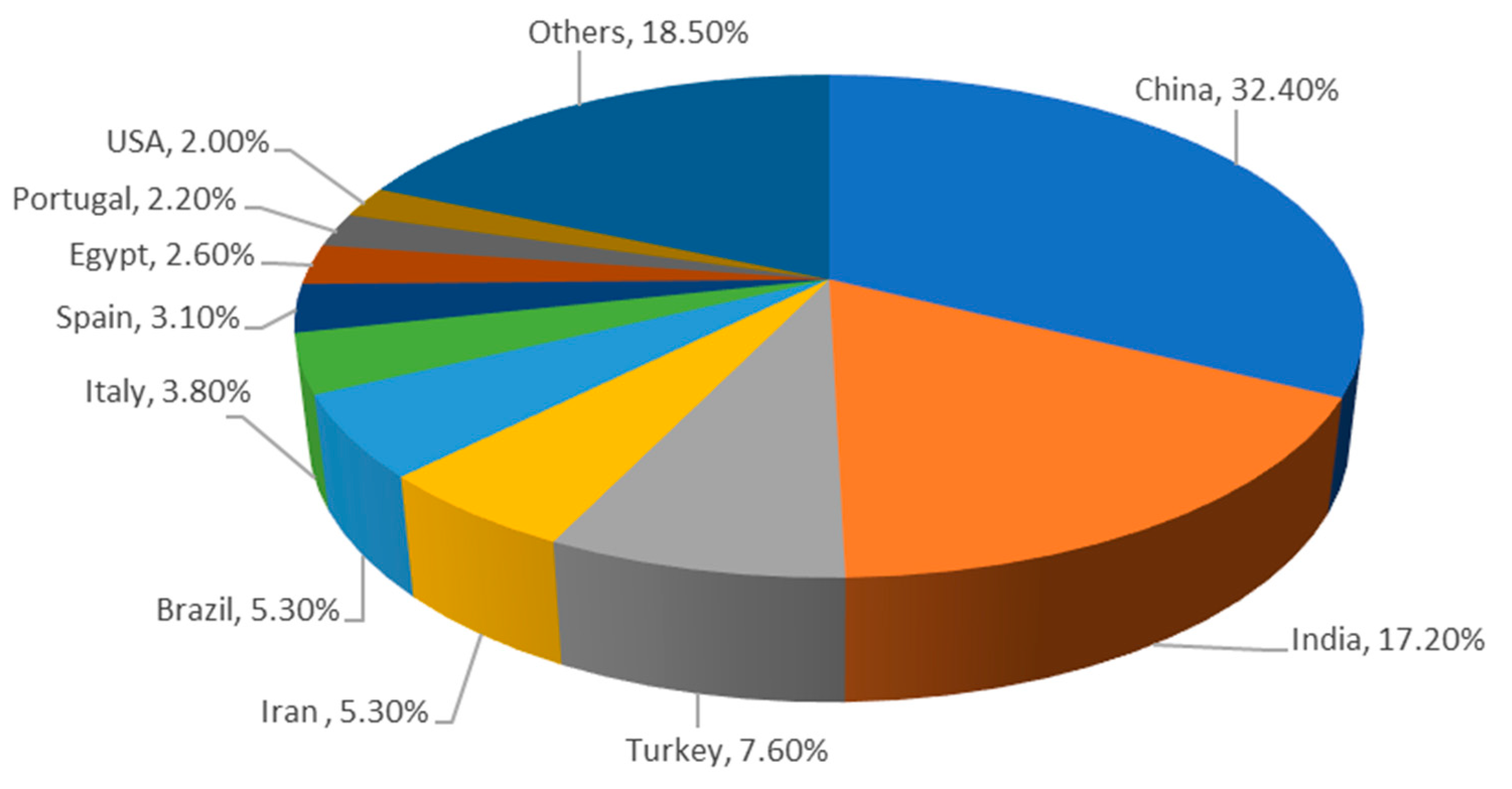

1. Introduction

2. Dimension stone extraction methods

2.1. Primitive Techniques

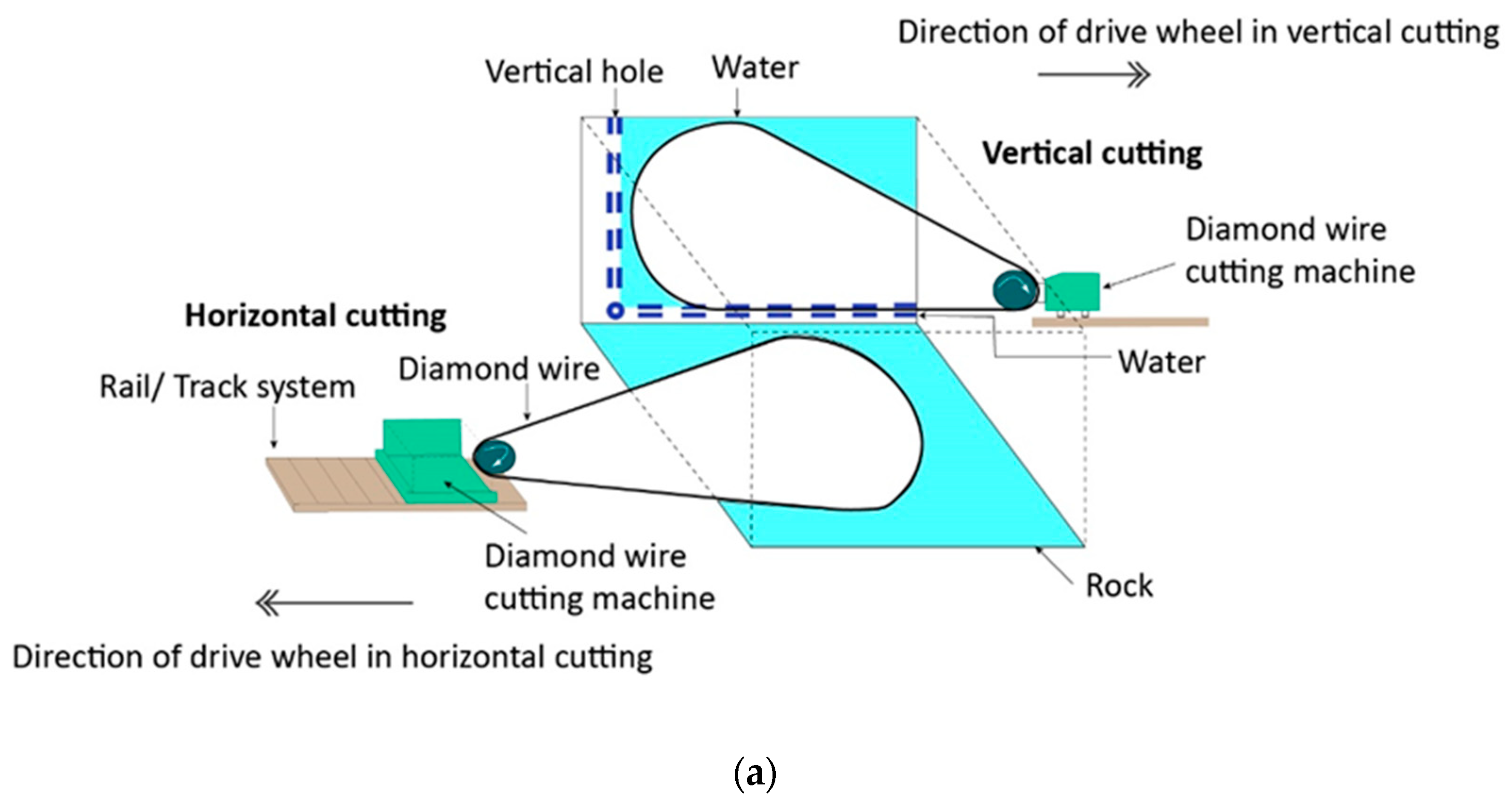

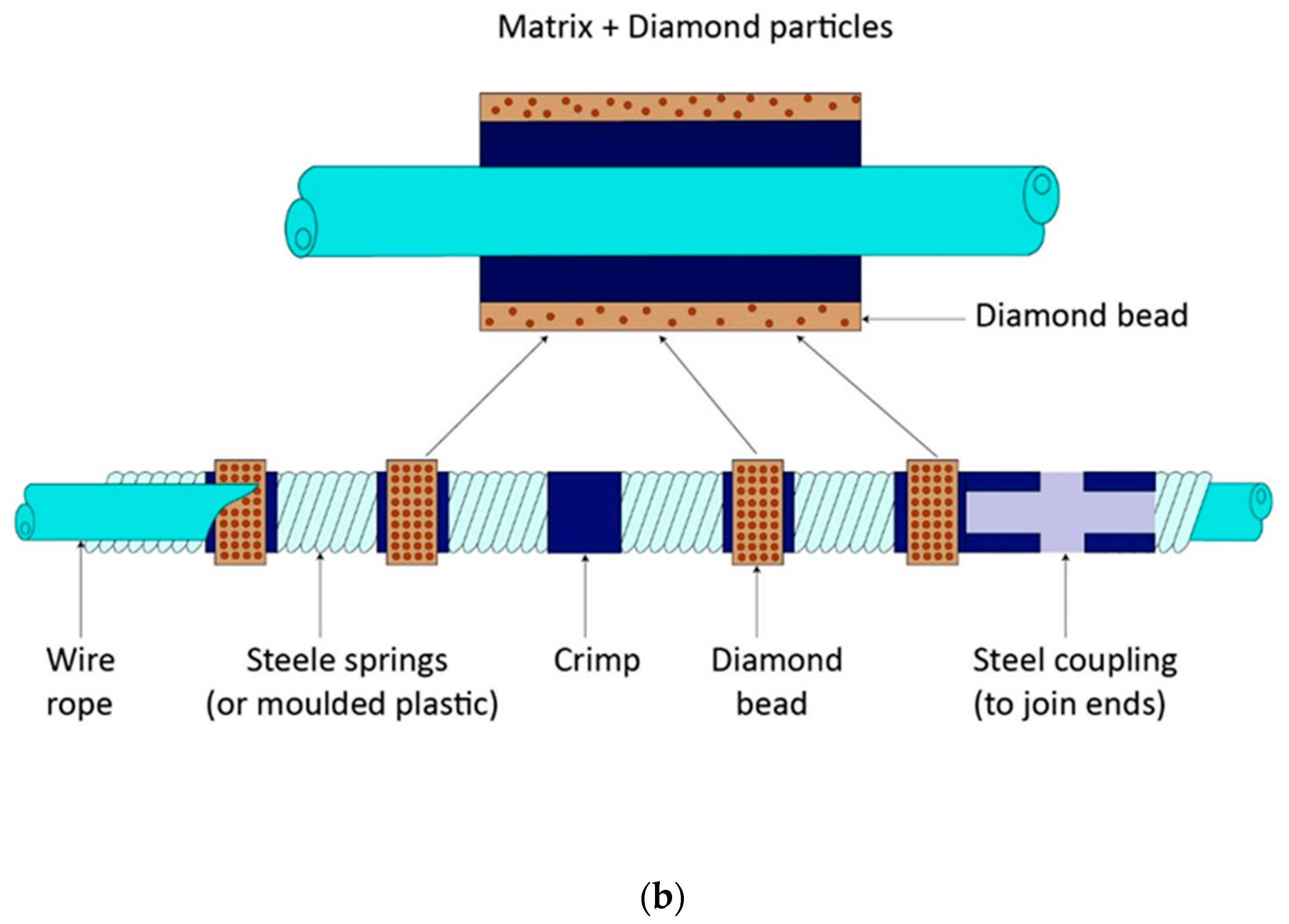

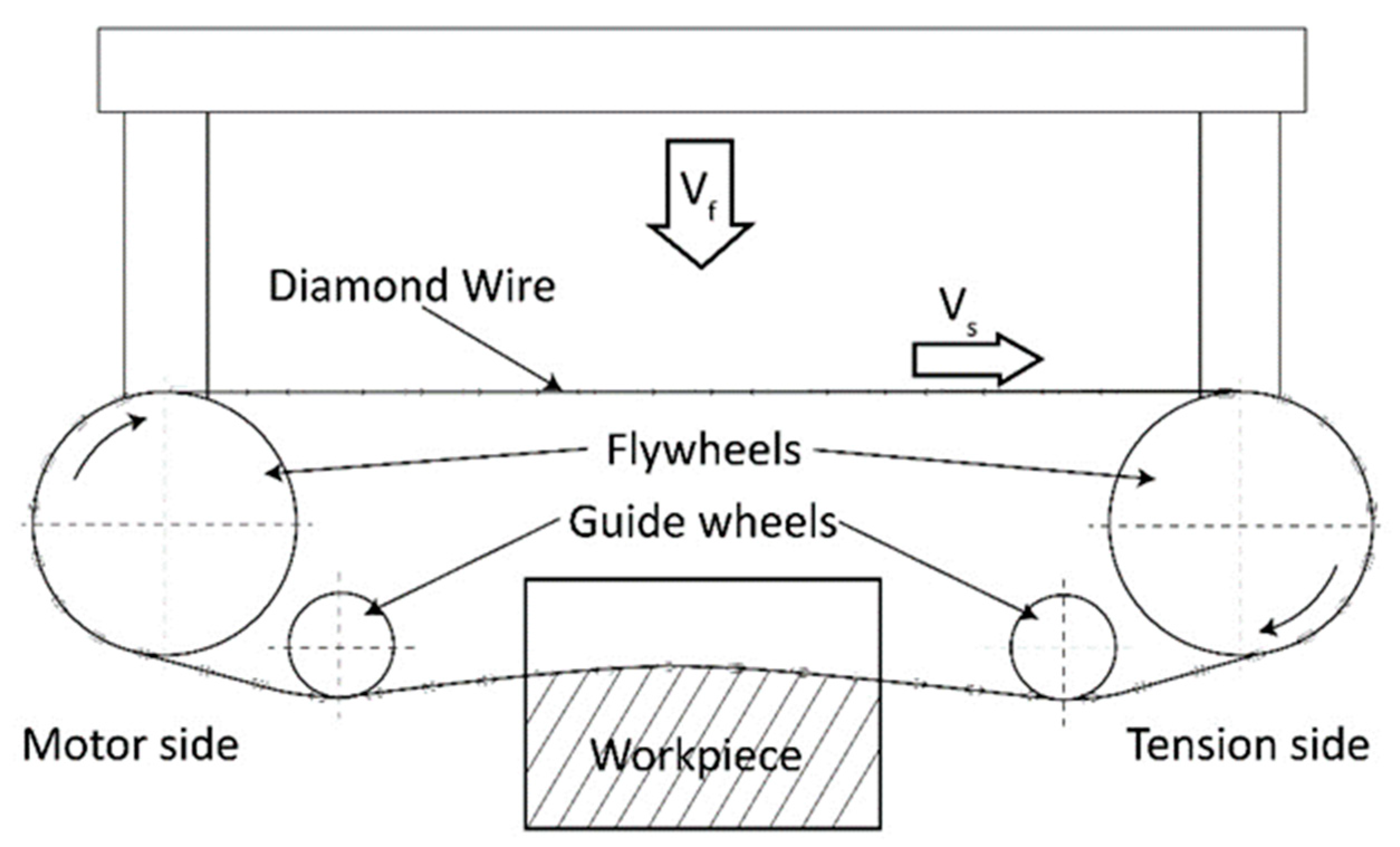

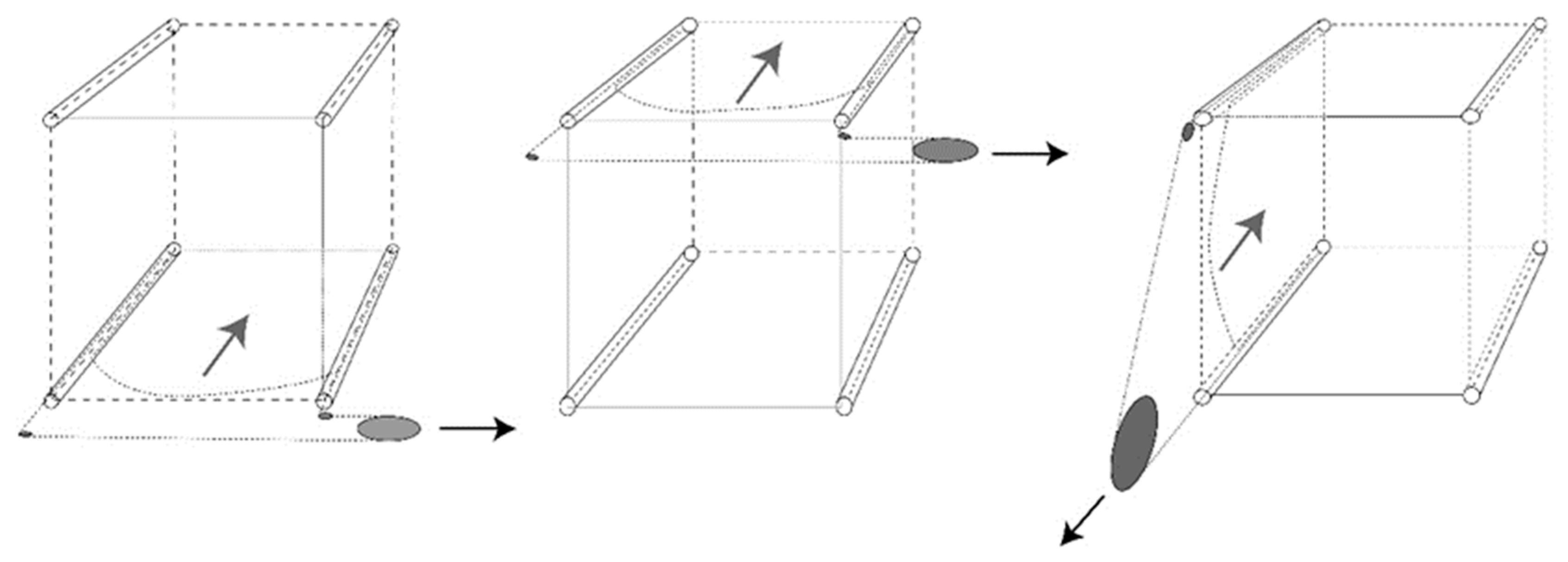

2.2. Diamond Wire Cutting

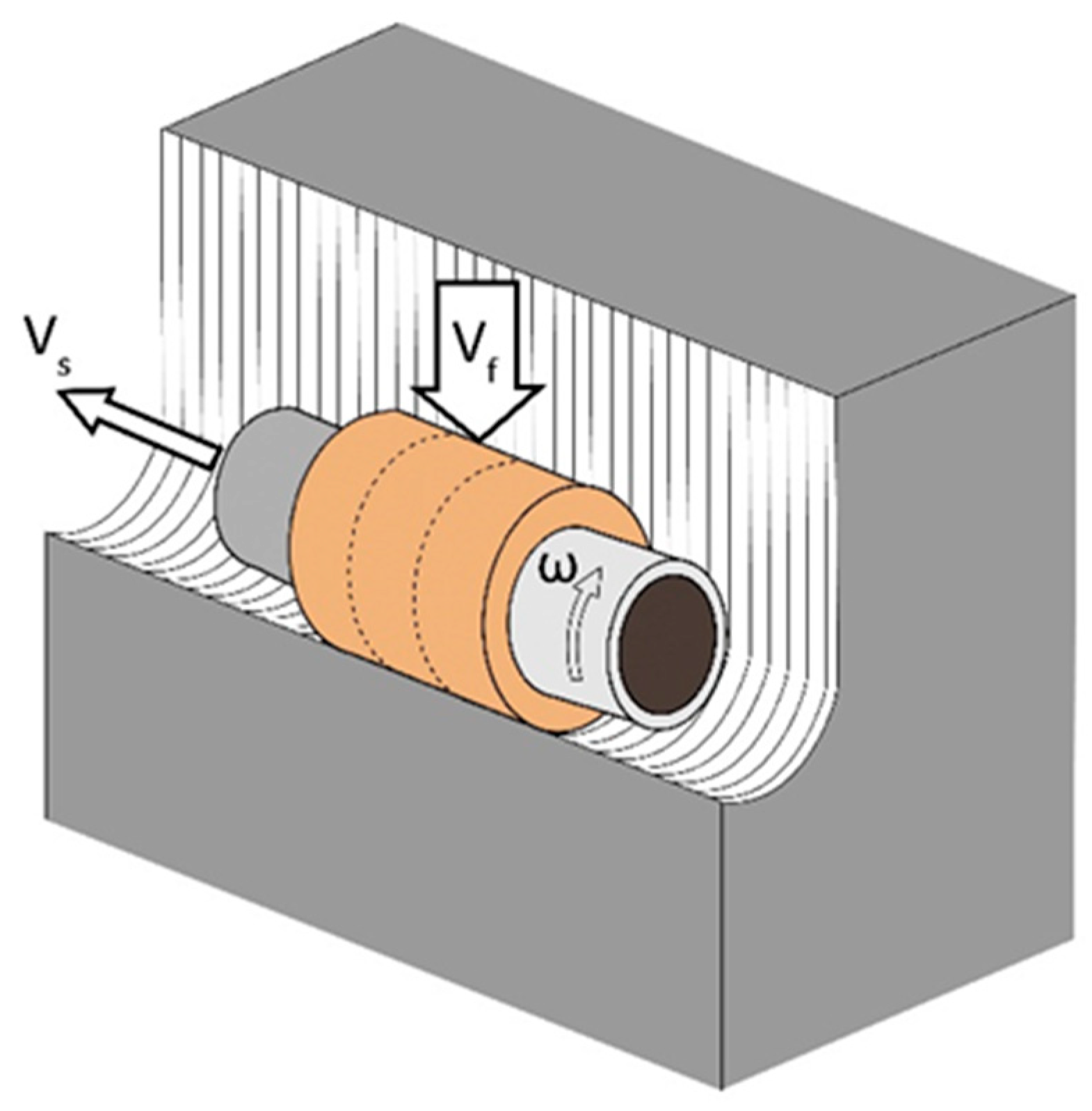

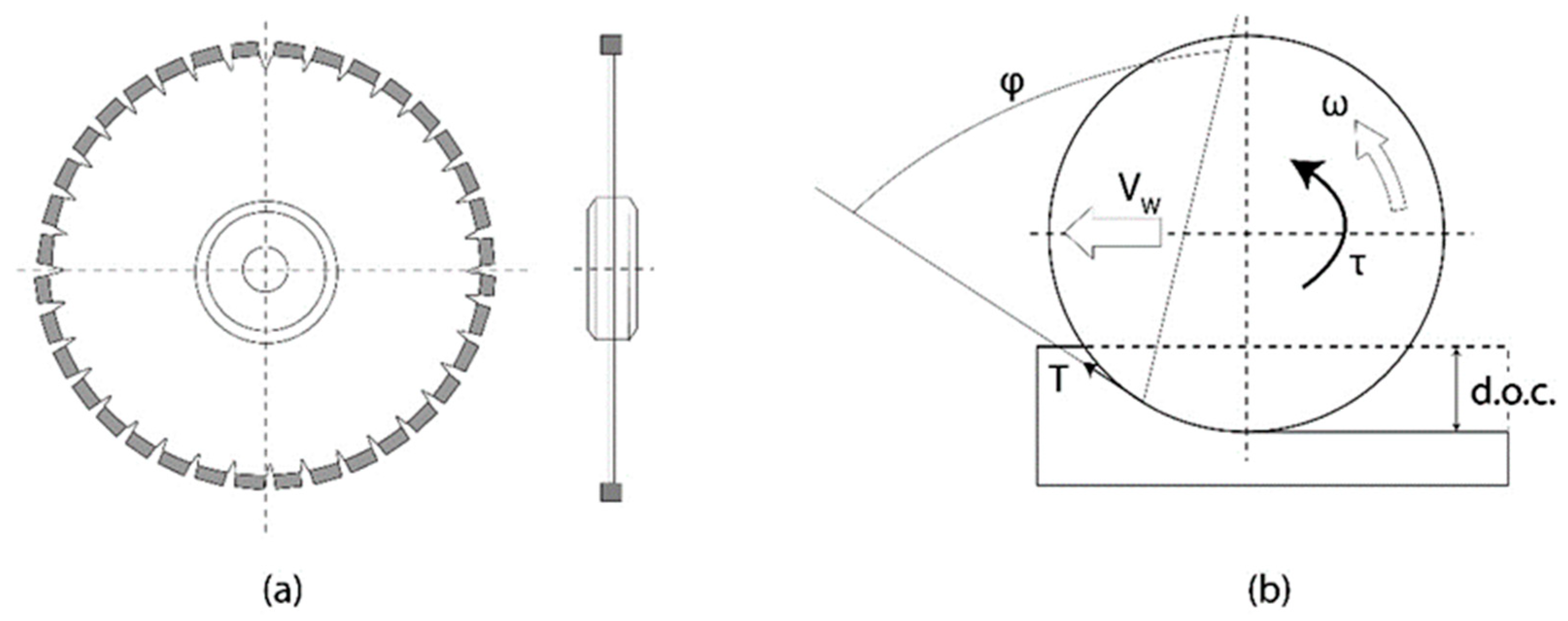

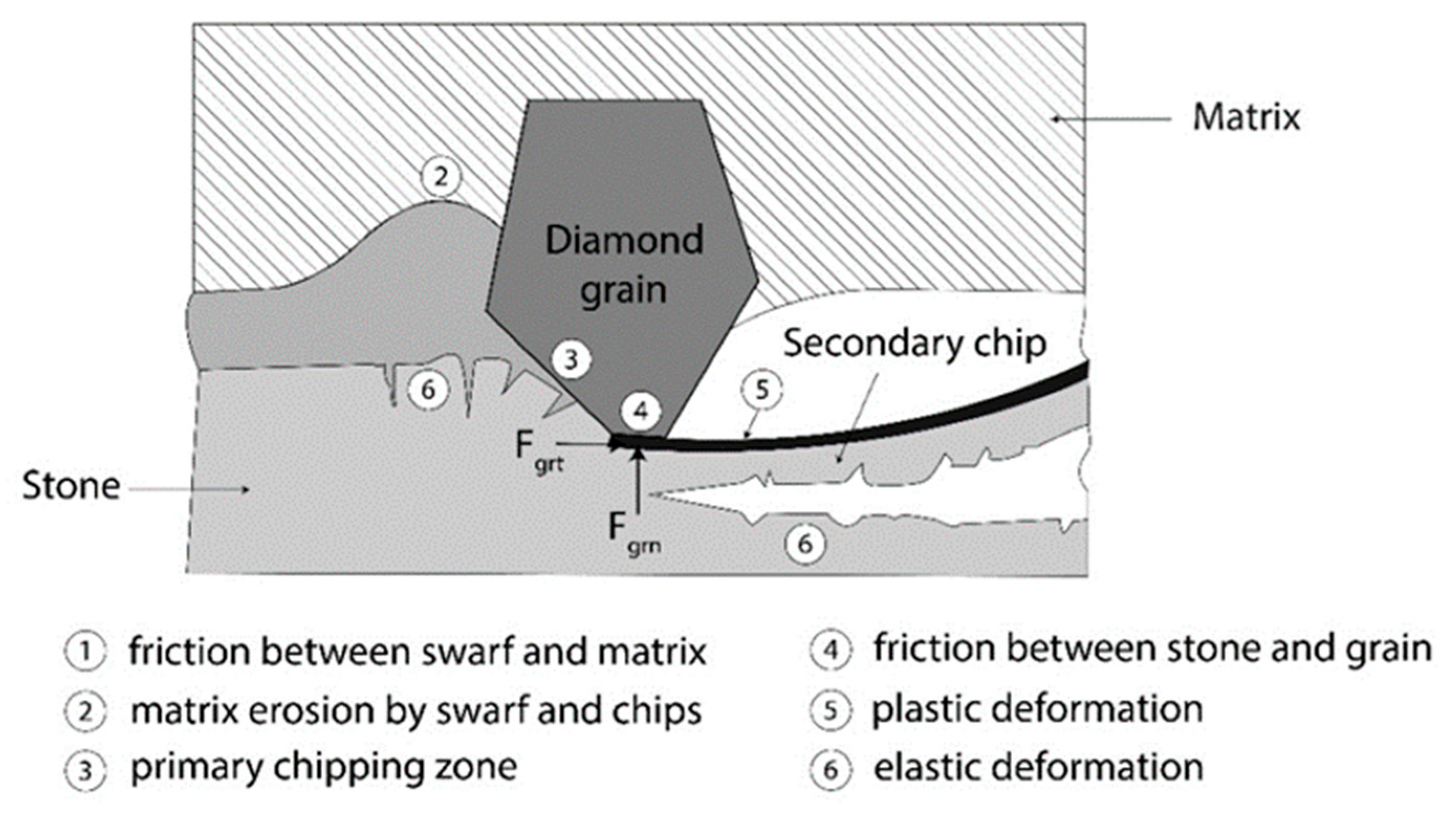

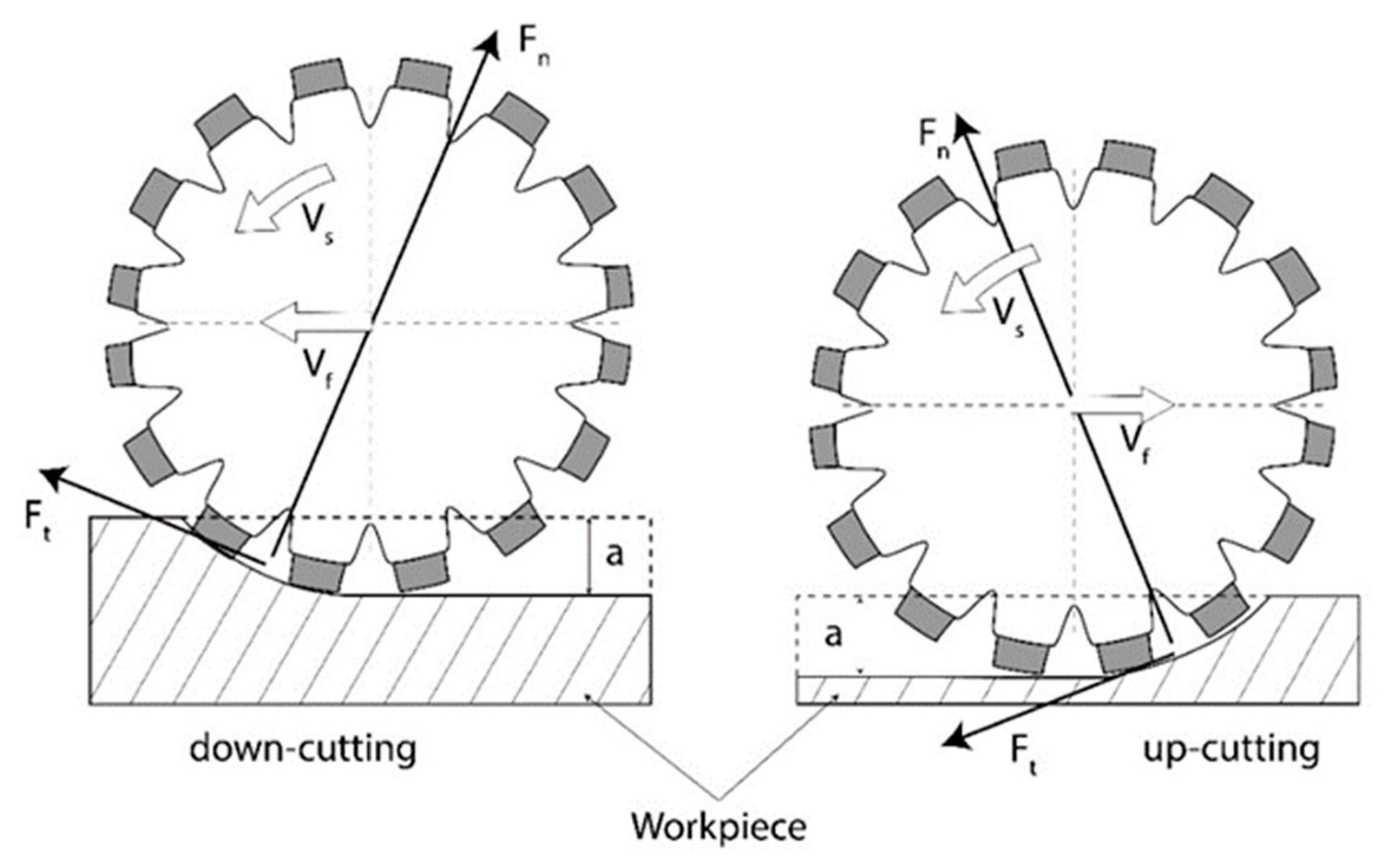

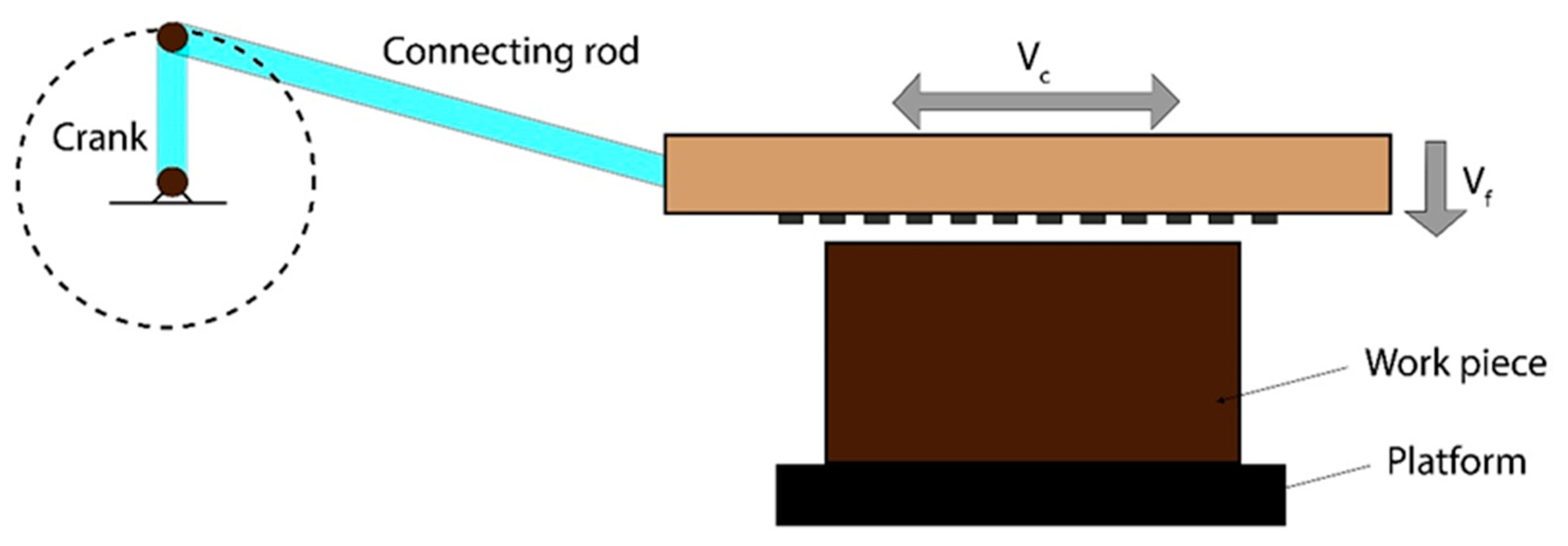

2.3. Diamond Saw Cutting/Circular Saw Cutting

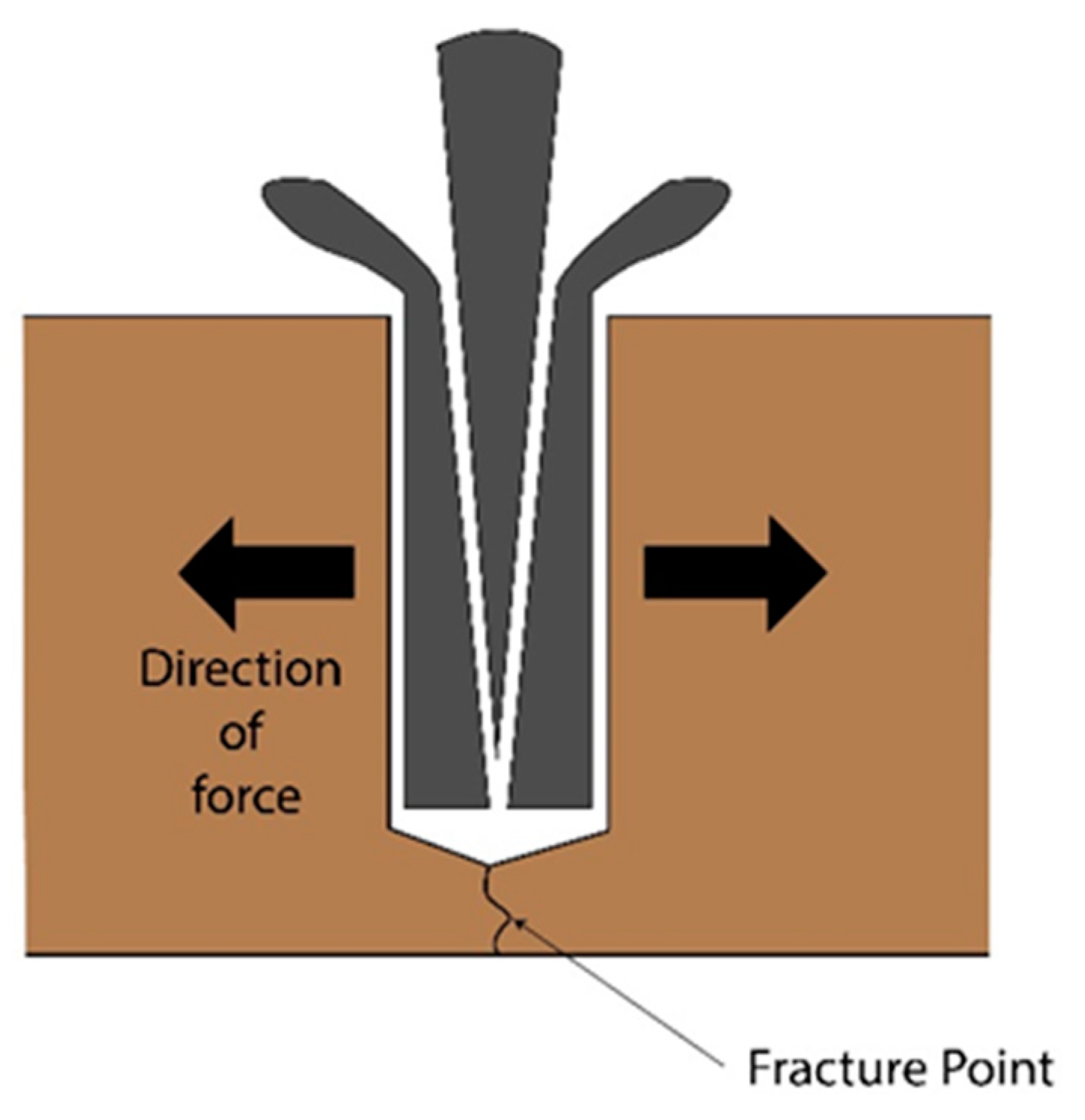

2.4. Expansive Mortar

3. Discussion

Funding

Acknowledgments

References

- Ashmole, I., & Motloung, M. (2008). Dimension stone: the latest trends in exploration and production technology. Proceedings of the International Conference on Surface Mining, 5(8).

- Ataei, M.; Mikaiel, R.; Sereshki, F.; Ghaysari, N. Predicting the production rate of diamond wire saw using statistical analysis. Arab. J. Geosci. 2011, 5, 1289–1295. [Google Scholar] [CrossRef]

- Cardu, M., Patrucco, M., Lovera, E., & Michelotti, E. (2005). Quarrying by explosive and diamond wire in hard dimension stones. Proceedings of the European Federation of Explosives Engineers.

- Çevim, K. C. (n.d.). Doğal Taş Fabrikalarında Kullanılan Dairesel Testereli Blok Kesme (s/t) Makineleri İçin Performans Tahmin Modelinin Geliştirilmesi. Fen Bilimleri Enstitüsü.

- De Silva, R.V.; Gamage, R.P.; Perera, M.S.A. An Alternative to Conventional Rock Fragmentation Methods Using SCDA: A Review. Energies 2016, 9, 958. [Google Scholar] [CrossRef]

- De Silva, V.; Ranjith, P.; Perera, M.; Wu, B.; Rathnaweera, T. A modified, hydrophobic soundless cracking demolition agent for non-explosive demolition and fracturing applications. Process. Saf. Environ. Prot. 2018, 119, 1–13. [Google Scholar] [CrossRef]

- Di Ilio, A.; Togna, A. A theoretical wear model for diamond tools in stone cutting. Int. J. Mach. Tools Manuf. 2003, 43, 1171–1177. [Google Scholar] [CrossRef]

- Ersoy, A.; Atıcı, U. Performance characteristics of circular diamond saws in cutting different types of rocks. Diamond and Related Materials 2004, 13, 22–37. [Google Scholar] [CrossRef]

- Ertingshausen, W. (1984). Zerspanung von Granit mit Diamanttrennscheiben (Dr. Dissertation, University of Hannover.

- Esmailzadeh, A.; Mikaeil, R.; Sadegheslam, G.; Aryafar, A.; Gharehgheshlagh, H.H. Selection of an Appropriate Method to Extract the Dimensional Stones Using FDAHP & TOPSIS Techniques. Journal of Soft Computing in Civil Engineering 2018, 2, 101–116. [Google Scholar] [CrossRef]

- Ghaysari, N.; Ataei, M.; Sereshki, F.; Mikaiel, R. Prediction of Performance of Diamond Wire Saw with Respect to Texture Characteristics of Rock / Prognozowanie Wydajności Pracy Strunowej Piły Diamentowej W Odniesieniu Do Charakterystyki Tekstury Skał. Arch. Min. Sci. 2012, 57, 887–900. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Ataie, M.; Aghababaie, H. A laboratory study of rock properties affecting the penetration rate of pneumatic top hammer drills. Journal of Mining and Environment 2014, 5, 25–34. [Google Scholar] [CrossRef]

- Kahraman Ulker, U.; Delibalta, M.S. A quality classification of building stones from P-wave velocity and its application to stone cutting with gang saws. Journal of the Southern African Institute of Mining and Metallurgy 2007, 107, 427–430. [Google Scholar]

- Konstanty, J. Theoretical analysis of stone sawing with diamonds. J. Mater. Process. Technol. 2002, 123, 146–154. [Google Scholar] [CrossRef]

- Konstanty, J. S. The mechanics of sawing granite with diamond wire. The International Journal of Advanced Manufacturing Technology 2021, 116, 2591–2597. [Google Scholar] [CrossRef]

- Korobiichuk, I.; Korobiichuk, V.; Iskov, S.; Nowicki, M.; Szewczyk, R. PECULIARITES OF NATURAL STONE EXTRACTION TECHNOLOGY WITH THE HELP OF DIAMOND WIRE MACHINES. International Multidisciplinary Scientific GeoConference: SGEM 2016, 2, 649–656. [Google Scholar]

- Mosch, S.; Nikolayew, D.; Ewiak, O.; Siegesmund, S. Optimized extraction of dimension stone blocks. Environ. Earth Sci. 2010, 63, 1911–1924. [Google Scholar] [CrossRef]

- Ozcelik, Y. (1999). Investigation of the working conditions of diamond wire cutting machines in marble industry. PhD Thesis, Hacettepe University, Ankara (in Turkish).

- Ozcelik, Y.; Polat, E.; Bayram, F.; Ay, A. Investigation of the effects of textural properties on marble cutting with diamond wire. Int. J. Rock Mech. Min. Sci. 2004, 41, 228–234. [Google Scholar] [CrossRef]

- Ozcelik, Y.; Yilmazkaya, E. The effect of the rock anisotropy on the efficiency of diamond wire cutting machines. Int. J. Rock Mech. Min. Sci. 2011, 48, 626–636. [Google Scholar] [CrossRef]

- Polini, W.; Turchetta, S. Force and specific energy in stone cutting by diamond mill. Int. J. Mach. Tools Manuf. 2004, 44, 1189–1196. [Google Scholar] [CrossRef]

- Saliu, M.; Shehu, S. Bench Blasting Design for Optimum Recovery of Blocks in Dimension Stone Quarries: A Case Study of Crushed Rock Industry, Supare-Nigeria. Glob. J. Eng. Res. 2013, 12, 85–92. [Google Scholar] [CrossRef]

- Thrush, P. W. (1968). A dictionary of mining, mineral, and related terms. US Bureau of Mines.

- Tönshoff, H.; Hillmann-Apmann, H.; Asche, J. Diamond tools in stone and civil engineering industry: cutting principles, wear and applications. Diam. Relat. Mater. 2002, 11, 736–741. [Google Scholar] [CrossRef]

- Tumac, D. Predicting the performance of large diameter circular saws based on Schmidt hammer and other properties for some Turkish carbonate rocks. Int. J. Rock Mech. Min. Sci. 2015, 75, 159–168. [Google Scholar] [CrossRef]

- Tumac, D. Artificial neural network application to predict the sawability performance of large diameter circular saws. Measurement 2016, 80, 12–20. [Google Scholar] [CrossRef]

- Tumac, D.; Shaterpour-Mamaghani, A. Estimating the sawability of large diameter circular saws based on classification of natural stone types according to the geological origin. Int. J. Rock Mech. Min. Sci. 2018, 101, 18–32. [Google Scholar] [CrossRef]

- Turchetta, S.; Polini, W.; Gelfusa, G.; Venafro, E. A new sawing machine by diamond wire. The International Journal of Advanced Manufacturing Technology 2014, 70, 73–78. [Google Scholar] [CrossRef]

- Turchetta, S.; Sorrentino, L.; Bellini, C. A method to optimize the diamond wire cutting process. Diam. Relat. Mater. 2017, 71, 90–97. [Google Scholar] [CrossRef]

- Tutmez, B.; Kahraman, S.; Gunaydin, O. Multifactorial fuzzy approach to the sawability classification of building stones. Constr. Build. Mater. 2007, 21, 1672–1679. [Google Scholar] [CrossRef]

- Ucun, I.; Aslantas, K.; Büyüksagis, I.S.; Tasgetiren, S. An investigation on the effect of diamond concentration and matrix material composition in the circular sawing process of granites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 225, 17–27. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, J.; Kang, J.; Zhang, H. Analysis of diamond wear morphology and segment wear evolution during the process of hard granite sawing. Int. J. Refract. Met. Hard Mater. 2023, 110, 106040. [Google Scholar] [CrossRef]

- Wei, X.; Wang, C.; Zhou, Z. Study on the fuzzy ranking of granite sawability. J. Mater. Process. Technol. 2003, 139, 277–280. [Google Scholar] [CrossRef]

- Wright, D. N.; Engels, J. A. The environmental and cost benefits of using diamond wire for quarrying and processing of natural stone. Industrial Diamond Review 2003, 4, 16–17. [Google Scholar]

- Xu, X.; Li, Y.; Malkin, S. Forces and Energy in Circular Sawing and Grinding of Granite. J. Manuf. Sci. Eng. 2000, 123, 13–22. [Google Scholar] [CrossRef]

- Yarahmadi, R.; Bagherpour, R.; Khademian, A. Safety risk assessment of Iran’s dimension stone quarries (Exploited by diamond wire cutting method). Saf. Sci. 2014, 63, 146–150. [Google Scholar] [CrossRef]

- Yılmazkaya, E. (2007). Investigation of some factors affecting block production with diamond wire cutting method. MSc Thesis, Hacettepe University, Turkey (in Turkish).

- Zhang, H.; Zhang, J.; Wang, Z.; Sun, Q.; Fang, J. A new frame saw machine by diamond segmented blade for cutting granite. Diam. Relat. Mater. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, F. A New Method of Grading the Sawability of Natural Rock Materials. Key Eng. Mater. 2003, 250, 293–296. [Google Scholar] [CrossRef]

| Reference | Objective of the study | Results and Conclusions |

|---|---|---|

| (Norling, 1971) | Investigation of the correlation between sawability with petrographic properties of the rock | The efficiency of the sawing process was found to be more significantly influenced by the grain size of the rock rather than the quartz content |

| (Ozcelik, 1999) | Working conditions of diamond wire cutting machines in the industry | The cutting efficiency in rock is contingent upon a combination of non-controlled parameters, including hardness, strength, moisture content, discontinuities, and textural properties, as well as partially or fully controlled parameters such as machine power, machine positioning (vertical or horizontal cutting), and the number of beads per meter. |

| (Ataei et al., 2012) | Prediction of production rates of diamond wire operation using statistical analysis | There is a strong negative correlation observed between the production rates and the increasing values of parameters such as uniaxial compressive strength (UCS), Brazilian tensile strength, and Schmidt hammer values. Conversely, there is a weak positive relationship between the production rates and the increasing values of the Los Angeles abrasion test. |

| (Ozcelik & Yilmazkaya, 2011) | Investigation of rock anisotropy with the bedding planes of the rock against the efficiency of diamond wire cutting machines | The influence of the rock’s bedding plane anisotropy on the cutting efficiency of diamond wire has been unveiled. For optimal cutting efficiency, it is recommended to conduct operations parallel to the bedding planes or as closely aligned as feasible, considering other prevailing constraints. |

| (Yilmazkaya & Ozcelik, 2016) | Effects of operational parameters (peripheral speed and cutting speed) in Mono- diamond wire cutting systems in Marble processing | A cubic model was introduced as the most suitable fit for predicting the wear of beads and unit energy values. The results indicated that the optimum peripheral speed exhibited an increasing trend, while cutting speed and unit wear values demonstrated a decreasing trend with the progressive enlargement of the average crystal size. |

| (Najmedin Almasi et al., 2017) | Bead wear in diamond wire sawing considering rock properties and production rate | The wear rate of diamond beads exhibits an upward trend as the values of uniaxial compressive strength (UCS) and abrasive factors increase. |

| (Mikaeil et al., 2017, 2019) | Evaluation of performance in diamond wire saw using harmony search algorithm | A novel adaptive soft computing algorithm was developed to assess the cutting efficiency of diamond wire. This algorithm possesses the capability to be customized for various quarries that involve different rock types, utilizing their distinctive mechanical and physical properties such as uniaxial compressive strength (UCS), Young’s modulus, abrasive factor, and hardness. |

| Researcher/Reference | Objective of the study | Results and Conclusions |

|---|---|---|

| (Tumac, 2015) | Prediction of large diameter circular diamond saws (LCDS) in cutting carbonate rocks | A multiple regression model was introduced to predict the performance of Laser-induced Crack Desorption System (LCDS) using data obtained from the Schmidt hammer test conducted on the stones prepared for cutting. |

| (Tumac, 2016) | Prediction of sawability and the performance of LCDS using artificial neural network | A prediction model was presented to evaluate the performance of the LCDS, taking into account factors such as Brazilian tensile strength, Cerchar abrasivity index, UCS, porosity, and density. |

| (Sengun & Altindag, 2013) | Prediction of specific energy consumption in carbonate stones processing by circular diamond saws | The specific energy (SE) value in cutting was compared with various rock properties including bulk density, apparent porosity, UCS, Brazilian tensile strength, flexural strength, Schmidt rebound hardness, shore hardness, point load strength index, Los Angeles abrasion, and P-wave velocity for 12 different carbonate rocks. Through regression analysis, it was observed that rocks with higher density, compressive strength, flexural strength, Schmidt and shore hardness, point load index, and P-wave velocity exhibited higher SE values during cutting. |

| (Ersoy & Atıcı, 2004) | Performance characteristics of circular diamond saws with different rocks | The performance of diamond saw blades is influenced by a combination of intricate factors, with the most significant parameters being the depth of cut, SE, and feed rate. These parameters play a critical role in controlling the rate of material removal during cutting operations. |

| (Dong et al., 2021) | Investigation of performance of traditional diamond saw in granite cutting | The performance of wire frame saws demonstrates an improvement as the feed rate and cutting length increase, while it shows a decline with the speed of the main shaft and the chip thickness per diamond crystal. Additionally, a larger contact arc and the consistent formation of longer chips contribute to enhancing the overall performance of the saw. |

| (Fener et al., 2007) | Performance prediction of Circular diamond saw machines cutting carbonate rocks | The predictability of sawability and cutting performance can be achieved by utilizing the values of compressive strength, tensile strength, and Los Angeles (LA) abrasion. Simple and multiple regression analysis can be employed to establish relationships and make predictions based on these parameters. |

| Uncontrollable rock mass properties | Partially or fully controlled parameters | |

|---|---|---|

| Properties related to machines and tools | Operating conditions | |

| ● Hardness ● Strength ● Moisture content ● Degree of weathering or alteration ● Discontinuities ● Mineralogical properties and textural characteristics |

● Machine power ● Machine positioning on either vertical or horizontal cutting ● Number of beads per meter ● Wire speed ● Cutting angle between wire and horizontal level ● Amount of cutting area with respect to angle variation ● Diamond bead structure ● Dimensions of block ● Diameter of pulley ● Machine Vibrations |

● Technical personnel ● Technique used |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).