Submitted:

11 July 2023

Posted:

12 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

Methods

3. Results

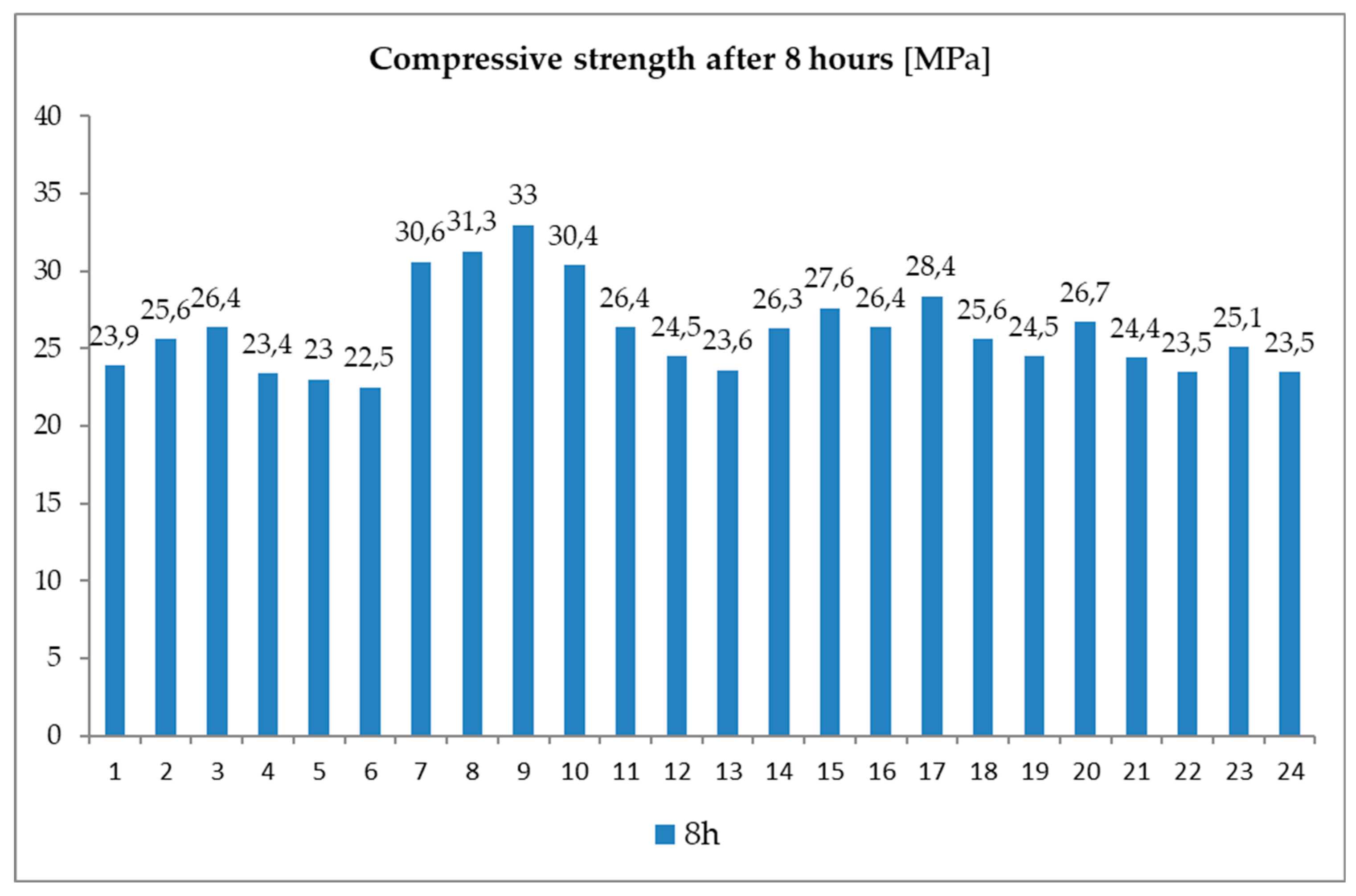

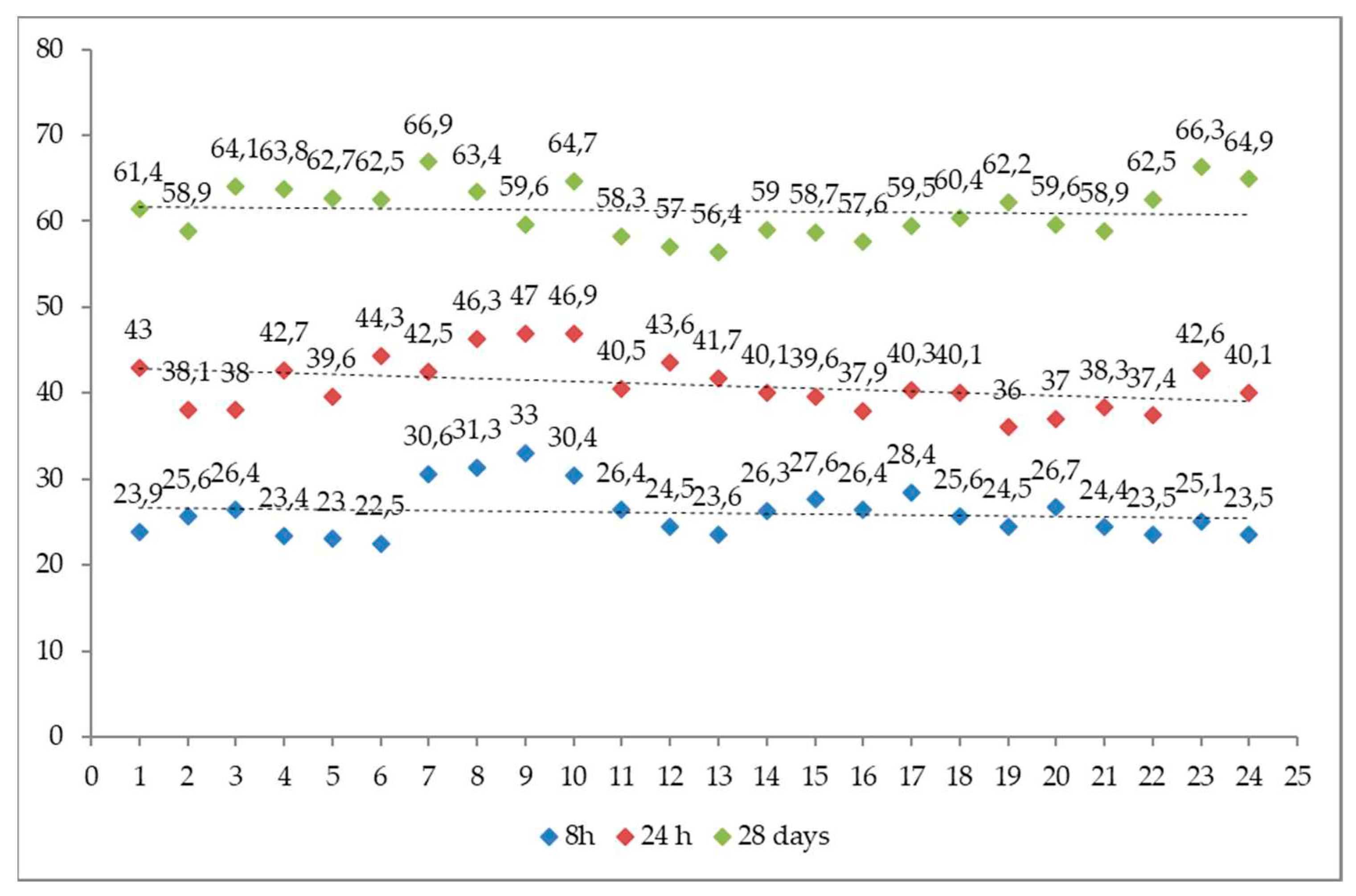

3.1. Compressive strength

3.2. Flexural strength and tensile strength of concrete

3.3. Determination of frost resistance after 150 cycles

3.4. Determination of resistance to freezing and thawing in the presence of de-icing salts

3.5. Technical and economic analysis of the use of fast-setting concrete

3.5.1. Road operator costs

- -

- the area of occupation of the surface for the replacement of a single slab, taking into account the space needed for technological service, including machine settings - 4.5mx30m=135m²,

- -

- occupation of the roadway to a width of 3.5 m, traffic lane + 0.5 m, marking = 4.0 m

- -

- costs of maintenance of the implemented temporary traffic organization - PLN 500/day,

- -

- cost of technological facilities and labour - PLN 4000/day,

- -

- costs of concrete care - PLN 500/day,

- -

- costs of traditional surface concrete - PLN 500/m³,

- -

- fast-setting concrete delivered from an external manufacturer - PLN 3,000/m³.

3.5.2. Costs and benefits of road users and the environment

- -

- cost of operating vehicles based on technical data: type of vehicle (SO, SD, SCb, SCp, A), topography (flat, undulating, mountainous), road function (normal traffic - generally accessible, fast traffic - motorway, express road), technical condition of the surface according to SOSN (A, B, C, D), travel speed of the motor vehicle,

- -

- cost of time for road infrastructure users in passenger transport and goods,

- -

- the cost of road accidents and casualties,

- -

- the cost of emission of toxic exhaust components.

- ○

- vehicle operating costs:

- -

- renovation in the traditional concrete technology, Ke = PLN 96525,

- -

- renovation in the technology of fast-setting concrete, Ke = PLN 3217.

- ○

- time costs of road infrastructure users in passenger transport:

- -

- renovation in traditional concrete technology, KC = PLN 11266,

- -

- renovation in the technology of fast-setting concrete, KC = PLN 376.

- ○

- costs of road accidents and victims of road infrastructure users:

- -

- renovation in the traditional concrete technology, Kw = PLN 174135,

- -

- renovation in the technology of fast-setting concrete, Kw = PLN 5804.

- ○

- environmental pollution costs of road infrastructure users:

- -

- renovation in traditional concrete technology, Ks = PLN 36985,

- -

- renovation in the technology of fast-setting concrete, Ks = PLN 1233.

3.6. Discussion

4. Conclusions

- (1)

- The compressive strength was 27.5 MPa after 8 hours and more than 42.8 MPa after 24 hours, which means that this concrete meets the highest requirements for repair concretes.

- (2)

- Values of frost resistance after 150 cycles of alternating freezing and thawing as well as determination of resistance to de-icing agents testify to very high quality and durability of concrete.

- (3)

- The concrete mix tested during delivery and after 2 hours of transport was characterized by high workability and the marked consistency was at the level of S3/S4.

- (4)

- An example of the practical use of concrete during the renovation of the Młodzieszyn bypass allows to shorten the time of repair or replacement of the concrete surface to one day, minimizing economic and social costs for road users and the road administrator.

References

- GLINICKI, M.A. Inżynieria betonowych nawierzchni drogowych. Wydawnictwo Naukowe PWN, Warszawa 2019.

- SHAHRAM, Asayesh; ALI AKBAR; SHIRZADI, Javid; HASAN, Ziari; MEHRI, Benyamin; Evaluating fresh state, hardened State, thermal expansion and bond properties of geopolymers for the repairing of concrete pavements under restrained conditions, Construction and Building Materials, Volume 292, 2021, 123398. [CrossRef]

- D.H. CHEN; W, ZHOU; L.i. KUN; Fiber reinforced polymer patching binder for concrete pavement rehabilitation and repair, Constr. Build. Mater. 48 (2013) 325–332. [CrossRef]

- P. DUAN; C. YAN; W. LUO; A novel waterproof, fast setting and high early strength repair material derived from metakaolin geopolymer, Constr. Build. Mater. 124 (2016) 69–73. [CrossRef]

- TIANXIONG, Guo; XINGZHONG, Weng; CONG, Liu; QINGKUN, Yu; CHUNXIAO, Zhang; YANZHAO, Li; Evaluation of the bonding and fatigue properties of an innovative rapid repair structure for concrete pavement, Constr. Build. Mater. 235 (2020). [CrossRef]

- I.-T. ROH; K.-C. JUNG; S.-H. CHANG; et al., Characterization of compliant polymer concretes for rapid repair of runways, Constr. Build. Mater. 78 (2015) 77–84. [CrossRef]

- Y.-L. CHEN; C.-J. LIN; M.-S. KO, et al., Characterization of mortars from belite-rich clinkers produced from inorganic wastes, Cem. Concr. Compos. 33 (2011) 261–266. [CrossRef]

- J.W. HAN; S.K. LEE; C. YU; C.G. PARK; Effect of rapid set binder on early strength and permeability of HES latex modified road repair pre-packed concrete, Mater. Sci. Eng. 103 (2015). [CrossRef]

- J.P. WON; J.M. KIM; S.J. LEE; S.W. LEE; S.K. PARK; Mix proportion of high-strength, roller-compacted, latex-modified rapid-set concrete for rapid road repair, Constr. Build. Mater. 25 (2011) 1796–1800. [CrossRef]

- Neeraj, BUCH; THOMAS, J; VAN DAM; Karl, PETERSON; Larry, SUTTER; Evaluation of high-early strength PCC mixtures used in full depth repairs, Constr. Build. Mater. 22 (2008) 162–174. [CrossRef]

- Kyung-Chae, JUNG; In-Taek, ROH; Seung-Hwan, CHANG; Evaluation of mechanical properties of polymer concretes for the rapid repair of runways, Compos.: Part B 58 (2014) 352–360. [CrossRef]

- Tianxiong, GUO; Yuchen, XIE; Xingzhong, WENG; Evaluation of the bond strength of a novel concrete for rapid patch repair of pavements, Constr. Build. Mater. 186 (2018) 790–800. [CrossRef]

- RUDNICKI, T.; The Impact of the Aggregate Used on the Possibility of Reducing the Carbon Footprint in Pavement Concrete. Sustainability 2022, 14, 16478. [CrossRef]

- RUDNICKI, T. The Influence of the Type of Cement on the Properties of Surface Cement Concrete. Materials 2022, 15, 4998. [Google Scholar] [CrossRef] [PubMed]

- JASICZAK, J.; WDOWSKA, A.; RUDNICKI, T.; Ultra-High Performance Concretes. Properties, technology, applications (in Polish). Association of Cement Producers (Stowarzyszenie Producentów Cementu), Kraków 2008.

- GDDKiA: Warunki Wykonania i Odbioru Robot Budowlanych D-05.03.04 Nawierzchnia z betonu cementowego. Warszawa 2017.

- PN-EN 206+A1:2016-12. Beton. Część 1: Wymagania, właściwości, produkcja i zgodność.

- EN 12390-2:2019 Testing hardened concrete - Part 2: Making and curing specimens for strength tests. Brussels, Belgium, 2019.

- Catalogue of Typical Structures of Rigid Pavements. GDDKiA, Warszawa, GDDKiA, 2014. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/Dokumenty%20techniczne/KTKNS.pdf (accessed on 30 September 2020).

- EN 12390-3:2019 Testing hardened concrete - Part 3: Compressive strength of test specimens. Brussels, Belgium, 2019.

- EN 12390-6:2019. Testing hardened concrete - Part 6: Tensile splitting strength of test specimens. Brussels, Belgium, 2019.

- EN 12390-5:2019. Testing hardened concrete - Part 5: Flexural strength when splitting test specimens. Brussels, Belgium, 2019.

- PN-B-06250:1988 Polish Standard Normal Concrete (in Polish); PKN: Warsaw, Poland, 1988.

- EN 12390 PKN-CEN/TS 12390-9 testing hardened concrete - Part 9: Freeze-thaw resistance.

- Rudnicki, T.; Boroński. J.; Stałowski, P.; Kaczmarek, P.; Witkowski, P.; Modern repair system for concrete pavement based on fast-setting concrete mixes. 14th International Symposium on Concrete Roads 2023. Kraków 2023.

- Stałowski, P.; Pawlik, M.; Technical requirements for the prevention of aggregate reactivity and the availability of materials. 14th International Symposium on Concrete Roads 2023. Kraków 2023.

| Property | Unit | Type of cement CEM I 52,5 R |

|---|---|---|

| Water Lust | % | 32.7 |

| Beginning of cement setting | min | 208 |

| End of cement setting | min | 266 |

| Consistency in volume | mm | 0.9 |

| Specific surface | cm2/g | 4612 |

| Specific density | cm3/g | 3.14 |

| Compressive strength F1 | MPa | 28.7 |

| Compressive strength F2 | MPa | 41.1 |

| Compressive strength F28 | MPa | 65.8 |

| SO3 | % | 3.1 |

| eqNa2O | % | 0.82 |

| Cl- | % | 0.07 |

| Sieve [mm] | Screening [%] | ||

|---|---|---|---|

| Granit 8/16 | Granit 2/8 | Sand 0/2 | |

| 16.000 | 1.7 | 0.0 | 0.0 |

| 8.000 | 96.3 | 1.2 | 0.0 |

| 4.000 | 2.0 | 59.7 | 0.0 |

| 2.000 | 0.0 | 39.1 | 2.5 |

| 1.000 | 0.0 | 0.0 | 15.9 |

| 0.500 | 0.0 | 0.0 | 25.5 |

| 0.250 | 0.0 | 0.0 | 43.4 |

| 0.125 | 0.0 | 0.0 | 11.9 |

| 0.000 | 0.0 | 0.0 | 0.8 |

| Samples | Length change over time [day] | |||||

|---|---|---|---|---|---|---|

| L7 | L14 | L28 | L91 | L182 | L365 | |

| 1 | -0.002 | 0.003 | 0.001 | 0.008 | 0.014 | 0.016 |

| 2 | -0.004 | 0.003 | 0.001 | 0.009 | 0.012 | 0.015 |

| 3 | -0.003 | 0.003 | 0.002 | 0.007 | 0.012 | 0.014 |

| Average value | -0.003 | 0.003 | 0.001 | 0.008 | 0.013 | 0.015 |

| Samples | Length change over time [day] | |||||

|---|---|---|---|---|---|---|

| L7 | L14 | L28 | L91 | L182 | L365 | |

| 1 | 0.000 | -0.001 | -0.002 | 0.006 | 0.018 | 0.027 |

| 2 | -0.001 | 0.000 | -0.003 | 0.006 | 0.016 | 0.019 |

| 3 | -0.001 | -0.001 | -0.001 | 0.006 | 0.016 | 0.022 |

| Average value | -0.001 | -0.001 | -0.002 | 0.006 | 0.017 | 0.023 |

| Materials | Concrete mix compositions, % |

|---|---|

| CEM I 52,5 R | 16.46 |

| Water | 15.31 |

| Granit 2/8 | 23.81 |

| Granit 8/16 | 19.51 |

| Sand 0/2 | 22.82 |

| PC 1 | 0.19 |

| PC 2 | 0.10 |

| PC 3 | 1.81 |

| Properties of pavement concrete | Requirements | Test method |

|---|---|---|

| Compressive strength class for traffic category KR5 ÷ KR7, not lower than: |

C40/50 | PN-EN 12390-3 |

| Flexural strength of concrete for traffic category KR5 ÷ KR7, not lower than: |

5.5 MPa | PN-EN 12390-5 |

| Tensile strength of concrete when splitting for traffic category KR5 ÷ KR7, not lower than: |

3.7 MPa |

PN-EN 12390-6 |

| Concrete frost resistance test F150: - weight loss of the sample, not more than, % - decrease in compressive strength, no more than, % |

5 % 20 % |

PN-B-06250 |

| Description of the designation | results | average result | requirement |

|---|---|---|---|

| Flexural strength, MPa | 7.2 | 7.9 | > 5.5 |

| 8.6 | |||

| 7.8 | |||

| Tensile strength, MPa | 4.8 | 5.1 | > 3.7 |

| 5.3 | |||

| 5.1 |

| Frost resistance test F150 | ||||

|---|---|---|---|---|

| Description of the designation | average result | Rc (MPa) |

Rc150 (MPa) | requirement |

| Mean decrease of the strength of specimens ΔR, % | 2.30% | 62.7 | 66.3 | < 20% |

| 68.4 | 66.7 | |||

| 73.8 | 70.1 | |||

| Mass change of specimens subjected to cyclical freezing and thawing ΔG, % | 2320 | 2314 | < 5% | |

| 0.29% | 2386 | 2378 | ||

| 2344 | 2337 | |||

| Mass loss (kg/m2) | Degree of defect | ||

|---|---|---|---|

| After 28 cycles | After 56 cycles | m56/m28 | requirement |

| 0.024 | 0.030 | 0.80 | < 2.0 |

| 0.013 | 0.015 | 0.87 | |

| 0.028 | 0.033 | 0.84 | |

| 0.027 | 0.032 | 0.85 | |

| Renovation item | time | unit price | traditional concrete | fast-setting concrete |

|---|---|---|---|---|

| cost of concrete | 1 | 2000x6m3 | 12 000 | |

| 30 | 500x6m3 | 3 000 | ||

| roadway cost | 1 | 135m2x10pln | 1 350 | |

| 30 | 135m2x10pln | 40 500 | ||

| costs of technical service of temporary traffic organization | 1 | 500pln/day | 500 | |

| 30 | 500pln/day | 15 000 | ||

| cost of technological facilities and labor | 1 | 4000pln/day | 4 000 | |

| 3 | 4000pln/day | 12 000 | ||

| concrete curing costs | 1 | 500 pln/day | 500 | |

| 10 | 500 pln/day | 5 000 | ||

| Sum of costs | 75 500 | 18 350 |

| User and environmental costs | Traditional road concrete | Fast-setting concrete |

|---|---|---|

| vehicle operating costs V=40km/h | 811 170 pln | 27 039 pln |

| vehicle operating costs V=90km/h | 714 645 pln | 23 822 pln |

| operating costs Ke V=40km/h – V=90km/h | 96 525 pln | 3 217 pln |

| User time costs V=40km/h | 20 279 pln | 676 pln |

| User time costs V=90km/h | 9 013 pln | 300 pln |

| User time costs Kc V=40km/h - V=90km/h | 11 266 pln | 375 pln |

| Costs of road accidents and casualties | 174 135 pln | 5 804 pln |

| Environmental pollution costs | 36 986 pln | 1 232 pln |

| User and environmental costs for V=40km/h | 318 911 pln | 10 630 pln |

| Savings compared to the use of traditional concrete | 0 pln | 308 281 pln |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).