Submitted:

05 July 2023

Posted:

07 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Splicing measurement of straightness error

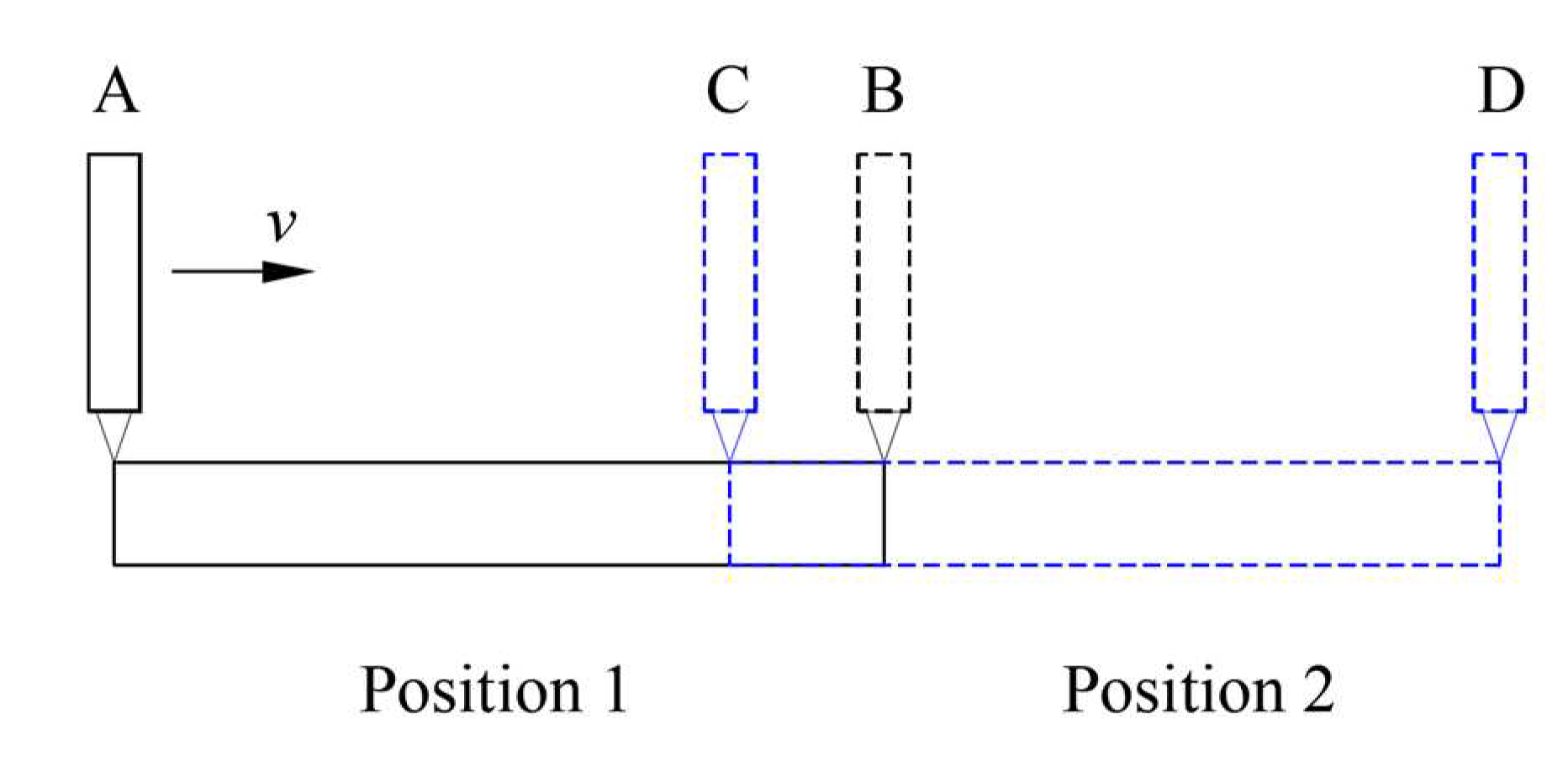

2.1. Principle of Splicing Measurement

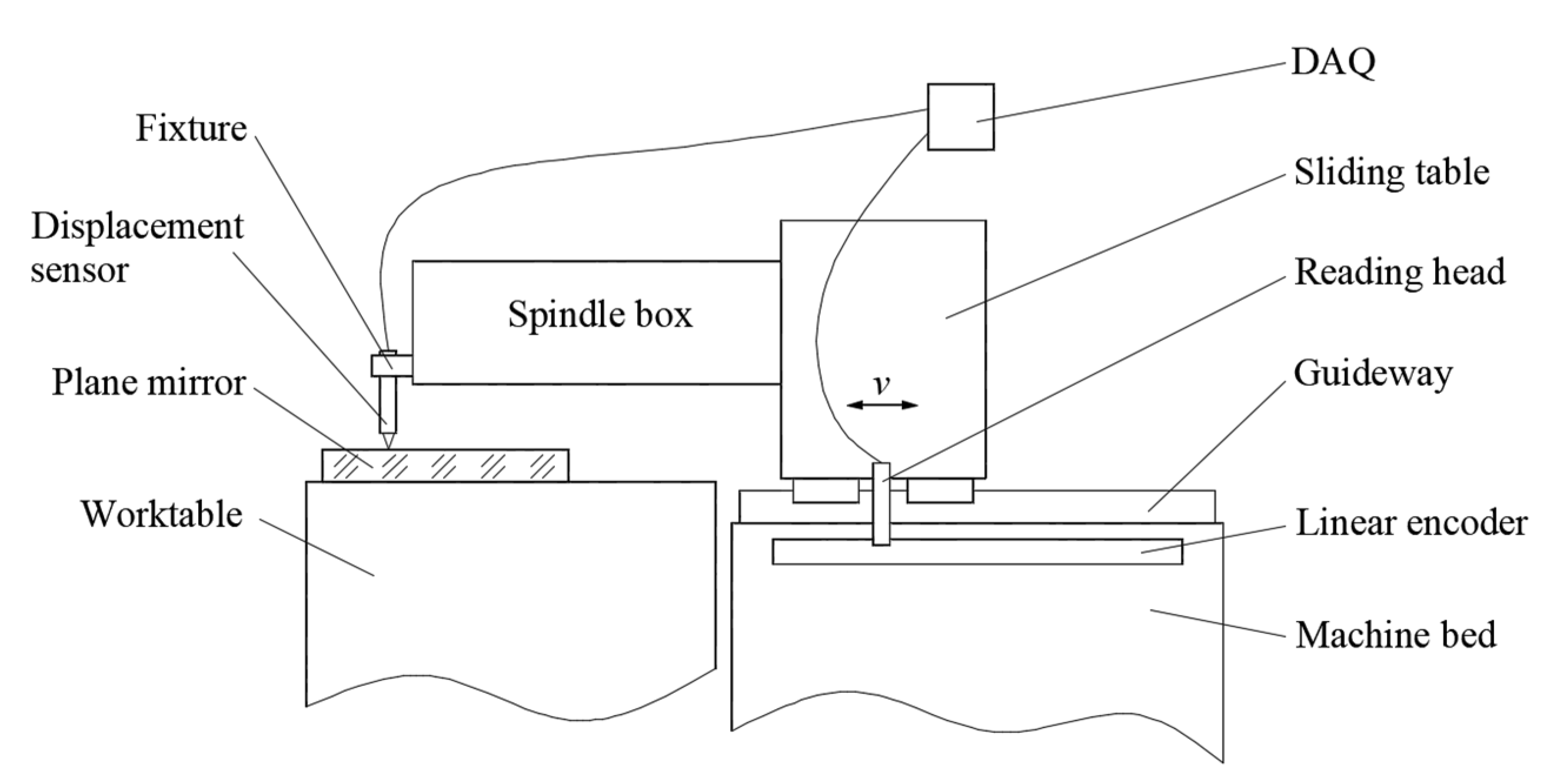

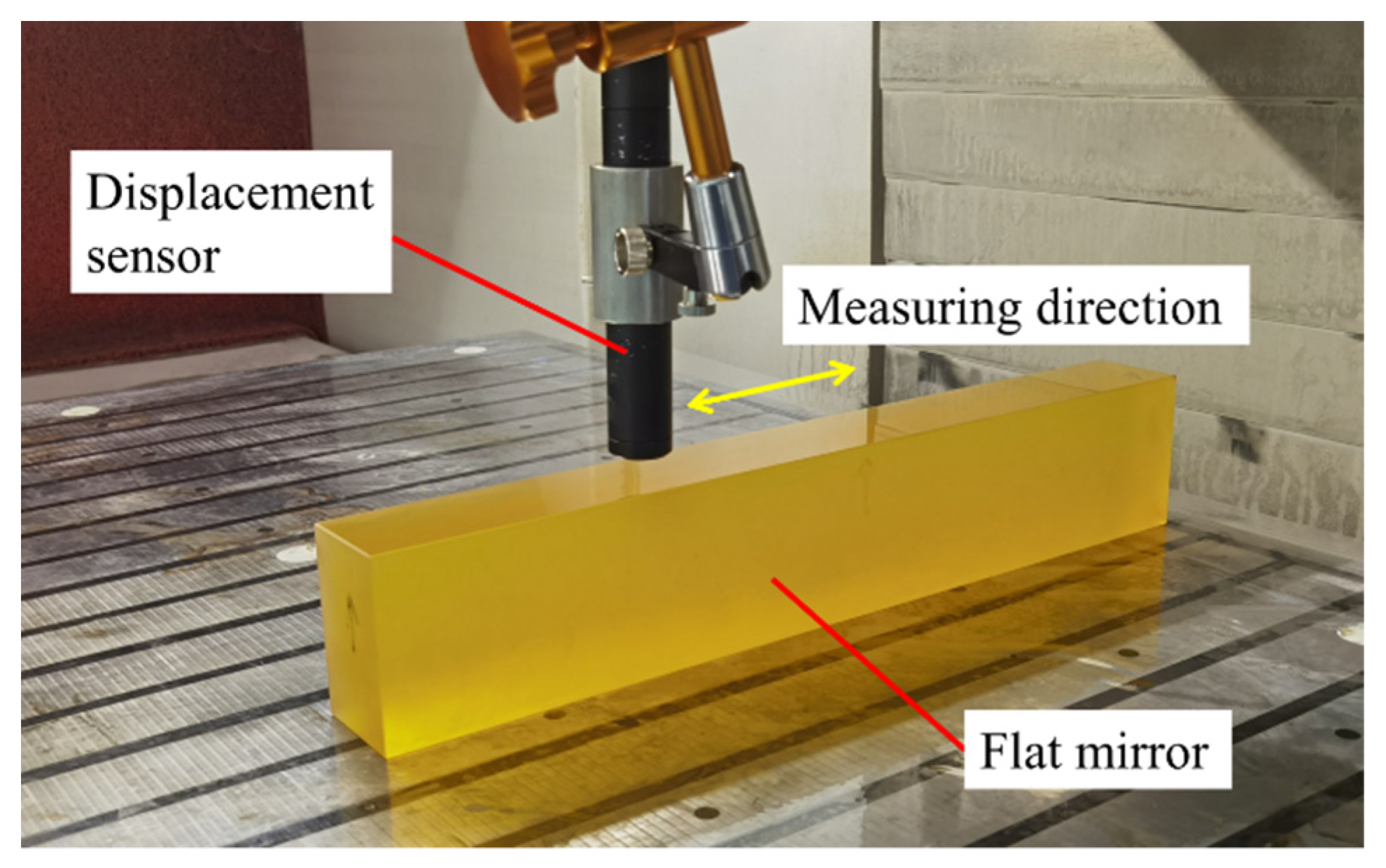

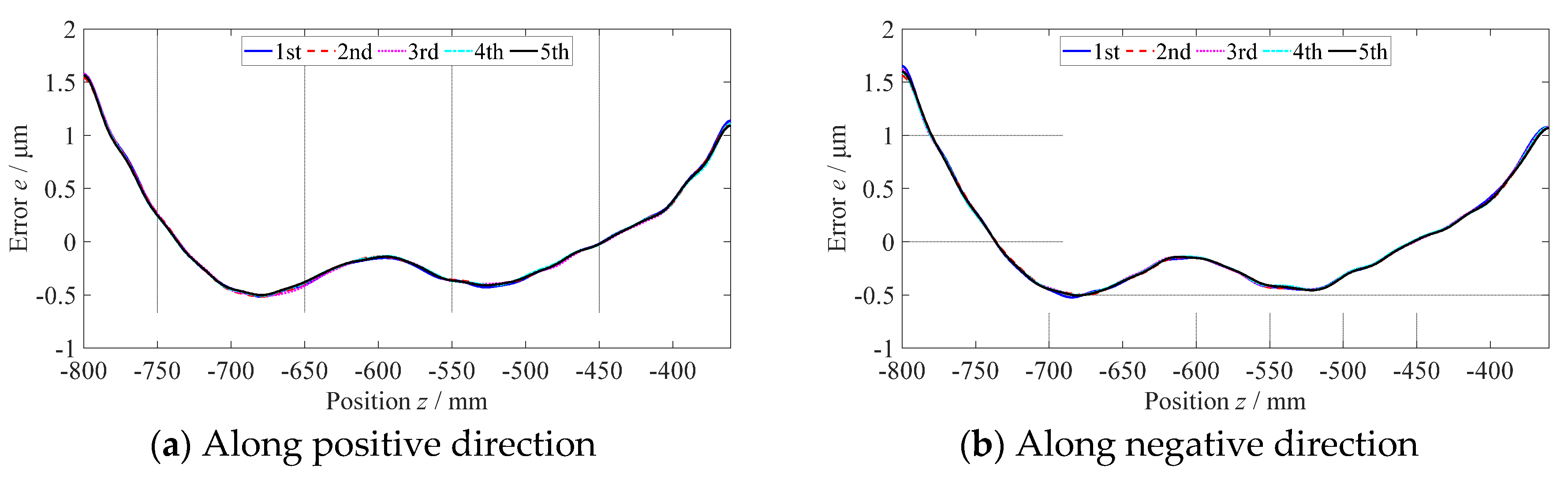

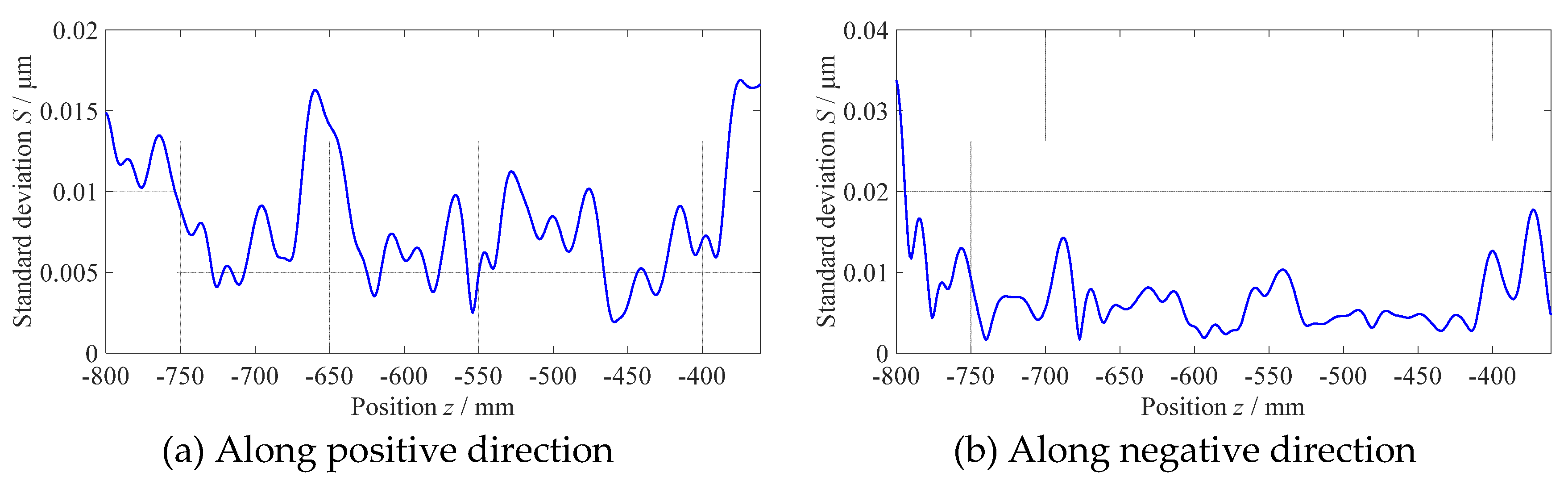

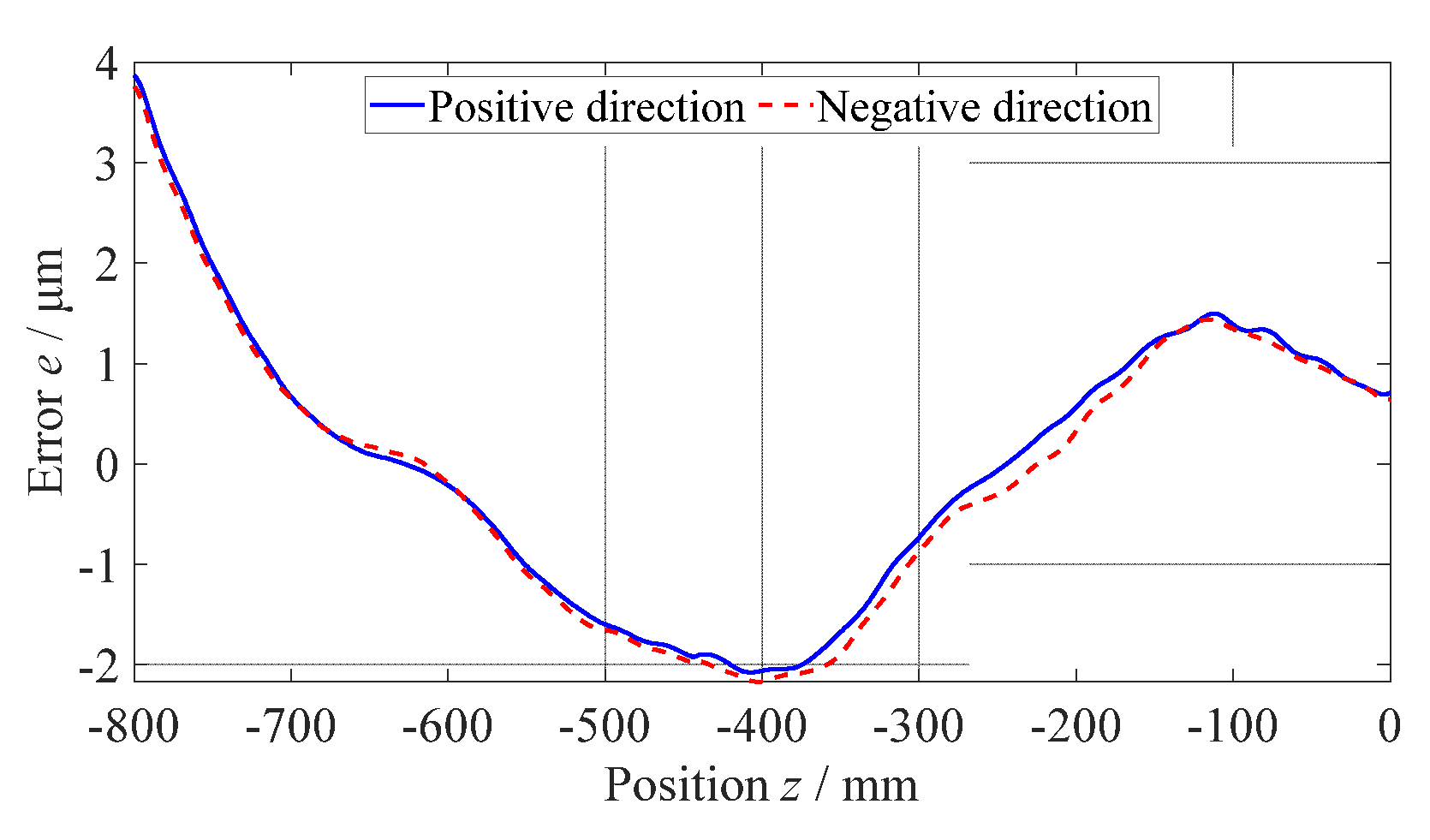

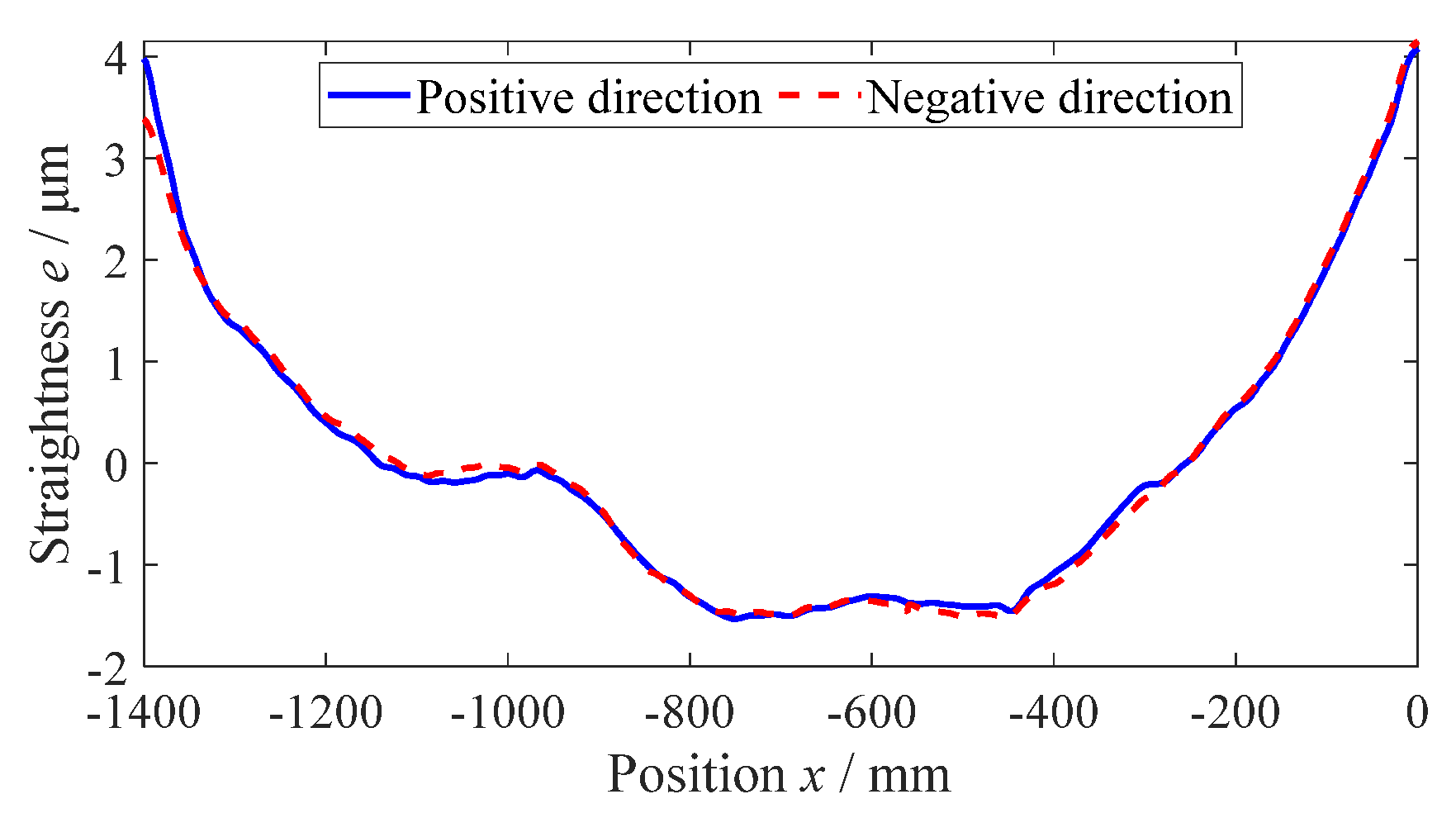

2.2. Experiments on measuring straightness error of guideways

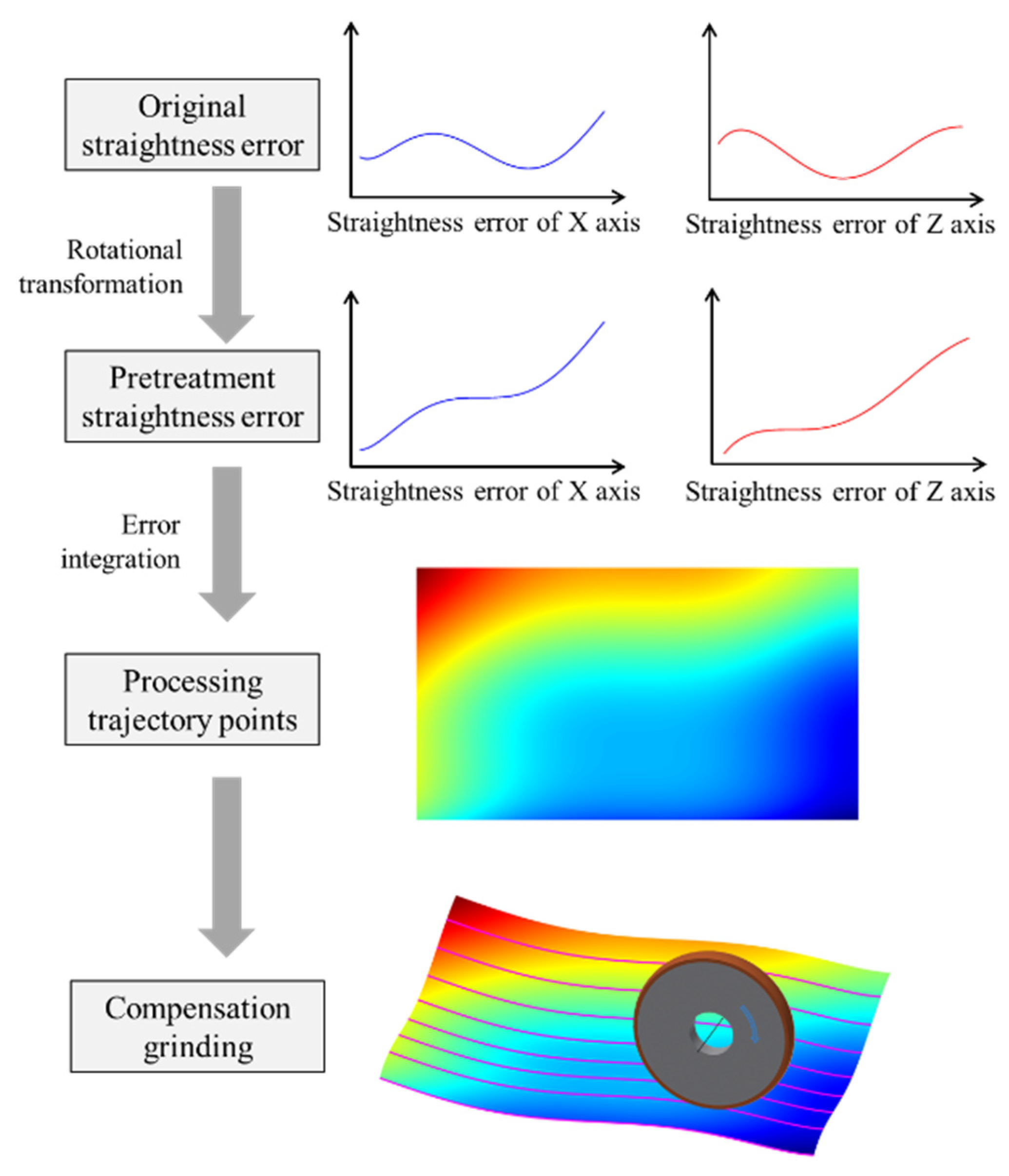

3. Compensation for Straightness Error of Guideways

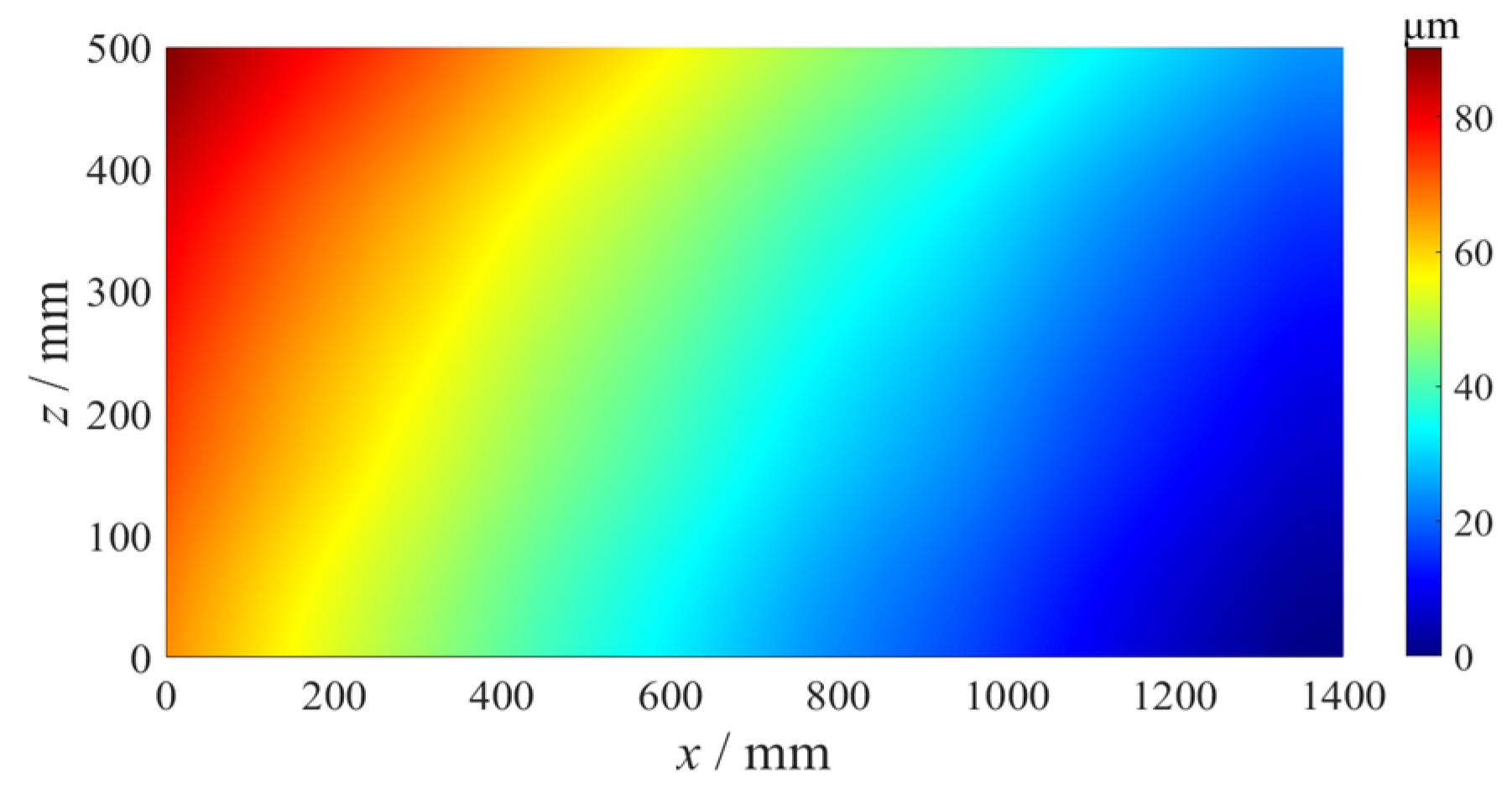

3.1. Analysis of Straightness Error Compensation

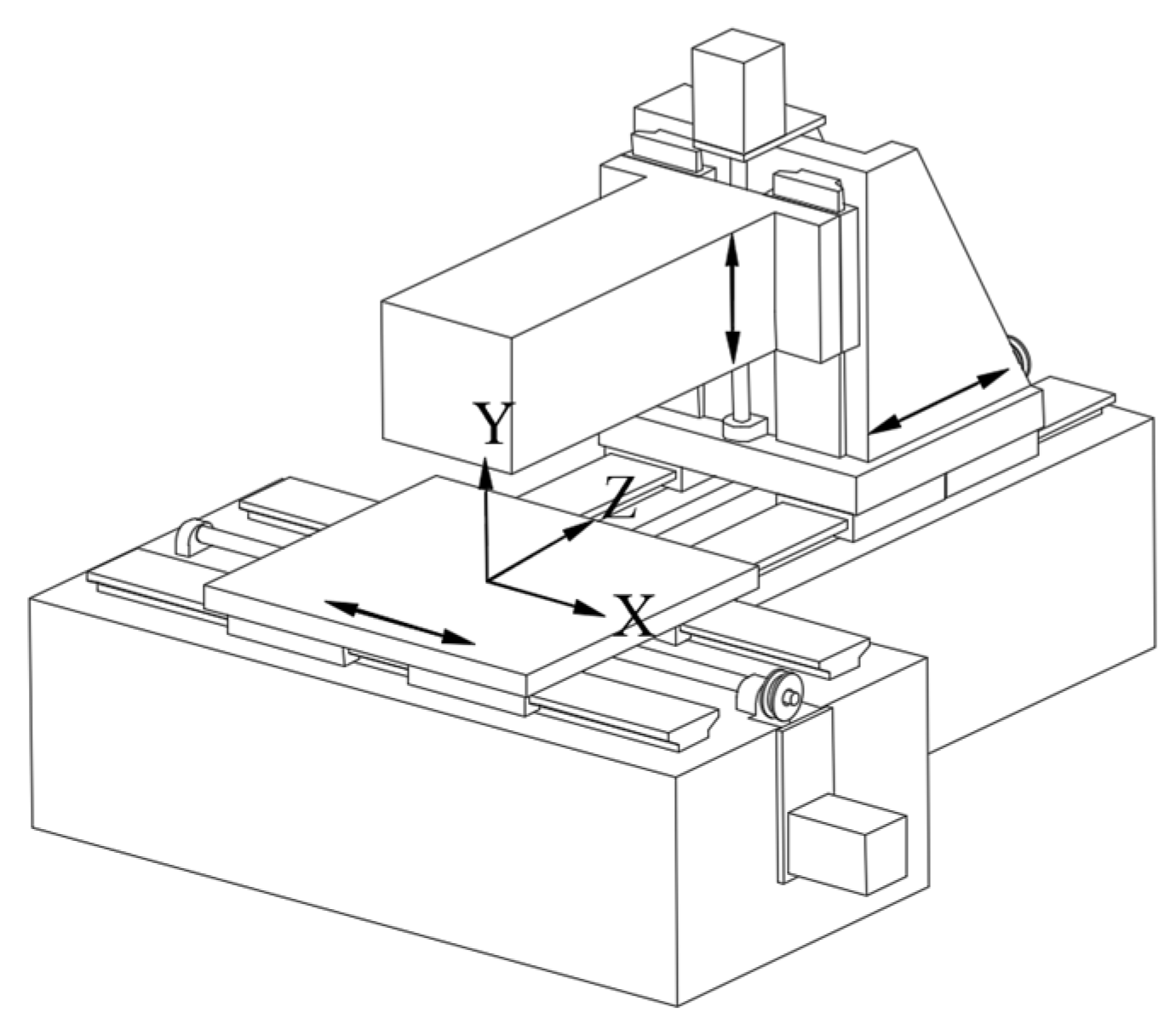

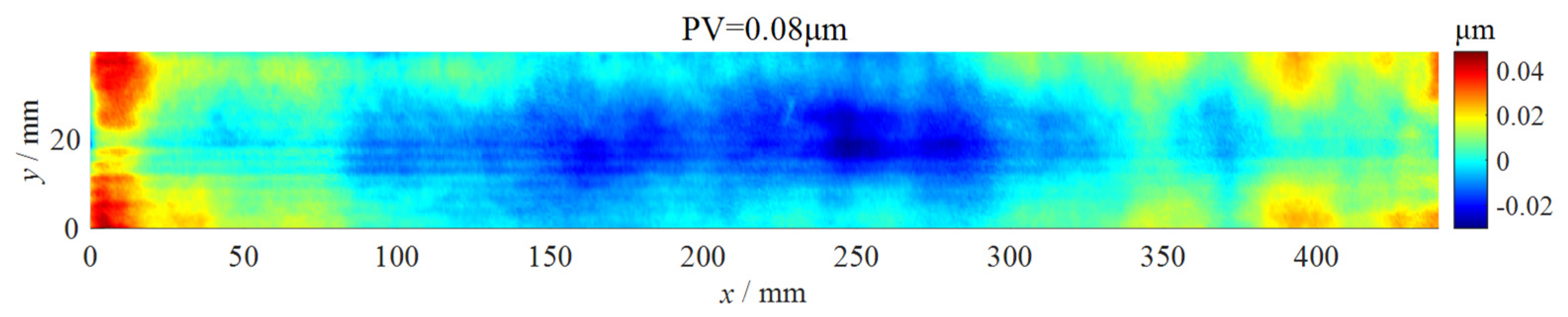

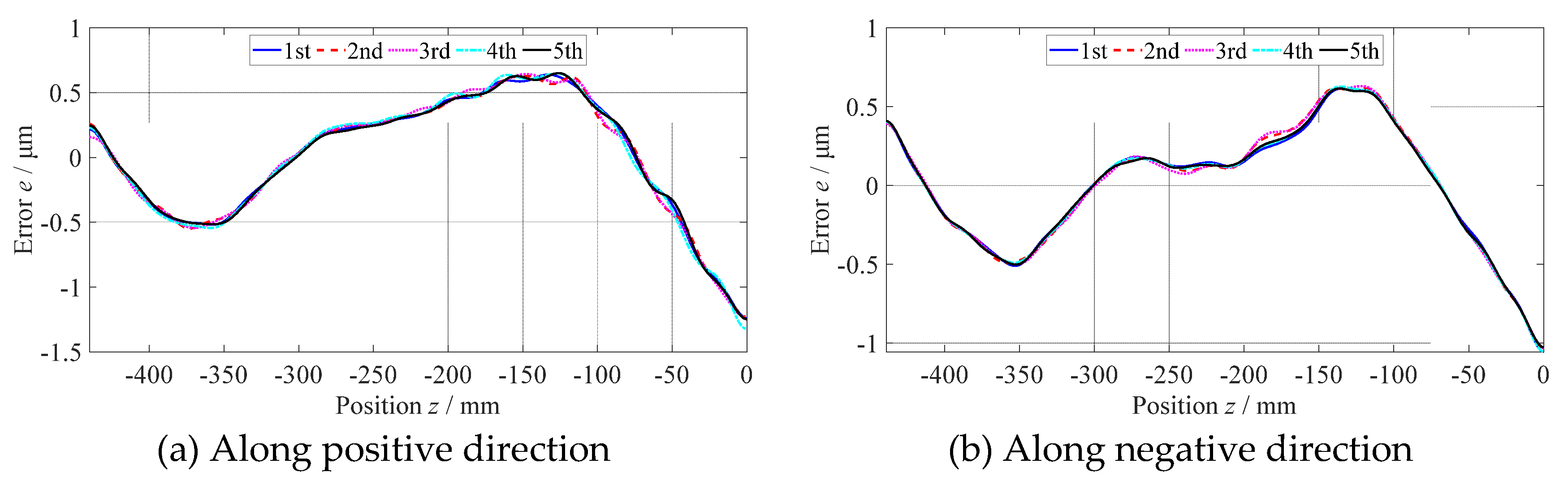

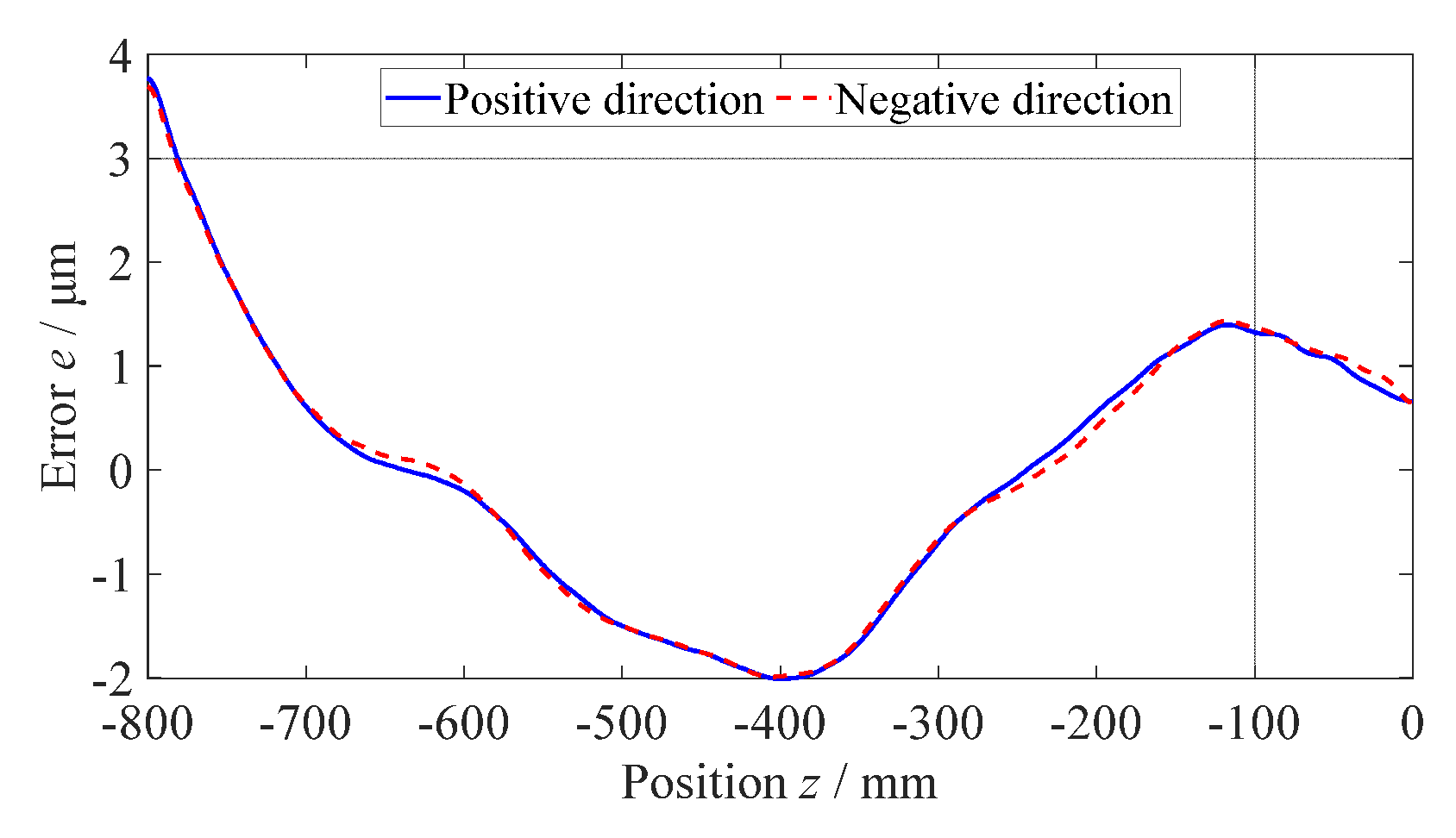

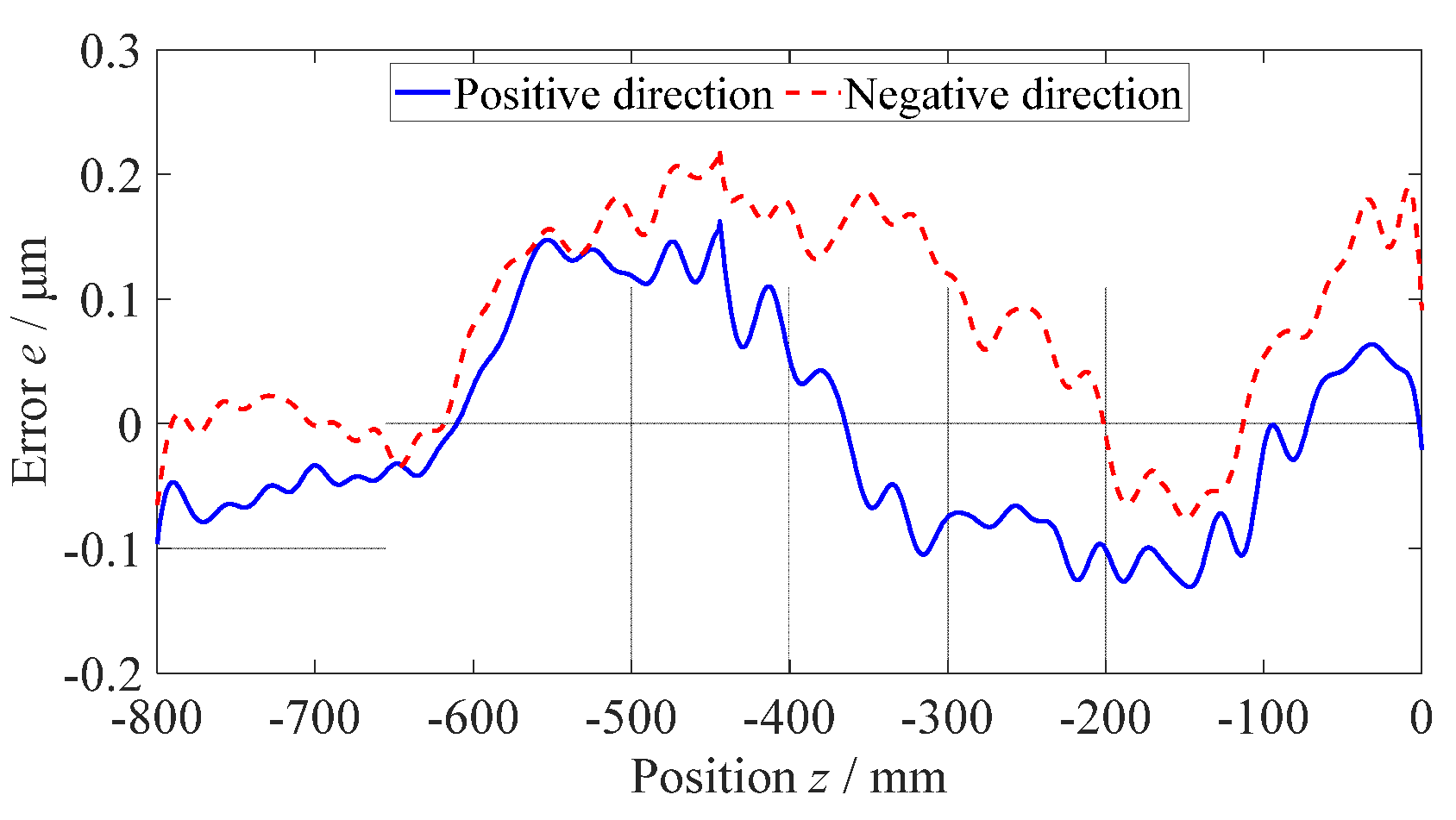

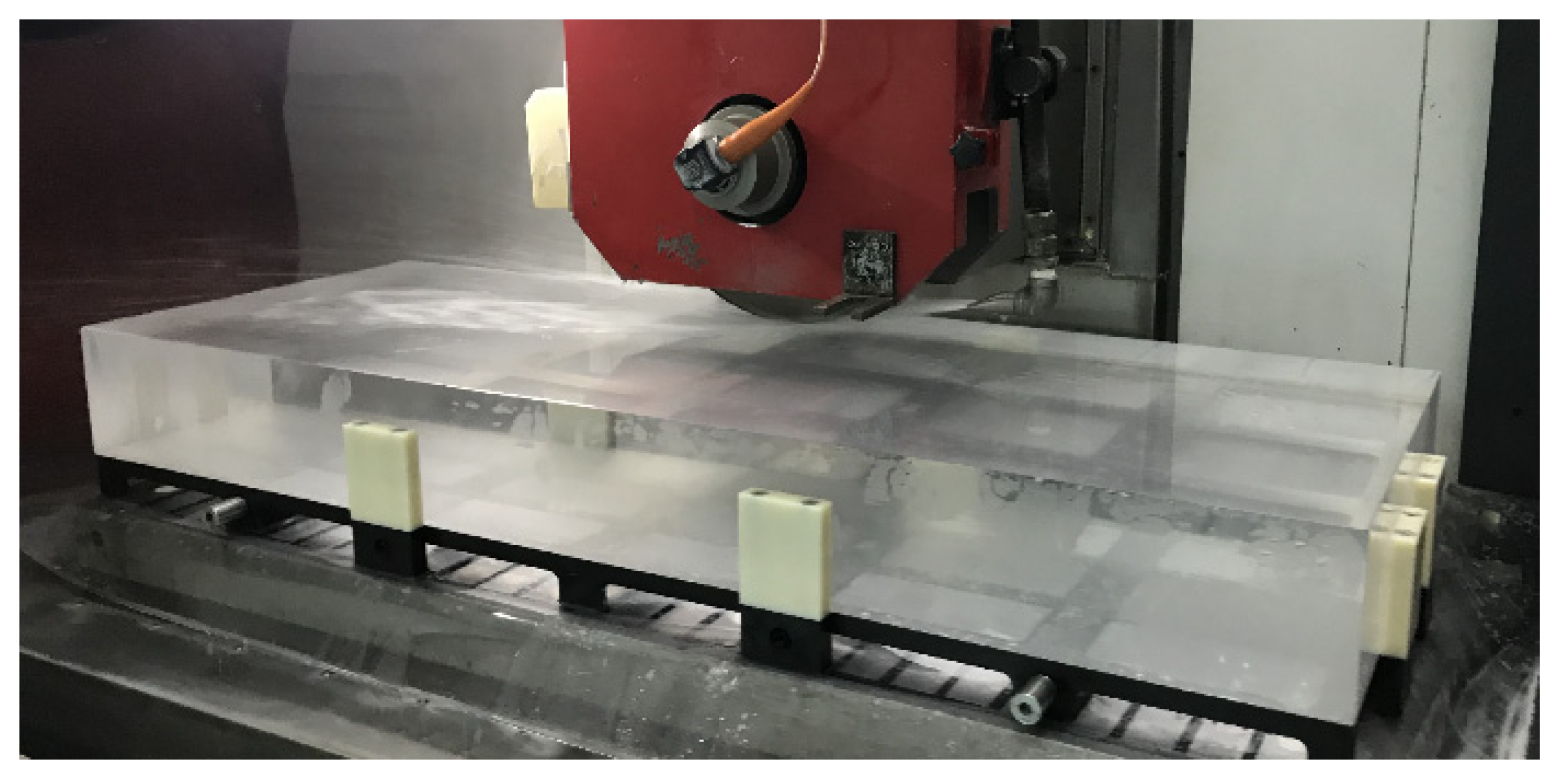

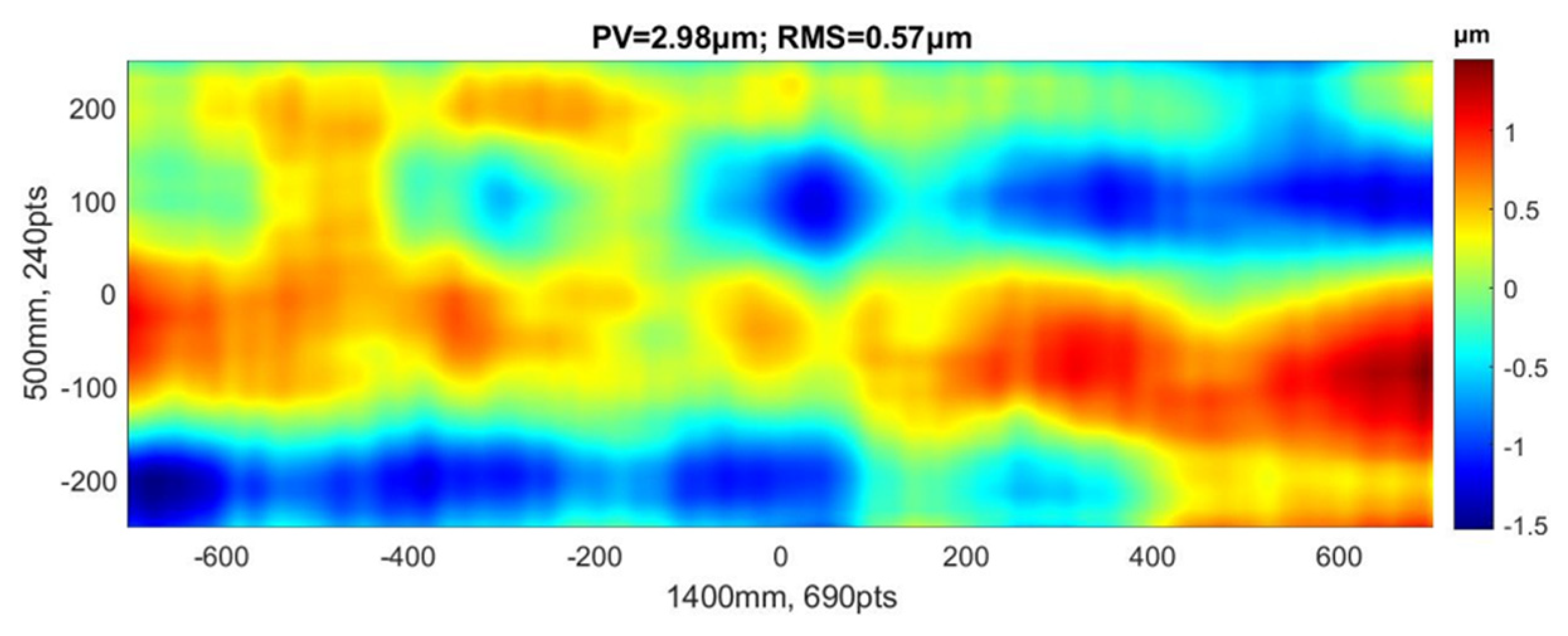

3.2. Compensation grinding experiment

4. Conclusions

References

- Hong, H.B.; Yin, Y.H. Ontology-based conceptual design for ultra-precision hydrostatic guideways with human-machine interaction. Journal of Industrial Information Integration 2016, 2, 11–18. [Google Scholar] [CrossRef]

- Patricio, F.; Jose, J. Theoretical Analysis of Straightness Errors in Coordinate Measuring Machines (CMM) with Three Linear Axes. International Journal of Precision Engineering and Manufacturing 2021, 22, 63–72. [Google Scholar]

- Zha, J.; Lv, D.; Jia, Q.; Chen, Y.L. Motion straightness of hydrostatic guideways considering the ratio of pad center spacing to guide rail profile error wavelength. The International Journal of Advanced Manufacturing Technology 2016, 82, 2065–2073. [Google Scholar] [CrossRef]

- Shi, C.C.; Wang, Z.Z.; Peng, Y.F.; Lei, P.L.; Li, C.L. Quasi-static kinematics model for motion errors of closed hydrostatic guideways in ultra-precision machining. Precision Engineering 2021, 71, 90–102. [Google Scholar] [CrossRef]

- Lei, P.; Wang, Z.; Shi, C.; Peng, Y.; Lu, F. Simulation, Modeling and Experimental Research on the Thermal Effect of the Motion Error of Hydrostatic Guideways. Micromachines 2021, 12, 1445. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.L.; Yao, X.D.; Arynov, A.; Yang, J.G. Straightness error compensation for large CNC gantry type milling centers based on B-spline curves modeling. International Journal of Machine Tools & Manufacture 2015, 88, 165–174. [Google Scholar]

- Sato, Y.; Fujlmoto, M.; Keita, R.; Kato, H.; Tasaki, R.; Ohishi, S. Designing and manufacturing of desktop type 5-axis NC precision grinder and its fundamental grinding characteristics. Journal of the Japan Society for Abrasive Technology 2021, 65, 153–161. [Google Scholar]

- Zheng, F.J.; Feng, Q.B.; Zhang, B.; Li, J.K.; Zhao, Y.Q. A high-precision laser method for directly and quickly measuring 21 geometric motion errors of three linear axes of computer numerical control machine tools. The International Journal of Advanced Manufacturing Technology 2020, 109, 1285–1296. [Google Scholar] [CrossRef]

- Ahmed, E.; Sarwat, Z. Comparative study of error determination of machine tools. The International Journal of Advanced Manufacturing Technology 2023, 124, 4575–4602. [Google Scholar]

- Vladas, V.; Mindaugas, J.; Vytautas, T. Optical device for straightness measurement. Applied Physics B: Lasers and Optics 2015, 121, 203–208. [Google Scholar]

- Wang, C.; Zhong, F.H.; Jonathan, D.E. Two-dimensional straightness measurement based on optical knife-edge sensing. Review of Scientific Instruments 2017, 88, 095109. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.Z.; Teng, X.Y.; Chen, B.Y.; Zhang, S.H.; Li, Z.Y. Three-degrees-of-freedom measurement system for measuring straightness errors and their position based on the Faraday effect. Applied Optics 2020, 59, 764–770. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.K. Testing linearity error of long guideway by laser tracker. Applied Optics 2013, 34, 686–689. [Google Scholar]

- Liu, W.Z.; Zhang, C.; Duan, F.J.; Fu, X.; Bao, R.J.; Yan, M. A method for noise attenuation of straightness measurement based on laser collimation. Measurement 2021, 182, 109643. [Google Scholar] [CrossRef]

- Li, T.; Miao, D.J.; Li, L.F.; Li, J.S.; Zhong, W. Research on stitching method for segment straightness measurement of the long guideway. Acta Metrologica Sinica 2022, 43, 837–843. [Google Scholar]

- Teng, Y.; Liu, H.L.; Liu, J.W.; Wang, C.; Ma, Z. J. A Rail Corrugation Measurement Method Based on Data splicing. Measurement 2020, 107560. [Google Scholar] [CrossRef]

- Yu, S.M.; Yao, P.; Xu, J.M.; Wang, W.; Li, Y.M.; Chu, D.K.; Qu, S.H; Huang, C.Z. Profile error compensation in ultra-precision grinding of aspherical-cylindrical lens array based on the real-time profile of wheel and normal residual error. Journal of Materials Processing Technology 2023, 312, 117849. [Google Scholar] [CrossRef]

- Zha, J.; Xue, F.; Chen, Y.L. Straightness error modeling and compensation for gantry type open hydrostatic guideways in grinding machine. International Journal of Machine Tools and Manufacture 2017, 122, 1–6. [Google Scholar] [CrossRef]

- Deng, Y.J.; Jin, X.; Zhang, Z.J. A macro–micro compensation method for straightness motion error and positioning error of an improved linear stage. The International Journal of Advanced Manufacturing Technology 2015, 80, 1799–1806. [Google Scholar] [CrossRef]

| Grinding wheel | Coolant | Grinding velocity | Feed speed | Grinding depth per time |

|---|---|---|---|---|

| Diamond wheel with grit size of 8µm~12µm | Water | 30m/s | 5000mm/min | 10µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).