1. Introduction

FGMs are defined as advanced composites because they eliminate the delamination and separation problem that is a disadvantage of conventional composites. With the use of FGMs, in-plane and transverse thickness direction stresses can be reduced, residual stress distribution can be controlled, superior thermal properties without delamination, and reduced stress intensity factors can be obtained [

1,

2,

3,

4,

5]. Therefore, it has been the subject of many studies on aviation and energy for the last 10 years [

6,

7]. However, effective FGMs manufacturing processes are still incomplete and real applications are rare. There are 3 methods in the literature regarding production processes, the first one is; They are deposition-based methods used for FGM coatings [

8,

9,

10,

11]. The second method is; They are liquid state method and involve the external addition of reinforcement particles to the melted material [

12,

13,

14,

15,

16].

The last method is; are solid state methods and these are additive manufacturing methods with powder metallurgy [

17,

18,

19,

20,

21,

22,

23].

Recently, the production of polymer composites and FGMs has been the subject of research and development for reasons such as high strength, easily customizable product properties, flexible manufacturing processes, high resistance to corrosion or erosion, and low cost. In addition, solid-state methods in polymer composite and FGM manufacturing facilitate the fabrication of complex parts and offer low cost and high accuracy. Among AM techniques, the FDM technique is the most widely used in the literature for composite and FGM production [

24,

25]. Some studies carried out in recent years in which FGM production was carried out with the FDM technique and its mechanical properties were investigated are summarized below.

Su et al. [

26] produced ABS and PLA polymers as FG using the FDM. They used X-ray computed tomography to evaluate the air gap distribution, Young's Modulus, strain history variation, and the unfilled fraction of the fabricated material and performed the tensile tests. They showed that the FDM method is suitable for FGM production and emphasized that the printing process of the material should be optimized. Wang et al. [

27] proposed a new method using continuous welding filaments to 3D print carbon fibers (CFs)/ glass fibers (GFs) Polyetheretherketone (PEEK) materials as FG. They also conducted a series of 3D printing experiments to validate their design method. They showed that 3D-printed FGMs composed of CF/GF-PEEK composites had good interlayer bonding performance and excellent toughness. They stated that the elongation at break of FGMs prepared in this study increased by 150% compared to fiber-reinforced PEEK composites. Salem et al. [

28] produced FG beams with PLA and ABS/Nylon materials using the 3D solid printing technique and investigated their post-buckling behavior. Theoretical and numerical models were developed to validate their results. They performed material topology optimization for the effect of energy released during bending mode transitions in FGM beams on material functions. Subramaniyan et al. [

29] fabricated WPC/Ceramic-PLA materials as FG with FDM and examined their tensile, compression, bending, impact, and hardness properties. They emphasized that the tensile strength of the FG structure is superior to weaker composites (such as wood polymer composite) and comparable to flexible materials (such as ceramic-reinforced polylactic acid). Anthony Xavior et al. [

30] produced ABS material with variable density in the form of FGM with additive manufacturing technology. They investigated the mechanical strength of FGM material under tension, bending, and compression. They stated that despite the decreasing density, the decrease in strength is minimal and can be used in large of tensile and bending loads. They emphasized that it is only used to a certain extent in applications involving large compression loads. Hasanov et al. [

31] produced and characterized FGM polymers (PLA-ABS) with FDM. They confirmed that the printing temperature and the volume fraction had an effect on the tensile test results. They used a data-driven approach to construct a linear regression model to formulate input data in FEA. They emphasized that 3D additive manufacturing provides a low-cost manufacturing process and that this method is a unique method for fabricating FGM structures. Hasanov et al. [

32] produced FGM by additive manufacturing using Carbon fiber and ABS materials and investigated the numerical and experimental characterization of these materials. They performed tensile testing to characterize the interface strength in direct and cascading models and stated that grading increases the strength of ABS material. They presented the results for different compositional gradient values and different interface models.

In light of all these studies, studies are continuing to show the efficiency of the FDM method in the production of FGMs and propose different numerical modeling methods in the light of experimental tests.

In this study, tensile tests were applied to FG structural samples produced by the FDM technique, and the effect of composition gradient on mechanical strength was investigated. A deficiency in additive manufacturing was observed in the ASTM standards recommended for the relevant tests, and a parametric study was presented in this context. Layer thickness, volume ratio, and total thickness, which are the basic parameters affecting the determined layer structures, were examined. On the other hand, the determined material properties were transferred to the finite element code for material modeling. The tensile behavior of FG structures was also confirmed by numerical analysis.

2. Experimental Process

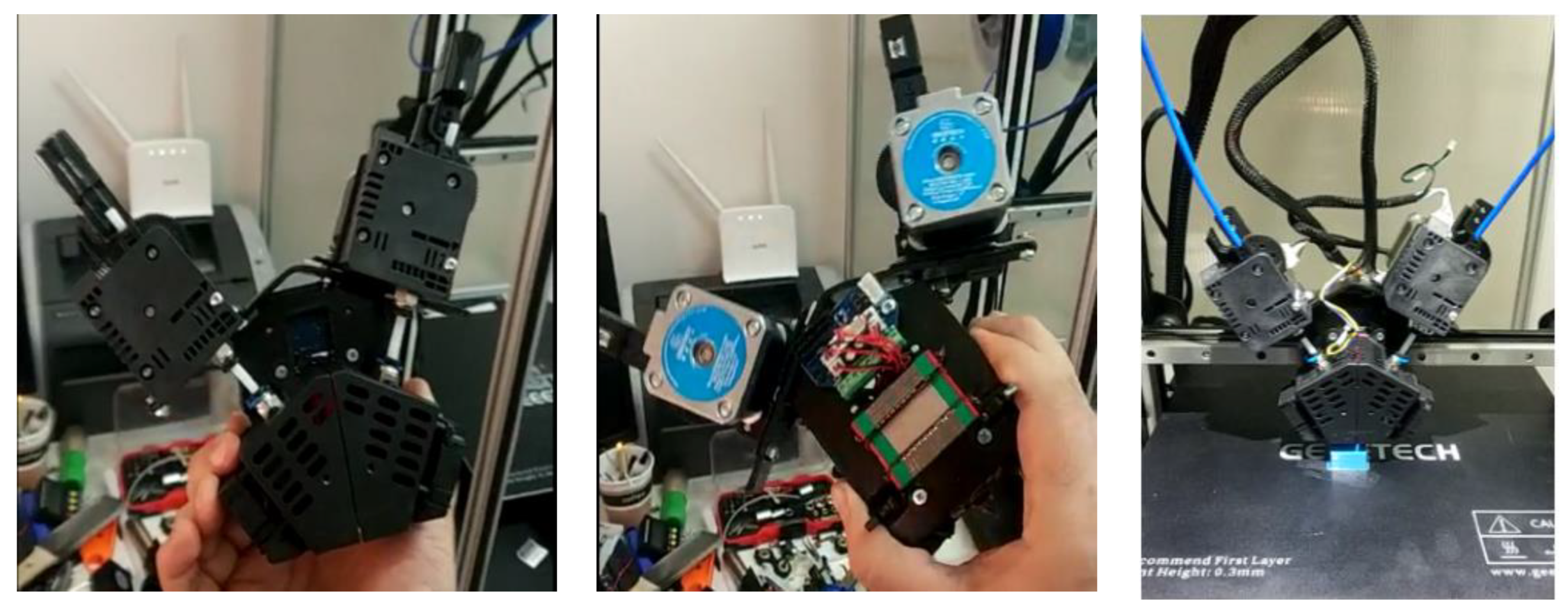

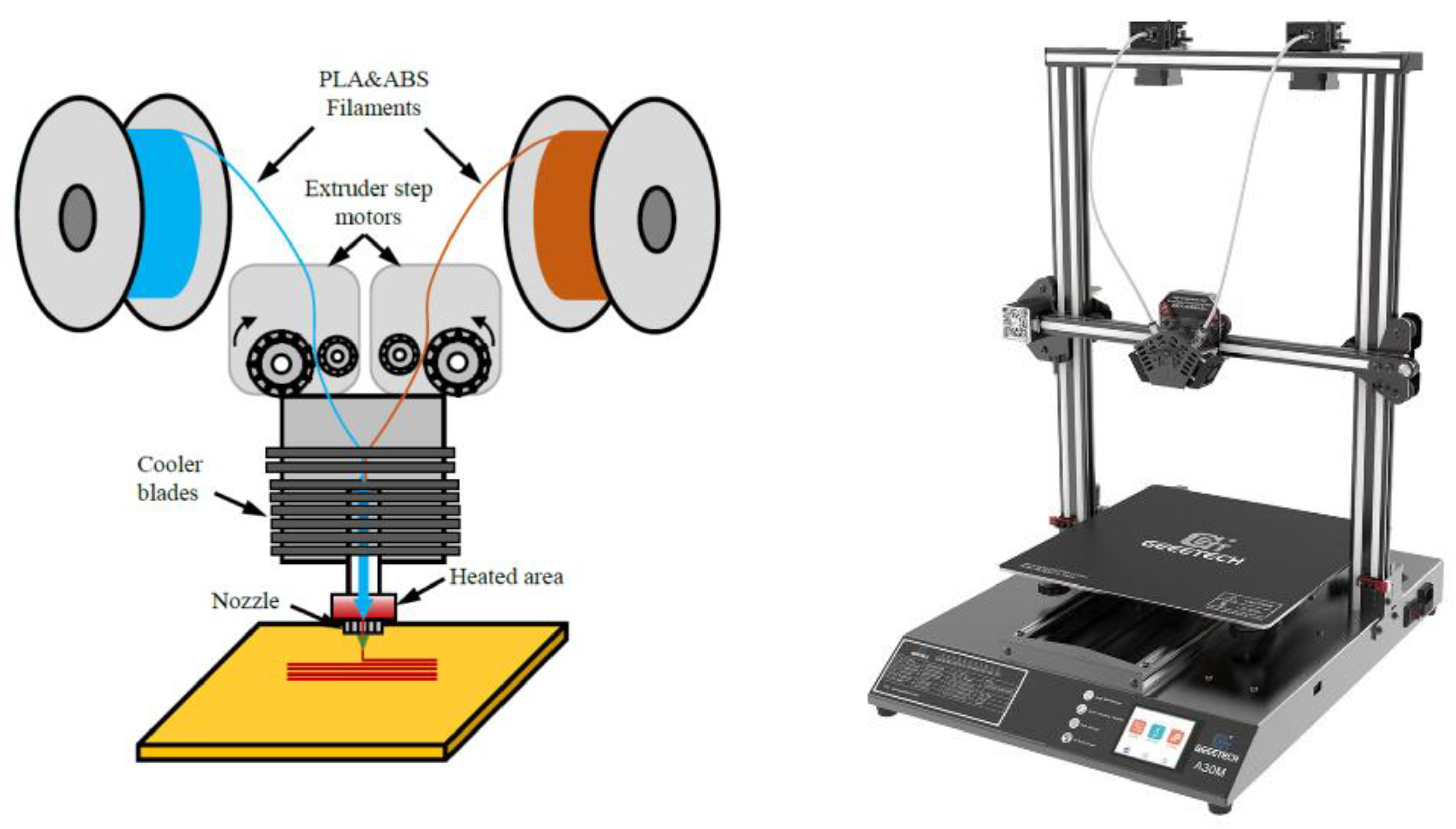

PLA and ABS filament supplied by Filameon were used in this study [

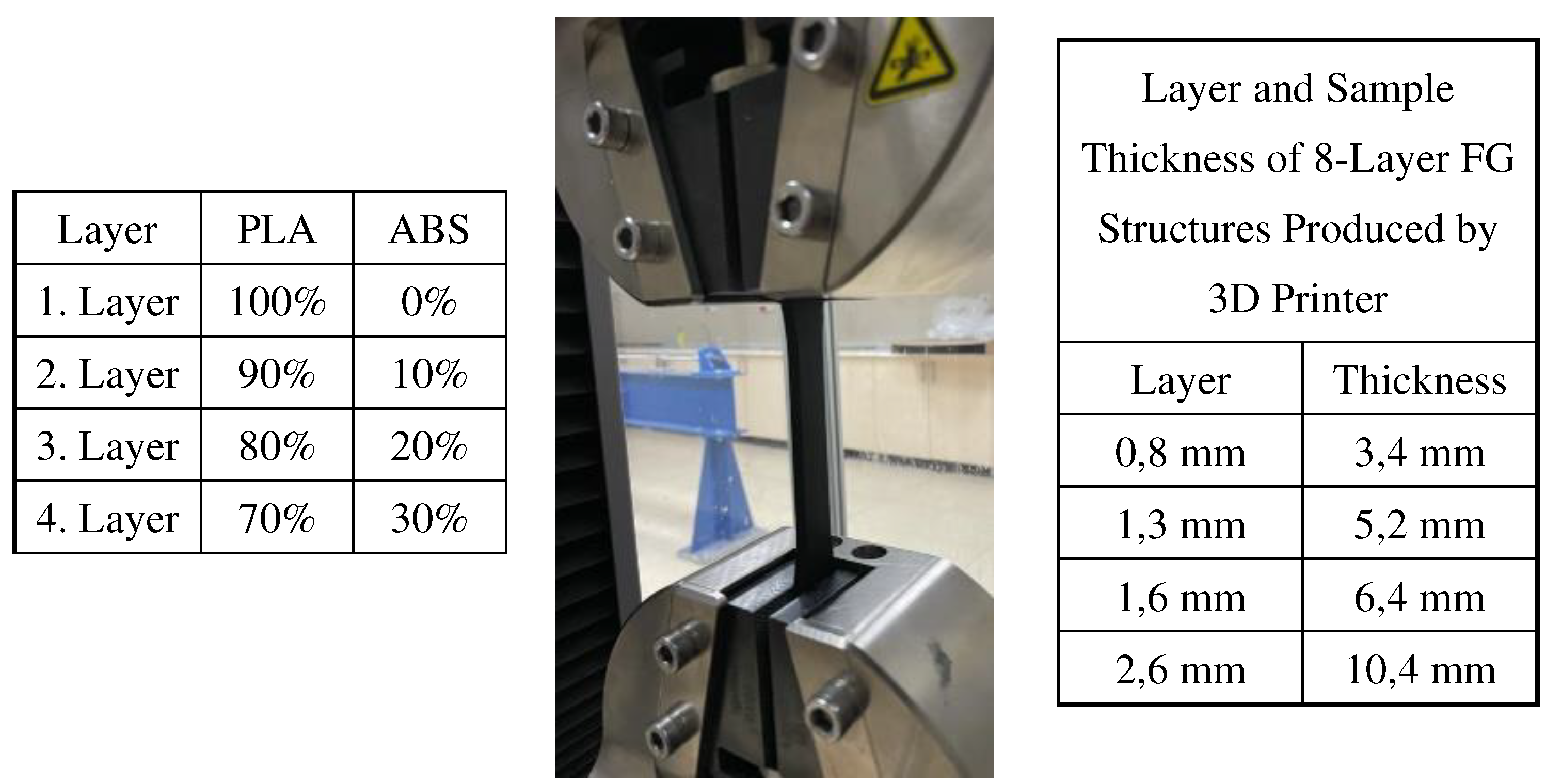

33]. The filaments are in a continuous wire. The filaments come from the spools to the feeding unit designed within the scope of the study and were written on a 300mm x 300mm heated table. A 3D printer with linear sliding ball bearings in each axis of motion was used. The printer has two inlet and one outlet printing nozzles that print by containing different materials and allow for adjustment of the mixing ratios using G-CODEs. The printing principle of the 3D printer with two inputs and one output is shown in

Figure 1. The printer has linear plain bearings and ball carriers in the X, Y, and Z axes. This ensures stable and accurate movements of the print head. The filament feed was done directly by the feeder motor unit on the X-axis movable print head. Each test specimen was produced individually and under identical conditions. Details about the printing parameters used for each test specimen are presented in

Table 1.

Since the chemical structures of PLA and ABS materials are different from each other, this necessitates that printing conditions should be designed under different conditions. Therefore, these changing conditions were taken into account when producing a functionally graded composite structure. These processes were neglected in most of the studies. For the best printing properties, the printing nozzle temperature and table temperature were gradually increased as the ABS content in the composite structure increased, and the cooling fan was turned off when the ABS content exceeded 20%. The designed test specimens were converted to.stl format via CAD program and GCODEs were created with Ultimaker CURA V4.10.0 slicing program [

34]. Mixture ratios and temperature adjustments were adjusted by editing the GCODEs by ourselves.

The properties of PLA and ABS materials produced under the conditions described above are detailed in

Table 2. This study investigated the tensile strengths of the specimens produced by determining the functionally specific volume ratios.

Figure 2.

Designed double nozzle system

Figure 2.

Designed double nozzle system

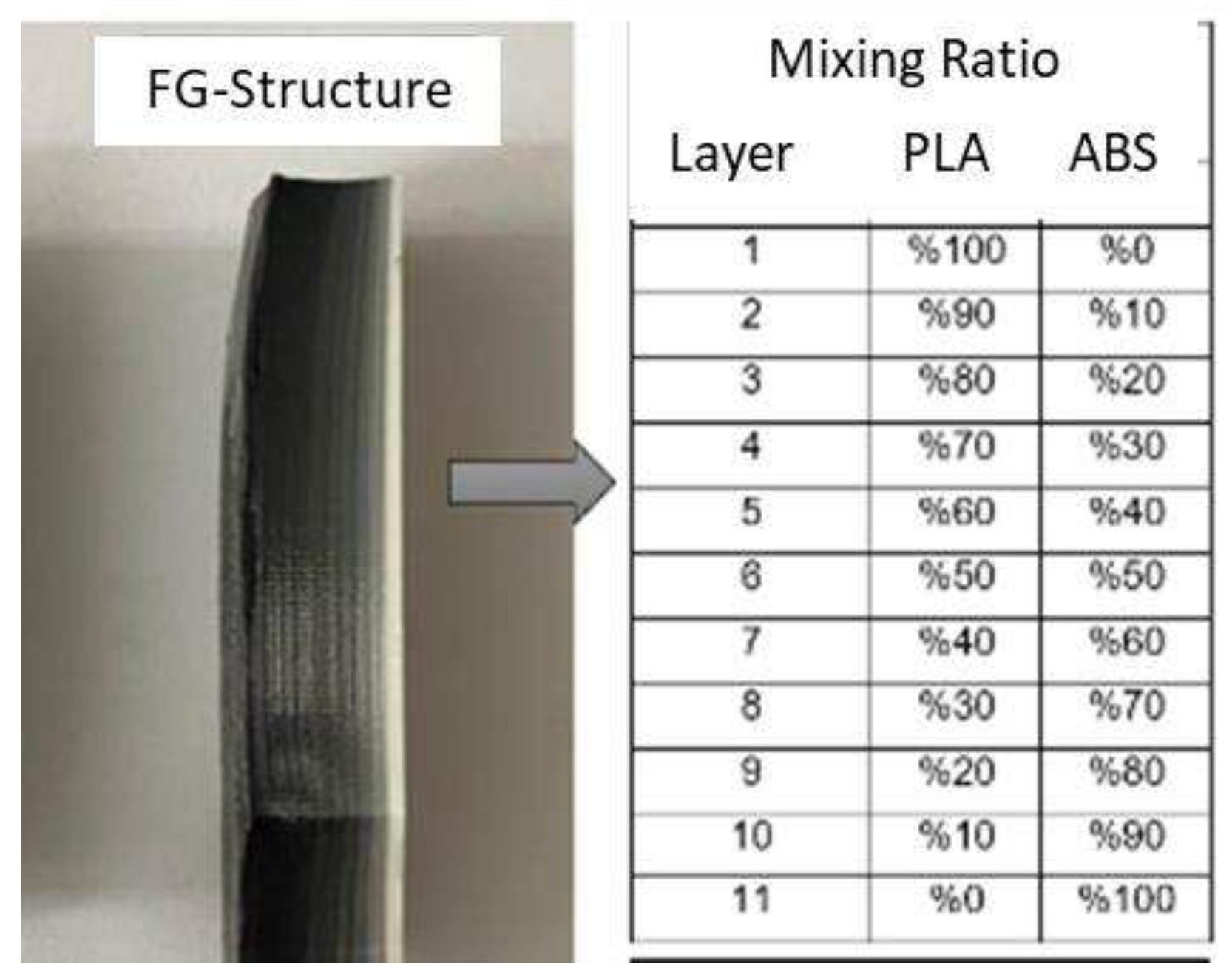

The variation of the compositional gradient exponent was considered linear in the grading of ABS and PLA materials. Functionally Graded samples for the 11 layers given in

Figure 3 were produced in all ratios. However, delamination occurred in compositions with less than 70% PLA (i.e. more than 30% ABS) (

Figure 4). Therefore, in the sample production made according to the ASTM D638 standard, the volume ratios in the FG production were made as given in

Figure 5.

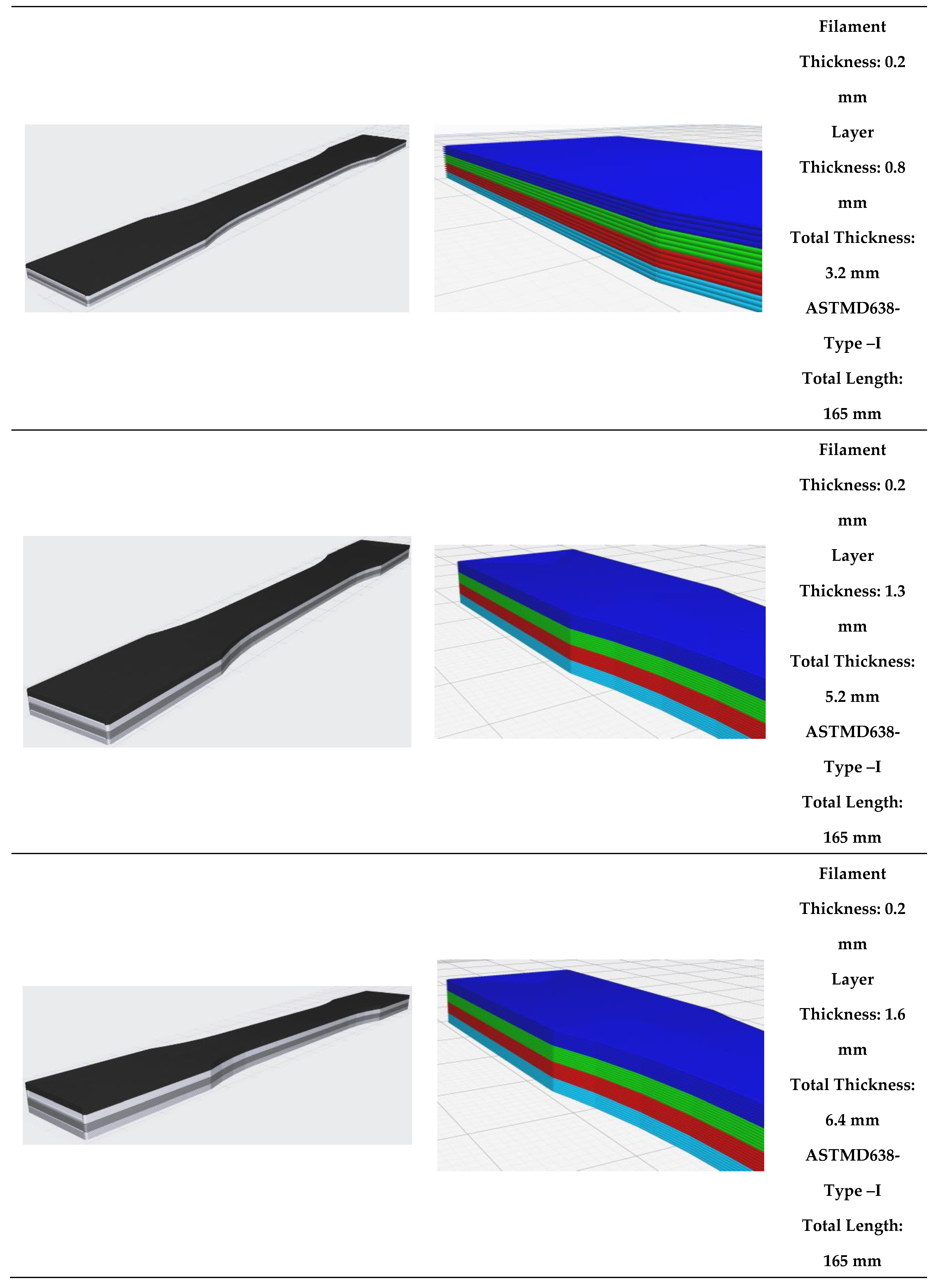

Considering the ASTM D638 standard, all dimensions change with changing thicknesses. Since the materials produced do not exhibit isotropic behavior, different parameters were planned and produced. In

Figure 5, layer thicknesses are given as 0.8, 1.3, 1.6 and 2.6 mm according to the planned functional change. The total specimen thickness resulting from these layer thicknesses represents two different types of ASTM standards. Accordingly, specimens were produced for both the same type of specimens and different thicknesses and subjected to tensile tests.

As a result of the specified layer thicknesses, the total thicknesses of the samples were 3.2, 5.2, 6.4 and 10.4 mm. The reasons for the selection of these thicknesses are as follows: Specimen thicknesses vary as a result of the layer thickness effect in FG structures whose tensile behavior was tried to be determined. According to the layer and total thicknesses to be determined, the specimen dimensions according to ASTM standard will emerge. In this respect, considering the printing parameters, the layer wall thickness is 0.4 mm. It was considered that single-walled productions may cause problems in terms of performance and a structure with 2 wall thicknesses was preferred as the first layer thickness and decided as 0.8 mm. After this stage, a layer thickness of 2 times 1.6 mm was first preferred to investigate the effect of layer thickness. At this stage, the sample thickness increased from 3.2 mm to 6.4 mm. This size range corresponds to Type I of the relevant ASTM standard. With the increase in layer thickness, the size range in the ASTM standard moves to Type III. In order to determine the differences between these dimensions, Type I was dimensioned with a layer thickness of 1.3 mm (total thickness 5.2 mm) and Type III with a layer thickness of 2.6 mm (total thickness 10.4 mm). In this way, the thickness increase within the same Type, i.e. within the same dimensions, will be analyzed and the thickness increase between different Types will be analyzed.

To determine the sizing in

Figure 5, an 11-layer FG structure was fabricated (

Figure 3) and subjected to tensile testing as shown in

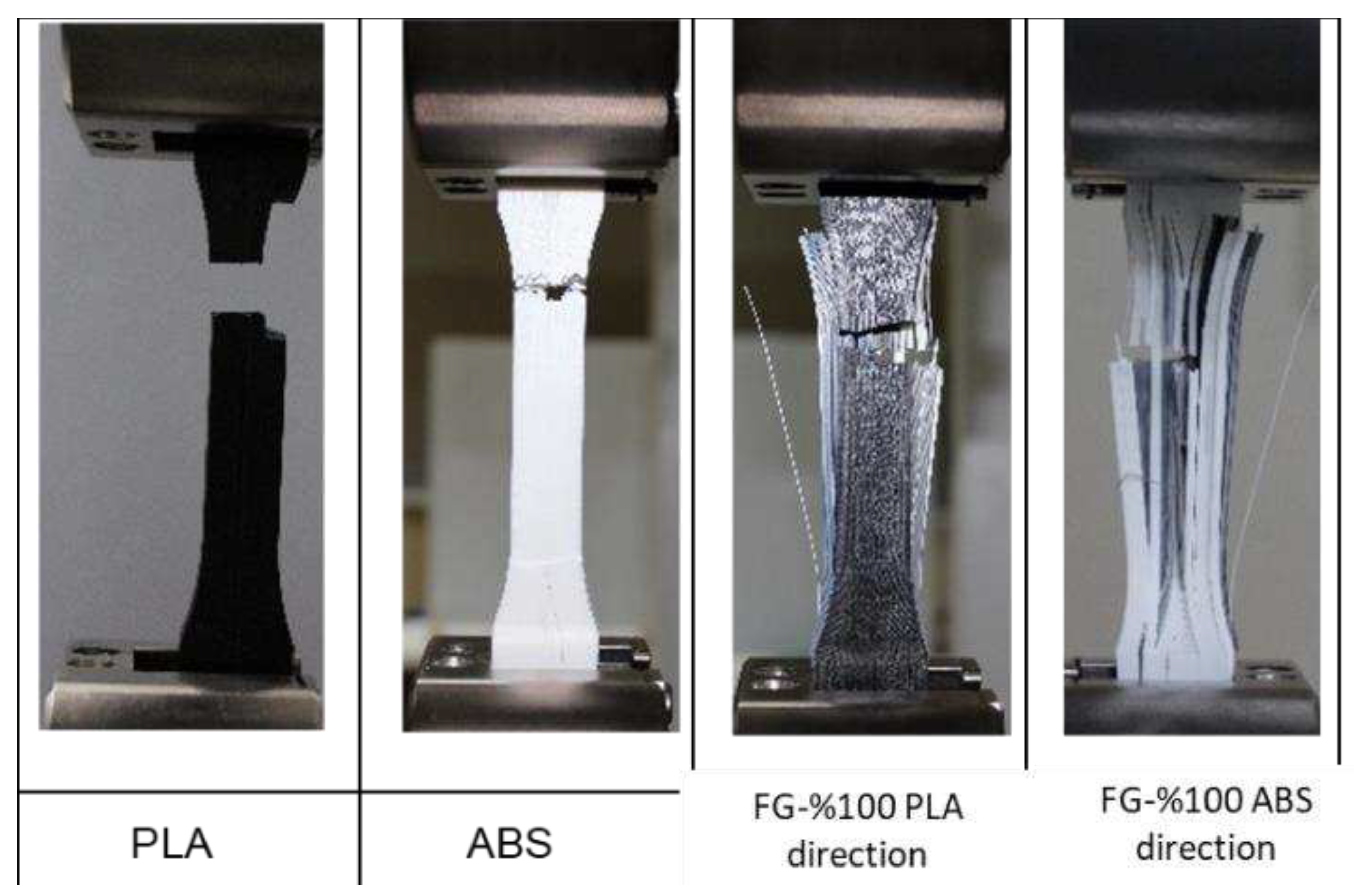

Figure 4. According to this test, delamination was observed in the FG structure. The layers did not adhere to each other. For this reason, it was aimed to prevent this situation by reducing the number of layered layers. As can be seen from the figure after the tensile test, the reduction of ABS layers significantly prevented delamination’s.

Figure 6 shows the printed images, layer changes and residuals of the designed structures.

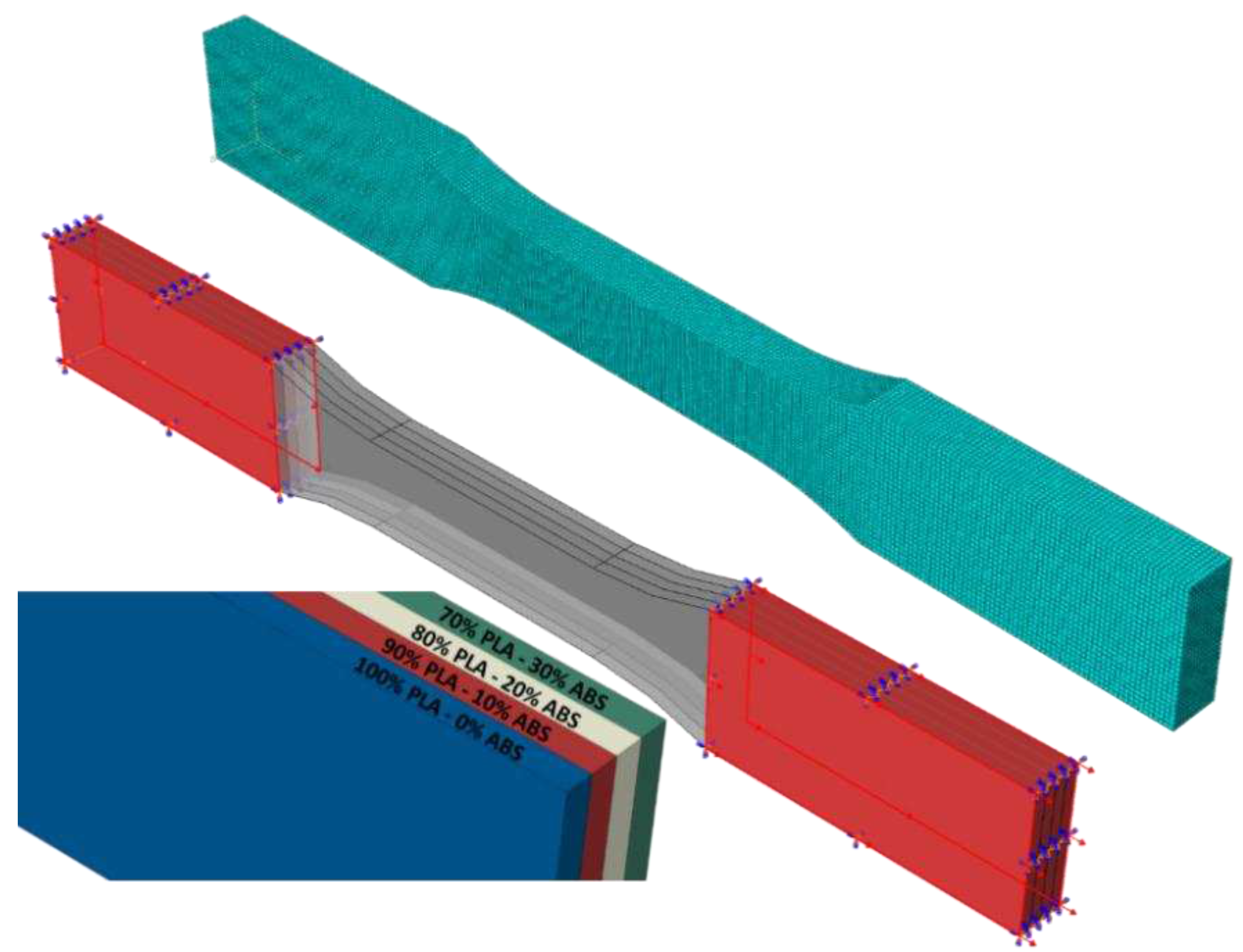

Figure 7 shows the experimental test setup and the fracture geometry of the FG structure subjected to tensile test. The tests were recorded with a camera and the related deformation images were analyzed.

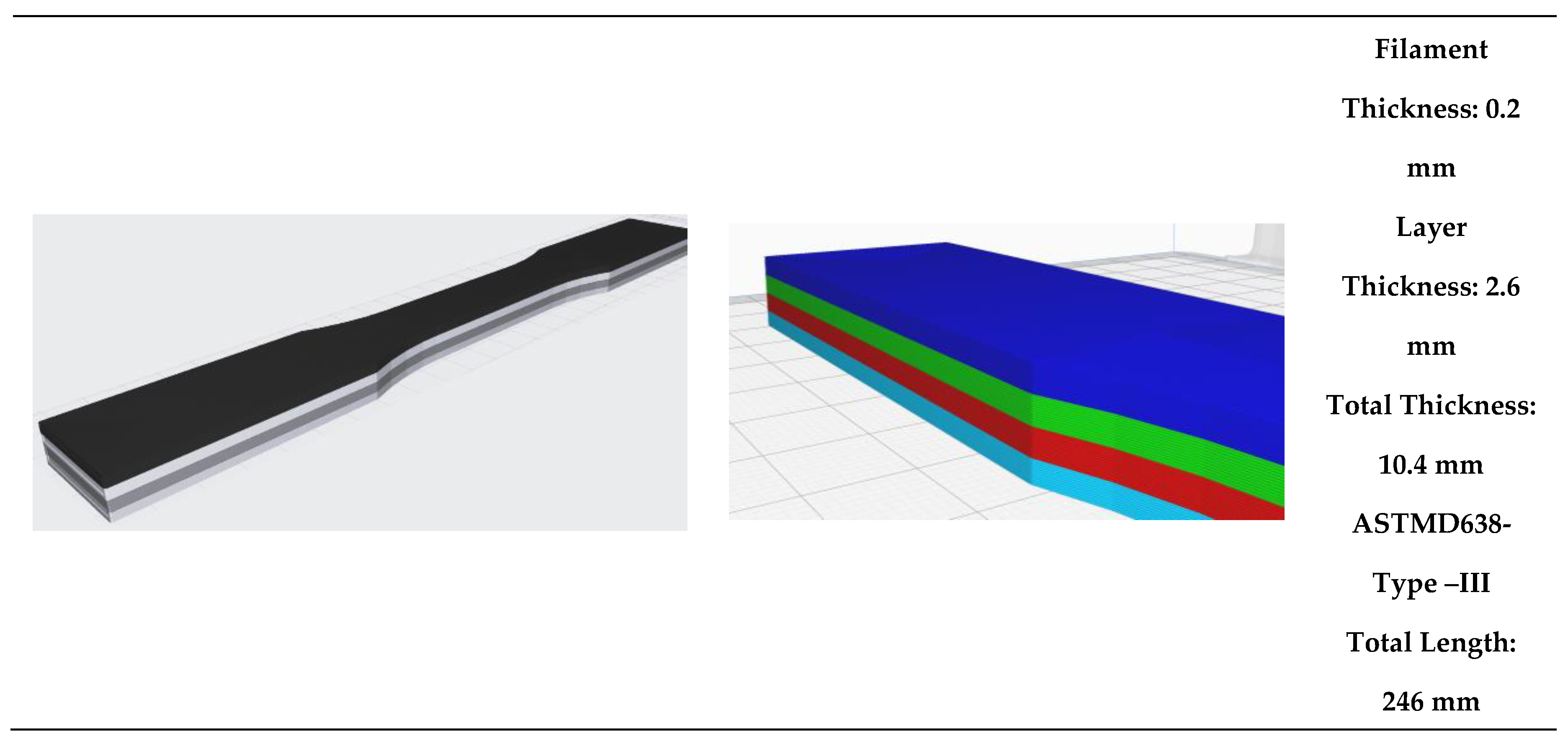

3. Numerical Modelling

The tensile behavior of FG structures was determined experimentally with all affecting parameters. The results that emerged in line with ASTM standards were in the direction that all parameters affect tensile behavior. The experimental results were transferred to a finite element code and the FG structure was modeled. Finite element analyses were performed using Abaqus/Standard software.

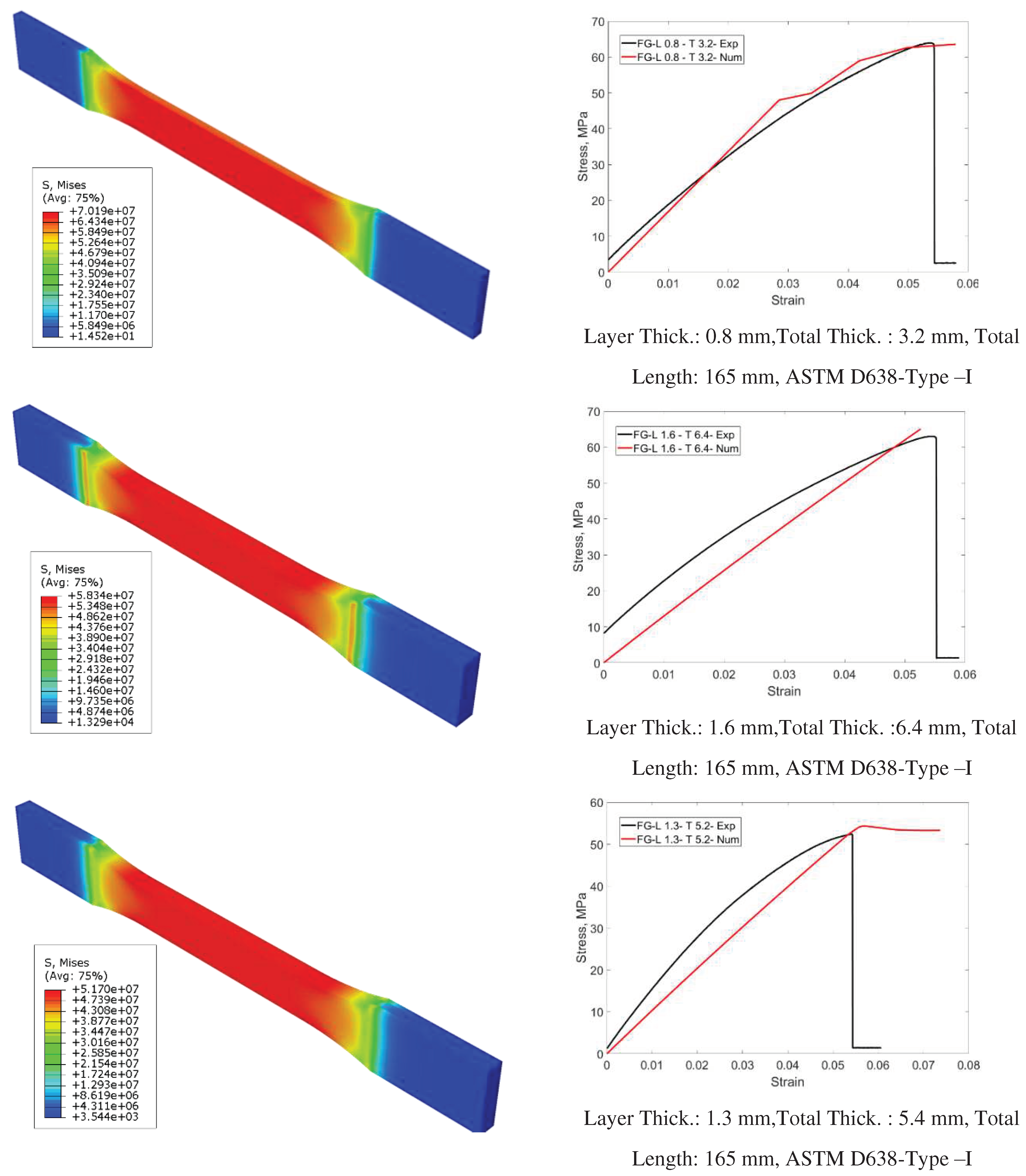

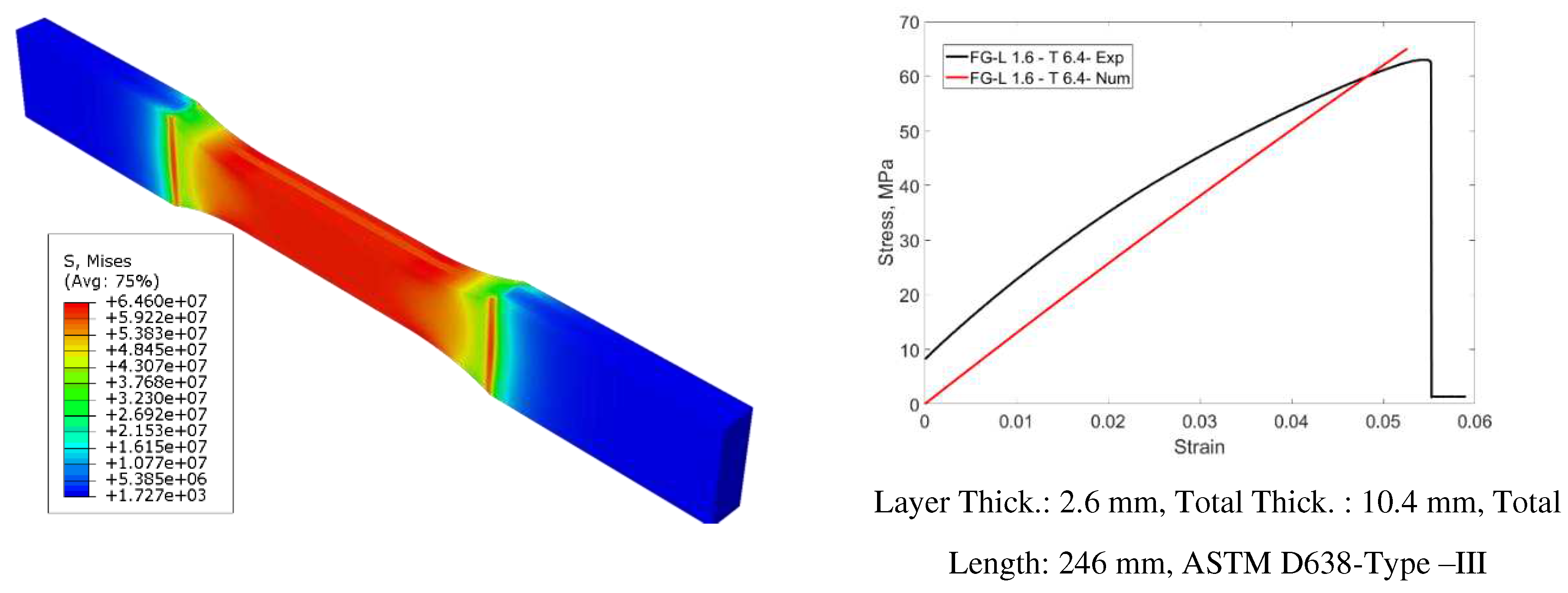

The layer structure was modeled by transferring the solid models of the tensile specimens to the finite elements. All samples were designed as eight layers with different layer thicknesses. The mesh structure was created with the C3D8R solid element. Each layer was transferred to the finite element code as a result of the tensile tests carried out in its own thickness. The experimental tensile test concept was transferred to the numerical model similarly. The outer surfaces of one end of the sample were fixed in all directions, and the other end was displaced according to the experimental displacements. The reaction forces were calculated by reading from the driven nodes. The detailed finite element model is given in

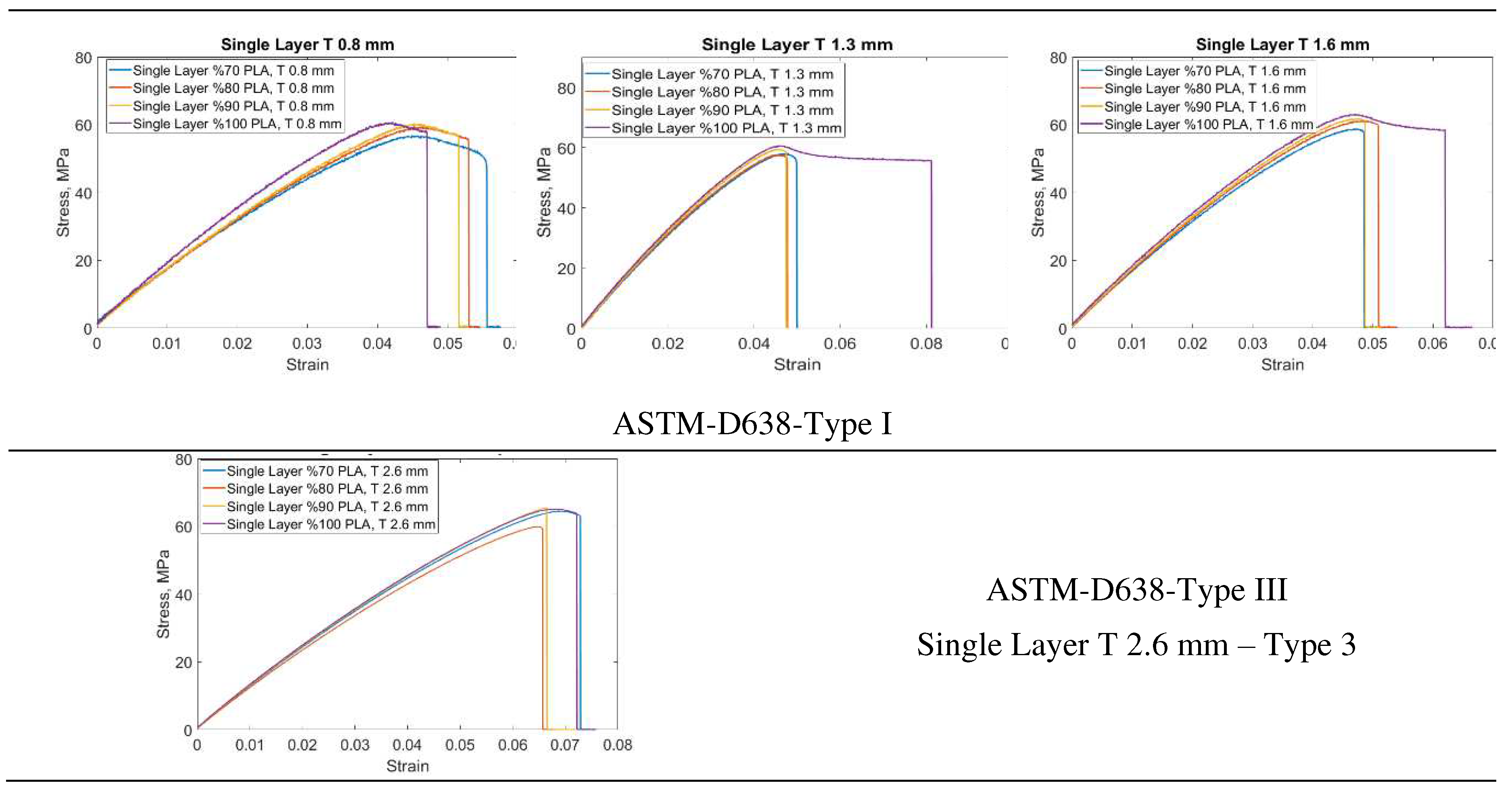

Figure 8. Analyzes were performed for four different FG configurations. The material model was elastoplastic, and no damage description was considered. The test results for the single layer given in

Figure 9 were used.

Figure 9 shows the tensile test results of single layer specimens with different functional gradients produced according to ASTM D638 Type I and III. The single layer specimens have thicknesses of 0.8, 1.3, 1.6 and 2.6 mm. The functional gradient ratios are 70% PLA-30% ABS, 80% PLA-20% ABS, 90% PLA-10% ABS and 100% PLA-0% ABS. The thicknesses of the sample produced for Type I are 0.8, 1.3 and 1.6 mm, while the lengths are 165 mm. The thickness of the sample produced for Type III is 2.6 mm while the length is 246 mm. Compared to Type I, the strain of the 0.8 mm thick specimen increased at similar stress levels with ABS reinforcement. In the 1.3 mm thick specimen, strain decreased with ABS reinforcement. Similar results were obtained for the 1.6 mm thick specimen. Compared to Type III, the 100% PLA sample with a layer thickness of 2.6 mm gave higher results in terms of both strain and stress.

4. Results

In this study, a parametric study was carried out to develop a numerical model of the FG structure produced by the FDM technique and to model its tensile behavior. The tensile test behavior of the produced specimens and the effect of gradation on mechanical strength were investigated. The main parameters affecting the tensile test results such as layer thickness, volume fraction and total thickness were also investigated. The main reason for the parametric study in this paper is that the dimensional variations in the ASTM standard for rigid plastics are not suitable for additive manufacturing. Specimens were designed according to the dimensional parameters in the standard and each variable parameter was transferred to the numerical model. The creation of a meaningful numerical model will avoid the uncertainties in the ASTM standard and will shed light on many parameters to be studied. The dimensional parameters in the ASTM D638 standard vary primarily according to the total thickness. The total thickness variation is determined by the additive manufacturing method and the layer thickness decision of the FG structure to be formed. With the development of technology, many filaments containing different materials suitable for additive manufacturing are available today. With the FG structure proposed in this study, it is possible to produce new material behaviors with many desired properties.

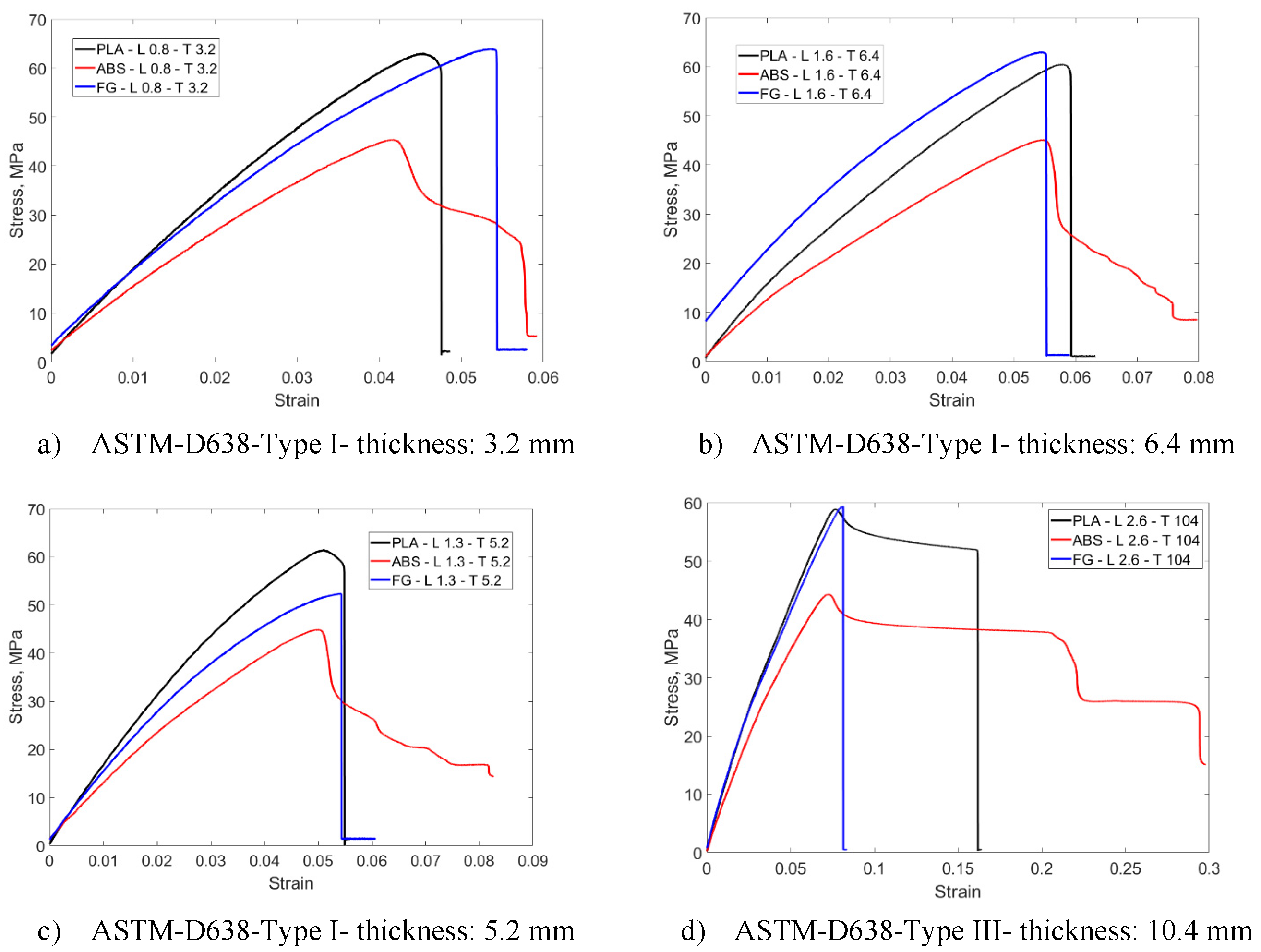

The stress-strain behavior of FG structures against PLA and ABS as a result of tensile testing according to two different ASTM standards is given in

Figure 10.

Figure 10-a shows the stress-strain behavior of FG, PLA and ABS materials for Type I for layer thickness 0.8 mm and specimen thickness 3.2 mm. The expected feature is that the FG structure exhibits a property between the other two materials. However, at these dimensions, higher strain was obtained at a similar stress level with the FG structure. A successful FG structure configuration has been demonstrated. When the thickness was doubled (

Figure 10-b, thickness 6.4 mm), the FG structure exhibited similar strain behavior to the other materials. However, an increase in the stress level is observed. These two thicknesses were made for ASTM D638 Type I for layer thickness and material variation. Considering the other thicknesses, a comparison was made between Types I and III. Specimens were manufactured and tensile tested for layer thicknesses of 1.3 and 2.6 mm and total thicknesses of 5.2 and 10.4 mm (

Figure 10-c-d). In the specimen with a layer thickness of 5.2 mm, the FG structure showed tensile behavior exactly in the middle of PLA and ABS at the same strain. When Type III was switched to Type III, the elongations were higher with the increase in the specimen length. With the FG structure, a more rigid material was obtained at the PLA stress level. Rupture occurred at the highest stress level. In general, ABS stress levels were around 40 MPA and PLA stress levels were around 60 MPA.

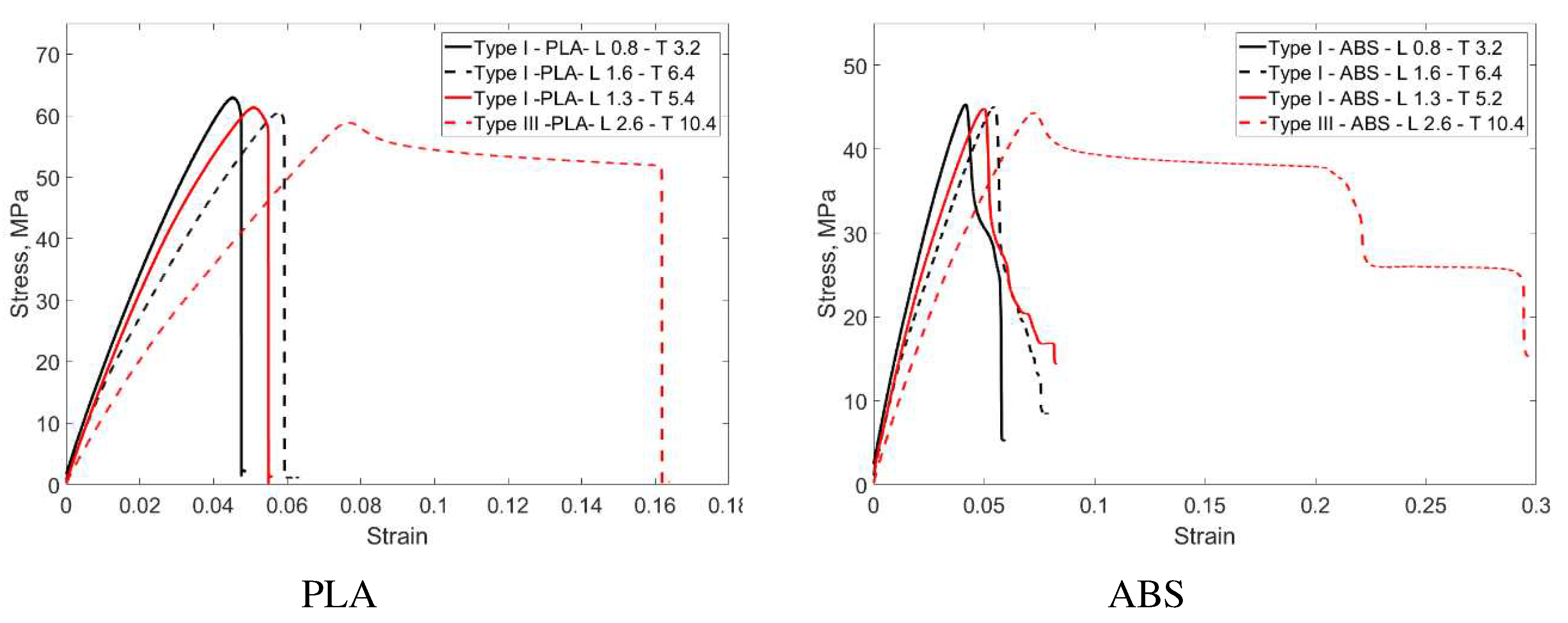

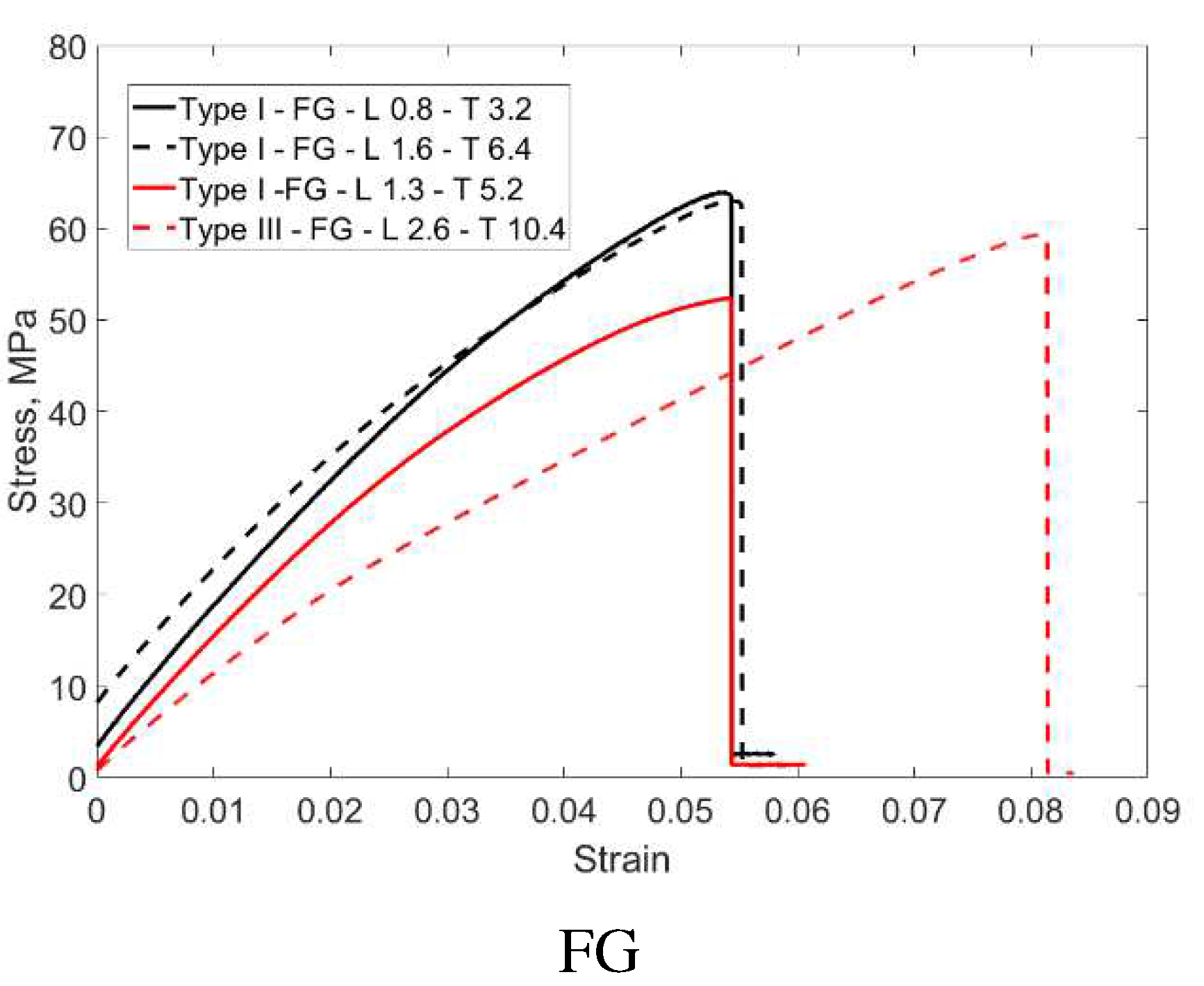

Figure 11 shows the stress-strain graphs obtained as a result of thickness variations for PLA, ABS and FG specimens. The graphs were organized as thickness comparison for Type I and thickness comparison for Type I and III. When the tensile test results of the samples produced from PLA-based material are compared, it is seen that they exhibit similar stress levels of around 60 MPa. In this context, it can be argued that this material shows a behavior close to isotropic behavior. However, when the test was analyzed for Type III, it was seen that the strain increased by 1% from 0.06% to 0.16%. In this context, the increase in material thickness has a serious effect on the results. This result is evident with all thickness increases, albeit partially. When the tensile test results for ABS material are analyzed according to the thickness increase, the stress levels are around 45 MPa. Similar strain behavior is observed for Type I, whereas strain increases from 0.05 to 0.3 for Type III. In this context, the thickness increase in this material, which shows more elongation than PLA, affects the results more significantly. This situation is also related to the ductility of the material. This problem was eliminated in the FG structure and almost isotropic material behavior was obtained, especially when compared to Type I. Stress-strain data were obtained at 3.2 and 6.4 mm thicknesses. When Type I and Type III are compared, there is a significant increase in strain with increasing thickness and a partial increase in stress. However, there was no elongation at the break in the materials.

In

Figure 12, numerical tensile test results of FG specimens are given as von-misses stress distribution. Numerical stress-strain results are compared with experimental results. Four different FG configurations were selected according to ASTM standards and different types were compared. The usability of the obtained experimental results as a numerical material model is demonstrated. After obtaining single-layer results, it is proved that finite element analysis is a serious alternative for designs, saving time and cost. The first configuration has a layer thickness of 0.8 mm and a total thickness of 3.2 mm. The average approximate modulus of elasticity of the structure was calculated to be 1.5 GPa. The stress distribution on the structure was in the same direction as the stress-strain diagram. Experimental and numerical tensile test graphs have similar behaviour. The second FG configuration has a total thickness of 6.4 mm and a layer thickness of 1.6 mm. The average modulus of elasticity was measured to be 1.43 GPa. The curve trend associated with the experimental tensile behaviour is similar. For Type I, a similar modulus of elasticity was obtained with increasing thickness. The other FG configuration has a total thickness of 5.2 mm and a layer thickness of 1.3 mm. The average and approximate modulus of elasticity was calculated as 1.43 GPa.

The configuration for Type III has a layer thickness of 2.6 mm and a total thickness of 20.8 mm. The modulus of elasticity was calculated to be 1.1 GPa. The difference in these results is a result of additive manufacturing. The non-isotropic structure and the production parameters vary according to the dimensions. In this study, this uncertainty in additive manufacturing has been significantly emphasized. As the thickness increased, the material became resistant to rupture and elongation increased. However, there was no increase in the stress level, resulting in a decrease in the elastic modulus. ABS makes the structure more ductile. In this respect, it is seen that the stress level is higher in PLA-rich final layers.

5. Conclusions

In this study, the tensile behaviour of PLA-ABS functional graded structures produced by additive manufacturing using ASTMD638 was investigated and a numerical model was proposed for this complex structure. Different manufacturing parameters such as layer thickness and specimen thickness were investigated. Parameters suitable for functional grading were determined by a preliminary study. The obtained single-layer tensile results were transferred to the finite element code and the tensile behaviour was modeled numerically. In the combination ratios, it was seen that there was no material combination in the use of more than 30% ABS and the combination ratios were used as 100% PLA, 90% PLA-10% ABS, 80% PLA-20% ABS, and 70% PLA-30% ABS. Production, tests, and analyses were carried out according to the different dimensions stipulated by the ASTM standard. This is due to the lack of isotropic behaviour in additive manufacturing products. This result is proved by all parameters. It was observed that the elastic modulus varies with each different parameter. The ductility of the material increased with the increase in specimen thickness. The strength of the material improved with the FG structure. In this study, which proposes a new material configuration by reducing the negative aspects of the most widely used additive manufacturing products such as PLA and ABS, it is concluded that the ASTM standard is inadequate for additive manufacturing products and tests should be performed in all changing parameters.

Author Contributions

Conceptualization, Ç.S, U.C.; M.D.D. and M.K.A.; methodology, Ç.S, U.C.; M.D.D.; software, U.C.; validation, U.C. and S.E.; investigation, Ç.S, U.C.; M.D.D. and S.E.; resources, M.D.D.; data curation, U.C. and S.E.; writing—original draft preparation, M.D.D.; Ç.S and U.C.; writing—review and editing, Ç.S, U.C. and M.D.D.; visualization, U.C.; supervision, M.D.D.; project administration, M.D.D. and M.K.A.; funding acquisition, M.D.D. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by The Scientific and Technological Research Council of Turkey (TÜBİTAK) with project number 122M643.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This study was supported by The Scientific and Technological Research Council of Turkey (TÜBİTAK) with project number 122M643.

Conflicts of Interest: The authors declare no conflict of interest.

References

- Koizumi, M.; Niino, M. Overview of FGM research in Japan. Mrs Bulletin 1995, 20, 19–21. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W. The mechanics of coating delamination in thermal gradients. Surface and Coatings Technology 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Kaysser, W.A.; Rabin, B.H.; Kawasaki, A.; Ford, R.G. (Eds.) Functionally graded materials: design, processing and applications; Springer Science & Business Media, 2013; Volume 5. [Google Scholar]

- Tan, S.C. Stress concentrations in laminated composites. Routledge 2017. [Google Scholar]

- Zhou, Y.C.; Hashida, T. Thermal fatigue failure induced by delamination in thermal barrier coating. International Journal of Fatigue 2002, 24, 407–417. [Google Scholar]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Composites Part B: Engineering 2020, 201, 108376. [Google Scholar]

- Ituarte, I.F.; Boddeti, N.; Hassani, V.; Dunn, M.L.; Rosen, D.W. Design and additive manufacture of functionally graded structures based on digital materials. Additive Manufacturing 2019, 30, 100839. [Google Scholar] [CrossRef]

- Hirai, T.; Sasaki, M. Vapor-deposited functionally gradient materials. JSME international journal. Ser. 1, Solid mechanics, strength of materials 1991, 34, 123–129. [Google Scholar] [CrossRef]

- Abdulrahman, K.O.; Abed, A.M.; Bayode, A.; Bhowmick, S.; Dey, S.; Hien, T.D.; ... , Akinlabi, E.T. Hierarchical Composite Materials: Materials, Manufacturing, Engineering. Walter de Gruyter GmbH & Co KG 2018 (8).

- Nagarajan, N.; Nicholson, P.S. Nickel–alumina functionally graded materials by electrophoretic deposition. Journal of the American Ceramic Society 2004, 87, 2053–2057. [Google Scholar] [CrossRef]

- Malinina, M.; Sammi, T.; Gasik, M.M. Corrosion resistance of homogeneous and FGM coatings. In Materials Science Forum. Trans Tech Publications Ltd. 2005, 492, 305–310. [Google Scholar]

- Watanabe, Y.; Inaguma, Y.; Sato, H.; Miura-Fujiwara, E. A novel fabrication method for functionally graded materials under centrifugal force: The centrifugal mixed-powder method. Materials 2009, 2, 2510–2525. [Google Scholar] [CrossRef]

- Ozieblo, A.; Wejrzanowski, T.; Konopka, K.; Szafran, M.; Kurzydlowski, K.J. Microstructure of Al2O3-Fe FGM obtained by modified slip-casting method. Materials Science Forum 2005, 492, 665–672. [Google Scholar] [CrossRef]

- Jamian, S.; Watanabe, Y.; Sato, H. Formation of compositional gradient in Al/SiC FGMs fabricated under huge centrifugal forces using solid-particle and mixed-powder methods. Ceramics International 2019, 2019 45, 9444–9453. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.N.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Materials & Design 2017, 131, 112–120. [Google Scholar]

- Gautam, R.; Idapalapati, S. Compressive properties of additively manufactured functionally graded Kagome lattice structure. Metals 2019, 9, 517. [Google Scholar] [CrossRef]

- Chen, F.; Jia, M.; She, Y.; Wu, Y.; Shen, Q.; Zhang, L. Mechanical behavior of AlN/Mo functionally graded materials with various compositional structures. Journal of Alloys and Compounds 2020, 816, 152512. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Progress in Materials Science 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Li, X.; Tan, Y.H.; Willy, H.J.; Wang, P.; Lu, W.; Cagirici, M.; Ong, C.Y.A.; Herng, T.S.; Wei, J.; Ding, J. Heterogeneously tempered martensitic high strength steel by selective laser melting and its micro-lattice: Processing, microstructure, superior performance and mechanisms. Materials & Design 2019, 178, 107881. [Google Scholar]

- Singh, N.; Singh, R.; Ahuja, I.P.S. On development of functionally graded material through fused deposition modelling assisted investment casting from Al 2 O 3/SiC reinforced waste low density polyethylene. Transactions of the Indian Institute of Metals 2018, 71, 2479–2485. [Google Scholar] [CrossRef]

- Liu, T.; Guessasma, S.; Zhu, J.; Zhang, W.; Belhabib, S. Functionally graded materials from topology optimisation and stereolithography. European Polymer Journal 2018, 108, 199–211. [Google Scholar] [CrossRef]

- Leoni, F.; Dal Fabbro, P.; Rosso, S.; Grigolato, L.; Meneghello, R.; Concheri, G.; Savio, G. Functionally Graded Additive Manufacturing: Bridging the Gap between Design and Material Extrusion. Applied Sciences 2023, 13, 1467. [Google Scholar] [CrossRef]

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. The International Journal of Advanced Manufacturing Technology 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Azari, A.; Nikzad, S. The evolution of rapid prototyping in dentistry: a review. Rapid Prototyping Journal 2009, 15, 216–225. [Google Scholar] [CrossRef]

- Elkaseer, A.; Schneider, S.; Scholz, S.G. Experiment-based process modeling and optimization for high-quality and resource-efficient FFF 3D printing. Applied Sciences 2020, 10, 2899. [Google Scholar] [CrossRef]

- Su, Z.; Inaba, K.; Karmakar, A.; Das, A. Characterization of Mechanical Property of PLA-ABS Functionally Graded Material Fabricated by Fused Deposition Modeling. Gas Turbine India Conference, American Society of Mechanical Engineers 2021, 85536, V001T01A003. [Google Scholar]

- Wang, P.; Zou, B.; Ding, S.; Zhuang, Y.; Liu, J.; Li, L. Functionally graded polyetheretherketone-based composites additively manufactured by material extrusion using a transition interface design method. Composites Part A: Applied Science and Manufacturing 2022, 158, 106977. [Google Scholar] [CrossRef]

- Salem, T.; Jiao, P.; Zaabar, I.; Li, X.; Zhu, R.; Lajnef, N. Functionally graded materials beams subjected to bilateral constraints: Structural instability and material topology. International Journal of Mechanical Sciences 2021, 194, 106218. [Google Scholar] [CrossRef]

- Subramaniyan, M.K.; Veeman, D.; Gurusamy John Kennedy, S.; Panda, B.; Yang, C. Mechanical performance and microscopic characterization of additively manufactured functionally graded material (WPC/Ceramic-PLA) via fused deposition modelling. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 2023, 09544089231166497. [Google Scholar] [CrossRef]

- Xavior, M.A.; Nishanth, D.; Kumar, N.N.; Jeyapandiarajan, P. Synthesis and Testing of FGM made of ABS Plastic Material. Materials Today: Proceedings 2020, 22, 1838–1844. [Google Scholar]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. Journal of Manufacturing Processes 2020, 2020 58, 923–935. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Alifui-Segbaya, F.; Fidan, I. Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Composite Structures 2021, 275, 114488. [Google Scholar] [CrossRef]

- Riiz Machinery ltd. co. FILAMEON. Available online: www.filameon.com (accessed on 12 December 2022).

- Ultimaker CURA. Available online: https://ultimaker.com/software/ultimaker-cura (accessed on 5 June 2021).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).