Submitted:

14 June 2023

Posted:

16 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

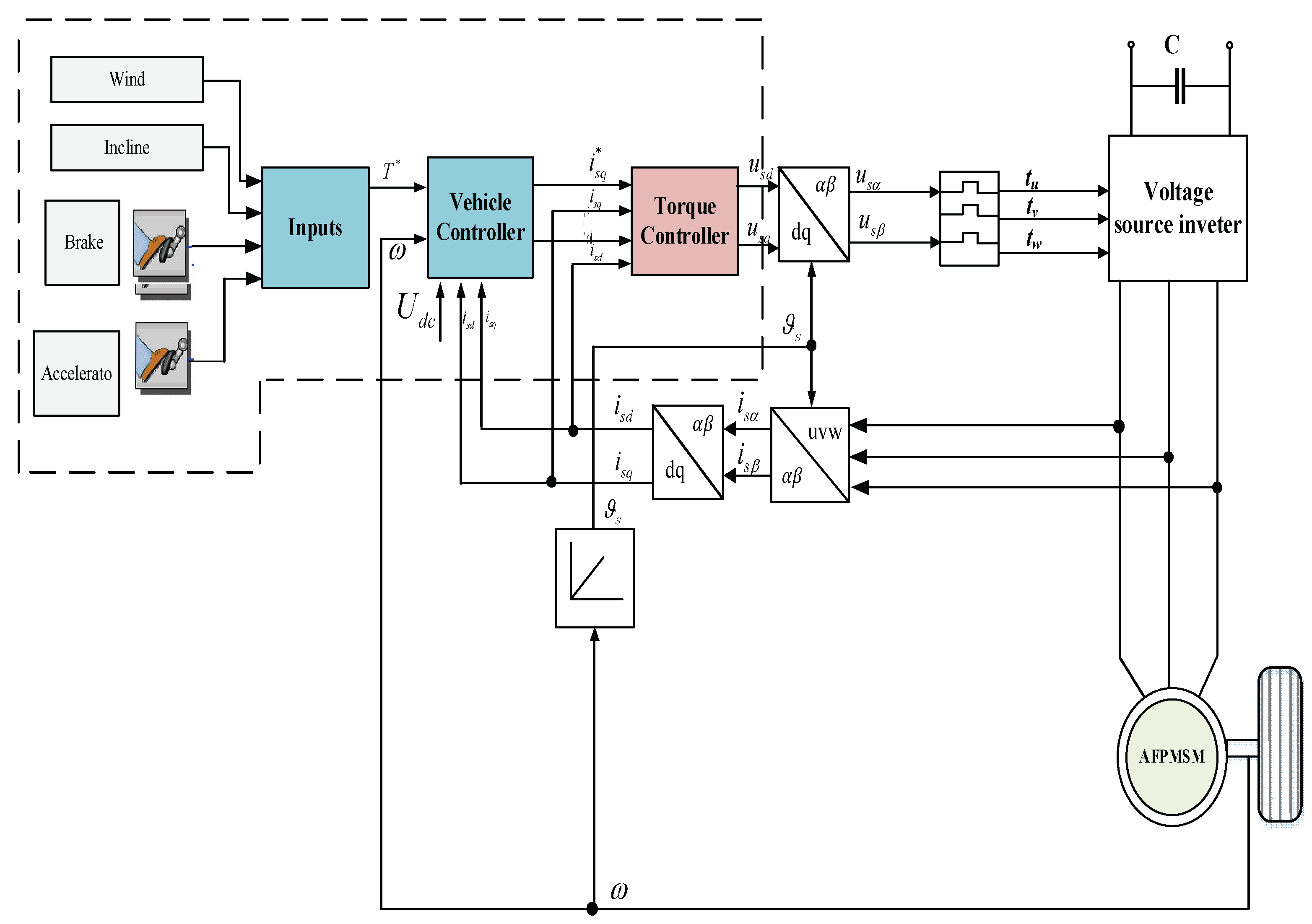

2. Thematical model and control of electric car power system

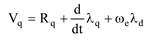

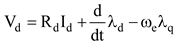

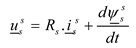

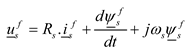

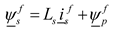

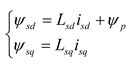

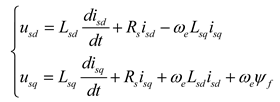

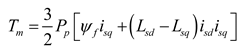

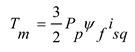

2.1. Mathematical model of the AFPMSM motor

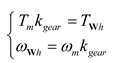

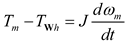

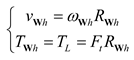

2.2. Mathematical model of electric vehicle

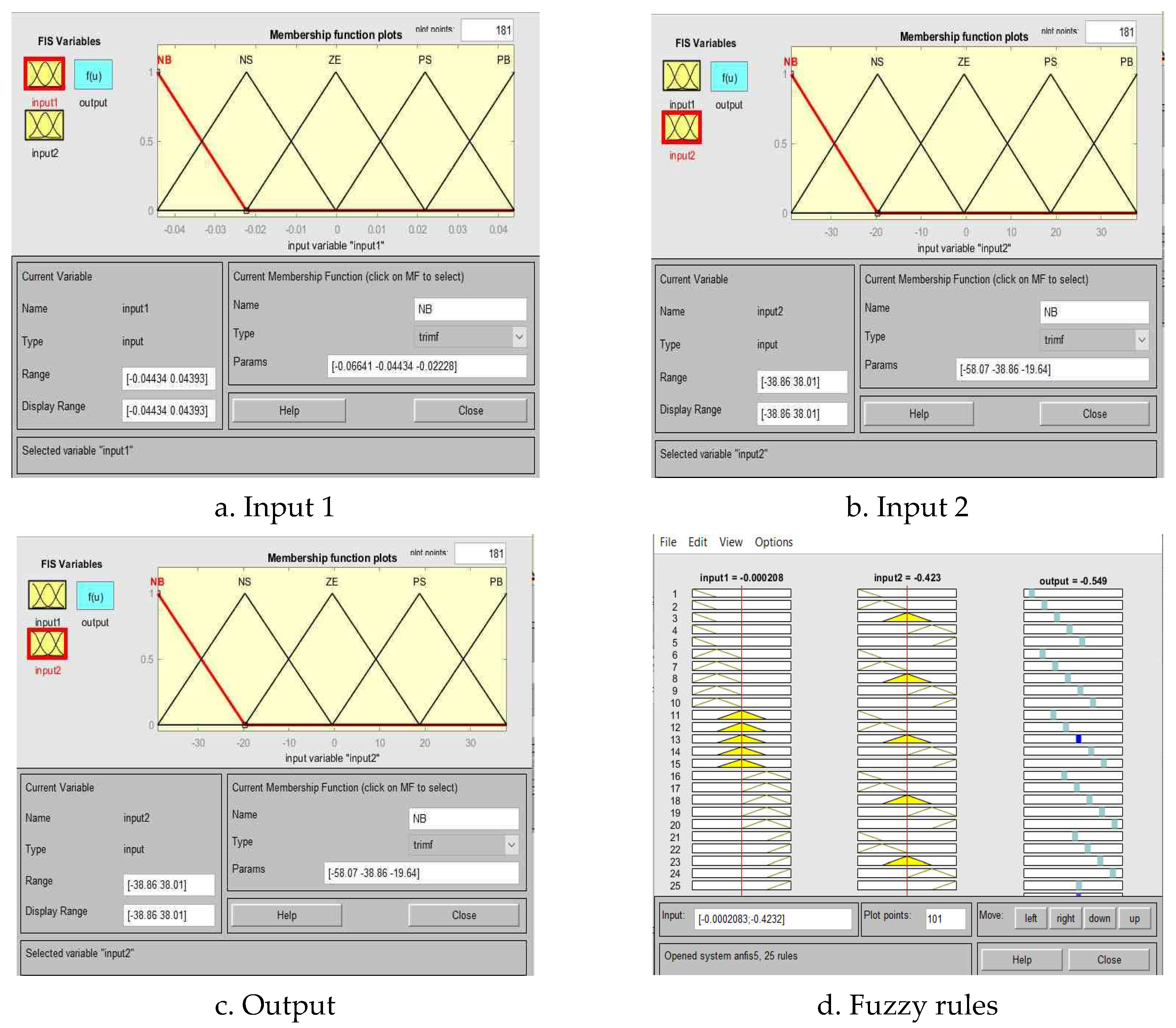

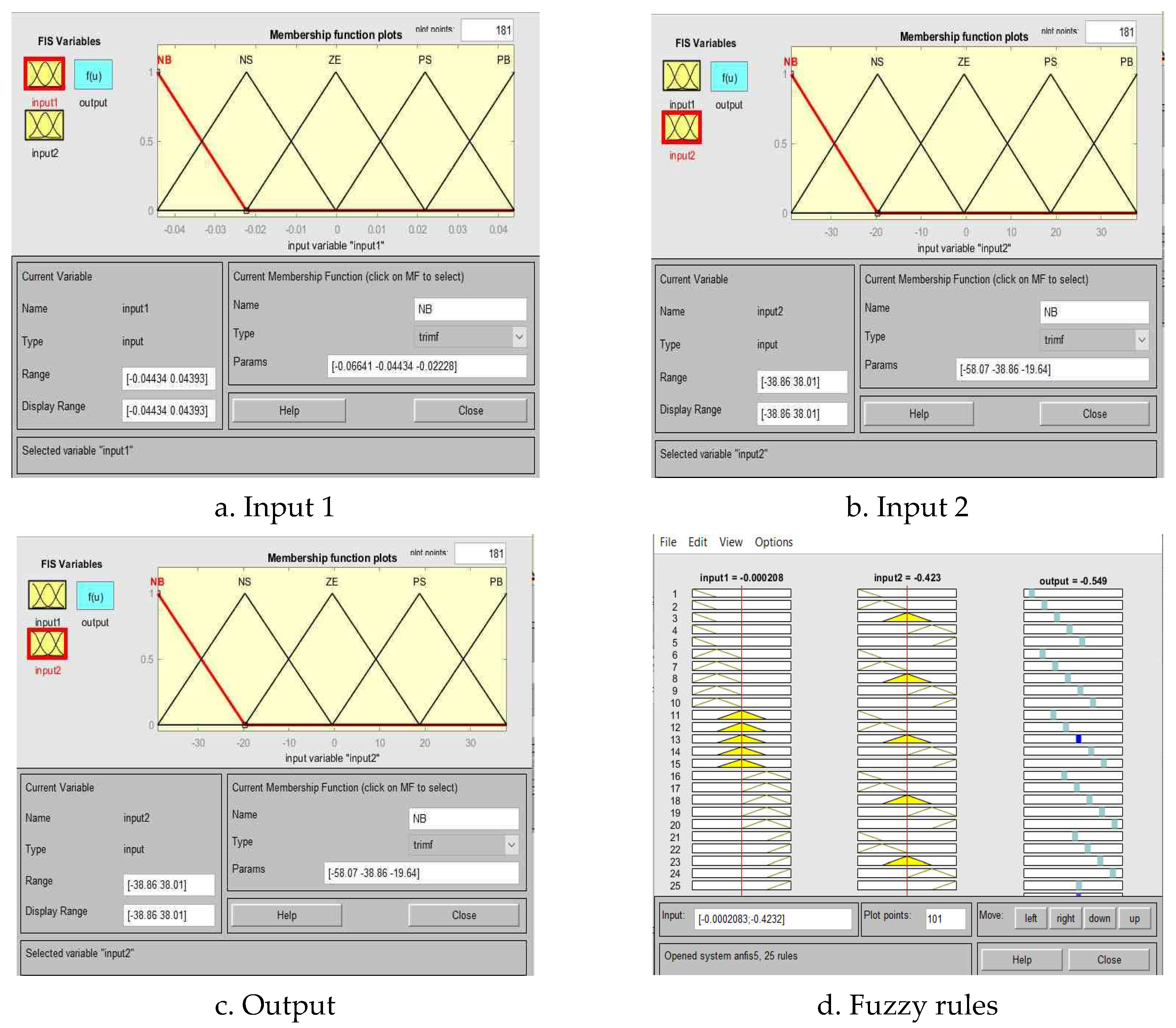

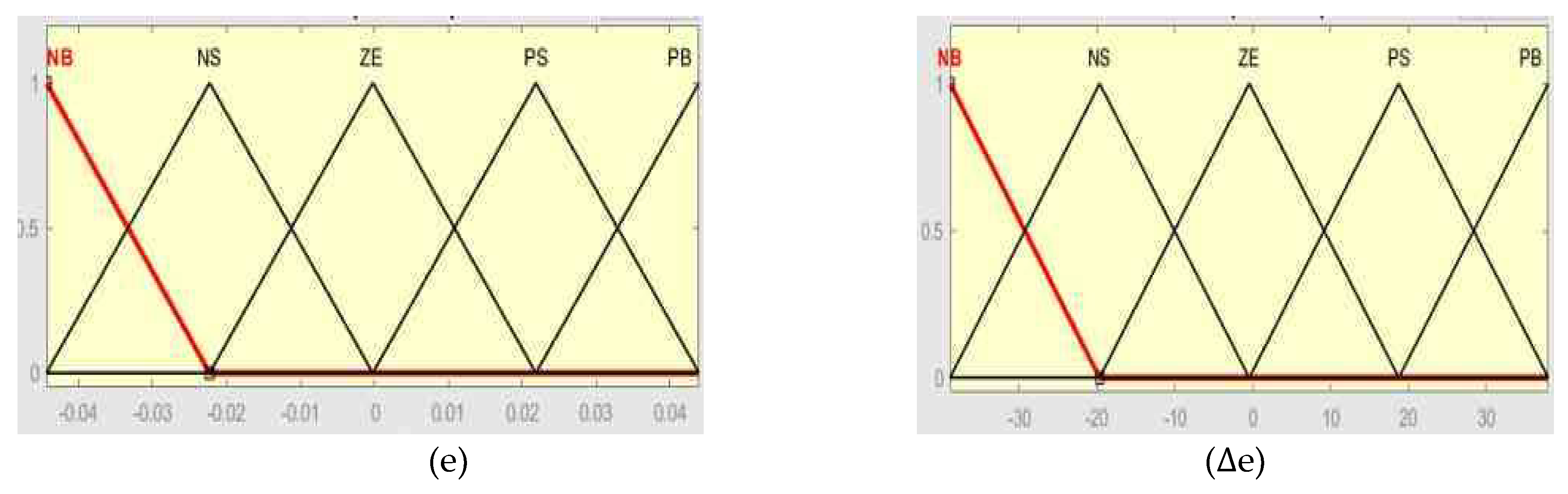

3. FLC torque controller design

- If (input 1 is NB) and (input 2 is NB), then (output is NB)

- If (input 1 is NB) and (input 2 is NS), then (output is NB)

- If (input 1 is NB) and (input 2 is ZE), then (output is NB)

- …………………..

- If (input 1 is PB) and (input 2 is PB), then (output is PB)

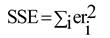

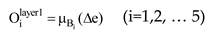

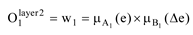

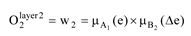

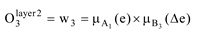

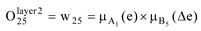

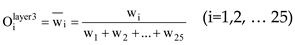

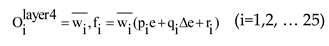

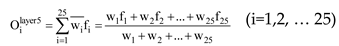

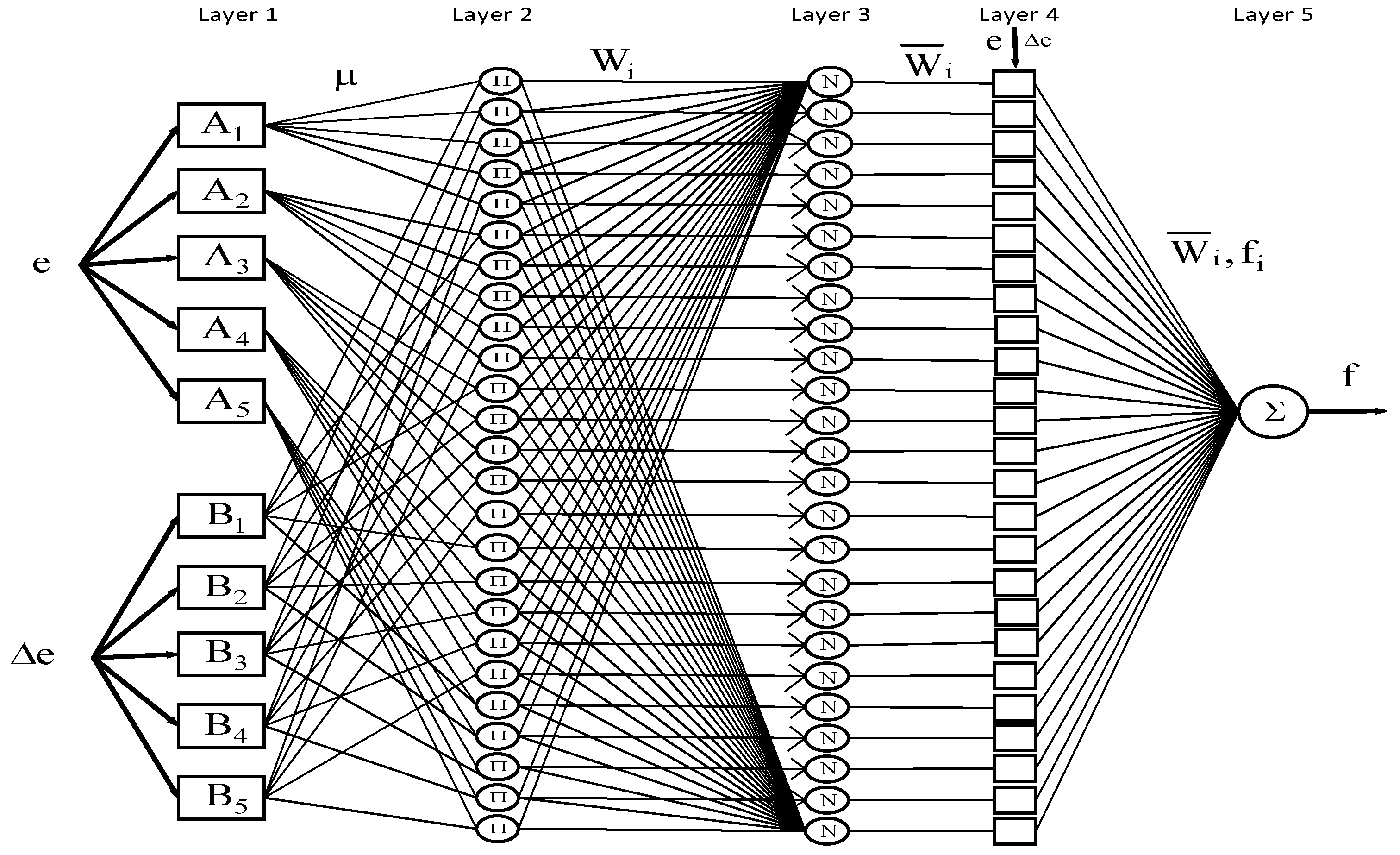

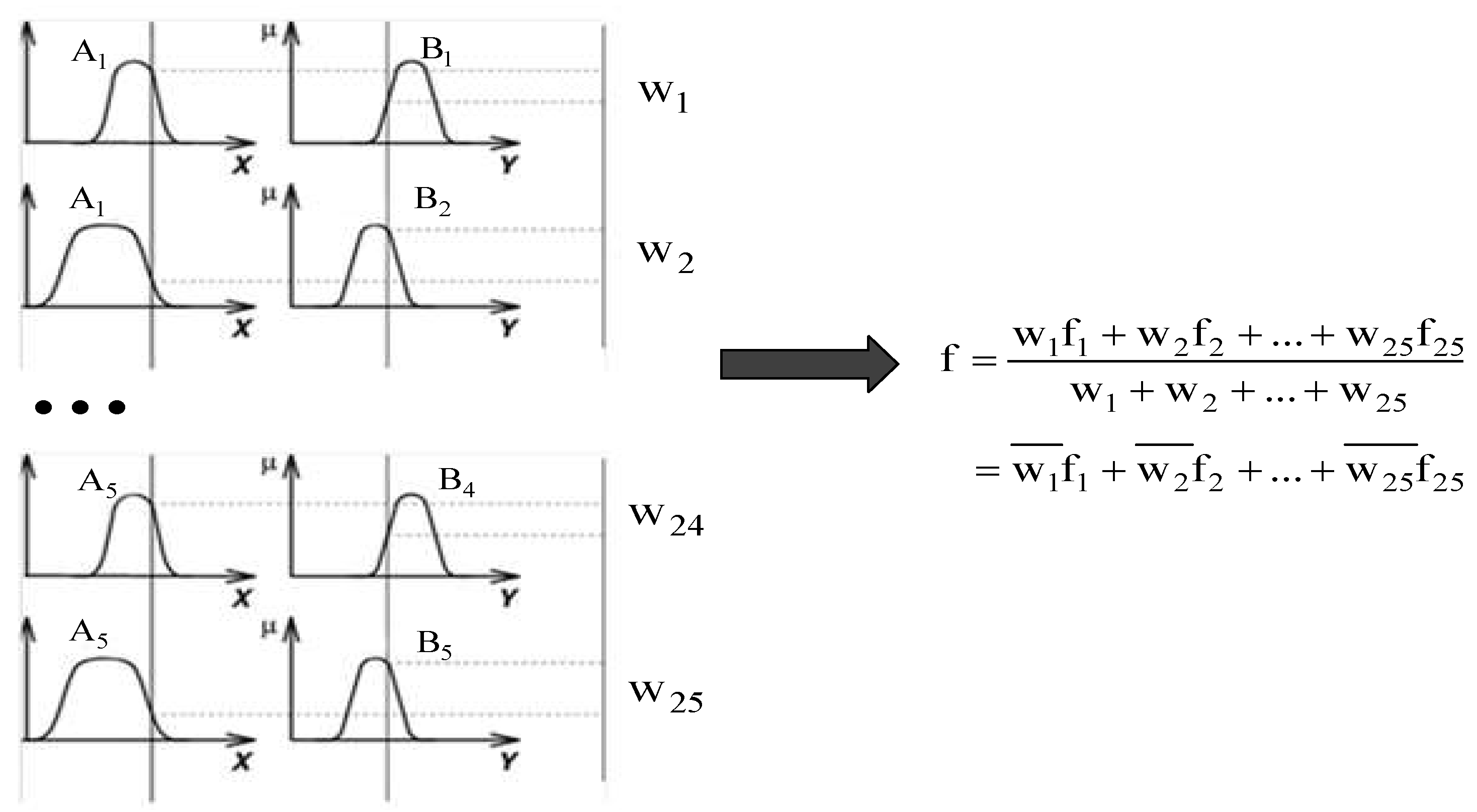

4. NFC torque controller design

- If x1 is A1 (NB) and x2 is B1 (NB), then f1 = p1e + q1∆e + r1

- If x1 is A1 (NB) and x2 is B2 (NS), then f2 = p2e + q2∆e + r2

- If x1 is A1 (NB) and x2 is B3 (ZE), then f3 = p3e + q3∆e + r3

- If x1 is A1 (NB) and x2 is B4 (PS), then f4 = p4e + q4∆e + r4

- If x1 is A1 (NB) and x2 is B5 (PB), then f5 = p5e + q5∆e + r5

- …

- If x1 is A25 (PB) and x2 is B25 (PB), then f25 = p25e + q25∆e + r25

5. Simulation results

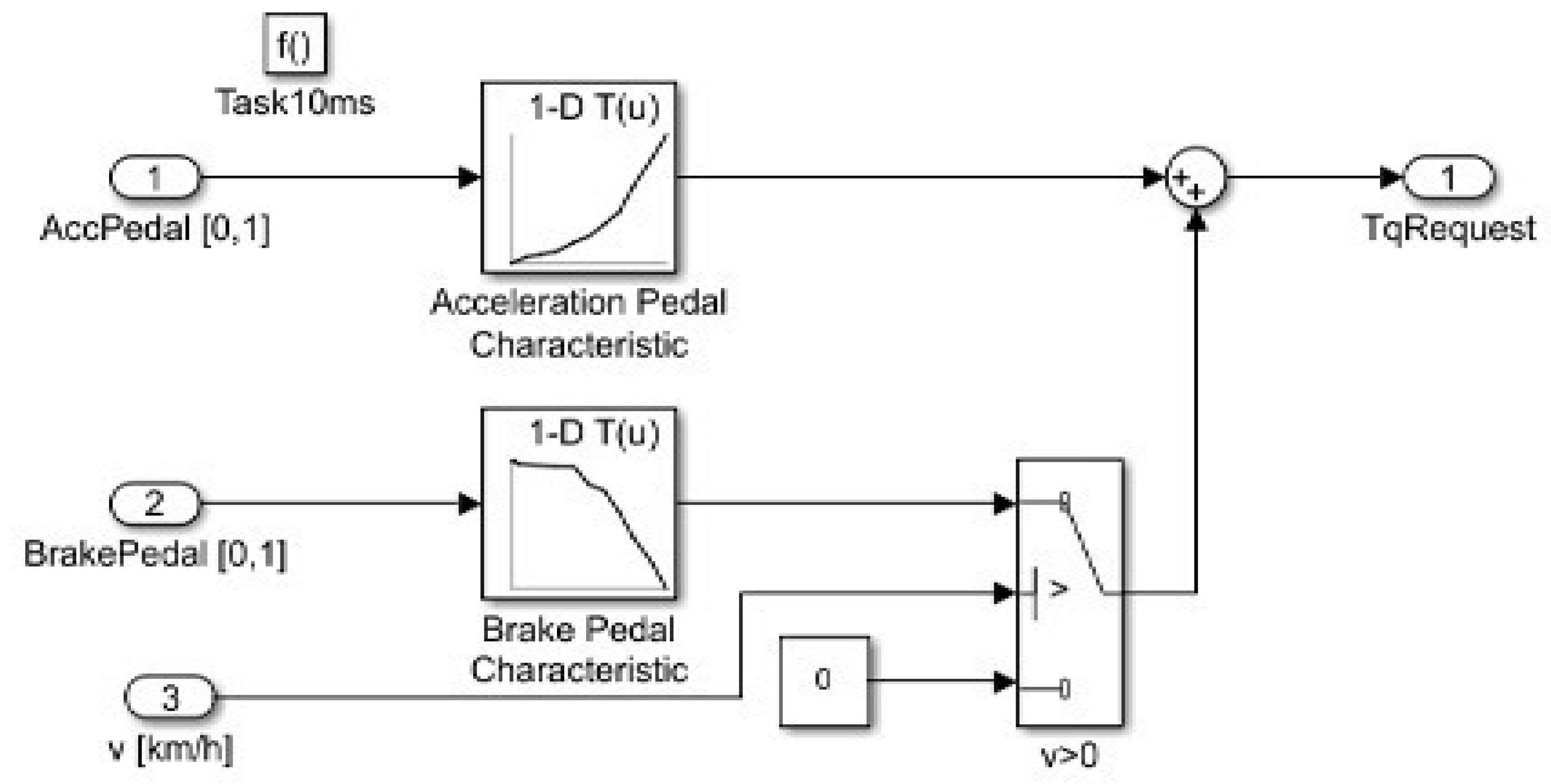

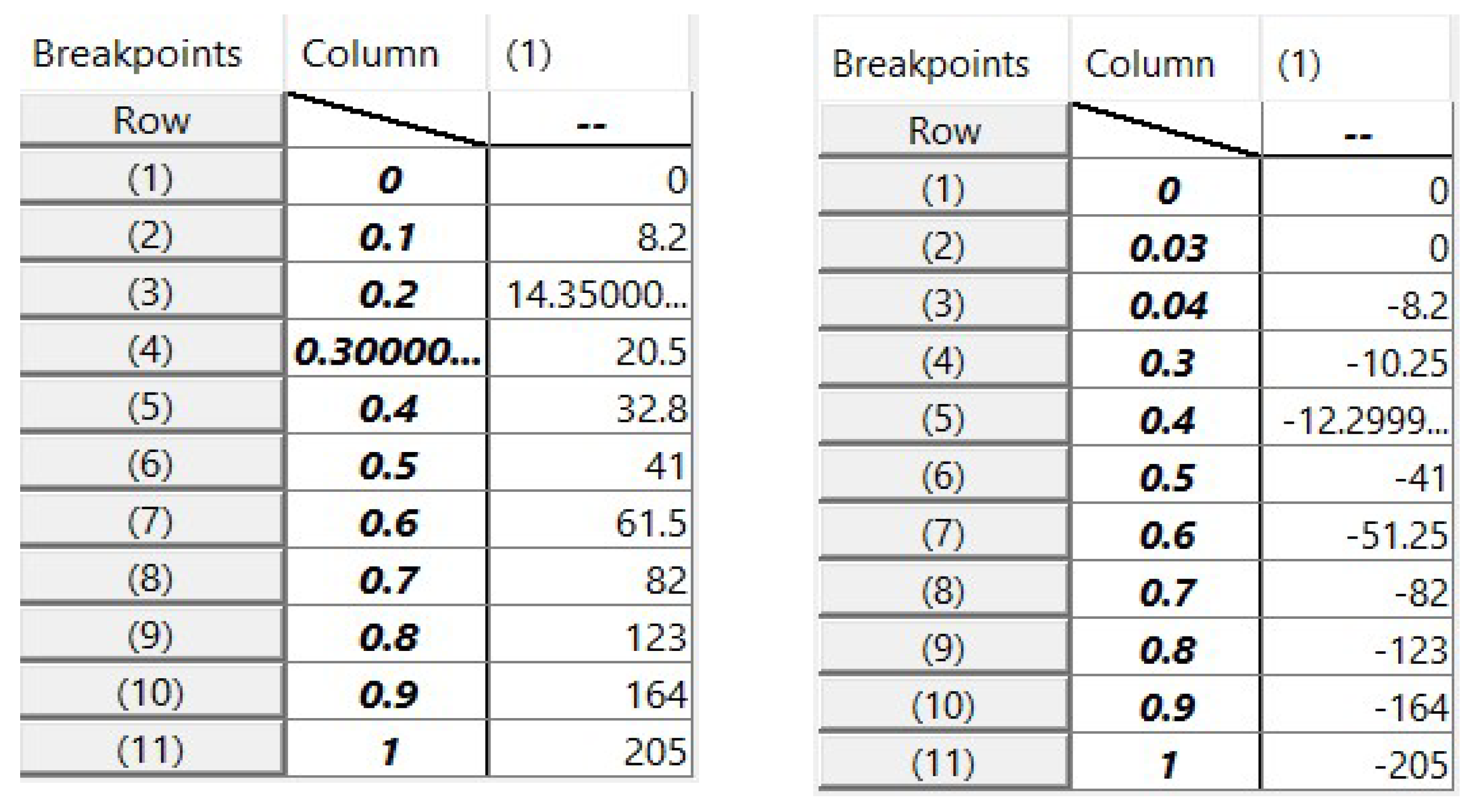

5.1. Building trajectories of accelerator, brake and operating modes of electric vehicles

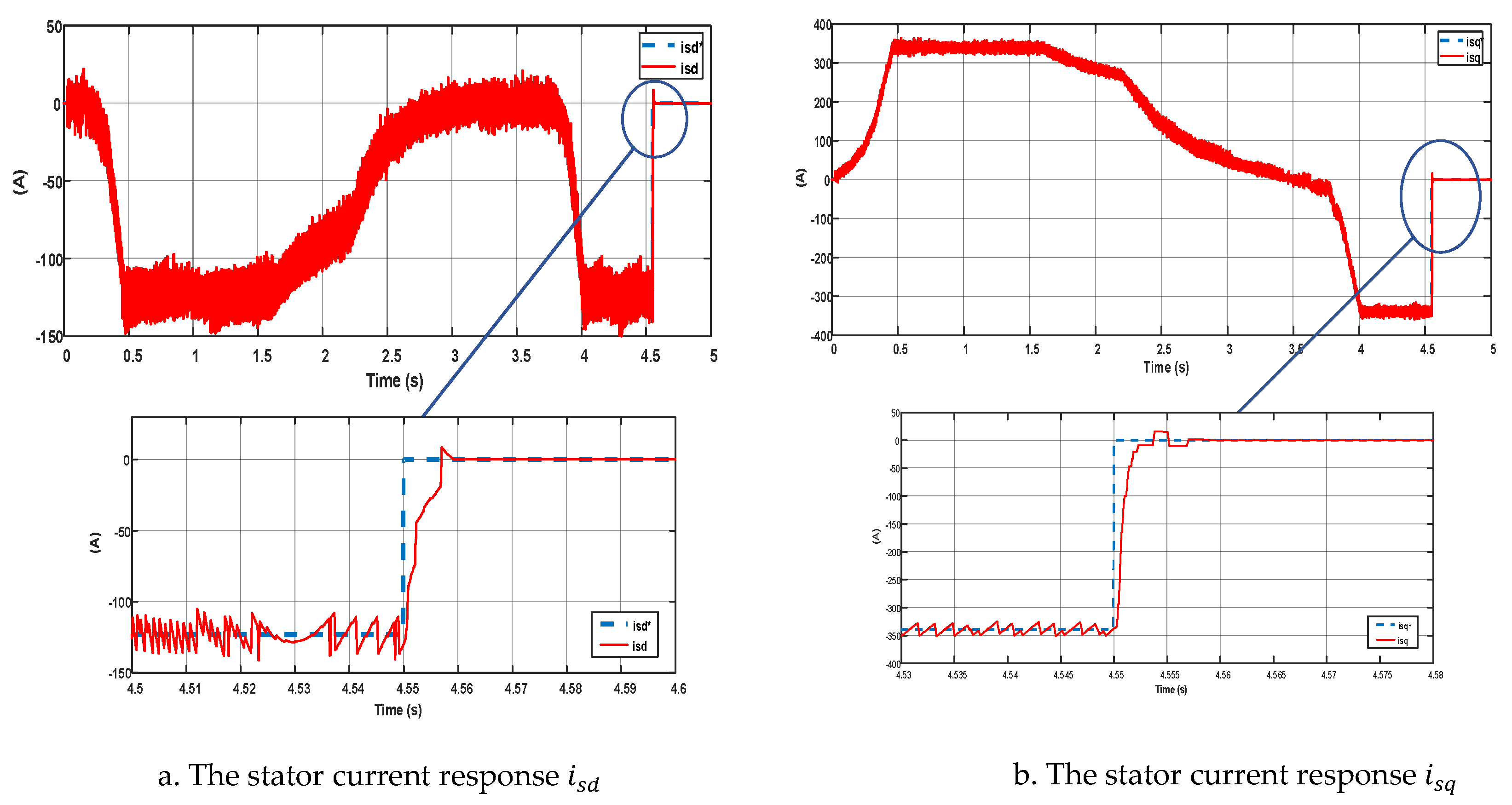

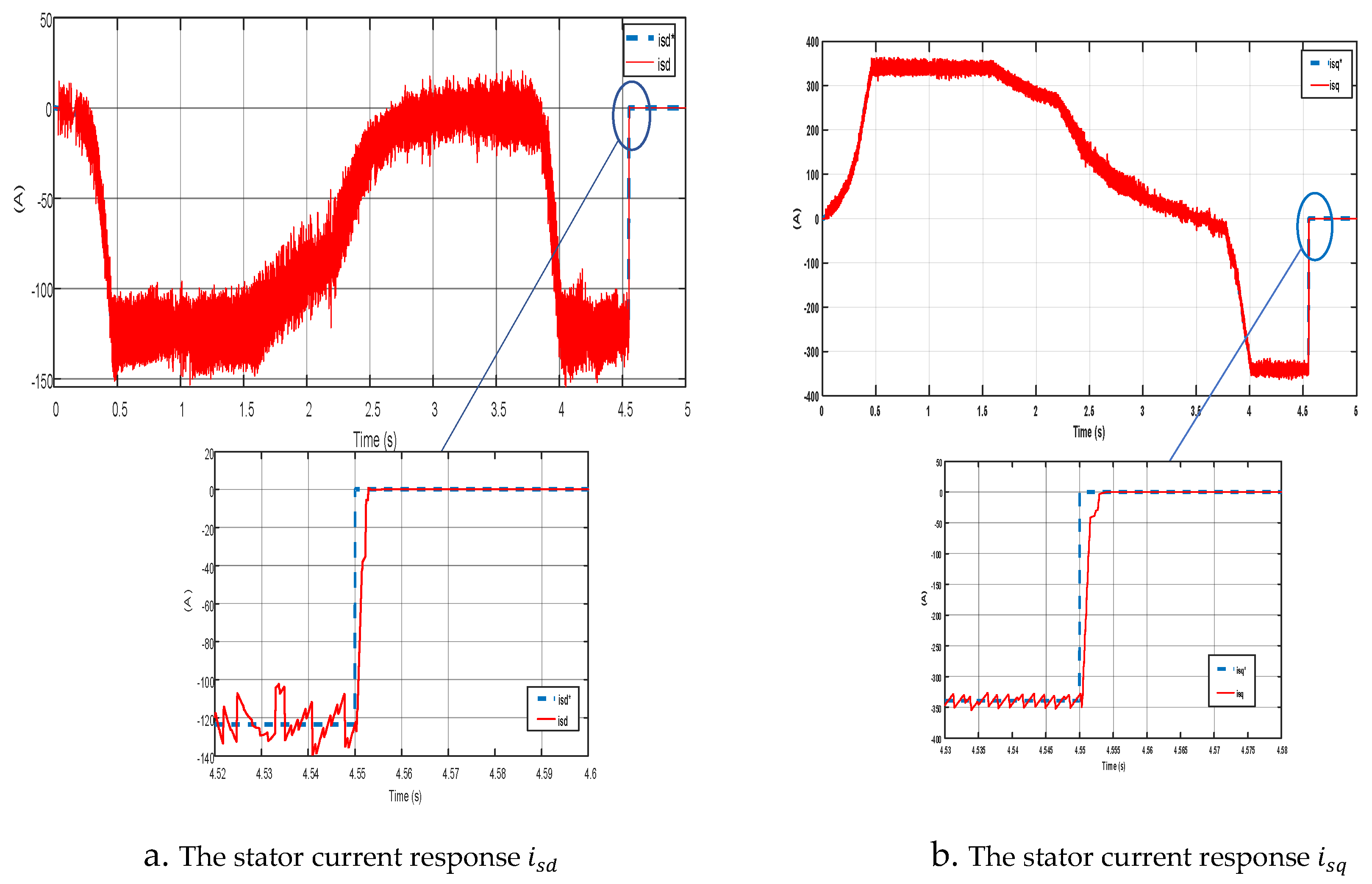

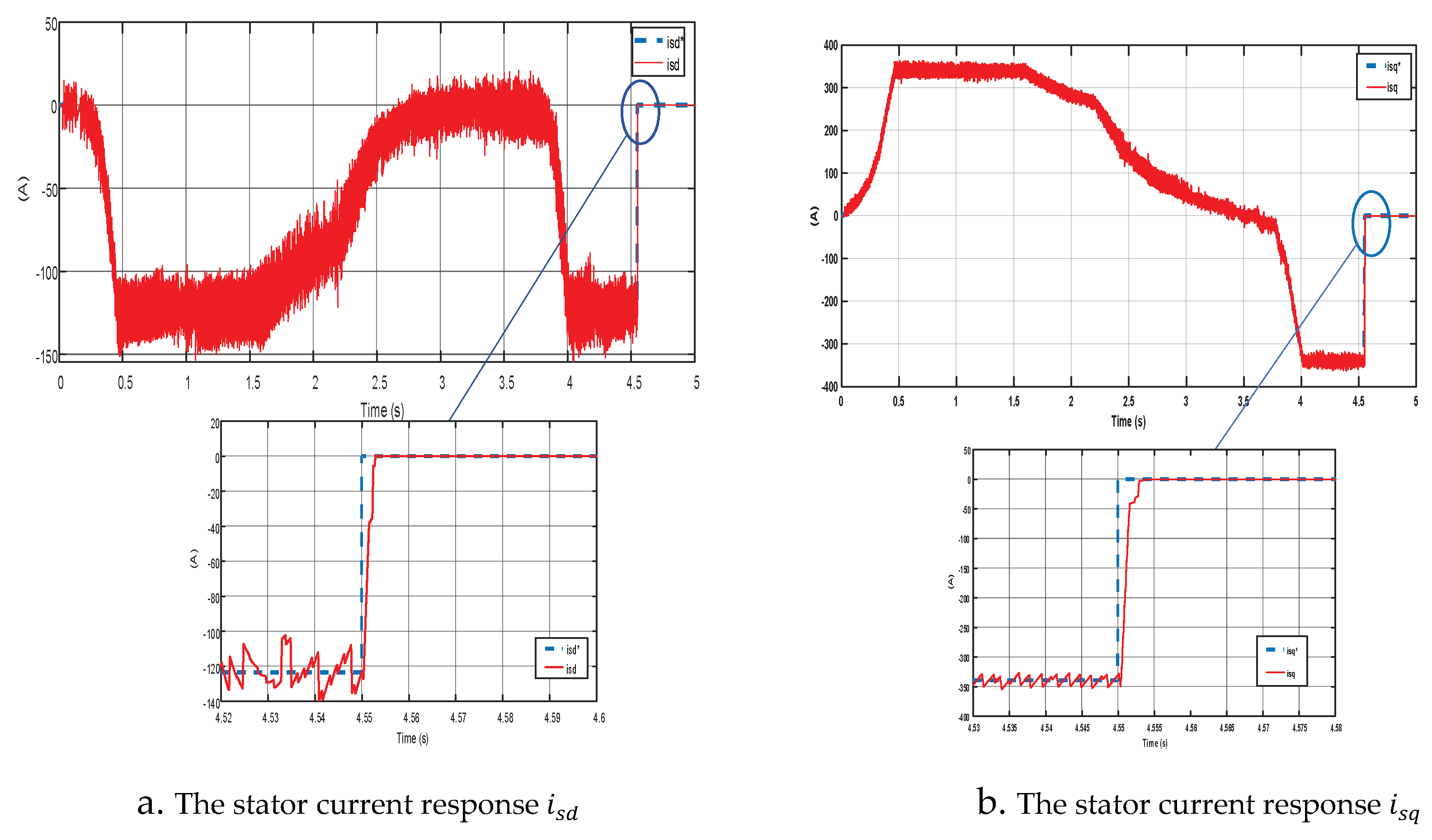

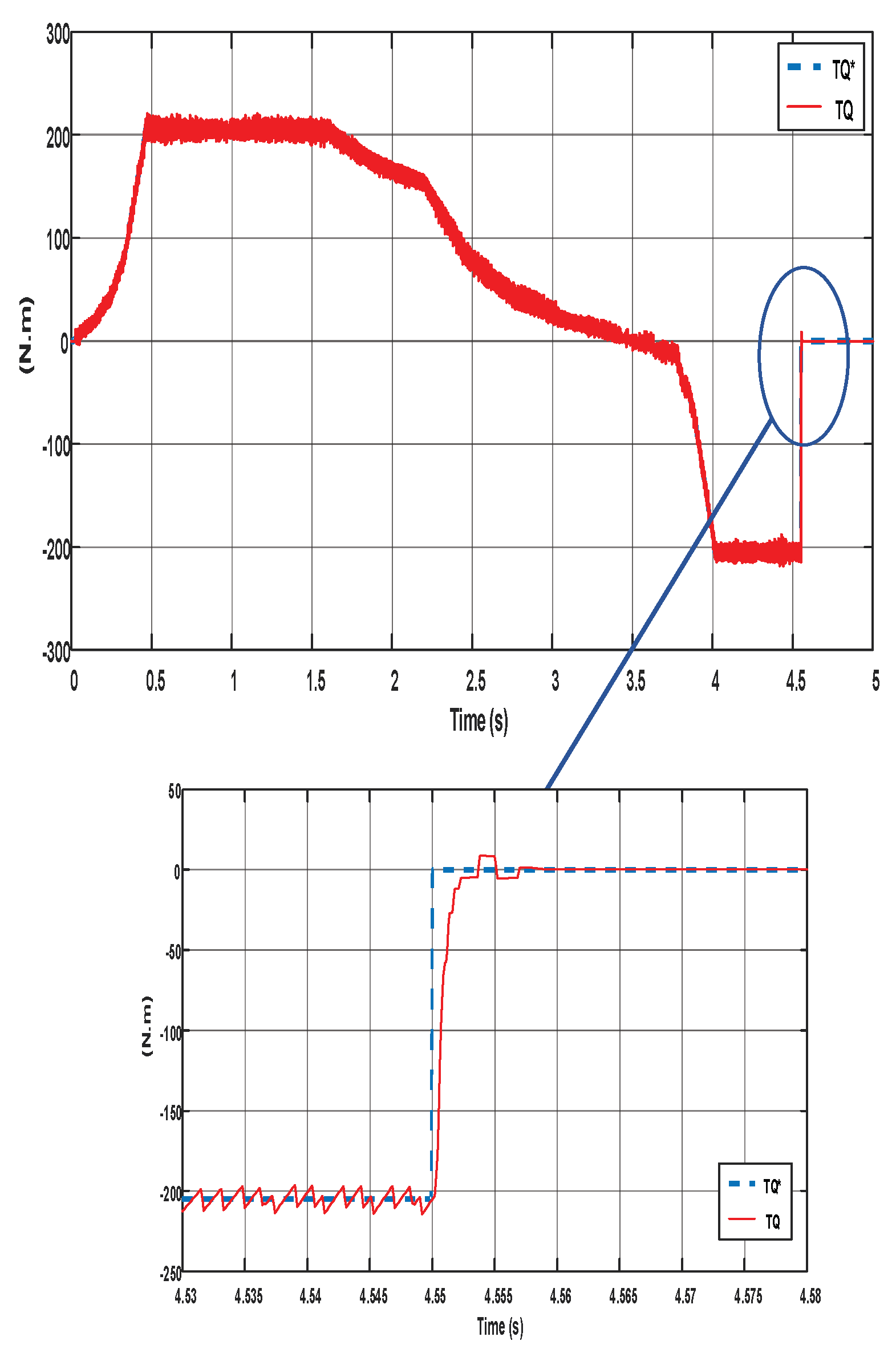

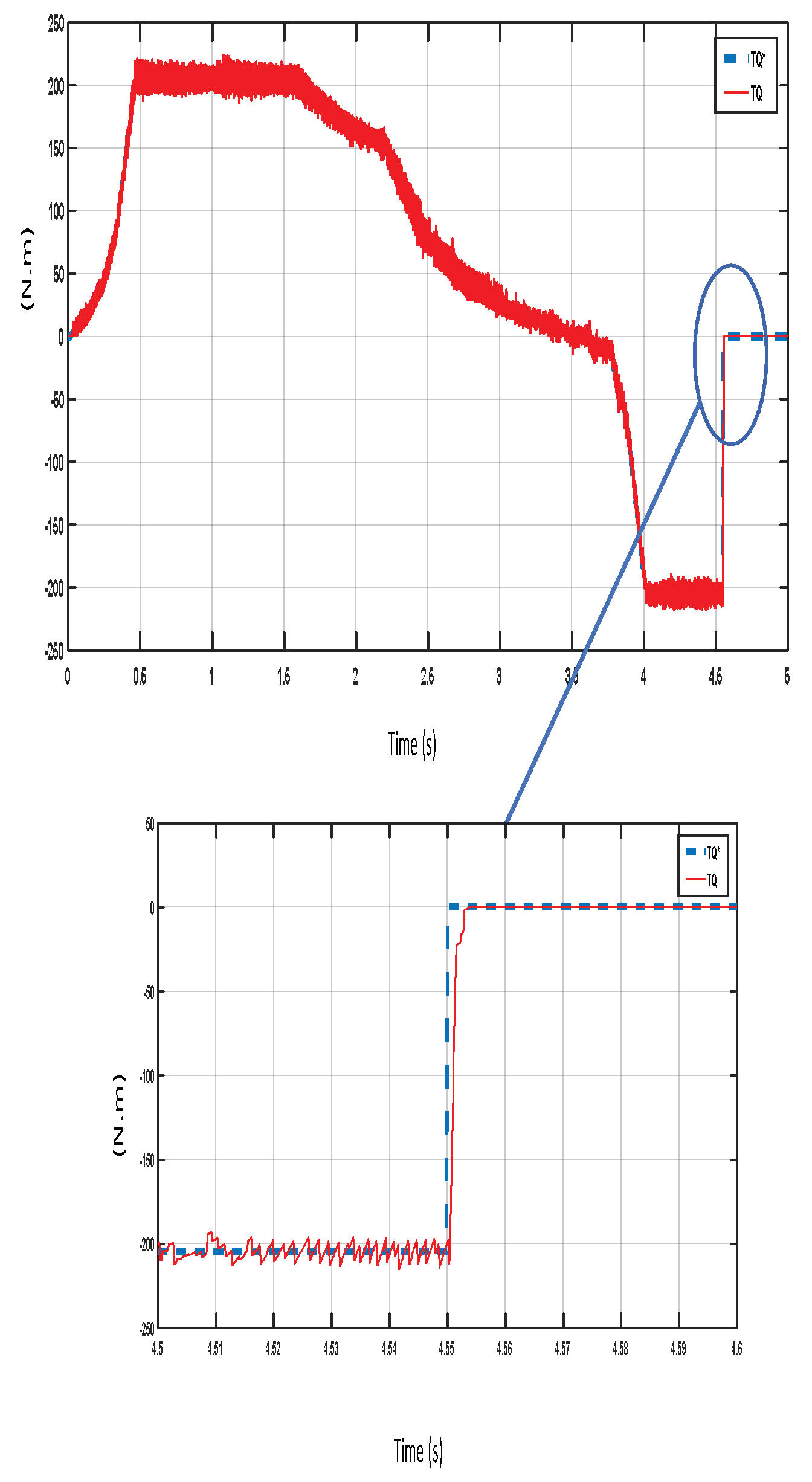

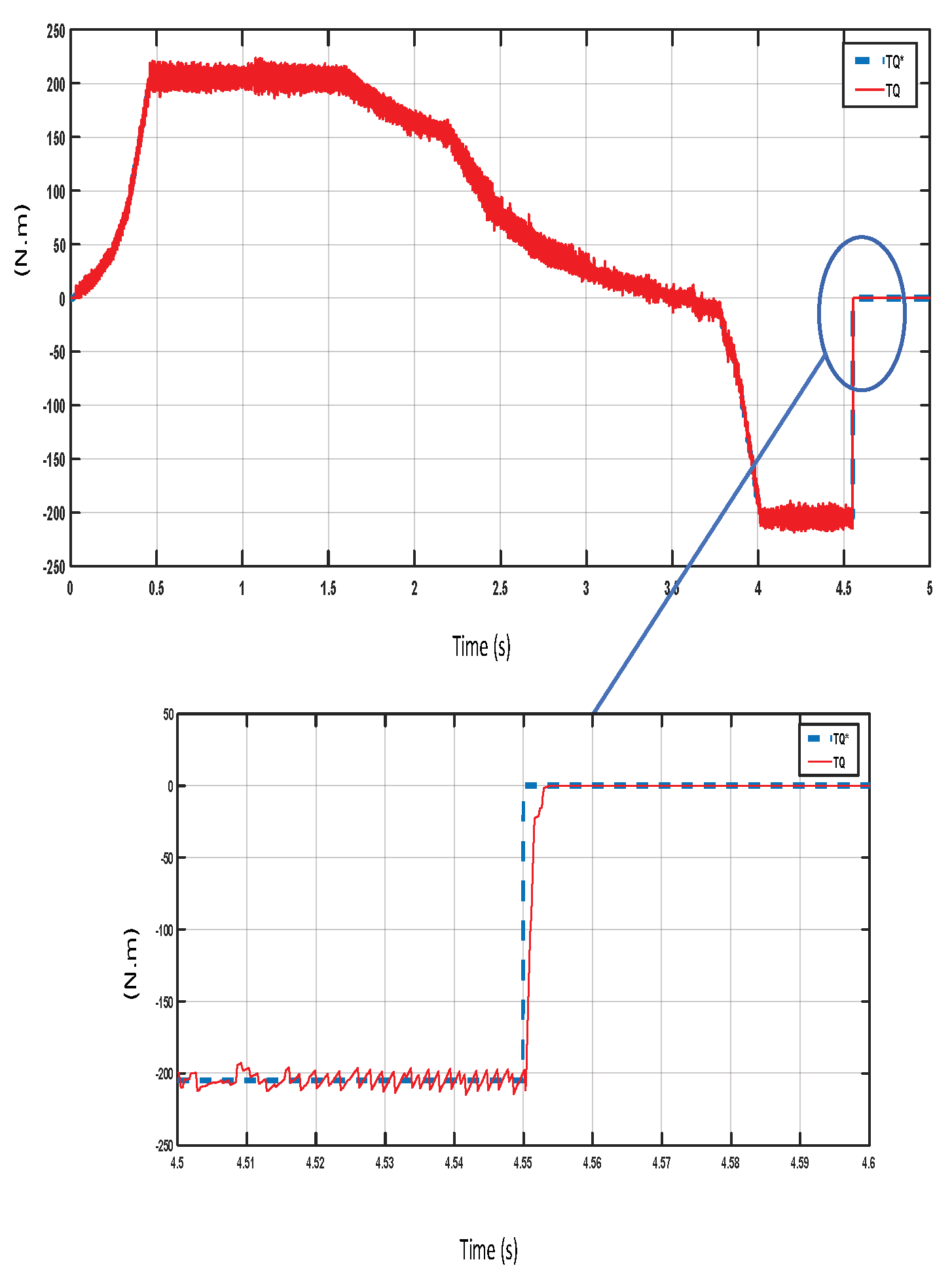

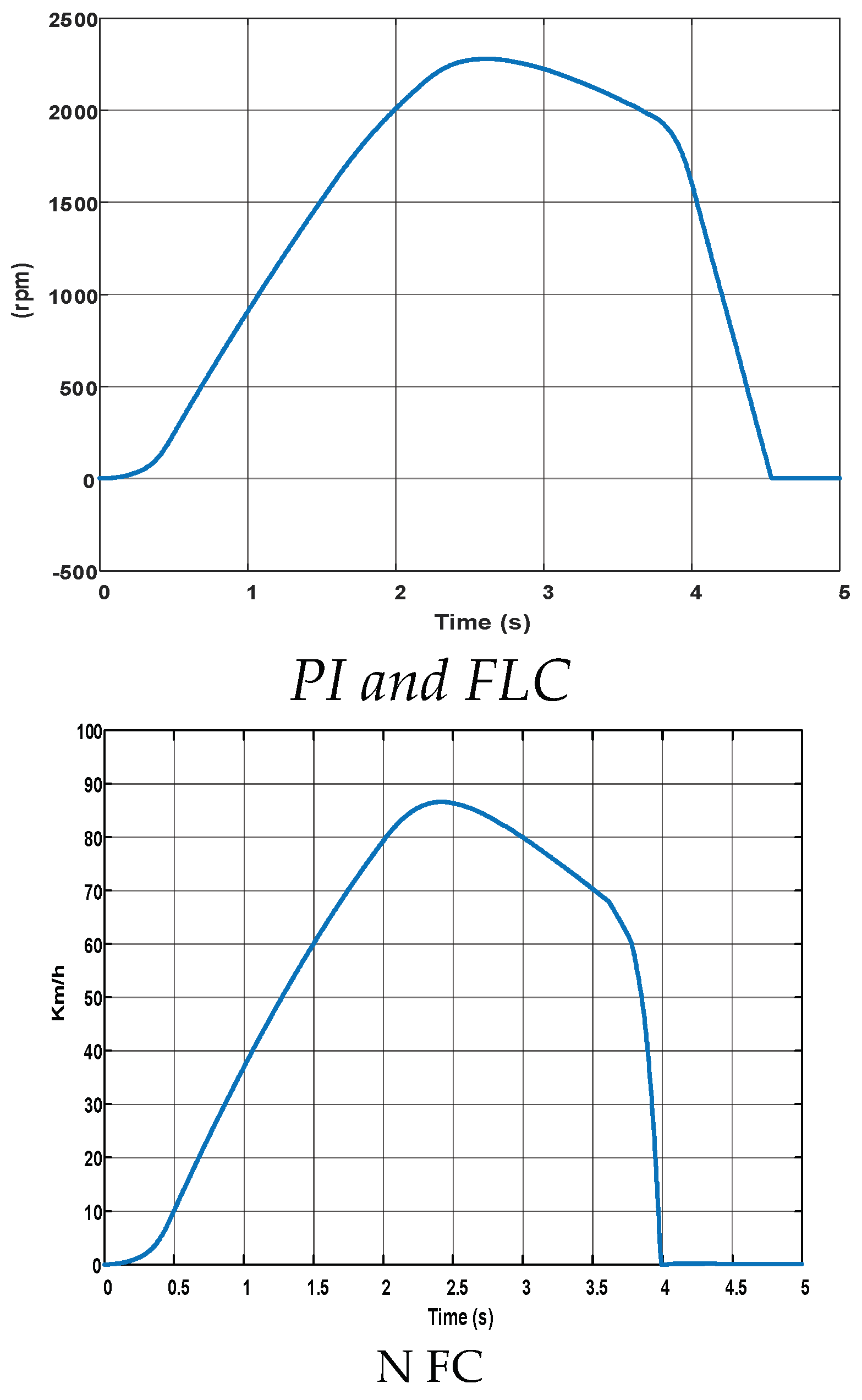

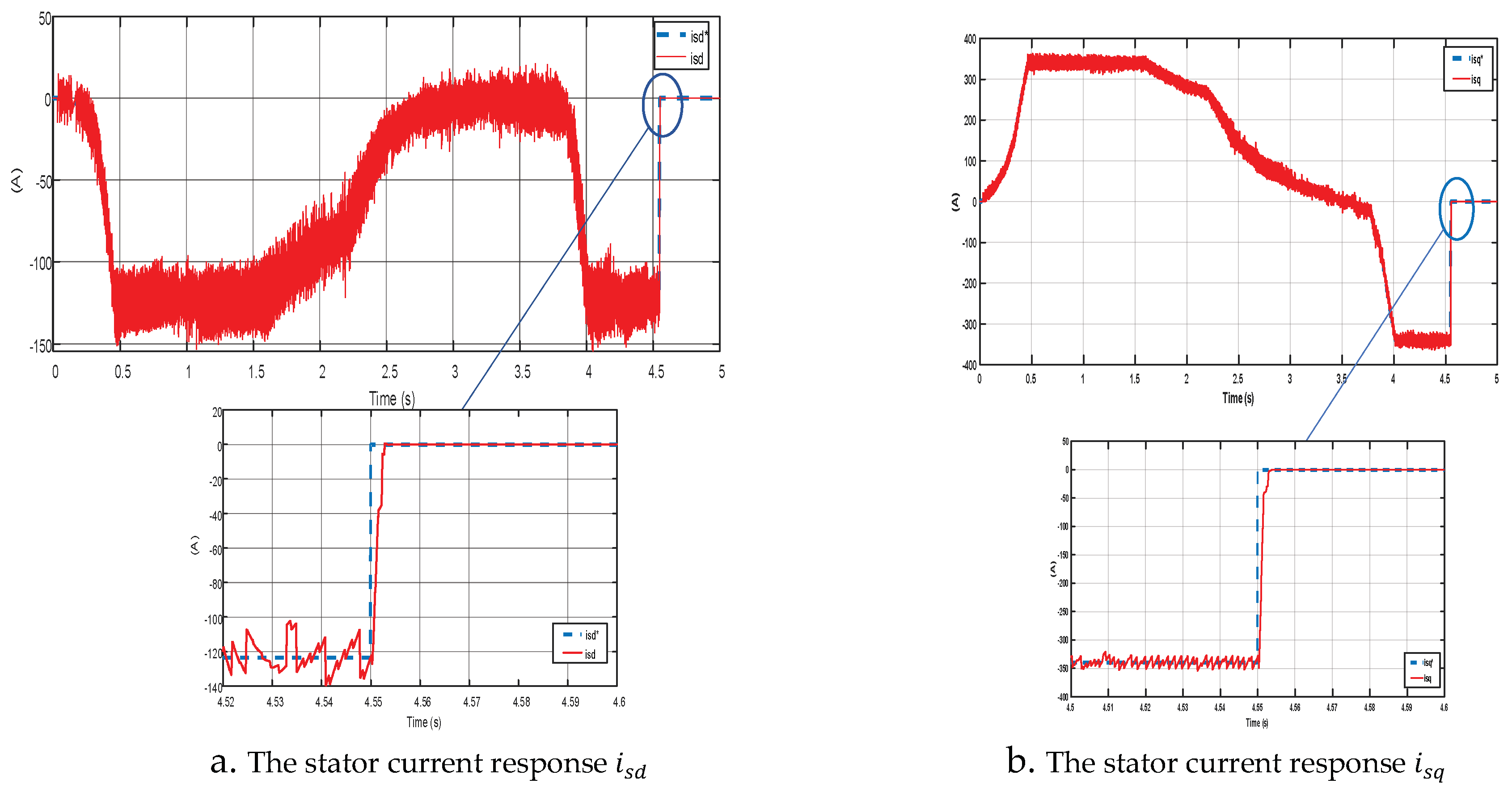

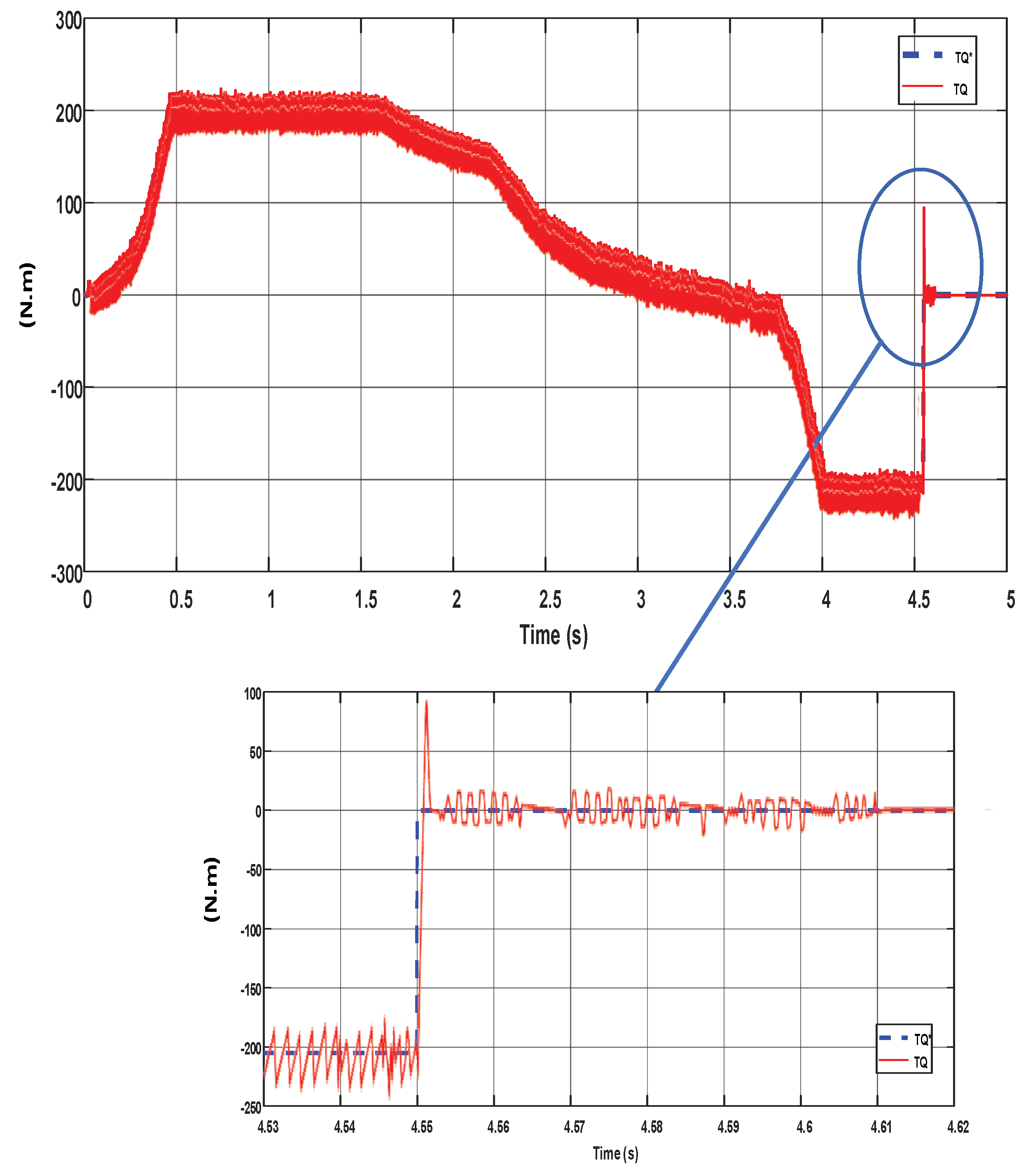

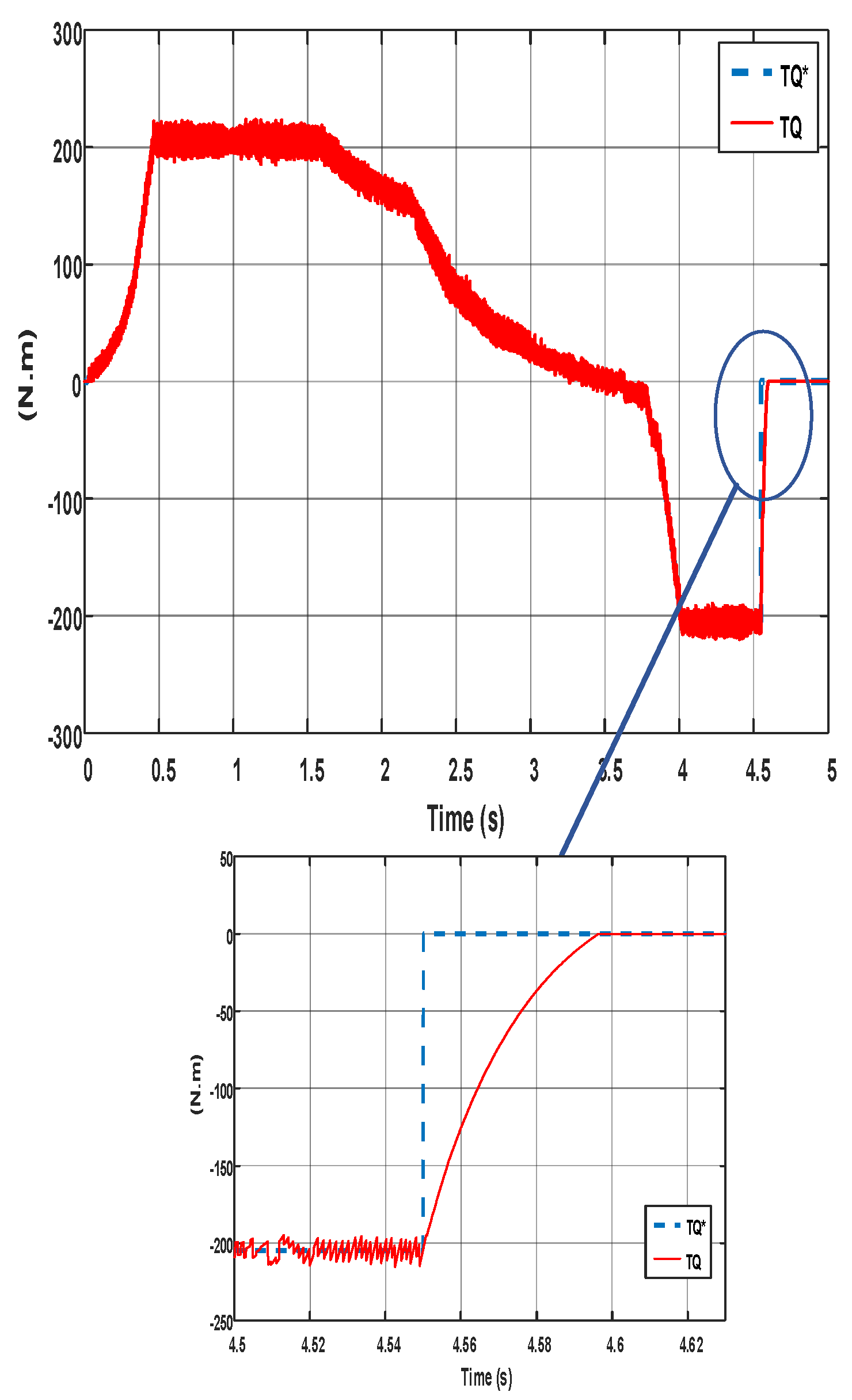

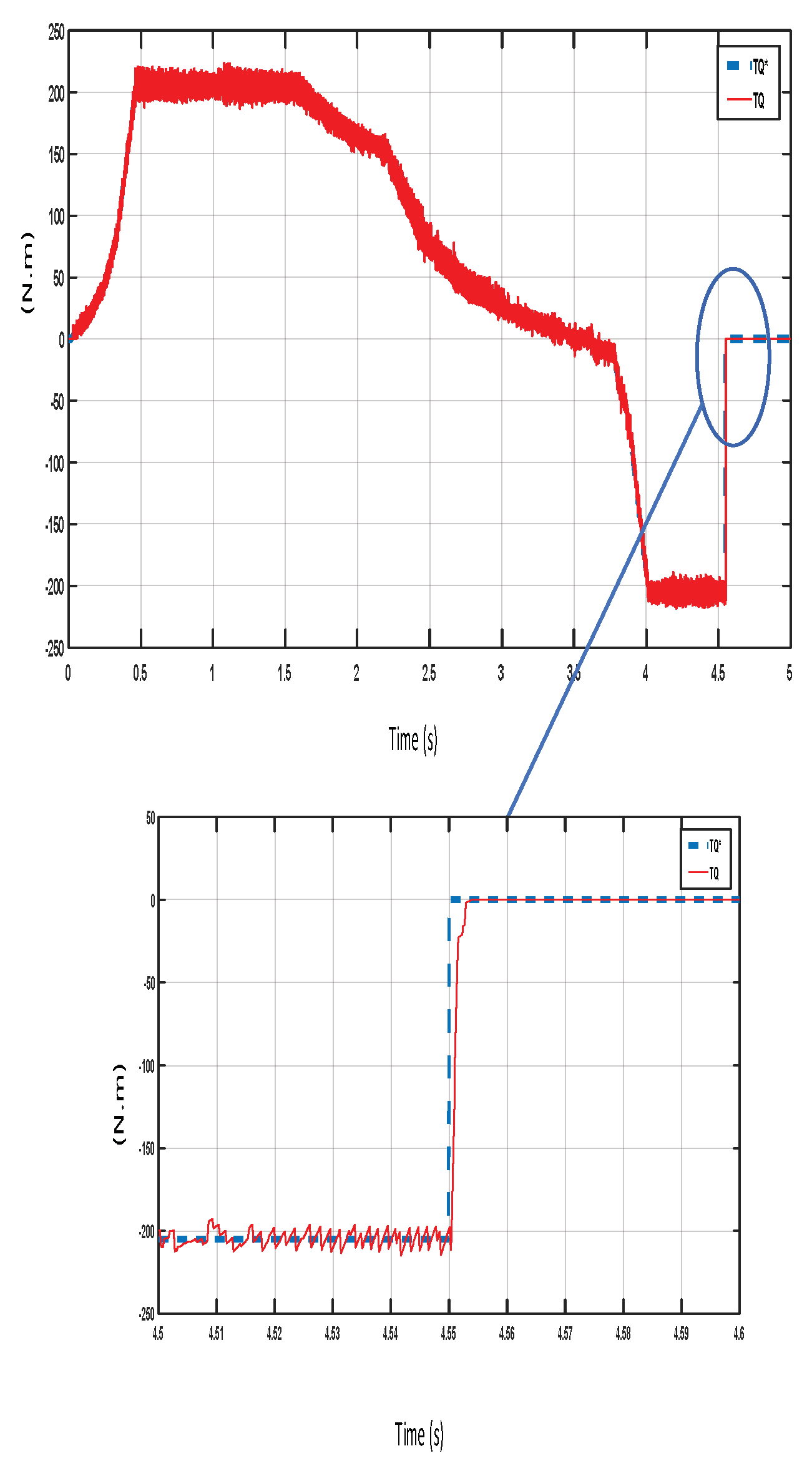

5.2. Simulation results for PI, FLC and NFC torque controllers

- Assume the speed of the wind is 0.

- The car moves on a flat road, but at t= 3.5s to 4.3s, the car goes downhill.

- At t = 0s, the car starts to accelerate the accelerator value increases from 0 to 1 after 0.45s. Torque reaches a maximum of 205 Nm and remains for 2s.

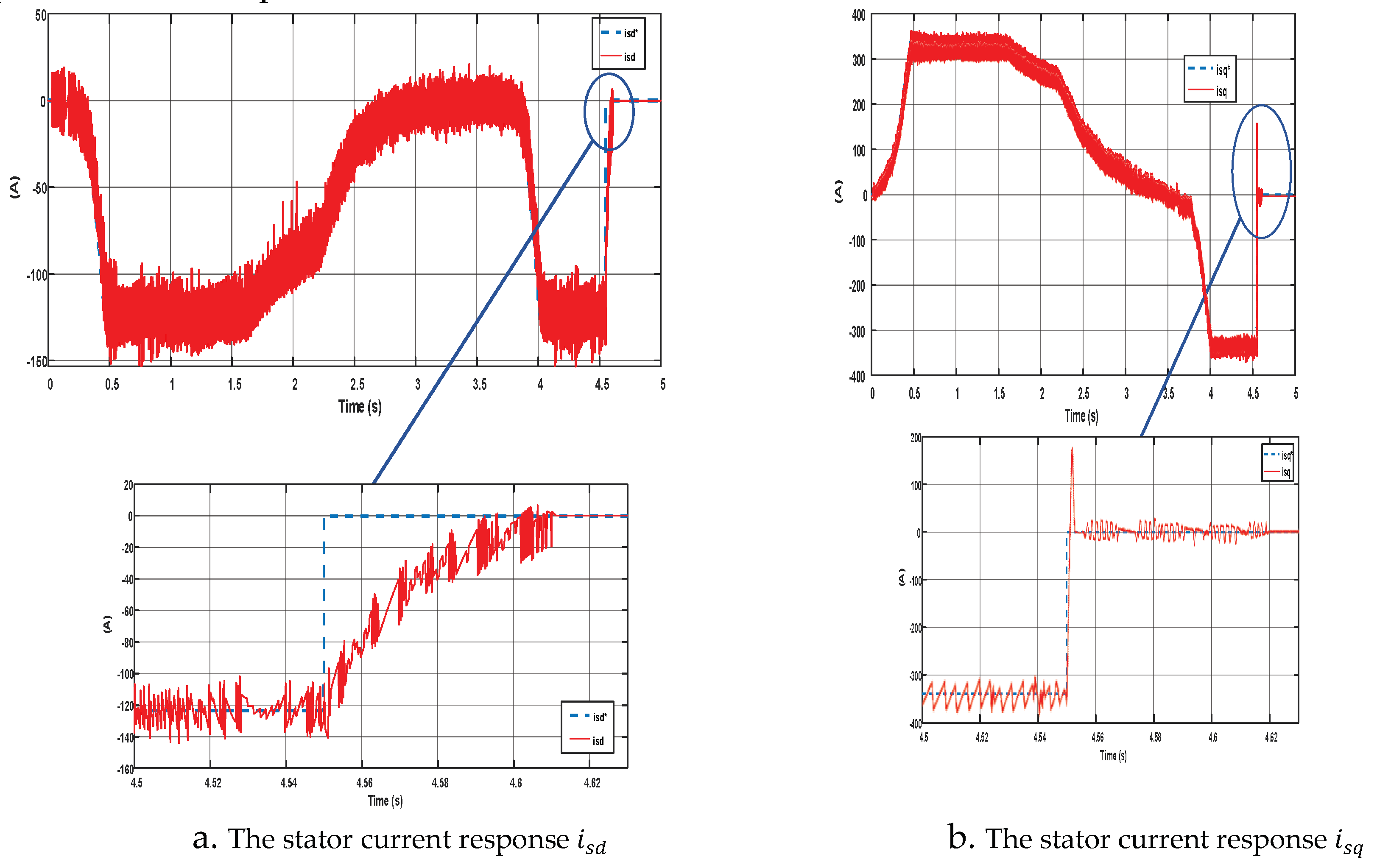

5.2.1. Subsubsection Ld, Lq parameters of the in-wheel AFPMSM motor remain unchanged

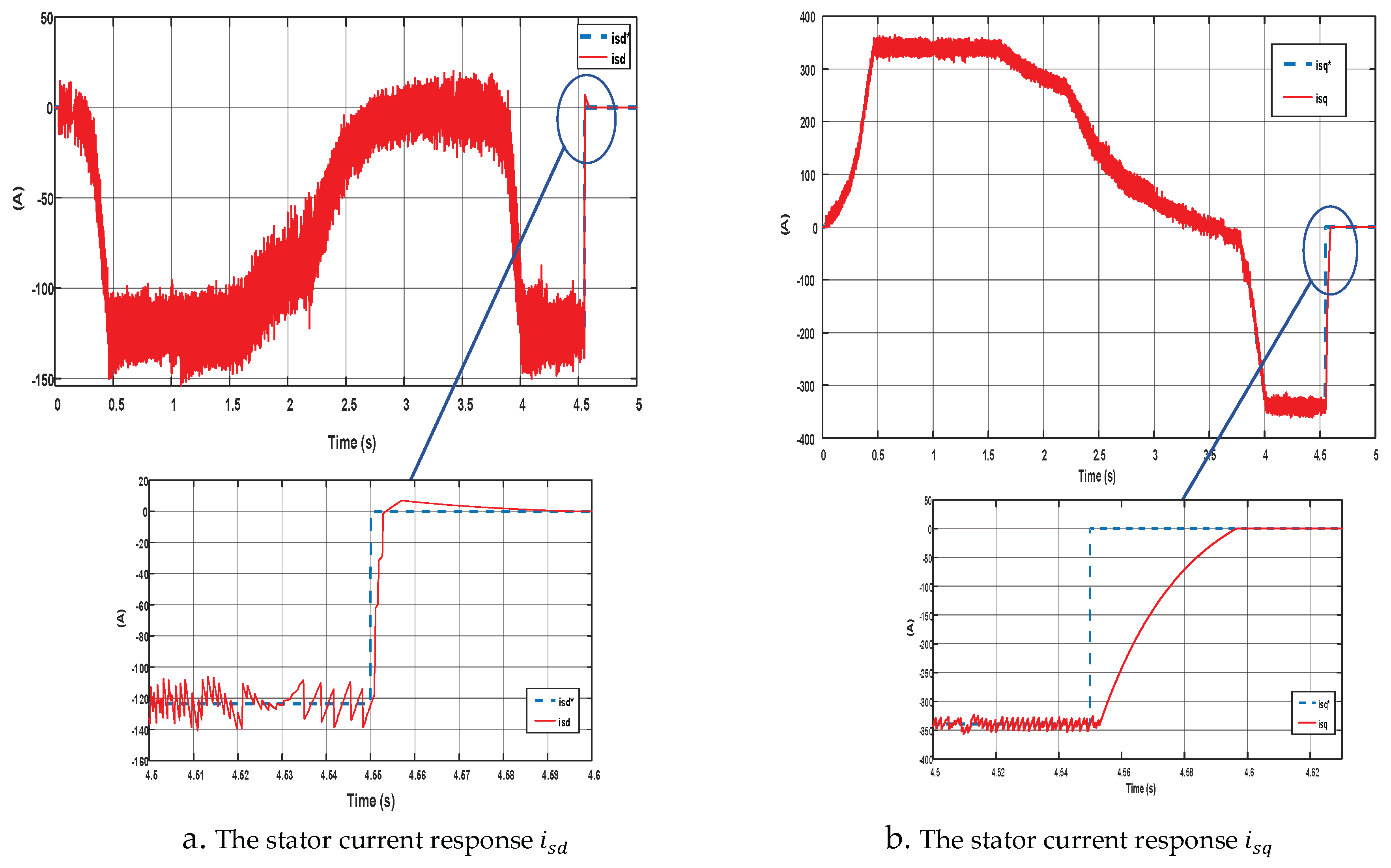

5.2.2. Ld , Lq parameters of the in –wheel AFPMSM motor changed by 20%

5. Conclusions

Acknowledgments

References

- X. Zhang, D. Göhlich and J. Li, "Energy-Efficient Toque Allocation Design of Traction and Regenerative Braking for Distributed Drive Electric Vehicles," in IEEE Transactions on Vehicular Technology, vol. 67, no. 1, pp. 285-295, Jan. 2018. [CrossRef]

- N. Mutoh, "Driving and Braking Torque Distribution Methods for Front- and Rear-Wheel-Independent Drive-Type Electric Vehicles on Roads With Low Friction Coefficient," in IEEE Transactions on Industrial Electronics, vol. 59, no. 10, pp. 3919-3933, Oct. 2012. [CrossRef]

- X. Yuan and J. Wang, "Torque Distribution Strategy for a Front and Rear-Wheel-Driven Electric Vehicle," in IEEE Transactions on Vehicular Technology, vol. 61, no. 8, pp. 3365-3374, Oct. 2012. [CrossRef]

- R. Wrobel, J. Goss, A. Mlot and P. H. Mellor, "Design Considerations of a Brushless Open-Slot Radial-Flux PM Hub Motor," in IEEE Transactions on Industry Applications, vol. 50, no 3, pp. 1757-1767, May-June 2014. [CrossRef]

- Wei Xu; Jianguo Zhu; Youguang Guo; Shuhong Wang; Yi Wang; Zhanghai Shi,” Survey on electrical machines in electrical vehicles”, 2009 International Conference on Applied Superconductivity and Electromagnetic Devices.

- Mohamed Arbi Khlifi, Marwa Ben Slimene, Ahmad Alradedi, Salah,” Al Ahmadi “Investigation of a Leakage Reactance Brushless DC Motor for DC Air Conditioning Compressor Engineering”, Technology & Applied Science Research, Vol. 12, No. 2, 2022.

- Merve Yıldırım, Mehmet Polat, H. Kurum,” A survey on comparison of electric motor types and drives used for electricvehicles,” 16th International Power Electronics and Motion Control Conference and Exposition Antalya, Turkey 21-24 Sept 2014.

- Tahir Aja Zarma, Ahmadu Adamu Galadima, Aminu A. Maruf,” Review of Motors for Electrical Vehicles”, October 2019 Journal of Scientific Research and Reports.

- Garcia, X. D. T. et al. Comparison between FOC and DTC Strategies for Permanent Magnet Synchronous Motors. Advances in Electrical and Electronic Engineering 5, 76-81, (2011).

- Pooja Bhatt, Hemant Mehar, Manish Sahajwani,” Electrical Motors for Electric Vehicle – A Comparative Study,” Proceedings of Recent Advances in Interdisciplinary Trends in Engineering & Applications (RAITEA) 2019.

- W. Yu and C. Gu, "Dynamic analysis of a novel clutch system for in-wheel motor drive electric vehicles," in IET Electric Power Applications, vol. 11, no. 1, pp. 90-98, 1 2017. [CrossRef]

- A. Darba, M. Esmalifalak and E. S. Barazandeh, Implementing SVPWM technique to axial flux permanent magnet synchronous motor drive with internal model current controller, 2010 4th International Power Engineering and Optimization Conference (PEOCO), Shah Alam, Malaysia, (2010), 126-131. [CrossRef]

- Krishnan, Ramu. Electric Motor Drives: Modeling, Analysis, and Control, Prentice-Hall Of India Pvt. Limited, (2001).

- Phạm Thi Giang, Vo Thanh Ha*, Vu Hoang Phương "Drive Control of a Permanent Magnet Synchronous Motor Fed by a Multi-level Inverter for Electric Vehicle Application" - Engineering, Technology & Applied Science Research, Vol. 12, No. 3, June 2022. [CrossRef]

- Vo Thanh Ha, Phạm Thi Giang, Vu Hoang Phương "T-type Multi-Inverter Application for Traction Motor Control" - Engineering, Technology & Applied Science Research, Vol. 12, No. 2, April 2022. [CrossRef]

- Vo Quang Vinh, Vo Thanh Ha ," Improved Torque Ripple of Switched Reluctance Motors using Sliding Mode Control for Electric Vehicles" - Engineering, Technology & Applied Science Research, Vol. 13, No. 1, February 2023. [CrossRef]

- Chunyu Yang; Leping Shen; Linna Zhou,” Fuzzy Sliding Mode Control for Permanent Magnet Synchronous Motors,” 2018 5th International Conference on Information, Cybernetics, and Computational Social Systems (ICCSS). [CrossRef]

- Trong Duy Nguyen, Student Member, IEEE, King-Jet Tseng, Senior Member, IEEE, Shao Zhang, Student Member, IEEE, and Hoan Thong Nguyen, “A Novel Axial Flux Permanent-Magnet Machine for Flywheel Energy Storage System: Design and Analysis”, IEEE Transactions on Industrial Electronics, Vol.58, No.9, September 2011. [CrossRef]

- Trong Duy Nguyen, Gilbert Foo Hock Beng, King-Jet Tseng, Don Mahinda Vilathgamuwa, and Xinan Zhang, “Modeling and Position-Sensorless Control of a Dual-Airgap Axial Flux Permanent Magnet Machine for Flywheel Energy Storage Systems”, Journal of Power Electronics, Vol. 12, No. 5, September 2012. [CrossRef]

- Quang Dich Nguyen and Satoshi Ueno, “Analysis and Control of NonSalient Permanent Magnet Axial-Gap Self-Bearing Motor”, IEEE Transactions on Industrial Electronics, Vol. PP, No. 99, pp. 1-8, 2010 (early access). [CrossRef]

- Garcia, X. D. T. et al. Comparison between FOC and DTC Strategies for Permanent Magnet Synchronous Motors. Advances in Electrical and Electronic Engineering 5, 76-81, (2011).

- S. Nakashima, Y. Inagaki, I. Miki, Sensorless initial rotor position estimation of surface permanentmagnet synchronous motors, IEEE Transactions on Industry Applications, 36, 6, (2000), 1598-1603. [CrossRef]

- Sensorless PMSM Vector Control, Design Reference Manual, freescale , semiconductor , (2009).

- V.K., Arun Shankar & Subramaniam, Umashankar & Sanjeevikumar, P. & Paramasivam, Sathesh, Adaptive Neuro-Fuzzy Inference System (ANFIS) based Direct Torque Control of PMSM driven centrifugal pump. International Journal of Renewable Energy Research. 7, (2017), 1437–1447.

- D. V. Lukichev, G. L. Demidova, A. Y. Kuzin and A. V. Saushev, Application of adaptive Neuro Fuzzy Inference System (ANFIS) controller in servodrive with multi-mass object, 2018 25th International Workshop on Electric Drives: Optimization in Control of Electric Drives (IWED), Moscow, (2018), 1-6. [CrossRef]

- Nagham Farhan, Abdulrahim T. Humod, Fadhil A. Hasan,” Field Oriented Control of AFPMSM for Electrical Vehicle Using Adaptive Neuro-Fuzzy Inference System (ANFIS),” Engineering Engineering and Technology Journal. [CrossRef]

| Input 1 (e) | NB | NS | ZE | PS | PB | |

|---|---|---|---|---|---|---|

| ) | ||||||

| NB | NB | NB | NB | NS | ZE | |

| NS | NB | NB | NS | ZE | PS | |

| ZE | NS | NS | ZE | PS | PB | |

| PS | ZE | ZE | PS | PB | PB | |

| PB | ZE | PS | PB | PB | PB | |

| Motor parameters | Value Symbol | Value Symbol |

|---|---|---|

| Power | Pđm | 35 kw |

| Rated speed | Nđm | 1800 rpm |

| Rated voltage | Uđm | 275V |

| Number of pole pairs | Zp | 8 |

| Magnetic flux density | 0.0437 | |

| Maximum torque | Pmax | 205Nm |

| Armature resistance | Rs | 0.0101 |

| Shaft inductance d | Ld | 2.4368e-4 H |

| Shaft inductance q | Lq | 2.9758e-4 H |

| Controller | Ki | Kp |

|---|---|---|

| Current controller Id | 7.103004e+2 | 0.8779 |

| Current controller Iq | 1.0615e+3 | 1.0744 |

| Controller/Parameter evaluation PI | PI | FLC | NFC |

|---|---|---|---|

| Stator current isd | |||

| Accelerated setting time | 0.4 (s) | 0.4 (s) | 0.4 (s) |

| Over-adjustment | 10% | 0% | 0% |

| Stator current isq | |||

| Set-up time | 0.4 (s) | 0.4 (s) | 0.4 (s) |

| Over-adjustment | 10% | 0% | 0% |

| Controller/Parameter evaluation PI | PI | FLC | NFC |

|---|---|---|---|

| Torque responses | |||

| Shape | Same as isq current response |

Same as isq current response | Same as isq current response |

| Torque ripple | 8% | 5% | 3% |

| Speed responses | |||

| Accelerated setting time | 2.2 (s) | 2.2 (s) | 2.2 (s) |

| Over-adjustment | 0% | 0% | 0% |

| Controller/Parameter evaluation PI | PI | FLC | NFC |

|---|---|---|---|

| Stator current isd | |||

| Accelerated setting time | 0.5 (s) | 0.5 (s) | 0.5 (s) |

| Over-adjustment | 10% | 5% | 0% |

| Stator current isq | |||

| Set-up time | 0.5 (s) | 0.5 (s) | 0.5 (s) |

| Over-adjustment | 20% | 5% | 0% |

| Controller/Parameter evaluation PI | PI | FLC | NFC | |

|---|---|---|---|---|

| Torque responses | ||||

| Shape | Same as isq current response | Same as isq current response | Same as isq current response | |

| Torque ripple | 30% | 16% | 5% | |

| Speed responses | ||||

| Accelerated setting time | 2.2 (s) | 2.2 (s) | 2.2 (s) | |

| Over-adjustment | 20% | 0% | 0% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).