1. Introduction

The building sector is one of the most significant contributors to global energy consumption and greenhouse gas emissions. Only the production of cement, a primary component of concrete in buildings, is responsible for a significant amount of carbon dioxide emissions and contributes to the depletion of natural resources [

1,

2]. In India, the impact of the building sector on the environment is particularly pronounced, where the net annual CO2 emissions in 2015 increased to 2.47 billion tonnes, a 5.1% increase from 2014. In Chile, buildings account for approximately 30% of the final energy consumption in the country, and 20% of its greenhouse gas emissions [

3]. Current regulation considers some limitations on commercial buildings and sets restrictions for both energy consumption and the comfort level of the occupants. To mitigate this problem, the Chilean government has established a national strategy for sustainable construction to reduce the environmental impact of the building sector by promoting the use of environmentally friendly materials and construction techniques to improve the energy efficiency of buildings, and reduce waste generation.

Concrete is perhaps the most used construction material in the history. Worldwide, more than 10 billion tons of this material are produced each year. A few reasons for this popularity are its excellent mechanical resistance in compression, durability, the ability to be molded in almost any shape, relative fire resistance, and to satisfy almost any reasonable set of performance specifications [

4]. In Chile, concrete is the predominant material used for building construction due to its capacity to withstand severe seismic loading conditions without reaching failure states or collapse, a critical aspect for countries prone to earthquakes. However, the concrete construction industry faces sustainability challenges. Firstly, it consumes significant amounts of virgin materials, which contributes to natural resource depletion. Secondly, the primary binder in concrete is Portland cement, which is responsible for significant greenhouse gas emissions implicated in global warming and climate change. Finally, the lack of durability of many concrete structures negatively impacts the resource productivity of the industry [

5]. These issues pose a challenge to the long-term sustainability of the construction industry and require urgent attention.

To produce concrete, a mixed proportion of cement, coarse and fine aggregates, and water are mixed together to obtain a fresh paste that sets with time. Each individual component plays fundamental roles in the final mechanical strength of concrete. In particular, aggregates are used as a low-cost inert filler, being a main component in the mix since they occupy between 55% and 80% of the total volume of the concrete [

6]. Therefore, this material is responsible for the unit weight, elastic modulus and dimensional stability of the concrete. Because of the over exploitation of aggregates, it has been warned in the past that if alternatives are not sought for aggregate use, the concrete industry will annually consume between 8 and 12 billion tons of natural aggregates. For this reason, the use of recycled aggregates or their substitution is sought [

6,

7]. Several authors have investigated the concrete resistance when partial sand content is replaced. For instance, recycled glass, plastic, copper slag and rubber had been used as sand replacement [

4,

8]. Other researchers have studied recycled concrete as both fine and coarse aggregate replacement in high resistance concrete [

6]. At the same time, the use of organic materials in the manufacture of concrete has been evaluated as reinforcement with vegetable fibers as sisal or coconut fibers increasing tensile strength of the specimens, as well as admixtures with gram flour obtaining increases in the compressive resistance. Sugarcane bagasse ash has been studied as a replacement of the sand content producing mortars with better mechanical results than the reference samples [

9,

10,

11]

In order to find alternative materials that can partially replace the fine aggregates without significantly compromising the properties of concrete, great efforts have been put into the study and characterization of waste organic materials. One such material is crushed hazelnut shell (herein referred as HS), an agricultural waste that is generated in large quantities. In Chile, it is estimated that by year 2030 there will be 60 000 ha planted, with a production in the order of 88 000 ton. More than 50% of the weight of the hazelnut corresponds only to the shell, which makes it an important waste or by-product of this industry [

12]. Nowadays, this waste material is used only as fuel and the remaining is disposed.

Hazelnut shells are considered as a lignocellulosic solid waste, which is a complex structural material found in the cell walls of plants. Lignocellulose is composed of cellulose, hemicellulose, and lignin. Cellulose is a linear polymer made up of glucose units and is the most abundant component of lignocellulosic materials. Hemicellulose, on the other hand, is a heteropolymer made up of different types of sugar units and is typically found in smaller quantities than cellulose. Lignin is a complex polymer that provides structural support to plant cells.

In this investigation, crushed hazelnut shell is used as a partial substitute of fine aggregates in percentages of 2.5%, 5%, and 10% by weight of sand, to determine the physical and mechanical properties of concrete specimens according to ASTM standards. In addition, a statistical study was performed to correlate the mechanical response of the concrete cylinders with physical properties. We aim to determine the optimum percentage of HS replacement that can be used in concrete without compromising its strength. The results of this study can contribute to the development of sustainable concrete mixtures and reduce the environmental impact of the construction industry.

2. Materials

2.1. Cement

Concrete mixtures were designed using a commercially available puzzolanic cement. This cement has been specially formulated for making concrete that requires high initial resistance of the specified strength at 28 days. The specification of this material is Type IP (puzzolanic Portland cement) based on the ASTM C595 standard [

13].

2.2. Additives

Sika ViscoCrete-6000 is used as hyperplasticizer addition to the concrete mix. This product is an aqueous chemical solution that reduces the water content in the production of concrete without negatively affecting the workability, but improving the performance of the hardening fresh paste [

14]. A dose of 0.35% of the cement weight was carefully diluted in 20 milliliters of tap water and poured into the fresh concrete during mixing. The intention here was to disperse both the HS and cement particles more effectively, allowing them to hydrate more completely and form stronger bonds.

2.3. Aggregates

Fine and coarse aggregate (gravel of maximum nominal size

mm) were used for the concrete mix in a

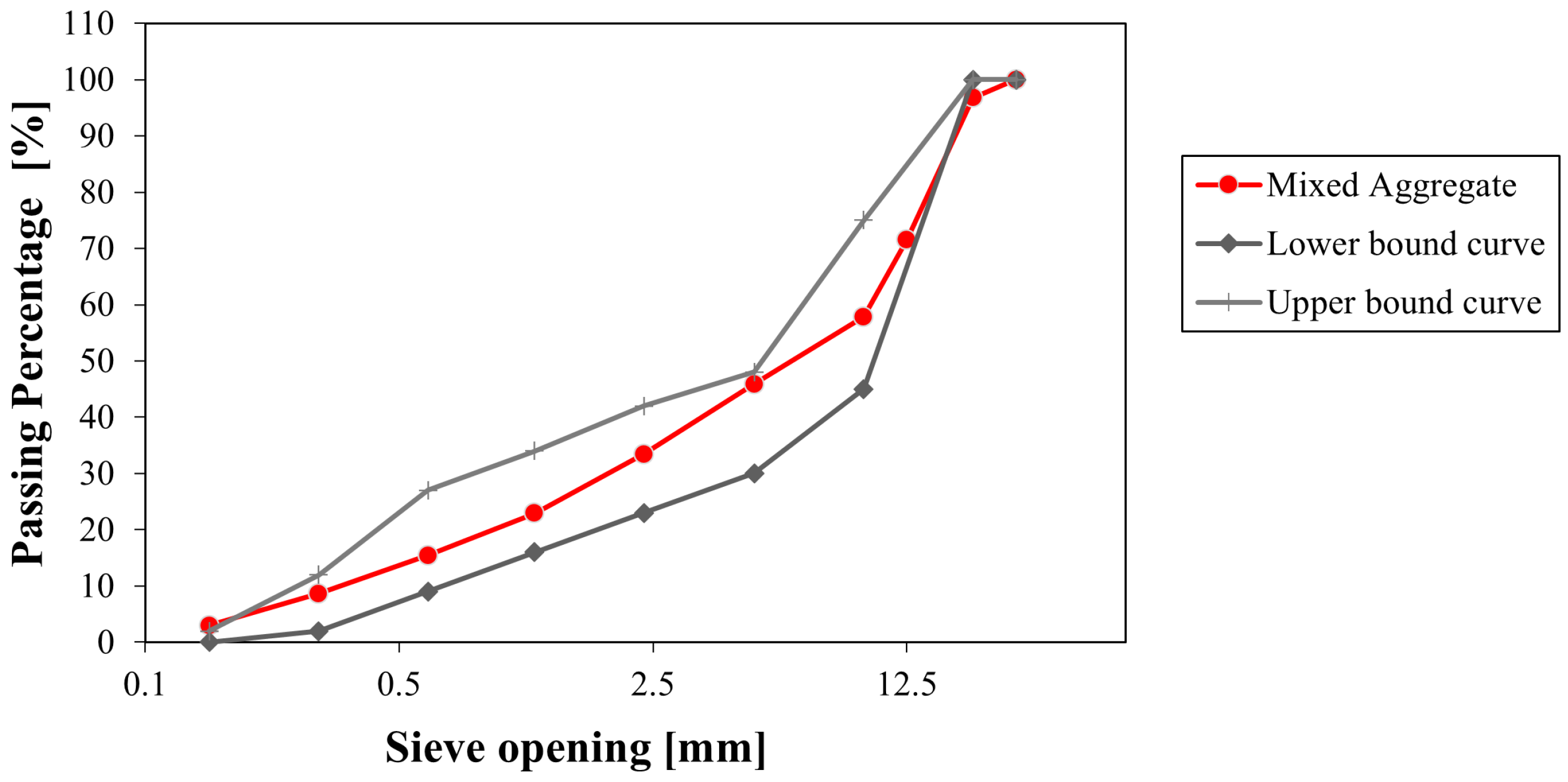

proportion. Sieve analysis was performed for the grading of both aggregates, as shown in

Table 1 and according to the Chilean standard NCh165:2009 [

15]. The combined aggregate adjusts to the curves specified in the Chilean standard NCh163:2013 [

16] for aggregates with 19 mm of maximum nominal size, as presented in

Figure 1.

Table 1.

Fine and coarse aggregate sieve test results

Table 1.

Fine and coarse aggregate sieve test results

| Sieve testing results |

| |

Fine Aggregate |

Coarse Aggregate |

| Sieve |

Passing percentage |

Passing percentage |

| mm |

[%] |

[%] |

| 25 |

100 |

100 |

| 19 |

100 |

94 |

| 12.5 |

100 |

48 |

| 9.5 |

100 |

23 |

| 4.75 |

99 |

1 |

| 2.36 |

74 |

0 |

| 1.18 |

50 |

0 |

| 0.6 |

34 |

0 |

| 0.3 |

19 |

0 |

| 0.15 |

7 |

0 |

Figure 1.

Sieve test results and comparison with curves of combine aggregate according to NCh163:2013 [

16]

Figure 1.

Sieve test results and comparison with curves of combine aggregate according to NCh163:2013 [

16]

Absorption and density test of the aggregate were conducted according to NCh1117:2010 [

17] for coarse aggregates, and according to NCh1239:2009 [

18] for fine aggregates. The results are shown in

Table 2. The curve of the combined aggregate falls between the lower curve that corresponds to more granular concrete mixtures and the upper curve that corresponds to more docile concrete mixtures. In this investigation, the experimental curve represents a balances amount of both fine and coarse aggregate [

19].

Table 2.

Aggregates absorption and density test results.

Table 2.

Aggregates absorption and density test results.

| Properties |

Coarse aggregates |

Fine aggregates |

| Absorption [%] |

1.4 |

1.9 |

| Density [] |

2630 |

2660 |

2.4. Crushed Hazelnut Shells (HS)

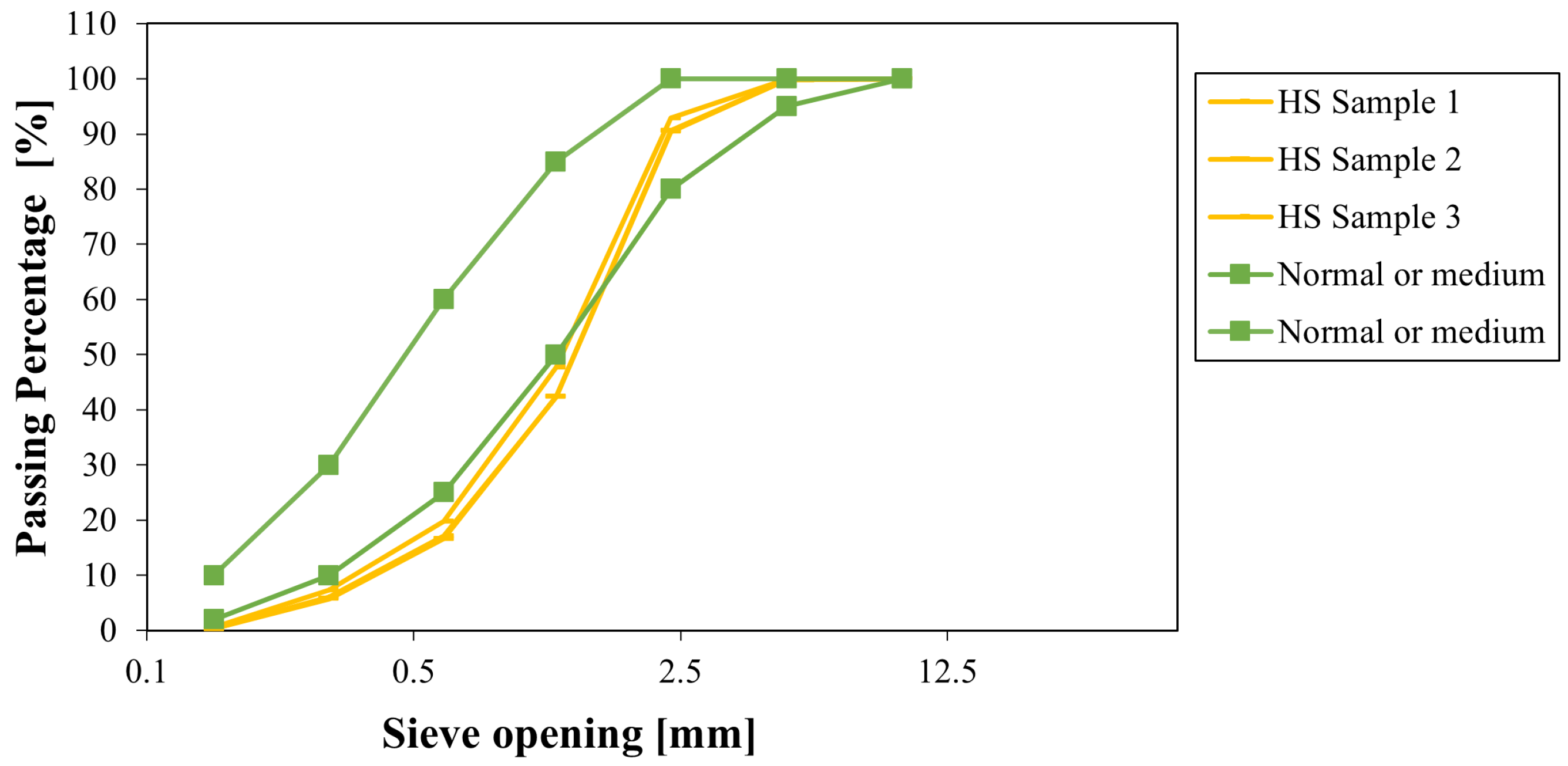

Hazelnut shells were collected in clean bags directly from the industrial cellar to avoid contamination and to maintain the product dry from exterior humidity. Once in the laboratory, the shells were crushed using a hand-made device consisting of an aluminum pot and an angle grinder with steel blades. The process to obtain different sizes was performed at 1100 rpm. After grinding, the material was dried in a temperature-controlled oven for 72 hours at 60°C, and then sieve sized to evaluate its similarity with the fine aggregate by comparing it with the ones specified in the Chilean standard NCh163:2013 [

16]. In

Figure 2 the comparison between sieve tests performed in three samples of crushed hazelnut shell and the limits for a normal or medium sized sand is presented. The curve of the hazelnut shell follows the shape of the band for this size, therefore it can be used as a substitute of fine aggregate in therms of size.

Figure 2.

Sieve test results for HS and comparison with granulometric types of fine aggregate.

Figure 2.

Sieve test results for HS and comparison with granulometric types of fine aggregate.

Studies on the density and the water absorption rate of the crushed hazelnut shell were conducted according to the ASTM C128-22 [

20] and shown in

Table 3. This standard can be used to determine the real and net density and absorption of fine aggregates used in mortars and concretes. However, to the best of the authors knowledge, there is no international standard to determine these properties in crushed HS. In this investigation, these parameters are presented because they can affect the physical and mechanical response of the organic material, such as strength, stiffness, and dimensional stability, and therefore modify the concrete mechanical behavior.

Additionally, crushed HS density was calculated empirically by means of the Archimedes principle. This modified procedure to obtain the absorption property of the HS was performed using 8 unwashed, oven-dried samples submerged in un-ionized water. These samples were agitated in a LabTech heavy duty orbital shaker model LSI-020, for 1 hour at 150 rpm. 2 samples were filtered after 1, 2, 4, and 24 hours, using a vacuum pump to obtain a wet (saturated) sample. The final mass of the sample was then measured, and the absorption percentage was calculated using Eq.

1. The water absorption data used in the design of the mixture corresponds to the average between the results obtained by these two methods at 24 h as shown in

Table 3.

Table 3.

Crushed HS absorption and density test results.

Table 3.

Crushed HS absorption and density test results.

| Property |

Value |

| Density (saturated surface dry) [] |

1316 |

| Density (oven dry) [] |

999 |

| Apparent relative density [] |

1462 |

| Water absorption [%] |

38 |

3. Experimental program

3.1. Mixing procedure and sample preparation

A total of 72 specimens were tested to determine the compressive strength at 7 and 28 days, and the bending tensile strength at 28 days. Two different concrete batches with water/cement ratio of 0.4 and 0.5 were poured and tested. The percentage of crushed HS added ranges from 0, 2.5, 5, and 10% replacement by weight of sand, as shown in

Table 4.

Table 4.

Specimen nomenclature utilized in the experimental procedure.

Table 4.

Specimen nomenclature utilized in the experimental procedure.

| Mixture |

w/c |

HS[%] |

Specimen nomenclature |

Compressive strength

at 7 days |

Compressive strength

at 28 days |

Bending tensile strength

at 28 days |

| M-0.4-0 |

0.4 |

0 |

M-0.4-0-C-7-A |

M-0.4-0-C-28-A |

M-0.4-0-T-28-A |

| M-0.4-0-C-7-B |

M-0.4-0-C-28-B |

M-0.4-0-T-28-B |

| M-0.4-0-C-7-C |

M-0.4-0-C-28-C |

M-0.4-0-T-28-C |

| M-0.4-2.5 |

0.4 |

2.5 |

M-0.4-2.5-C-7-A |

M-0.4-2.5-C-28-A |

M-0.4-2.5-T-28-A |

| M-0.4-2.5-C-7-B |

M-0.4-2.5-C-28-B |

M-0.4-2.5-T-28-B |

| M-0.4-2.5-C-7-C |

M-0.4-2.5-C-28-C |

M-0.4-2.5-T-28-C |

| M-0.4-5 |

0.4 |

5 |

M-0.4-5-C-7-A |

M-0.4-5-C-28-A |

M-0.4-5-T-28-A |

| M-0.4-5-C-7-B |

M-0.4-5-C-28-B |

M-0.4-5-T-28-B |

| M-0.4-5-C-7-C |

M-0.4-5-C-28-C |

M-0.4-5-T-28-C |

| M-0.4-10 |

0.4 |

10 |

M-0.4-10-C-7-A |

M-0.4-10-C-28-A |

M-0.4-10-T-28-A |

| M-0.4-10-C-7-B |

M-0.4-10-C-28-B |

M-0.4-10-T-28-B |

| M-0.4-10-C-7-C |

M-0.4-10-C-28-C |

M-0.4-10-T-28-C |

| M-0.5-0 |

0.5 |

0 |

M-0.5-0-C-7-A |

M-0.5-0-C-28-A |

M-0.5-0-T-28-A |

| M-0.5-0-C-7-B |

M-0.5-0-C-28-B |

M-0.5-0-T-28-B |

| M-0.5-0-C-7-C |

M-0.5-0-C-28-C |

M-0.5-0-T-28-C |

| M-0.5-2.5 |

0.5 |

2.5 |

M-0.5-2.5-C-7-A |

M-0.5-2.5-C-28-A |

M-0.5-2.5-T-28-A |

| M-0.5-2.5-C-7-B |

M-0.5-2.5-C-28-B |

M-0.5-2.5-T-28-B |

| M-0.5-2.5-C-7-C |

M-0.5-2.5-C-28-C |

M-0.5-2.5-T-28-C |

| M-0.5-5 |

0.5 |

5 |

M-0.5-5-C-7-A |

M-0.5-5-C-28-A |

M-0.5-5-T-28-A |

| M-0.5-5-C-7-B |

M-0.5-5-C-28-B |

M-0.5-5-T-28-B |

| M-0.5-5-C-7-C |

M-0.5-5-C-28-C |

M-0.5-5-T-28-C |

| M-0.5-10 |

0.5 |

10 |

M-0.5-10-C-7-A |

M-0.5-10-C-28-A |

M-0.5-10-T-28-A |

| M-0.5-10-C-7-B |

M-0.5-10-C-28-B |

M-0.5-10-T-28-B |

| M-0.5-10-C-7-C |

M-0.5-10-C-28-C |

M-0.5-10-T-28-C |

The materials were sequentially added into a mechanical mixer in a specific order. Firstly, half of the water was added to the gravel and sand, and mixed for 30 seconds until a uniform mixture was obtained. Then, the cement was added and mixed for a duration of one minute. Subsequently, the remaining water was added, and the mixture was mixed again for one minute. Lastly, the additive was introduced and mixed for a duration of three minutes. Cases using crushed HS, the material was pre-mixed with the fine aggregate prior to being added to the mixer.

To prepare the samples, a total of six cylindrical molds with a diameter of 10 centimeters and a height of 20 centimeters were used for each mixture, along with three prismatic molds measuring 10 centimeters in height, 10 centimeters in width, and 40 centimeters in length [

21]. The cylindrical molds were filled in two layers, while the prism molds were filled in one layer and were compacted either manually or mechanically, depending on the docility obtained from the slump test. For manual compaction, a standardized rod was used to tamp the concrete cylinder 25 times per layer until it was completely filled with fresh paste, while for mechanical compaction, internal vibration was used. After compacting the samples, 10-15 strokes were given with a mallet to eliminate gaps resulting from the chosen method. The setting time for the cylindrical specimens was 20 ± 4 hours, while for prism specimens, it was set to 44 hours for added safety before demolding, as per the ASTM C192 [

22] standard.

3.2. Fresh concrete tests

Prior to setting, fresh concrete mixtures were subjected to tests in order to characterize their properties. These tests were conducted to obtain information about the workability, consistency, and homogeneity of the mixtures. Once the mixtures were characterized, the results were compared to the mechanical strengths obtained from compression and tensile tests. This allowed for an investigation of any potential correlations or relationships between the properties of the fresh concrete and the mechanical resistances of the hardened concrete.

3.2.1. Slump test

Slump tests were performed according to the ASTM C143 [

23] standard. These results conditioned the method of consolidation used for the confection of the cylindrical and prismatic specimens for the compression and tensile strength tests. In essence, slump values lower than 5 cm, vibration method was used, whereas for slump values greater than 5 cm, rodding method was used, as shown in

Table 5. Rodding method was defined for specimen M-0.5-2.5 depict the fact slump was greater than the upper limit described in the ASTM standard.

3.2.2. Air content and bulk density

The air content of the concrete was determined following the guidelines of ASTM C231 [

24] using an air meter that comprised a bowl and a cover assembly. The air content measurement was performed within the first 15 minutes after the mixing process and after the slump test was completed. Based on the slump value achieved, the appropriate consolidation method was chosen. Subsequently, the cover assembly was securely placed and sealed according to the standard instructions. Through this procedure, the air content in the concrete mixture was determined as a percentage.

Bulk density was determined by weighing the content of the bowl after it was consolidated. This procedure was performed according to the ASTM C138 / C138M [

25] standard. For air content and bulk density results refer to

Table 5.

Table 5.

Slump test results, consolidation method, air content and bulk density in fresh concrete mixture.

Table 5.

Slump test results, consolidation method, air content and bulk density in fresh concrete mixture.

| Mixture |

Slump [cm] |

Consolidation |

Air content |

Bulk density |

| |

[cm] |

method |

[%] |

[] |

| M-0.4-0 |

10.5 |

Rodding |

1.40 |

2426 |

| M-0.4-2.5 |

14.0 |

Rodding |

1.50 |

2394 |

| M-0.4-5 |

8.5 |

Rodding |

1.10 |

2394 |

| M-0.4-10 |

3.5 |

Vibration |

1.70 |

2377 |

| M-0.5-0 |

4.5 |

Vibration |

1.00 |

2419 |

| M-0.5-2.5 |

- |

Rodding |

1.30 |

2374 |

| M-0.5-5 |

11.0 |

Rodding |

1.90 |

2377 |

| M-0.5-10 |

11.0 |

Rodding |

2.50 |

2347 |

3.3. Hardened concrete tests

3.3.1. Compressive strength

The compressive strength of the concrete samples was determined using cylindrical specimens at 7 and 28 days of age, in accordance with ASTM C39 [

26]. A Tecnotest hydraulic press was used to apply a step load of 0.25 MPa/sec during the testing process. The compressive strength values obtained were recorded for each sample and used to evaluate the overall strength of the concrete mixtures at different ages .

3.3.2. Bending tensile strength

Bending tensile strength was obtained from prismatic specimens at 28 days of age. A Tecnotest hydraulic press using a step load of

MPa/sec according to ASTM C293 [

27].

4. Results and discussion

4.1. Influence of physical properties on mechanical resistances.

The influence of physical properties on the mechanical resistances was evaluated by calculating the data presented in

Table 6. Additionally,

Table 7 shows the relationship between densities for fresh and hardened concrete and the crushed HS replacement percentage. To conduct these analyses, a normality test using Shapiro-Wilks was initially performed on each set of data. Then, the correlation test method was selected based on the distribution of the data: Pearson for normally distributed data, and Spearman for non-normally distributed data. A regression analysis was also conducted for each correlation to illustrate the behavior of each relationship graphically and determine the adjustment coefficient. The relationships presented in

Table 6 have a correlation coefficient greater than 0.6 or lower than -0.6 and were deemed significant based on a 5% error significance test [

7].

Table 6.

Correlation analysis between compressive and bending tensile strength with fresh density, and compressive with hazelnut shell.

Table 6.

Correlation analysis between compressive and bending tensile strength with fresh density, and compressive with hazelnut shell.

| Variable |

Correlation analysis |

Regression analysis |

| Dependent |

w/c |

Independent |

P-value |

rs |

Coefficients |

Equation |

R2

|

Compressive strength

at 28 days- CS (MPa) |

0.4 |

Docility-

D (cm) |

p <0.05 |

0.8 |

a =0.0635 |

CS= a(D)2 +b(D)+c |

0.595 |

| b =-0.645 |

| c =14.447 |

| 0.5 |

Air content -

AC (%) |

p <0.05 |

-0.6 |

a =10027 |

CS= a(AC)2 +b(AC)+c |

0.606 |

| b =245.32 |

| c =12.223 |

| 0.4 |

Hazelnut shell-

HS(%) |

p <0.05 |

-0.6 |

a = 322.18 |

CS= a(HS)2 +b(HS)+c |

0.366 |

| b = -72.321 |

| c = 16.873 |

| 0.5 |

p <0.05 |

-0.6 |

a = -145.21 |

CS= a(HS)2 +b(HS)+c |

0.670 |

| b = -3.143 |

| c = 13.8 |

Bending tensile strength -

TS (MPa) |

0.5 |

Air content-

AC(%) |

p <0.05 |

-0.8 |

a =-54.05 |

TS= a(AC)+b |

0.618 |

| b =5.9968 |

Docility -

D(cm) |

p <0.05 |

-0.8 |

a =-0.1362 |

TS= a(AC)+b |

0.8874 |

| b =6.3363 |

Hazelnut shell-

HS(%) |

p <0.05 |

-0.9 |

a =150.1 |

TS= a(HS)2 +b(HS)+c |

0.8237 |

| b =-24.163 |

| c =5.6561 |

Table 7.

Correlation and regression analysis for densities and HS percentage replacement.

Table 7.

Correlation and regression analysis for densities and HS percentage replacement.

| Variable |

Correlation analysis |

Regression analysis |

| Dependent |

w/c |

Independent |

P-value |

rs |

Coefficients |

Equation |

R2

|

Hardened density at 7 days

(for compressive)- HD () |

0.4 |

Hazelnut shell

-HS(%) |

p <0.05 |

-0.8 |

a =483.8 |

HD= a(HS)2+b(HS)+c |

0.765 |

| b =-654.81 |

| c =2407 |

| 0.5 |

p <0.05 |

-0.8 |

a =1469.2 |

HD= a(HS)2+b(HS)+c |

0.605 |

| b =-511.74 |

| c =2379.4 |

Hardened density at 28 days

(for compressive) -HD () |

0.4 |

p <0.05 |

-0.6 |

a =6976.9 |

HD= a(HS)2+b(HS)+c |

0.520 |

| b =360.02 |

| c =2381.4 |

| 0.5 |

p <0.05 |

-0.8 |

a =224.29 |

HD= a(HS)2+b(HS)+c |

0.620 |

| b = -493.74 |

| c =2384 |

Hardened density at 28 days

(for bending tensile)-HD () |

0.4 |

p <0.05 |

-0.6 |

a =10101 |

HD= a(HS)2+b(HS)+c |

0.639 |

| b =-1587.6 |

| c = 2405 |

| 0.5 |

p <0.05 |

-0.6 |

a =52653 |

HD= a(HS)2+b(HS)+c |

0.434 |

| b =1364.7 |

| c =2375.2 |

| Bulk density - BD() |

0.4 |

p <0.05 |

-0.9 |

a =5078.2 |

BD= a(HS)2+b(HS)+c |

0.908 |

| b =-964.86 |

| c =2423.3 |

| 0.5 |

p <0.05 |

-0.8 |

a =5713 |

BD= a(HS)2+b(HS)+c |

0.894 |

| b =1230.1 |

| c =2414.1 |

Table 7 reveals a significant inverse correlation between the HS replacement percentage and both the fresh and hardened densities. Specifically, as the HS replacement percentage increases, the bulk and hardened densities of the concrete decrease. This behavior can be attributed to the lower density of crushed HS compared to traditional aggregates, which results in a lower overall density of the composite. Hence, the reduced mass of the HS-embedded specimens is the underlying reason for the observed lower densities, indicating that the HS has a diluting effect on the composite.

4.2. Compressive strength results

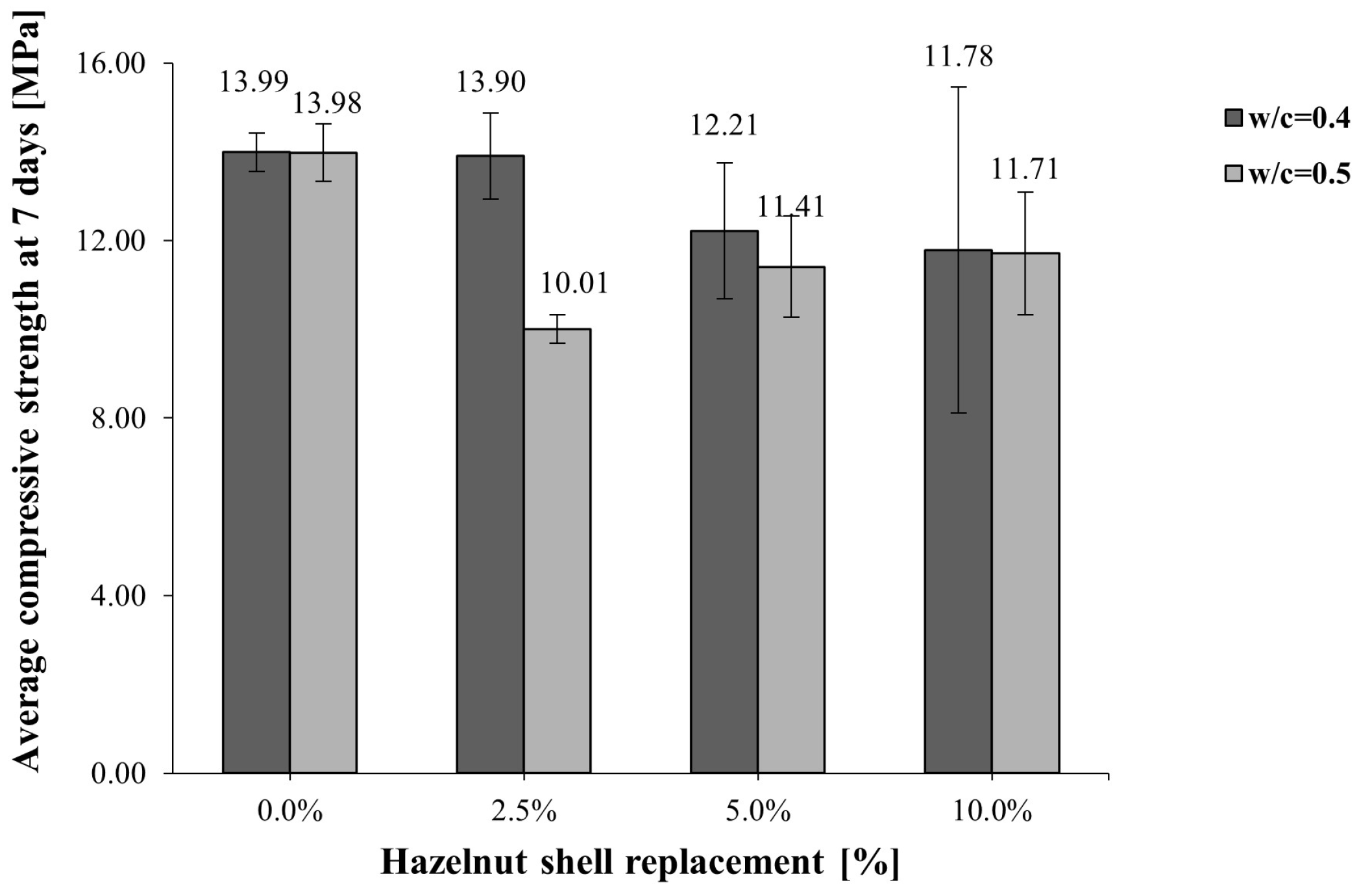

Figure 3 shows the results of compressive strength tests at 7 days for different HS replacement percentages and water-cement ratios. The data indicates that the specimens prepared with a 0.4 w/c ratio have higher strengths than those with a 0.5 w/c ratio. Furthermore, a decreasing trend in strength is observed as the HS replacement percentage increases for the 0.4 w/c ratio specimens, whereas an increase in strength is noted with increasing HS replacement percentage for the 0.5 w/c ratio specimens. The maximum strength is achieved at a 2.5% HS replacement for the 0.4 w/c ratio, almost the same as the standard.

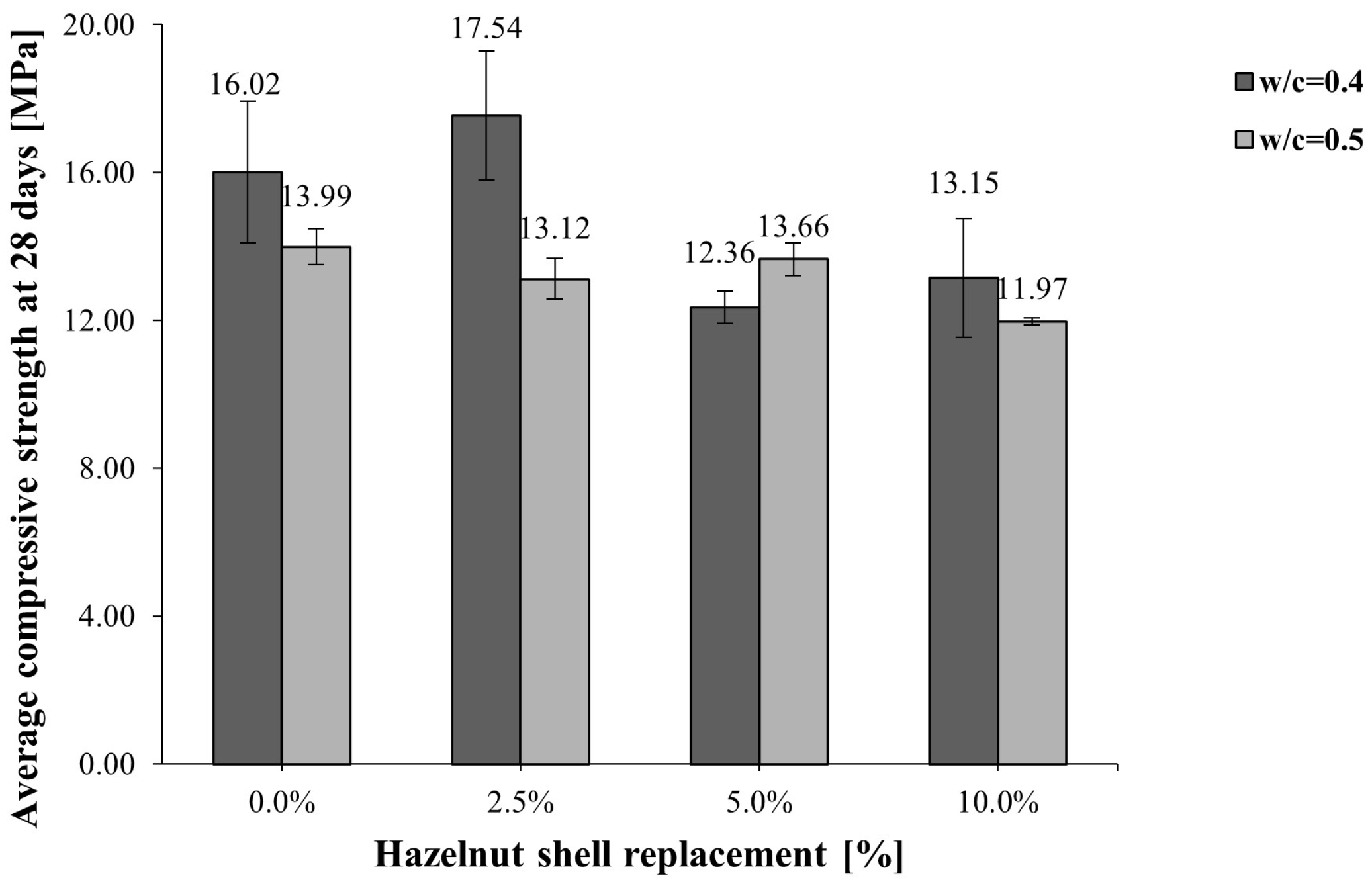

Figure 4 presents the compressive strength results at 28 days, where the strengths are higher compared to those at 7 days. The specimens with a 0.4 w/c ratio have higher strengths than those with a 0.5 w/c ratio, with a maximum increase of 9.5% observed for the 2.5% HS replacement percentage compared to the standard. This increase in strength may be attributed to the improved workability of the mixture as reflected by the larger slump values observed for this HS replacement percentage in

Table 5. The better workability may have reduced the difficulties encountered during the compacting by tamping, resulting in better resistance. Additionally, a strong direct relationship was found between these two variables, with a correlation coefficient,

, of 0.8 (

Table 6).

Figure 3.

Average compressive strength results at seven days for 0.4 and 0.5 water cement ratio.

Figure 3.

Average compressive strength results at seven days for 0.4 and 0.5 water cement ratio.

Figure 4.

Average compressive strength results at 28 days for 0.4 and 0.5 water cement ratio.

Figure 4.

Average compressive strength results at 28 days for 0.4 and 0.5 water cement ratio.

In

Table 6, it is observed that the

correlation coefficients between HS replacement and compressive resistance at 28 days are -0.6 for both w/c ratios, indicating a moderate inverse relation. This suggests that an increase in HS percentage replacement leads to a decrease in compressive resistance. The maximum reduction in resistance for both w/c ratios is around 23% compared to the standard specimens. This can be attributed to the micro-structure of hazelnut shells, which is rough, fibrous, and porous. As porosity is a limiting factor for concrete compressive strength, there exists an inverse relationship between these factors.

Furthermore, the w/c ratio directly affects the porosity of the concrete mixture. A higher w/c ratio leads to increased porosity, which results in lower resistance of the concrete specimens. Hence, it can be inferred that the compressive resistance results for a 0.4 w/c ratio are greater than those obtained with a 0.5 w/c ratio. Interestingly, the correlation between compressive resistance and air content of the mixture for the 0.5 w/c ratio at 28 days is moderately inverse, with a coefficient of -0.6.

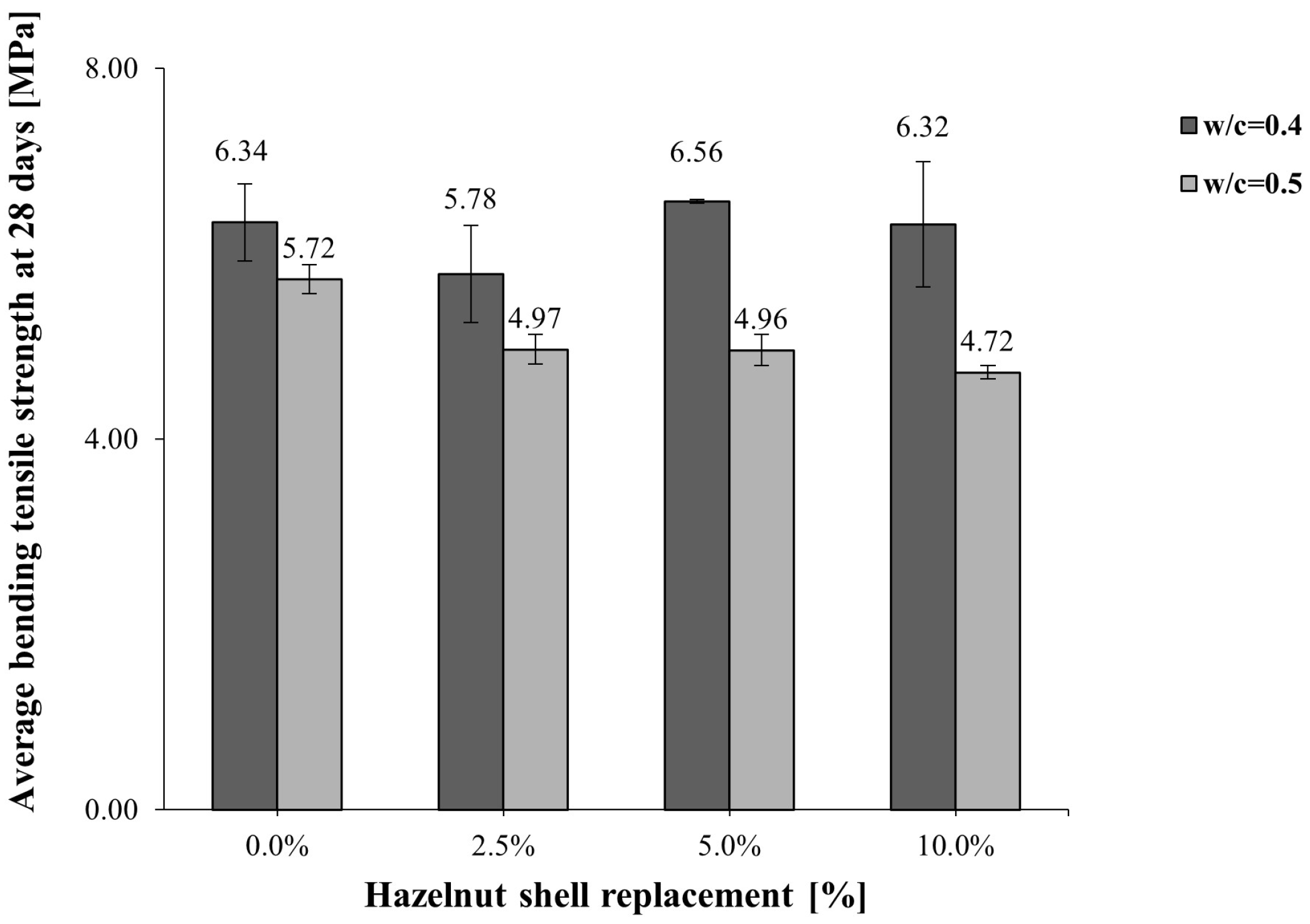

4.3. Bending tensile strength results

The bending tensile strength results for both water-cement ratios are shown in

Figure 5. For the 0.4 w/c ratio, the bending tensile resistances vary by -8.8%, +3.5%, and 0.3% for HS replacement percentages of 2.5%, 5%, and 10%, respectively, compared to standard specimens. These results indicate that the resistances tend to remain stable or even slightly increase as the HS replacement percentage increases.

However, for the 0.5 w/c ratio, a progressive decrease in the resistances is observed as the HS replacement percentage increases. This is consistent with the strong inverse correlation (

) presented in

Table 6, indicating that the bending tensile strength decreases as the HS replacement percentage increases. These findings are in agreement with the results presented in

Figure 5.

Figure 5.

Average tensile strength results at 28 days for 0.4 and 0.5 water cement ratio.

Figure 5.

Average tensile strength results at 28 days for 0.4 and 0.5 water cement ratio.

The compressive strength results for a w/c ratio of 0.4 were found to be higher than those for a w/c ratio of 0.5. In the case of the latter, a strong inverse correlation was observed between the strength results and the docility of the mixture (indicated by a slump test), as well as the air content of the mixture. Both of these correlations were characterized by a strong negative Spearman’s correlation coefficient (

=-0.8), as shown in

Table 6.

5. Conclusions

In this paper, the fine aggregate on concrete mixes has been partially replaced by crushed hazelnut shells to study the influence on the mechanical compressive and tensile strength. Standardized concrete cylinders were tested according to ASTM standards. An statistical study was performed to correlate the mechanical response with physical properties. Based on these results, the following conclusions and recommendations can be drawn:

The compressive strength at 28 days was improved by the addition of hazelnut shells as a replacement for fine aggregate. The highest compressive strength was achieved with a 2.5% HS replacement for a 0.4 w/c ratio, which resulted in a 9.5% increase in strength compared to the standard specimens.

The bending tensile strength of the concrete was also improved with the addition of HS, with the highest results obtained with a 5% HS replacement for a 0.4 w/c ratio. This resulted in a 3.5% increase in strength compared to the standard specimens.

The use of a 0.4 w/c ratio consistently produced better results for both compressive and bending tensile strength, with fewer and lower reductions in mechanical resistances compared to the standard mixture. The correlation analysis showed that the strength results were inversely related to the water-cement ratio and air content of the mixture.

Based on the results obtained, concrete mixes with a HS replacement of 2.5% can be used in constructive systems with compression strengths lower than 17 MPa.

Concrete mixtures with a HS replacement of at most 10% of the fine aggregate can be used in structures with tensile bending stress requirements lower than 6 MPa. These results indicate that the use of hazelnut shells as a partial replacement for fine aggregate is a viable option for reducing environmental impact and improving the mechanical properties of concrete. However, it is important to consider the specific requirements of each application when determining the optimal percentage of HS replacement.

Author Contributions

Conceptualization, S.J.Y., S.G.S. and J.C.P.; methodology, S.J.Y. and S.G.S; formal analysis, S.J.Y., N.G.C. and G.M.A.; investigation, S.J.Y., N.G.C. and G.M.A.; resources, S.J.Y.; data curation, N.G.C. and G.M.A.; writing—original draft preparation, N.G.C. and G.M.A.; writing—review and editing, S.J.Y., N.G.C. and G.M.A.; visualization, N.G.C. and G.M.A.; supervision, S.J.Y., S.G.S. and J.C.P.; project administration, S.J.Y.; funding acquisition, S.J.Y. All authors have read and agreed to the published version of the manuscript.

Funding

Sergio J. Yanez acknowledges the financial support from Universidad de Santiago de Chile, Usach, through project DICYT N°052018YC, Dirección de Investigación Científica y Tecnológica, Dicyt.

Acknowledgments

The authors would like to express our sincere gratitude to AgriChile S.A. for providing the hazelnut shell used in this study. Without their generous contribution, this research would not have been possible. We appreciate their collaboration and support in helping us achieve our research goals.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Manjunatha, M.; Preethi, S.; Malingaraya.; Mounika, H.G.; Niveditha, K.N.; Ravi. Life cycle assessment (LCA) of concrete prepared with sustainable cement-based materials. Materials Today: Proceedings 2021, 47, 3637–3644. doi:10.1016/j.matpr.2021.01.248. [CrossRef]

- Jyosyula, S.K.R.; Surana, S.; Raju, S. Role of lightweight materials of construction on carbon dioxide emission of a reinforced concrete building. Materials Today: Proceedings 2020, 27, 984–990. doi:10.1016/j.matpr.2020.01.294. [CrossRef]

- Kairies-Alvarado, D.; Muñoz-Sanguinetti, C.; Martínez-Rocamora, A. Contribution of energy efficiency standards to life-cycle carbon footprint reduction in public buildings in Chile. Energy and Buildings 2021, 236, 110797.

- Meyer, C. The greening of the concrete industry. Cement and Concrete Composites 2009, 31, 601–605. doi:10.1016/j.cemconcomp.2008.12.010. [CrossRef]

- Mehta, P.K. High-performance, high-volume fly ash concrete for sustainable development. Proceedings of the international workshop on sustainable development and concrete technology. Iowa State University Ames, IA, USA, 2004, pp. 3–14.

- Tu, T.Y.; Chen, Y.Y.; Hwang, C.L. Properties of HPC with recycled aggregates. Cement and Concrete Research 2006, 36, 943–950. doi:10.1016/j.cemconres.2005.11.022. [CrossRef]

- Yanez, S.; Márquez, C.; Valenzuela, B.; Villamar-Ayala, C.A. A Bibliometric-Statistical Review of Organic Residues as Cementitious Building Materials. Buildings 2022, 12, 597.

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Construction and Building Materials 2021, 269, 121242. doi:10.1016/j.conbuildmat.2020.121242. [CrossRef]

- Laverde, V.; Marin, A.; Benjumea, J.M.; Rincón Ortiz, M. Use of vegetable fibers as reinforcements in cement-matrix composite materials: A review. Construction and Building Materials 2022, 340, 127729. doi:10.1016/j.conbuildmat.2022.127729. [CrossRef]

- Deo, S. Parametric Study of Natural Organic Materials as Admixture in Concrete. International Journal of Applied Engineering Research 2016, 11, 6271–6277.

- Sales, A.; Lima, S.A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Management 2010, 30, 1114–1122. doi:10.1016/j.wasman.2010.01.026. [CrossRef]

- Pérez-Armada, L.; Rivas, S.; González, B.; Moure, A. Extraction of phenolic compounds from hazelnut shells by green processes. Journal of Food Engineering 2019, 255, 1–8. doi:10.1016/j.jfoodeng.2019.03.008. [CrossRef]

- ASTM C595 / C595. Standard specification for blended hydraulic cements; ASTM International, West Conshohocken, PA 19428-2959. United States, 2008.

- Guvalov, A.; Abbasova, S. Influence of rheological active additives on the properties of self-compacting concrete. Journal of Wuhan University of Technology-Mater. Sci. Ed. 2021, 36, 381–386.

- NCh165:2009. Áridos para morteros y hormigones - tamizado y determinación de la granulometría; Instituto nacional de normalización, Av. Libertador Bernardo O’Higgins 1449 Tower N° 7, Santiago Downtown, Piso 16. Chile, 2009.

- NCh163:2013. Áridos para morteros y hormigones - requisitos; Instituto nacional de normalización, Av. Libertador Bernardo O’Higgins 1449 Tower N° 7, Santiago Downtown, Piso 16. Chile, 2013.

- NCh1117:2010. Áridos para morteros y hormigones - determinación de las densidades reales y neta y de la absorción de aguas de las gravas; Instituto nacional de normalización, Av. Libertador Bernardo O’Higgins 1449 Tower N° 7, Santiago Downtown, Piso 16. Chile, 2010.

- NCh1239:2009. Áridos para morteros y hormigones - determinación de las densidades real y neta y de la absorción de agua de las arenas; Instituto nacional de normalización, Av. Libertador Bernardo O’Higgins 1449 Tower N° 7, Santiago Downtown, Piso 16. Chile, 2009.

- Witkowska-Dobrev, J.; Szlachetka, O.; Spiek, P. Impact of curing conditions for concrete on its mechanical properties. Budownictwo i Architektura 2020, 19, 101–110. Number: 2, doi:10.35784/bud-arch.1672. [CrossRef]

- ASTM C128/C128M-22. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate 2022.

- ASTM C470 / C470M -15. Standard specification for molds for forming concrete test cylinders vertically; ASTM International, West Conshohocken, PA 19428-2959. United States, 2015.

- ASTM C192 / C192M -14. Standard practice for making and curing concrete test specimens in the laboratory; ASTM International, West Conshohocken, PA 19428-2959. United States, 2014.

- ASTM C143 / C143M -00. Standard test method for slump of hydraulic cement concrete; ASTM International, West Conshohocken, PA 19428-2959. United States, 2000.

- ASTM C231 / C231M -09a. Standard test method for air content of freshly mixed concrete by the pressure method; ASTM International, West Conshohocken, PA 19428-2959. United States, 2009.

- ASTM C138 / C138M -17a. Standard test method for density (unit weight), yield, and air content (gravimetric) of concrete; ASTM International, West Conshohocken, PA 19428-2959. United States, 2017.

- ASTM C39 / C39M. Standard test method for compressive strength of cylindrical concrete specimens; ASTM International, West Conshohocken, PA 19428-2959. United States, 2001.

- ASTM C293 / C293M -16. Standard test method for flexural strength of concrete (using simple beam with center-point loading); ASTM International, West Conshohocken, PA 19428-2959. United States, 2016.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).