1. Introduction

Wire and arc additive manufacturing (WAAM) is a directed energy deposition (DED) AM process that is capable of producing near net shape and large scale metallic structures, at low manufacturing cost, high deposition rates and virtually no porosity defects in high strength titanium parts [

1,

2,

3]. Amongst all the materials studied by WAAM and other AM processes, titanium alloy Ti6Al4V (Ti64) has been extensively studied because of its high manufacturing cost using conventional routes and its wider applications in the aerospace, biomedical and energy sectors [

1,

2,

3]. When considered the mechanical properties, yield and ultimate tensile strengths of WAAM Ti64 are comparable with conventional wrought and considerably higher than the cast materials. Moreover, these properties meet the minimum requirements for tensile loads as outlined by ASTM F2924 for AM-built Ti64 [

4]. However, WAAM Ti64 showed approximately 42% lower elongation at failure compared to its wrought counterpart due to presence of columnar grains as the result of repeated thermal cycles and fine

α lath width due to faster cooling rates in AM processes [

4]. Under cyclic loads, WAMM Ti64 has similar fatigue strength as wrought at 10

7 cycles and higher strength than the cast materials [

4]. Despite the enormous advantages and comparable mechanical performance as the conventional materials, one of the remaining challenges faced by WAAM process is the poor surface finish in the as deposited materials. Due to the large layer height in the WAAM process, an obvious stairstep occurs between two layers resulting in higher surface roughness, which is referred as

surface waviness in this paper for WAAM, compared to the powder-based AM processes.

Load bearing parts produced by AM built Ti64 are subjected to cyclic loading in service. Therefore, fatigue performance is one of the most important design criteria. Although AM provides near net shape parts, the nature of layer wise deposition causes unfavourable surface roughness or waviness which will act as stress concentration zones and lead to fatigue life reduction. Considerable efforts have been made to understand the influence of as built surface on the fatigue performance of AM Ti64, particularly in the high cycle fatigue regime [

5,

6,

7,

8,

9,

10]. In powder bed AM, surface roughness in Ti64 resulted in three times lower fatigue strength at a given life compared to machined and polished surface [

8]. At the same applied stress, increase in surface roughness led to an approximately 75% reduction in fatigue strength [

8]. Initial studies have correlated the surface parameters with fatigue life and found that roughness parameters i.e., average roughness (

Ra) and maximum height of the profile (

Rt) gave a correlation to high cycle fatigue (HCF) life where increased

Ra and

Rt caused decreased fatigue life as these features replicated as micro-notches on the as built surface leading to early crack initiation thereby premature failure [

9,

10,

11]. Similar observations were made in another study [

12] where influence of as-built surface roughness parameters on the HCF performance of Ti64 manufactured via electron beam (EBLBF) and laser powder fusion (LPBF) processes and found 35% decrease in fatigue strength (at 10

7 cycles) for a 50% increase in the

Ra and

Rt values. Nevertheless, such correlation between

Ra,

Rt and fatigue life was not found in other materials such as nickel-based alloys [

13]. A more holistic approach by Sanaei et al.[

14] found a good correlation between parameters such as maximum profile peak height and maximum profile trough depth across various materials. Kahlin et. al [

15] studied the fatigue behaviour of purposely built notched as built Ti64 built by LPBF and EBPBF processes. Presence of surface roughness was the single most severe factor for fatigue life reduction resulting in a fatigue notch factor having a rougher surface.

Efforts have also been devoted to fatigue life prediction. They are the notch stress method [

6,

16,

17] and fracture mechanics based method [

18,

19,

20,

21]. Dinh et al.[

17] applied the notch stress method and finite element analysis to study the synergistic effects of gas pores and surface roughness on the fatigue life of powder bed fusion Ti64. Vayssette et. al. [

22] used a fracture mechanics based numerical model, in which surface roughness profiles were measured using optical light interferometer and the result was used to build a realistic finite element model. However, the fatigue strength was not well predicted since the micro-notches associated with the as built surface were not well described. Peng and Jones et al. [

18,

19] treated the surface waviness profile as a series of small cracks to predict the durability of specimens made of 18Ni 250 maraging steel and Ti64 based on the crack growth life.

With regard to the surface waviness of WAAM materials, limited research is available in open literature. Dirisu et. al. [

23] studied the influence of as built waviness on the tensile and fatigue strength of WAAM ER70S-6 structural steel. Thicker layer deposition associated with WAAM process caused stair steps between the layers and resulted in surface waviness of 0.18 mm between peak and trough [

23]. A surface waviness of 0.08 mm and 0.18 mm caused approximately 75% fatigue strength reduction for a given life compared to samples with machined surfaces. In a similar study on ER50-6 steel the as built surface waviness was about 0.136 mm between peak and trough [

24]. To the author’s knowledge, there is no published data available on the influence of as built surface waviness on the fatigue performance of WAAM built Ti64. Although, surface waviness can be reduced by subsequent machining process, with an increasing emphasis on sustainability and reducing the buy-to-fly ratios, it is vital to reduce the materials waste, particularly for metals which are either expensive to purchase or hard to machine. On the other hand, it is not always possible to remove the surface roughness, or the presence of minimal surface roughness is acceptable in certain applications where the service loads are moderate or low. In such scenarios, it is important to understand the acceptable surface waviness and to propose a methodology for fatigue life prediction in the presence of surface waviness.

Therefore, the work reported in this paper aims to investigate the influence of as-built surface waviness on the fatigue life of WAAM Ti64. Fatigue tests were conducted under bending loads. Two different predictive methods were used; one is based on the traditional notch stress method treating a waviness trough as a micro-notch; the other is based on the fracture mechanics treating a waviness trough as an initial crack. The modified Hartman-Schijve equation and small crack growth data were employed. The fatigue life of as-built WAAM was then computed and was compared with the experimental data.

2. Materials and Methods

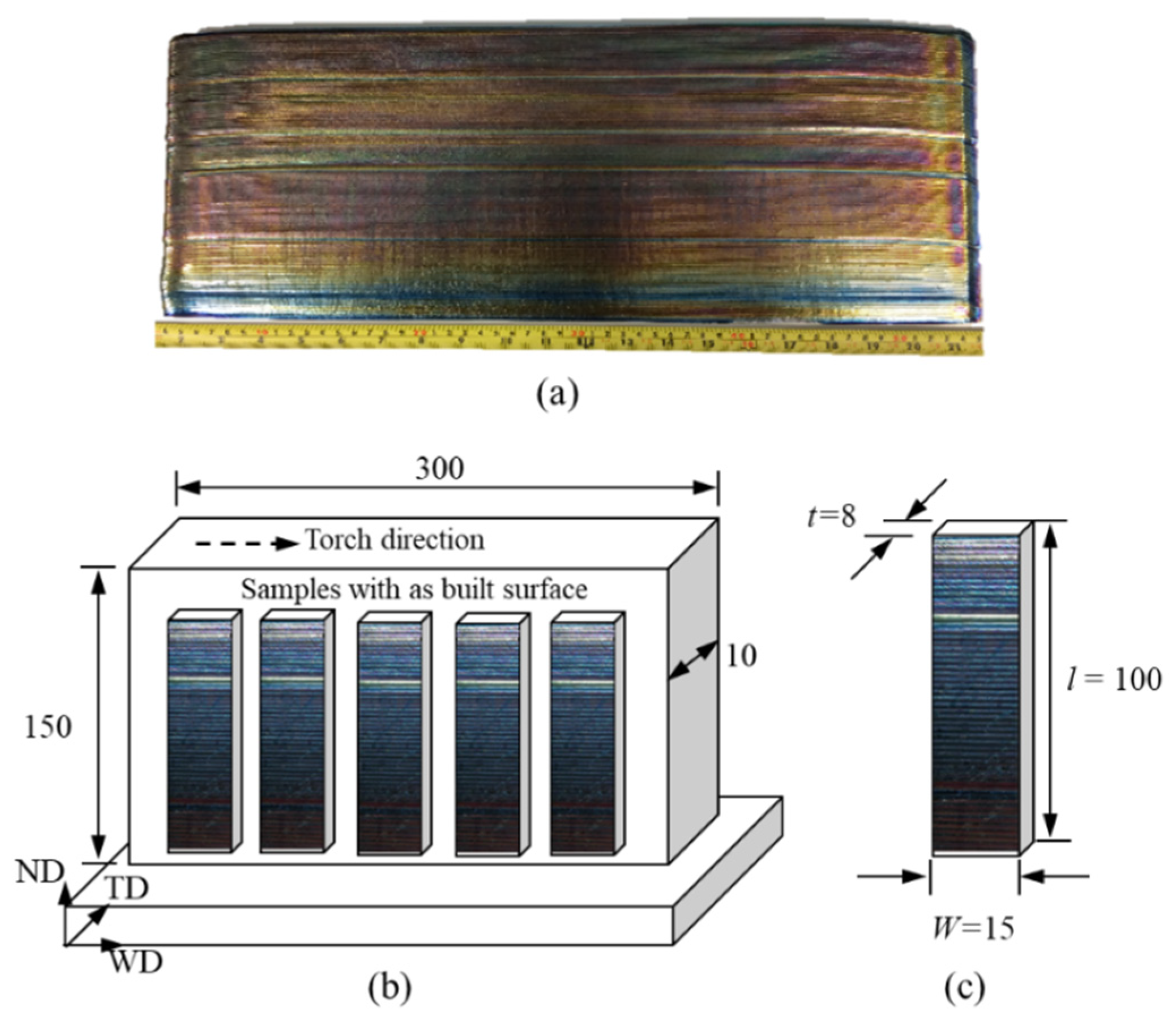

For extracting fatigue test specimens, a wall was built on a 12 mm thick forged Ti64 plate by the WAAM process with a single bead deposition strategy. The grade-5 Ti64 wire of 1.2 mm diameter was used as feed stock. Plasma arc was used as a heat source and Argon gas of 99.99% purity was directed precisely at the melt pool to prevent oxidation. The dimension of the wall was 300 x 150 x 10 mm

3 as shown in

Figure 1a.

After the deposition, the wall was cut off from the substrate and used for extracting fatigue testing samples of rectangular shape by wire electric discharge machining (W-EDM) as shown in

Figure 1b & 1c. To investigate the influence of surface waviness on fatigue life, two types of samples were prepared, i.e., 22 with the as-deposited surface (no machining) and 14 with machined and polished surface. For the samples with as-deposited surface, one side of the sample was machined to facilitate sample mounting on the bending test frame. In order to observe the crack propagation path during the fatigue testing, some of the as-deposited samples were ground and polished on the ND-TD plane (

Figure 1b) using SiC paper, polished using 0.06 µm silica suspension and subsequently etched using Kroll’s reagent for approx. 45 seconds. For samples with the machined surfaces, the as-deposited surface was removed using high precision milling machine, and subsequently ground incrementally and polished to achieve an average surface roughness of 0.2 µm as recommended by ASTM E466 [

25]. In the following text, samples with as-deposited surface are called as-deposited samples, and samples with machined and polished surfaces are called machined samples.

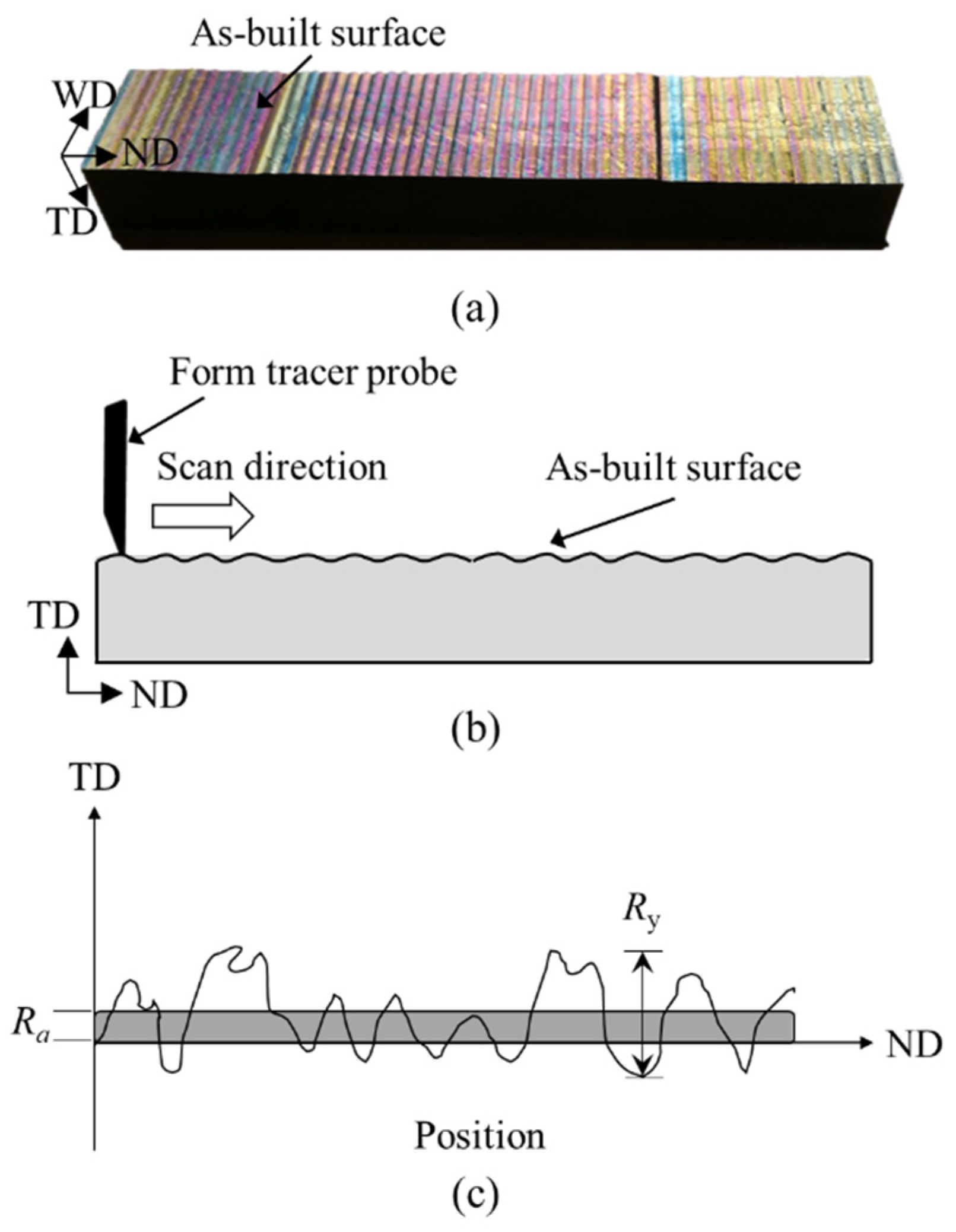

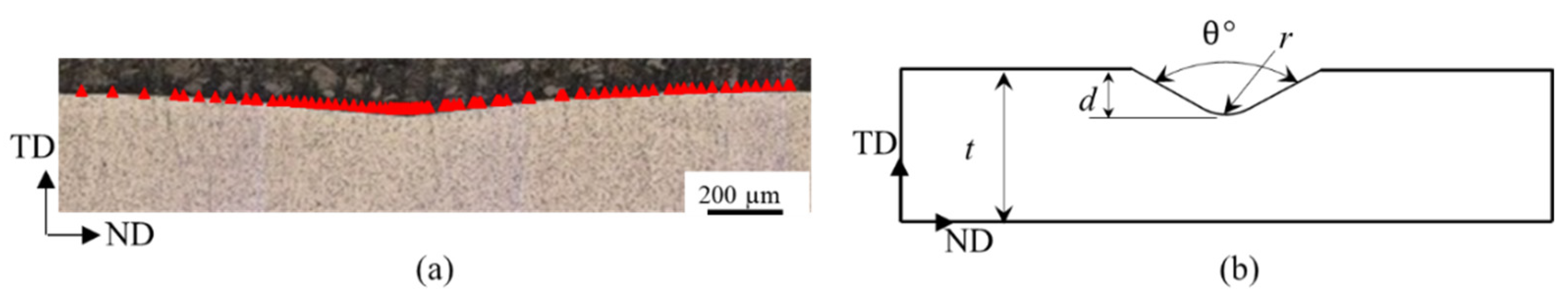

2.1. Characterisation of surface waviness

The as-deposited surface was characterised using a metrology tool called Formtracer, which is a type of contact mode surface measurement technique where the probe touches and scans the surface (Figure 2a and 2b). The Mitutoyo FT SV-C3200/4500 series with an arm containing a diamond tip stylus of 4 µm diameter was used. A load of 5 mN was applied to keep the stylus in contact with the sample surface as illustrated schematically in

Figure 2b. The scanned data was recorded and analysed using the SurfAnalysis software. Here the term “

surface roughness” is used to quantify the following representative parameters employing commonly used equations, i.e.,

Ra being the arithmetical mean height,

Ry the maximum depth of troughs, and

Rz is the average of 10-point surface roughness where

and

are the 5 higher local maxima and lower local minima respectively [

20,

26], see

Figure 2c. These surface roughness parameters are defined by eqs. 1-3.

However, the conventional surface roughness parameters do not correlate well with the fatigue life of bending specimens as the surface waviness at sample’s mid-span plays a more dominant role than owing to the maximum bending stress and stress gradient through the specimen’s height. Therefore, the commonly used surface roughness parameters (

Ra,

Ry and

Rz) are only used for characterisation of surface waviness of the as-built material. For fatigue analysis, a “notch” profile (

Figure 3a) representing typical surface waviness profile was further characterised in terms of the notch depth (

d), notch mouth opening angle (

θ), and notch base radius (

r) as shown in

Figure 3b. Parameter

r is calculated by a polynomial equation generated from the spline created by the data points obtained by the Formtracer, which was used to compute the first and second derivatives,

f /(

z),

f // (

z)

used in eq. 4 [

27].

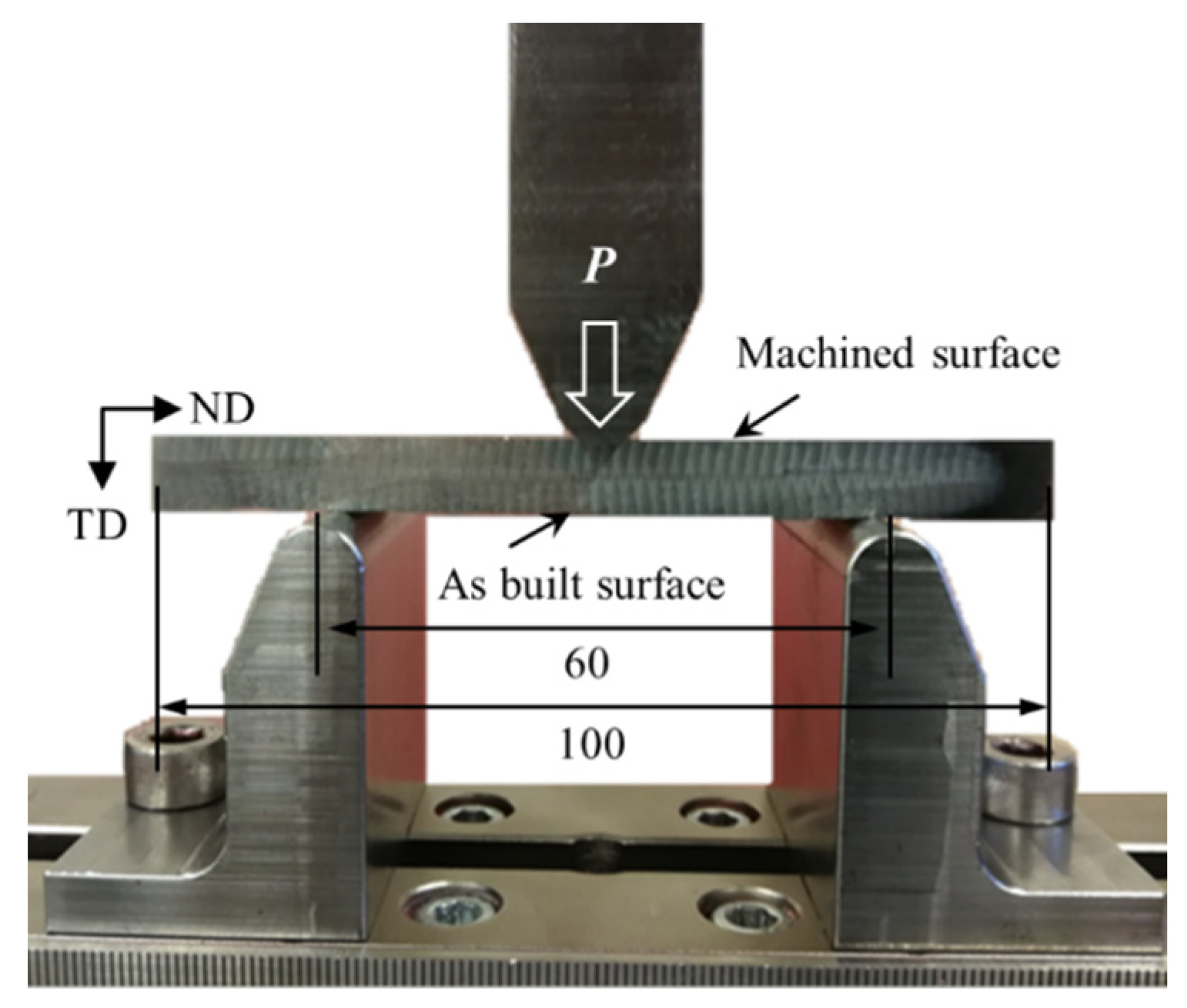

2.2. Fatigue testing

Three-point bending (3-point-bending) fatigue test was performed under constant amplitude load-controlled condition on a 10 kN Instron servo-hydraulic test machine using a standard sinusoidal waveform with a cyclic load ratio

R = 0.1 and loading frequency 10 Hz. The experimental setup of an as-deposited sample is shown in

Figure 4. The maximum nominal tensile stress acting on specimen’s bottom surface was calculated using eq. 5 [

28].

where

Smax is the maximum tensile stress on sample bottom surface at mid-span,

P the applied load,

L the distance between the supporting rollers (beam sample span length = 60 mm),

W and

t the width and thickness of the sample, respectively.

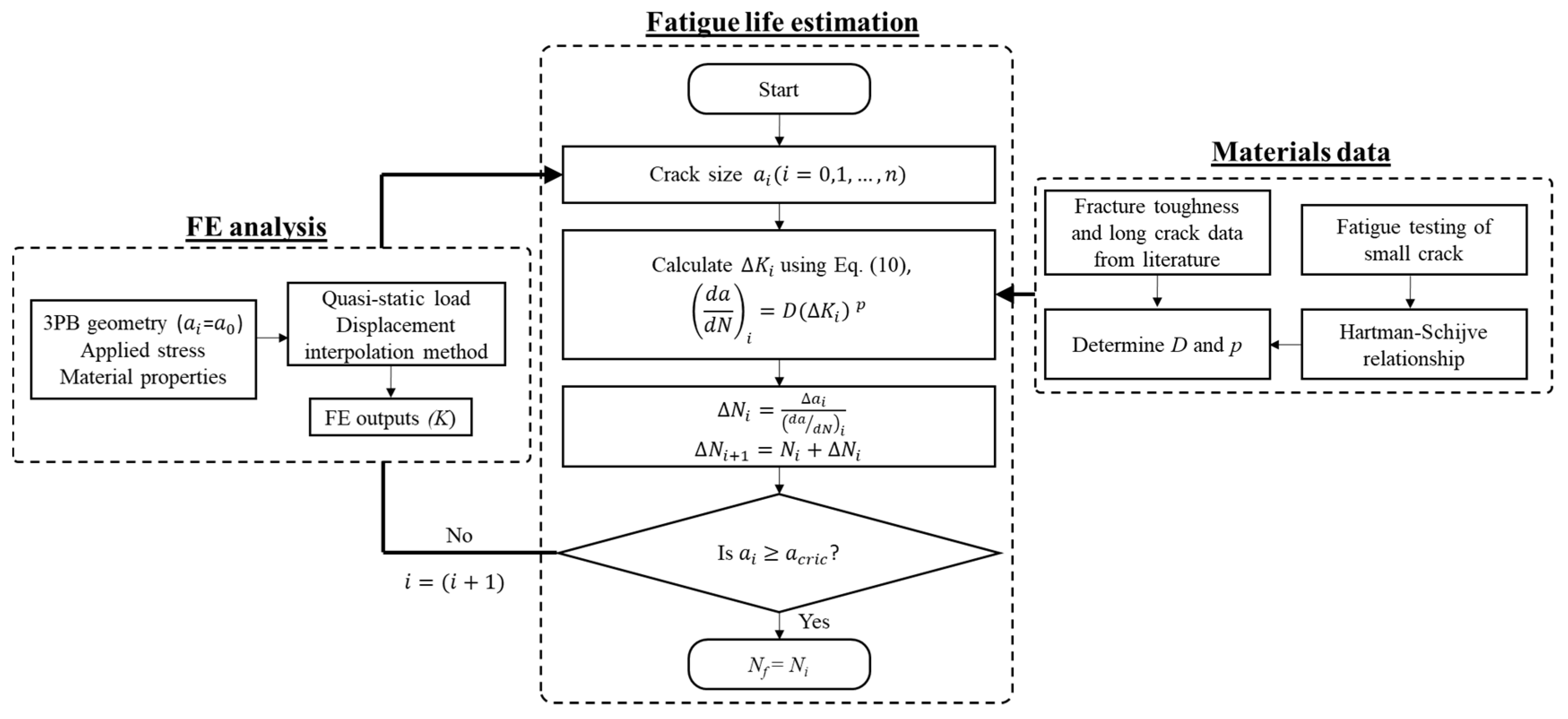

2.3. Life prediction methods

Two different methods are used for predicting the fatigue life of bending fatigue test specimens. One is based on the traditional method for durability analysis using the material’s

S-

N data in conjunction with the notch stress concentration factor (

Kt) arising from the surface waviness; the other is based on the fracture mechanics approach treating the notch as a crack and using the stress intensity factor range (Δ

K) and the material’s fatigue crack propagation rate property. The analyses of

Kt and Δ

K are presented in

Section 3.

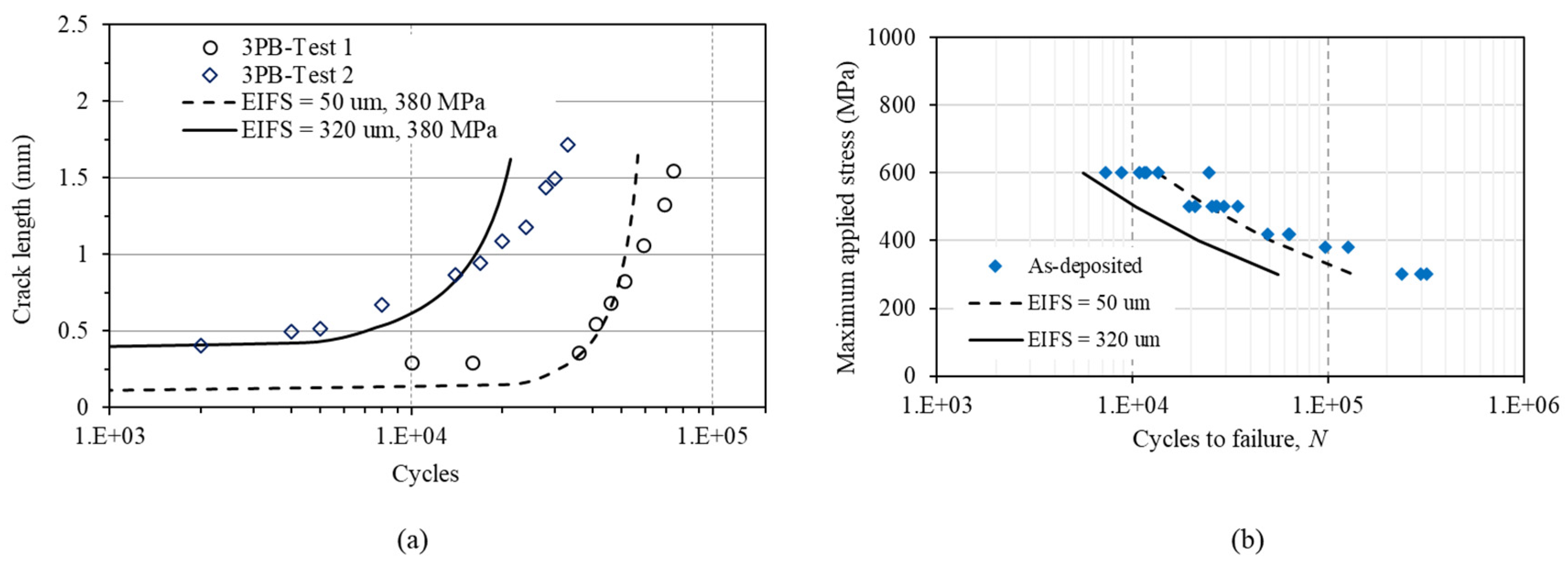

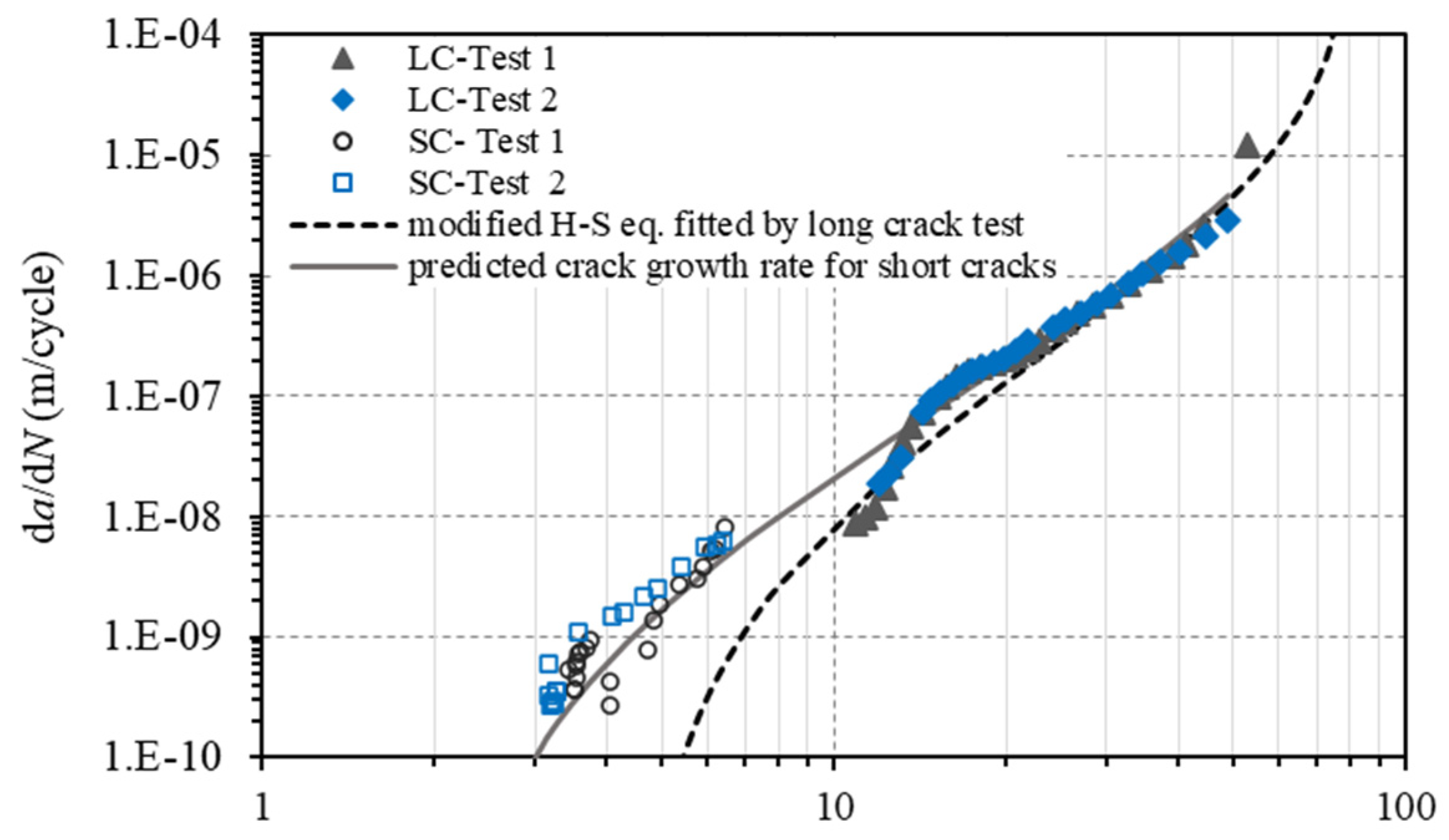

For the fracture mechanics method, small crack growth rate data is used based on our previous work [

29], where the crack growth rates of small and long cracks were obtained for the same material are used in this study, which is shown in

Figure 5. The result indicates that small cracks exhibited higher crack growth rates than long cracks under the same applied Δ

K. The observed difference in crack growth rates can be attributed to the difference in constraints imposed by the elastic material surrounding the crack, which can vary in the case of small cracks [

30]. The constraints experienced by small cracks that initiate from or grow on a free surface of smooth samples differ from those experienced by through-thickness long cracks in the same material [

31]. Consequently, even when the loading conditions and crack sizes follow the requirements of Linear Elastic Fracture Mechanics (LEFM), the physically small cracks exhibited faster crack growth rates. Furthermore, long cracks usually have longer plastic wake that reduce the crack growth rate due to the crack closure effect [

30].

The modified Hartman-Schijve equation [

32,

33,

34,

35,

36], eq. 6, was used to represent the small crack growth rate as shown in

Figure 5.

where,

Kmax is the maximum stress intensity factor, ∆

K the stress intensity factor range,

A the cyclic fracture toughness,

D and

p are material constants. Term ∆

Kthr is the effective threshold of stress intensity factor range for small cracks. For long cracks, threshold ∆

Kth is the value of applied ∆

K corresponding to a crack growth rate of 10

-10 m/cycle according to the ASTM E647 standard.

Work in [

37,

38,

39,

40,

41] has demonstrated that the variability in crack growth rates can be modelled using the modified Hartman-Schijve equation. In this work, eq. 6 was used to compute the variability in the crack growth rates in WAAM Ti64 where the material constants

D and

p were obtained from long crack test data [

29]. The values suggested by [

33,

42] may be suitable for microstructurally small cracks but may be impractical for physically small cracks initiated from defects found in WAAM Ti64, as work in [

43,

44] found higher Δ

Kthr values for small cracks in Ti64 as 1.8–3.0 MPa

. In this study, Δ

Kthr = 2 MPa

was used in eq. 6 for predicting the small crack growth behaviour in the material; the prediction curve is shown in

Figure 5.

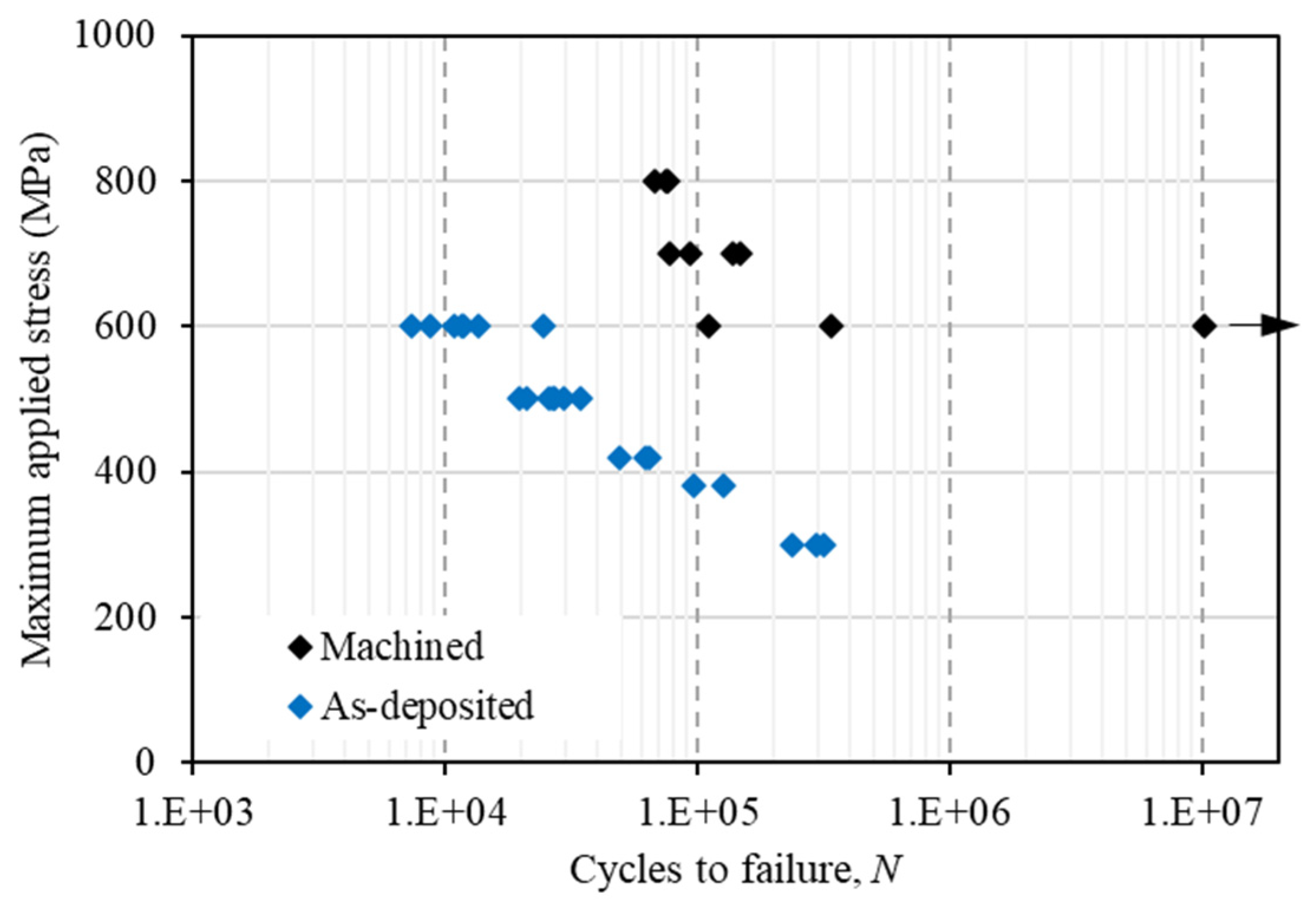

4. Experimental test results

The stress vs. life (

S-

N) data of as-deposited and machined specimens under bending fatigue load is presented in

Figure 9. It shows a large reduction in fatigue strength at a given life; the worst case being 50% decrease in strength at 300,000 load cycles. Fatigue life was significantly reduced under the same applied stress, e.g., life was reduced by 10 times at applied stress 600 MPa. These were owing to the stress concentration arising from the surface waviness resulting in premature crack initiation at the notch roots. In this study, fatigue cracks always initiated from a single ‘notch-like’ feature that experienced the maximum tensile stress in the bending test.

As mentioned in [

28], the three parameters

r, d and

θ determine the notch profile and the stress concentration factor value for the specimen. Therefore, after sample failure, the crack initiating notch was identified and traced using recorded surface measurement. This has enabled the determination of

r, d and

θ of the crack initiating notch in all the as-deposited samples.

Figure 9 also shows that the scatter in test data varied at different applied stress levels. In the machined samples, scatter was the smallest at 800 MPa applied bending stress as the stress level is closer to the yield strength of the material. The scatter increased as the applied stress decreased. This is because at the higher stress levels the surface condition was less likely to influence crack nucleation as micro-cracks were formed much earlier in the fatigue life, which was followed by crack growth as shown for axially loaded samples in [

47]. This could be the reason for lower scatter in all the samples tested at 800 MPa. At lower applied stress levels, the surface condition became more relevant, and crack initiation depends on the surface irregularities which vary among the test samples, hence larger scatter was observed for the machined samples tested at 600 MPa. For the as-deposited samples, the scatter was smaller at 600 MPa than the machined samples because the as-deposited samples were dominated by crack growth from the centre notch as a result of the surface waviness, whereas the machined sample fatigue life was dominated by the crack initiation stage.

Author Contributions

Conceptualization, M.S., A.K.S. and X.Z.; methodology, M.S., A.K.S., W.S., and X.Z.; software, M.S.; validation, M.S.; formal analysis, M.S.; resources, X.Z.; data curation, M.S.; writing, original draft preparation, M.S., A.K.S. and X.Z.; writing—review and editing, M.S., A.K.S. and X.Z.; visualization, M.S.; supervision, A.K.S. and X.Z.; project administration, X.Z.; funding acquisition, X.Z. All authors have read and agreed to the published version of the manuscript.

Figure 1.

(a) Photo of a WAAM Ti64 wall built by single-pass deposition method, (b) schematic of sample extraction plan, (c) geometry and dimensions of as-deposited bending test samples (unit: mm); WD = weld torch movement direction, TD = transverse direction, ND = normal direction.

Figure 1.

(a) Photo of a WAAM Ti64 wall built by single-pass deposition method, (b) schematic of sample extraction plan, (c) geometry and dimensions of as-deposited bending test samples (unit: mm); WD = weld torch movement direction, TD = transverse direction, ND = normal direction.

Figure 2.

(a) Photograph of fatigue samples with as-deposited surface waviness, (b) schematic of as-deposited surface waviness using a Formtracer, (c) schematic of surface waviness parameters.

Figure 2.

(a) Photograph of fatigue samples with as-deposited surface waviness, (b) schematic of as-deposited surface waviness using a Formtracer, (c) schematic of surface waviness parameters.

Figure 3.

(a) A high-resolution Formtracer data overlaid onto an optical microscopic image of a single waviness (referred as a “notch”) for depiction of the notch profile, (b) schematic of notch base radius (r), notch depth (d), and notch mouth opening angle (θ).

Figure 3.

(a) A high-resolution Formtracer data overlaid onto an optical microscopic image of a single waviness (referred as a “notch”) for depiction of the notch profile, (b) schematic of notch base radius (r), notch depth (d), and notch mouth opening angle (θ).

Figure 4.

Setup of 3-point bending fatigue test showing the positions of the loading and supporting rollers with the as-deposited surface waviness facing downwards (unit: mm).

Figure 4.

Setup of 3-point bending fatigue test showing the positions of the loading and supporting rollers with the as-deposited surface waviness facing downwards (unit: mm).

Figure 5.

Curve representing the modified Hartman-Schijve equation fitted by long crack test data and predicted crack growth curve for small crack growth rate using long crack data with ΔKthr = 2 MPa, A = 90 MPa (LC = long crack, SC = small crack).

Figure 5.

Curve representing the modified Hartman-Schijve equation fitted by long crack test data and predicted crack growth curve for small crack growth rate using long crack data with ΔKthr = 2 MPa, A = 90 MPa (LC = long crack, SC = small crack).

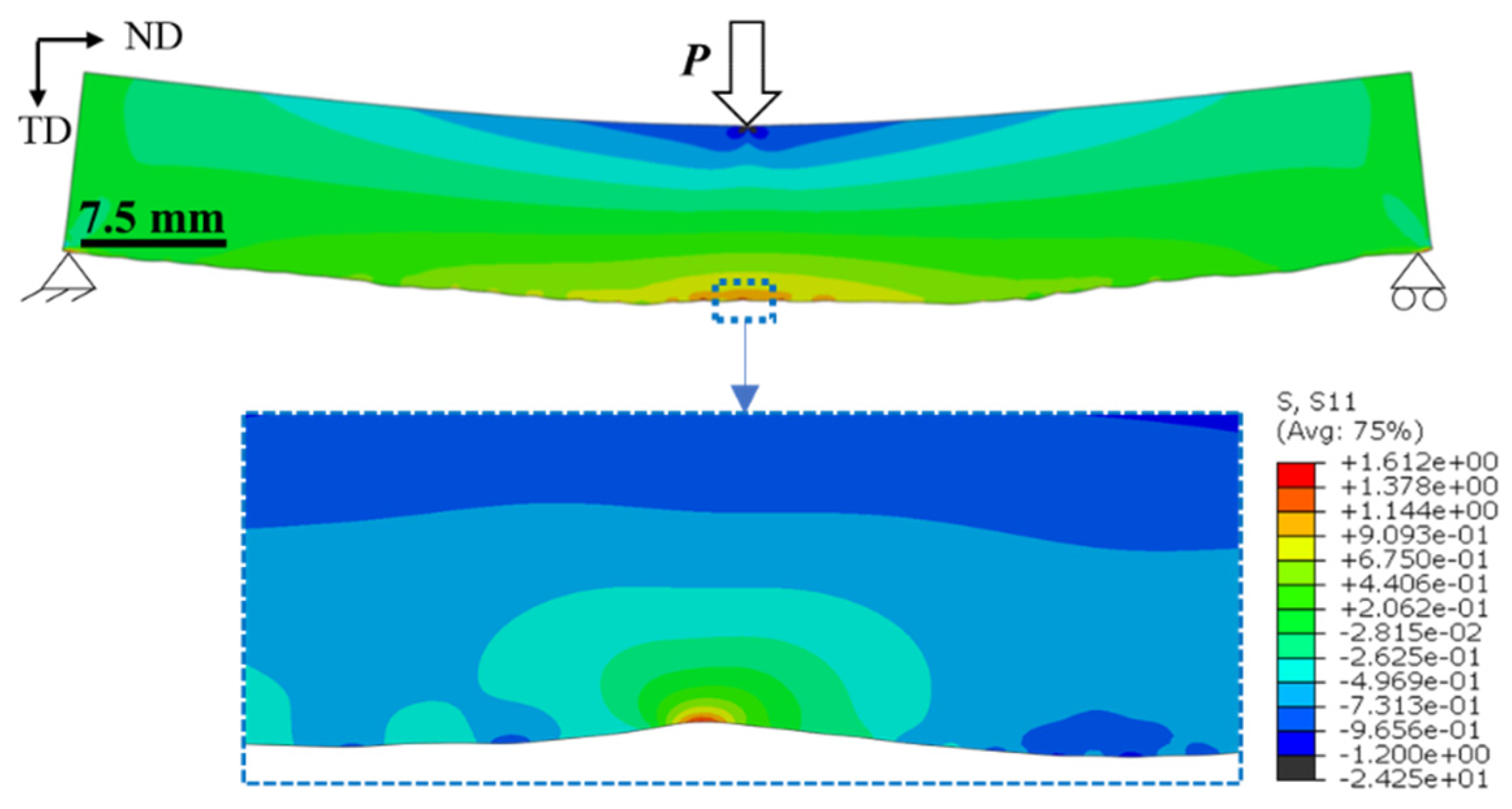

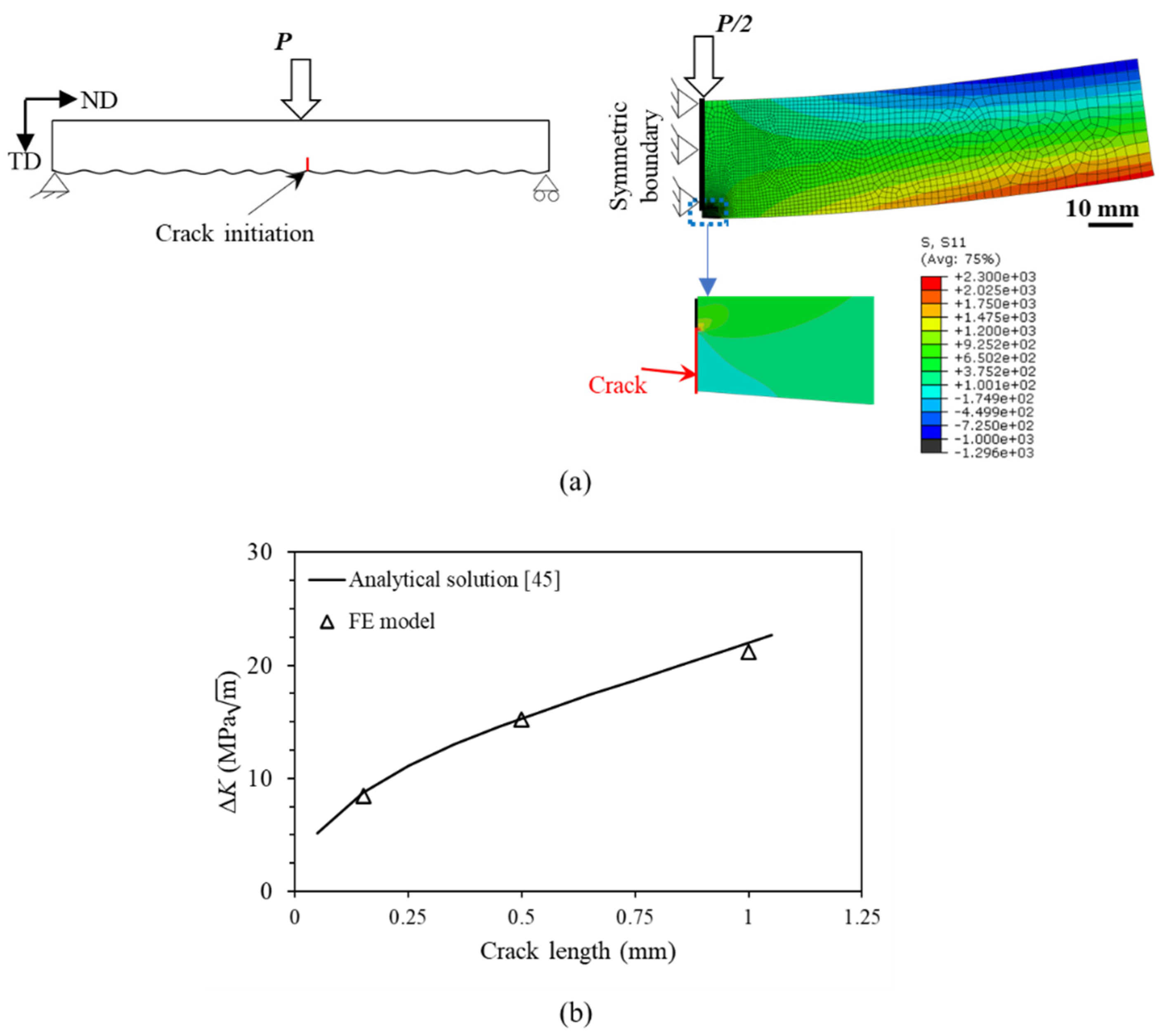

Figure 6.

A finite element model for the sample subjected to 3-point-bending testing, and a zoomed view of a single notch.

Figure 6.

A finite element model for the sample subjected to 3-point-bending testing, and a zoomed view of a single notch.

Figure 7.

(a) Schematic representation and finite element model to calculate stress intensity factor of a notch at mid-span representing a typical surface waviness profile, (b) comparison of stress intensity factor values between finite element model and analytical solution [

45].

Figure 7.

(a) Schematic representation and finite element model to calculate stress intensity factor of a notch at mid-span representing a typical surface waviness profile, (b) comparison of stress intensity factor values between finite element model and analytical solution [

45].

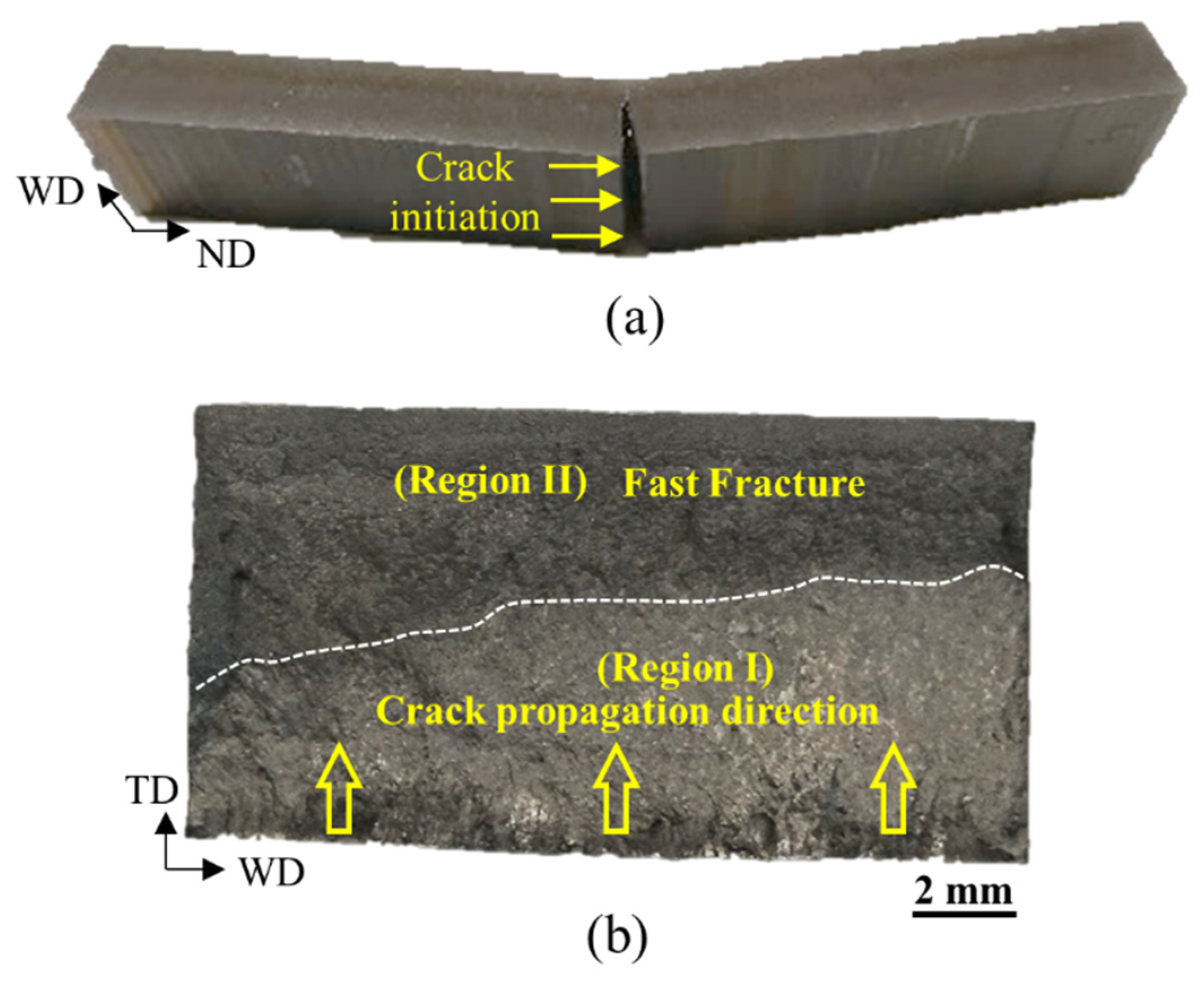

Figure 8.

(a) a specimen with as-built surface showing fracture failure at the mid-span, (b) fracture surface showing stable crack growth stage (Region I) and fast fracture (Region II).

Figure 8.

(a) a specimen with as-built surface showing fracture failure at the mid-span, (b) fracture surface showing stable crack growth stage (Region I) and fast fracture (Region II).

Figure 9.

S-N data of 3-point-bending fatigue tests for machined and as-deposited WAAM Ti64 samples. The y-axis represents the maximum bending stress on the beam lower surface at the mid-span.

Figure 9.

S-N data of 3-point-bending fatigue tests for machined and as-deposited WAAM Ti64 samples. The y-axis represents the maximum bending stress on the beam lower surface at the mid-span.

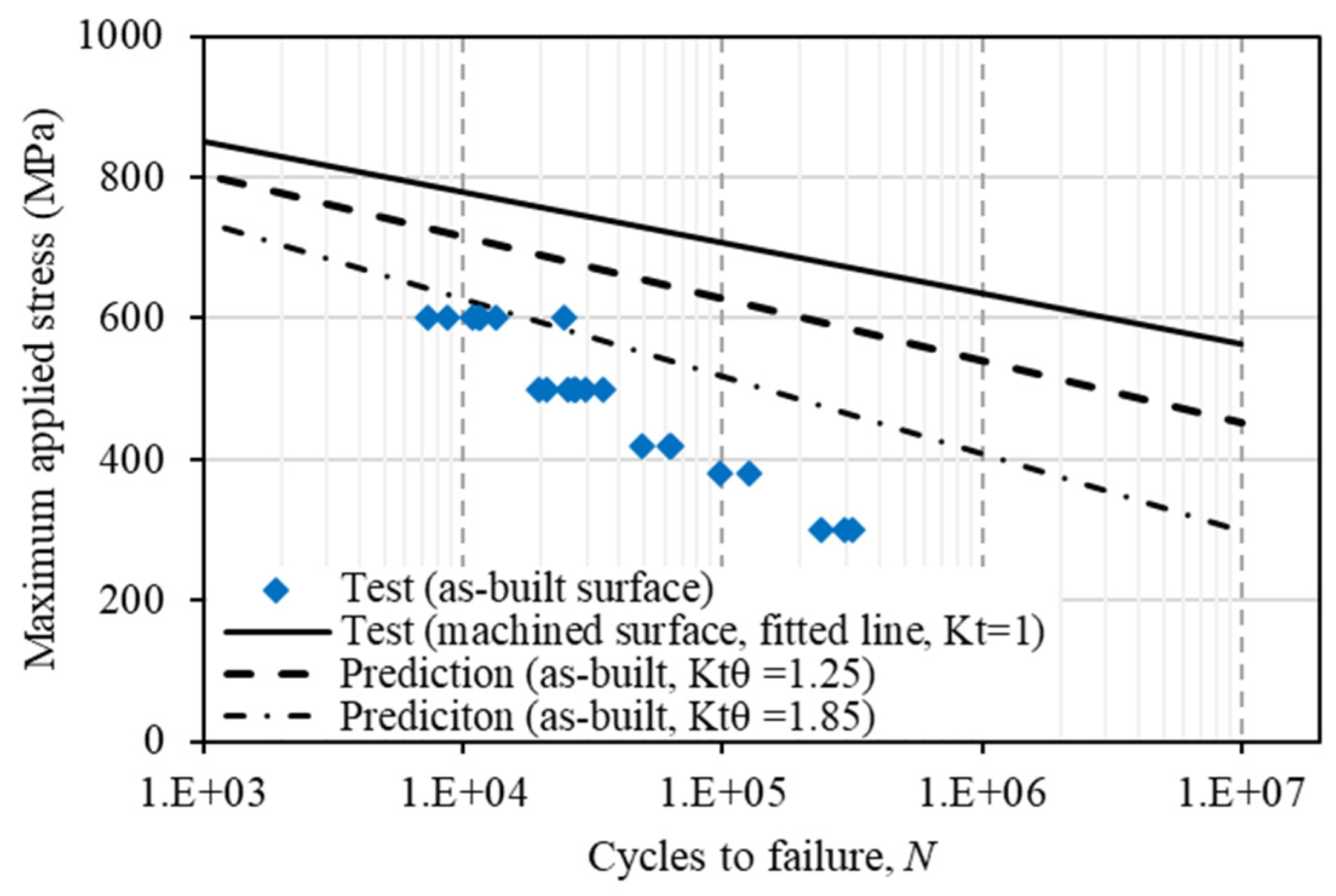

Figure 10.

Fatigue life prediction for as-deposited specimens using the notch stress approach.

Figure 10.

Fatigue life prediction for as-deposited specimens using the notch stress approach.

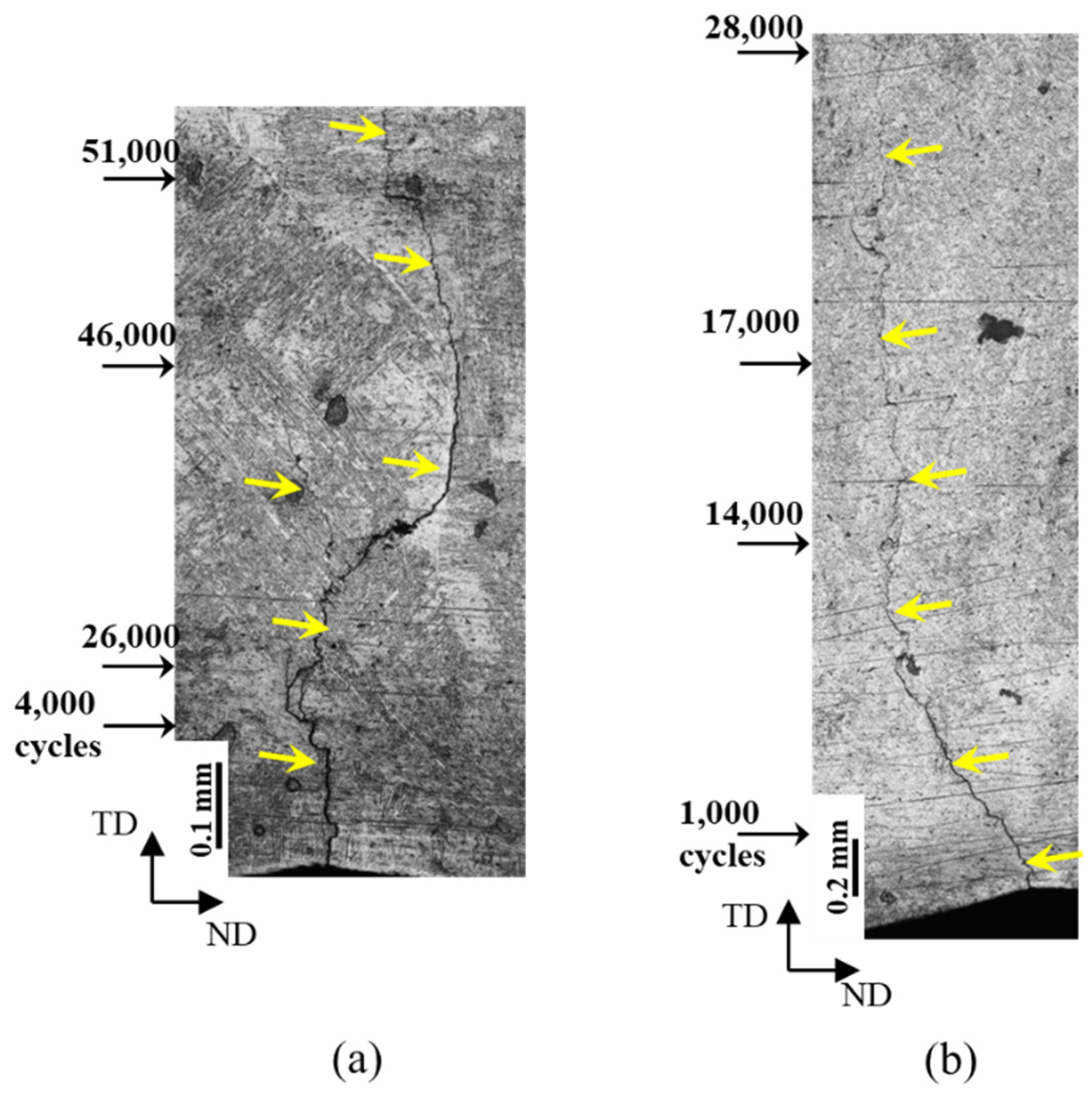

Figure 11.

Macroscopic images of the crack propagation trajectories with indicators of accumulated load cycle numbers at crack measurement points for (a) 3PB-Test 1 (σmax=380 MPa, Ni = 31,000, Np = 74,000 and Nt = 126,737), (b) 3PB-Test 2 (σmax=380 MPa, Ni = 3,000, Np = 33,000 and Nt = 96,875), where Ni denotes the crack initiation life corresponding to initiation of a 0.5 mm crack, Np the crack propagation life from 0.5 mm to around 1.5 mm, and Nt the total life from the first cycle to fracture. The images only captured part of the specimens’ height.

Figure 11.

Macroscopic images of the crack propagation trajectories with indicators of accumulated load cycle numbers at crack measurement points for (a) 3PB-Test 1 (σmax=380 MPa, Ni = 31,000, Np = 74,000 and Nt = 126,737), (b) 3PB-Test 2 (σmax=380 MPa, Ni = 3,000, Np = 33,000 and Nt = 96,875), where Ni denotes the crack initiation life corresponding to initiation of a 0.5 mm crack, Np the crack propagation life from 0.5 mm to around 1.5 mm, and Nt the total life from the first cycle to fracture. The images only captured part of the specimens’ height.