Submitted:

24 May 2023

Posted:

26 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Multiple Criteria and Performance Assessment Factors

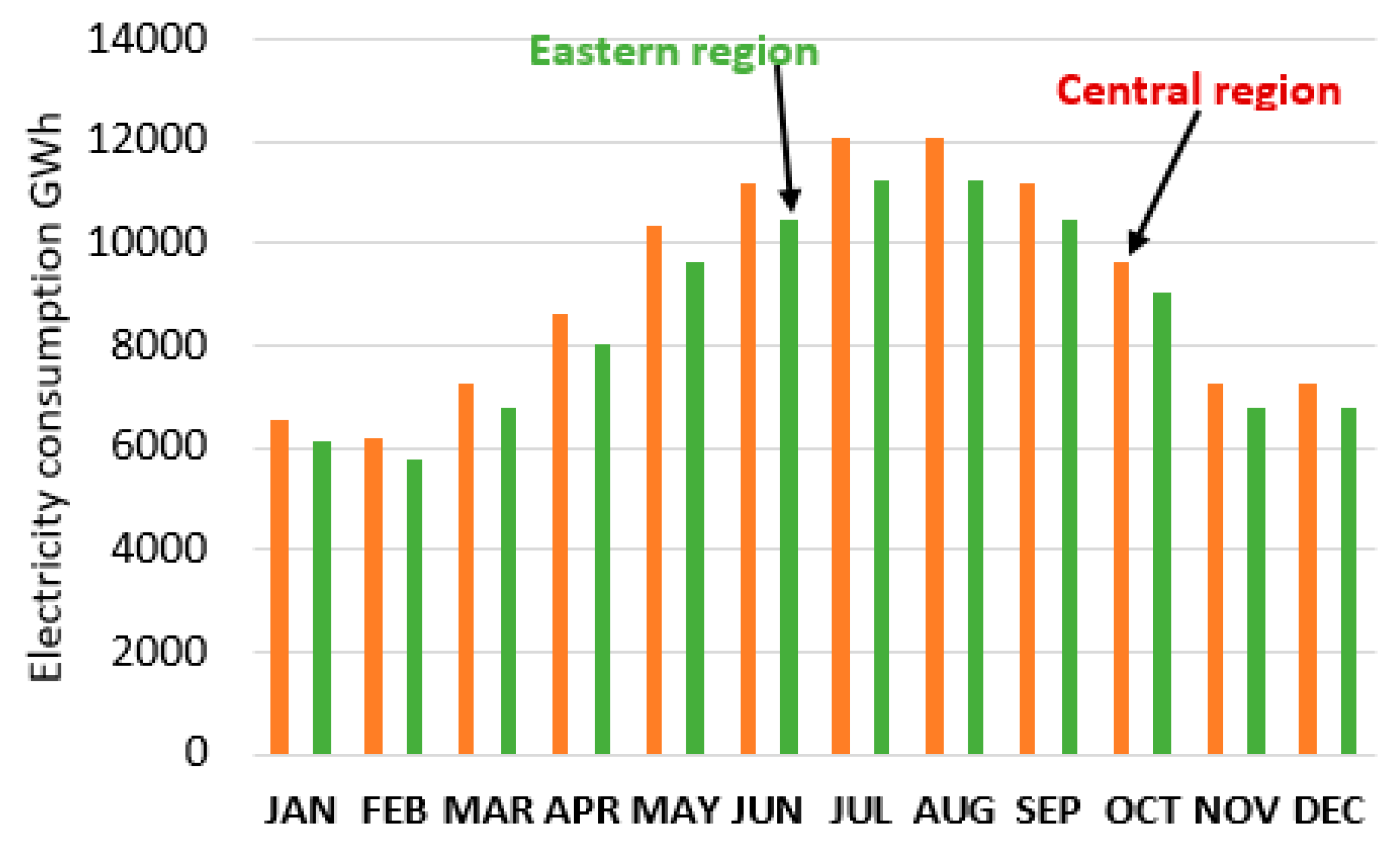

2.1. Electricity Consumption

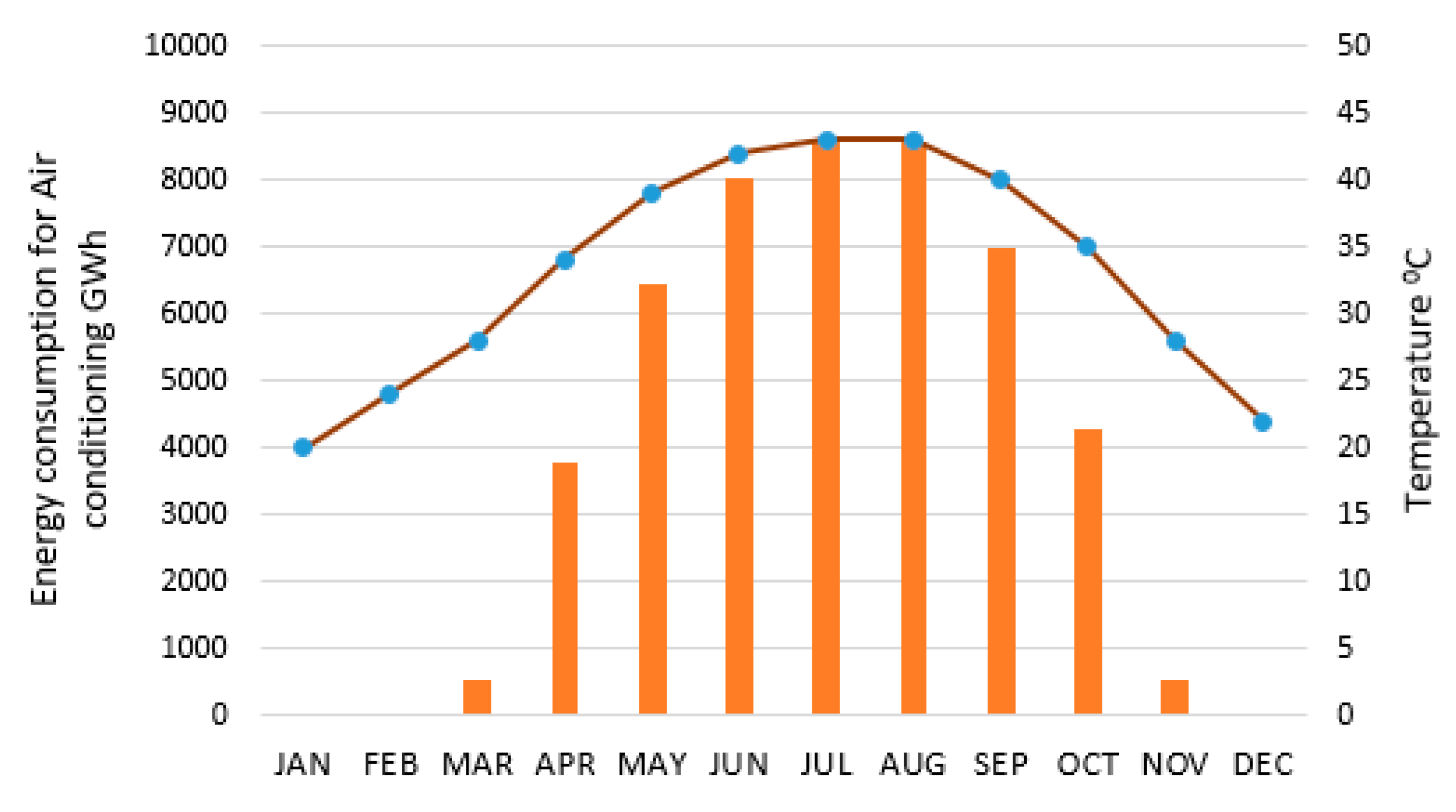

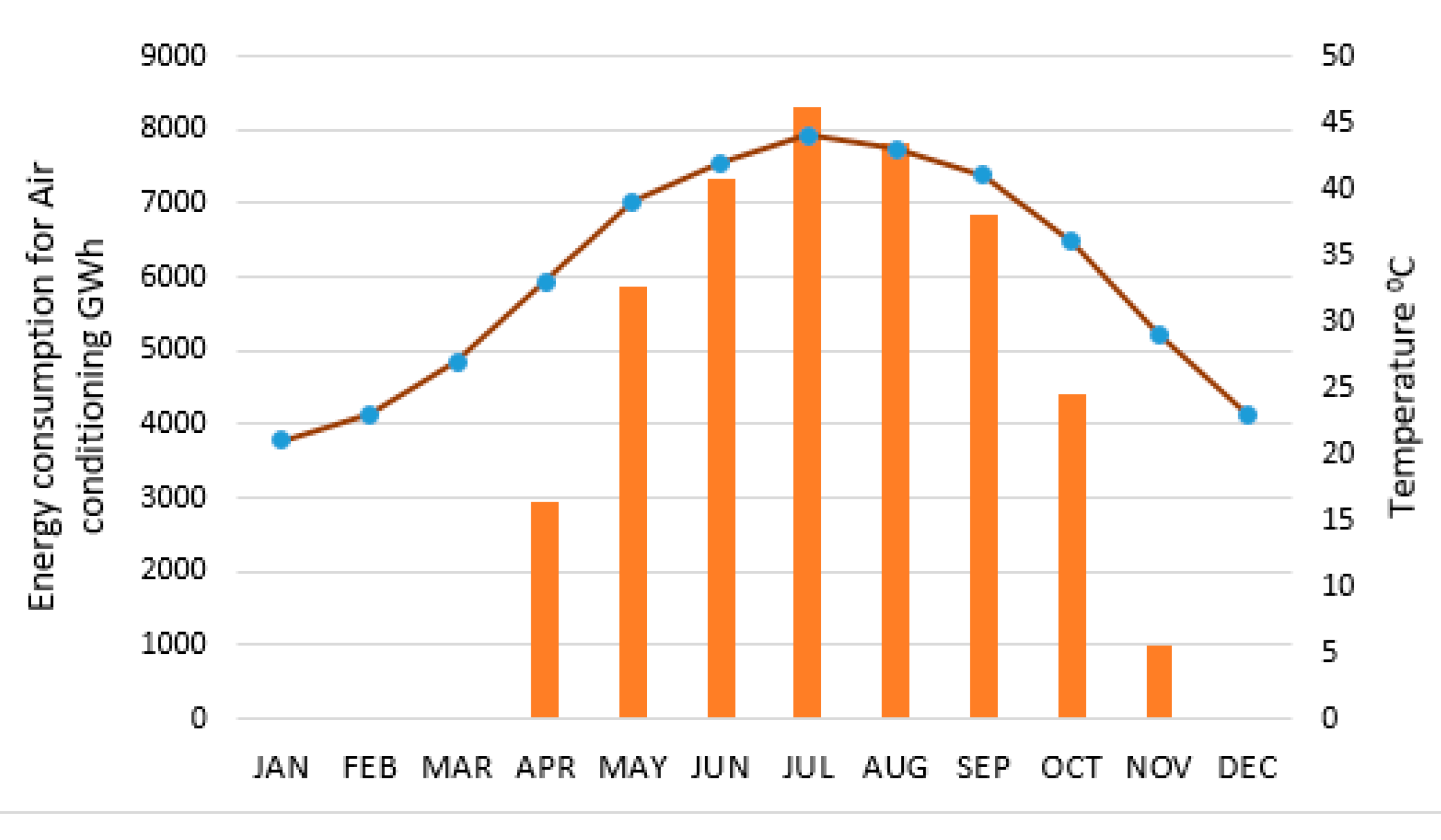

2.2. Cooling Energy Requirement

- Monthly energy required for cooling is calculated based on difference between actual average maximum temperature in the region and minimum temperature required to be maintained.

- The total cooling energy required is 66% of monthly energy consumption

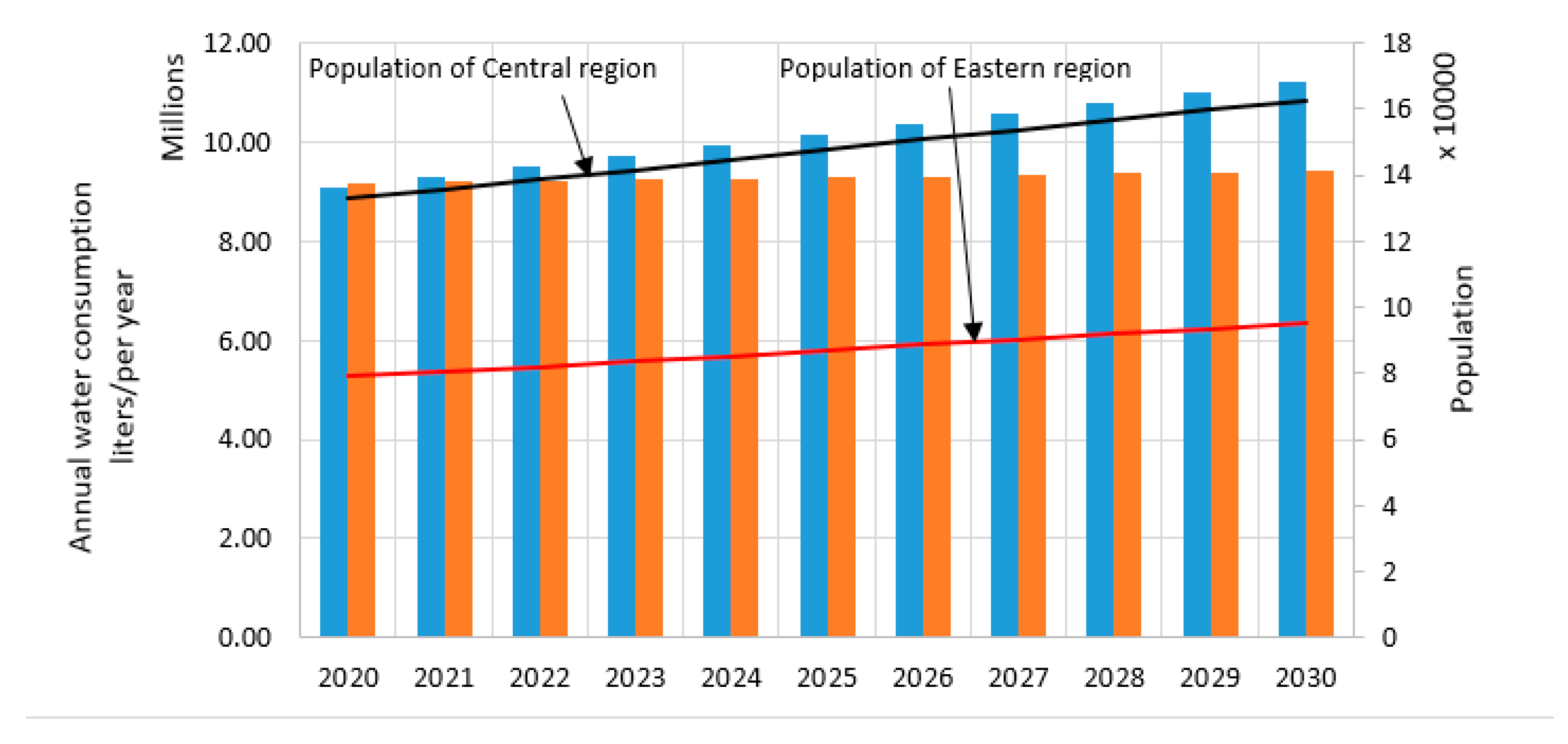

2.3. Fresh Water Requirement

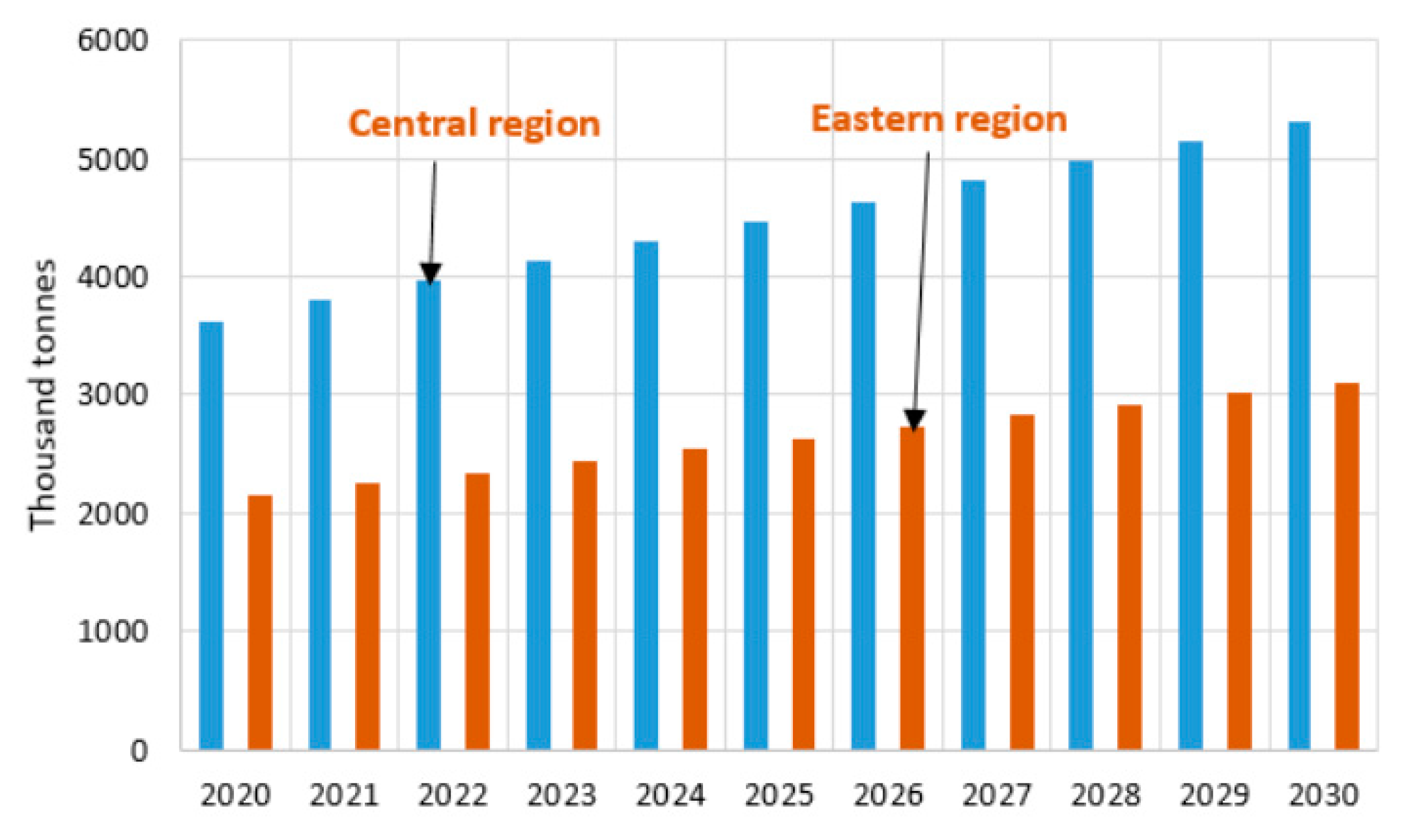

3. Municipal Waste Collection, Disposal and Characteristics

4. Performance Assessment Factors

4.1. Fuel Supply Requirements

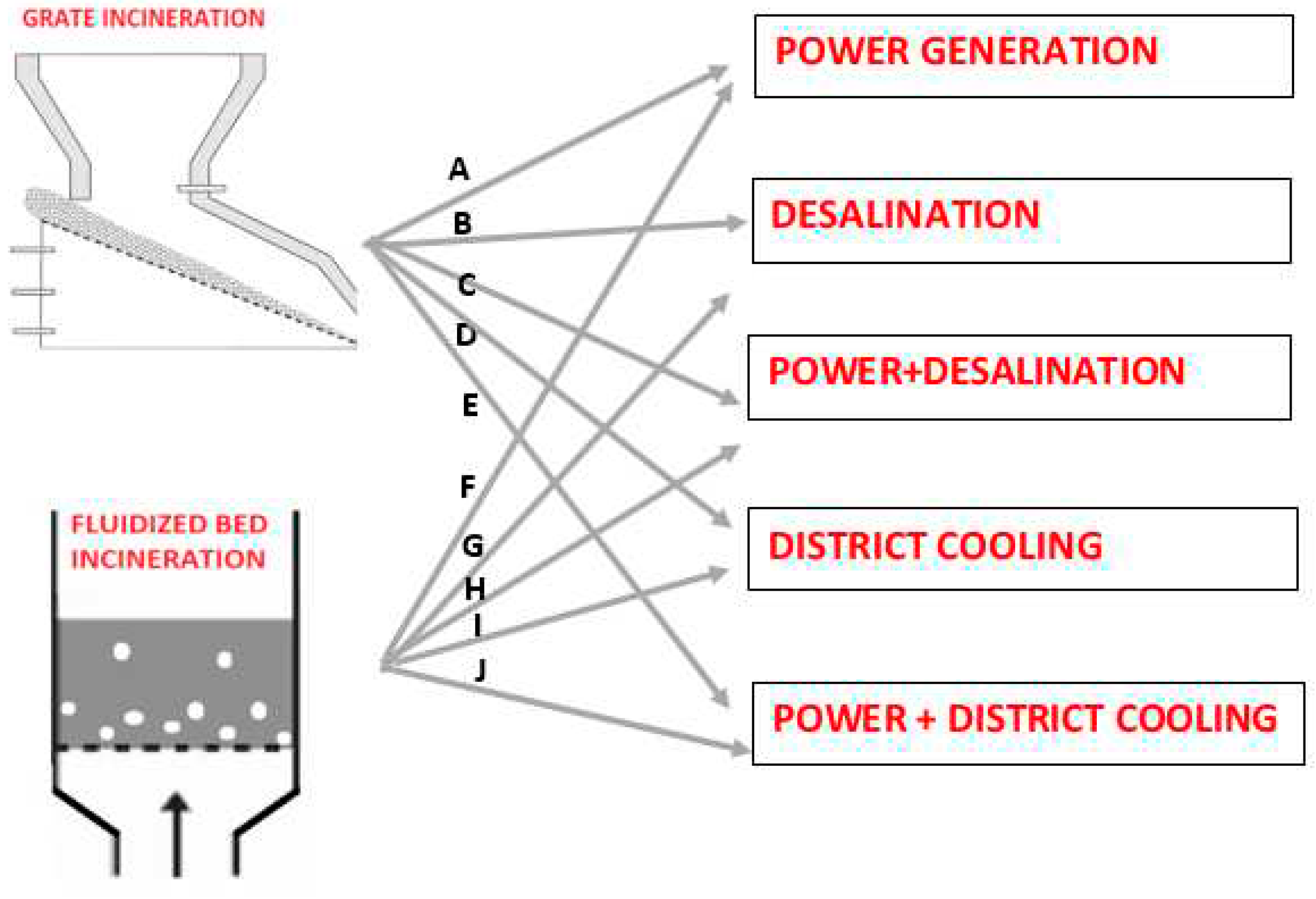

4.2. Incinerator Performance

4.3. End Use Performance:

4.4. Emissions Factors:

4.5. Economic Factors:

| It | : | investment expenditures in the year t |

| Mt | : | operations and maintenance expenditures in the year t |

| Ft | : | fuel expenditures in the year t |

| Et | : | electrical energy generated in the year t |

| r | : | discount rate taken as 10% |

| n | : | expected lifetime of system or power station taken as 15 years |

5. MCDM Approach to Evaluate Ideal MSW Incineration and Utilization Technology

5.1. Structure of the Decision Matrix and Its Standardization

| Evaluation Criterion (j)→ Alternative MSW Incineration Option (i)↓ |

1 | 2 | . | n |

|---|---|---|---|---|

| 1 | X11 | X12 | . | X1n |

| 2 | X21 | X22 | . | X2n |

| . | . | . | . | . |

| . | . | . | . | . |

| M | Xm1 | Xm2 | . | Xmn |

| Criterion Weight → | W1 | W2 | . | Wn |

| Option | A | B | C | D | E | F | G | H | I | J | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel supply requirement | |||||||||||

|

C1 |

Fuel heating value requirement, MJ/kg(min) | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 |

|

C2 |

Fuel drying requirement, % (max) | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 2 |

|

C3 |

Fuel handling requirement (max) | 2 | 2 | 2 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

|

C4 |

Storage (max) | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| Incinerator performance | |||||||||||

|

C5 |

Capacity flexibility (min) |

1 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 |

|

C6 |

Conversion efficiency (max) | 40% | 40% | 40% | 40% | 40% | 60% | 60% | 60% | 60% | 60% |

|

C7 |

Co-firing adaptability (min) |

3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 |

|

C8 |

Operation and Maintenance requirement (min) |

2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| End Use Performance | |||||||||||

|

C9 |

Energy efficiency (min) | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 2 |

|

C10 |

Exergy Efficiency (min) |

2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

|

C11 |

% of existing usage | 8.07 | 28.34 | 14.17 | 20.00 | 10.00 | 10.5 | 37.7 | 18.85 | 26.4 | 13.2 |

| Emission factors | |||||||||||

|

C12 |

Bottom Ash/Fly ash ratio (max) | 90/10 | 90/10 | 90/10 | 90/10 | 90/10 | 30/70 | 30/70 | 30/70 | 30/70 | 30/70 |

|

C13 |

emissions (CO2) kg/kg (min) |

1200 | 1200 | 1200 | 1200 | 1200 | 1250 | 1250 | 1250 | 1250 | 1250 |

|

C14 |

emissions (CO) mg/m3 (min) |

50 | 50 | 50 | 50 | 50 | 20 | 20 | 20 | 20 | 20 |

|

C15 |

NOX formation mg/m3. (min) |

12 | 12 | 12 | 12 | 12 | 6 | 6 | 6 | 6 | 6 |

|

C16 |

Leachates problems (min) |

3 | 3 | 3 | 4 | 4 | 1 | 1 | 1 | 2 | 2 |

| Economic factors | |||||||||||

|

C17 |

Investment cost of incinerator USD per ton (min) |

83.40 | 83.40 | 83.40 | 83.40 | 83.40 | 75.06 | 75.06 | 75.06 | 75.06 | 75.06 |

|

C18 |

Waste Collection cost USD per ton (min) |

37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 |

|

C19 |

Fuel preparation cost (USD per ton) (min) |

21.43 | 21.43 | 21.43 | 21.43 | 21.43 | 42.87 | 42.87 | 42.87 | 42.87 | 42.87 |

|

C20 |

Levelized cost of Energy (USD) (min) |

2450 | 2350 | 2430 | 2600 | 2500 | 2200 | 2150 | 2350 | 2300 | 2130 |

5.2. Estimation of Criterion Entropy Weights

| Evaluation Criterion (j) ↓ | Ej Entropy Weight Values | |||

|---|---|---|---|---|

| Scenario1 | Scenario2 | Scenario3 | Scenario4 | |

| C1 | 0.0215 | 0.0175 | 0.0210 | 0.0211 |

| C2 | 0.0432 | 0.0440 | 0.0422 | 0.0423 |

| C3 | 0.0200 | 0.0204 | 0.0464 | 0.0465 |

| C4 | 0.0389 | 0.0397 | 0.0380 | 0.0381 |

| C5 | 0.0365 | 0.0372 | 0.0357 | 0.0357 |

| C6 | 0.0200 | 0.0204 | 0.0196 | 0.0196 |

| C7 | 0.0475 | 0.0204 | 0.0464 | 0.0465 |

| C8 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C9 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C10 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C11 | 0.0110 | 0.0112 | 0.0107 | 0.0108 |

| C12 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C13 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C14 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C15 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C16 | 0.0215 | 0.0484 | 0.0210 | 0.0211 |

| C17 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C18 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C19 | 0.0475 | 0.0484 | 0.0464 | 0.0465 |

| C20 | 0.2648 | 0.2571 | 0.2553 | 0.2535 |

5.3. Normalization of the Decision Matrix

5.4. Determine Best and Worst MSW Incineration and Utilization Technologies for a Given Criterion

5.5. Determine the Closeness to Ideal Solution for Each Alternative MSW Incineration and Utilization Technologies for a Given Criterion and Ranking the Alternative

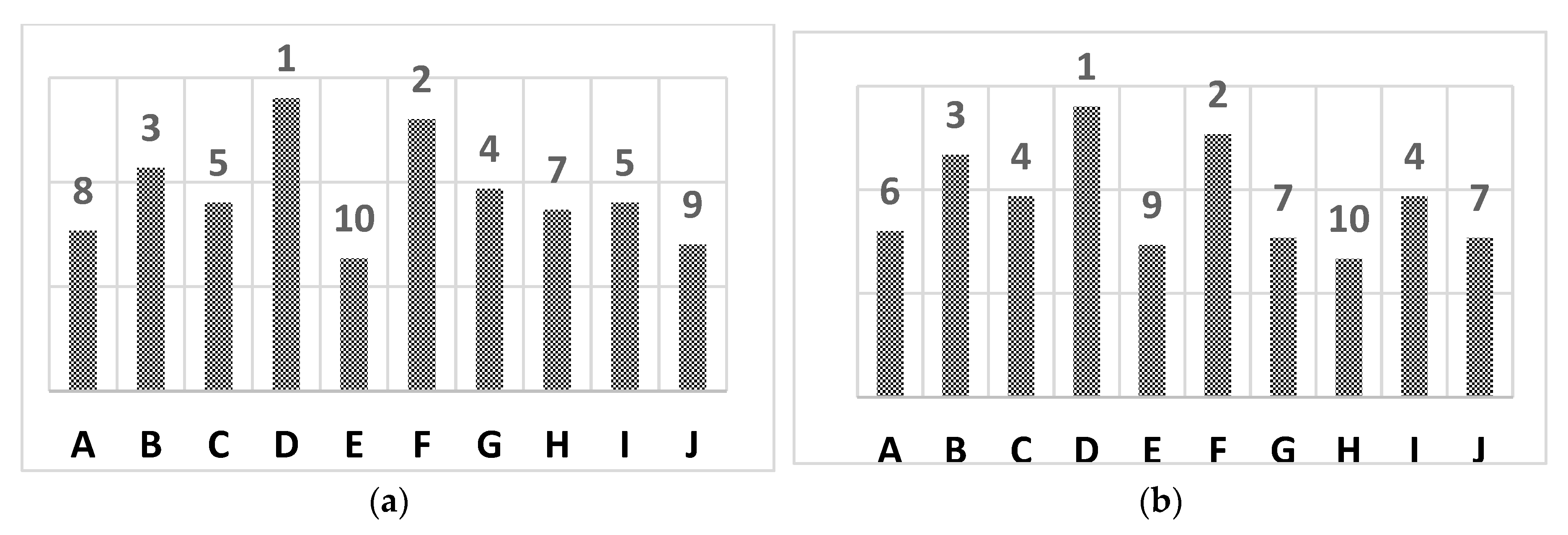

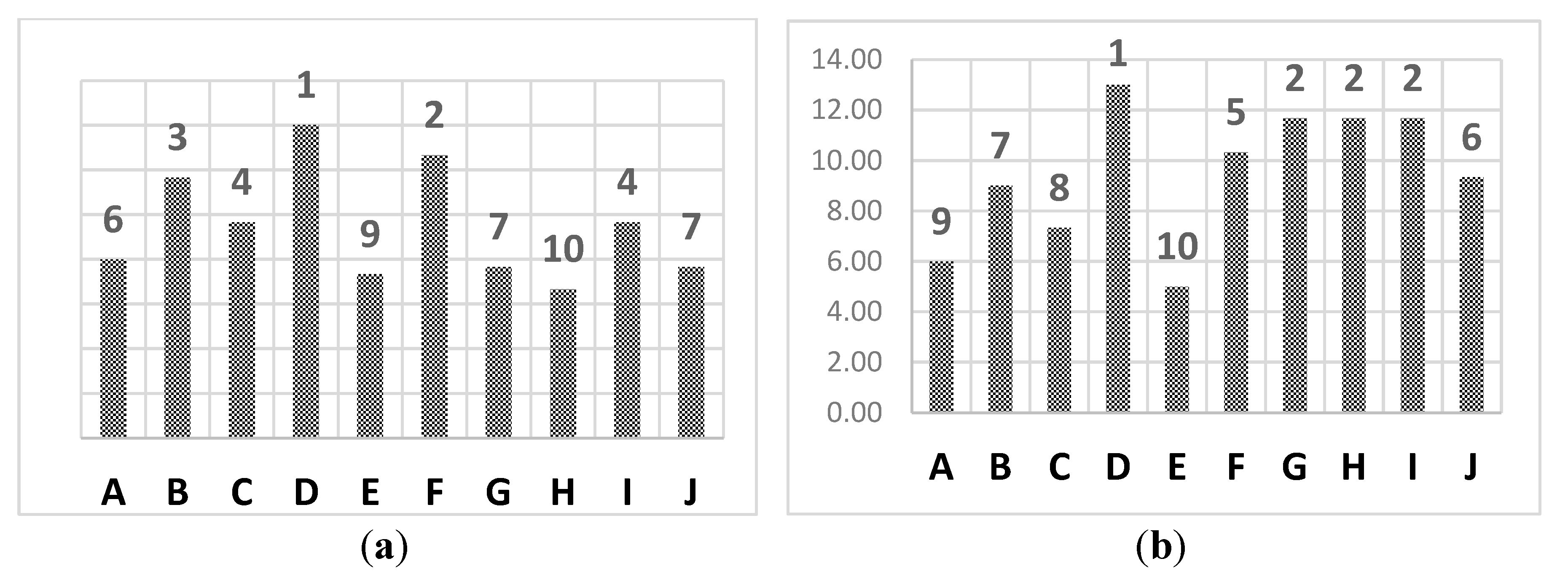

6. Results and Discussion

| Option → | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Meeting Fuel supply requirement | ||||||||||

| Heating value requirement ranking (min) | 4 | 2 | 4 | 1 | 4 | 3 | 2 | 3 | 1 | 3 |

| Fuel drying requirement, % (max) | 4 | 2 | 4 | 1 | 4 | 4 | 4 | 4 | 1 | 4 |

| Fuel handling requirement (max) | 3 | 2 | 2 | 2 | 2 | 4 | 1 | 1 | 1 | 1 |

| Storage problems ranking (max) | 3 | 1 | 4 | 4 | 1 | 3 | 1 | 4 | 1 | 4 |

| Incinerator performance | ||||||||||

| Capacity flexibility ranking (min) |

3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

| Conversion efficiency ranking (max) | 2 | 3 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | 2 |

| Co-firing adaptability ranking (min) | 3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 |

| Operation and Maintenance requirement ranking (min) | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| End Use Performance | ||||||||||

| Energy efficiency ranking (min) | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 2 |

| Exergy Efficiency ranking (min) |

2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| % of existing usage (max) | 8.07 | 28.34 | 14.17 | 20.00 | 10.00 | 10.5 | 37.7 | 18.85 | 26.4 | 13.2 |

| Emission factors | ||||||||||

| Bottom Ash/Fly ash ratio (max) |

90/10 | 90/10 | 90/10 | 90/10 | 90/10 | 30/70 | 30/70 | 30/70 | 30/70 | 30/70 |

| emissions (CO2) kg/kg (min) |

1200 | 1200 | 1200 | 1200 | 1200 | 1250 | 1250 | 1250 | 1250 | 1250 |

| emissions (CO) mg/m3 (min) |

50 | 50 | 50 | 50 | 50 | 20 | 20 | 20 | 20 | 20 |

| NOX formation mg/m3. (min) |

12 | 12 | 12 | 12 | 12 | 6 | 6 | 6 | 6 | 6 |

| Leachates problems ranking (min) |

3 | 3 | 3 | 4 | 4 | 1 | 1 | 1 | 2 | 2 |

| Economic factors | ||||||||||

| Investment cost of incinerator USD per ton (min) |

83.40 | 83.40 | 83.40 | 83.40 | 83.40 | 75.06 | 75.06 | 75.06 | 75.06 | 75.06 |

| Waste Collection cost USD per ton (min) |

37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 | 37.9 |

| Fuel preparation cost (USD per ton) (min) |

21.43 | 21.43 | 21.43 | 21.43 | 21.43 | 42.87 | 42.87 | 42.87 | 42.87 | 42.87 |

| Levelized cost of Energy (USD) (min) |

0.16 | 0.18 | 0.18 | 0.19 | 0.18 | 0.17 | 0.20 | 0.20 | 0.21 | 0.20 |

| Option → | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Fuel supply requirement | ||||||||||

| Heating value requirement ranking (min) | 4 | 2 | 4 | 1 | 3 | 3 | 2 | 3 | 1 | 2 |

| Fuel drying requirement, % (max) | 4 | 2 | 4 | 1 | 4 | 4 | 4 | 4 | 1 | 4 |

| Fuel handling requirement (max) | 3 | 2 | 2 | 2 | 2 | 4 | 1 | 1 | 1 | 1 |

| Storage problems ranking (max) | 3 | 1 | 4 | 4 | 1 | 3 | 1 | 4 | 1 | 4 |

| Incinerator performance | ||||||||||

| Capacity flexibility ranking (min) | 3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

| Conversion efficiency ranking (max) | 2 | 3 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | 2 |

| Co-firing adaptability ranking (min) |

2 | 3 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | 2 |

| Operation and Maintenance requirement ranking (min) |

3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 |

| End Use Performance | ||||||||||

| Energy efficiency ranking (min) | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 2 |

| Exergy Efficiency ranking (min) |

2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| % of existing usage (max) | 7.63 | 26.78 | 13.39 | 18.90 | 9.45 | 9.92 | 35.63 | 17.81 | 24.95 | 12.47 |

| Emission factors | ||||||||||

| Bottom Ash/Fly ash ratio (max) |

90/10 | 90/10 | 90/10 | 90/10 | 90/10 | 30/70 | 30/70 | 30/70 | 30/70 | 30/70 |

| emissions (CO2) kg/kg (min) | 1134 | 1134 | 1134 | 1134 | 1134 | 1181 | 1181 | 1181 | 1181 | 1181 |

| emissions (CO) mg/m3 (min) | 1134 | 1134 | 1134 | 1134 | 1134 | 1181 | 1181 | 1181 | 1181 | 1181 |

| NOX formation mg/m3 (min) | 11 | 11 | 11 | 11 | 11 | 6 | 6 | 6 | 6 | 6 |

| Leachates problems (min) | 50 | 50 | 50 | 50 | 50 | 20 | 20 | 20 | 20 | 20 |

| Economic factors | ||||||||||

| Investment cost of incinerator USD per ton (min) |

78.81 | 78.81 | 78.81 | 78.81 | 78.81 | 70.93 | 70.93 | 70.93 | 70.93 | 70.93 |

| Waste Collection cost USD per ton (min) |

36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 |

| Fuel preparation cost (USD per ton) (min) |

20 | 20 | 20 | 20 | 20 | 41 | 41 | 41 | 41 | 41 |

| Levelized cost of Energy (USD) (min) |

0.15 | 0.17 | 0.17 | 0.18 | 0.17 | 0.17 | 0.19 | 0.19 | 0.20 | 0.19 |

7. Conclusion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saudi Arabia’s Mobile Desalination Plants Achieving a New World Record “2.27 KW per m3” Lowest Energy Consumption Available online: https://idadesal.org/saudi-arabias-mobile-desalination-plants-achieving-a-new-world-record-2-27-kw-per-cubic-meter-lowest-energy-consumption/ (accessed on 15 May 2023).

- Howarth, N.; Odnoletkova, N.; Alshehri, T.; Almadani, A.; Lanza, A.; Patzek, T. Staying Cool in A Warming Climate: Temperature, Electricity and Air Conditioning in Saudi Arabia. Climate 2020, 8, 4. [CrossRef]

- Carlos Escobar Palacio, J.; Joaquim Conceição Soares Santos, J.; Luiza Grillo Renó, M.; Corrêa Furtado Júnior, J.; Carvalho, M.; Martín Martínez Reyes, A.; José Rúa Orozco, D. Municipal Solid Waste Management and Energy Recovery. In Energy Conversion - Current Technologies and Future Trends; H. Al-Bahadly, I., Ed.; IntechOpen, 2019 ISBN 978-1-78984-904-2.

- Una Nowling, P. POWER Magazine. September 1 2016,.

- Trindade, A.B.; Palacio, J.C.E.; González, A.M.; Rúa Orozco, D.J.; Lora, E.E.S.; Renó, M.L.G.; del Olmo, O.A. Advanced Exergy Analysis and Environmental Assesment of the Steam Cycle of an Incineration System of Municipal Solid Waste with Energy Recovery. Energy Conversion and Management 2018, 157, 195–214. [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid Waste Management Challenges for Cities in Developing Countries. Waste Management 2013, 33, 220–232. [CrossRef]

- €70 Billion Trash Business: Lessons from Germany’s Waste Management System. UNEP/UNESCO/BMUV course program 2020.

- US EPA, O. U.S. National Recycling Goal Available online: https://www.epa.gov/circulareconomy/us-national-recycling-goal (accessed on 15 May 2023).

- Reaching 2030’s Residual Municipal Waste Target — Why Recycling Is Not Enough — European Environment Agency Available online: https://www.eea.europa.eu/publications/reaching-2030s-residual-municipal-waste (accessed on 15 May 2023).

- National Waste Policy Action Plan - DCCEEW Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/national-waste-policy-action-plan (accessed on 15 May 2023).

- Cheng, H.; Hu, Y. Curbing Dioxin Emissions from Municipal Solid Waste Incineration in China: Re-Thinking about Management Policies and Practices. Environmental Pollution 2010, 158, 2809–2814. [CrossRef]

- Holmes, T.; Baker, B.; Shoemaker, L. Materials for Service in Municipal Waste- & Biomass-Fired Power Generation … a Review of Recent Experience.; March 6 2016; p. NACE-2016-7493.

- Tsai, W.-T.; Kuo, K.-C. An Analysis of Power Generation from Municipal Solid Waste (MSW) Incineration Plants in Taiwan. Energy 2010, 35, 4824–4830. [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Nita, V. The Role of Biomass and Bioenergy in a Future Bioeconomy: Policies and Facts. Environmental Development 2015, 15, 3–34. [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.-F. Status and Opportunities for Energy Recovery from Municipal Solid Waste in Europe. Waste Biomass Valor 2019, 10, 2425–2444. [CrossRef]

- McKay, G. Dioxin Characterisation, Formation and Minimisation during Municipal Solid Waste (MSW) Incineration: Review. Chemical Engineering Journal 2002, 86, 343–368. [CrossRef]

- Leckner, B.; Lind, F. Combustion of Municipal Solid Waste in Fluidized Bed or on Grate – A Comparison. Waste Management 2020, 109, 94–108. [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash Deposition in Biomass Combustion or Co-Firing for Power/Heat Generation. Energies 2012, 5, 5171–5189. [CrossRef]

- Bolhar-Nordenkampf, M.; Nummelin, T.; Luomaharju, T.; Viljanen, J. Operating Experience from the World´s Largest Waste Fired Circulating Fluidized Bed Reactor in Västerås. In; 2015; pp. 167–178 ISBN 978-3-944310-22-0.

- Fitzgerald, G.C. Pre-Processing and Treatment of Municipal Solid Waste (MSW) Prior to Incineration. In Waste to Energy Conversion Technology; Elsevier, 2013; pp. 55–71 ISBN 978-0-85709-011-9.

- Tozlu, A.; Abusoglu, A.; Ozahi, E.; Anvari-Moghaddam, A. Municipal Solid Waste-Based District Heating and Electricity Production: A Case Study. Journal of Cleaner Production 2021, 297, 126495. [CrossRef]

- Udomsri, S.; Martin, A.R.; Martin, V. Thermally Driven Cooling Coupled with Municipal Solid Waste-Fired Power Plant: Application of Combined Heat, Cooling and Power in Tropical Urban Areas. Applied Energy 2011, 88, 1532–1542. [CrossRef]

- Fabricius, M.; Øland Tarp, D.; Wehl Rasmussen, T.; Arabkoohsar, A. Utilization of Excess Production of Waste-Fired CHP Plants for District Cooling Supply, an Effective Solution for a Serious Challenge. Energies 2020, 13, 3319. [CrossRef]

- Nubi, O.; Morse, S.; Murphy, R.J. Prospective Life Cycle Costing of Electricity Generation from Municipal Solid Waste in Nigeria. Sustainability 2022, 14, 13293. [CrossRef]

- Ding, L.; Shao, Z.; Zhang, H.; Xu, C.; Wu, D. A Comprehensive Evaluation of Urban Sustainable Development in China Based on the TOPSIS-Entropy Method. Sustainability 2016, 8, 746. [CrossRef]

- Almutairi, K.; Almutairi, M.S.; Harb, K.M.; Marey, O. A Thorough Investigation of Renewable Energy Development Strategies through Integrated Approach: A Case Study. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 2023, 45, 708–726. [CrossRef]

- Yu, Y.; Li, C.; Fu, Y.; Yang, W. A Group Decision-Making Method to Measure National Energy Architecture Performance: A Case Study of the International Energy Agency. Applied Energy 2023, 330, 120285. [CrossRef]

- Electrical Energy Production and Consumption Increase in 2020 Available online: https://www.argaam.com/en/article/articledetail/id/1611319 (accessed on 17 May 2023).

- ArgaamPlus Saudi Arabia’s Electricity Consumption Rises 4.2% in 2021 Available online: https://www.argaam.com/en/article/articledetail/id/1611319 (accessed on 17 May 2023).

- Aoun, M.-C.; Nachet, S. The Saudi Electricity Sector: Pressing Issues and Challenges. 2015.

- Krarti, M.; Howarth, N. Transitioning to High Efficiency Air Conditioning in Saudi Arabia: A Benefit Cost Analysis for Residential Buildings. Journal of Building Engineering 2020, 31, 101457. [CrossRef]

- Energy-Efficient Air Conditioning: A Case Study of the Maghreb Available online: https://documents1.worldbank.org/curated/en/754361472471984998/pdf/105360-REVISED-PUBLIC-MENA-Digital-Print-English-sep-2016.pdf (accessed on 15 May 2023).

- Saudi Arabia Climate Data Historical Available online: https://climateknowledgeportal.worldbank.org/country/saudi-arabia/climate-datahistorical#:~:text=Summers%20in%20the%20central%20region,coastal%20areas%20of%20Red%20Sea (accessed on 3 January 2023).

- Dammam Climate, Weather By Month, Average Temperature (Saudi Arabia) - Weather Spark Available online: https://weatherspark.com/y/104953/Average-Weather-in-Dammam-Saudi-Arabia-Year-Round (accessed on 17 May 2023).

- King Abdullah Petroleum Studies and Research Center (KAPSARC) The Future of Cooling in Saudi Arabia: Technology, Market and Policy Options; King Abdullah Petroleum Studies and Research Center, 2020;

- Ammar, E.A.; Dayil, A.B. Window Air Conditioners Transition and Restriction in Saudi Arabia. JPEE 2022, 10, 1–21. [CrossRef]

- Alessi, Y.M.; Al-Rabiah, A.A. A Feasibility Study of Utilizing Nuclear Energy for an Existing MED-TVC Desalination Plant. Applied Sciences 2022, 12, 9506. [CrossRef]

- Encyclopedia of Desalination and Water Resources: Energy Requirements of Desalination Processes Available online: https://www.desware.net/Energy-Requirements-Desalination-Processes.aspx (accessed on 17 May 2023).

- General Authority of Statistics Environmental indicators Available online: https://www.stats.gov.sa/ar/node/10131 (accessed on 17 May 2023).

- Population Estimates by Region, Sex and Nationality for Saudi Arabia - Public Knoema Data Hub Available online: https://public.knoema.com/qfkyjsf/population-estimates-by-region-sex-and-nationality-for-saudi-arabia (accessed on 17 May 2023).

- Jayakumar Menon, V.; Palackal, A. Centralized Anddecentralized Approaches to Solid Waste Management – a Case Study. Holist. approach environ. 2022, 12, 155–164. [CrossRef]

- Xie, Y.; Lu, J.-W.; Xie, B.; Shi, L.; Zhou, J.; Hai, J. Systematic Evaluation of Decentralized Thermal Treatment of Rural Solid Waste: Status, Challenges, and Perspectives. Resources, Conservation & Recycling Advances 2022, 15, 200116. [CrossRef]

- Xiong, J.; Ng, T.S.A.; Wang, S. An Optimization Model for Economic Feasibility Analysis and Design of Decentralized Waste-to-Energy Systems. Energy 2016, 101, 239–251. [CrossRef]

- Kuznetsova, E.; Cardin, M.-A.; Diao, M.; Zhang, S. Integrated Decision-Support Methodology for Combined Centralized-Decentralized Waste-to-Energy Management Systems Design. Renewable and Sustainable Energy Reviews 2019, 103, 477–500. [CrossRef]

- Latosińska, J.; Miłek, D.; Komór, A.; Kowalik, R. Selective Collection of Municipal Waste in a Residential District with Multi-Family Buildings—Case Study from Poland. Resources 2021, 10, 83. [CrossRef]

- Rada, E.C. Effects of MSW Selective Collection on Waste-to-Energy Strategies.; Bucharest, Romania, June 19 2013; pp. 3–13.

- Al-Waked, R.; Ouda, O.K.M.; Raza, S.A. Potential value of waste-to-energy facility in Riyadh city - Saudi Arabia. 2014. [CrossRef]

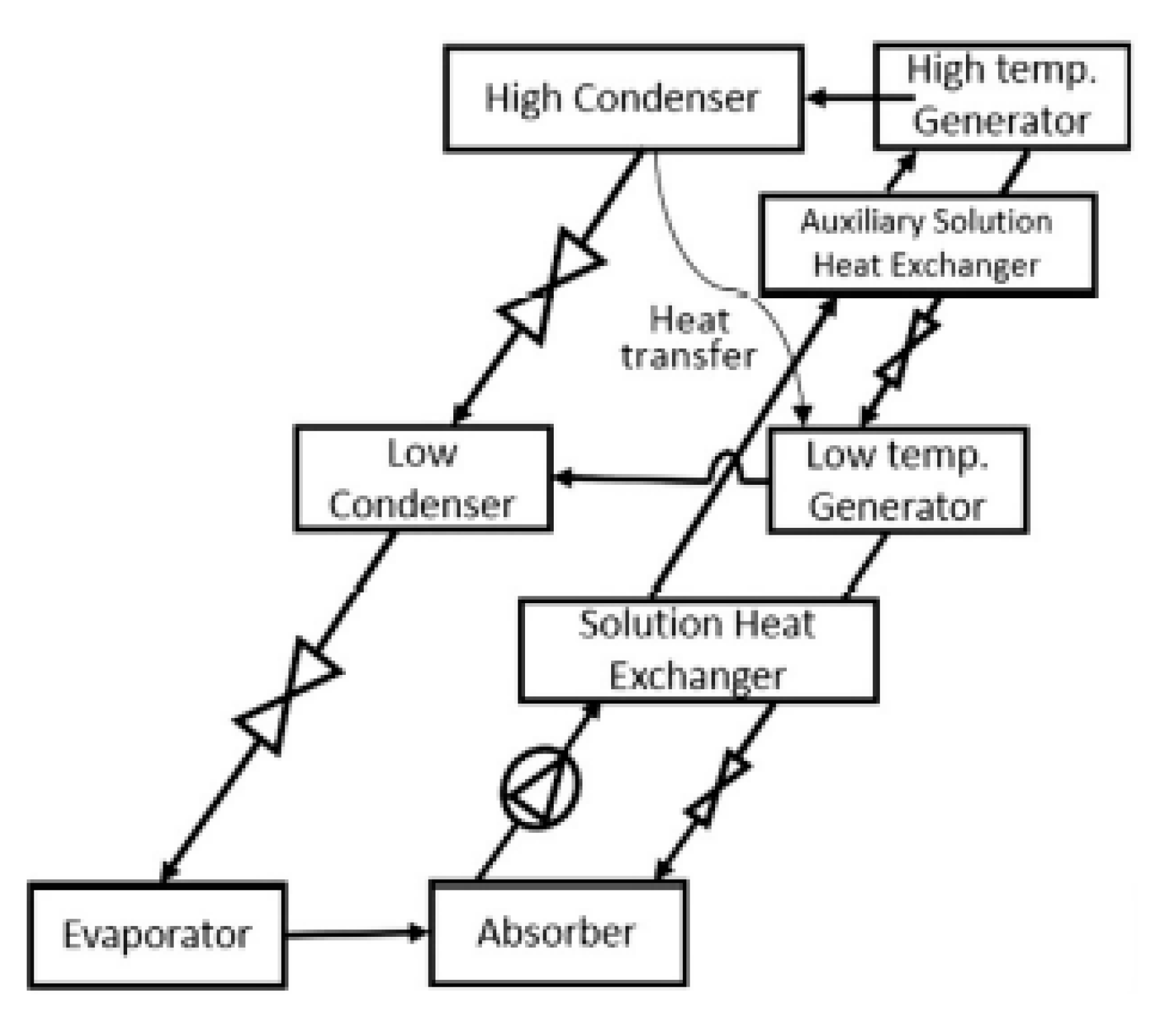

- Kong, X.; Meng, X.; Li, J.; Shang, Y.; Cui, F. Comparative Study on Two-Stage Absorption Refrigeration Systems with Different Working Pairs. J. Shanghai Jiaotong Univ. (Sci.) 2021, 26, 155–162. [CrossRef]

- Huang, Q.; Chi, Y.; Themelis, N.J. A Rapidly Emerging WTE Technology: Circulating Fluid Bed Combustion. In Proceedings of the Conference proceedings, international thermal treatment technologies (IT3) 33rd, Air and Waste Management Association, San Antonio; 2013.

- Dong, J.; Chi, Y.; Tang, Y.; Ni, M.; Nzihou, A.; Weiss-Hortala, E.; Huang, Q. Effect of Operating Parameters and Moisture Content on Municipal Solid Waste Pyrolysis and Gasification. Energy Fuels 2016, 30, 3994–4001. [CrossRef]

- Liang, L.; Sun, R.; Fei, J.; Wu, S.; Liu, X.; Dai, K.; Yao, N. Experimental Study on Effects of Moisture Content on Combustion Characteristics of Simulated Municipal Solid Wastes in a Fixed Bed. Bioresource Technology 2008, 99, 7238–7246. [CrossRef]

- Sarkar, D.K. Fluidized-Bed Combustion Boilers. In Thermal Power Plant; Elsevier, 2015; pp. 159–187 ISBN 978-0-12-801575-9.

- Khan, M.S.; Kadam, S.T.; Kyriakides, A.-S.; Papadopoulos, A.I.; Hassan, I.; Rahman, M.A.; Seferlis, P. A New Correlation for Performance Prediction of Small and Large Capacity Single-Effect Vapor Absorption Refrigeration Systems. Cleaner Energy Systems 2022, 1, 100002. [CrossRef]

- Yin, C.; Li, S. Advancing Grate-Firing for Greater Environmental Impacts and Efficiency for Decentralized Biomass/Wastes Combustion. Energy Procedia 2017, 120, 373–379. [CrossRef]

- Saqib, N.; Bäckström, M. Distribution and Leaching Characteristics of Trace Elements in Ashes as a Function of Different Waste Fuels and Incineration Technologies. Journal of Environmental Sciences 2015, 36, 9–21. [CrossRef]

- Understanding the Carbon Impacts of Waste to Energy Incineration Available online: https://zerowasteeurope.eu/2020/03/understanding-the-carbon-impacts-of-waste-to-energy/ (accessed on 17 May 2023).

- Thunman, H.; Lind, F.; Breitholtz, C.; Berguerand, N.; Seemann, M. Using an Oxygen-Carrier as Bed Material for Combustion of Biomass in a 12-MWth Circulating Fluidized-Bed Boiler. Fuel 2013, 113, 300–309. [CrossRef]

- Campos-Alba, C.M.; Garrido-Rodríguez, J.C.; Plata-Díaz, A.M.; Pérez-López, G. The Selective Collection of Municipal Solid Waste and Other Factors Determining Cost Efficiency. An Analysis of Service Provision by Spanish Municipalities. Waste Management 2021, 134, 11–20. [CrossRef]

- Leckner, B. Fluidized Bed Combustion. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier, 2016; p. B9780124095472122000 ISBN 978-0-12-409547-2.

- Boskovic, G.; Jovicic, N.; Jovanovic, S.; Simovic, V. Calculating the Costs of Waste Collection: A Methodological Proposal. Waste Manag Res 2016, 34, 775–783. [CrossRef]

- Āriņa, D.; Kļavenieks, K.; Burlakovs, J. The Cost-Estimation of Mechanical Pre-Treatment Lines of Municipal Solid Waste in Latvia. Proceedings of the Latvia University of Agriculture 2014, 32, 17–28. [CrossRef]

- Short, W.; Packey, D.J.; Holt, T. A Manual for the Economic Evaluation of Energy Efficiency and Renewable Energy Technologies; National Renewable Energy Lab.(NREL), Golden, CO (United States), 1995;

| Central region | Eastern region | ||||||

|---|---|---|---|---|---|---|---|

| Components | LHV kJ/kg |

LHV kWh/kg |

% | LHV per Kg |

% | LHV per Kg |

Contents of the Components |

| Paper | 13484 | 3.75 | 28.5 | 1.03 | 16.03 | 0.60 | Wasted Papers, cardboard, box board, bags, magazines, tissue, newspapers, tissues |

| Plastic | 35000 | 9.72 | 5.2 | 0.60 | 5.8 | 0.56 | Disposable glass, spoons, plates, wrapping films, wrapping film, plastic bottle, polythene |

| Glass | 0 | 0.00 | 4.6 | 0.00 | 6.86 | 0.00 | Bottles, glassware, bulbs, ceramics etc. |

| Wood | 16979.8 | 4.72 | 8 | 0.38 | 9.63 | 0.45 | Bottles, glassware, bulbs, ceramics etc. |

| Textiles | 18840.6 | 5.23 | 6.4 | 0.39 | 5.77 | 0.30 | Cloths, diapers, etc. |

| Organics | 5582.4 | 1.55 | 37 | 0.56 | 37 | 0.57 | Food stuff, fruits and vegetable refuse, peel etc. |

| Others | 12095.2 | 3.36 | 10.3 | 0.35 | 18.91 | 0.64 | Leathers, rubber, fibers, rubber, yard waste, soils, tire, appliances, electronics |

| Total Energy content (kWh/kg) | 3.31 | 3.13 | |||||

| Total Energy content after recycling(kWh/kg) | 1.297 | 1.66 | |||||

| Options→ | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Output→ | Energy GWh | Water m3 | Water m3 | Cooling kW | Cooling kW | Energy GWh | Water m3 | Water m3 | Cooling kW | Cooling kW |

| Central region | 16 | 1452024 | 726012 | 292 | 146 | 21 | 1936033 | 968017 | 389 | 122 |

| Eastern region | 9 | 849557 | 424778 | 171 | 85 | 12 | 1132743 | 566372 | 228 | 114 |

| Evaluation Criterion (j) ↓ | Alternative MSW Incineration and Utilization Technologies (I) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | G | H | I | J | |

| C1 | 0.4339 | 0.2169 | 0.4339 | 0.1085 | 0.4339 | 0.3254 | 0.2169 | 0.3254 | 0.1085 |

| C2 | 0.3682 | 0.1841 | 0.3682 | 0.0921 | 0.3682 | 0.3682 | 0.3682 | 0.3682 | 0.0921 |

| C3 | 0.4472 | 0.2981 | 0.2981 | 0.2981 | 0.2981 | 0.5963 | 0.1491 | 0.1491 | 0.1491 |

| C4 | 0.3235 | 0.1078 | 0.4313 | 0.4313 | 0.1078 | 0.3235 | 0.1078 | 0.4313 | 0.1078 |

| C5 | 0.4743 | 0.4743 | 0.4743 | 0.3162 | 0.3162 | 0.1581 | 0.1581 | 0.1581 | 0.1581 |

| C6 | 0.2649 | 0.3974 | 0.3974 | 0.3974 | 0.3974 | 0.1325 | 0.2649 | 0.2649 | 0.2649 |

| C7 | 0.4243 | 0.4243 | 0.4243 | 0.4243 | 0.4243 | 0.1414 | 0.1414 | 0.1414 | 0.1414 |

| C8 | 0.2481 | 0.2481 | 0.2481 | 0.2481 | 0.2481 | 0.3721 | 0.3721 | 0.3721 | 0.3721 |

| C9 | 0.3721 | 0.3721 | 0.3721 | 0.3721 | 0.3721 | 0.2481 | 0.2481 | 0.2481 | 0.2481 |

| C10 | 0.2481 | 0.2481 | 0.2481 | 0.2481 | 0.2481 | 0.3721 | 0.3721 | 0.3721 | 0.3721 |

| C11 | 0.1227 | 0.4308 | 0.2154 | 0.3040 | 0.1520 | 0.1596 | 0.5731 | 0.2866 | 0.4013 |

| C12 | 0.4467 | 0.4467 | 0.4467 | 0.4467 | 0.4467 | 0.0213 | 0.0213 | 0.0213 | 0.0213 |

| C13 | 0.3097 | 0.3097 | 0.3097 | 0.3097 | 0.3097 | 0.3226 | 0.3226 | 0.3226 | 0.3226 |

| C14 | 0.4152 | 0.4152 | 0.4152 | 0.4152 | 0.4152 | 0.1661 | 0.1661 | 0.1661 | 0.1661 |

| C15 | 0.4000 | 0.4000 | 0.4000 | 0.4000 | 0.4000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 |

| C16 | 0.3586 | 0.3586 | 0.3586 | 0.4781 | 0.4781 | 0.1195 | 0.1195 | 0.1195 | 0.2390 |

| C17 | 0.3324 | 0.3324 | 0.3324 | 0.3324 | 0.3324 | 0.2992 | 0.2992 | 0.2992 | 0.2992 |

| C18 | 0.3162 | 0.3162 | 0.3162 | 0.3162 | 0.3162 | 0.3162 | 0.3162 | 0.3162 | 0.3162 |

| C19 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.4000 | 0.4000 | 0.4000 | 0.4000 |

| C20 | 0.2697 | 0.3034 | 0.3034 | 0.3203 | 0.3034 | 0.2866 | 0.3371 | 0.3371 | 0.3540 |

| Option → | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Meeting Fuel supply requirement | ||||||||||

| Heating value requirement ranking (min) | 4 | 2 | 4 | 1 | 4 | 3 | 2 | 3 | 1 | 3 |

| Fuel drying requirement, % (max) | 4 | 2 | 4 | 1 | 4 | 4 | 4 | 4 | 1 | 4 |

| Fuel handling requirement (max) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Storage problems ranking (max) | 3 | 1 | 4 | 4 | 1 | 3 | 1 | 4 | 1 | 4 |

| Incinerator performance | ||||||||||

| Capacity flexibility ranking (min) |

3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

| Conversion efficiency ranking (max) | 2 | 3 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | 2 |

| Co-firing adaptability ranking (min) | 3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 |

| Operation and Maintenance requirement ranking (min) | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| End Use Performance | ||||||||||

| Energy efficiency ranking (min) | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 |

| Exergy Efficiency ranking (min) | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| % of existing usage (max) | 3.22 | 11.33 | 5.66 | 8 | 4 | 4.2 | 15.08 | 7.54 | 10.56 | 5.28 |

| Emission factors | ||||||||||

| Bottom Ash/Fly ash ratio (max) | 90/10 | 90/10 | 90/10 | 90/10 | 90/10 | 30/70 | 30/70 | 30/70 | 30/70 | 30/70 |

| emissions (CO2) kg/kg (min) | 480 | 480 | 480 | 480 | 480 | 500 | 500 | 500 | 500 | 500 |

| emissions (CO) mg/m3 (min) | 20 | 20 | 20 | 20 | 20 | 8 | 8 | 8 | 8 | 8 |

| NOX formation mg/m3 (min) | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 |

| Leachates problems ranking (min) |

3 | 3 | 3 | 4 | 4 | 1 | 1 | 1 | 2 | 2 |

| Economic factors | ||||||||||

| Investment cost of incinerator USD per ton (min) |

83.4 | 83.4 | 83.4 | 83.4 | 83.4 | 75.06 | 75.06 | 75.06 | 75.06 | 75.06 |

| Waste Collection cost USD per ton (min) |

14.02 | 14.02 | 14.02 | 14.02 | 14.02 | 14.02 | 14.02 | 14.02 | 14.02 | 14.02 |

| Fuel preparation cost (USD per ton) (min) |

7.92 | 7.92 | 7.92 | 7.92 | 7.92 | 15.87 | 15.87 | 15.87 | 15.87 | 15.87 |

| Levelized cost of Energy (USD)(min) | 0.14 | 0.15 | 0.15 | 0.16 | 0.15 | 0.13 | 0.14 | 0.14 | 0.15 | 0.14 |

| Option → | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Meeting Fuel supply requirement | ||||||||||

| Heating value requirement ranking (min) | 4 | 2 | 4 | 1 | 4 | 3 | 2 | 3 | 1 | 3 |

| Fuel drying requirement, % (max) | 4 | 2 | 4 | 1 | 4 | 4 | 4 | 4 | 1 | 4 |

| Fuel handling requirement (max) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Storage problems ranking (max) | 3 | 1 | 4 | 4 | 1 | 3 | 1 | 4 | 1 | 4 |

| Incinerator performance | ||||||||||

| Capacity flexibility ranking (min) |

3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

| Conversion efficiency ranking (max) | 2 | 3 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | 2 |

| Co-firing adaptability ranking (min) | 3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 |

| Operation and Maintenance requirement ranking (min) | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| End Use Performance | ||||||||||

| Energy efficiency ranking (min) | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 |

| Exergy Efficiency ranking (min) | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| % of existing usage (max) | 3.07 | 10.77 | 5.38 | 7.60 | 3.80 | 3.99 | 14.33 | 7.16 | 10.03 | 5.02 |

| Emission factors | ||||||||||

| Bottom Ash/Fly ash ratio (max) |

90/10 | 90/10 | 90/10 | 90/10 | 90/10 | 30/70 | 30/70 | 30/70 | 30/70 | 30/70 |

| emissions (CO2) kg/kg (min) |

456 | 456 | 456 | 456 | 456 | 475 | 475 | 475 | 475 | 475 |

| emissions (CO) mg/m3 (min) | 19 | 19 | 19 | 19 | 19 | 7.6 | 7.6 | 7.6 | 7.6 | 7.6 |

| NOX formation mg/m3 (min) | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 |

| Leachates problems ranking (min) |

3 | 3 | 3 | 4 | 4 | 1 | 1 | 1 | 2 | 2 |

| Economic factors | ||||||||||

| Investment cost of incinerator USD per ton (min) |

79.2 | 79.2 | 79.2 | 79.2 | 79.2 | 71.3 | 71.3 | 71.3 | 71.3 | 71.3 |

| Waste Collection cost USD per ton (min) |

13.32 | 13.32 | 13.32 | 13.32 | 13.32 | 13.32 | 13.32 | 13.32 | 13.32 | 13.32 |

| Fuel preparation cost (USD per ton) (min) |

7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 15.1 | 15.1 | 15.1 | 15.1 | 15.1 |

| Levelized cost of Energy (USD)(min) | 0.13 | 0.14 | 0.14 | 0.15 | 0.14 | 0.12 | 0.13 | 0.13 | 0.14 | 0.13 |

| Evaluation Criterion (j) ↓ | V+ | MSW Incineration and Utilization Technology | V- | MSW Incineration and Utilization Technology |

|---|---|---|---|---|

| C1 | 0.0023 | D/I | 0.0093 | A/C/E |

| C2 | 0.0040 | I | 0.0159 | A/C/E/F/G/H/J |

| C3 | 0.0119 | F | 0.0030 | G/H/I/J |

| C4 | 0.0168 | C/D/H/J | 0.0042 | B/G/I |

| C5 | 0.0058 | FGHIJ | 0.0173 | AB |

| C6 | 0.0080 | BCD | 0.0027 | F |

| C7 | 0.0067 | FGHIJ | 0.0202 | ABCDE |

| C8 | 0.0118 | ABCDE | 0.0177 | FGHIJ |

| C9 | 0.0118 | FGHIJ | 0.0177 | ABCDE |

| C10 | 0.0118 | ABCDE | 0.0177 | FGHIJ |

| C11 | 0.0063 | G | 0.0013 | A |

| C12 | 0.0212 | ABCDE | 0.0010 | FGHIJ |

| C13 | 0.0147 | ABCDE | 0.0153 | FGHIJ |

| C14 | 0.0079 | FGHIJ | 0.0197 | ABCDE |

| C15 | 0.0095 | FGHIJ | 0.0190 | ABCDE |

| C16 | 0.0026 | FGH | 0.0103 | DE |

| C17 | 0.0142 | FGHIJ | 0.0158 | ABCDE |

| C18 | 0.0150 | ABCDEFGHIJ | 0.0150 | ABCDEFGHIJ |

| C19 | 0.0095 | ABCDE | 0.0190 | FGHIJ |

| C20 | 0.0714 | A | 0.0938 | I |

| Central Region (Not Recycled) | Central Region (Not Recycled) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MSW Incineration and Utilization Technologies (i) ↓ | Scenario 1: Entropy Weights | |||||||||

| Di+ (Distance from the Best Ideal) | Di- (Distance from the Worst Ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0293 | 0.0262 | 0.4725 | 5 | ||||||

| B | 0.0301 | 0.0298 | 0.4976 | 4 | ||||||

| C | 0.0305 | 0.0308 | 0.5028 | 3 | ||||||

| D | 0.0276 | 0.0327 | 0.5422 | 1 | ||||||

| E | 0.0321 | 0.0286 | 0.4716 | 6 | ||||||

| F | 0.0286 | 0.0334 | 0.5386 | 2 | ||||||

| G | 0.0358 | 0.0267 | 0.4275 | 10 | ||||||

| H | 0.0339 | 0.0289 | 0.4603 | 7 | ||||||

| I | 0.0364 | 0.0286 | 0.4399 | 9 | ||||||

| J | 0.0341 | 0.0283 | 0.4534 | 8 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 1: Experts Weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0410 | 0.0342 | 0.4547 | 8 | ||||||

| B | 0.0365 | 0.0371 | 0.5044 | 4 | ||||||

| C | 0.0402 | 0.0356 | 0.4696 | 7 | ||||||

| D | 0.0365 | 0.0402 | 0.5239 | 1 | ||||||

| E | 0.0449 | 0.0326 | 0.4210 | 10 | ||||||

| F | 0.0388 | 0.0406 | 0.5109 | 2 | ||||||

| G | 0.0398 | 0.0405 | 0.5047 | 3 | ||||||

| H | 0.0401 | 0.0382 | 0.4879 | 6 | ||||||

| I | 0.0393 | 0.0375 | 0.4883 | 5 | ||||||

| J | 0.0419 | 0.0341 | 0.4488 | 9 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 1: Equal weights to all | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0445 | 0.0324 | 0.4211 | 9 | ||||||

| B | 0.0384 | 0.0366 | 0.4881 | 5 | ||||||

| C | 0.0435 | 0.0344 | 0.4420 | 8 | ||||||

| D | 0.0359 | 0.0415 | 0.5363 | 1 | ||||||

| E | 0.0476 | 0.0305 | 0.3907 | 10 | ||||||

| F | 0.0396 | 0.0416 | 0.5119 | 2 | ||||||

| G | 0.0408 | 0.0417 | 0.5052 | 3 | ||||||

| H | 0.0412 | 0.0383 | 0.4820 | 6 | ||||||

| I | 0.0395 | 0.0398 | 0.5016 | 4 | ||||||

| J | 0.0433 | 0.0352 | 0.4485 | 7 | ||||||

| Eastern Region (Not Recycled) | Eastern Region (Not Recycled) | |||||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 2: Entropy weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0289 | 0.0262 | 0.4748 | 6 | ||||||

| B | 0.0303 | 0.0296 | 0.4942 | 4 | ||||||

| C | 0.0306 | 0.0308 | 0.5020 | 3 | ||||||

| D | 0.0272 | 0.0327 | 0.5456 | 1 | ||||||

| E | 0.0313 | 0.0287 | 0.4782 | 5 | ||||||

| F | 0.0296 | 0.0310 | 0.5115 | 2 | ||||||

| G | 0.0361 | 0.0257 | 0.4159 | 10 | ||||||

| H | 0.0341 | 0.0281 | 0.4520 | 8 | ||||||

| I | 0.0367 | 0.0282 | 0.4346 | 9 | ||||||

| J | 0.0340 | 0.0283 | 0.4541 | 7 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 2: Experts Weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0388 | 0.0336 | 0.4641 | 6 | ||||||

| B | 0.0350 | 0.0364 | 0.5100 | 2 | ||||||

| C | 0.0392 | 0.0347 | 0.4692 | 5 | ||||||

| D | 0.0311 | 0.0404 | 0.5649 | 1 | ||||||

| E | 0.0395 | 0.0328 | 0.4536 | 8 | ||||||

| F | 0.0388 | 0.0357 | 0.4789 | 3 | ||||||

| G | 0.0400 | 0.0346 | 0.4636 | 7 | ||||||

| H | 0.0404 | 0.0316 | 0.4389 | 10 | ||||||

| I | 0.0388 | 0.0351 | 0.4747 | 4 | ||||||

| J | 0.0407 | 0.0322 | 0.4412 | 9 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 2: Equal weights to all | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0436 | 0.0320 | 0.4230 | 9 | ||||||

| B | 0.0387 | 0.0360 | 0.4821 | 4 | ||||||

| C | 0.0441 | 0.0334 | 0.4313 | 8 | ||||||

| D | 0.0335 | 0.0417 | 0.5542 | 1 | ||||||

| E | 0.0444 | 0.0306 | 0.4077 | 10 | ||||||

| F | 0.0395 | 0.0395 | 0.5002 | 2 | ||||||

| G | 0.0410 | 0.0382 | 0.4820 | 5 | ||||||

| H | 0.0416 | 0.0343 | 0.4520 | 7 | ||||||

| I | 0.0392 | 0.0388 | 0.4972 | 3 | ||||||

| J | 0.0421 | 0.0350 | 0.4545 | 6 | ||||||

| Central Region (Recycled) | Central Region (Recycled) | |||||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 3: Entropy weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0287 | 0.0246 | 0.4618 | 9 | ||||||

| B | 0.0293 | 0.0261 | 0.4710 | 8 | ||||||

| C | 0.0297 | 0.0273 | 0.4782 | 7 | ||||||

| D | 0.0280 | 0.0304 | 0.5200 | 3 | ||||||

| E | 0.0313 | 0.0248 | 0.4425 | 10 | ||||||

| F | 0.0273 | 0.0308 | 0.5296 | 1 | ||||||

| G | 0.0293 | 0.0277 | 0.4866 | 6 | ||||||

| H | 0.0270 | 0.0297 | 0.5240 | 2 | ||||||

| I | 0.0286 | 0.0282 | 0.4961 | 5 | ||||||

| J | 0.0273 | 0.0292 | 0.5170 | 4 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 3: Experts Weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0404 | 0.0316 | 0.4392 | 9 | ||||||

| B | 0.0341 | 0.0363 | 0.5156 | 5 | ||||||

| C | 0.0381 | 0.0348 | 0.4771 | 8 | ||||||

| D | 0.0343 | 0.0395 | 0.5357 | 2 | ||||||

| E | 0.0430 | 0.0317 | 0.4246 | 10 | ||||||

| F | 0.0387 | 0.0358 | 0.4809 | 6 | ||||||

| G | 0.0347 | 0.0405 | 0.5381 | 1 | ||||||

| H | 0.0351 | 0.0381 | 0.5207 | 4 | ||||||

| I | 0.0341 | 0.0373 | 0.5227 | 3 | ||||||

| J | 0.0371 | 0.0340 | 0.4781 | 7 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 3: Equal weights to all | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0437 | 0.0284 | 0.3941 | 9 | ||||||

| B | 0.0352 | 0.0356 | 0.5025 | 5 | ||||||

| C | 0.0406 | 0.0333 | 0.4502 | 8 | ||||||

| D | 0.0325 | 0.0406 | 0.5558 | 1 | ||||||

| E | 0.0450 | 0.0292 | 0.3935 | 10 | ||||||

| F | 0.0394 | 0.0348 | 0.4688 | 7 | ||||||

| G | 0.0337 | 0.0415 | 0.5517 | 3 | ||||||

| H | 0.0342 | 0.0382 | 0.5273 | 4 | ||||||

| I | 0.0321 | 0.0396 | 0.5520 | 2 | ||||||

| J | 0.0367 | 0.0350 | 0.4881 | 6 | ||||||

| Eastern Region (Recycled) | Eastern Region (Recycled) | |||||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 4: Entropy weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0288 | 0.0247 | 0.4614 | 9 | ||||||

| B | 0.0297 | 0.0263 | 0.4696 | 8 | ||||||

| C | 0.0301 | 0.0274 | 0.4767 | 7 | ||||||

| D | 0.0288 | 0.0305 | 0.5144 | 4 | ||||||

| E | 0.0316 | 0.0250 | 0.4415 | 10 | ||||||

| F | 0.0274 | 0.0314 | 0.5342 | 1 | ||||||

| G | 0.0294 | 0.0281 | 0.4886 | 6 | ||||||

| H | 0.0272 | 0.0301 | 0.5254 | 2 | ||||||

| I | 0.0290 | 0.0283 | 0.4941 | 5 | ||||||

| J | 0.0274 | 0.0295 | 0.5185 | 3 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 4: Experts Weights | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0404 | 0.0317 | 0.4394 | 9 | ||||||

| B | 0.0342 | 0.0364 | 0.5156 | 5 | ||||||

| C | 0.0382 | 0.0348 | 0.4772 | 8 | ||||||

| D | 0.0343 | 0.0395 | 0.5356 | 2 | ||||||

| E | 0.0430 | 0.0318 | 0.4247 | 10 | ||||||

| F | 0.0387 | 0.0358 | 0.4809 | 6 | ||||||

| G | 0.0348 | 0.0405 | 0.5379 | 1 | ||||||

| H | 0.0351 | 0.0381 | 0.5206 | 4 | ||||||

| I | 0.0341 | 0.0373 | 0.5224 | 3 | ||||||

| J | 0.0372 | 0.0340 | 0.4780 | 7 | ||||||

| MSW incineration and utilization technologies (i) ↓ | Scenario 4: Equal weights to all | |||||||||

| Di+ (distance from the best ideal) | Di- (distance from the worst ideal) | Di- /(Di++ Di-) | Rank Ci | |||||||

| A | 0.0437 | 0.0284 | 0.3943 | 9 | ||||||

| B | 0.0352 | 0.0356 | 0.5026 | 5 | ||||||

| C | 0.0406 | 0.0333 | 0.4503 | 8 | ||||||

| D | 0.0325 | 0.0406 | 0.5556 | 1 | ||||||

| E | 0.0450 | 0.0292 | 0.3936 | 10 | ||||||

| F | 0.0394 | 0.0348 | 0.4689 | 7 | ||||||

| G | 0.0338 | 0.0415 | 0.5515 | 3 | ||||||

| H | 0.0342 | 0.0382 | 0.5271 | 4 | ||||||

| I | 0.0321 | 0.0396 | 0.5517 | 2 | ||||||

| J | 0.0367 | 0.0350 | 0.4881 | 6 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).