Submitted:

15 May 2023

Posted:

16 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

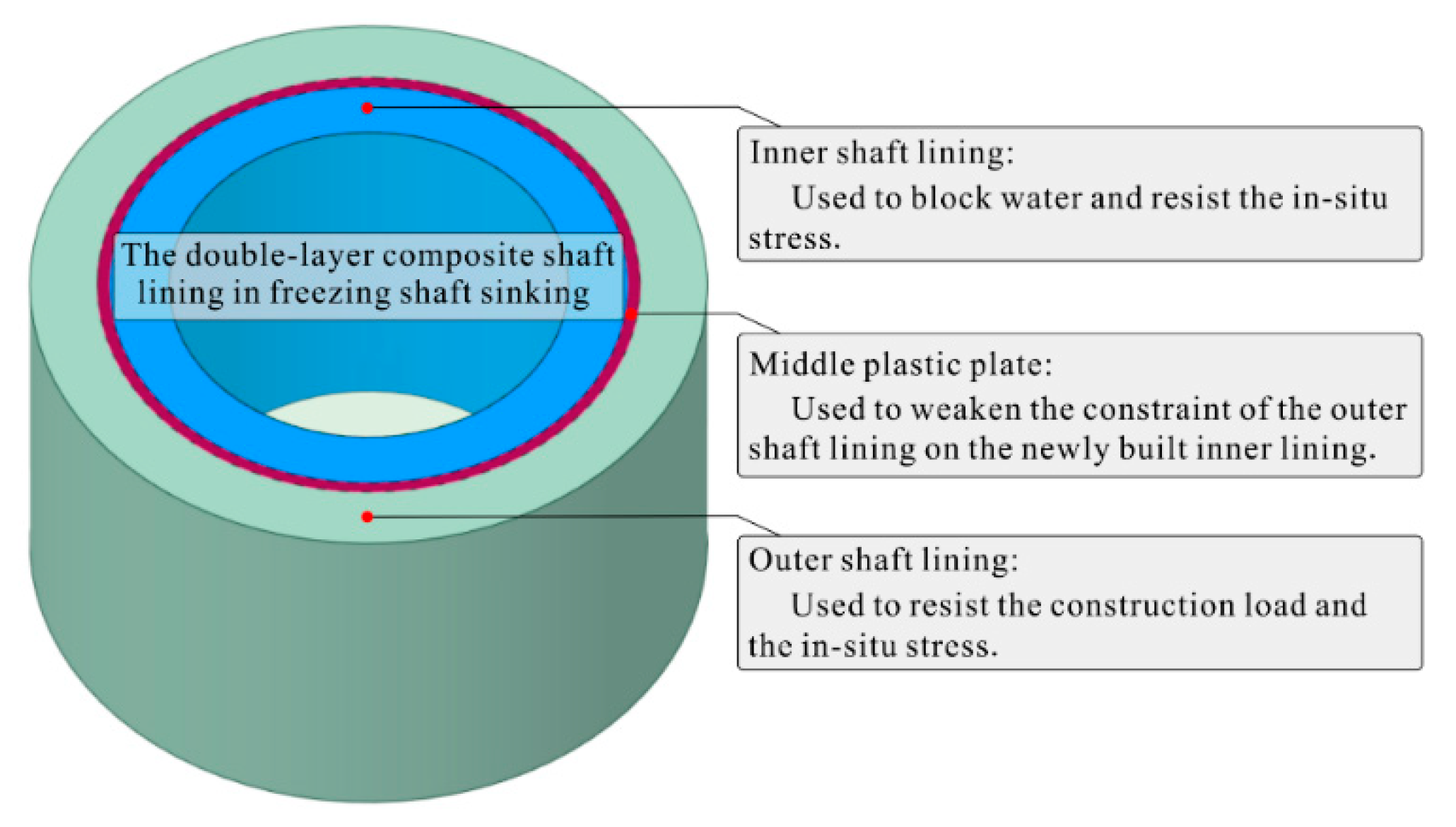

2. Test methodology

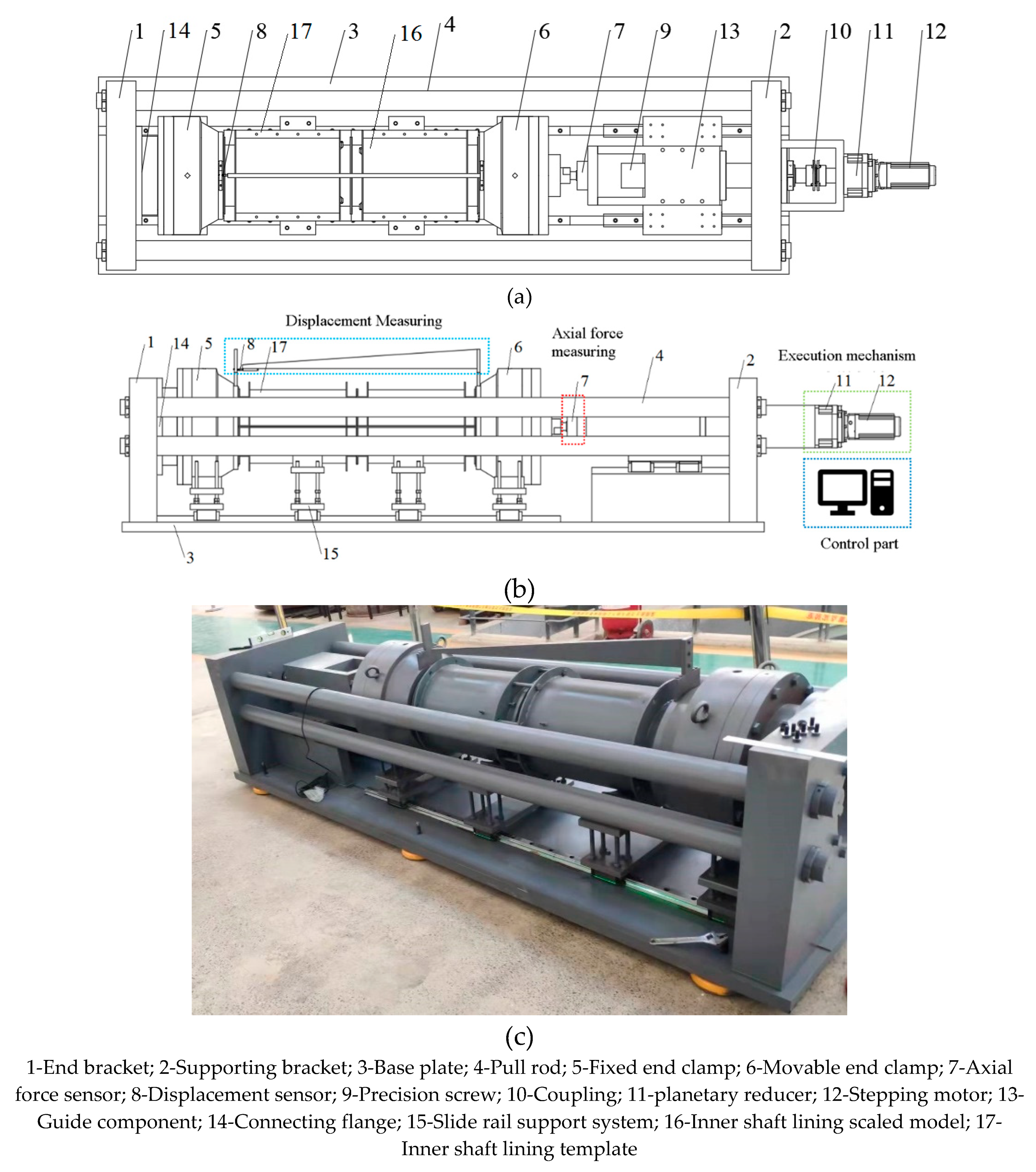

2.1. Development of the testing machine

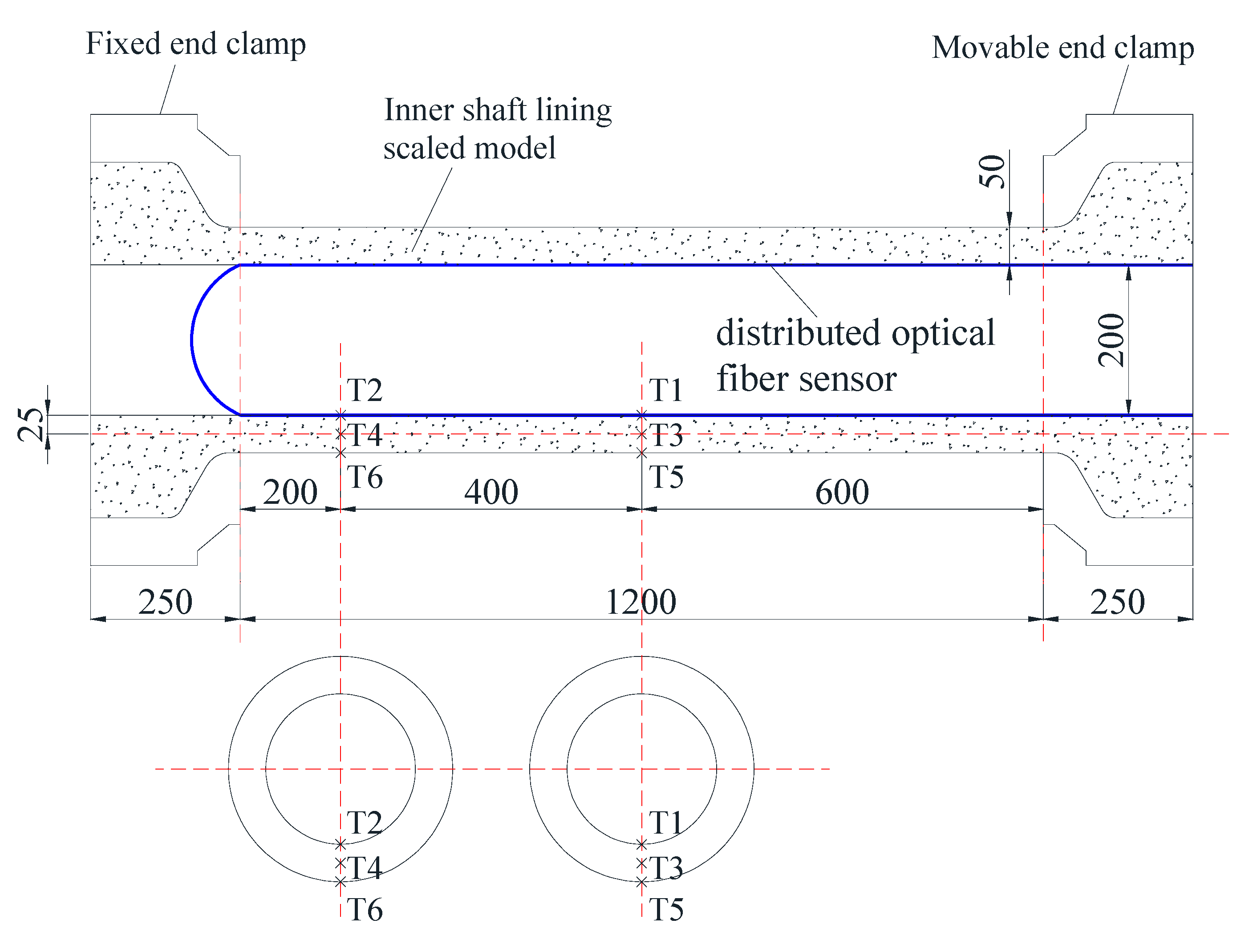

2.2. Temperature field measurement method of the simulated inner wall

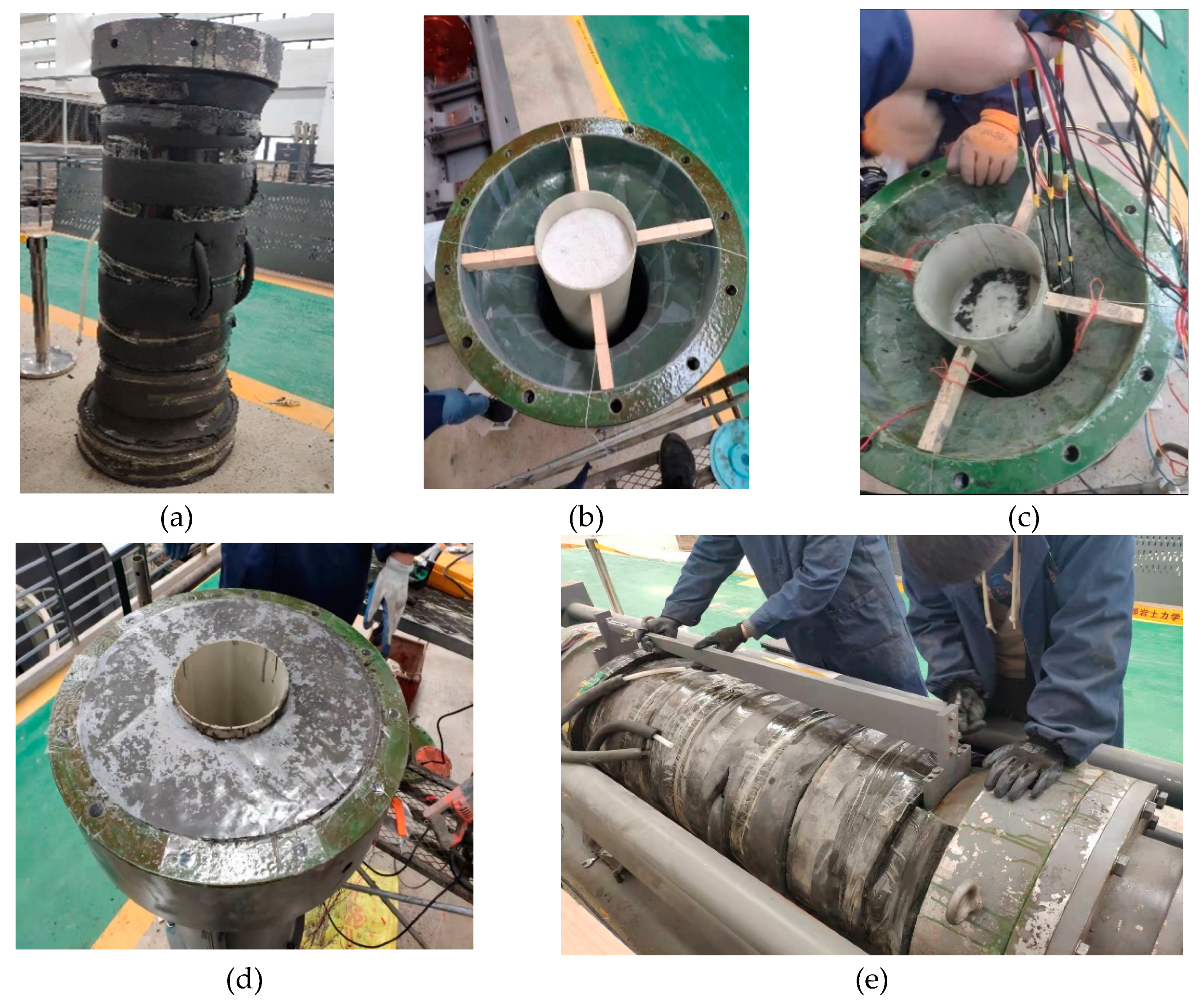

2.3. Testing procedure

2.4. Sensor layout

3. Results

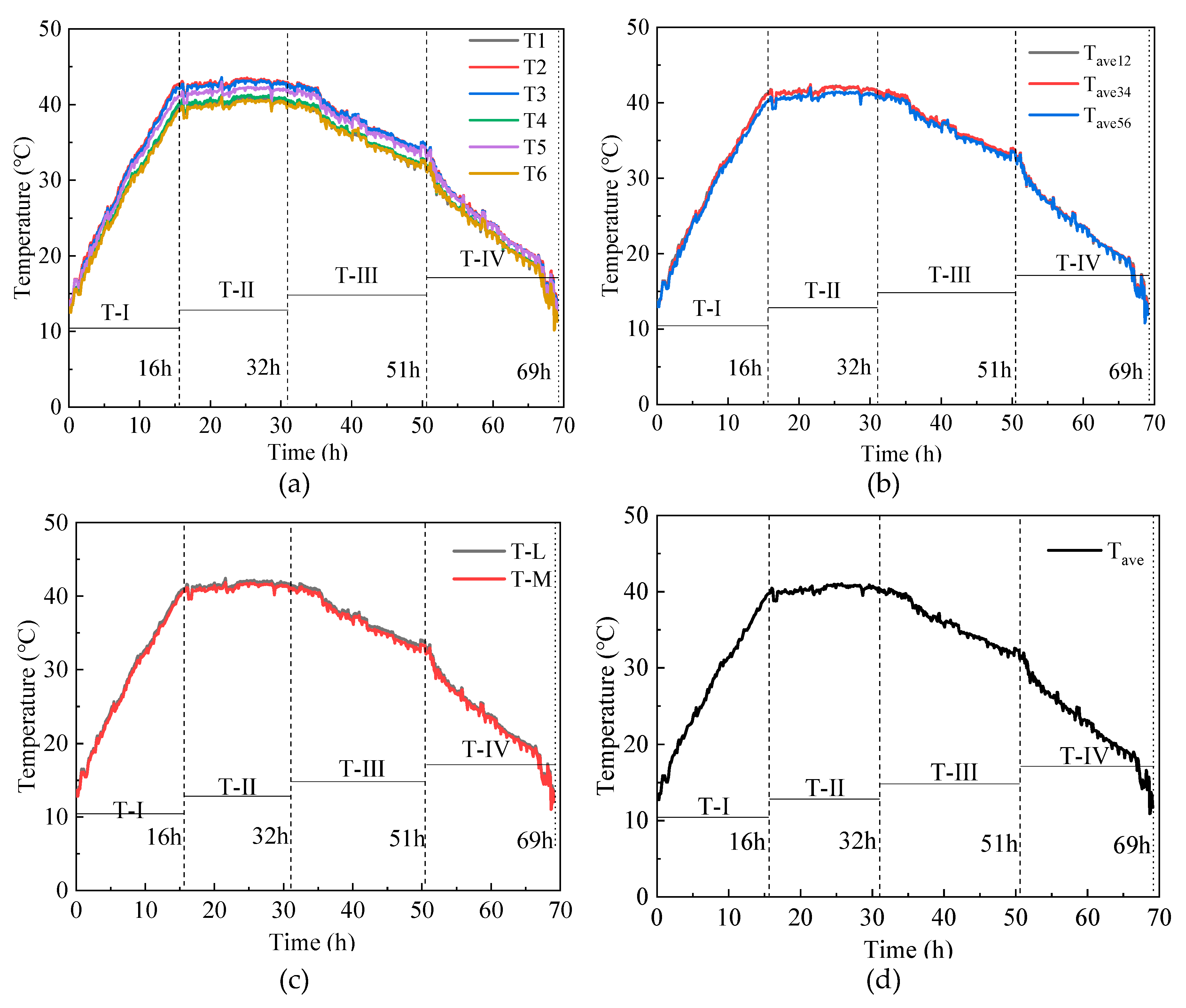

3.1. Temperature field of the inner shaft lining scaled model

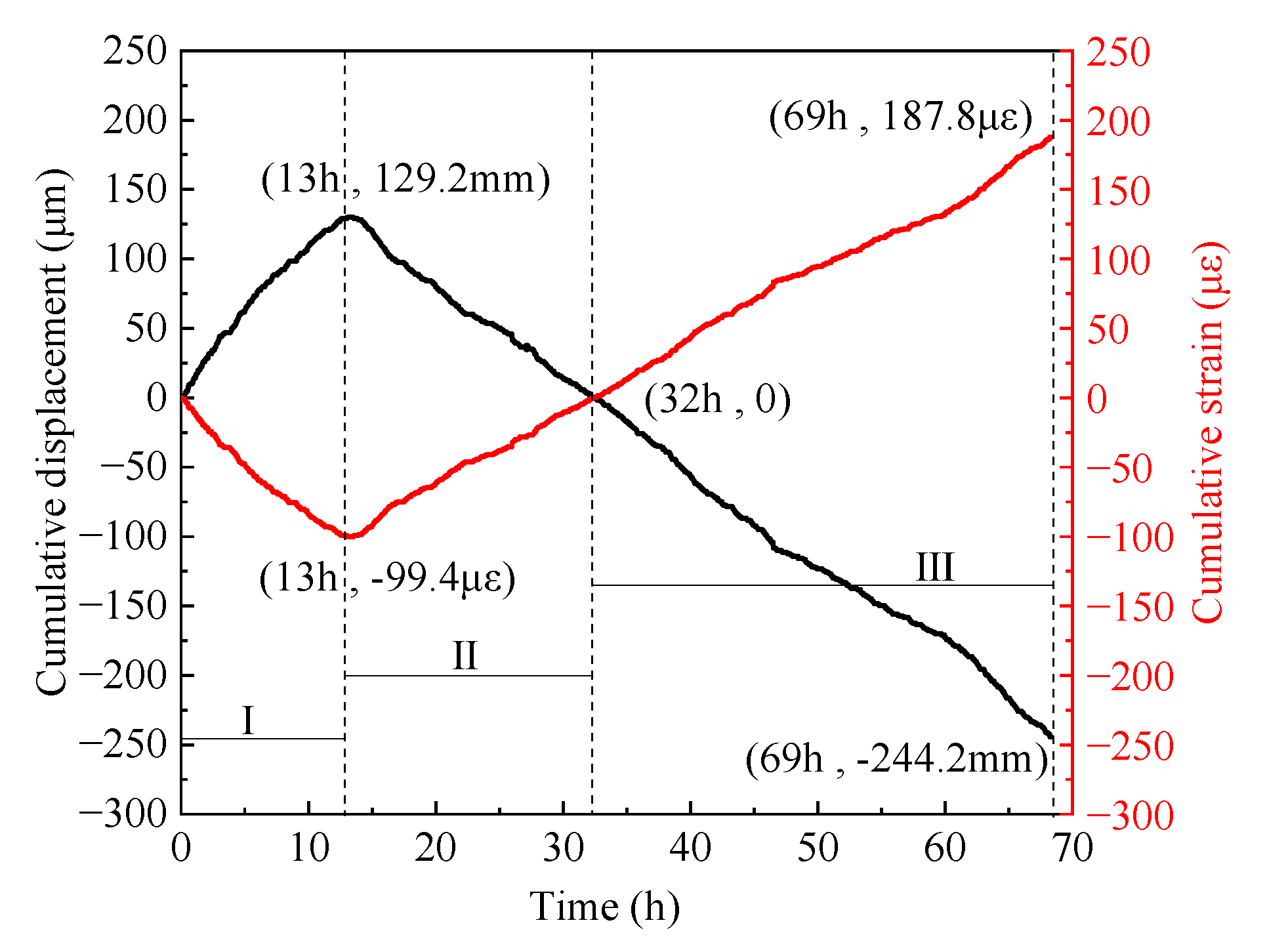

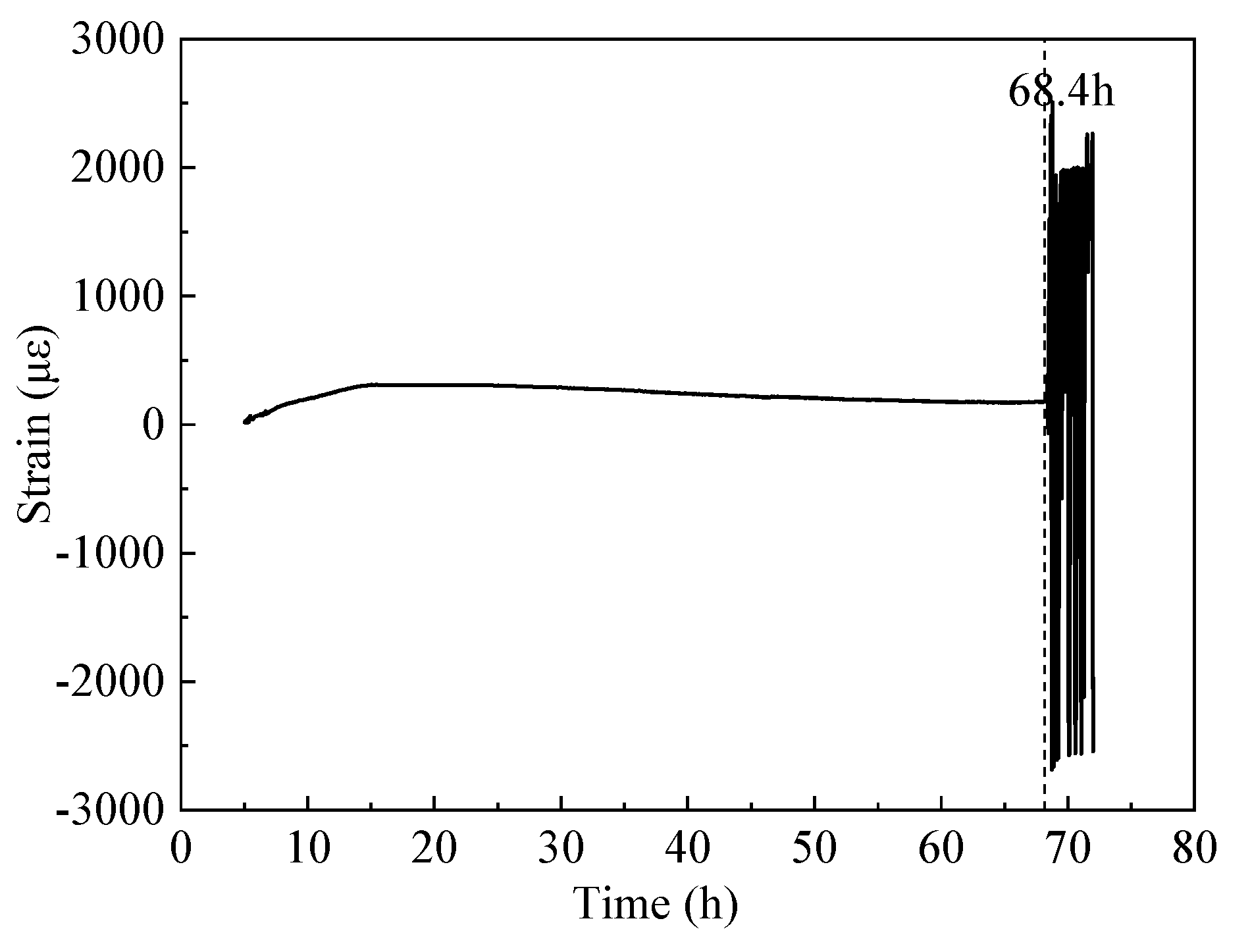

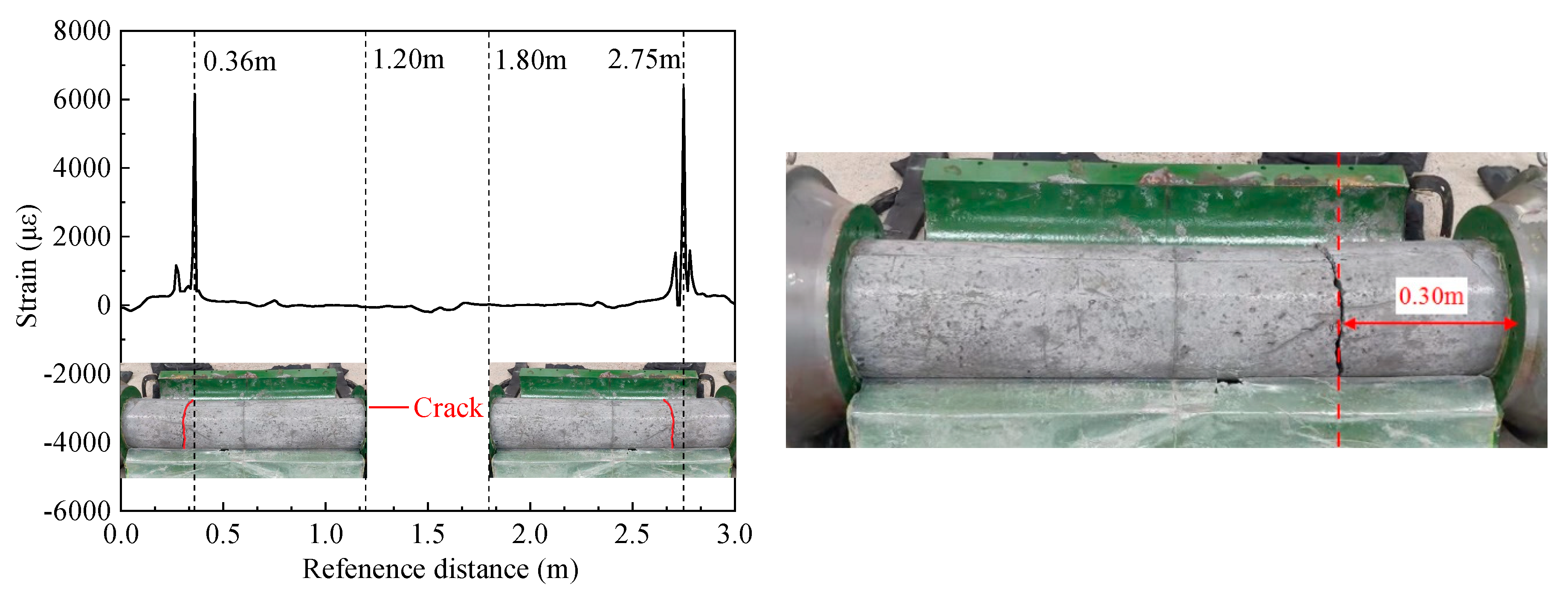

3.2. Cumulative strain

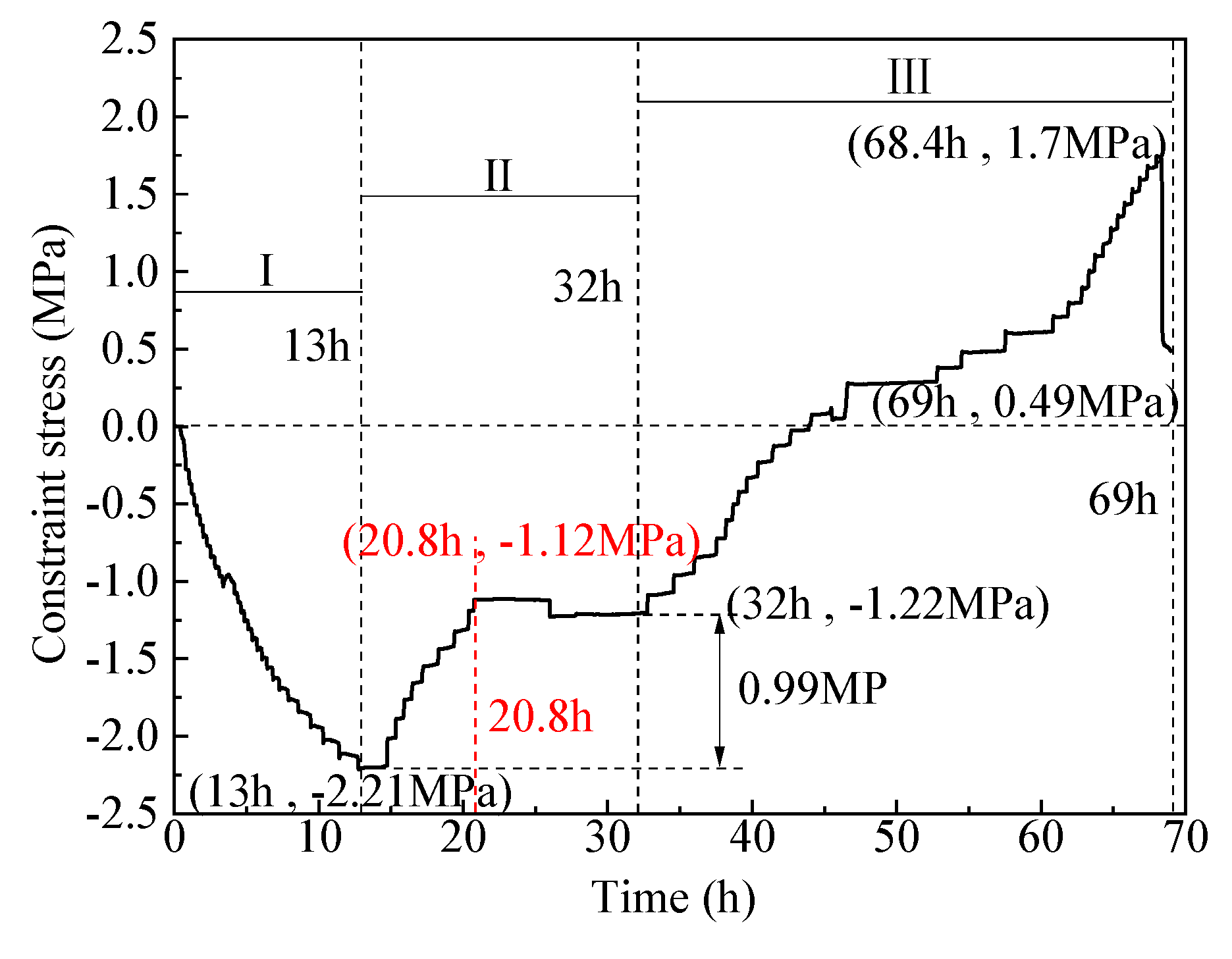

3.3. Constraint stress

4. Conclusion

References

- He, M. Research progress of deep shaft construction mechanics. Meitan Xuebao/Journal China Coal Soc. 2021, 46, 726–746. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, C.; Song, F.; Zou, J.; Gao, Y.; Yang, W. Breakage behavior of silica sands during high-pressure triaxial loading using X-ray microtomography. Acta Geotech. 2023. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, C.; Luo, T. Effect of stress anisotropy on deformation and particle breakage of silica sand at high-pressure compression tests. Constr. Build. Mater. 2022, 316, 125835. [Google Scholar] [CrossRef]

- Deng, W.; Shen, J.; Qiao, G. Some problems in the construction of coal mines in western China. Min. Eng. 2010, 31, 29–33. [Google Scholar] [CrossRef]

- Yang, W. Development and prospect of freeze drilling technology in China over the past ten years. Proc. High-Level Acad. Forum 50th Anniv. China Coal Soc. 2012, 1–7.

- Cheng, H.; Cai, H. Safety Situation and Thinking about Deep Shaft Construction with Freezing Method in China. J. Anhui Univ. Sci. Technol. Nat. Sci. 2013, 33, 1–6. [Google Scholar]

- GB-50384-2016. Design specification for coal mine shafts and chambers; Ministry of Housing and Urban-Rural Development of the People’s Republic of China.

- Zhou, Y.; Zhou, G.Q. Axisymmetric deformation analysis for the double layer shaft with a plastic interlayer. Meitan Xuebao/Journal China Coal Soc. 2010, 35, 1470–1475. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, C.; Zou, J. Interface shear behavior of a shaft lining concrete-high density polyethylene material under different pre-imposed normal stresses. PLoS One 2022, 17, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhou, G.; Shang, X.; Hu, K.; Li, T. Optimization calculation of double-layer shaft lining considering vertical additional force and temperature stress. J. Xi’an Univ. Archit. Technol. 2010, 42, 283–287. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, W.; Chen, G.; Huang, J.; Han, T.; Zhang, C. Monitoring and analysis of hydration heat temperature field for high performance mass concrete freezing shaft lining. Caikuang yu Anquan Gongcheng Xuebao/Journal Min. Saf. Eng. 2016, 33, 290–296. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Nguyen, V.T.; Lura, P.; Dao, V.T.N. Temperature-stress testing machine - A state-of-the-art design and its unique applications in concrete research. Cem. Concr. Compos. 2019, 102, 28–38. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, H.; Fang, B.; Sun, Y.; Zhong, Y.; Shi, T. Tensile creep model of slab concrete based on microprestress-solidification theory. Materials (Basel). 2020, 13. [Google Scholar] [CrossRef] [PubMed]

- Kheir, J.; Klausen, A.; Hammer, T.A.; De Meyst, L.; Hilloulin, B.; Van Tittelboom, K.; Loukili, A.; De Belie, N. Early age autogenous shrinkage cracking risk of an ultra-high performance concrete (UHPC) wall: Modelling and experimental results. Eng. Fract. Mech. 2021, 257, 108024. [Google Scholar] [CrossRef]

- Estensen, A.; Terje, K.; Øyvind, K.; Sellevold, E.J. The effect of realistic curing temperature on the strength and E-modulus of concrete. Mater. Struct. 2018, 51, 1–14. [Google Scholar] [CrossRef]

- Riding, K.A.; Poole, J.L.; Schindler, A.K.; Juenger, M.C.G.; Folliard, K.J. Quantification of effects of fly ash type on concrete early-age cracking. ACI Mater. J. 2008, 105, 149–155. [Google Scholar] [CrossRef]

- Kovler, K. Testing system for determining the mechanical behaviour of early age concrete under restrained and free uniaxial shrinkage. Mater. Struct. 1994, 27, 324–330. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Kang, J.; Yang, Q.; Li, M.; Li, C.; Zeng, X. Early-age autogenous shrinkage and tensile creep of hooked-end steel fiber reinforced concrete with different thermal treatment temperatures. Cem. Concr. Compos. 2022, 131, 104550. [Google Scholar] [CrossRef]

- Abdi Moghadam, M.; Izadifard, R.A. Prediction of the tensile strength of normal and steel fiber reinforced concrete exposed to high temperatures. Int. J. Concr. Struct. Mater. 2021, 15. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, C.; Pan, S.Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Li, L.; Dao, V.; Lura, P. Autogenous deformation and coefficient of thermal expansion of early-age concrete: Initial outcomes of a study using a newly-developed Temperature Stress Testing Machine. Cem. Concr. Compos. 2021, 119, 103997. [Google Scholar] [CrossRef]

- Yin, J. Thermo-physical and mechanical properties of the similar material of inner shaft lining concrete during construction period, China University of Mining and Technology, 2020.

| Type | Geometric scale ratio |

Net diameter of inner wall (mm) |

Thickness of inner wall (mm) | Thickness of plastic plate (mm) | Height of inner wall (mm) |

|---|---|---|---|---|---|

| Engineering prototype | 1 | 8000 | 2000 | 3 | — |

| Similar model | 40 | 200 | 50 | 0.075 | 1200 |

| Water (kg) | Cement (kg) | Iron slag (kg) | Fine aggregate (kg) | Coarse aggregate (kg) | Water reducer (kg) |

|---|---|---|---|---|---|

| 189 | 359 | 251 | 527 | 1173 | 1.22 |

| Time/h | T1 /℃ |

T2 /℃ |

T3 /℃ |

T4 /℃ |

T5 /℃ |

T6 /℃ |

Tave-12 /℃ |

Tave-34 /℃ |

Tave-56 /℃ |

T-L /℃ |

T-M /℃ |

Tave /℃ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 12.7 | 13.3 | 13.2 | 12.7 | 13.4 | 12.5 | 13.0 | 13.0 | 13.0 | 12.8 | 13.1 | 13.0 |

| 16 | 40.5 | 43.1 | 42.7 | 40.7 | 41.7 | 39.8 | 41.8 | 41.7 | 40.8 | 41.2 | 41.6 | 41.4 |

| 32 | 39.8 | 42.4 | 42.3 | 40.2 | 41.4 | 39.6 | 41.1 | 41.2 | 40.5 | 40.7 | 41.2 | 40.9 |

| 51 | 31.3 | 33.8 | 33.7 | 31.6 | 33.3 | 31.5 | 32.5 | 32.7 | 32.4 | 32.3 | 32.8 | 32.5 |

| 69 | 13.1 | 14.5 | 14.3 | 13.1 | 13.9 | 12.6 | 13.8 | 13.7 | 13.3 | 13.4 | 13.7 | 13.6 |

| Note: Tave12 = (T1+T2) / 2; Tave-4 = (T3+T4) / 2; Tave56 = (T5+T6) / 2; T-L = (T2+T4+T6) / 3; T-M = (T1+T3+T5) / 3; Tave = (T1+T2+T3+T4+T5+T6) / 6 | ||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).