1. Introduction

Waste cooking oil (WCO) is a food waste generated domestically and industrially as a result of cooking and frying food using edible vegetable oil [

1,

2].

WCOs primarily consist of triglycerides, monoglycerides, diglycerides, and free fatty acids, with varying amounts typically ranging from 5 to 20% by weight. These components are generated during the frying process [

3]. The physicochemical properties of WCO largely rely on the cooking process. When cooking oil is repeatedly used, it tends to exhibit higher viscosity and darken in color. These changes indicate an increase in acidity and contribute to an unpleasant odor in the WCO [

4].

The current global production of WCO is approximately 15 million tons per year [

5]. This amount corresponds to 20-32% of the total consumption of edible oil [

1,

6]. When considering European countries, around one million tons of WCO is generated each year[

3]. Over 60% of this amount is improperly disposed of, and in some countries, the disposal may even be illegal [

7].

The uncontrolled disposal of WCO results in negative environmental impacts and economic loss [

8]. When WCO is disposed of into the sewer system, it creates blockages that impede the flow of sewage to wastewater treatment plants [

4]. Moreover, this improper disposal leads to other several consequences. These include the formation of foam, an increase in the organic load on water sources, a reduction in dissolved oxygen concentration, and an alteration of ecosystem balance [

9]. If WCO is dumped into municipal solid waste landfills, it causes water and soil pollution [

4]. In addition to the negative environmental impacts, the energy and economic costs associated with the improper discard of waste cooking oil (WCO) are estimated to be around 3 kWh/kg and approximately 0.45 euro/kg, respectively [

10].

From a circular economy perspective, WCO can be viewed as a promising and sustainable feedstock for various industrial products [

11]. This approach aims to maximize the utilization of biowastes by recovering valuable resources and simultaneously addressing the problem of disposal [

12]. In this context, the most common application of WCO is to use it as a feedstock for biodiesel synthesis [

4]. Also in Italy, reported data indicate that 90% of the collected WCO is currently used for biofuel production, which aligns with the general pattern observed in Europe [

10].

Recently, the oleochemical potential of WCO has been explored to determine its suitability as a substitute for virgin vegetable oils in the production of various value-added green chemicals. This includes biolubricants and biosurfactants [

4,

6]. According to Foo et al. (2022), the estimated global production of WCO is sufficient to replace virgin vegetable oil as a raw material in oleochemical industries. This is true even though a significant portion of WCO is currently being used as a feedstock for biodiesel production [

4].

Utilizing waste cooking oil (WCO) as a substitute for virgin vegetable oils in industrial applications offers significant advantages in both environmental and economic terms [

13]. Additionally, it helps resolve the conflict with the food sector over crop areas [

14,

15].

In this context, the study focuses on assessing three different recycling pathways for WCO used as a feedstock in the production of biodiesel (A1), biolubricant (A2), and biosurfactant (A3). The main aim of the study was to identify the most suitable solution for valorizing WCO in terms of technical, economic, and environmental considerations. This was achieved by applying a multi-criteria decision analysis (MCDA) approach and involving a team of experts as decision-makers.

2. Materials and methods

2.1. Description of the three considered alternative uses of WCO as feedstock

In this section, information regarding the three recycling pathways for utilizing WCO as a feedstock in the synthesis of A1_biodiesel, A2_biolubricant, and A3_biosurfactant is provided.

2.1.1. WCO as feedstock for biodiesel (A1_Biodiesel)

Diesel is one of the most commonly used fossil fuels worldwide as an energy source for vehicles, machinery, and electricity generation [

16]. However, in an effort to mitigate the depletion of fossil resources and address the global warming issue, biodiesel has garnered substantial attention in recent years [

17].

Biodiesel can be defined as a renewable fuel that comprises monoalkyl esters of long-chain fatty acids obtained from a sustainable lipid feedstock, such as vegetable oil [

15]. Compared to fossil fuels, biodiesel offers significant advantages, including renewability, biodegradability, lower carbon emissions, lower toxicity levels, a low flash point, and engine lubrication properties [

16]. However, the primary barrier to the widespread commercialization of biodiesel is its high production cost [

18], with feedstock accounting for approximately 70–80% of the total biodiesel production expenses [

9,

19]. In this regard, WCO has the potential to serve as a viable fuel supplement [

20], as it stands out as one of the most economically favorable feedstocks for biodiesel production [

17,

21]. WCO exhibits several advantageous characteristics, including ready availability, low cost, high product yield, and environmental friendliness [

9]. Utilizing WCO as a bioenergy resource resolves the challenges associated with first-generation bioenergy, particularly biofuels derived from virgin vegetable oils, such as food security concerns and high fertilizer requirements[

19].

Numerous studies have been conducted on biodiesel production from WCO, investigating various production technologies [

9]. However, the most commonly employed pathway is transesterification, as this process yields high-quality fuel. Transesterification involves the reaction of oil with alcohol, resulting in the formation of esters and glycerol[

4].

When it comes to the environmental sustainability of WCO biodiesel, several authors concur that it yields significantly lower impacts compared to fossil diesel [

7,

10] and biodiesel derived from virgin vegetable oils [

19]. Different perspectives arise when considering the economic sustainability of WCO-based biodiesel. Some technoeconomic studies indicate that utilizing WCO as a feedstock for biodiesel production can be financially viable, presenting economic benefits [

12,

15]. On the other hand, other authors have reported that the total production cost of WCO biodiesel is higher compared to fossil diesel [

7]. This difference is attributed to the relatively high cost of the necessary pretreatment process, despite WCO having a low commercial price [

18].

2.1.2. WCO as feedstock for biolubricant production (A2_Biolubricant)

Lubricants are oil-based chemicals that create a thin protective layer between two moving surfaces, effectively reducing friction and wear [

13]. Furthermore, they find widespread use in inhibiting oxidation, preventing corrosion, minimizing overheating, and providing surface coating to safeguard against dust, dirt, and water [

22]. Lubricants are primarily manufactured from mineral oil, a derivative of petroleum that is non-renewable, exhibits low biodegradability, and possesses high toxicity levels [

4].

Approximately 40 million metric tons of lubricating oils are produced annually worldwide, with nearly half of this quantity being lost to the environment [

22]. Furthermore, non-renewable petroleum-based lubricants currently dominate the global lubricant market, accounting for 85-90% of its share [

14,

23].

Mineral lubricants pose significant environmental hazards. A mere kilogram of mineral lubricant has the potential to contaminate up to one million liters of water [

23], contributing to chronic respiratory issues, inflammation, and carcinogenic effects [

22]. Moreover, several researchers and industry experts have estimated that fossil-based oils may soon become unavailable [

24].

Due to their biodegradability and sustainability, biolubricants produced from vegetable oils have been gaining increasing attention as viable alternatives to petroleum-based lubricants [

14]. Moreover, vegetable oils exhibit superior physicochemical properties compared to mineral lubricants, including a higher viscosity index, higher flash point, lower volatility, and better metal adherence [

13]. However, the production cost of biolubricants derived from virgin oils is 70 to 80% higher [

4], and the use of edible oils for industrial purposes may result in a scarcity of cooking oil for food [

22]. Therefore, the utilization of WCO, which contains edible oils, is a preferable option as a feedstock for biolubricant production due to its relatively low cost and environmentally friendly nature [

4].

Vegetable oils, including WCO, cannot be directly used as lubricants due to their low oxidation stability and high pour point [

23]. Therefore, chemical modifications such as hydrolysis, esterification, transesterification, epoxidation, and estolide formation are necessary to obtain high-performance biolubricants [

3,

25]. Several studies have explored the potential of WCO in biolubricant synthesis by employing combinations of these reactions [

3,

4,

22], and Joshi et al. (2023)[

3] extensively discussed various routes for biolubricant production from WCO and the implications of utilizing specific reaction combinations. Regardless of the chosen production process, the conducted research has consistently demonstrated satisfactory performance in terms of thermal-oxidative stability, oxidation stability, and other tribological properties of WCO-based lubricants [

4]. Moreover, certain studies have highlighted that such biolubricants exhibit better environmental sustainability and human health characteristics than mineral oil-based lubricants, while also having lower total production costs [

5,

26].

In conclusion, WCO emerges as a cost-effective, easily accessible, high-performance, sustainable, and environmentally friendly feedstock for biolubricant production [

9].

2.1.3. WCO as feedstock for biosurfactant production (A3_Biosurfactant)

Surfactants play a crucial role as essential bulk chemicals utilized in nearly every aspect of human daily life, ranging from detergents, cleaning products, and cosmetics to food, textiles, pharmaceuticals, mining, agriculture, paper production, and more [

11].

he majority of surfactants currently in use are petroleum-based and are produced chemically, which is considered a primary cause of surfactant toxicity [

27]. To address this critical issue, there has been significant scientific and industrial interest in bio-based surfactants due to their renewable, environmentally friendly nature, and biodegradability [

27]. However, the commercial-scale production of bio-based surfactants is challenging due to the high cost of raw materials [

4]. Nevertheless, the utilization of WCO as a substrate can significantly reduce the overall production costs [

28].

WCO presents a wide range of potential applications as a substitute for petroleum-based surfactants. It primarily consists of triglyceride esters of glycerol with long-chain fatty acids (>C12), particularly oleic acid and linoleic acid [

29]. These abundant fatty acids offer distinct advantages as starting materials to produce bio-based surfactants [

29]. Therefore, the investigation of WCO in the synthesis of bio-based surfactants holds significant importance, as it could pave the way for the commercialization of bio-based surfactants as an alternative to fossil resources [

4]. Extensive research has been carried out in this field, highlighting the potential of WCO in surfactant synthesis.

Several studies have directed their attention to the production of ethyl ester sulfonate (MES) utilizing WCO as a feedstock [

2,

30]. MES is recognized as one of the leading renewable surfactants [

9]. It is an environmentally friendly anionic surfactant derived from oleochemicals, and its synthesis is relatively straightforward. Furthermore, MES finds wide application in detergent formulations [

2].

The production process of MES using WCO as a feedstock involves several steps. Firstly, WCO undergoes pre-treatment to prepare it for further processing. Next, transesterification of the treated WCO is carried out to convert it into methyl esters. Finally, the methyl esters are further transformed into MES using sodium bisulfite (NaHSO

3) as a sulfonating agent [

9]. When compared to petroleum-based detergents, MES exhibits superior detergency even at lower doses. Additionally, MES demonstrates lower toxicity and better skin compatibility [

2].

In terms of environmental implications, several studies have examined the environmental performance of biodetergent production using WCO as a feedstock [

1]. These studies have consistently shown that the use of WCO leads to significant reductions in environmental impacts compared to the use of other feedstocks [

31].

2.2. Multi-criteria decision analysis (MCDA) procedure

Multi-criteria decision analysis (MCDA) is a valuable decision-making tool utilized to determine the optimal alternatives by comprehensively evaluating various criteria and their relative importance (i.e., weight) in the decision-making process [

32]. MCDA is particularly suitable in contexts with multiple objectives, incommensurable criteria, mixed data, and the involvement of multiple participants, as it offers ease of use and facilitates analysis [

33,

34].

In an MCDA procedure, each alternative is evaluated (i.e., 'measured') with respect to each criterion. The basic structure consists of an evaluation matrix (namely the alternative matrix) with evaluation criteria in the column vector, alternatives in the row vector, and a weight vector representing the values of relative importance assigned to the criteria by the decision-makers, with a unit sum.

A group of ten chemical engineers working in the WCO recycling sector were selected as decision-makers and actively participated in identifying alternatives to compare and defining the evaluation criteria used for the analysis.

After identifying the alternative solutions for comparison (as described in the previous section), the applied MCDA procedure can be divided into the following steps: (1) defining the criteria for evaluating the alternatives; (2) determining the weighting criteria and calculating the weight vectors; (3) establishing and processing the alternative matrix, and calculating the priority index; (4) selecting the best alternative.

2.2.1. Defining the criteria for evaluating the alternatives

Table 1 presents the four evaluation criteria that were defined to compare the three WCO recycling alternatives. These criteria allow for assessing the economic and environmental performance of the alternatives, as well as evaluating their technical performance in terms of management complexities and process yields.

All criteria are categorized into three levels of values, with higher levels indicating better performance of the alternative for that criterion. Each decision-maker assessed each alternative for all evaluation criteria by completing his/her alternative matrix where alternatives are listed in columns and criteria are listed in rows.

2.2.2. Determining the weighting criteria and calculating the weight vectors

According to De Feo and De Gisi (2010)[

35], the priority scale was adopted to define the criteria weights vector for each decision-maker. This technique involves assigning criteria to different levels on a ladder, where a higher level indicates higher importance. Further details regarding the description and structure of this technique can be found in De Feo and De Gisi (2010)[

35]. Each decision-maker also provided their own priority scale.

The conversion of each priority scale into the corresponding criteria weights vector is performed using the Paired Comparison Technique [

35], which is based on the following three levels of judgment:

- -

1 = the criterion is more important than another;

- -

0 = the criterion is less important than another;

- -

0.5 = the two criteria have the same importance

This technique allows for a systematic comparison of criteria and facilitates the determination of their relative weights. For each criterion, the judgment values are recorded in a pairwise comparison matrix. To prevent the possibility of a null value for any evaluation criterion, a dummy criterion is included in the matrix, always assigned a value of 0 when compared to other criteria. The weights vector for each decision-maker is calculated by taking the ratio between the sum of judgment values assigned to each criterion and the sum of judgment values for all criteria.

2.2.3. Establishing and processing the alternative matrix, and calculating the priority index

Following the methodology outlined in De Feo and De Gisi (2010)[

35], the evaluation process involved constructing a solved alternative matrix, where the alternatives were represented as column headings and the evaluation criteria as rows. The matrix values were determined using the Simple Additive Weighting (SAW) method, which involved multiplying the performance values of each alternative for each criterion (extracted from the alternative matrix) by the corresponding values of the weighting vector. The row-wise summation of values in the solved alternative matrix yielded the priority indices for each alternative. Thus, for each decision-maker, a solved alternative matrix and a priority index consisting of three values were computed.

2.2.4. Selecting the best alternative

The best WCO recycling alternative will be the one that achieves the highest average value of the priority indexes corresponding to the ten decision-makers.

3. Results and Discussion

This section shows the main results of the study divided in two sub-sections. The first part reports the results about the priority scales provided by all decision-makers and the weights vector values calculated with the paired comparison technique; while in the second part the results about the priority index vales used to identify the best alternative of WCO recycling are reported with a focus on the assessment of each alternative in function of each evaluation criterion adopted.

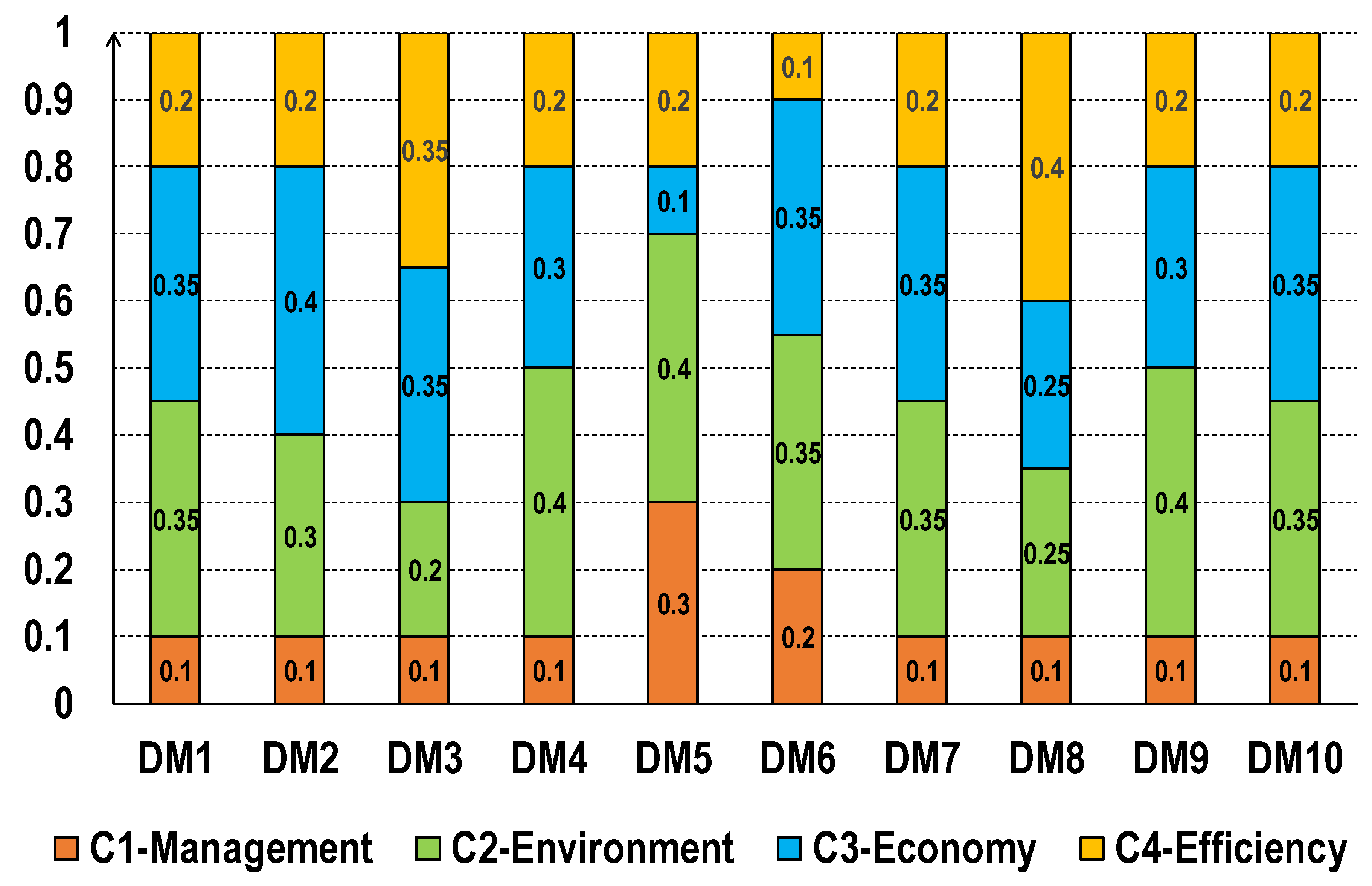

3.1. Weights vector results

Using the priority scale approach, each decision-maker provided their preferred order of the proposed alternatives. The priority scales of all decision-makers are presented in

Table 2. Following the same procedure outlined in previous studies, the weight vector values (shown in

Figure 1) were calculated from the evaluation criteria's priority scale provided by each decision-maker using a paired comparison matrix [

35,

36].

According to the results depicted in

Figure 1, the environmental sustainability aspect (C2 criterion) of the WCO recycling processes emerges as the most critical evaluation criterion based on the perspective of the decision-makers involved in the analysis. This aligns with the findings of Gherghel et al. (2020)[

36], who demonstrated the paramount importance of minimizing greenhouse gas emissions in their MCDA study on identifying the optimal treatment scheme for a wastewater treatment plant [

36]. Furthermore, Soltani et al. (2015) [

37] also observed that sustainability criteria held greater significance in the majority of MCDA studies conducted in the waste management sector.

Consistent with other similar studies, the economic aspect was deemed highly significant [

38]. However, in contrast, the management aspect (C1 criterion) of the WCO recycling processes was generally considered the relatively least important criterion.

The weight vector was utilized to solve the alternative matrix for each decision-maker, following the methodology described in the materials and methods section. The solved alternative matrices, along with the completed alternative matrices, Priority Scales, and weights vectors, are documented in the supplementary material for all the decision-makers.

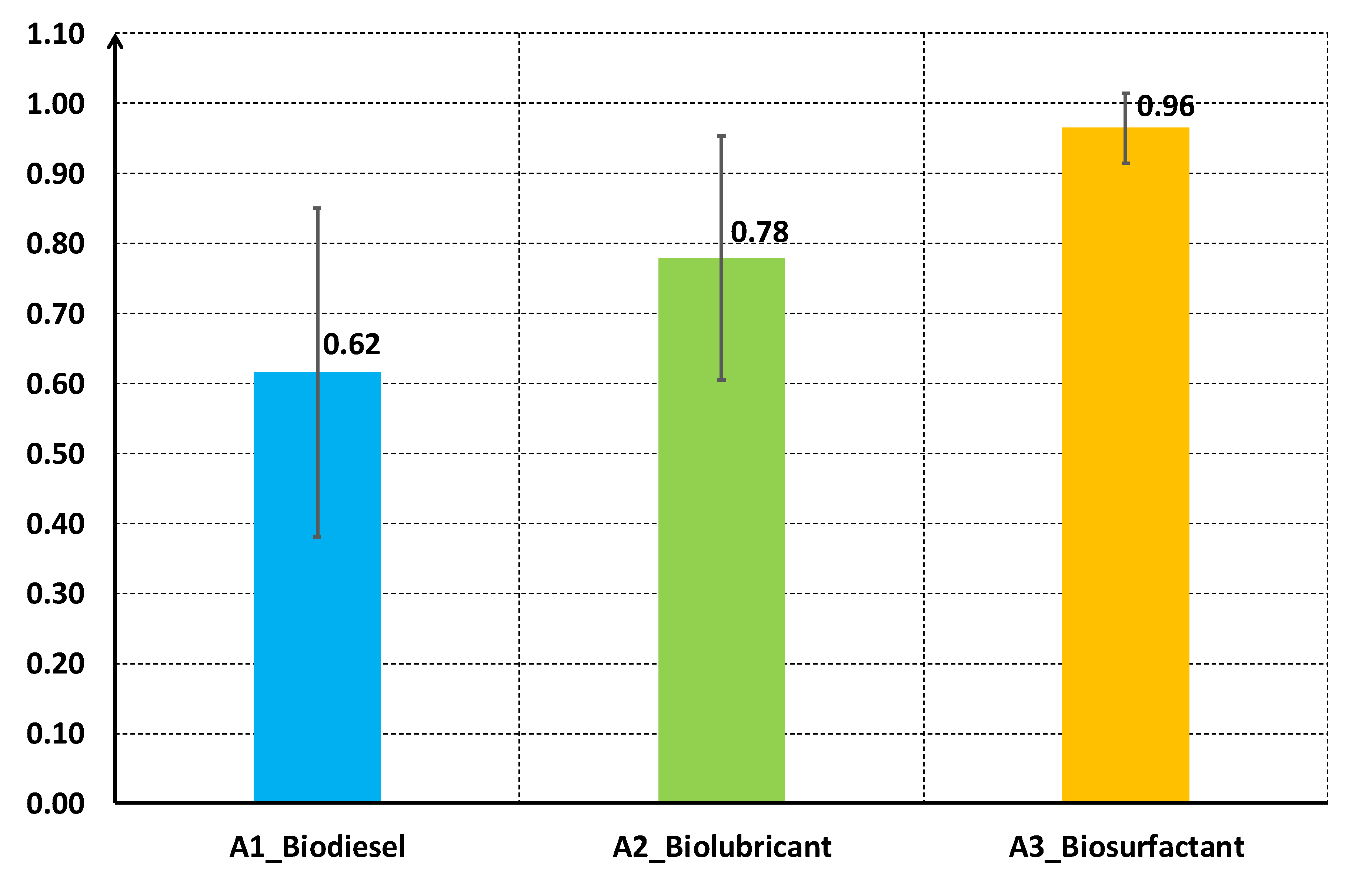

3.2. Selection of the best alternative of WCO recycling

Using the resolved alternative matrixes for each decision-maker, the priority index values (shown in

Table 3) were calculated, following the methodology described in the materials and methods section. Additionally, at the bottom of

Table 3, the average priority index value for each alternative is reported, along with the corresponding standard deviation.

As shown in

Table 3, the utilization of WCO as a feedstock for biosurfactant production was determined to be the most favorable alternative for WCO recycling, preferred by 50% of the decision-makers. On the other hand, the production of biolubricant was considered the second-best alternative, while the production of biofuel from WCO was deemed the least favorable. Moreover, the biosurfactant production alternative exhibited the lowest coefficient of variation, with a value of 12.6%. In contrast, the other alternatives had higher coefficient values: 22.4% for WCO used in biolubricant production and 32.2% for biofuel production from WCO.

The varying ranges of the three alternatives are also depicted in

Figure 2, which graphically presents the average values of the normalized priority index for each alternative.

These results indicate that the selection of biosurfactant production as the optimal alternative for WCO recycling is evident and trustworthy. In contrast, the assessment of the biofuel production alternative exhibited the widest variation range, highlighting substantial disagreement among decision-makers.

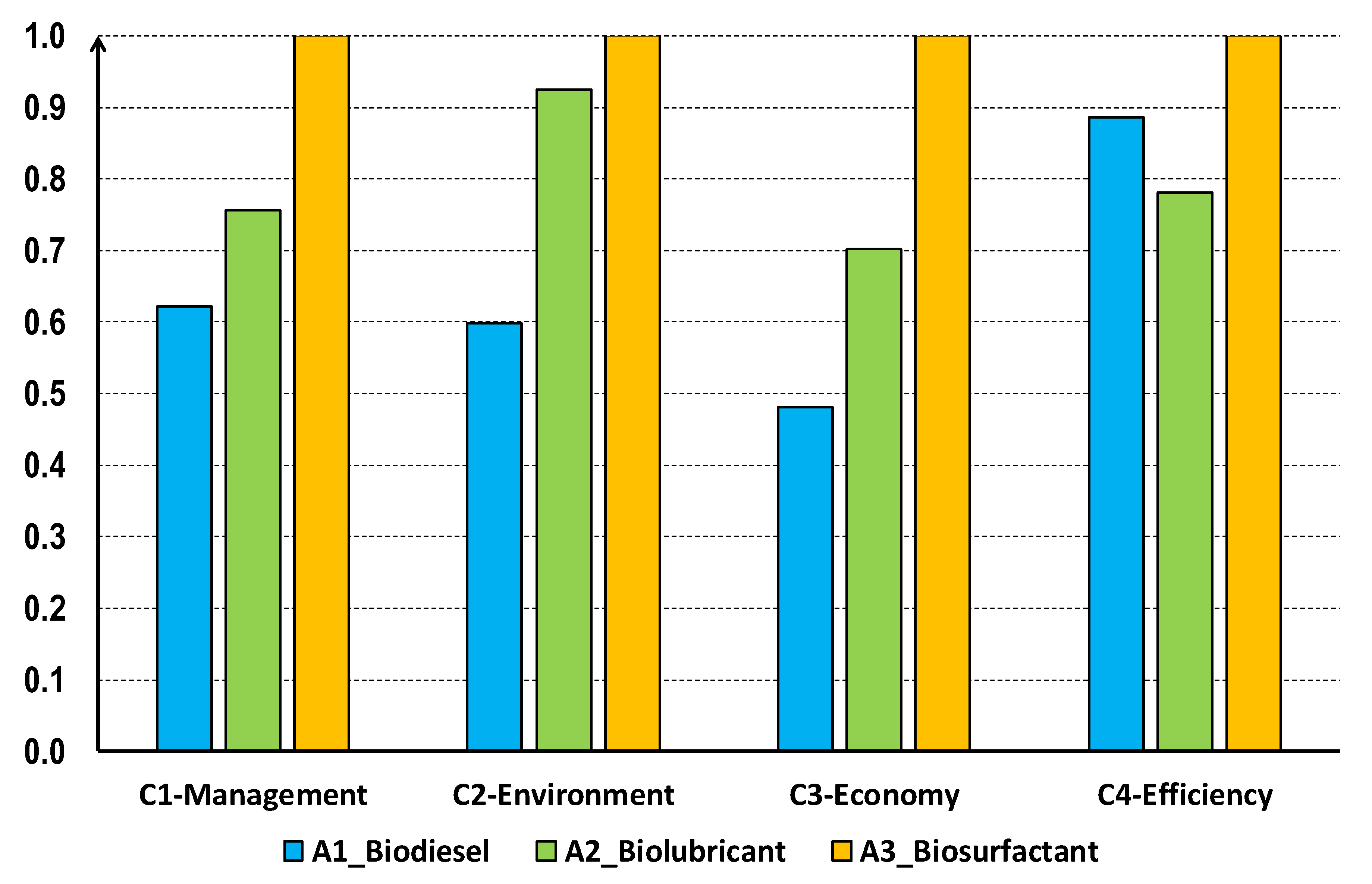

Another significant aspect is the emphasis on assessing the WCO recycling alternatives based on different criteria to determine if the optimal alternative varies when considering variations in the overall results. In this context,

Table 4 presents the comprehensive resolved alternative matrix, wherein each value represents the sum of all corresponding values from the resolved alternative matrices for each decision-maker.

Next, by normalizing the results presented in

Table 4 relative to the maximum value achieved by the alternatives for each criterion, the findings shown in

Figure 3 were obtained. It is noteworthy that the evaluation of alternatives for each criterion reaffirmed the overall results, underscoring that decision-makers regarded biosurfactant production as the optimal WCO recycling alternative in terms of economic and environmental considerations, as well as management and efficiency of the recycling process.

The efficiency criterion, which evaluates the product yield efficiency of WCO recycling alternatives and the amount of waste produced during the process, yielded slightly different findings compared to the overall results. Specifically, in terms of recycling process efficiency, the decision-makers considered biodiesel production to be a superior WCO recycling alternative compared to biolubricant production.

The adopted MCDA approach, which has been utilized in other similar studies [

35,

36,

38], demonstrated its reliability and effectiveness in clearly identifying the preferred WCO recycling alternative among the assessed options. This methodology enables the utilization of decision-makers' expertise and knowledge through a streamlined and efficient process that yields dependable results for selecting the optimal solution from various alternatives. However, it is important to highlight that all the assessed WCO recycling alternatives currently face significant challenges that must be addressed to facilitate widespread utilization of WCO as a feedstock, in alignment with the goals of the circular economy [

6].

First and foremost, one of the primary challenges lies in enhancing the collection of waste cooking oil (WCO). Several studies focusing on the economic and environmental evaluation of WCO recycling alternatives have identified the difficulty in effectively collecting WCO as a significant concern [

7,

10]. Therefore, it is crucial to establish an appropriate network for WCO collection and management at the municipal scale, considering key factors such as collection point locations, container volumes, collection vehicle routes, collection point capacities, and collection frequency [

4]. Furthermore, citizen cooperation plays a vital role in improving the WCO recovery rate [

39,

40]. Research on identifying the primary barriers to efficient WCO collection has emphasized the need to involve citizens in effective collection programs and conduct environmental education campaigns to enhance their environmental awareness [

8].

Additional challenges that need to be addressed include the improvement of WCO pretreatment and purification processes due to its high impurity content and compositional variations [

9,

17]. Furthermore, the implementation of appropriate policies and economic incentives is essential [

4,

17]. Thus, future efforts in these areas are crucial to promote the large-scale valorization of WCO as a feedstock, making a significant contribution to the implementation of circular economy principles.

4. Conclusions

This study aimed to assess three distinct alternatives for waste cooking oil (WCO) recycling: (1) WCO used as a feedstock for biodiesel production, (2) WCO utilized for biolubricant production, and (3) WCO employed in biosurfactant production. The evaluation of these alternatives considered environmental, economic, and technical aspects by employing a multi-criteria decision analysis (MCDA) approach. The decision-making process involved a group of chemical engineers specializing in the WCO recycling sector.

By employing the priority scale along with the paired comparison technique, it was determined that the decision-makers involved in the study regarded the environmental sustainability aspect of the WCO recycling process as the most crucial evaluation criterion. The economic criterion followed closely in terms of importance. On the other hand, the aspect of process management was deemed to be of lesser significance.

The utilization of WCO as a feedstock for biosurfactant production was determined to be the optimal WCO recycling alternative, with biolubricant production considered the second-best solution. Additionally, biosurfactant production exhibited the lowest coefficient of variation, indicating a clear and reliable identification of the best alternative.

The adopted MCDA approach proved to be a dependable and effective tool for clearly identifying the preferred WCO recycling alternative among the options evaluated. This streamlined yet reliable procedure harnessed the expertise and knowledge of the decision-makers to select the optimal solution from the available alternatives.

However, in order to implement WCO recycling on an industrial scale in alignment with circular economy targets, several critical issues need to be addressed. These include challenges associated with WCO collection, transportation, as well as pretreatment and purification processes. Therefore, future research focusing on these aspects is essential to identify potential solutions and provide recommendations for overcoming the difficulties encountered in large-scale WCO recycling.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org.

Author Contributions

Conceptualization, G.D.F.; methodology, G.D.F.; software, L.G..; validation, G.D.F., C.F. and L.S.O.; formal analysis, C.F.; investigation, G.D.F., C.F., L.G. and L.S.O.; resources, L.S.O.; data curation, G.D.F., L.G. and C.F.; writing—original draft preparation, C.F.; writing—review and editing, G.D.F.; visualization, L.G. and L.S.O.; supervision, G.D.F. and L.S.O.; project administration, G.D.F.; funding acquisition, L.S.O. All authors have read and agreed to the published version of the manuscript.” Please turn to the CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This research received no external funding

Data Availability Statement

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thushari, I.; Babel, S. Comparative Study of the Environmental Impacts of Used Cooking Oil Valorization Options in Thailand. J. Environ. Manage. 2022, 310, 114810. [Google Scholar] [CrossRef] [PubMed]

- Permadani, R.L.; Ibadurrohman, M. ; Slamet Utilization of Waste Cooking Oil as Raw Material for Synthesis of Methyl Ester Sulfonates (MES) Surfactant. IOP Conf. Ser. Earth Environ. Sci. 2018, 105, 012036. [Google Scholar] [CrossRef]

- Joshi, J.R.; Bhanderi, K.K.; Patel, J.V. Waste Cooking Oil as a Promising Source for Bio Lubricants- A Review. J. Indian Chem. Soc. 2023, 100, 100820. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent Advances in the Conversion of Waste Cooking Oil into Value-Added Products: A Review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Cui, X.; Sun, N.; Cao, P.; Guo, J.; Ming, P. Preparation and Application of Sustainable Nanofluid Lubricant from Waste Soybean Oil and Waste Serpentine for Green Intermittent Machining Process. J. Manuf. Process. 2022, 77, 508–524. [Google Scholar] [CrossRef]

- Orjuela, A.; Clark, J. Green Chemicals from Used Cooking Oils: Trends, Challenges, and Opportunities. Curr. Opin. Green Sustain. Chem. 2020, 26, 100369. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Zhang, L.; Chang, Y.; Hao, Y. Converting Waste Cooking Oil to Biodiesel in China: Environmental Impacts and Economic Feasibility. Renew. Sustain. Energy Rev. 2021, 140, 110661. [Google Scholar] [CrossRef]

- De Feo, G.; Di Domenico, A.; Ferrara, C.; Abate, S.; Sesti Osseo, L. Evolution of Waste Cooking Oil Collection in an Area with Long-Standing Waste Management Problems. Sustainability 2020, 12, 8578. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V.; Aigbodion, V.S.; Panda, S. Advances in Biotechnological Applications of Waste Cooking Oil. Case Stud. Chem. Environ. Eng. 2021, 4, 100158. [Google Scholar] [CrossRef]

- Frota De Albuquerque Landi, F.; Fabiani, C.; Castellani, B.; Cotana, F.; Pisello, A.L. Environmental Assessment of Four Waste Cooking Oil Valorization Pathways. Waste Manag. 2022, 138, 219–233. [Google Scholar] [CrossRef]

- Liepins, J.; Balina, K.; Soloha, R.; Berzina, I.; Lukasa, L.K.; Dace, E. Glycolipid Biosurfactant Production from Waste Cooking Oils by Yeast: Review of Substrates, Producers and Products. Fermentation 2021, 7, 136. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.-H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in Utilisation of Waste Cooking Oil for Sustainable Biodiesel and Biojet Fuel Production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Sarno, M.; Iuliano, M.; Cirillo, C. Optimized Procedure for the Preparation of an Enzymatic Nanocatalyst to Produce a Bio-Lubricant from Waste Cooking Oil. Chem. Eng. J. 2019, 377, 120273. [Google Scholar] [CrossRef]

- Zhang, W.; Ji, H.; Song, Y.; Ma, S.; Xiong, W.; Chen, C.; Chen, B.; Zhang, X. Green Preparation of Branched Biolubricant by Chemically Modifying Waste Cooking Oil with Lipase and Ionic Liquid. J. Clean. Prod. 2020, 274, 122918. [Google Scholar] [CrossRef]

- Silva Filho, S.C.D.; Miranda, A.C.; Silva, T.A.F.; Calarge, F.A.; Souza, R.R.D.; Santana, J.C.C.; Tambourgi, E.B. Environmental and Techno-Economic Considerations on Biodiesel Production from Waste Frying Oil in São Paulo City. J. Clean. Prod. 2018, 183, 1034–1042. [Google Scholar] [CrossRef]

- Farid, M.A.A.; Roslan, A.M.; Hassan, M.A.; Hasan, M.Y.; Othman, M.R.; Shirai, Y. Net Energy and Techno-Economic Assessment of Biodiesel Production from Waste Cooking Oil Using a Semi-Industrial Plant: A Malaysia Perspective. Sustain. Energy Technol. Assess. 2020, 39, 100700. [Google Scholar] [CrossRef]

- Avinash, A.; Sasikumar, P.; Murugesan, A. Understanding the Interaction among the Barriers of Biodiesel Production from Waste Cooking Oil in India- an Interpretive Structural Modeling Approach. Renew. Energy 2018, 127, 678–684. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Adamu, A.; Zhu, Z. Economic Evaluation and Production Process Simulation of Biodiesel Production from Waste Cooking Oil. Curr. Res. Green Sustain. Chem. 2021, 4, 100091. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Kalogirou, S.A.; Gupta, V.K.; Park, Y.-K.; Fallahi, A.; Sulaiman, A.; Ranjbari, M.; Rahnama, H.; Aghbashlo, M.; et al. Environmental Life Cycle Assessment of Biodiesel Production from Waste Cooking Oil: A Systematic Review. Renew. Sustain. Energy Rev. 2022, 161, 112411. [Google Scholar] [CrossRef]

- Ho, S.-H.; Wong, Y.-D.; Chang, V.W.-C. Evaluating the Potential of Biodiesel (via Recycled Cooking Oil) Use in Singapore, an Urban City. Resour. Conserv. Recycl. 2014, 91, 117–124. [Google Scholar] [CrossRef]

- Chen, C.; Chitose, A.; Kusadokoro, M.; Nie, H.; Xu, W.; Yang, F.; Yang, S. Sustainability and Challenges in Biodiesel Production from Waste Cooking Oil: An Advanced Bibliometric Analysis. Energy Rep. 2021, 7, 4022–4034. [Google Scholar] [CrossRef]

- Perera, M.; Yan, J.; Xu, L.; Yang, M.; Yan, Y. Bioprocess Development for Biolubricant Production Using Non-Edible Oils, Agro-Industrial Byproducts and Wastes. J. Clean. Prod. 2022, 357, 131956. [Google Scholar] [CrossRef]

- Dehghani Soufi, M.; Ghobadian, B.; Mousavi, S.M.; Najafi, G.; Aubin, J. Valorization of Waste Cooking Oil Based Biodiesel for Biolubricant Production in a Vertical Pulsed Column: Energy Efficient Process Approach. Energy 2019, 189, 116266. [Google Scholar] [CrossRef]

- Borugadda, V.B.; Goud, V.V. Improved Thermo-Oxidative Stability of Structurally Modified Waste Cooking Oil Methyl Esters for Bio-Lubricant Application. J. Clean. Prod. 2016, 112, 4515–4524. [Google Scholar] [CrossRef]

- Li, W.; Wang, X. Bio-Lubricants Derived from Waste Cooking Oil with Improved Oxidation Stability and Low-Temperature Properties. J. Oleo Sci. 2015, 64, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Li, Y.; Guo, J.; Ming, P. Analysis of a Sustainable MQL Machining Process Combining Modified Waste Cooking Oil and Multifunctional Biomimetic Microstructure. Sustain. Mater. Technol. 2021, 29, e00311. [Google Scholar] [CrossRef]

- Sharma, K.; Toor, S.S.; Brandão, J.; Pedersen, T.H.; Rosendahl, L.A. Optimized Conversion of Waste Cooking Oil into Ecofriendly Bio-Based Polymeric Surfactant- A Solution for Enhanced Oil Recovery and Green Fuel Compatibility. J. Clean. Prod. 2021, 294, 126214. [Google Scholar] [CrossRef]

- Gaur, V.K.; Sharma, P.; Sirohi, R.; Varjani, S.; Taherzadeh, M.J.; Chang, J.-S.; Yong Ng, H.; Wong, J.W.C.; Kim, S.-H. Production of Biosurfactants from Agro-Industrial Waste and Waste Cooking Oil in a Circular Bioeconomy: An Overview. Bioresour. Technol. 2022, 343, 126059. [Google Scholar] [CrossRef]

- Zhang, Q.-Q.; Cai, B.-X.; Xu, W.-J.; Gang, H.-Z.; Liu, J.-F.; Yang, S.-Z.; Mu, B.-Z. The Rebirth of Waste Cooking Oil to Novel Bio-Based Surfactants. Sci. Rep. 2015, 5, 9971. [Google Scholar] [CrossRef]

- Djohan, G.; Ibadurrohman, M. ; Slamet Synthesis of Eco-Friendly Liquid Detergent from Waste Cooking Oil and ZnO Nanoparticles. AIP Conf. Proc. 2019, 2085, 020075. [Google Scholar] [CrossRef]

- Lucchetti, M.G.; Paolotti, L.; Rocchi, L.; Boggia, A. The Role of Environmental Evaluation within Circular Economy: An Application of Life Cycle Assessment (LCA) Method in the Detergents Sector. Environ. Clim. Technol. 2019, 23, 238–257. [Google Scholar] [CrossRef]

- Anwar, M. Biodiesel Feedstocks Selection Strategies Based on Economic, Technical, and Sustainable Aspects. Fuel 2021, 283, 119204. [Google Scholar] [CrossRef]

- De Feo, G.; Galasso, M.; Landi, R.; Donnarumma, A.; De Gisi, S. A Comparison of the Efficacy of Organic and Mixed-Organic Polymers with Polyaluminium Chloride in Chemically Assisted Primary Sedimentation (CAPS). Environ. Technol. 2013, 34, 1297–1305. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniam, A.; Voulvoulis, N. The Appropriateness of Multicriteria Analysis in Environmental Decision-Making Problems. Environ. Technol. 2005, 26, 951–962. [Google Scholar] [CrossRef]

- De Feo, G.; De Gisi, S. Using an Innovative Criteria Weighting Tool for Stakeholders Involvement to Rank MSW Facility Sites with the AHP. Waste Manag. 2010, 30, 2370–2382. [Google Scholar] [CrossRef] [PubMed]

- Gherghel, A.; Teodosiu, C.; Notarnicola, M.; De Gisi, S. Sustainable Design of Large Wastewater Treatment Plants Considering Multi-Criteria Decision Analysis and Stakeholders’ Involvement. J. Environ. Manage. 2020, 261, 110158. [Google Scholar] [CrossRef] [PubMed]

- Soltani, A.; Hewage, K.; Reza, B.; Sadiq, R. Multiple Stakeholders in Multi-Criteria Decision-Making in the Context of Municipal Solid Waste Management: A Review. Waste Manag. 2015, 35, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Vlachokostas, C.; Michailidou, A.V.; Achillas, C. Multi-Criteria Decision Analysis towards Promoting Waste-to-Energy Management Strategies: A Critical Review. Renew. Sustain. Energy Rev. 2021, 138, 110563. [Google Scholar] [CrossRef]

- Cho, S.; Kim, J.; Park, H.-C.; Heo, E. Incentives for Waste Cooking Oil Collection in South Korea: A Contingent Valuation Approach. Resour. Conserv. Recycl. 2015, 99, 63–71. [Google Scholar] [CrossRef]

- Yaakob, Z.; Mohammad, M.; Alherbawi, M.; Alam, Z.; Sopian, K. Overview of the Production of Biodiesel from Waste Cooking Oil. Renew. Sustain. Energy Rev. 2013, 18, 184–193. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).