Submitted:

05 May 2023

Posted:

05 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

| Types | Name and Functions | Types | Name and Functions |

|---|---|---|---|

| Narrow Band | |||

|

Microstrip Patch => A resonant patch to a 50-ohm transmission line |  |

Inverted F Antenna => Phones use single-sided resonant structures as their GPS antenna |

|

Yagi-Uda => Narrowband directional antenna, used for point-to-point communications |  |

Helical Antenna => Narrowband directional or omnidirectional antenna based on dimensions of helix |

| Wide Band | |||

|

Planar Bow Tie => Wideband planar antenna, here seen as a single-sided configuration |  |

Antipodal Vivaldi => Wideband planar antenna, the same geometry used in this thesis |

|

Horn Antenna => Wideband antenna, 1 GHz to 18 GHz calibration |  |

Parabolic Reflectors => are used as “Satellite Dishes” with horn antenna for satellite TV |

2. Antenna Design and Fabrication

| Fc (GHz) | Materials (Substrates) | Technology | εr | Eff. % | Size(mm3) | BW (GHz) | Gain (dBi) | RL (dB) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 125/280 | glass & Kapton | inkjet print. | NA | NA | 63.5×63.5×0.05 | 35/70 | 24/145 | 10 | [44] |

| 94 | LCP | inkjet print. | 2.6 | NA | 210×297×0.15 | 8.1 | 7.65 | 10 | [45] |

| 28 | Ultra-thin glass | inkjet print. | 5.4 | 80 | 7.13×5.4×0.147 | 5.4 | 6.96 | 10 | [46] |

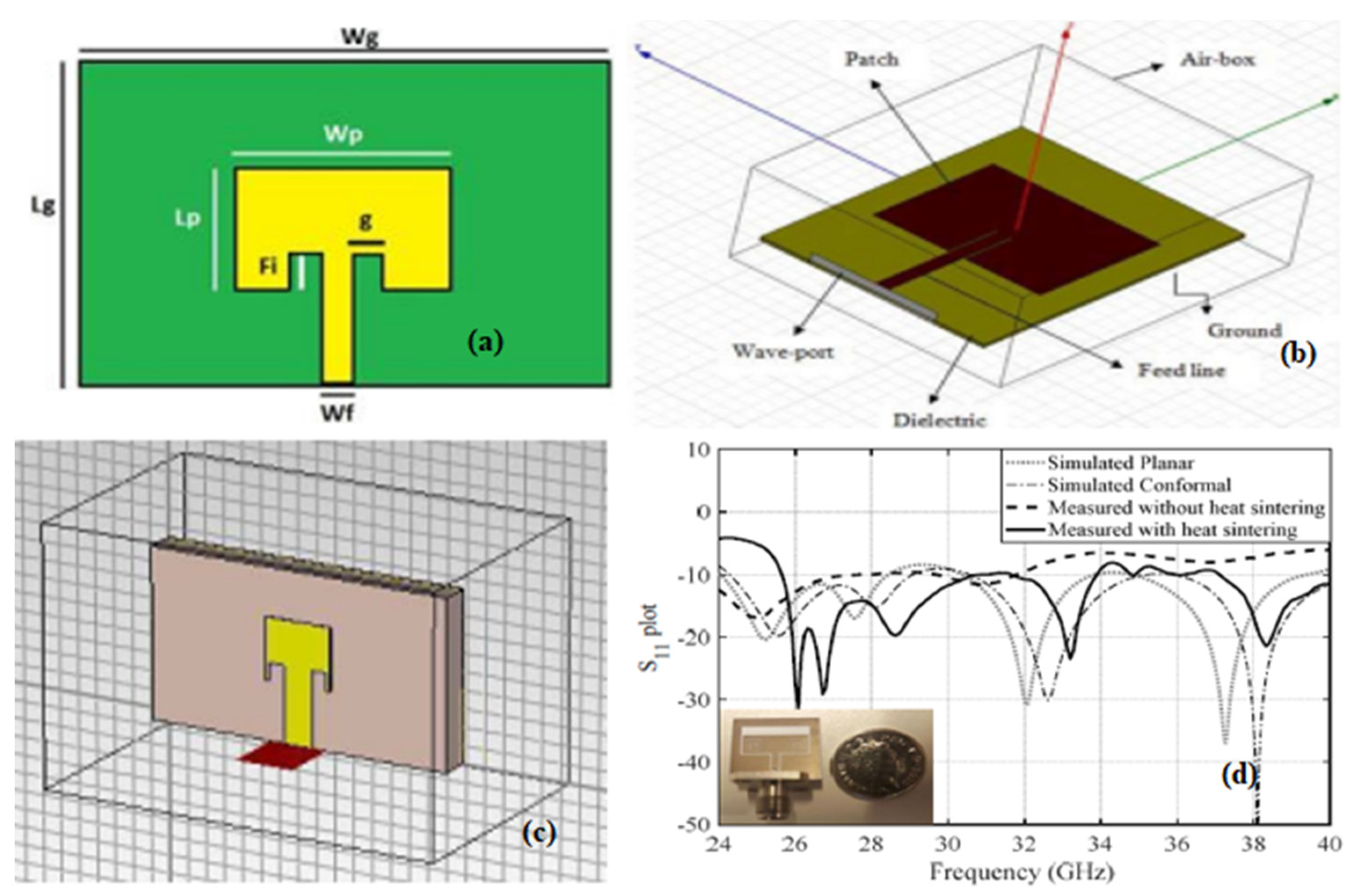

| 26.5/37 | PET | inkjet print. | 3.2 | 95 | 16×19×0.135 | 1.2/3 | 7.2/9.7 | 10 | [47] |

| 60 | PET | inkjet print. | NA | NA | 50×60×0.11 | 2.7 | 24.4 | 10 | [48] |

| 28 | ABS Fingernail | inkjet print. | 2.7 | 70 | 14.96×117.45×0.5 | 2.87 | 7.5 | 10 | [49] |

| 28 | FLGR02 | inkjet print. | 3 | NA | 5×9×1.7 | 8 | 5 | 10 | [50] |

| 34 | PET | inkjet print. | 3.2 | NA | 11×25.4×0.147 | 12.7 | 6.2 | 10 | [51] |

| 26.26 | PET | inkjet print. | 3.2 | NA | 3.1×3.4×0.15 | NA | NA | 10 | [21] |

| 39 | PET | inkjet print. | 3.2 | NA | 12×4.7×0.123 | 26–40 | 7.44 | NA | [34] |

| 28 | PET | Spray coating | 3.38 | 70 | 7.11×3.556×0.508 | 2.5 | 8.8 | 10 | [52] |

| 35 | LCP | inkjet print. | 2.9 | NA | 11×12×0.1 | 14 | 9 | NA | [53] |

| 28 | Polyester fabric | Screen print. | 2.2 | NA | 25×12.7×0.35 | 7.8 | 4.2 | 18 | [54] |

| 28 | RO4350 | PCB | 2.2 | 45.6 | 3.53×3.53×0.16 | 6.72 | 19.2 | 10 | [55] |

| 28 | Roger RO3003 | PCB | 3 | - | 130×70×0.762 | 24 | 8 | 10 | [13] |

| 28 | FR-4 | PCB | 2.2 | N/A | 2.50×3.20×0.1 | 1 | 11.23 | 10 | [56] |

| 28 | TLY-5A | PCB | 2.17 | N/A | 3.3×3.3×0.254 | 0.9 | 10 | 13.8 | [57] |

| 28 & 38 | RT 5880 | PCB | 2.2 | N/A | NA | 2 & 4 | 10 | 13 | [12] |

| 28 | FR4 | PCB | 4.4 | 85 | NA | 7.2 | 10.8 | 10 | [58] |

| 28 & 38 | RT/D6002 | PCB | 2.2 | 63/81 | 30×30×1.52 | 4.3/5.3 | 8.7/8.2 | 10 | [32] |

| 28 | RO4003C | PCB | 2.2 | N/A | 2×2.2×0.25 | 4 | 5.5 | 12 | [16] |

| 50 | FR 04 | PCB | 4.4 | N/A | 40×34×4.8 | 20 | 7.5 | 10 | [59] |

| 60 | N/A | PCB | - | 85 | 15×15×3 | 3.6 | 18.5 | 10 | [60] |

| 60 | Isola tachyon | BGA | 3.02 | 90 | 9.6×2.8×0.568 | 3.6 | 10.51 | <10 | [61] |

| 60 | RT 5880 | PCB | 2.2 | NA | NA | 4 | 17.1 | 40 | [62] |

| 60 | PTFE | PCB | 2.2 | 57.2 | 44.5×20.0×2.16 | 5.6 | 15.6 | 2.1 | [63] |

| 140 | RGD837 | LTCC | NA | 77.5 | 7×7×2.5 | 19.17 | 15.5 | 13 | [33] |

3.1. Fabrication Methods for Printable Antennas

3.2. Conductive materials

| Gain (dBi) | X-polarization ratio (dB) | Beam width (deg) | |||

|---|---|---|---|---|---|

| Solid copper tape | 7.35 | -20.42 (E) | -18.55 (H) | 73 (E) | 60 (H) |

| Knitted copper fabric | 6.77 | -16.03 | -17.74 | 75 | 54 |

| Vertically cut copper tape | 6.82 | -17.73 | -18.52 | 74 | 61 |

| Horizontally cut copper tape | 5.01 | -20.83 | -17.99 | 74 | 62 |

| Horiz. cut and soldered copper tape | 7.26 | -24.72 | -18.90 | 73 | 62 |

| Aracon fabric | 0.57 | -12.09 | -15.73 | 75 | 60 |

3.3. Substrates

3.4. Chemical Etching

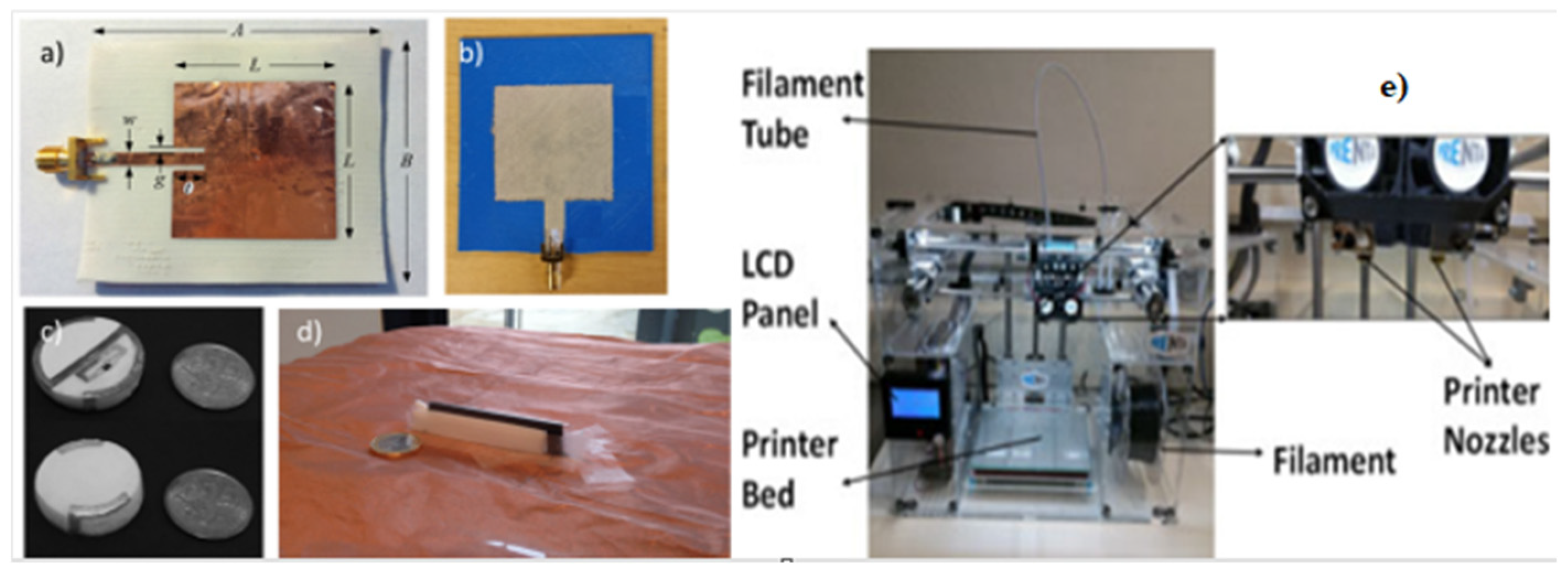

4.1. 3D-Printed Antenna

4.2. Screen Printing

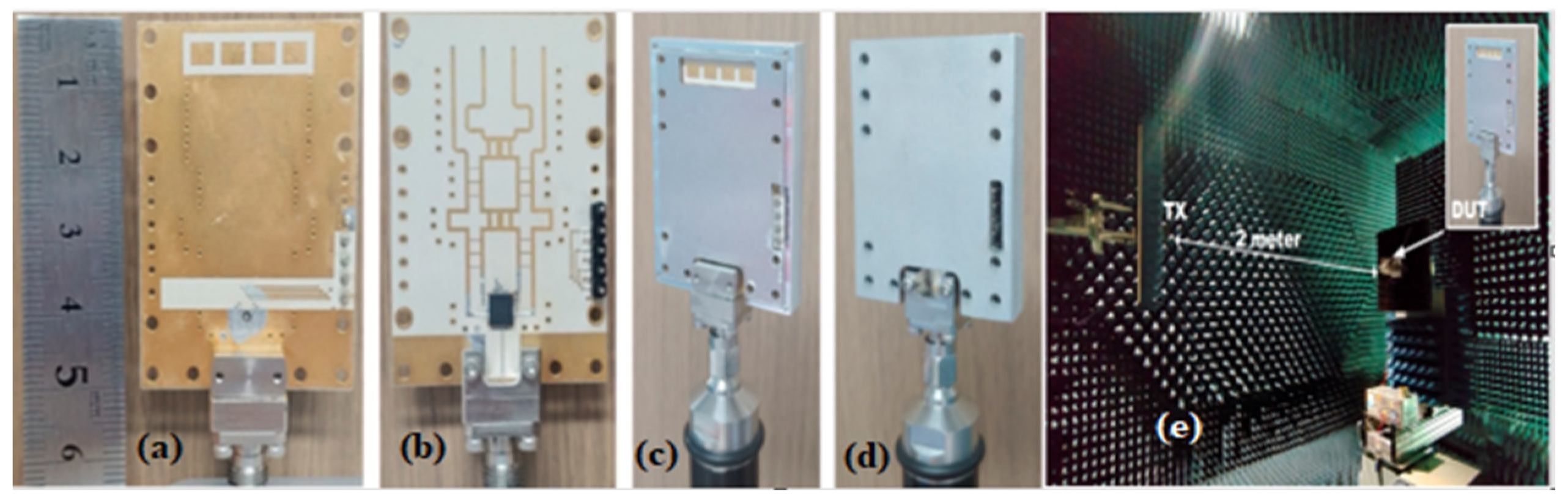

4.3. PCB Printing

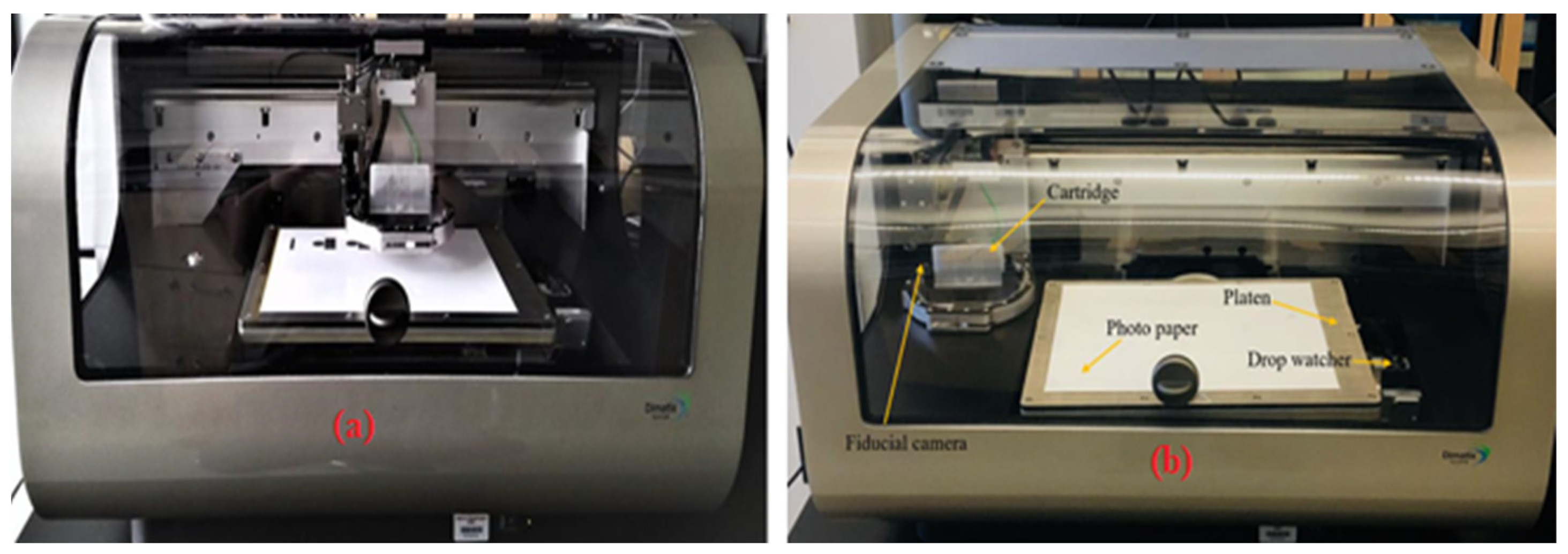

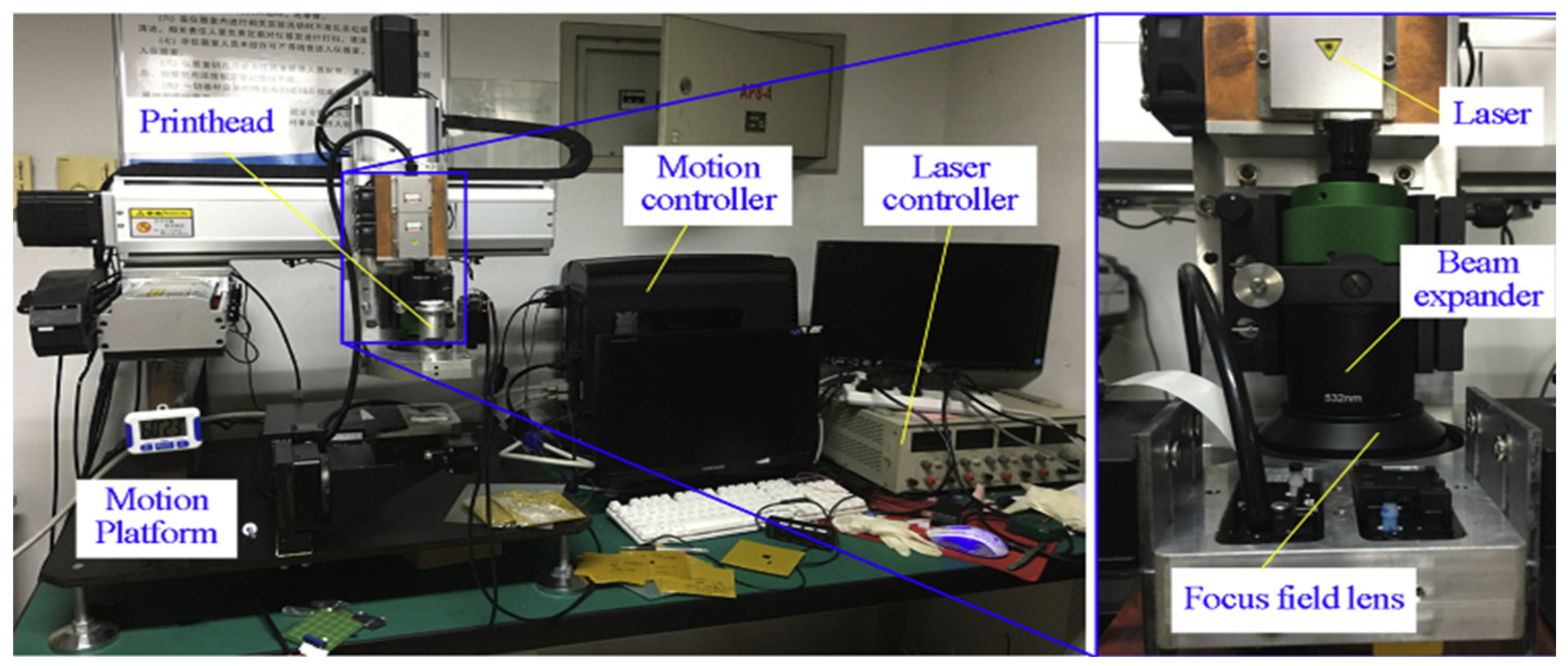

4.4. Inkjet Printing

| Antenna Type | FcGHz | Tech. | substrate | Ink type | Subεr | Sub.tan δ | Size (mm2) | SH mm2 | BW(GHz) | Gain(dBi) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Multi-Band | 5 | Inkjet Print. | Teslin | Nanoparticles | 2.00 | 0.022 | 35×40 | 0.26 | 1 | 2 | [82] |

| Monopole | 12.4 | Inkjet Print. | polyimide | silver nanoparticle | 3.5 | 0.0027 | 13×13 | 0.125 | 5.4 | 4.4 | [94] |

| NA | 2.4 | Inkjet Print. | PET | GO ink | 3.2 | 0.022 | 75*5 | 0.84 | NA | [95] | |

| Multiband | 3.4 | Inkjet Print. | Photo paper | silver nanoparticle | 3.2 | 0.05 | 30x40 | 0.44 | 2.5 | 2 | [96] |

| mimo monopole | 3.4 | Inkjet Print. | Kapton polyimide | silver nanoparticle | 3:4 | NA | 22*31 | 0.125 | 3.43 to10.1 | 2.31 | [97] |

| Patch Antenna | 4.9 | Inkjet Print. | Kapton polyimide | silver nanoparticle | 3.4 | NA | 22×31 | 0.245 | 0.25 | 4.5 | [98] |

| monopole | 2.45.2 | Inkjet Print. | photo paper | silver nanoparticle | 3 | NA | 51*34 | 0.18 | 0.451.60 | 1.42.78 | [99] |

| Dual-Ban | 2.45/5.8 | Inkjet Print. | PET | silver nanoparticle | 3.2 | 0.022 | 45×40 | 0.135 | 0.83/2.55 | 1.81/3.92 | [100] |

| Dual-Band | 2.4/ 5.2 | Inkjet Print. | photopaper | nanoparticle silver | 3 | NA | 210×282.5 | 0.177 | 0.5/2.9 | 3.74/4.96 | [101] |

| graphene | 5.65 | Inkjet Print. | Polyamide | graphene | 3.5 | 0.002 | 9×7 | 0.125 | 3 | 0.35 | [102] |

| Patch antenna | 2.45 | Inkjet Print. | Ninja Flex | Silver paste | 2.8 | 0.05 | 65×54 | 0.2 | 0.99 | 7.2 | [78] |

| Dipole | 2.45 | Inkjet Print. | porous elastomer | Graphene | 3.6 | 0.06 | NA | NA | 0.9 | 0.3 | [103] |

| Patch | 1.11 | Inkjet Print. | PET | Silver ink | 4 | 0.01 | 30×40 | 0.135 | 0.037 | NA | [104] |

| Monopole | 2.55 | Inkjet Print. | Textile substrate | Silver ink | 3.74 | 0.15 | 37.5×23 | 0.49 | 2.09 | 1.5 | [105] |

| monopole | 2.4/5.8 | Inkjet Print. | photo paper | silver nanoparticle | 3.2 | 0.05 | 86.25/22 | 0.22 | 0.71/1.96 | 2.24/4.42 | [106] |

| Dipole | 3.8 | Inkjet print. | Wound dressing | Nano silver Ink | 3.2 | 0.05 | 43.5×42.5 | 0.7 | 3.2–4.6 | 0.67 | [107] |

| monopole | 2.45 | Inkjet print. | PET | Silver nanoparticle | 2.7 | 0.135 | 30×40 | 0.125 | NA | 1.44 | [71] |

5. Future Prospects and Challenges of Inkjet-printed Antennas

6. inkjet-printed Antenna for Future Wireless Solutions

7. Conclusions

References

- Kamal, S.; et al. Wheel-shaped miniature assembly of circularly polarized wideband microstrip antenna for 5G mmWave terminals. Alexandria Engineering Journal 2021, 60. [Google Scholar]

- Mohammed, A.S.B.; et al. Mathematical Modelling on the Effects of Conductive Material and Substrate Thickness for Air Substrate Microstrip Patch Antenna. Appl Comput Electromagn Soc J 2020, 35. [Google Scholar]

- Mohammed, A.S.B.; et al. Mathematical model on the effects of conductor thickness on the centre frequency at 28 GHz for the performance of microstrip patch antenna using air substrate for 5G application. Alexandria Engineering Journal 2021, 60. [Google Scholar]

- Kamal, S.; et al. A Novel Lumped LC Resonator Antenna with Air-Substrate for 5G Mobile Terminals. Progress In Electromagnetics Research Letters 2020, 88, 75–81. [Google Scholar] [CrossRef]

- Kamal, S.; et al. A 28 GHz mmWave Circular Microstrip Antenna with Rectangular Slots on Air-Substrate. In Proceedings of the 2020 IEEE International RF and Microwave Conference (RFM); 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Kamal, S.; et al. A novel negative meander line design of microstrip antenna for 28 GHz mmwave wireless communications. Radioengineering 2020, 29, 479–485. [Google Scholar] [CrossRef]

- Mohammed, A.S.B.; et al. Analysis of the Proposed Boundary Conditions for the Conductive Material and Substrate Thickness of Air-Substrate Microstrip Patch Antenna via Graphical Verification Method. In Lecture Notes in Electrical Engineering; 2022; Volume 829 LNEE. [Google Scholar] [CrossRef]

- Kamal, S.; et al. A Compact MIMO Antenna for Wideband Circularly Polarized mmWave Communications. In Lecture Notes in Electrical Engineering; 2022; Volume 829 LNEE. [Google Scholar] [CrossRef]

- Zubir, I.A.; et al. A low-profile hybrid multi-permittivity dielectric resonator antenna with perforated structure for Ku and K band applications. IEEE Access 2020, 8. [Google Scholar]

- Kamal, S.; et al. An Assessment of Progress in 5.8 GHz Quasi-lumped Element Resonator Antennas. IETE Technical Review (Institution of Electronics and Telecommunication Engineers, India). Taylor and Francis Ltd., 2021; Volume 38, no. 3, pp. 328–346. [Google Scholar] [CrossRef]

- Mohammed, A.S.B.; et al. Improving the Gain Performance of Air Substrate Patch Antenna Array Using the Effect of Conductive Material Thickness Study for 5G Applications. Journal of Physics: Conference Series 2020, 1529. [Google Scholar] [CrossRef]

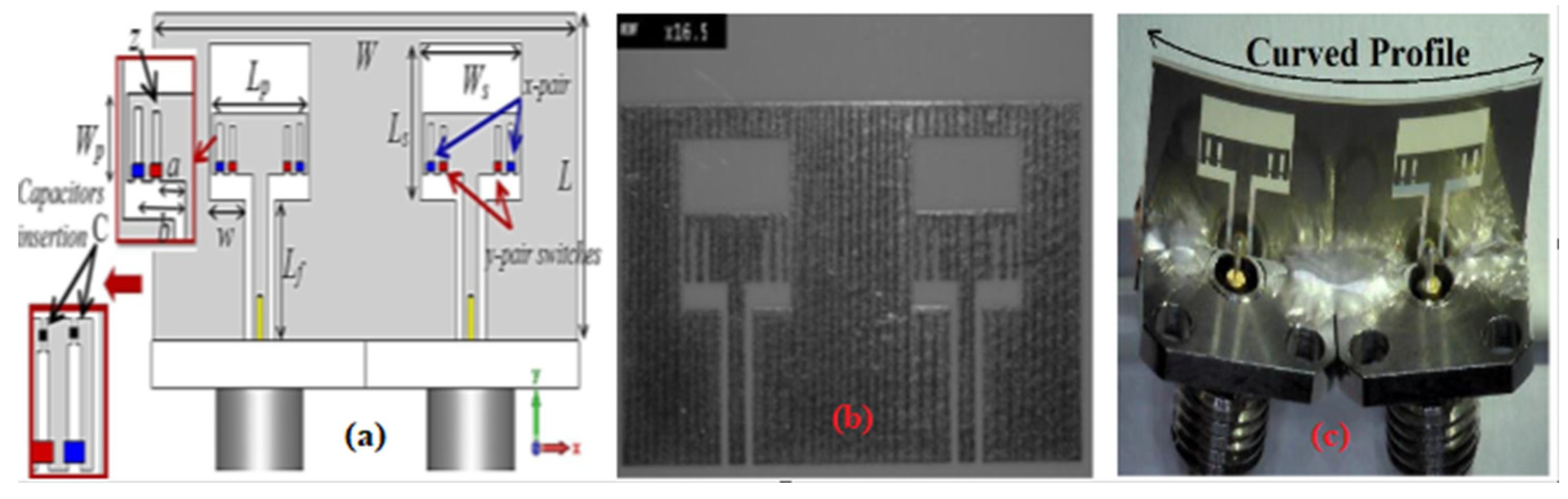

- Ojaroudi Parchin, A.; Citation Ojaroudi Parchin N, R.A.; Yia, A.-Y. Frequency Reconfigurable Antenna Array for MM-Wave 5G Mobile Handsets Item Type Conference paper. 2018. Available online: http://hdl.handle.net/10454/16680.

- di Paola, C.; Zhang, S.; Zhao, K.; Ying, Z.; Bolin, T.; Pedersen, G.F. Wideband Beam-Switchable 28 GHz Quasi-Yagi Array for Mobile Devices. IEEE Trans Antennas Propag 2019, 67, 6870–6882. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Wang, W.; Ma, L. Wideband mm-wave high-gain multibeam antenna array fed by 4 × 4 groove gap waveguide butler matrix with modified crossover. AEU—International Journal of Electronics and Communications 2022, 154, 154287. [Google Scholar] [CrossRef]

- Merlin Teresa, P.; Umamaheswari, G. Compact Slotted Microstrip Antenna for 5G Applications Operating at 28 GHz. IETE J Res 2020. [Google Scholar] [CrossRef]

- Salarrahimi, M.; et al. A Cost-Efficient 28 GHz Integrated Antenna Array with Full Impedance Matrix Characterization for 5G NR. IEEE Antennas Wirel Propag Lett 2020, 19, 666–670. [Google Scholar] [CrossRef]

- Ghosh, S.; Baghel, G.S.; v Swati, M. A low-profile, high gain, dual-port, planar array antenna for mm-wave powered 5G IoT systems. AEU—International Journal of Electronics and Communications 2022, 155, 154354. [Google Scholar] [CrossRef]

- Saha, T.K. High-performance antenna design for IoT, wearable, and 5G communications/. Washington State University: Pullman, Washington, 2019. [Google Scholar]

- Gu, C.; et al. A D-Band 3D-Printed Antenna. IEEE Trans Terahertz Sci Technol 2020, 10, 433–442. [Google Scholar] [CrossRef]

- Xu, B.; et al. Radiation Performance Analysis of 28 GHz Antennas Integrated in 5G Mobile Terminal Housing. IEEE Access 2018, 6, 48088–48101. [Google Scholar] [CrossRef]

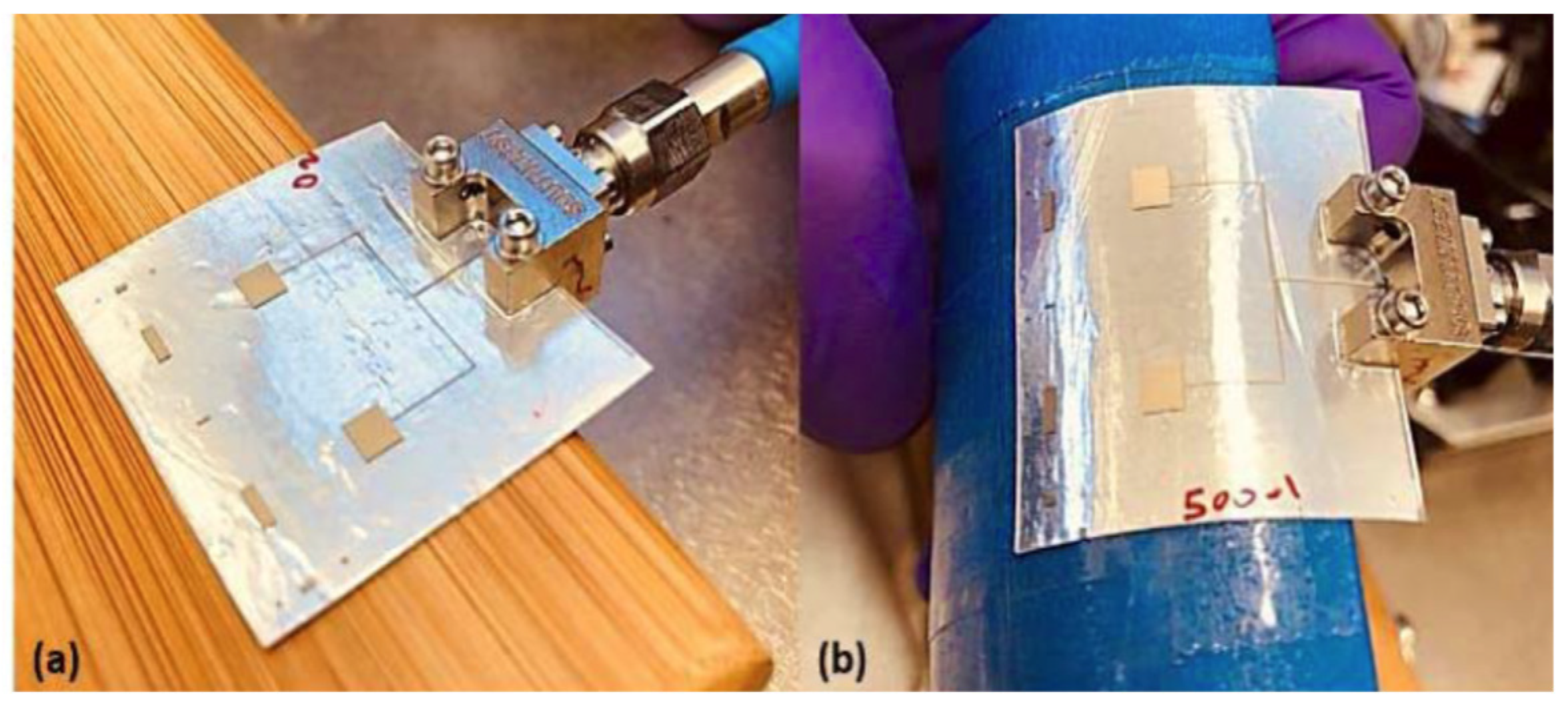

- Khinda, G.S.; et al. Flexible inkjet-printed Patch antenna array on mesoporous PET substrate for 5G applications with stable RF performance after mechanical stress cycling. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC); 2020; pp. 1824–1831. [Google Scholar] [CrossRef]

- Khan, A.Q.; Riaz, M.; Bilal, A. Various Types of Antenna with Respect to their Applications: A Review. International Journal of Multidisciplinary Sciences and Engineering 2016, 7. [Google Scholar]

- Kirtania, S.G.; et al. Flexible antennas: A review. Micromachines 2020, 11, 847. [Google Scholar] [PubMed]

- Belen, M.A. Design and realization of dual band stacked antenna via three-dimensional printing technology. Microw Opt Technol Lett 2020, 62. [Google Scholar] [CrossRef]

- Xu, J.; Ke, H.; He, Y.; Luo, Y. A Wideband U-Slot Microstrip Patch Antenna for Large-Angle Mmw Beam Scanning. In Proceedings of the 2018 IEEE International Conference on Computer and Communication Engineering Technology, CCET 2018; 2018. [Google Scholar] [CrossRef]

- Feng, B.; Tu, Y.; Chen, J.; Chung, K.L.; Sun, S. High-performance dual circularly-polarized antenna arrays using 3D printing for 5G millimetre-wave communications. AEU—International Journal of Electronics and Communications 2021, 130, 153569. [Google Scholar] [CrossRef]

- Jain, K.; Kushwah, V.S. Design and development of dual band antenna for sub-6 frequency band application. Mater Today Proc 2021, 47, 6795–6798. [Google Scholar] [CrossRef]

- Shah, I.A.; et al. Design and analysis of a hexa-band frequency reconfigurable antenna for wireless communication. AEU—International Journal of Electronics and Communications 2019, 98, 80–88. [Google Scholar] [CrossRef]

- Mishra, R.; Mishra, R.G.; Chaurasia, R.K.; Shrivastava, A.K. Design and analysis of microstrip patch antenna for wireless communication. International Journal of Innovative Technology and Exploring Engineering 2019, 8. [Google Scholar] [CrossRef]

- Godaymi Al-Tumah, W.A.; Shaaban, R.M.; Duffy, A.P. Design, simulation, and fabrication of a double annular ring microstrip antenna based on gaps with multiband feature. Engineering Science and Technology, an International Journal 2022, 29, 101033. [Google Scholar] [CrossRef]

- Ramprakash, K. Design, analysis and fabrication of a microstrip slot antenna. International Journal of Innovative Technology and Exploring Engineering 2018, 8. [Google Scholar]

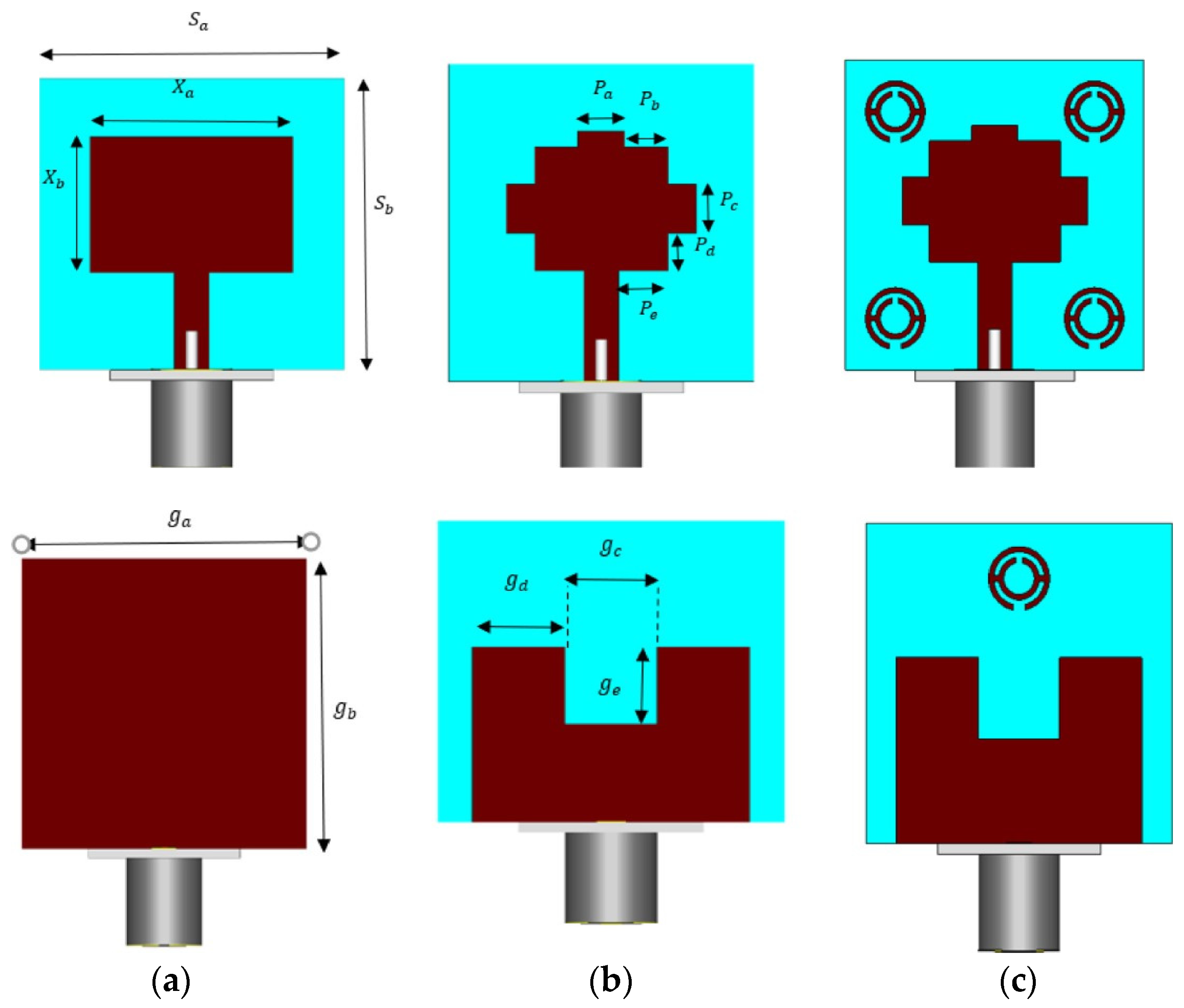

- Singh, M.; Singh, S.; Islam, M.T. CSRR loaded high gained 28/38GHz printed MIMO patch antenna array for 5G millimeter wave wireless devices. Microelectron Eng 2022, 262, 111829. [Google Scholar] [CrossRef]

- Gu, C.; et al. A D-Band 3D-Printed Antenna. IEEE Trans Terahertz Sci Technol 2020, 10, 433–442. [Google Scholar] [CrossRef]

- Jilani, S.F.; Abbasi, Q.H.; Alomainy, A. Inkjet-Printed Millimetre-Wave PET-Based Flexible Antenna for 5G Wireless Applications. In Proceedings of the 2018 IEEE MTT-S International Microwave Workshop Series on 5G Hardware and System Technologies (IMWS-5G); 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Tariq, S.; Psychoudakis, D.; Eliezer, O.; Khan, F. A new approach to antenna beamforming for millimeter-wave fifth generation (5G) systems. In Proceedings of the 2018 Texas Symposium on Wireless and Microwave Circuits and Systems, WMCS 2018; 2018. [Google Scholar] [CrossRef]

- IEEE Staff. 2017 Texas Symposium on Wireless and Microwave Circuits and Systems (WMCS). IEEE, 2017. [Google Scholar]

- Valkonen, R. Compact 28-GHz phased array antenna for 5G access. In IEEE MTT-S International Microwave Symposium Digest; 2018; Volume 2018-June. [Google Scholar] [CrossRef]

- Bang, J.; Choi, J. A Compact Hemispherical Beam-Coverage Phased Array Antenna Unit for 5G mm-Wave Applications. IEEE Access 2020, 8. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, T.; Li, L.; Zheng, F.C. A low-cost dual-polarized 28 GHz phased array antenna for 5G communications. In Proceedings of the 2018 IEEE International Workshop on Antenna Technology, iWAT2018—Proceedings; 2018. [Google Scholar] [CrossRef]

- Zhang, H.; Bosma, S.; Neto, A.; Llombart, N. A Dual-Polarized 27 dBi Scanning Lens Phased Array Antenna for 5G Point-to-Point Communications. IEEE Trans Antennas Propag 2021, 69, 5640–5652. [Google Scholar] [CrossRef]

- Gu, X.; et al. Novel Phased Array Antenna-in-Package Development and Active Module Demonstration for 5G Millimeter-Wave Wireless Communication. In Proceedings of the Electronic Components and Technology Conference; 2021; Volume 2021-June. [Google Scholar] [CrossRef]

- Kapusuz, K.Y.; Lemey, S.; Rogier, H. Dual-Polarized 28-GHz Air-Filled SIW Phased Antenna Array for Next-Generation Cellular Systems. In IEEE International Symposium on Phased Array Systems and Technology; 2019; Volume 2019-October. [Google Scholar] [CrossRef]

- Nafe, A.; Sayginer, M.; Kibaroglu, K.; Rebeiz, G.M. 2x64 Dual-Polarized Dual-Beam Single-Aperture 28 GHz Phased Array with High Cross-Polarization Rejection for 5G Polarization MIMO. In IEEE MTT-S International Microwave Symposium Digest; 2019; Volume 2019-June. [Google Scholar] [CrossRef]

- Shastri, A.; et al. 3D Printing of Millimetre Wave and Low-Terahertz Frequency Selective Surfaces Using Aerosol Jet Technology. IEEE Access 2020, 8, 177341–177350. [Google Scholar] [CrossRef]

- He, Y.; Craton, M.T.; Chahal, P.; Papapolymerou, J. A Bi-material Fully Aerosol Jet printed W-band Quasi-Yagi-Uda Antenna. In Proceedings of the 2018 11th Global Symposium on Millimeter Waves (GSMM); 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Ali, M.; et al. Package-Integrated, Wideband Power Dividing Networks and Antenna Arrays for 28-GHz 5G New Radio Bands. IEEE Trans Compon Packaging Manuf Technol 2020, 10, 1515–1523. [Google Scholar] [CrossRef]

- Ghavidel, A.; Araghi, A.; Myllymäki, S.; Sonkki, M. High gain dual-band millimeter wave antenna using flexible PET substrate. In Proceedings of the 12th European Conference on Antennas and Propagation (EuCAP 2018); 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Pourahmadazar, J.; Denidni, T.A. Millimeter-wave planar antenna on flexible polyethylene terephthalate substrate with water base silver nanoparticles conductive ink. Microw Opt Technol Lett 2018, 60. [Google Scholar] [CrossRef]

- Njogu, P.; Sanz-Izquierdo, B.; Elibiary, A.; Jun, S.Y.; Chen, Z.; Bird, D. 3D Printed Fingernail Antennas for 5G Applications. IEEE Access 2020, 8, 228711–228719. [Google Scholar] [CrossRef]

- Lin, T.-H.; Bahr, R.; Tentzeris, M.M.; Raj, P.M.; Sundaram, V.; Tummala, R. Novel 3D-/Inkjet-Printed Flexible On-package Antennas, Packaging Structures, and Modules for Broadband 5G Applications. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC); 2018; pp. 214–220. [Google Scholar] [CrossRef]

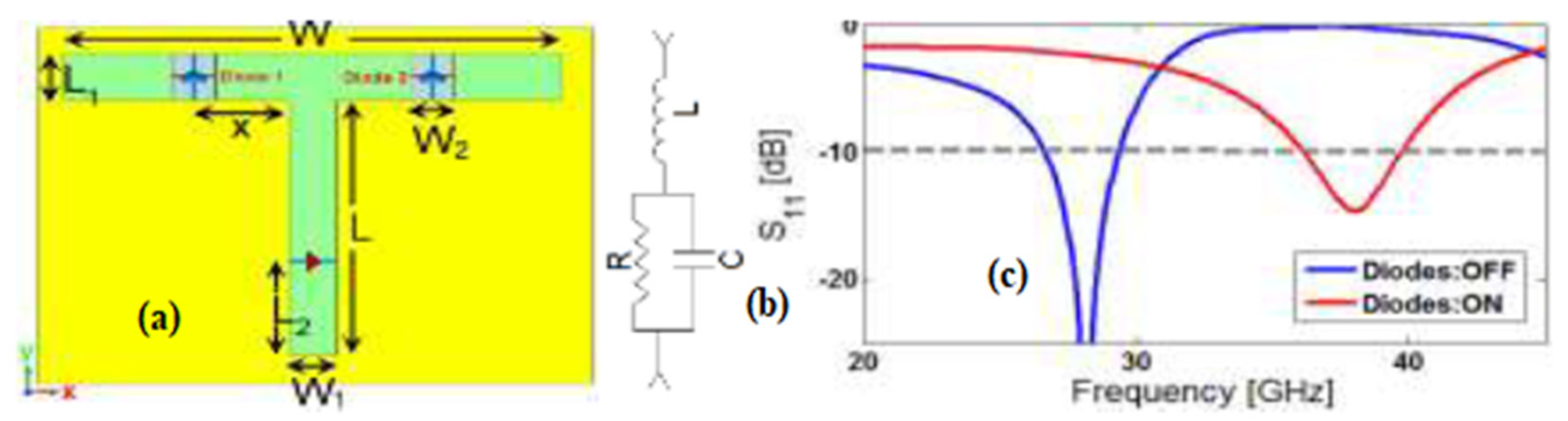

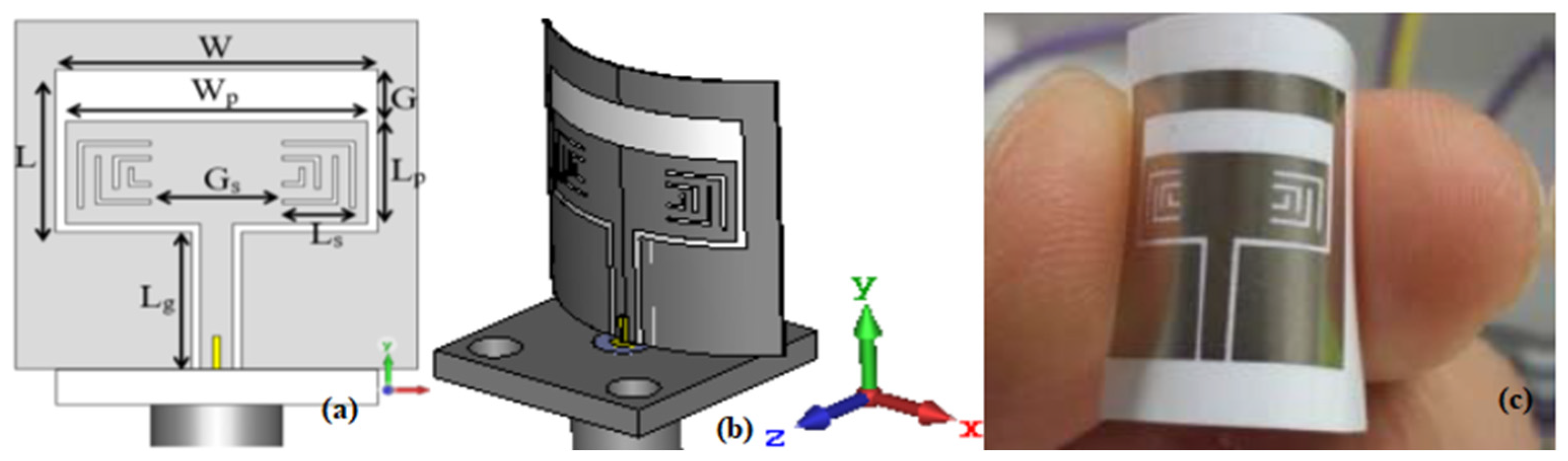

- Jilani, S.F.; Rahimian, A.; Alfadhl, Y.; Alomainy, A. Low-profile flexible frequency-reconfigurable millimetre-wave antenna for 5G applications. Flexible and Printed Electronics 2018, 3, 35003. [Google Scholar] [CrossRef]

- Alkaraki, S.; et al. Compact and Low-Cost 3-D Printed Antennas Metalized Using Spray-Coating Technology for 5G mm-Wave Communication Systems. IEEE Antennas Wirel Propag Lett 2018, 17, 2051–2055. [Google Scholar] [CrossRef]

- Jilani, S.F.; Munoz, M.O.; Abbasi, Q.H.; Alomainy, A. Millimeter-Wave Liquid Crystal Polymer Based Conformal Antenna Array for 5G Applications. IEEE Antennas Wirel Propag Lett 2019, 18, 84–88. [Google Scholar] [CrossRef]

- Li, E.; Li, X.J.; Seet, B.-C.; Lin, X. Ink-printed flexible wideband dipole array antenna for 5G applications. Physical Communication 2020, 43, 101193. [Google Scholar] [CrossRef]

- Yi, H.; Mu, Y.; Han, J.; Li, L. Broadband Millimeter-Wave Metasurface Antenna Array with Printed Ridge Gap Waveguide for High Front-to-Back Ratio. Journal of Information and Intelligence. 2022. [Google Scholar] [CrossRef]

- El_Mashade, M.B.; Hegazy, E.A. Design and Analysis of 28GHz Rectangular Microstrip Patch Array Antenna. WSEAS Transactions on Communications 2018, 17. [Google Scholar]

- Kim, S.; Yoon, S.; Lee, Y.; Shin, H. A miniaturized butler matrix based switched beamforming antenna system in a two-layer hybrid stackup substrate for 5g applications. Electronics 2019, 8, 1232. [Google Scholar] [CrossRef]

- de Paula, I.; et al. Cost-Effective High-Performance Air-Filled SIW Antenna Array for the Global 5G 26 GHz and 28 GHz Bands. IEEE Antennas Wirel Propag Lett 2021, 20, 194–198. [Google Scholar] [CrossRef]

- Sharma, M.; Gautam, A.K.; Singh, N.; Garigapati, N.S.; Agrawal, N. Design of a Novel Dual Band Printed Antenna for Future Mobile Applications. Procedia Comput Sci 2020, 171, 917–923. [Google Scholar] [CrossRef]

- Li, J.; Matos, C.; Ghalichechian, N. A Low-Cost Vertically Integrated Antenna Array at 60 GHz with 85% Efficiency. IEEE Antennas Wirel Propag Lett 2021, 20, 513–517. [Google Scholar] [CrossRef]

- Govindarajulu, S.R.; Hokayem, R.; Alwan, E.A. A 60 GHz Millimeter-Wave Antenna Array for 3D Antenna-in-Package Applications. IEEE Access 2021, 9, 143307–143314. [Google Scholar] [CrossRef]

- IEEE Circuits and Systems Society; Institute of Electrical and Electronics Engineers. In Proceedings of the 2020 IEEE 63rd International Midwest Symposium on Circuits and Systems (MWSCAS): on-line proceedings. 9–12 August 2020; Springfield Sheraton Hotel: Springfield, MA, USA. [Google Scholar]

- Tomura, T.; Saito, Y.; Hirokawa, J. 8 × 2-Element 60-GHz-Band Circularly Polarized Post-Wall Waveguide Slot Array Antenna Loaded with Dipoles. IEEE Access 2020, 8, 85950–85957. [Google Scholar] [CrossRef]

- Heino, M.; Icheln, C.; Haarla, J.; Haneda, K. PCB-Based Design of a Beamsteerable Array with High-Gain Antennas and a Rotman Lens at 28 GHz. IEEE Antennas Wirel Propag Lett 2020, 19. [Google Scholar] [CrossRef]

- Jafari-Chashmi, M.; Rezaei, P.; Haghparast, A.H.; Zarifi, D. Dual circular polarization 2 × 2 slot array antenna based on printed ridge gap waveguide technology in Ka band. AEU—International Journal of Electronics and Communications 2022, 157, 154433. [Google Scholar] [CrossRef]

- Monne, M.A.; Grubb, P.M.; Stern, H.; Subbaraman, H.; Chen, R.T.; Chen, M.Y. Inkjet-Printed graphene-based 1 x 2 phased array antenna. Micromachines 2020, 11, 863. [Google Scholar] [CrossRef]

- Salonen, P.; Rahmat-Samii, Y.; Hurme, H.; Kivikoski, M. Effect of conductive material on wearable antenna performance: A case study of WLAN antennas. In IEEE Antennas and Propagation Society, AP-S International Symposium (Digest); 2004; Volume 1. [Google Scholar] [CrossRef]

- Tseghai, G.B.; Mengistie, D.A.; Malengier, B.; Fante, K.A.; van Langenhove, L. PEDOT:PSS-based conductive textiles and their applications. Sensors 2020, 20, 1881. [Google Scholar] [CrossRef]

- Park, J.; Park, S.; Yang, W.; Kam, D.G. Folded aperture coupled patch antenna fabricated on FPC with vertically polarised end-fire radiation for fifth-generation millimetre-wave massive MIMO systems. IET Microwaves, Antennas and Propagation 2019, 13, 1660–1663. [Google Scholar] [CrossRef]

- Cetiner, B.A.; Qian, J.Y.; Chang, H.P.; Bachman, M.; Li, G.P.; de Flaviis, F. Monolithic integration of RF MEMS switches with a diversity antenna on PCB substrate. IEEE Trans Microw Theory Tech 2003, 51, 332–335. [Google Scholar] [CrossRef]

- Paracha, K.N.; Rahim, S.K.A.; Chattha, H.T.; Aljaafreh, S.S.; Rehman, S.U.; Lo, Y.C. Low-cost printed flexible antenna by using an office printer for conformal applications. Int J Antennas Propag 2018, 2018. [Google Scholar] [CrossRef]

- Lajevardi, M.E.; Kamyab, M. A low-cost wideband Quasi-Yagi SIW-based textile antenna. Progress in Electromagnetics Research Letters 2017, 67. [Google Scholar] [CrossRef]

- Moro, R.; Agneessens, S.; Rogier, H.; Bozzi, M. Circularly-polarised cavity-backed wearable antenna in SIW technology. IET Microwaves, Antennas and Propagation 2018, 12, 127–131. [Google Scholar] [CrossRef]

- McCormack, J.; Gambardella, C.C. Growing and Evolving 3D Prints. 2021. [Google Scholar] [CrossRef]

- Noferesti, M.; Djerafi, T. 3D-Printed Dual Polarized Dielectric Rod Antenna for Millimeter-Wave Communication. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, IEEECONF 2020—Proceedings; 2020. [Google Scholar] [CrossRef]

- Rao, J.; Nai, K.; Vaitukaitis, P.; Li, Y.; Hong, J. Compact 3-D Metal Printed Filtering Antenna. IEEE Antennas Wirel Propag Lett 2022, 21, 386–390. [Google Scholar] [CrossRef]

- Bicer, M.B.; Aydin, E.A. A novel 3D printed curved monopole microstrip antenna design for biomedical applications. Phys Eng Sci Med 2021, 41. [Google Scholar] [CrossRef] [PubMed]

- Rizwan, M.; Khan, M.W.A.; Sydänheimo, L.; Virkki, J.; Ukkonen, L. Flexible and Stretchable Brush-Painted Wearable Antenna on a Three-Dimensional (3-D) Printed Substrate. IEEE Antennas Wirel Propag Lett 2017, 16, 3108–3112. [Google Scholar] [CrossRef]

- Meredov, A.; Klionovski, K.; Shamim, A. Screen-Printed, Flexible, Parasitic Beam-Switching Millimeter-Wave Antenna Array for Wearable Applications. IEEE Open Journal of Antennas and Propagation 2020, 1, 2–10. [Google Scholar] [CrossRef]

- Rashidian, A.; Shafai, L.; Sobocinski, M.; Perantie, J.; Juuti, J.; Jantunen, H. Printable Planar Dielectric Antennas. IEEE Trans Antennas Propag 2016, 64. [Google Scholar] [CrossRef]

- Goliya, Y.; et al. Next Generation Antennas Based on Screen-Printed and Transparent Silver Nanowire Films. Adv Opt Mater 2019, 7. [Google Scholar] [CrossRef]

- Abutarboush, H.F. Silver nanoparticle inkjet-printed multiband antenna on synthetic paper material for flexible devices. Alexandria Engineering Journal 2022, 61, 6349–6355. [Google Scholar] [CrossRef]

- Raja, K.B.; Pandian, S.C. Low-profile metamaterial-based T-shaped engraved electrically small antenna design with wideband operating capability for WLAN/5G applications. Physica B Condens Matter 2022, 646, 414359. [Google Scholar] [CrossRef]

- Herbstová, M.; Litvín, R.; Gardian, Z.; Komenda, J.; Vácha, F. Localization of Pcb antenna complexes in the photosynthetic prokaryote Prochlorothrix hollandica. Biochim Biophys Acta Bioenerg 2010, 1797, 89–97. [Google Scholar] [CrossRef]

- Zhang, W.; Li, N.; Kasper, E.; Zheng, Z.; Shi, L. Impact Analysis of High-Frequency Material and PCB Fabrication Technology on Antenna Design for 77/79 GHz Automotive Radar. In Proceedings of the 2019 IEEE Asia-Pacific Microwave Conference (APMC); 2019; pp. 655–657. [Google Scholar] [CrossRef]

- Hayat, T.; Esselle, K.P.; Afzal, M.U.; Singh, K. 3D Printed All Dielectric Phase Correcting Surface for Resonant Cavity Antenna. In Proceedings of the 2018 IEEE 7th Asia-Pacific Conference on Antennas and Propagation, APCAP 2018; 2018. [Google Scholar] [CrossRef]

- Lee, S.; Lee, Y.; Shin, H. A 28-GHz switched-beam antenna with integrated butler matrix and switch for 5G applications. Sensors 2021, 21, 5128. [Google Scholar] [CrossRef]

- Amendola, S.; Palombi, A.; Marrocco, G. Inkjet Printing of Epidermal RFID Antennas by Self-Sintering Conductive Ink. Available online: www.pervasive.ing.uniroma2.it.

- Colella, R.; Catarinucci, L.; Michel, A. Circularly polarized antenna in 3d printing technology to feed a wearable fully-integrated WiFi-RFID reader for biomedical applications. In Proceedings of the 2020 International Workshop on Antenna Technology, iWAT 2020; 2020. [Google Scholar] [CrossRef]

- Lv, S.; et al. Reactive inkjet printing of graphene based flexible circuits and radio frequency antennas. J Mater Chem C Mater 2021, 9. [Google Scholar] [CrossRef]

- Zhao, P.; Huang, J.; Nan, J.; Liu, D.; Meng, F. Laser sintering process optimization of microstrip antenna fabricated by inkjet printing with silver-based MOD ink. J Mater Process Technol 2020, 275, 116347. [Google Scholar] [CrossRef]

- Chen, Y.S.; Huang, S.X. Performance Enhancements of Fully Inkjet-Printing Technology for Antenna-in-Package and Substrate Integrated Waveguides. Int J Antennas Propag 2022, 2022. [Google Scholar] [CrossRef]

- Tomaszewski, G.; Jankowski-Mihułowicz, P.; Potencki, J.; Pietrikova, A.; Lukacs, P. Inkjet-printed HF antenna made on PET substrate. Microelectronics Reliability 2022, 129, 114473. [Google Scholar] [CrossRef]

- Islam, M.S.; Azam, S.K.; Hossain, A.Z.; Ibrahimy, M.I.; Motakabber, S.M. A low-profile flexible planar monopole antenna for biomedical applications. Engineering Science and Technology, an International Journal 2022, 35, 101112. [Google Scholar] [CrossRef]

- Lv, S.; et al. Reactive inkjet printing of graphene based flexible circuits and radio frequency antennas. J Mater Chem C Mater 2021, 9. [Google Scholar] [CrossRef]

- Abutarboush, H.F.; Shamim, A. A Reconfigurable Inkjet-Printed Antenna on Paper Substrate for Wireless Applications. IEEE Antennas Wirel Propag Lett 2018, 17, 1648–1651. [Google Scholar] [CrossRef]

- Li, W.; Hei, Y.; Grubb, P.M.; Shi, X.; Chen, R.T. Compact inkjet-printed flexible MIMO antenna for UWB applications. IEEE Access 2018, 6. [Google Scholar] [CrossRef]

- Li, W.T.; Hei, Y.Q.; Grubb, P.M.; Shi, X.W.; Chen, R.T. Inkjet Printing of Wideband Stacked Microstrip Patch Array Antenna on Ultrathin Flexible Substrates. IEEE Trans Compon Packaging Manuf Technol 2018, 8. [Google Scholar] [CrossRef]

- Njogu, P.M.; et al. Evaluation of Planar Inkjet-Printed Antennas on a Low-Cost Origami Flapping Robot. IEEE Access 2020, 8. [Google Scholar] [CrossRef]

- Bait-Suwailam, M.M.; Alomainy, A. Flexible analytical curve-based dual-band antenna for wireless body area networks. Progress In Electromagnetics Research M 2019, 84. [Google Scholar] [CrossRef]

- Jun, S.; Heirons, J.; Sanz-Izquierdo, B. Inkjet printed dual band antenna for paper UAVs. In Proceedings of the 2017 11th European Conference on Antennas and Propagation, EUCAP 2017; 2017. [Google Scholar] [CrossRef]

- Labiano, I.I.; Alomainy, A. Flexible inkjet-printed graphene antenna on Kapton. Flexible and Printed Electronics 2021, 6. [Google Scholar] [CrossRef]

- Li, X.; et al. Self-reinforcing graphene coatings on 3D printed elastomers for flexible radio frequency antennas and strain sensors. Flexible and Printed Electronics 2017, 2. [Google Scholar] [CrossRef]

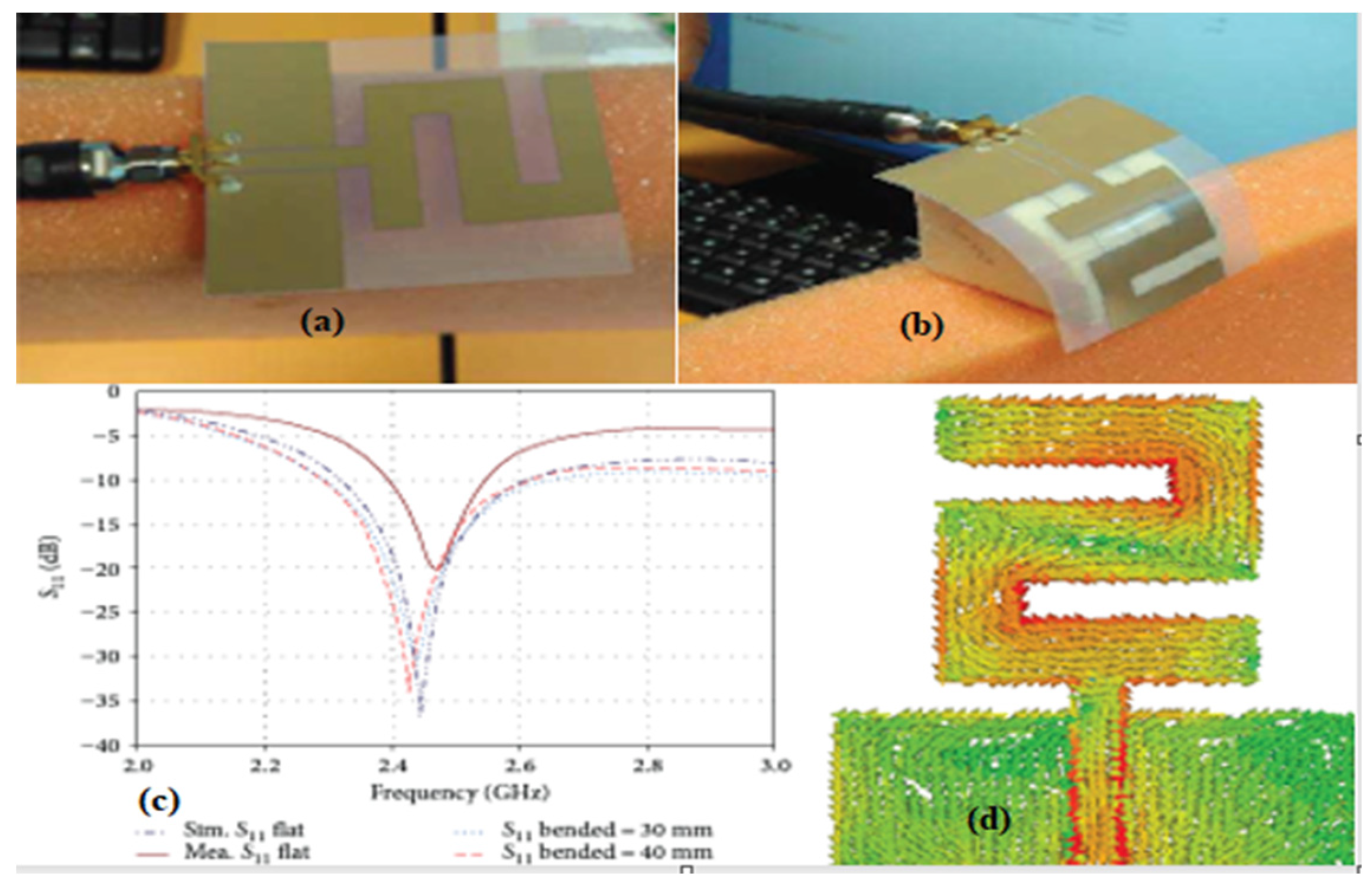

- Zhou, Y.; et al. Study of Electrical and Mechanical Characteristics of Inkjet-Printed Patch Antenna Under Uniaxial and Biaxial Bending. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC); 2019; pp. 1939–1945. [Google Scholar] [CrossRef]

- Kao, H.-L.; Chuang, C.-H.; Cho, C.-L. Inkjet-Printed Filtering Antenna on a Textile for Wearable Applications. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC); 2019; pp. 258–263. [Google Scholar] [CrossRef]

- Nair, N.M.; Ray, D.; Swaminathan, P. Paper-based printed CPW-fed antenna for Wi-Fi applications. January 2022. Available online: http://arxiv.org/abs/2202.03266.

- Chen, C.B.; et al. Wound-Dressing-Based Antenna Inkjet-Printed Using Nanosilver Ink for Wireless Medical Monitoring. Micromachines 2022, 13, 1510. [Google Scholar] [CrossRef]

- Amram-Bengio, E.; et al. High efficiency carbon nanotube thread antennas. Appl Phys Lett 2017, 111. [Google Scholar] [CrossRef]

- Tsolis, A.; Whittow, W.G.; Alexandridis, A.A.; Vardaxoglou, J.Y.C. Embroidery and related manufacturing techniques for wearable antennas: Challenges and opportunities. Electronics 2014, 3, 314. [Google Scholar] [CrossRef]

- Hassan, A.; Ali, S.; Hassan, G.; Bae, J.; Lee, C.H. Inkjet-printed antenna on thin PET substrate for dual band Wi-Fi communications. Microsystem Technologies 2017, 23, 3701–3709. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Li, W.; Zhang, Q.; Zong, W.H.; Yao, Z. A Novel Flexible Low Profile Antenna with Ultra-Wideband. In Proceedings of the 2019 IEEE International Workshop on Electromagnetics: Applications and Student Innovation Competition, iWEM 2019—Proceedings; 2019. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).