Submitted:

18 April 2023

Posted:

19 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Design of experiments

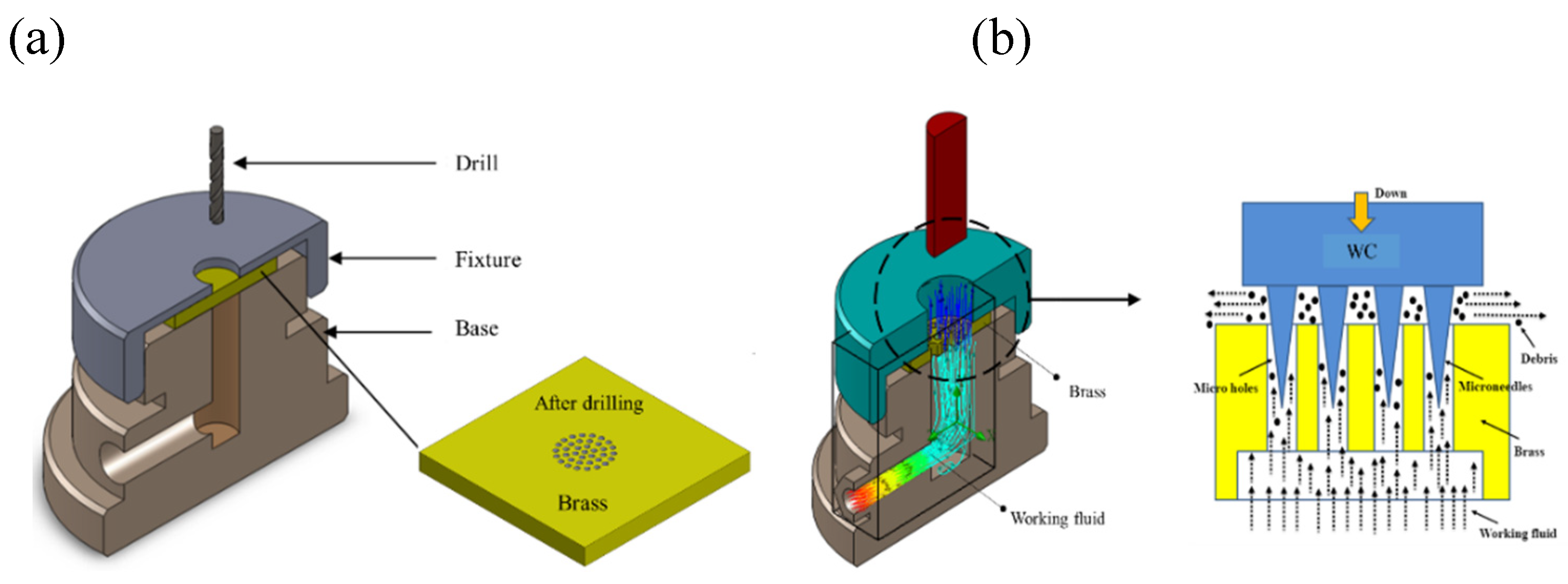

2.2. Punch head manufacturing

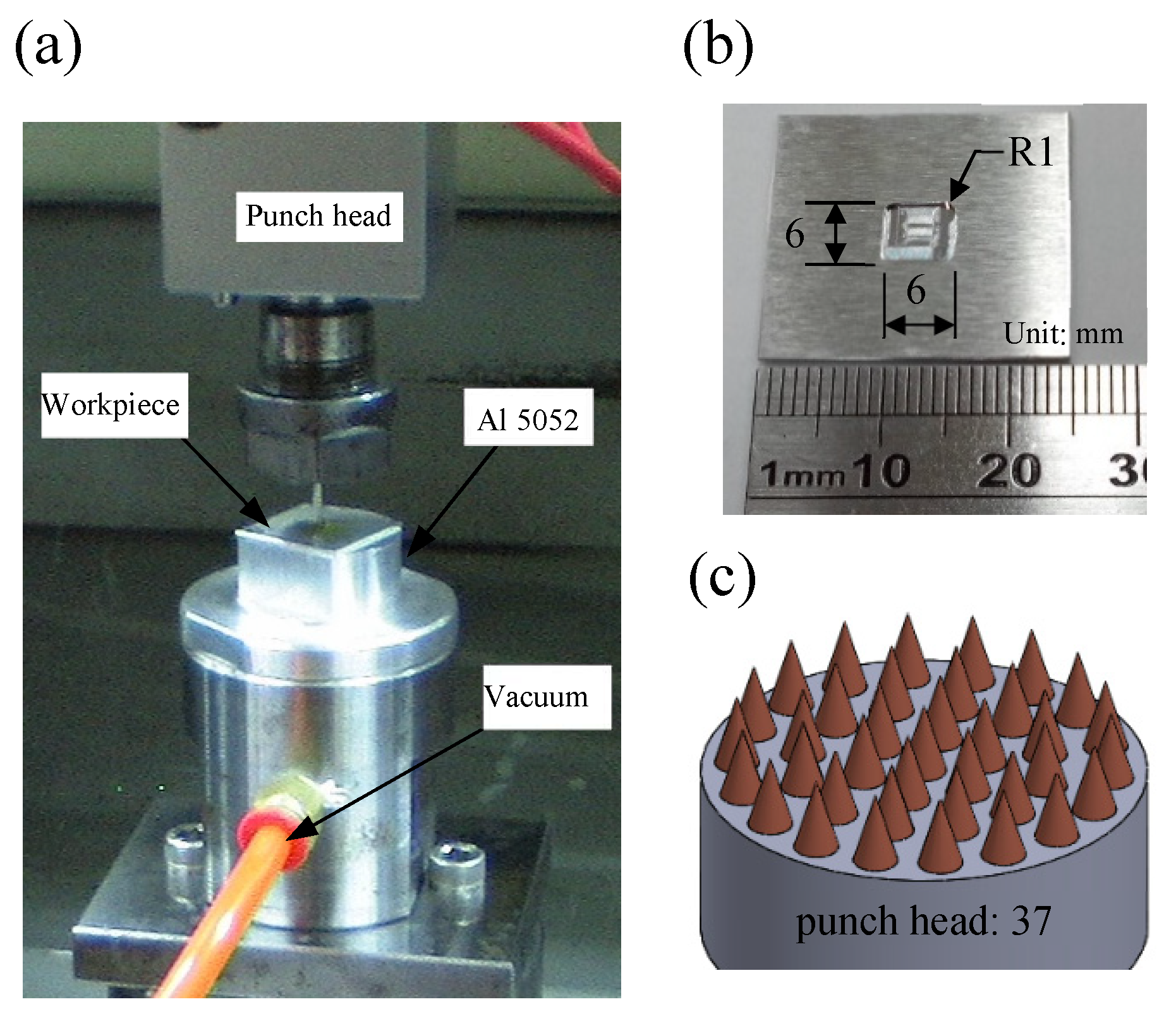

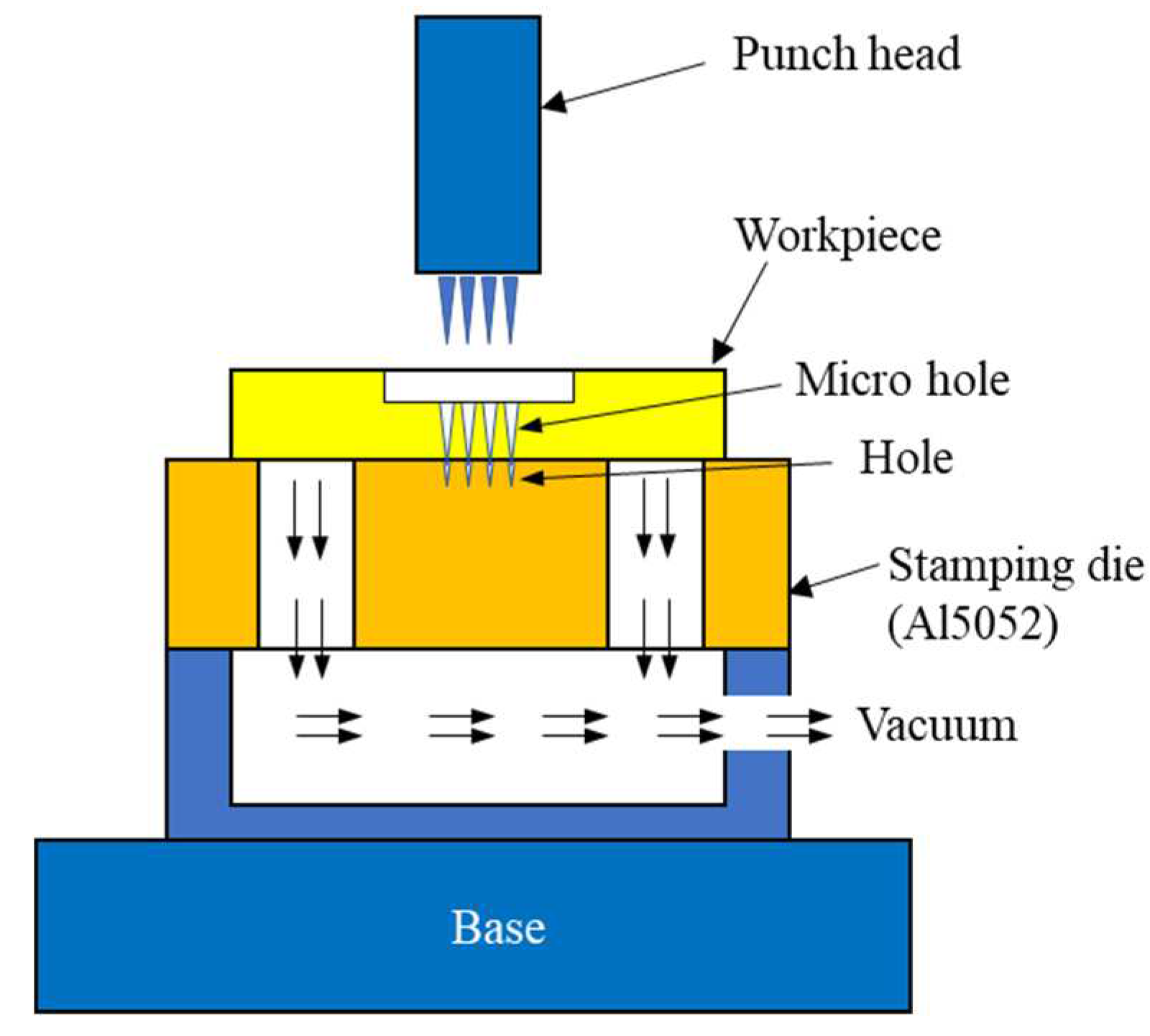

2.3. Stamping experiment

| Sample | Sample thickness | Punch angle | Stamping speed | Quantity of microholes | Stamping depth | Stamped quantity |

| Al6061 | 260μm | 15.8° | 0.5mm/min | 37 | 350 μm | 50 pcs |

3. Results and discussion

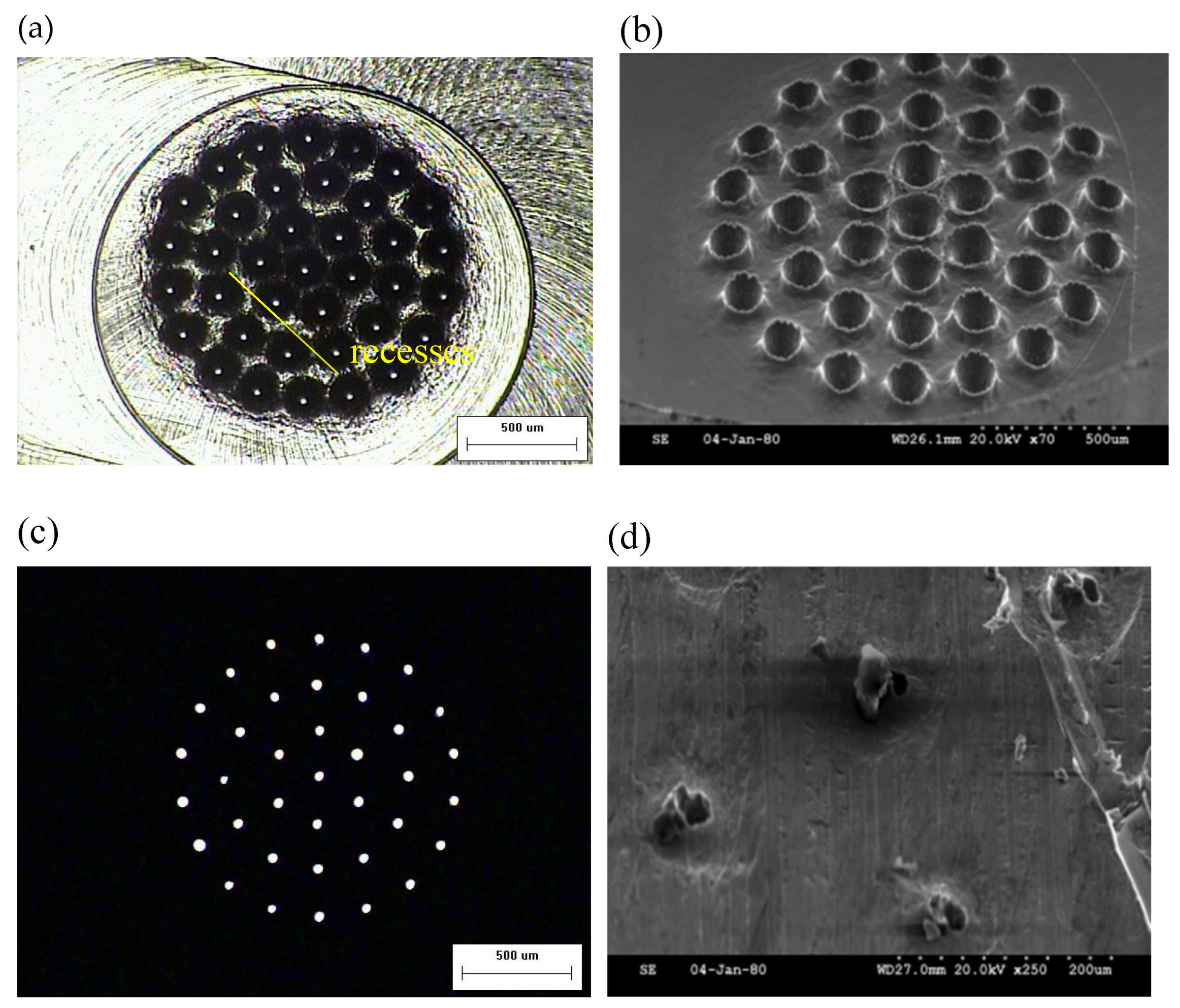

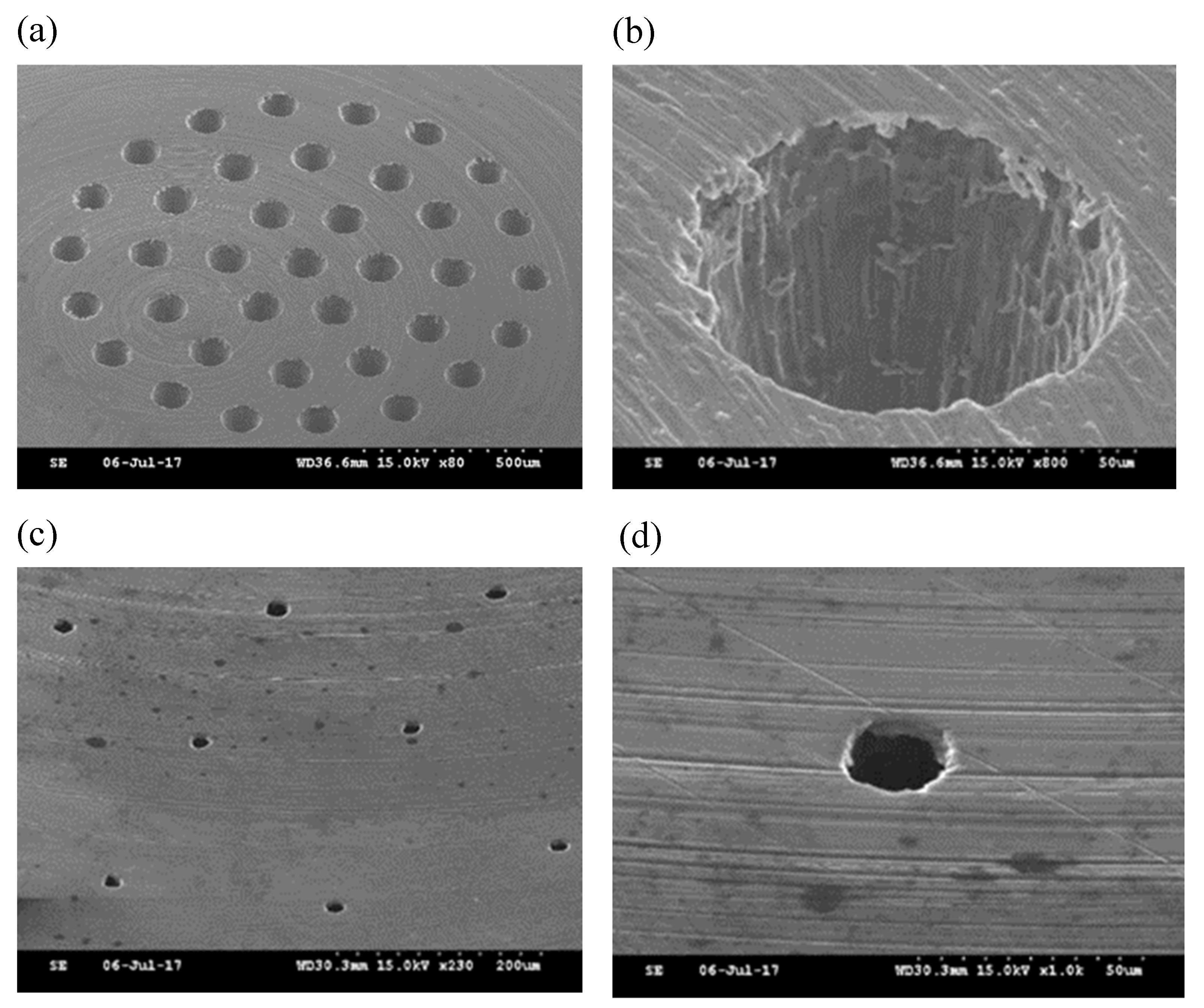

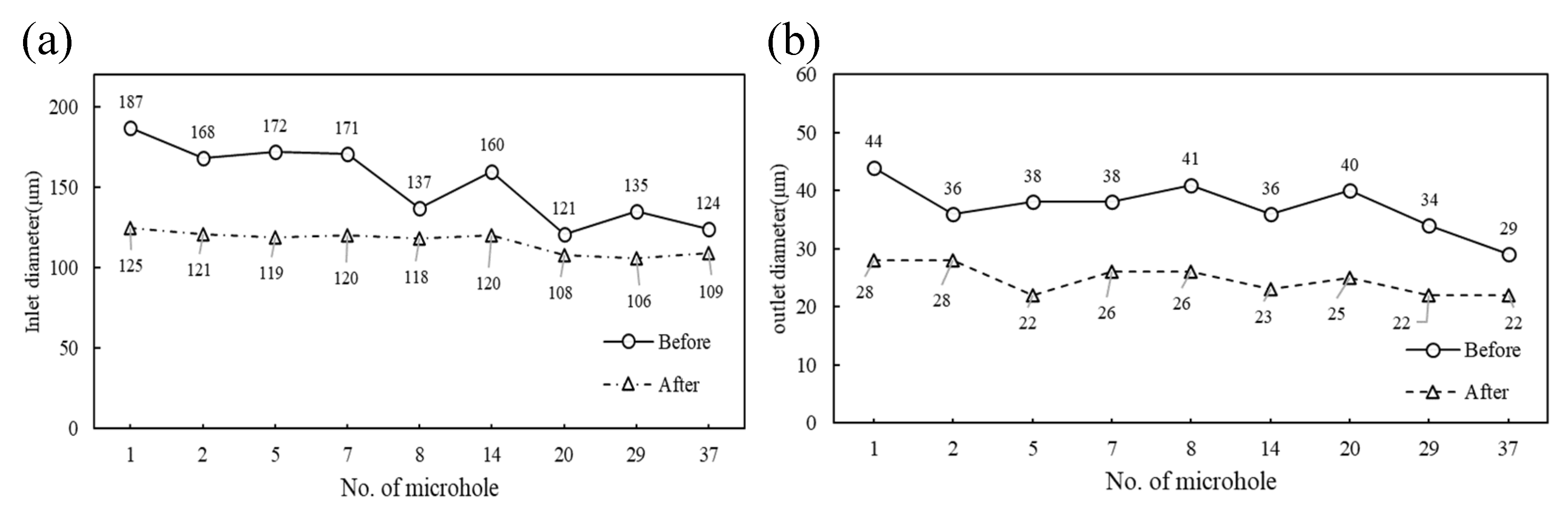

3.1. Sample inlet and outlet

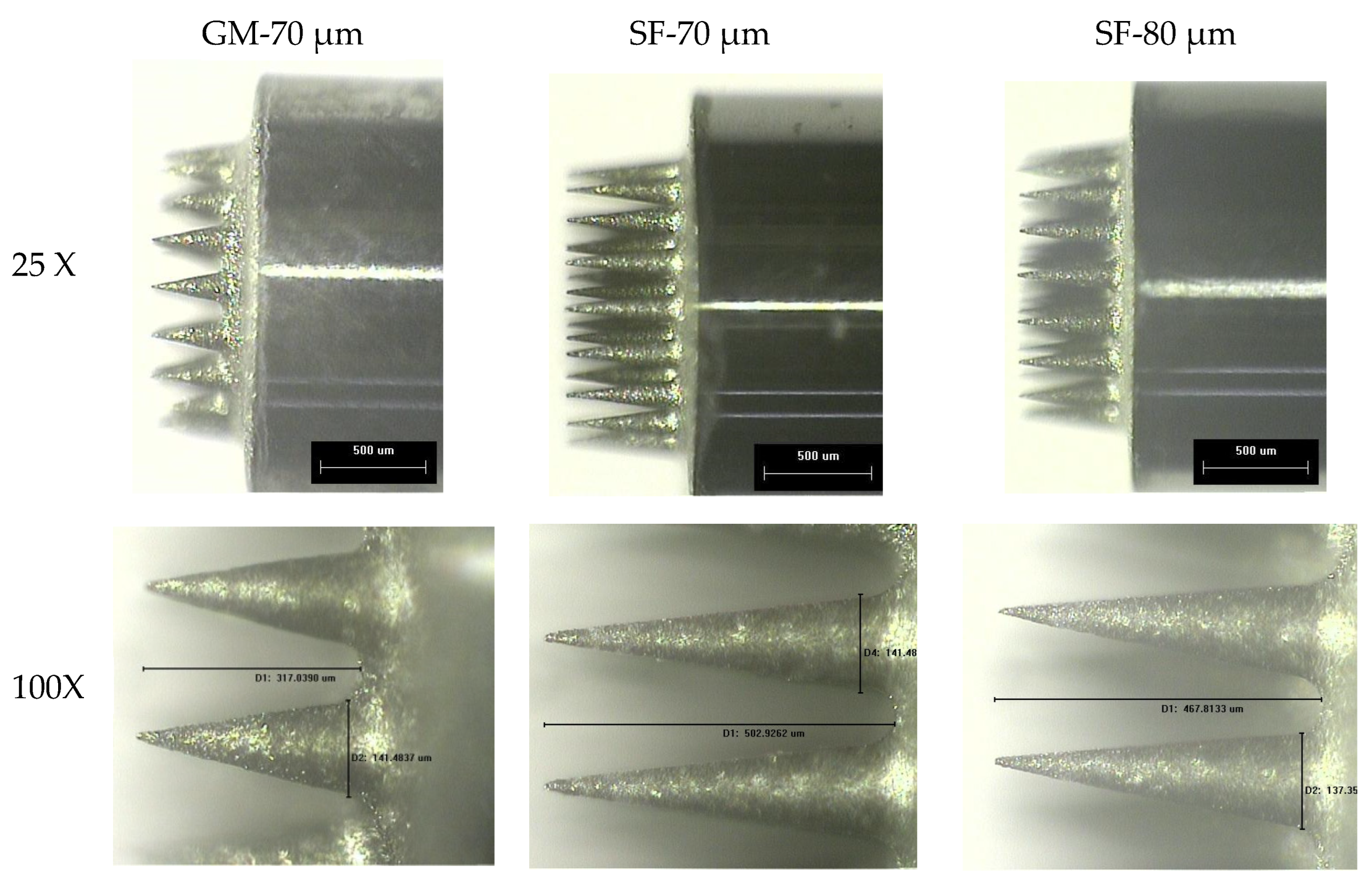

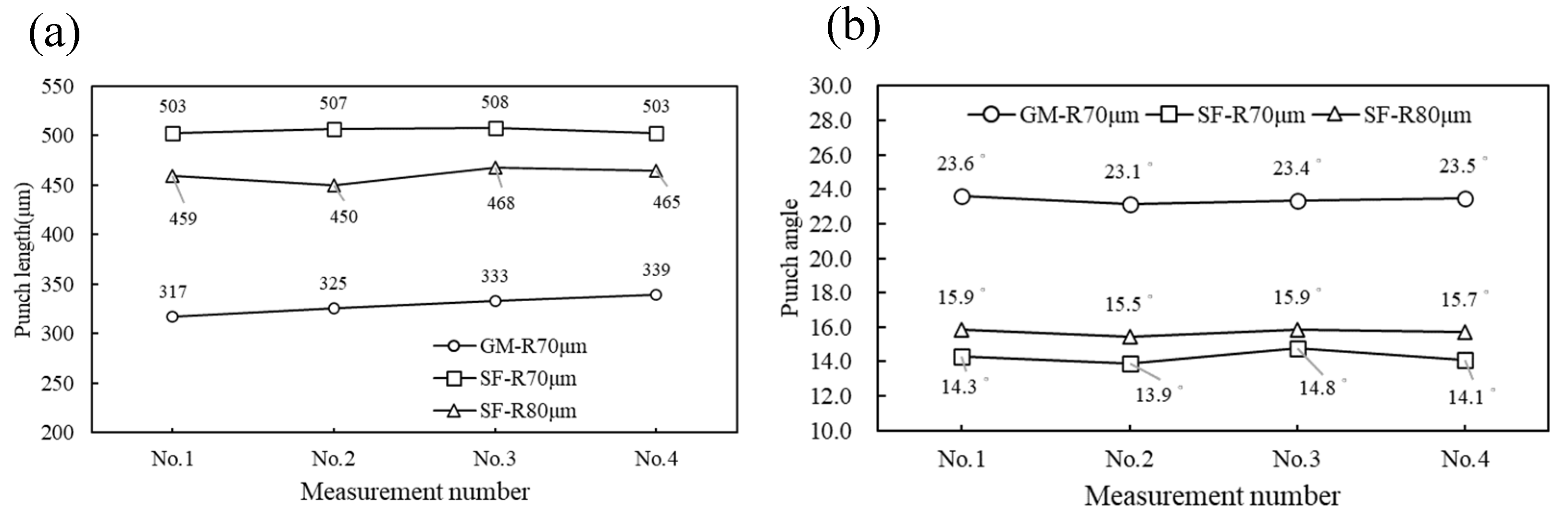

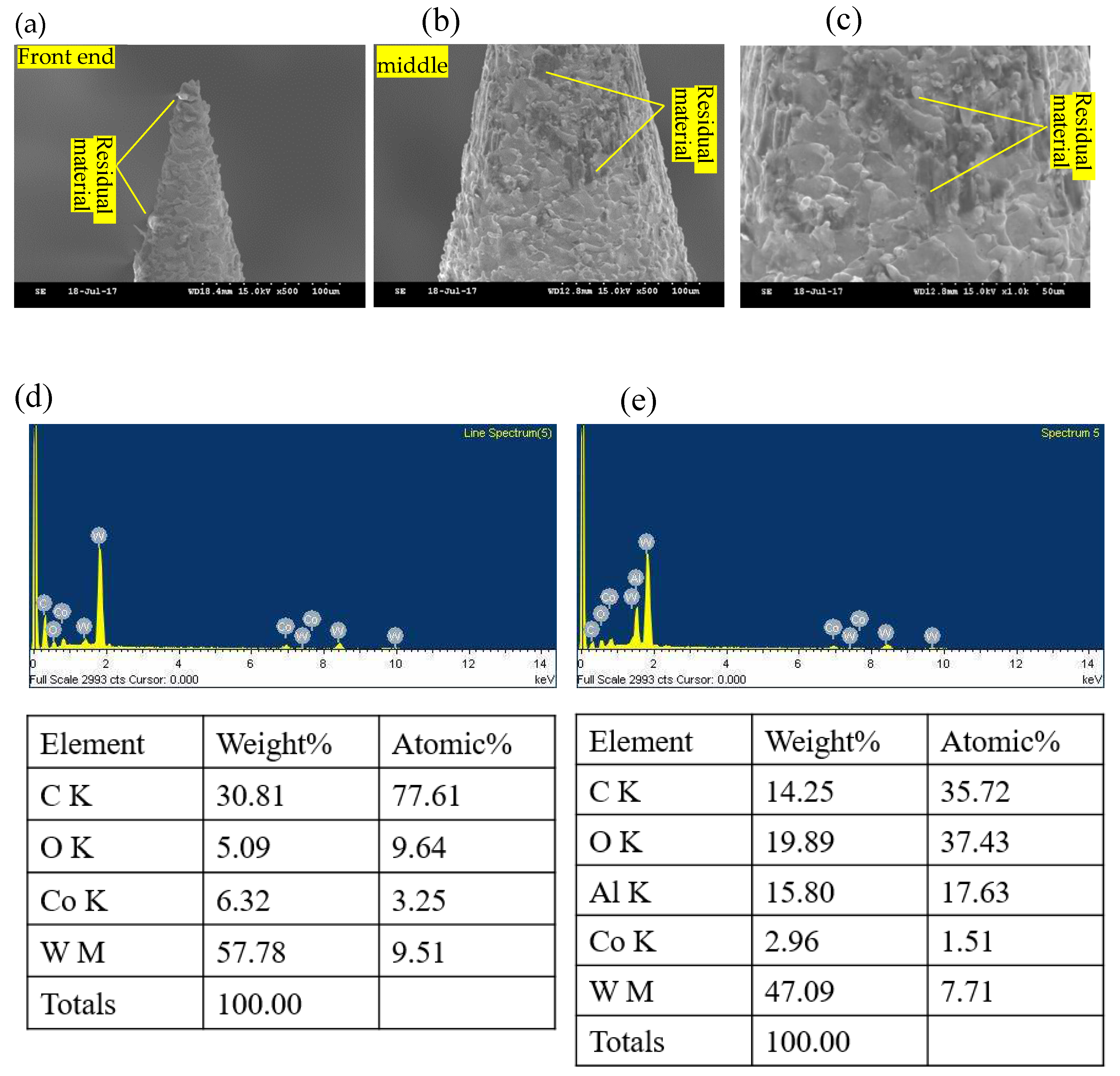

3.2. Punch head surface analysis

3.3. Sample surface grinding

4. Conclusions

- The sample is adsorbed by vacuum, and the sheet and nonmagnetic materials can be milled effectively. This method is applicable to clamping stamping samples.

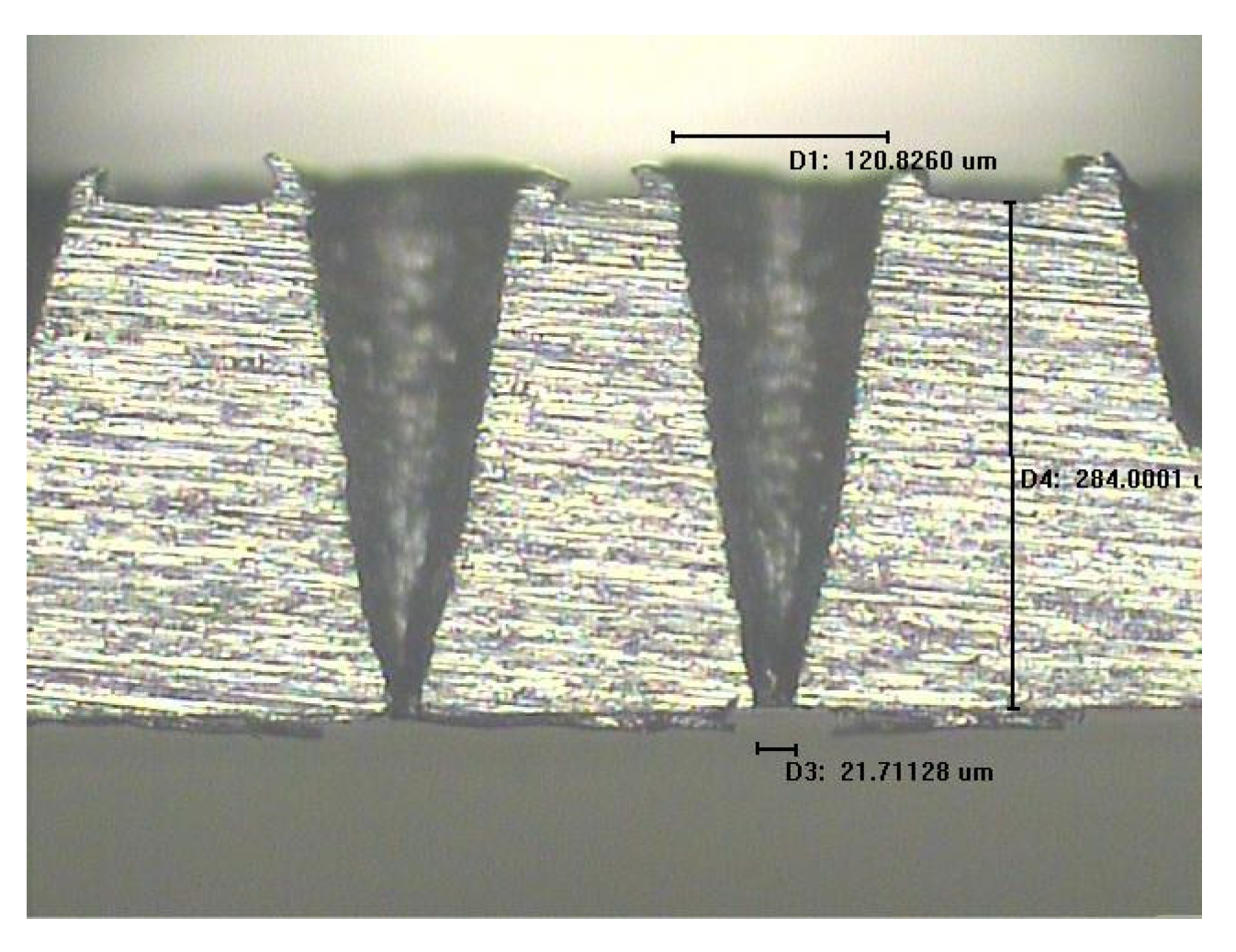

- The lower die holes are directly formed by stamping. The precision positioning problem of the punch head and lower die can be overcome. The microholes are punched by tapered punch heads. Finally, it is used in the micro stamping of Al6061 sample. The tapered microhole stamping forming is implemented successfully. The average inlet and outlet diameters of tapered microholes are 128 μm and 36 μm, respectively.

- There are 37 array punch heads used in this study. The brass electrode can be produced by reverse discharge in the future. Elastic design can be used to meet the required size and quantity of the products, hoping to meet different needs.

- The problems caused by inlet bulge, incomplete tear of outlet and bulge defects often occur in the micro stamping process. To effectively remove the inlet bulge defect, a high-speed spindle is combined with a grinding rod to grind the sample surface. Different models of sandpaper can be selected, such as #240, #1000 and #2000. A larger the sandpaper model has lower surface roughness value Ra. The average Ra value after grinding with #2000 sandpaper is 0.565. Finer sandpaper will be used for grinding in the future, the Ra value is expected to be further increased.

References

- Hourmand, M., Sarhan, A. A. D., & Yusof, N. M. (2017). Development of new fabrication and measurement techniques of micro-electrodes with high aspect ratio for micro EDM using typical EDM machine. Measurement, 97, 64-78. [CrossRef]

- Yin, Q. F., Wang, B. R., Zhang, Y. B., Ji, F., & Liu, G. M. (2014). Research of lower tool electrode wear in simultaneous EDM and ECM. Journal of Materials Processing Technology, 214(8), 1759-1768. [CrossRef]

- Perez-Diaz, O., & Quiroga-Gonzalez, E. (2020). Silicon Conical Structures by Metal Assisted Chemical Etching. Micromachines, 11(4), Article 402. [CrossRef]

- Zhang, J. Z., Ming, P. M., Zhang, X. M., Qin, G., Yan, L., Zhao, X. K., & Zheng, X. S. (2020). Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process. Micromachines, 11(1), Article 70. [CrossRef]

- Zhanwen, A., Chen, L. L., Wu, Y., Du, R. B., Bai, H. L., & Zou, G. S. (2021). Controlling of Diameter and Taper in Ultrafast Laser Helical Drilling. Chinese Journal of Lasers-Zhongguo Jiguang, 48(8), Article 0802017. [CrossRef]

- Chang, Y. J., Hung, Y. C., Kuo, C. L., Hsu, J. C., & Ho, C. C. (2017). Hybrid stamping and laser micromachining process for micro-scale hole drilling. Materials and Manufacturing Processes, 32(15), 1685-1691. [CrossRef]

- Hung, Y. C., Chang, Y. J., Kuo, C. L., Hsu, J. C., & Ho, C. C. (2016). Comparison between Laser and Stamping without Die (SWD) for Micro Tapered Hole Forming. Applied Sciences-Basel, 6(3). [CrossRef]

- Hwang, Y. L., Kuo, C. L., & Hwang, S. F. (2010). Fabrication of a micro-pin array with high density and high hardness by combining mechanical peck-drilling and Reverse-EDM. Journal of Materials Processing Technology, 210(9), 1103-1130. [CrossRef]

- Talla, G., Gangopadhyay, S., & Kona, N. B. (2017). Experimental investigation and optimization during the fabrication of arrayed structures using reverse EDM. Materials and Manufacturing Processes, 32(9), 958-969. [CrossRef]

- Xu, J., Guo, B., Shan, D. B., Wang, C. J., Li, J., Liu, Y. W., & Qu, D. S. (2012). Development of a micro-forming system for micro-punching process of micro-hole arrays in brass foil. Journal of Materials Processing Technology, 212(11), 2238-2246. [CrossRef]

- Yu, Z. Y., Li, D. P., Yang, J. F., Zeng, Z. J., Yang, X. L., & Li, J. Z. (2019). Fabrication of micro punching mold for micro complex shape part by micro EDM. International Journal of Advanced Manufacturing Technology, 100(1-4), 743-749. [CrossRef]

- Hourmand, M., Sarhan, A. A. D., & Yusof, N. M. (2017). Development of new fabrication and measurement techniques of micro-electrodes with high aspect ratio for micro EDM using typical EDM machine. Measurement, 97, 64-78. [CrossRef]

- Yin, Q. F., Wang, B. R., Zhang, Y. B., Ji, F., & Liu, G. M. (2014). Research of lower tool electrode wear in simultaneous EDM and ECM. Journal of Materials Processing Technology, 214(8), 1759-1768. [CrossRef]

- Funazuka, T., Dohda, K., Shiratori, T., Hiramiya, R., & Watanabe, I. (2021). Effect of Punch Surface Grooves on Microformability of AA6063 Backward Microextrusion. Micromachines, 12(11), Article 1299. [CrossRef]

- Wang, X., Zhang, D., Gu, C. X., Shen, Z. B., & Liu, H. X. (2014). Research on the Micro Sheet Stamping Process Using Plasticine as Soft Punch. Materials, 7(6), 4118-4131. [CrossRef]

- Gu, W. H., Jeong, Y. S., Kim, K., Kim, J. C., Son, S. H., & Kim, S. (2012). Thermal oxidation behavior of WC-Co hard metal machining tool tip scraps. Journal of Materials Processing Technology, 212(6), 1250-1256. [CrossRef]

- Processes: A Comprehensive Review. Nanomaterials, 12(23), Article 4214. [CrossRef]

- Wang, Q. Y., Vohra, M. S., Bai, S. W., & Yeo, S. H. (2021). Rotary ultrasonic-assisted abrasive flow finishing and its fundamental performance in Al6061 machining. International Journal of Advanced Manufacturing Technology, 113(1-2), 473-481. [CrossRef]

| Experiment | Circuit | Current | Discharge time | Off time | Shaking radius (R) |

| Ⅰ | GM | 0.1A | 6μs | 24μs | 70μm |

| Ⅱ | SF | 1000pF | 0 | 0 | 70μm |

| Ⅲ | SF | 1000pF | 0 | 0 | 80μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).