Specifications Table

| Subject code |

1508 – Process Chemistry and Technology |

|

| Specific subject area |

The patented technology refers to the circular synthesis of polyesters and polyamides with high commercial value, enhancing waste that is currently irrecoverable. |

|

| Industry code |

C08J: WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H |

|

| Details of inventors |

Flavio Tollini (flavio.tollini@polimi.it; Politecnico di Milano - CMIC Department “Giulio Natta)

Massimo Morbidelli (massimo.morbidelli@polimi.it; Politecnico di Milano - CMIC Department “Giulio Natta)

Giuseppe Storti (giuseppe.storti@polimi.it; Politecnico di Milano - CMIC Department “Giulio Natta)

Davide Moscatelli (davide.moscatelli@polimi.it; Politecnico di Milano - CMIC Department “Giulio Natta)

|

|

| Dates of invention |

Conception: 2019

Disclosure: the patent application has been publicity disclosed in patent databases.

|

|

| Patent details (only if patented) |

Date patent filed: 9 June 2021 (the Italian patent application No. 102021000015005 is still under examination); an international patent application has been filed on June7th 2022, with the No. PCT/IB2022/055289 and published on December 15th, 2022, with the No. WO 202/259142 A1; at the end of the international phase Politecnico entered the US national phase and the EP regional phase (filing No. 21782818.5)

Patent owner: Politecnico di Milano

Patent attorney or agent: Raffaella Asensio (Perani & Partners)

Contact for service: Massimo Barbieri (Technology Transfer Office – Politecnico di Milano)

Link to patent: the patent application has not been yet published

|

|

| Intended use |

Both the Italian, US and EP patent applications are available for a license agreement |

|

| Related research article |

None |

| Related other sources: (datasets, software, diagrams, plans, etc.) |

None |

Value of the invention

The patented process allows the complete recycling of polyesters, polyamides, cotton textiles and packaging with a simpler, cheaper, and safer process as compared to the actual recycling technologies.

The patented process allows the recycling of waste materials that nowadays are incinerated. Moreover, this technology can increase the value of the original waste, performing real upcycling.

The patented process allows the complete removal of heavy and light contaminants, regardless of source material and color, without any degradation of the polymer.

The modular configuration of the technology can be easily integrated with the actual recycling system. In this way, actual processes can extend their starting feed and increase the value of their products.

Invention Description

The invention is focused on the polyesters and polyamides recycling process through partial depolymerization of the waste polymer, directly followed by a ring-opening polymerization (ROP) step.

Modular technology is comprised of three main units. In the first one, the polymer is partially depolymerized exploiting the advantages of the distillation-assisted cyclo-depolymerization (DA-CDP). This reaction allows both the production of a fraction of oligomers (in the range between 0-40 %) as well as an increase of the average molecular weight of the residual polymer. This step can be performed in different operating conditions, depending on the feed conditions. The reaction is performed at the boiling point of the mixture, in the pressure range (200-1000 mbar), and in a time scale ranging from 0-6 hours.

Butyltin(IV) oxide and tin(II) ethylhexanoate have been used as catalysts in a molar concentration between 0.01 % and 1 %.

The starting ratio polymer/solvent can be exploited in the range between 50 and 350 g/L. The reaction is assisted by a continuous distillation which aims to remove a fraction of solvent and by-products in a weight amount ranging from 0 to 10 % hourly. Moreover, the distillation allows the removal of low-boiling contaminants.

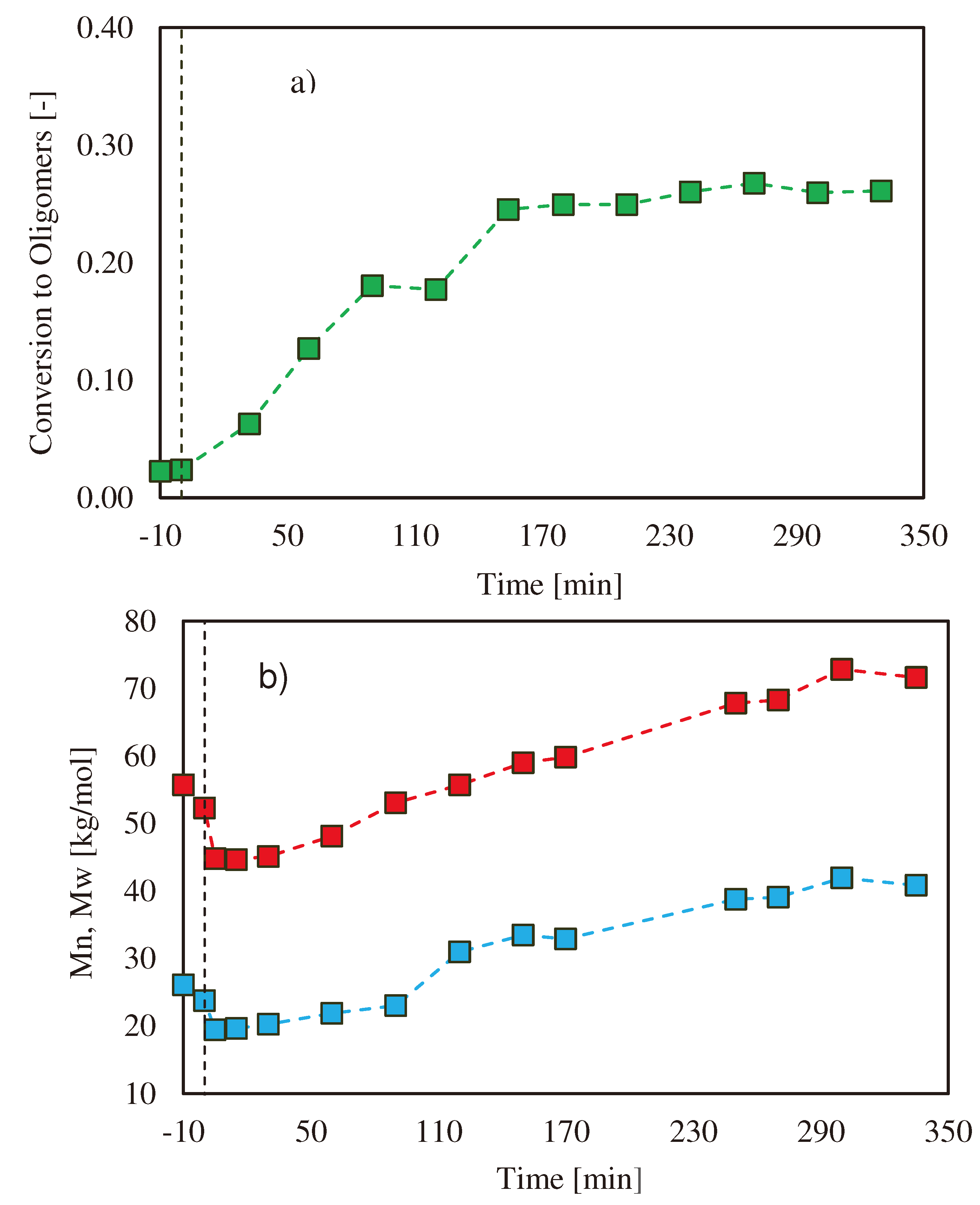

Due to the thermodynamic equilibria, at higher reaction times and with a robust system, an increase in the average molecular weight can be highlighted (polycondensation reactions are favored). Cyclization reactions (end- and back-biting) are favored at lower reaction times as shown in

Figure 1.

Once the reaction has been performed, the final solution is cooled down, precipitated, and then purified. A clean solvent is involved in the washing of the solid. This step is crucial to remove all the dyes and heavy contaminants that are present in the waste polymer.

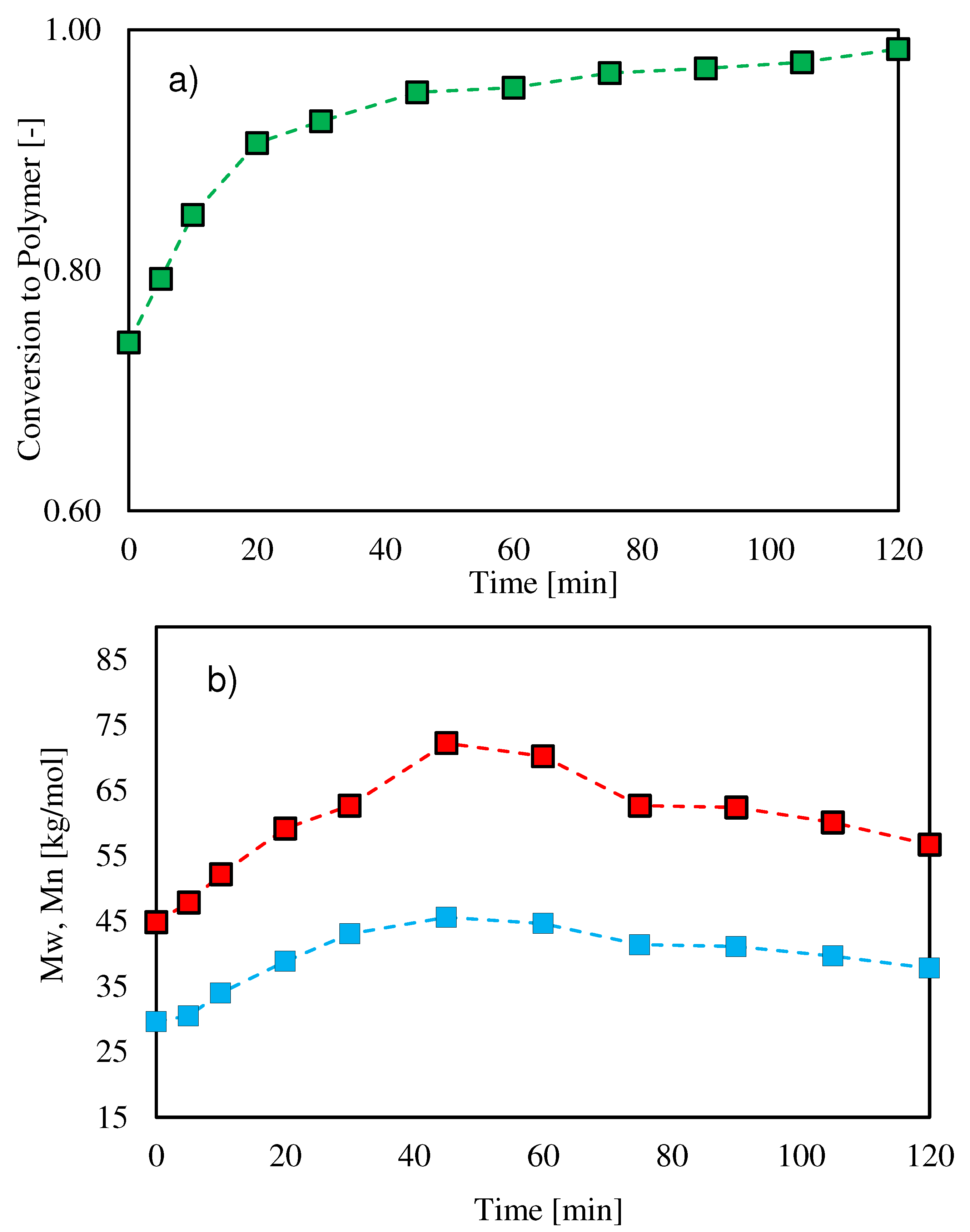

Then, the pre-polymer can be re-polymerized exploiting the ring-opening polymerization (ROP). This widely used technique can be directly performed in the extruder, saving time, costs, and equipment. Pre-polymer is fed inside the reactor and the system is carried at a temperature between 250°C and 300°C, under vacuum conditions. Thanks to the fast ROP, it is possible to recover the initial molecular weight in less than 30 minutes and to increase the molecular weight in less than 1 hour.

Inside the whole process, polymer degradation is avoided due to oligomer formation, temperature, and time control. These oligomers can then be re-polymerized together with the linear polymer, increasing the molecular weight of the polymer in a very short time, as shown in

Figure 2.

The final waste solvent, coming from each unit, is collected, and regenerated, maintaining the circularity of the system. A final recycled polymer with high technical grade can be recovered at the end of the process.

Background

The patented process has several advantages over the prior art: it’s a partial cyclodepolymerization associated with a simultaneous solvent distillation and can remove most of the byproducts and contaminants. Polymers are only partially decomposed, and the products obtained are cyclic oligomers only.

As compared to conventional chemical processes, it is not necessary to conduct a complete depolymerization.

Before the filing of the priority patent application, a novelty search [1, 2] was carried out to prove the patentability requirements of the invention proposal, using Orbit intelligence as a patent database.

The search was conducted by using a list of keywords and classification codes (at a subclass level – C08G Macromolecular compounds obtained otherwise than by reactions only involving unsaturated carbon-to-carbon bonds) but relevant documents were not retrieved.

The Italian patent application was evaluated by the EPO, who classified the application according to the IPC system (see

Table 1) and carried out the patentability search (technical fields searched: C08G, and C08J).

The Search Report listed four prior art documents:

D1: Cyclo-depolymerization of poly(propylene terephthalate): some ring-opening polymerizations of the cyclic oligomers produced

D2: EP 3778744 A1

D3: Cyclodepolymerizaton as a method for the synthesis of macrocyclic oligomers

D4: EP 3606980A1

The cited references were deemed to be background art by the examiner (classified under the A category) and all claims were considered both novel and inventive over the cited prior art in the Written Opinion. Therefore, the patent application is likely to be granted.

In order to confirm the outcome of the search report, a validity search was carried out using both Espacenet and Orbit databases (accessed March 8th, 2023), with the following search queries.

- (1)

Espacenet: cl any "C08G63" AND cl any "C08J" AND ftxt any "depolymeri#ation" AND ftxt any "distillation-assisted" AND ftxt any "polyester?" AND ftxt any "polyamide?" [85 results]

- (2)

Orbit: ((DEPOLYMERI#ATION)/TI/AB/CLMS/ICLM AND (POLYESTER? AND POLYAMIDE?)/TI/AB/CLMS/ICLM/DESC/ODES ) AND (C08G-063+ AND C08J+)/IPC/CPC [60 results]

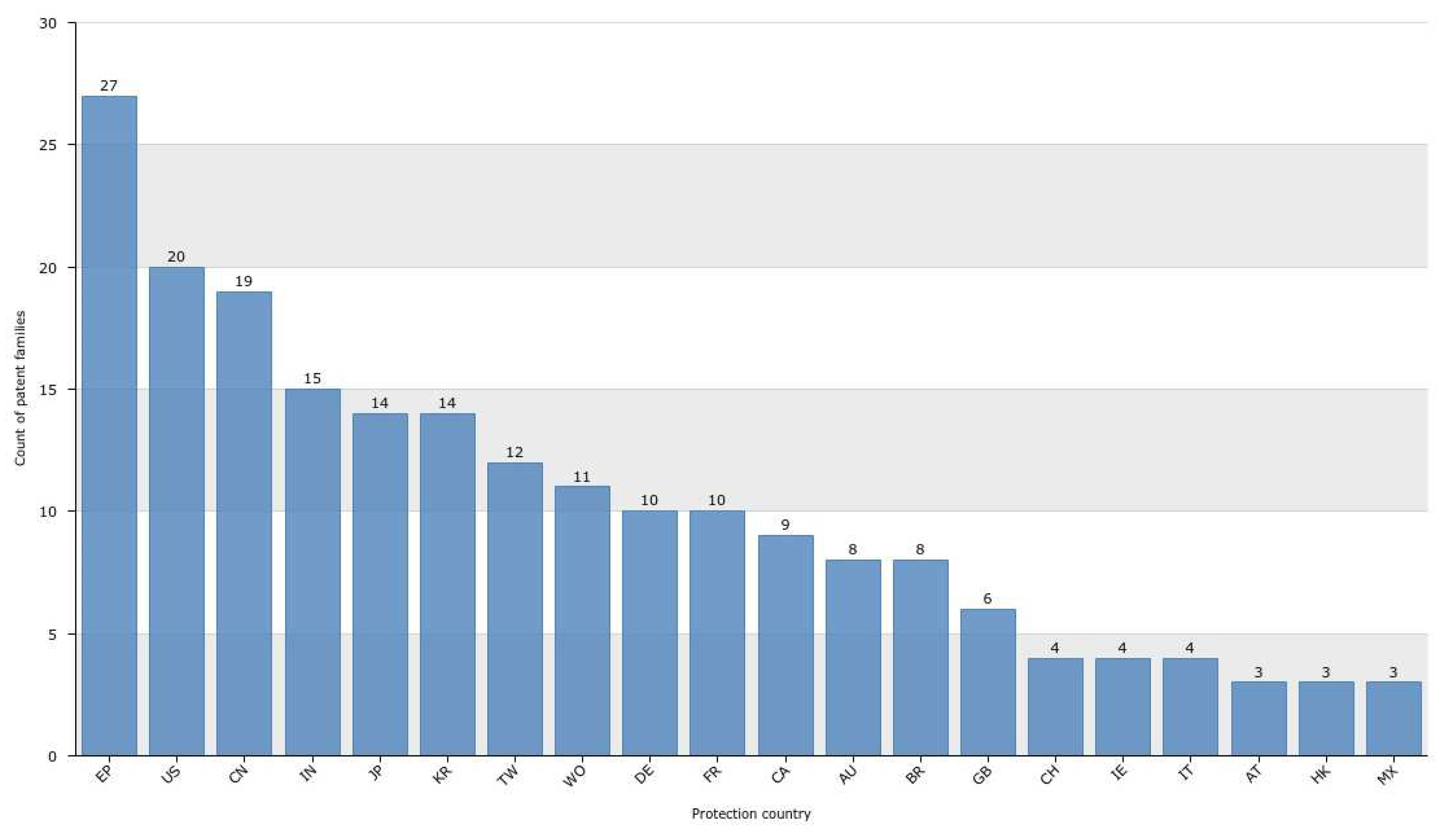

Analyzing data obtained with Orbit database, it can be argued that the technology investment trend over last 20 years is growing (

Figure 3), while the top markets are Europe, USA, and China (

Figure 4).

Application potential

The global size of the plastics market was valued at 593 billion U.S. dollars in 2021 and predicted to grow in the coming years to reach a value of 811 billion U.S. dollars by 2028, registering a CAGR of 3.7% during the forecast period of 2022 to 2030.

The global recycled plastics market was valued at 47.6 billion U.S. dollars in 2022 and is expected to grow at a CAGR of 4.8% from 2022 to 2030.

The global plastics production increased to 390.7 Mt in 2021, of which 90.2% was fossil-based.

To meet the expected growth in demand for recycled PET (polyethylene terephthalate), whose market is expected to grow at a CAGR of 5.2% over the period 2022- 2030, at least 430 new plants will have to be built over the next few years, thus determining a potential market for the sale of plants estimated at 1.5 billion euros.

This technology is addressed to both manufacturing and recycling companies, aiming to be modular and configurable according to customer needs and this results in a huge advantage, given that current processes are not flexible at all.

The patented process allows contaminants to be easily removed from PET, unlike mechanical processes, while maintaining their simplicity. In addition, by exploiting the rapid ROP system, it is possible to carry out polymerization directly inside the extruder, thus avoiding conducting the process in a dedicated reactor as in conventional processes. The modular solution allows to configure the recycling system in a complementary way to the technologies already used and can provide a customized solution to specific requests.

Ethics statements

No specific ethics statement.

Author Contributions

E.T.: Conceptualization, Investigation, Supervision, Data curation and Writing- Original draft preparation. F.T.: Conceptualization, Investigation, Supervision, Data curation- Original draft preparation. G.S.: Supervision. M.B.: Data curation, Writing- Reviewing and Editing. D.M.: Supervision, Reviewing.

Funding

This work was supported by a grant provided by ENI Joule within the Switch To Product (S2P -

https://s2p.it) competition.

Declaration of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- M. Barbieri, Patent Prior Art Searches: Basic Principles and Strategies. Preprints 2022, 2022050054. [CrossRef]

- M. Barbieri, Innovation, and Industrial Property Rights (September 10, 2017). Chapter in book: "Developing Biomedical Devices" (2014). Available online: https://ssrn.com/abstract=3034950.

- S. D. Kamau et al., Cyclo-depolymerization of poly(propylene terephthalate): some ring-opening polymerizations of the cyclic oligomers produced, Polymers for Advanced Technologies 14 7 (2013) 492-501.

- P. Zutautas et al., Processes for recycling polyethylene terephthalate. European Patent Application EP 3778744 A1. European Patent Office. 17 Feb 2021.

- P. Hodge, Cyclodepolymerization as a method for the synthesis of macrocyclic oligomers, Reactive and Functional Polymer 80 (2014) 21-32.

- L. Costa et al., A process to prepare a cyclic oligomer and a cyclic oligomer obtainable thereby and a process to polymerize it. European Patent Application EP 3606980 A1. European Patent Office. 25 Oct 2018.

- Market size value of plastics worldwide from 2021 to 2039. Available online: https://www.statista.com/statistics/1060583/global-market-value-of-plastic/.

- Plastics – The Facts 2022, October 2022. Available online: https://plasticseurope.org.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).