Submitted:

29 January 2023

Posted:

31 January 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Wi– Bond work index (kWh/t);

- Pc – the size of the opening of the control sieve (µm);

- G– the mass of the newly created screen of the control sieve per revolution of the mill (g/rev);

- F80– the size of the opening of the sieve through which 80% of the feed passes before grinding (µm);

- P80– the size of the sieve opening through which 80% of the comparative sieve from the last grinding cycle passes (µm).

2. Objectives of the Investigation

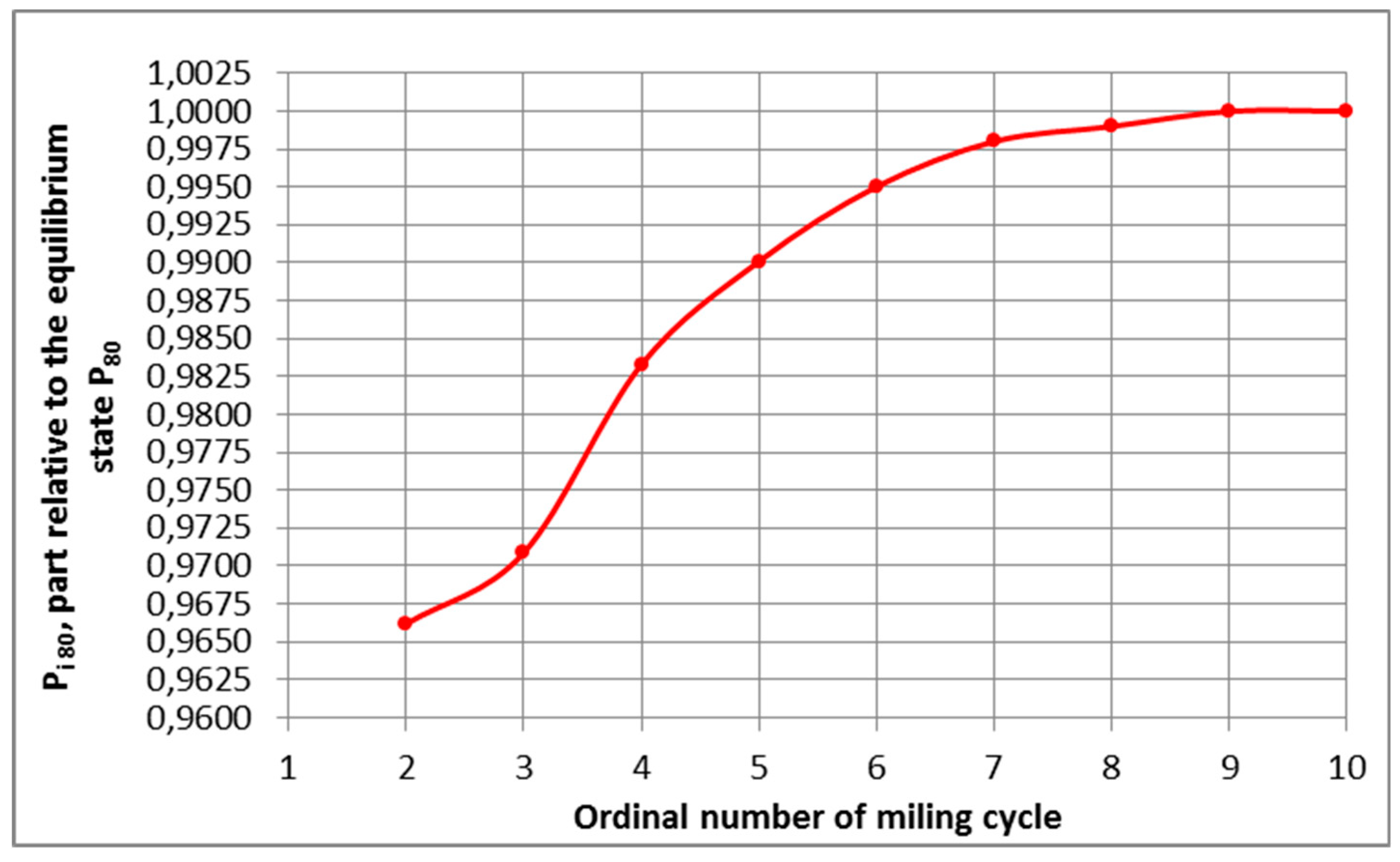

3. Theoretical Basis of Novel Procedure

- Where are:

- R– reflection of the comparative sieve at the moment (t),

- R0– screening of the comparative sieve at the beginning of grinding (t=0),

- k– grinding rate constant,

- t– grinding time.

- Where are:

- N– the total number of revolutions of the mill,

- n– number of mill revolutions per minute.

- Where are:

- M– the mass of the starting sample (700cm3),

- X– class content +Pc in the initial sample (in parts of the unit).

4. Experimental

4.1. Materials

4.1. Method - Procedure for Performing a Quick Procedure for Assessing the Value of a Bond Work Index

- Grinding of the sample to a size of 100 % -3.327 mm;

- Determination of the granulometric composition of the initial sample and the parameter F80 (µm) and the participation of a class larger than the opening of the comparative sieve X (in parts of the unit);

- A volume sample is taken 700 cm3, its mass M (g) is determined, it is loaded into a Bond mill with balls and ground for an arbitrary number of revolutions of the mill (N1 = 50, 100 or 150 revolutions);

- After grinding, the sample is sieved on a comparative sieve and the mass of sieves D, (g) and sieves R, (g) is determined. Sieve D consists of the mass of sieve Du introduced with the inlet and the mass of newly created sieve in mill Dn:

- The mass of the newly created sieve is calculated Dn:

- In the first experiment is:

- In the following experiments is:

- Where is:

- D(n-1)– the sieve mass from the previous experiment, g.

- The mass of the newly created sieve is calculated per one revolution of the mill:

- Where is:

- N– the number of revolutions in the experiment in question.

- The mill speed is calculated for the following grinding experiment:

- A fresh sample is added to the screening of the comparative sieve, the mass of which is equal to the mass of the sieve from the previous experiment D(n-1). The entrance thus formed is inserted into the mill and grinds Nn rev.;

- After grinding, the sample is sown on a comparative sieve and the reflection is measured R (g);

- The constant k is calculated using formula (3):

- Using the constant k and formula (6), the required number of revolutions N is calculated in case the quantity of raw material is ground at the same speed as in the second grinding as when the circular batch is 250 %;

- The parameter G2e (g / rev.) is calculated using formula (7) and the value of N. The value of G2e is multiplied by the constant g2DT = 1.158 and the value of Ge is obtained, which is close to the value of G in the last grinding cycle of the standard Bond test;

- On the sieving of the second grinding cycle, granulometric analysis is performed and parameter P2 80 is read from the graph. The read value is multiplied by the constant p2DT = 1.035. The obtained Pe80 result is close to the value of the P80 sieving parameter of the last grinding cycle of the standard Bond test;

- Using the formula (1) and the calculated values of the parameters Ge and Pe80, an approximate value of Wi (kWh / t) is obtained.

5. Results and Discussion

5. Conclusion

Acknowledgments

References

- Maxson, W.L.; Cadena, F.; Bond, F.C. Grindability of Various Ores. Trans AIME Min. Eng. 1933, 112, 130. [Google Scholar]

- Mwanga, A.; Rosenkranz, J.; Lamberg, P. Development and experimental validation of the Geometallurgical Comminution Test(GCT). Miner. Eng. 2017, 108, 109–114. [Google Scholar] [CrossRef]

- Bond, F.C. Standard grindability test tabulated, Trans AIME Min. Eng. 1949, 183, 313. [Google Scholar]

- Bond, F.C. The third theory of communition, Trans AIME Min. Eng. 1952, 193, 484–494. [Google Scholar]

- Bond, F.C. Crushing and grinding calculation part I and II. Brit. Chem. Eng. 6 (6 and 8), 1961, 378-385 & 543-548.

- Mucsi, G. Fast test method for the determination of the grindability of fine materials. Chem. Eng. Res. Des. 2008, 86, 395–400. [Google Scholar] [CrossRef]

- WEISS, N.L. Mineral Processing Handbook, Society of Mining Engineers; AIMM: New York, NY, USA, 1985. [Google Scholar]

- Berry, T.F. Bruce R. W., A simle method of determining the grindability of ores., Can. Min. J. 1966, 87, 63–65. [Google Scholar]

- Horst, W.E. Bassarear J. H., Use of simplified ore grindability technique to evaluate plant preformance, Trans. Soc. Min. Eng. (AIME) 1977, 260, 348–351. [Google Scholar]

- Mular, A.L.; Jergensen, G.V. , Design and Installation of Comminution Circuits, Society of Mining Engineers of the American Institute of Mining; Metallurgical, and Pegroleum Engineers, Inc.: New York, NY, USA, 1982; p. 1022. [Google Scholar]

- Nematollahi, H. New size laboratory ball mill for Bond work index determination. Min. Eng. 1994, 46, 352–353. [Google Scholar]

- Menéndez-Aguado, J.M.; Dzioba, B.R.; Coello-Velazquez, A.L. Determination of work index in a common laboratory mill. Miner.Metall. Process. 2005, 22, 173–176. [Google Scholar] [CrossRef]

- Saeidi, N.; Noaparast, M.; Azizi, D.; Aslani, S.; Ramadi, A. A developed approach based on grinding time to determine ore comminution properties, J. Min. Environ 2013, 4, 105–112. [Google Scholar]

- Kapur, P.C. Analysis of the Bond grindability test, Trans. Inst. Min. Metal L 1970, 79, 103–107. [Google Scholar]

- Karra, V.K. Simulation of the Bond Grindability test. CIM Bulletin 1981, 74, 195–199. [Google Scholar]

- Lewis, K.A.; Pearl, M.; Tucker, P. Computer Simulation of the Bond ni test. Mineral Engineering 1990, 3, 199–206. [Google Scholar] [CrossRef]

- Smith, R.W. Lee K. H., A Comparison of data from Bond type simulated closed-circuit and batch type grindability in batch ball mill, Trans. Metall. Soc. AIME 1968, 241, 91–99. [Google Scholar]

- Aksani, B.; Sönmez, B. Simulation of bond grindability test by using cumulative based kinetic model. Miner. Eng. 2000, 13, 673–677. [Google Scholar] [CrossRef]

- Ford, E.; Sithole, V. A Comparison of Test Procedures for Estimating the Bond Ball Work Index on Zambian/DRC Copper-Cobalt Ores and Evaluation of Suitability for Use in Geometallurgical Studies, Copper Cobalt Africa. In Proceedings of the 8th Southern African Base Metals Conference, Livingstone, Zambia, 6–8 July 2015; pp. 65–68. [Google Scholar]

- Gharehgheshlagh, H.H. Kinetic grinding test approach to estimate the ball mill work index. Physicochem. Probl. Miner. Process. 2015, 52, 342–352. [Google Scholar]

- Ciribeni, V.; Bertero, R.; Tello, A.; Puerta, M.; Avellá, E.; Paez, M. Menéndez-Aguado, J. M. Application of the Cumulative KineticModel in the Comminution of Critical Metal Ores. Metals 2020, 10, 925. [Google Scholar]

- Magdalinovic, N. A Procedure for Rapid Determination of the Bond Work Index, Int. J. Miner. Process. 1989, 27, 125. [Google Scholar] [CrossRef]

- Austin, L.G. Bagga P. nad Celik M., Breakege Properties of some Materials in Laboratory Ball Mill, Powder Technol. 1981, 28, 235–241. [Google Scholar]

- Ahmadi, R. Shahsavari Sh. , Procedure for determination of ball Bond work index in the commercial operations, Miner. Eng. 2009, 22, 104–106. [Google Scholar]

- Magdalinovic, N. Abbreviated test for quick determination of Bond’s Work index, J. Min. And Metall. 2003, 39, 1–10. [Google Scholar]

- Todorovic, D.; Trumic, M.; Andric, L.; Milosevic, V.; Trumic, M. A quick method for Bond work index approximate value determination. Physicochem. Probl. Miner. Process 2017, 53, 321–332. [Google Scholar]

- Nikolic, V.; García, G.; Trumic, M.; Coello-Velázquez, A.; Menéndez-Aguado, J.; Trumic, M. A Review of Alternative Procedures to the Bond Ball Mill Standard Grindability Test. Metals 2021, 11, 1114. [Google Scholar] [CrossRef]

| Chemical element | Cu | S | Cuox | SiO2 | Al2O3 | CaO |

| Content, % | 0.184 | 3.51 | 0.040 | 64.130 | 17.430 | 0.420 |

| Chemical element | MgO | Fe2O3 | K2O | Na2O | TiO2 | GŽ |

| Content, % | 1.250 | 6.000 | 3.990 | 0.849 | 0.50 | 5.15 |

| Chemical element | Zn | Cr | Pb | Cd | Mn | Ni |

| Content, ppm | 30.49 | 42.49 | 20.00 | 0.10 | 93.50 | 44.90 |

| Chemical element | Mo | / | / | / | / | / |

| Content, ppm | 47.99 | / | / | / | / | / |

| Chemical element | Cuuk. | Cuox. | Cusulf. | S | Al2O3 | SiO2 |

| Content, % | 0.440 | 0.017 | 0.423 | 4.88 | 17.10 | 57.52 |

| Chemical element | Fe | Fe2O3 | CaO | / | / | / |

| Content, % | 3.21 | <0.03 | 7.22 | / | / | / |

| Chemical element | Au | Ag | Mo | / | / | / |

| Content, g/t | 30.49 | 42.49 | 20.00 | / | / | / |

| Chemical element | Cu | Cusulf | Cuox | S |

| Content, % | 0.881 | 0.761 | 0.120 | 0.720 |

| Mill diameter, Dm | 30.48 cm |

| The length of the mill, Lm | 30.48 cm |

| Mill lining geometry | Smooth |

| The number of revolutions of the mill per minute, n | 70 min-1 |

| Mass of balls, Mb | 21.125 kg |

| Vsample | 700 cm3 |

| Type of grinding | Dry |

| Sample | Sieve, µm | G, g/rev |

2 Grinding | 3 Grinding | 4 Grinding | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ge2, g/rev |

Differ., % |

Ge3, g/rev |

Differ., % |

Ge4, g/rev |

Differ., % |

|||||

| Limestone | : | andesite | 105 | 1.190 | 1.223 | +2.77 | 1.261 | +3.28 | 1.234 | +1.15 |

| 0 | : | 100 | 150 | 1.540 | 1.645 | +7.14 | 1.580 | +2.60 | 1.556 | +1.01 |

| Limestone | : | andesite | 105 | 1.270 | 1.259 | -0.79 | 1.289 | +1.57 | 1.276 | +0.43 |

| 25 | : | 75 | 150 | 1.660 | 1.697 | +2.14 | 1.678 | +1.20 | 1.649 | -0.67 |

| Limestone | : | andesite | 105 | 1.480 | 1.436 | -2.70 | 1.442 | -2.70 | 1.441 | -2.61 |

| 50 | : | 50 | 150 | 1.810 | 1.893 | +4.42 | 1.864 | +2.76 | 1.804 | -0.31 |

| Limestone | : | andesite | 105 | 1.600 | 1.538 | -3.75 | 1.529 | -4.38 | 1.556 | -2.78 |

| 75 | : | 25 | 150 | 1.960 | 1.908 | -2.55 | 1.958 | 0.00 | 1.898 | -3.18 |

| Limestone | : | andesite | 105 | 1.810 | 1.785 | -1.66 | 1.733 | -4.42 | 1.742 | -3.75 |

| 100 | : | 0 | 150 | 2.160 | 2.029 | -6.02 | 2.112 | -2.31 | 2.126 | -1.58 |

| Slag | : | Cu ore | 150 | 1.85 | 2.00 | +8.11 | 1.92 | +3.78 | 1.89 | +2.16 |

| 100 | : | 0 | ||||||||

| Slag | : | Cu ore | 150 | 1.97 | 2.11 | +7.11 | 2.03 | +3.05 | 1.97 | 0.00 |

| 75 | : | 25 | ||||||||

| Slag | : | Cu ore | 150 | 2.00 | 2.17 | +8.50 | 2.13 | +6.50 | 2.00 | 0.00 |

| 50 | : | 50 | ||||||||

| Slag | : | Cu ore | 150 | 2.11 | 2.13 | +0.95 | 2.16 | +2.37 | 2.19 | +3.79 |

| 25 | : | 75 | ||||||||

| Slag | : | Cu ore | 150 | 2.13 | 2.19 | +2.82 | 2.08 | -2.35 | 2.10 | -1.41 |

| 100 | : | 0 | ||||||||

| Maximum error | / | 8.11 | 6.50 | 3.79 | ||||||

| Mean error | / | 4.09 | 2.88 | 1.65 | ||||||

| Sample | Sieve, µm | P80, µm |

2 Grinding | 3 Grinding | 4 Grinding | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| P80 e2, µm |

Differ., % |

P80 e3, µm |

Differ., % |

P80 e4, µm |

Differ., % |

|||||

| Limestone | : | andesite | 105 | 86.00 | 87.98 | +2.30 | 87.55 | +1.80 | 87.46 | +1.70 |

| 0 | : | 100 | 150 | 121.00 | 121.10 | +0.08 | 121.54 | +0.45 | 121.02 | +0.02 |

| Limestone | : | andesite | 105 | 86.00 | 84.87 | -1.31 | 87.55 | +1.80 | 86.45 | +0.52 |

| 25 | : | 75 | 150 | 121.00 | 121.10 | +0.08 | 120.51 | -0.40 | 122.04 | +0.86 |

| Limestone | : | andesite | 105 | 87.00 | 87.98 | +1.13 | 90.64 | +4.18 | 88.48 | +1.70 |

| 50 | : | 50 | 150 | 122.00 | 123.17 | +0.96 | 125.66 | +3.00 | 124.07 | +1.70 |

| Limestone | : | andesite | 105 | 89.00 | 87.98 | -1.15 | 90.64 | +1.84 | 90.51 | +1.70 |

| 75 | : | 25 | 150 | 124.00 | 122.13 | -1.51 | 123.60 | -0.32 | 124.07 | +0.06 |

| Limestone | : | andesite | 105 | 91.00 | 94.19 | +3.51 | 90.64 | -0.40 | 88.48 | -2.77 |

| 100 | : | 0 | 150 | 124.00 | 116.96 | -5.68 | 120.51 | -2.81 | 123.06 | -0.76 |

| Slag | : | Cu ore | 150 | 127.00 | 126.27 | -0.57 | 126.69 | 0.00 | 129.16 | +1.70 |

| 100 | : | 0 | ||||||||

| Slag | : | Cu ore | 150 | 122.00 | 125.00 | +2.65 | 126.00 | +3.00 | 124.00 | +1.70 |

| 75 | : | 25 | ||||||||

| Slag | : | Cu ore | 150 | 122.00 | 123.00 | +0.95 | 124.00 | +1.31 | 123.00 | +0.87 |

| 50 | : | 50 | ||||||||

| Slag | : | Cu ore | 150 | 120.00 | 116.00 | -3.40 | 118.00 | -1.29 | 121.00 | +0.85 |

| 25 | : | 75 | ||||||||

| Slag | : | Cu ore | 150 | 118.00 | 115.00 | -2.60 | 115.00 | -2.60 | 115.00 | -2.60 |

| 100 | : | 0 | ||||||||

| Maximum error | / | 5.68 | 4.18 | 2.77 | ||||||

| Mean error | / | 1.86 | 1.68 | 1.30 | ||||||

| Sample | Sieve, µm | Wi, kWh/t |

2 Grinding | 3 Grinding | 4 Grinding | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wie2, kWh/t |

Differ., % |

Wie3, kWh/t |

Differ., % |

Wie4, kWh/t |

Differ., % |

|||||

| Limestone | : | andesite | 105 | 16.93 | 17.15 | +1.26 | 16.68 | -1.53 | 16.96 | +0.14 |

| 0 | : | 100 | 150 | 16.01 | 15.17 | -5.24 | 15.72 | -1.76 | 15.88 | -0.81 |

| Limestone | : | andesite | 105 | 16.41 | 16.38 | -0.15 | 16.39 | -0.09 | 16.40 | -0.02 |

| 25 | : | 75 | 150 | 15.13 | 14.87 | -1.74 | 14.96 | -1.14 | 15.30 | +1.14 |

| Limestone | : | andesite | 105 | 14.60 | 15.07 | +3.23 | 15.31 | +4.88 | 15.08 | +3.30 |

| 50 | : | 50 | 150 | 14.26 | 13.83 | -3.00 | 14.20 | -0.39 | 14.46 | +1.41 |

| Limestone | : | andesite | 105 | 13.91 | 14.27 | +2.55 | 14.61 | +5.00 | 14.40 | +3.46 |

| 75 | : | 25 | 150 | 13.59 | 13.75 | +1.18 | 13.57 | -0.15 | 13.96 | +2.73 |

| Limestone | : | andesite | 105 | 12.77 | 13.21 | +3.45 | 13.20 | +3.37 | 12.94 | +1.32 |

| 100 | : | 0 | 150 | 12.63 | 12.77 | +1.12 | 12.62 | -0.13 | 12.73 | +0.78 |

| Slag | : | Cu ore | 150 | 15.02 | 14.01 | -6.73 | 14.55 | -3.14 | 14.95 | -0.50 |

| 100 | : | 0 | ||||||||

| Slag | : | Cu ore | 150 | 13.71 | 13.17 | -3.93 | 13.63 | -0.58 | 13.89 | +1.34 |

| 75 | : | 25 | ||||||||

| Slag | : | Cu ore | 150 | 13.40 | 12.62 | -5.81 | 12.83 | -4.27 | 13.47 | +0.50 |

| 50 | : | 50 | ||||||||

| Slag | : | Cu ore | 150 | 12.58 | 12.19 | -3.15 | 12.25 | -2.63 | 12.27 | -2.51 |

| 25 | : | 75 | ||||||||

| Slag | : | Cu ore | 150 | 12.22 | 11.73 | -3.99 | 12.26 | +0.34 | 12.15 | -0.56 |

| 100 | : | 0 | ||||||||

| Maximum error | / | 6.73 | 5.00 | 3.46 | ||||||

| Mean error | / | 3.10 | 1.96 | 1.37 | ||||||

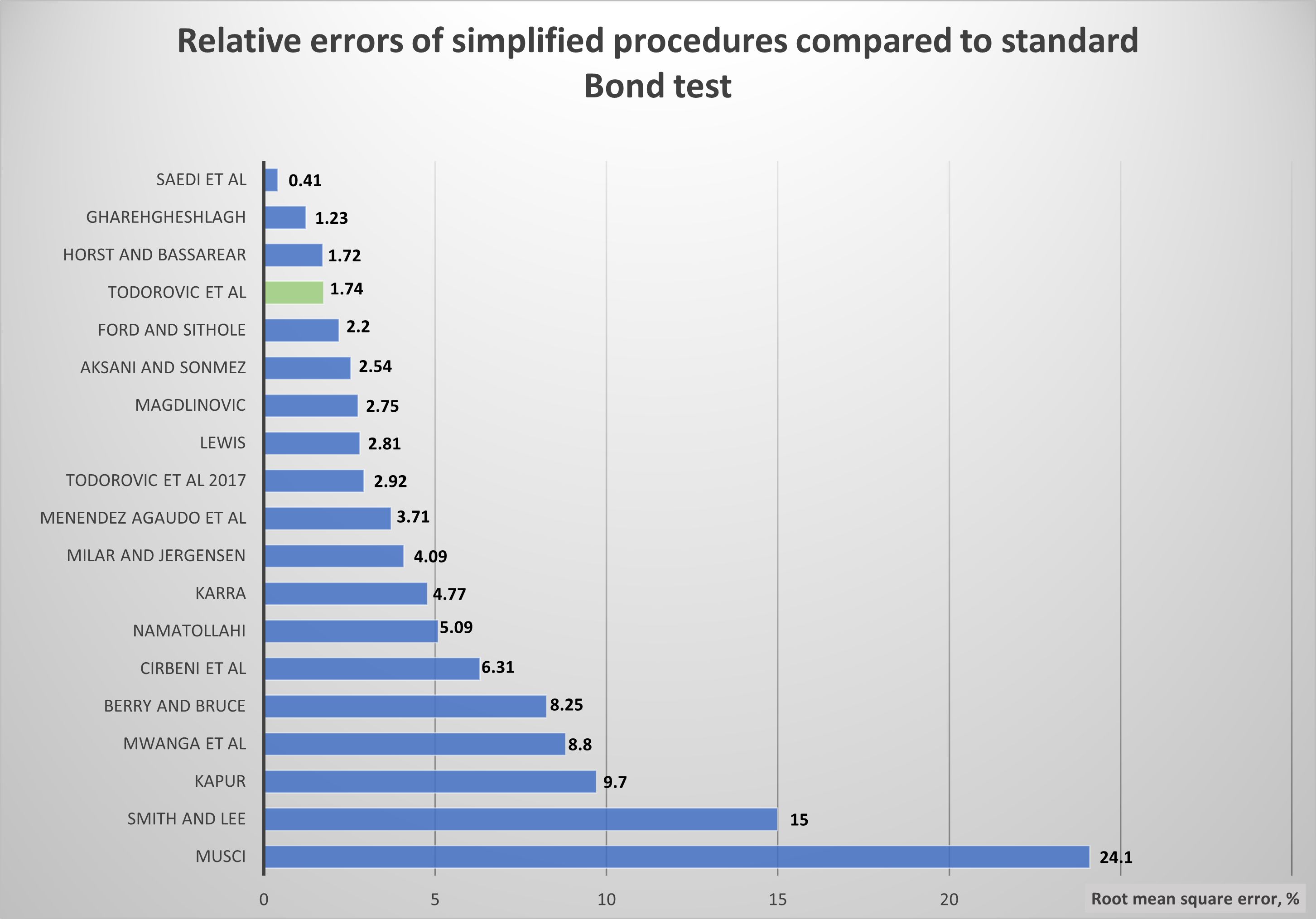

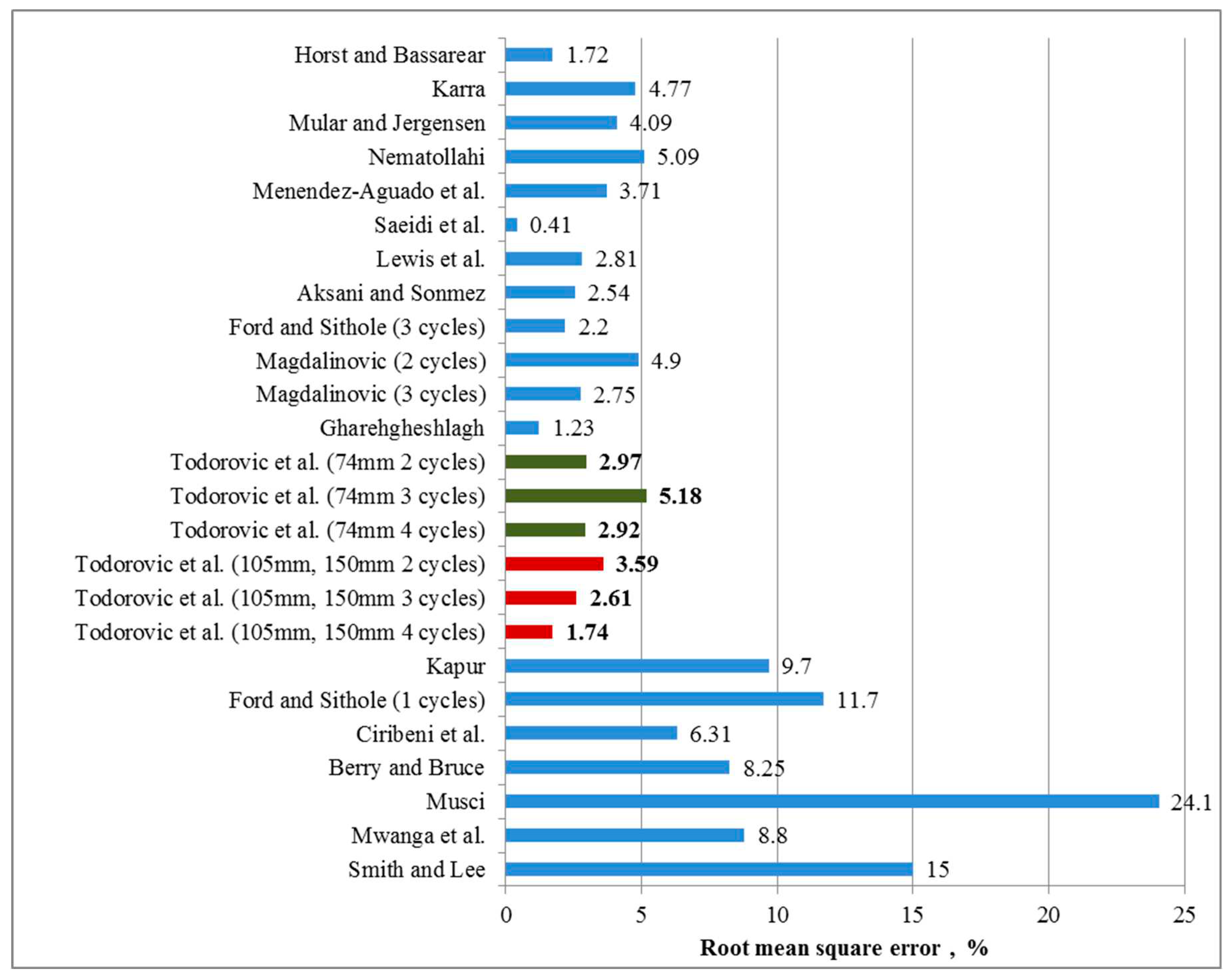

| Root mean square error | / | 3.59 | 2.61 | 1.74 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).