Introduction

The problem of disposal of radioactive waste (RW) is still largely unresolved. To date, a huge amount of liquid radioactive waste has been accumulated, requiring conditioning and disposal [

1]. Solid radioactive waste (SRW), already buried for hundreds and thousands of years, requires constant monitoring and protection. At the same time, the question of the possibility of storing radioactive waste for hundreds and thousands of years is questionable due to social and political reasons. No country has ever existed for so many years without the complete destruction of its state structure, industrial and technological potential due to wars, revolutions, crises. The current international situation convinces us that the irreconcilable enmity between the various poles of the world order is not only inevitable, but it will certainly continue to intensify, due to transcendental causes which lie in the depths of the collective unconscious of various nations. These transcendental causes have not yet been disclosed by philosophers, psychologists, historians and sociologists [

2].

Wars will not only be the cause of environmental disasters caused by the violation of the conditions for the storage of RW, but also the intentional depreservation of radioactive waste for military needs. The question arises about the possibility of such storage of RW, which will not allow it to be used for military purposes in the future. A method was proposed for the utilization of RW, when they are processed in order to extract chemical elements and compounds used in the space industry for the construction of space probes and planetary rovers. Thus, RW is utilized of by sending it into space in the form of a radioactive payload for the purposes of space researches [

3,

4].

This article proposes to process radioactive waste, making precious stones from them using the same technology that produces artificial gems. Two approaches are suggested: 1) to manufacture precious stones entirely from vitrified and cemented RW; 2) to make gemstones from the same materials used for production the non-radioactive gemstones, but with the addition of radioactive material. In the latter case, it is possible to reduce the specific activity of the material from high to medium or low activity. Radioactive gems can be viewed as real estate that can be invested in. Being deactivated after hundreds and thousands of years, this property will be of great scientific interest due to its antiquity.

Methods for the production of radioactive gems

The first and last artificial radioactive minerals used in jewelry came from the testing of the first atomic bomb, Trinity, in 1945. Quartz sand on the surface of the polygon had been drawn into a plasma ball, where it has evaporated and, after condensation and solidification, fell back to the surface in the form of vitrified minerals of various shapes and sizes [

5,

6]. This glassy material was named trinitite. Its main components (wt. %) are silica SiO

2 51.3–96.8%, alumina Al

2O

3 0.35–18.82%, calcium oxide CaO 0.52–27.33%, TiO

2 0.08–1.89%, Na

2O 0.1–3.14%, FeO 0–4.29%, MgO 0.1–2.28% and other components from atomic bomb evaporation and supporting structures, radioactive fission products [

5,

6]. The cost of samples of trinitite prepared as jewelry or for mineral collections is up to

$50 per gram [

7].

In terms of chemical composition, trinitite is similar to a combination of components of glass-forming and cement matrices for radioactive waste storage. Thus, for glass-forming matrices we have the main chemical composition (wt. %) – silica SiO

2 15–20%, Na

2O 9–12%, datolite CaBSiO

4(OH) 24–32%, bentonite Al

2[Si

4O

10](ОH)

2·nH

2О 9–12%, Fe

2O

3 3–4%, and up to 20% high-level radioactive waste (HLW) [

8]. The composition of Portland cement – calcium oxide CaO 64–67%, silica 21–25%, alumina Al

2O

3 4–8%, Fe

2O

3 2–4%, Na

2O and K

2O 0.5–1%, MgO 0.5–5%, TiO

2 0.1–0.3%, P

2O

5 0.3–0.5% [

9]. The cement matrix based on Portland cement contains up to 30% by weight of medium or low active radioactive waste [

10]. Suppose we decide to create an analogue of trinitite from vitrified and cemented radioactive waste in order to sell, resell them and carry out the same monetary transactions with them as with any real estate during the storage of the obtained radioactive gemstones. After the expiration of the storage period for radioactive gems, i.e. in hundreds and thousands of years, they will already be of interest as an antique rarity. In addition, the storage of radioactive gems with their simultaneous sale and resale at auctions will offset the costs of storage and monitoring. How can all this be done?

Quartz sand at the nuclear test site is presented in the form of micro and millimeter particles. Solid radioactive waste (SRW) needs to be crushed to these sizes.

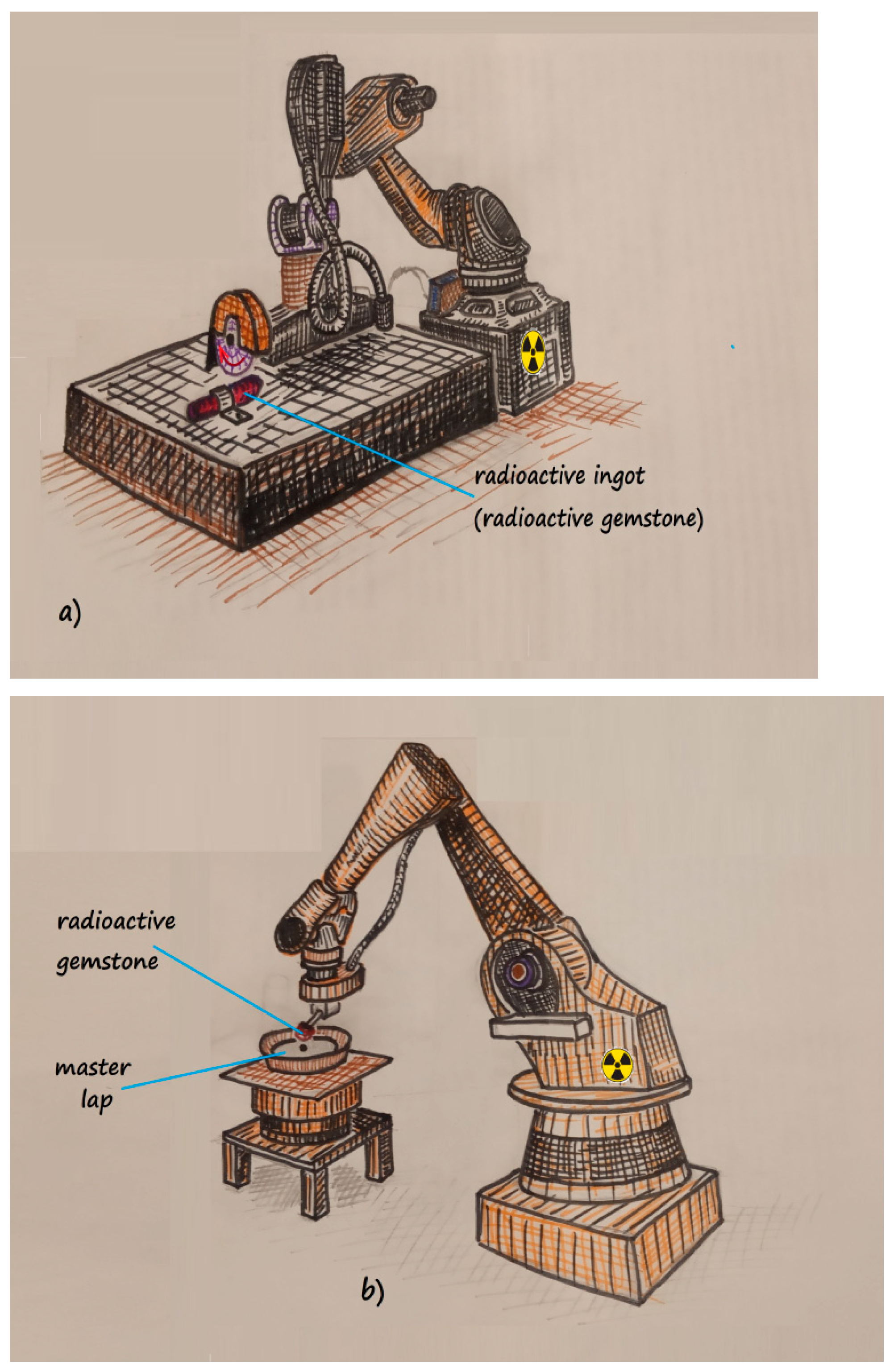

Figure 1a) shows an opened container with SRW and a robot similar to Brokk 900 destroying a cement or glass-like matrix with a chipper.

The crushed radioactive material is then sent to ball mills (

Figure 1b), where it is grinded to millimeter and micrometer sizes [

13]. After the mills, we obtain a product similar to what lies at the test site before the explosion of the atomic bomb. The only difference is that our sand is already radioactive. To reduce the activity of highly radioactive waste, non-radioactive material can be added to the ball mill. For example, for the production of radioactive sapphire, non-radioactive oxides of aluminum, iron and titanium can be added to a ball mill along with pieces of radioactive waste.

Now we have to reproduce the temperature of a nuclear whirlwind of several thousand degrees Celsius to melt the radioactive powder material. To date, the industry has mastered the production of artificial corundum, a variety of which is sapphire and ruby, and the production of many other precious stones. The melting temperature of alumina micro powder, from which corundum is obtained, is 2200°С. To obtain corundum (as well as sapphire and ruby), the Verneuil method is used [

14], although there are other methods, but we will limit ourselves to this. The procedure for melting the radioactive powder and its crystallization by the Verneuil method is shown in

Figure 2.

The impeller forces the mechanical impactor to act on the container with RW powder or with a mixture of RW powders and non-radioactive material, which is poured through the filter into the combustion area. In the combustion chamber, hydrogen and oxygen interact with the release of heat, which provides the required temperature of about 2200°C. Micro particles of radioactive powder melt, radioactive drops fall onto a seed (in the form of boule) from some glassy or crystalline substance, which gradually moves down from the high temperature region. On the boule, radioactive droplets solidify, forming a crystalline or amorphous phase. So we get a cylindrical boule of solidified radioactive material. The growth rate of the boule in modern devices is several millimeters per hour. The composition of the RW powder and the rate of cooling of the liquid phase on the boule will determine the ratio between the amorphous and crystalline phases in the resulting sample.

Next, it is necessary to cut the radioactive boule into pieces, which is done by a remote-controlled robot similar to Robo SawJet 2.0 (

Figure 3a).

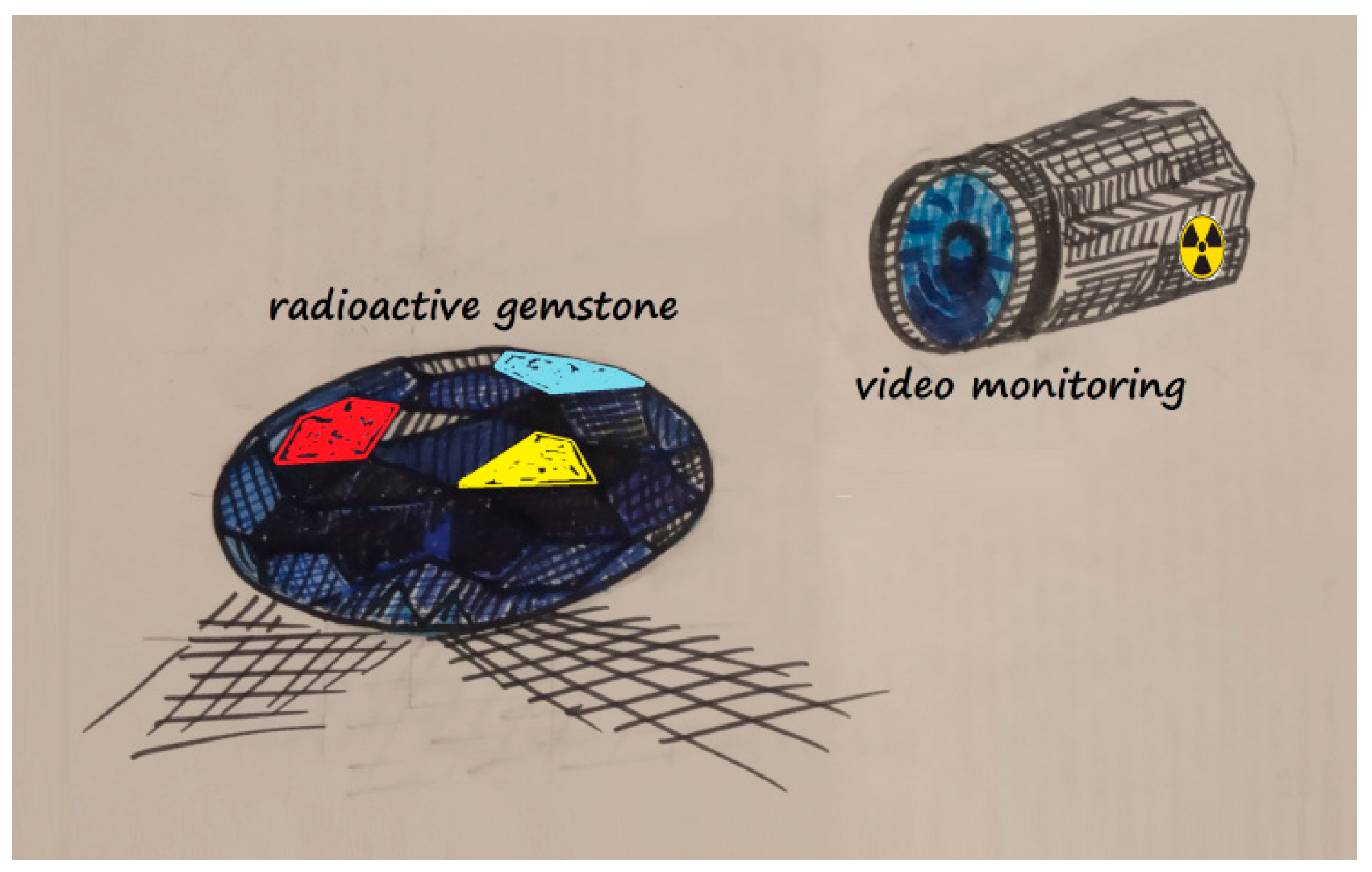

Further polishing of each sample of radioactive material to give it the necessary form, which has artistic value, can be carried out by robots such as KUKA KR QUANTEC series (

Figure 3b). In order to sell the received radioactive products during the period of their storage, in addition to monitoring the gemmological characteristics of the samples using the necessary detectors, a video camera must record the state of the radioactive gems (

Figure 4).

Stones obtained from RW or from a mixture of RW and non-radioactive material will contain additional inclusions, impurities and defects that will make them unique in comparison with conventional artificial gemstones, because the uniqueness of precious stones is determined precisely by the variety of defects and impurities [

17].

Conclusion

A method has been proposed for the manufacture of precious stones from reopened RW by crushing, grinding, mixing, melting, solidifying according to the method used in the manufacture of artificial precious stones, and subsequent faceting and polishing to give radioactive gemstones an artistic form. The modern industry already possesses the installations and robots with remote control and software necessary for these processes. Storage of radioactive gemstones until their deactivation with video monitoring of their condition and sale at auctions will provide compensation for the costs of processing, monitoring and storage of RW. Because during the storage of radioactive stones for hundreds and thousands of years, many world events will take place, which they will witness, then after deactivation these stones will be of not only jewelry and scientific interest, but also historical. In the manufacture of radioactive stones from a mixture of highly active RW and non-radioactive material, the resulting product can be obtained with medium and low activity, which will reduce the environmental and terrorist threat from their possible use for military purposes.