1. Introduction

1.1. Research Background and Objective

The construction industry worldwide has been notorious for its negative features, i.e., numerous accidents and lower productivity and digitalization levels than other industries such as manufacturing and medicine. According to a McKinsey study, the industry suffers from a great deal of inefficiency; so to speak, large construction projects usually take 20% longer than planned to complete and are up to 80% over budget [

1,

2].

The chronic problems are dedicated to the unique nature of construction operations includng labor-intensive, complex, and fragmented. To manage the complexity and enhance the efficiency, thereby setting it up again as a new driving force for national development, a number of developed countries have pursued innovation in construction technology through merging with various emerging digital technologies. This movement has been called Smart Construction [

3,

4] or Construction 4.0 [

5,

6,

7] in individual countries. While the names are diverse, there is no doubt that the core concept under the names is, as stated just above, to combine traditional construction methods with the digital technologies, such as Building Information Modeling (BIM), Internet of Things (IoT), Digital Twins (DT), Artificial Intelligence (AI), Unmanned Aerial System (UAS), Laser Scanning (LS), and robotics to improve construction productivity and safety [

8,

9,

10].

Among the technologies, UAS, known as a drone, has been recently well acknowledged as a significant technique for collecting valuable data and insights in diverse construction processes. DroneDeploy, a cloud software platform for commercial drone, presented remarkable statistics on drone application in 2018 [

11]. It pointed that drone use in the construction industry has raised steeply up to 239% compared to 2017, which is greater than other industries, i.e., mining 198%, agriculture 172%, surveying 171%, and real estate 118%. Furthermore, the speedy improvements in drone flight ability, data capabilities, and camera technology continuously increase the use of a drone in construction business. According to Allied Market Research, the global construction drone market size was valued at

$4,800 million in 2019 and is estimated to move up to

$11,970 million by 2027, showing a compound annual growth rate of 15.4% from 2020 to 2027 [

12].

A drone performs analogous function to the LS in the construction quality monitoring through Scan-to-BIM process [

13,

14]. Both technologies digitally scan or capture the as-built physical objects into the computer world as a digital 3D representation and the data scanned is transferred to BIM milieu to create either accurate as-built models or to inform the design with the real world surroundings. Through the Scan-to-BIM process, the missing design data such as 2D drawings and 3D BIM models are generated through Reverse Engineering (RE). The RE process enables engineers to figure out how a portion of a product was designed so that they can reconstruct it. [

15].

While it is described that the LS has been the major technique of the Scan-to-BIM process, a number of digital professionals address the shortcomings of the LS such as time-consuming process, static nature in collecting data, and casting a shadow due to scanning mechanism [

16] and emphasize that drones are an alternative solution which readily recovers the shortcomings of the LS. The drones are best utilized when scanning the externals of buildings due to their speed. Unlike laser scanners, the drones are able to scan roof tops meaning that a full and complete data set can now be achieved, and due to their mobile nature, they suffer much less from shadowing from nearby objects. A drone technology provides clients with accurate point cloud data which can be processed and imported into BIM software such as Autodesk Revit & Archicad to create an intelligent 3D model. This is why UAV-to-BIM is used interchangeably with the Scan-to-BIM [

17].

In 2018, the Ministry of Land, Infrastructure and Transport, Korea (MOLIT), the central governmental entity responsible for developing public policies to provide quality infrastructures in Korea, established “Smart Construction Technology Roadmap” as the policy of implementing Construction 4.0 and announced the plan to utilize the drones and the LS for monitoring construction operation quality in major public projects by 2025 [

4]. It is therefore necessary for contractors to train their engineers to be competitive in the projects. However, the two technologies

are not so popular in general construction projects in Korea. Among 12,651 general contractors nationwide, only top 50 level contractors have from time to time utilized those in their projects [

18].

A successful drone flight or the LS for construction is not just operating the equipment, but gathering the image data and editing the data to well fit to the objectives of the intended operation. The tasks require skills and experience.

The universities where Construction Engineering and Management (CE&M) program have been implemented in Korea are requested to develop curricula for providing education of the technologies for the contractors. While a number of the schools deliver either graduate or undergraduate BIM curricula, none of them have operated a drone and the LS curriculum yet. The CONECTtech Lab in GeorgiaTech, Georgia, USA has recently carried out a new course called “Technology Applications in the Construction Industry [

19].” The course encompasses multiple construction technologies, i.e., the LS, 4D BIM, photogrammetry, virtual reality, mobile applications and project management software. But the major concentration and attraction for students of the course is positioned on drones. The CONECTtech Lab provides a good reference for Korean universities to develop a drone oriented curriculum in the CE&M program.

The construction industry in Korea faces, nevertheless, difficulties in enhancing the utilization of drones as well as laser scanners. The biggest hurdle is finding an experienced and skilled workforce.

There are very few drone and LS experts knowledgeable to develop the curriculum in academia as well. Developing the curriculum should systematically organize clear learning objectives, proper methodologies to the objectives, potential limitations and risks, the amount of time required, trainees’ initial knowledge and general behavior, and the final product of education [

20,

21].

Each component affects and interacts with other components. To avoid trial and error in progressing the drone and LS curriculum and successfully implementing it later on, it is very essential for the schools to understand pros and cons of the technologies and perform a preliminary study on the items empirically thereby minimizing the potential barriers or failure in the curriculum.

The main objective of this study is to perform the preliminary study through experimental drone and LS applications with the beginners in the construction industry and identify valuable lessons that would be beneficial to promote the UAV-to-BIM curriculum for construction engineers. The study also identifies the pros and cons, limitations, and the needs for collaboration of the two technologies. In the process of identifying the lessons, the following questions are specifically answered: (1) Is it necessary for developing the drone education curriculum in the universities for construction engineers? (2) What contents are essentially embraced in the curriculum? and (3) What formats and supports are desirable to successfully develop and implement the curriculum?

1.2. Research Methodology

The methodology of the study consisted of four activities: (1) reviewing the existing body of knowledge on drone and laser scanning usage in construction and on the curricular of their education; (2) operating LS and flying drones with the participants of the study, i.e., the novices of the instruments in the construction industry, to capture as-built conditions of experimental facilities; (3) analyzing the results and findings of the experiment; and (4) dig up the lessons from step (3) to be applicable to exploit the UAV to BIM curriculum. Performing the experiment is exploratory in that there has not been such a study before. As well, investigating the lessons inevitably reflects the commonality from diverse approaches done by professionals, so that very descriptive rather than analytical.

For the step (2), the authors arranged 19 students in the CE&M program at Seoul National University of Science and Technology (SNUST) located in Seoul metropolitan area, Korea, as the participants of the study. Twelve out of the 19 were undergraduates and the other 7 part-time graduates. While the graduates had worked at competitive construction firms for more than several years, they did not used the tools before. In parallel with preparing the participants arrangement, 2 facilities with different shapes and sizes in the campus were selected as the subject facilities to be experimented. The authors incorporated a drone education module into one of the existing CE&M classes, called Free-form Facade Engineering (FFE), in the Department of Architectural Engineering, School of Architecture at SNUST. Two drone education professionals were invited from the private drone flight training institution which has been certified as a drone education provider in accordance with Article 126 (Designation, etc. of Training Center Specializing in Ultra-Light Vehicle), Korean Aviation Safety Act (KASA) [

22].

In the steps (3), after finishing step (2), a presentation seminar was implemented. The participants presented their experimental findings, problems, feelings, and any difficulties freely in the seminar. The two professionals of drone education participated in the seminar to discuss as well as critique the findings and deliver their experience regarding those items.

In the step (4), the workshop having a Focus-group Interview (FGI) format was conducted with the two professionals and the 7 part-time graduates to specifically figure out the lessons. The authors used a workshop rather than a questionnaire survey because the former can get more specific and comprehensive findings. FGI are interviews conducted with a group of participants to bring together a variety of information [

23]. These generate large amount of data and authentic responses based on the synergy of group discussion and interaction in a relatively short time span and the findings can be used to precede further qualitative procedures. In the process of FGI, a moderator asks a question to the participants, then just takes a step back and lets natural dialogs arise based on the question. In the workshop, the authors performed the role of the moderator and identified valuable lessons with the interviewees together.

2. Literature Review

2.1. Industry 4.0 and Construction 4.0

During the last decade, distinguished technological advancements worldwide have been achieved thanks to Industry 4.0, which is introduced by

the German Federal Government (GFG) in 2011 [

5]

. The GFG defined Industry 4.0 as “a new technological age for manufacturing that uses cyber-physical systems and Internet of Things, Data and Services to connect production technologies with smart production processes.” Schwab [

23] later described it as the stage that enabled the full integration between people and digitally connected machines with the help of internet and information technology. As well, Helman et al. [

24] explained it as a new level of value chain organization and management across the lifecycle of products. A number of professionals have appraised that networking and connectivity are the cornerstones of Industry 4.0 and it leads to enhance seamless data harmonization and communication between the machines through the IoT so that human interventions are significantly reduced.

Construction 4.0 is the term used to represent Industry 4.0 in the construction industry [

25]. The first article that mentioned Industry 4.0 and construction together dates back to September 2014 [

26]. Regarding Construction 4.0, Ronald Berger initially described in his article in 2016 [

27]. The European Industry Construction Federation (FIEC) expressed it as the counter part of the Industry 4.0 in the Architectural, Engineering & Construction (AEC) industry to efficiently and productively design, build, and operate diverse built assets through digitalization [

28]. Rastogi [

29] stated that the main goal of Construction 4.0 is to create a digital construction site that monitors progress throughout the life cycle of a project by using diverse digital technologies. Many professionals pointed that the adoption of Construction 4.0 would not only change the construction process but it could change the organization and project structure, shifting the fragmented construction industry into an integrated one [

30].

A variety of digital technologies and systems are cooperated in Construction 4.0. Sawhney et al. [

31] recently defined Construction 4.0 as a convergent and transformative framework where

physical-to-digital and digital-to-physical transformations take place among the extensive technologies in the following three categories in the process of effectively incarnating physical assets:

- (1)

Industrial production: prefabrication, 3D printing and assembly, offsite manufacture

- (2)

Cyber-physical systems: actuators, sensors, IoT, robots, cobots, drones

- (3)

Digital and computing technologies: BIM, video and laser scanning, AI and cloud computing, big data and data analytics, reality capture, Block chain, simulation, augmented reality, data standards and interoperability, and vertical and horizontal integration

2.2. Drone & LS Application in Construction

As stated above, a drone is one of the main digital technologies that lead to digital transformation in construction. A number of current research, i.e., Tatum and Liu [

32], Li and Liu [

33], and Mahajan [

34] presented comprehensive literature review on drone usage being operated on construction sites and future uses being contemplated in the construction industry. The distinguished feature of drone technology that makes such dominance is that unlike traditional geographical technologies, drones can cover large areas fastly and easily and create detailed 3D imagery of the project-surrounding area delivering digital surface models and detailed point cloud. Relying on the large amounts of data from drones, architects and site managers can have access to powerful insights that suggest a more practcal model of the site. This is crucial to getting informed and data-driven decisions and invaluable for capturing current conditions and making subsequent design changes.

Drones perform analogous function to 3D laser scanners. Both drones and 3D scanners have become a critical mean necessary to complete Scan to BIM cycle [

13,

14]. The 3D scanning technology digitally captures the as-built size and shape of physical objects into the computer world as a digital 3-dimensional representation by use of a line of laser light [

35]. In a Scan to BIM process, the data captured by drones or scanners is imported into a 3D environment by such a software that transfer the scan data to BIM milieu to create either accurate as-built models or to inform the design with the real world surroundings as Pix4D, Cloudworx, Edgewise, Pointsense, and Revit Add-in [

36].

Through Scan to BIM process, the missing design data such as 2D drawings and 3D BIM models are generated through Reverse Engineering (RE). RE is, often called back engineering or reverse design, is the process where machines, automobiles, buildings, and other products are decomposed to extract design information, codes, and knowledge from them [

6]. Engineering in general produces drawings through engineering translation and generates products on the drawings. However, in the world of RE, original product drawings of a product are pulled out from the finished product. The RE process, hence, allows for figuring out how a portion of a product was designed so that they can reconstruct it.

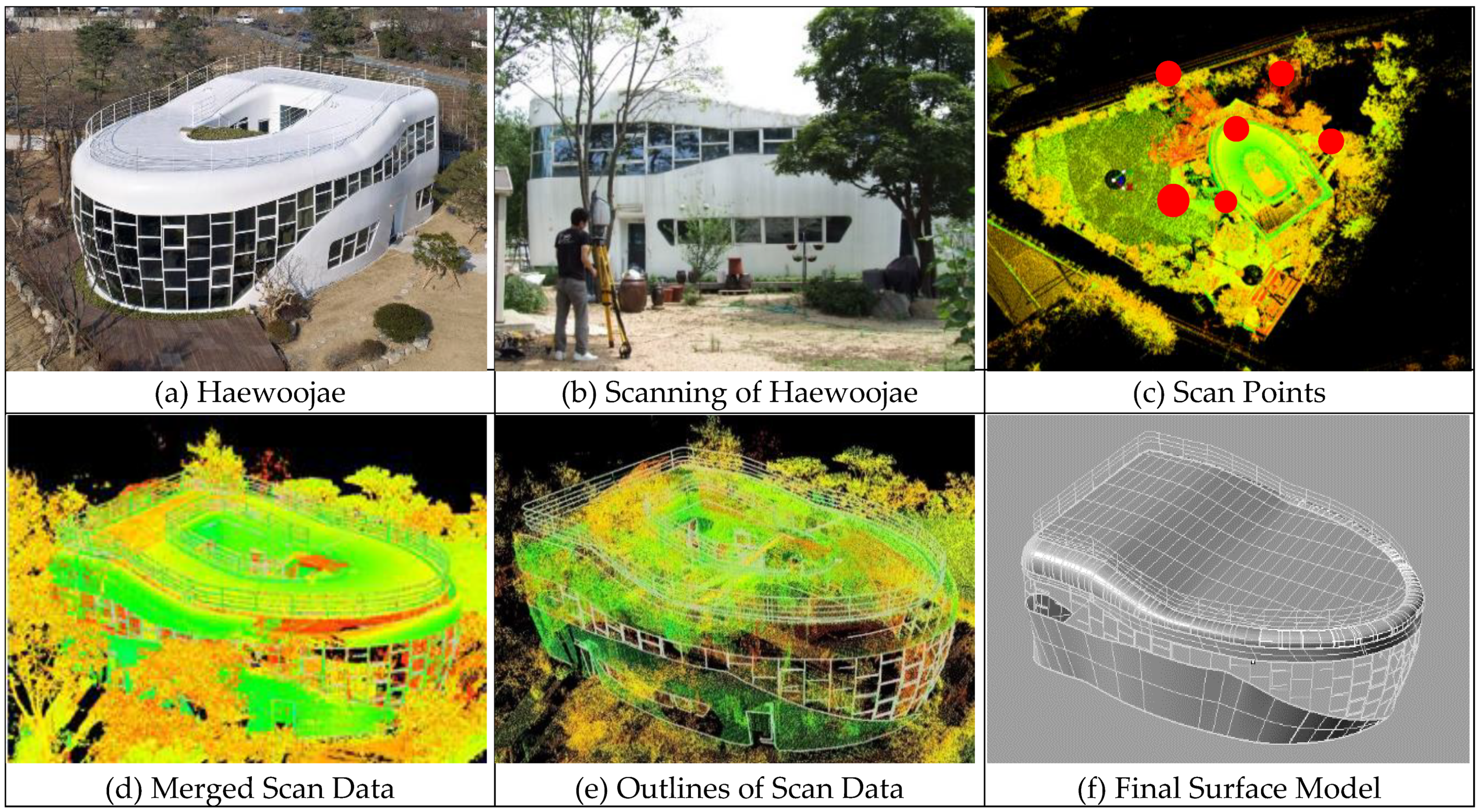

Ock [

14] presents the RE process distinctively through a case study as shown in

Table 1. The figure in

Table 1-(a) shows the scanned facility having 2,900m

3 with two-story and 418 m

2 gross floor area. The initial step of laser scanning was to set up scan points. The figure in

Table 1-(c) presents 6 scan points established to get the point cloud data of the facility, i.e., five points around the facility and one on the roof. The points were arranged to secure enough overlap of scanned areas thereby obtaining a confident shape of the facility. Bright green lines at around the center of the five red circles indicated the boundary of the facility scanned. The scanned data were then refined removing unnecessary noise in each scanned area for incarnating the facility and merged together. Merge process was performed following the overlapped location and shapes in each of the six scanned areas. Based on the merged shape, the building outline and surface were made as the sequential figures in

Table 1-(d), (e), and (f).

In the construction industry, data capture through the Scan to BIM process and the digital data superimposition technique have been jointly applied to develop augmented reality (AR) and mixed reality (MR) systems as a project progress monitoring scheme, which visualize the discrepancy between the as-built and as-planned performance on a project [

37]. Superimposition literally means the placement of one image on top of an already existing image to enhance the overall image quality. AR superimposes digital information on real-world components, retaining the real world central but enhancing it with digital applications. MR is the merging of real and virtual worlds to produce new environments and visualizations, where physical and digital objects co-exist and interact in real time.

Ratajczak et al. [

38] proposed a BIM-based AR. The application combined Location-based Management System and BIM to visualize progress and performance of construction works by use of superimposition. Raimbaud et al.

presented a MR application based on BIM data and drone videos, allowing off-site construction supervision [

39]

.

2.3. Drone Education

Drones have been widely used for data collection across various careers and research areas. These phenomena have led to a call for increased integration of drones into education in the engineering, construction, science, and technology professions [

40]. Al-Tahir et al. [

41] suggest three different methods to introduce drones into education: have students conduct a capstone project with drones, incorporate a drone education module into an existing course, or create an entire course on drones. Alkaabi et al. [

42] found that a hands-on drone workshop for students at the United Arab Emirates University improved the student’s teamwork, communication, and critical-thinking skills. The study also found that the drone workshop taught students real-world problem-solving skills.

While recent studies have explored integrating drones into education curricula, most of them focus on training students to fly and control drones [

43,

44]. However, for drone education to apply to students’ future careers, they must learn how to obtain data, process it, and utilize it for analysis. Bolick et al. [

45] developed a drone education module and laboratory exercise for natural resource science students. Students were taught the steps of drone data acquisition and processing through lectures and drone simulation videos. Students applied the knowledge by completing a lab exercise that used previously collected drone data. Their knowledge retention and understanding were evaluated using an online quiz to determine the effectiveness of the education module. Whilst the students expressed positive opinions overall about the drone education module, some students would have preferred a hands-on experience for some parts of the exercise. As well, He et al. [

46] designed a virtual interactive drone exercise to teach students how to capture drone data and process it into a 3D model recreation of an open-pit mine. Based on the findings from the study, the researchers provided educators with crucial recommendations to improve access to drone-related educational content.

Although it is presumed that virtual drone education is beneficial for comprehending drone usage in construction, the best practice is definitely to perform in-person education for construction professionals. Sanson [

47] introduced the Civil and Construction Engineering Technology (CCET) Department of Youngstown State University (YSU), Ohio, USA has taken steps to implement the use of drones in the curriculum; faculty were licensed to operate the drones under the current Federal Aviation Administration (FAA) regulations and the department has purchased two DJI Phantom 4 drones. As mentioned earlier, the CONECTtech Lab in GeorgiaTech, Georgia, USA has recently carried out a new course called “Technology Applications in the Construction Industry [

19].” The course encompasses multiple construction technologies, i.e., LS, 4D BIM, photogrammetry, virtual reality, mobile applications and project management software. But a main concentration and the major attraction for students of the course is positioned on drones.

The construction industry in Korea is facing difficulties pertaining to maximizing the utilization of drone as well as laser scanners. The biggest hurdle is finding an experienced and skilled workforce. While construction companies are reluctant to adopt a wide range of high-tech digital technologies due to their complexity, high risk, and conservatism, major IT vendors, BIM companies, and some universities are confident that education can accelerate the introduction of high-tech technologies.

3. Experimental Design

3.1. Course Description

As mentioned earlier, the authors went for merging a drone education with the FFE class. The class had been developed several years before to provide students with procedures and theories of designing free-form façades based on the principles originated by Frank Gehry, the distinguished free-form building designer in the USA [

48,

49], securing as-built quality of the free-form facades with the laser scanning technology, measuring discrepancy between as-built and as-designed free-form facades through the digital data superimposition methodology, and implementing the Scan-to-BIM process as well as RE procedures in conjunction with laser scanning application. The FFE is a three-credit undergraduate elective coursework and can be taken at the graduate level. The students in the course are in general architectural-engineering major and the majority of enrollment are seniors with a few juniors and graduate students, typically having more or less 20 students.

3.2. Experiment Motivation

While both drones and laser scanners perform similar functions to come up with the Scan to BIM cycle, the drones had not been used before in the FFE class. As well, other trial to incorporate the drone into the real-world CE&M curriculum in the academia has rarely been performed in Korea either. While there have been vivid and continuous needs in the market for furnishing advanced drone or laser scanning technologies for construction professionals, it is very little progress that has taken place in Korean academia in reality up to date.

The main motivation of the experiment was to execute a preliminary estimate of the off-line rather than on-line drone applicability to the real-world CE&M curriculum. The authors wished to possibly upgrade the FFE class by using the drones in parallel with the laser scanners. It was expected that a comprehensive drone-oriented CE&M coursework could be developed based on the finding from the experiment later on.

A great number of the construction professionals either in jobsites or in offices in Korea are beginners in drones. Through the preliminary study, in addition to upgrade the FFE class, the authors not only identified the feeling of drone beginners as to if they felt comfortable or sensed any fear when flying the drones around buildings but also figured out if the drones could improve drawbacks of the laser scanners and if so, what they should learn to confidentially handle the drones.

3.3. Experimental Settings

Nineteen students, i.e., 12 seniors and 7 part–time Master level graduates participated in the experiment. While the 7 graduates had been working in competitive construction companies, they mentioned that they had never been involved in using a drone or laser scanner for their projects at all up to date and added most of the engineers in their companies rarely utilized those in their construction operation.

Table 2 represents the Construction Capacity Evaluation Criteria (CCEC) prepared by the MOLIT, Korea in 2021. The CCEC, developed since 1996, groups Korean general contractors into 8 levels according to their contract amount last year, technical capacity, and financial status [

50]. Belonging to a higher level indicates that the contractors in the level can be awarded more volumes of works than the contractors in lower levels. The CCEC, however, does not describe how competent contractors are in effectively utilizing digital technologies. Among the 7 graduates, 4 have been working for the companies in the level 1, and 3 others in the level 2. All of the 7 graduates have had more than 10 year field experience as a quantity surveyor, scheduler, or field manager. As a matter of course, the number 7 is too small to represent reality of the digital innovation levels of Korean construction engineers

. However, it could be a clue to infer that many Korean companies even in Level 1 and 2 are simply in infancy toward pursuing digital implementation using drones or laser scanners.

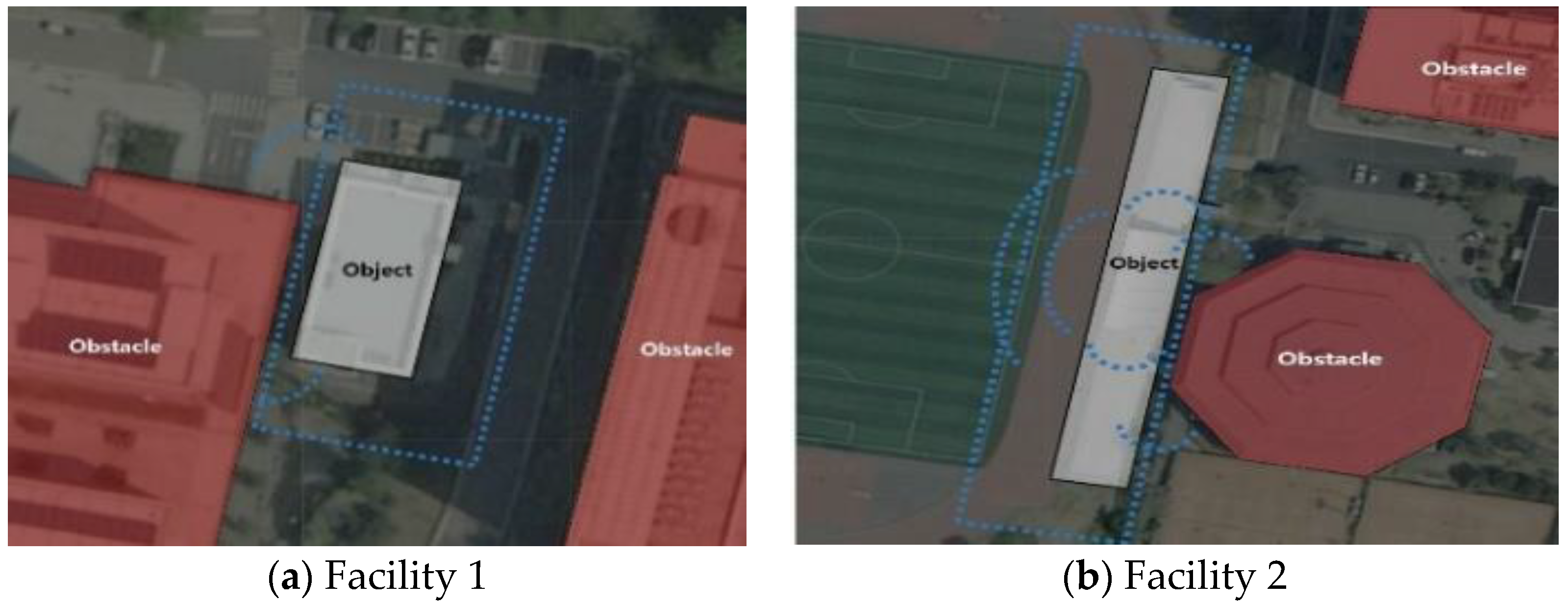

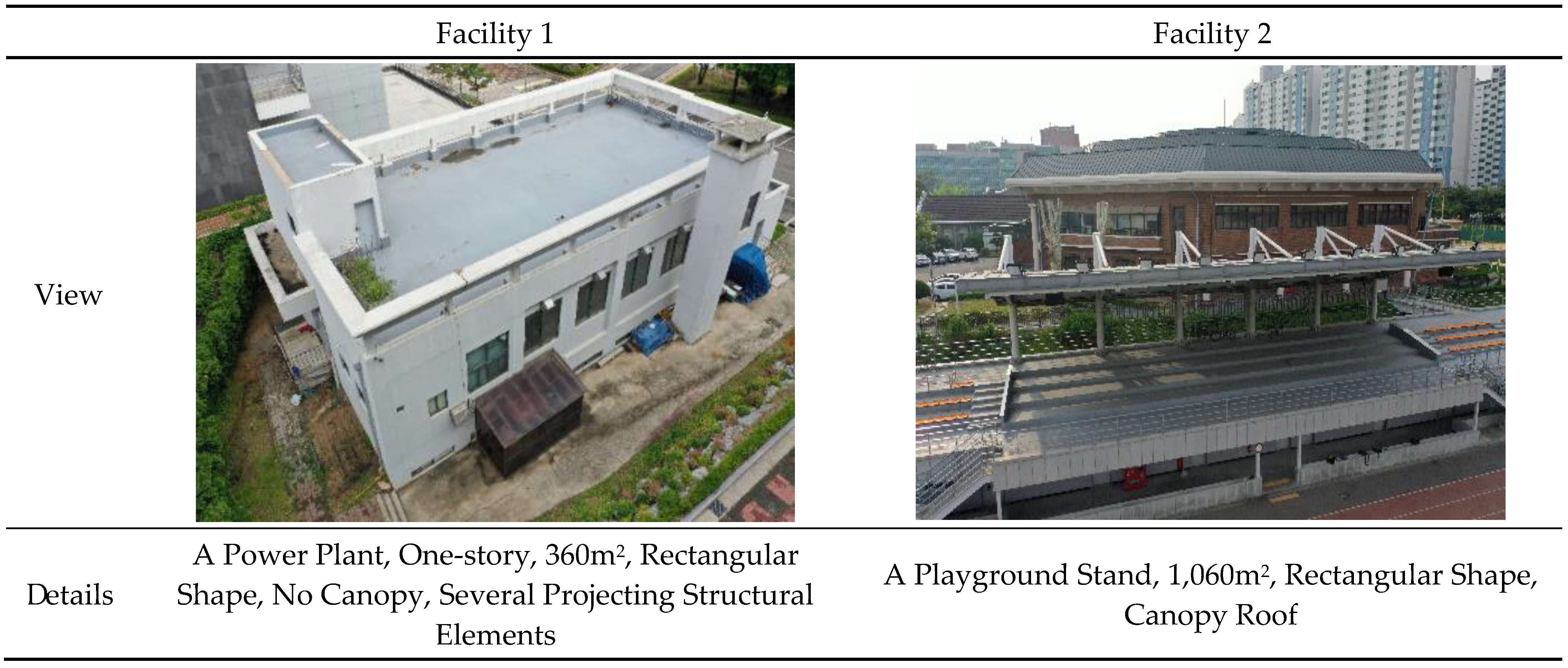

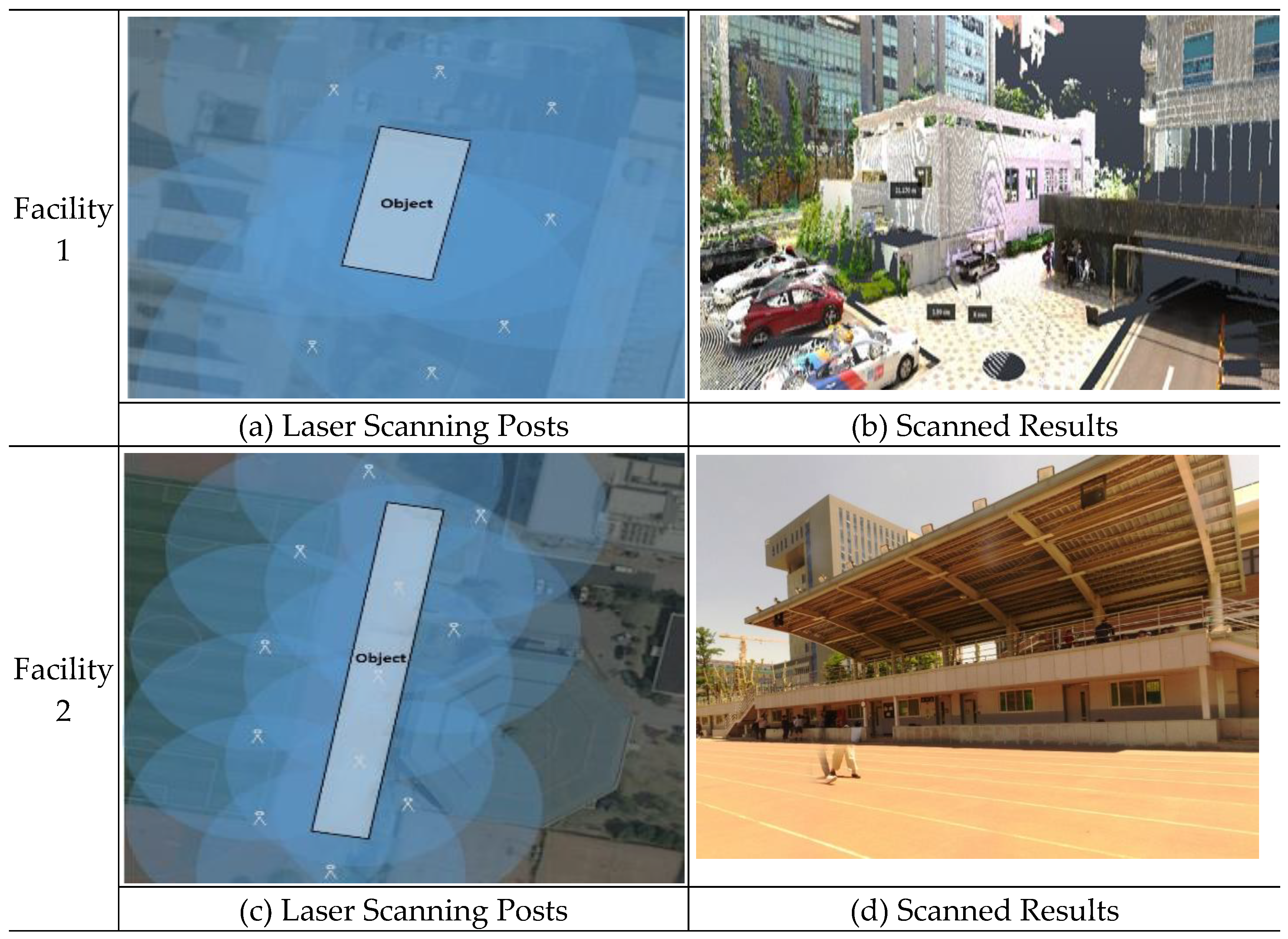

Two facilities were arranged for the experiment as shown in

Table 3. Each of the facilities includes the different shape and size. Since the experiment was proceeded in the campus, the authors had to be very careful in selecting the facilities in order not to cause any incidents to other buildings as well as pedestrians and any troubles to other classes due to drone noise. The size and shape of the facilities were chosen to support the students to comprehend the workability level of a drone as well as a laser scanner in capturing as-built environments of the facilities in reflection of their configuration and to figure out what activities were necessary for enhancing quality of the as-built scanned data.

The first facility in

Table 3 is a one-story and small power plant. It is located at the outskirt of the campus so that little interference and congestion by pedestrians was expected during experiment. The exterior of the facility is finished with white painting and the configuration of the parapet and the chimney impose a little complexity on the facility. The second is a playground stand, located at the edge of the campus as well so that little restrictions seemed to be projected to students’ activities in the experiment. The exterior of the stand is constructed with steel pipes and panels. The canopy roof and the stand chairs seem to make it complex to gather the as-built data of the facility.

The authors organized the students into 6 groups, i.e., 3-4 students in a group. While it was desirable for each student to be involved in the experiment of the two facilities, therefore possible to get more experiment data, due to time limitation of a semester, three groups of students were solicited to perform the experiment of drone flight toward one building, e.g., group 1, 2, and 3 to the power plant. The experimental FFE class consisted of two modules: lecture module and experiment module. The lecture module progressed until the midterm covering the theories of designing free-form façades, securing as-built data of the facades with the drone and laser scanner, and measuring discrepancy between the as-built and as-designed.

After the mid-term, the students got involved in the experiment module for 7 weeks. The experiment consisted of six steps: (1) a theory and equipment-learning session; (2) a laser scanning operation; (3) a laser-scanned data development; (4) a drone flight operation; (5) a drone-flown data exploitation; and (6) an experiment results presentation. Based on the experiment results, the students were requested to figure out the pros and cons of the two technologies, the good or bad outcomes from the technologies in the experiment, and analyze the usability of the technologies in conjunction with the distinct features of the facilities.

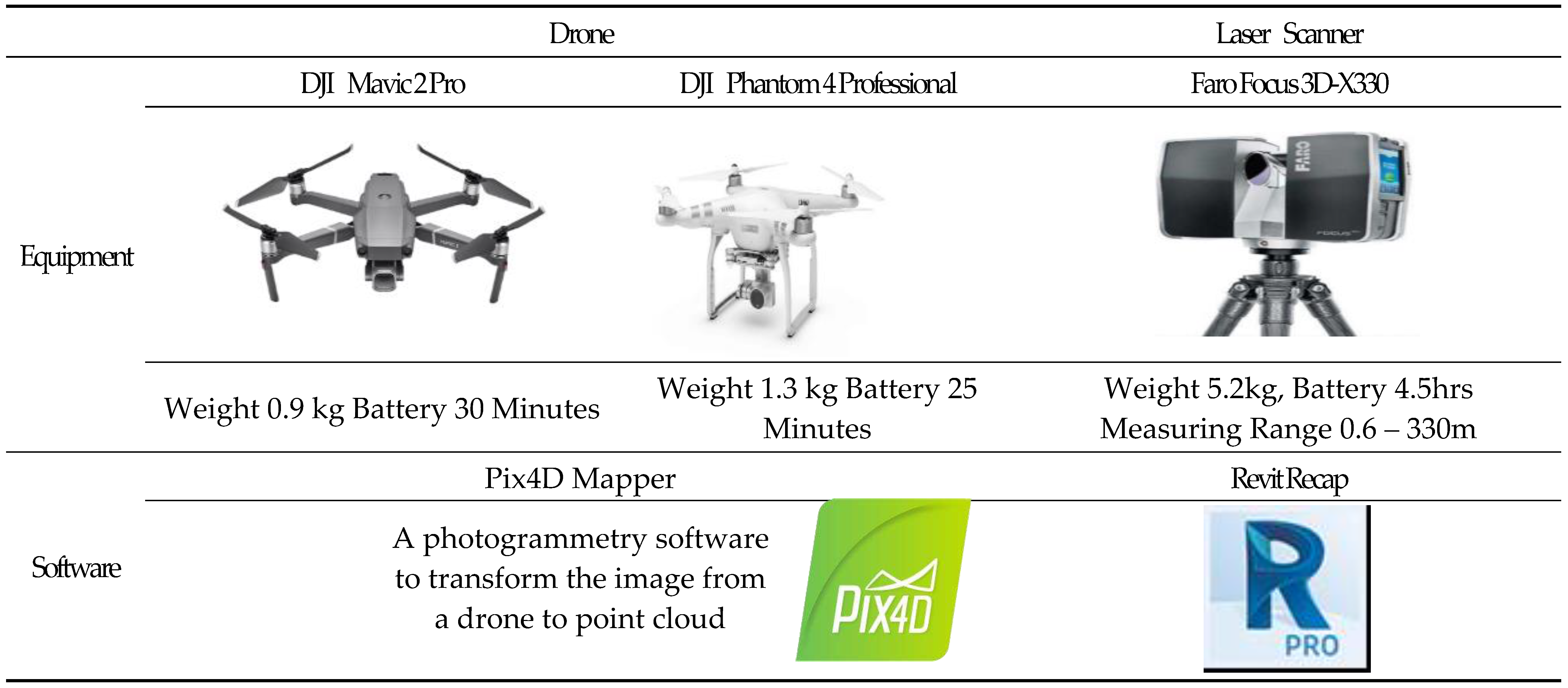

3.4. Equipment

Table 4 shows the equipments as well as the related software used in the experiment. Among a number of laser scanners, the study utilized Faro Focus 3D-X330 Time of Flight (TOF) scanner. There are two common operating principles for laser scanning, i.e., TOP and phase comparison [

51]. TOF laser scanning computes the coordinates of its surroundings on the basis of the amount of time a single laser signal takes to return to the scanner after being echoed. This process takes place a great number of times until the given range of data assembly is achieved.

Two quadcopter drones were used in the experiment including DJI Mavic 2 Pro and DJI Phantom 4 professional. The former features a 3 axis gimbal with a 1* CMOS camera that provides 4K video, 20-megapixcel photos and filters [

52]. It has a maximum flight speed of 72km/hr and a maximum flight time of 31 minutes. The latter contains 12.4 megapixcel camera with 4K resolution video at up to 30 frames per second recording capabilities [

53]. Its maximum flight time is up to around 28 minutes. The main drone prepared for the experiment was DJI Phantom 4 professional. DJI Mavic 2 Pro was adopted right after the Phantom 4 became unworkable due to the flight accident happened in the middle of the experiment.

4. Experimental Process and Results

4.1. Flight Licenses and Permits

As the initiation of the experiment, the students were solicited to take a 6-hour e-learning class regarding drones delivered by the Korean Transportation Safety Authority (KOTSA), a public entity

to protect lives and properties in all areas including land, aviation, and railroad in Korea. The e-learning class is a mandatory qualification to fly drones with weight of 0.25–2kg [

54].

To hover drones bigger than the size, operators should take a strict license exam and register the license. According to Korean Aviation Safety Act (KASA), the license requirement is different with respect to the weight of drones ranging from the 1st to 4th levels: the 1st class license covering drones with 25-150 kg, the 2nd class 7-25 kg; the 3rd class 2-7kg, and the 4th class 0.25-2kg. While the first 3 level licenses require a certain period of aviation experience and an exam, the 4th level demands only taking a 6-hour e-learning class without any aviation experience as well as an exam. The contents of the e-learning class cover the basic knowledge of airspace system, specific operation limitations, UAV platform requirements, and human operator responsibilities.

The experiment was not subject to any aviation approval from public authorities. As a matter of course, in Korea, when a person intends to operate the flight using a drone, he/she should obtain an approval for flight from the MOLIT by Article 127, KASA. However, the Article provides clear exceptions of the approval under the following circumstances: when the flying altitude is less than 150m or when the weight on board including drone self-load is less than 25kg. The drones adopted in the experiment were only 0.9-1.3kg and the flight height was less than 50m.

4.2. Learning Session Proceeding

All the 19 students attended the learning session to clarify the control and operational process of LS and drone flight and the tasks to be performed in the experiment. In the first place, the scanner, Faro Focus 3D-X330 was introduced to the students. The menus and setting on the touch-screen style user interface were displayed in order for the students to become comfortable with operating the scanner and identifying what settings were included in the instrument. The authors then delivered basic theories and procedures of LS to the students. These include: a laser scanner is mounted on a tripod and positioned at several spots around a object to secure enough overlap of scanned data; the laser spins at very high speed to image the surrounding site of the object; the laser beam captures each point of the surface and the relative position between the point and the scanner records the point as X, Y, and Z values commonly referred to as a point cloud; and an accumulation of point clouds creates an accurate 3D digital image. Keeping the scanner on, the authors demonstrated not only how to set up the scanning parameters in the scanner to adjust scan resolution and quality, scan range, color setting, and scan duration but also how to form the as-built environment through refining and merging point clouds.

As stated earlier, in order to secure safety during the experiment, two drone education professionals were invited from the private drone flight training institution which has been certified as a drone education provider in accordance with Article 126 (Designation, etc. of Training Center Specializing in Ultra-Light Vehicle), KASA [

54]. The roles of the professionals featured supporting the authors to manage experimental procedures overall and participating in the workshop after the experiment. The professionals delivered the presentation regarding the components of the two drones and their functions. They also demonstrated drone flights a few times by performing the following tasks: taking off and climbing to an altitude of 50m, hovering in place, performing diverse flight patterns manually, showing automatic flying patterns, taking images of the facilities, and returning to the home location and landing.

After the demonstration, the authors presented the fundamental theories and processing steps necessary for reconstructing as-built environment with a drone. The contents of the presentation mainly covered how to prepare a suitable image acquisition plan before flying a drone. A bad image acquisition plan leads to inaccurate results or processing failure and necessitates to obtain images again. Showing the video lecture that illustrated a drone operation case study, the major processing options equipped in the commercial drone data mapping software were introduced for obtaining point clouds, removing and filtering noise in the point clouds, and improving restructured 3D models.

4.3. Experiment Proceeding—Laser Scanning

4.3.1. Setting up Scan Points

The initial step of LS was to set up scan points.

Table 5-(a) and (c) present 7 and 9 scan points established to get the point cloud data of the facilities 1 and 2 respectively, securing enough overlap of scanned areas thereby obtaining a confident shape of the facilities. Each facility was scanned in the field just once by all the student together as a team. The individual group of the students was then requested to refine point clouds removing unnecessary noise in each scanned area and merge together to form a 3D model following the overlapped location and shapes in each of the scanned areas.

For the facility 1, LS was conducted for a total of 3.5 hours at 7 locations maintaining a distance of 25m from the center of the facility. In case of the facility 2, the laser scanner placed 4 locations at a 30m distance from the center of the facility, 2 locations at a 10m distance from the side walls of the facility to scan the lower part of the canopy and stand seats, and 3 locations at a 5m distance from the backside wall of the facility to secure data in a narrow space between the stand and adjacent structures. A total of 6 hours was spent in LS of the facility.

4.3.2. LS Application Results

It is well known that LS allows contractors to provide both accurate and up-to-date data valuable throughout the different design and construction stages, verify as-built models, monitor progress on a project, and create as-built models for existing structures [

55]. Opposite to the usability, it also has certain weakness. The major disadvantage of laser scanners is the immobile nature of their collecting data [

16]. Laser scanners assemble point clouds by spinning laser beams from a designated position and gauging the time taken for the laser to reflect back to the scanner. Since laser can only travel in a straight line, if there are any obstacles between the scanner and the object, a shadow is cast that definitely causes holes in the data. To get over the shortcoming, the scanner should be moved around on site to make sure all the details of the object are captured. Selecting suitable scanner positions is very labor-intensive and requires experience and skill. Even with the most skilled users, there are still surfaces, such as roofs, which cannot be scanned.

In the expriment, the students were requested to identify the disadvantegeous circumstances that influenced the quality of the scanned images in addition to the disadvantages described above. They were solicited to estimate as well if a drone could be an alternative to be able to overcome the situations. The followings summarize the findings from the students:

Picture (b) in

Table 5 shows the 3D modeling result of the facility 1 based on the point clouds generated in the experiment. The students indicated that since the main scanning locations were placed close to the parking lots of adjacent buildings as shown in

Figure 2-(a), frequent vehicle traffics and reflection lights from the vehicles were likely to hinder them from having high quality outputs from scanning.

The exterior of the facility 1 is finished with white painting that reflects light. The bending in the point clouds of the picture (b) in

Table 5 seemed to be occurred due to the light reflection. Previous research presents that strong light and the glare of the sun can limit the scanner’s ability to capture desired objects [

56]. It is best to perform scanning in early or late in the day when the sun is not directly overhead, or ideally on days that are cloudy. It is weather that cannot be controlled but needs to be considered when scanning.

The authors guided the student that whenever scanning a facility, the primary task was to organize the scanning job overall, which covered imagining the desired scan result, observing the areas to be scanned, and then simulating to figure out the best scan positions to achieve the result. Setting suitable scan positions is not the work that can be done arbitrarily. It is very related to the time required from the beginning to the end of the scan job.

Figure 1 shows the scanned outcomes of the facility 2. These were the outcomes from the test scanning of the facility to select appropriate scan positions for the experiment. It is quite easy to acknowledge that the scan points were too far from the object so that the scanned results were not able to deliver what constructional elements were involved in the facility. Clarifying scan objectives is very significant to organize overall scanning procedures.

As stated above, 3.5 hours were taken to scan the facility 1 and 6 hours to scan the facility 2. In case of scanning buildings, properly estimating the amount of time of scan operation in the field and the frequency of pedestrian traffics around the buildings allows for choosing the best time to perform scanning [

56]. People and vehicles moving around the buildings can act as temporary obstacles that cause shadows and damage the quality of the scanning, frequently leading to rescanning. The two pictures down side in

Figure 1 demonstrated the shadows triggered by the people between the object and the scanner. The shadows lead to missing data and noise in point clouds, requiring a big investment in time and manual effort to remove.

The students got to appreciate the difference of scan resolution, i.e., high or low resolution, through comparing the scan result represented in the picture (d) in

Table 5 with those in

Figure 1. Resolution is the smallest possible distance between any two given points within 3D model [

56]. The higher scan resolution, the better details of the scanned data as well as the more scan time. Most laser scanners capture as much as possible during scanning, and resolution parameters are then set during post processing in the software. The students were instructed how to set scan resolution parameter in the learning session of the experiment for efficient scanning operation.

Scan accuracy is an important consideration when using the data from a laser scanner. In 3D scanning, accuracy is how close the scanner’s measurements are to the object’s true size [

56]. Some of the students questioned how to measure the accuracy of the point clouds obtained with the scanner compared to the object itself. In scanning an object, a large number of 3D coordinates on the object’s surface is measured in a very short time. Deviations are possibly to be noticed after the object has been extracted from the point clouds. If the geometric properties of the object are known, the deviation of certain points from the object’s surface can be an indication for scan accuracy [

30]. As a simple and primary method, the authors solicited the students to set a few measurements on the façade elements of each facility and use them to verify the ones taken from the point clouds.

Since the scanner set on the ground, the scanning operation was proceeded from the bottom to the top of an object using a bottom-up angle. While LS easily measures areas that are visible, due to the bottom-up angle layout, certain parts of a building’s exterior are not accessible to capture the scan data, such as rooftop and ceiling areas. Pictures in

Figure 1 and the picture (d) in

Table 5 did not deliver the overall roof shape of the facility 2 due to the same resaon. The scanner should have been positioned in the rooftop of the stand to obtain the point clouds of the stand roof shape. There was no ladder or corridor that allowed for carrying up the laser scanner to the position and this constraint made it impossible to complete reconstructing the overall 3D shape of the stand.

4.4. Experiment Proceeding—Drone Flight

There are three types of drone operation control in accordance with the intervention level of a drone pilot: a manual control, an automatic control, and an autonomous control [

57]. Whilst the

autonomous control refers to conducting a drone flight without the intervention of a pilot with the help of artificial intelligence, the

automatic control means that a drone flies pre-determined routes defined by the drone pilot before starting the flight. A manual control indicates that the pilot determines the drone’s flight path. The authors guided the students to utilize the manual control for the purpose of leading them to be intimate to drone operation. Each of the drone education professionals was assigned to three student groups respectively to guide and control their drone flight performance.

4.4.1. Drone Flight Routes and an Accident

The blue dotted lines in the pictures of

Figure 2-(a) and (b) show the planned routes on which the drones were supposed to be aviated along the facilities. Each group of the students flew the drones around one of the facilities assigned to them for around 25-30 minutes while taking photos. In case of facility 1, operation was conducted to secure the overall data of the facility by maintaining a distance of 8m to 25m from the center of the facility. An average of 83 images were collected with an overlap of 50 to 60%. In the part where filming was disadvantageous due to adjacent facilities, 10 pictures of each end were additionally filmed with an overlap of 70%. The angle formed by the camera was maintained at 30 to 60

°. In case of facility 2, by maintaining a distance of 20m and 60m from the center of the facility, manual shooting collected an average of 224 images in 30 minutes with an overlap of 40 to 50%. The angle formed by the camera was maintained between 30 and 90

°.

In the middle of the experiment with the DJI Phantom 4 professional, a drone crush accident happened around facility 1. As shown in

Figure 1-(a) and

Table 5-(a), facility 1 was located very close to an adjacent building. The distance between facility 1 and the adjacent building is 5m. According to the student of the accident, when he/she moved the drone promptly back from the direction of the adjacent building to facility 1, the drone was crushed to the side wall of the building and fell down to the ground. Fortunately, there was no pedestrian in that morning. Three propellers were broken down but the students participating in the experiment at that time stood from the accident spot away more than 10m, so the fragments of the propellers did not hurt anyone.

A number of drone crush reports identify a variety of reasons for drone accidents such as malfunctioning rotors, no Global Positioning System (GPS) signal, compass error, disconnected video transmission, incorrect home point, power failure, insufficient battery, and pilot inexperience [

58,

59]

. It was not clear why the accident occurred. But considering such comments by the students in the experiment as that the drone did not show any problems before the accident,

the cause of the accident seemed to be abrupt operation of the control sticks in the remote controller possibly due to nervousness or insufficient flight practice.

Although it is known that the drone equips an obstacle sensing system that constantly scans for obstacles in front and bottom of it so that allowing it to avoid collisions by going around, it has the certain limits of detection ranges, i.e., 60

° in front and 50

° in bottom and cannot sense and avoid the obstacles that are not within the range [

52]. In addition, it is very cautious that flying at high speeds over 10m/second at 2 meters or 5m/second at 1meter may cause problems in the obstacle and vision positioning system of the drone. While the students were instructed to operate the drone as slowly as possible since the manual flight mode was applied not easy to follow or to be confident, many of them regarded the drone as a toy easy to fly.

4.4.2. Drone Application Results

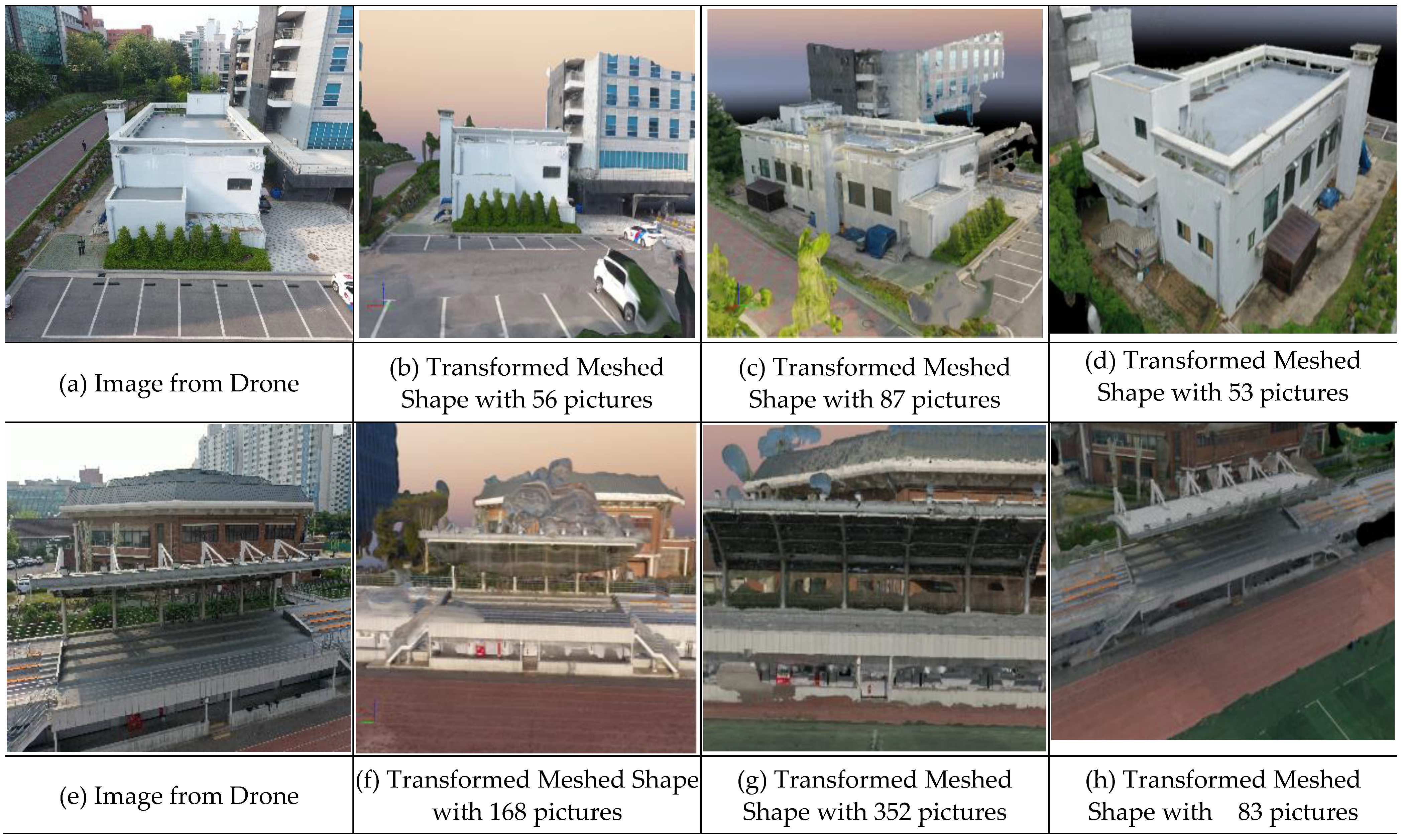

Table 6 shows the transformed meshed shapes of facility 1 and 2 respectively from the point clouds with the photogrammetry software, Pix4D mapper, based on the number of pictures taken by each group of students with the drones. The Pix4D mapper is a drone mapping software to work with drones to transform a large number of images into accurate point clouds and 3D textured mesh [

57]. The softwares that provide similar function to Pix4D mapper include PhotoScan, DroneDeploy, Precision Hawk, and 3D Robotics.

Reviewing 3D modeling results in

Table 6, i.e., pictures (b), (c), (d) of facility 1 and pictures (f), (g), and (h) of facility 2, it is very obvious that the shapes modeled with Pix4D mapper are much vague to figure out the configuration of the facilities compared to the images taken by the drones, i.e., picture (a) and (e). Although it is necessary to analyze and research comprehensively to come up with the reasons for those elusive transformed outputs, it can be inferred that the students are not good at yet reconstructing the images to a 3D model by means of the drones and Pix4D mapper. The overall quality of the experimet results was worse than expected and acknowledged not to be applicable to the procedure of develop a UAV-to-BIM application without certain remedy actions to improve the quality. A number of drone professionals emphasize that

operating a drone is more about the data and presentation than about the flying. The study confirmed the expression and the need for advanced education to comprehensively plan a drone flight and skillfully handle the outputs from the flight.

Whereas 30 minutes were taken for each group of the students to photograph the individual faciliy, manipulating the photo images with the Pix4D mapper took 3 hours on average. After photographing the facilities, the students followed the modeling procedures presented in the Pix4D mapper manual to creat 3D models of the facilities consisting of initial processing, densifying point clouds, and delivering 3D textured meshes [

60]. In the initial processing, the students selected an area of orthomosaic with cloud points and got the image dataset on which point clouds and 3D textured meshes were prepared. Afterward, the densified point clouds were then computed based on the automatic tie points,

which were automatically detected and matched in the photo images. Based on the densified point clouds, the 3D textured meshes were created. The meshes are the derivatives of the densified point clouds so that the quality of the meshes directly depends on the quality of the densified point clouds.

The followings summarize the findings from the drone experiment by the students and the critiques and discussons of the authors and the two drone professionals with respect to the student presention after the experiment:

The students felt at first nervous about flying a drone but found that it was very much easier than expected as soon as the drone started to hover. They felt like moving it faster and faster just like a toy in spite of being educated in the learning session to fly it as slow as possible around the facilities to prevent any incidents from happening.

The drone education professionals pointed that safety should be a primary concern when dealing with a drone, however, during the experiment, safety around the experimental surroundings did not appear to be the first issue to be met and furthermore seemed to be forgotten from time to time. The learning session was too short for the students to understand that a drone was an aircraft system that should be managed methodically and strictly as a unit for safety including a pilot on the ground, the drone itself, a control system, and communication links. It was also criticized that although the experiment was implemented in the open ground and the spot where pedestrains were rarely to come and go, it should have been implemented as if the drones had flown over the place where a number of crowds stayed.

Reviewing the accident case, it is very clear that if a building to be photographed with a drone is very adjacent to a nearby building, special caution is required to avoid disastrous incidents. As well, a specific image acquisition plan is necessary for accurate and sharp images reflecting the narrow configurations of the buildings and the need for another supportive technical means of capturing the demanded image.

In the pictures (f) and (g) in

Table 5, it is easy to recognize noise above the roof of the stand. The students who worked on the facilities presumed that this could be caused by the rolling shutter phenomenon during the drone rotation process when photographing. It was discussed that the assumption was not reasonable because before operating the drones, the shutter speed, aperture and ISO in the cameras of the drones were configured on automatic so that the shutter control hardly influenced the quality of the images taken.

Some students questioned that the noise in pictures (f) and (g) could be due to sunlight. They wondered if building façades were finished with the materials that reflected sunlight as described in the laser scanning experiment, errors in getting images were likely to occur. The 2 professionals explained whereas it might be one of the causes of the blurry modeling results, more realistic cause would be improperly acquiring the images. When obtaining the images, the first item to be satisfied with is to highly overlap between images since occupying the image dataset to create point clouds relies on visual similarities between the overlapped images. According to the Pix4D mapper manual, the recommended overlap is at least 75% frontal overlap with respect to the flight direction and at least 60% side overlap between flying tracks [

60].

Although overlapping the images are significant, it was questionable for the students to be able to maintain a suitable degree of overlap during the experiment since they were inexperienced in handling the image data as well as flying a drone and requested to use a manual flight mode in spite of the inexperience. More specific guides were available from the manual, which were not specifically delivered to the students for the experiment in the learning session though, as follows for securing accurate and clear images in the initial processing stage: recommend to use a circular flight plan for a building; fly around the buiding a first time with a 45

°camera angle; fly a second and third time increasing the flight height and decreasing the camera angle with each round; take one image every 5 to 10

°to ensure enough overlap depending on the size of the building and distance to it; more images should be taken for shorter distances and larger buildings; when flying higher, the images suffer less distortions and it is easier to detect visual similarities between overlapping images [

60].

Pictures (b), (c), (d), (f), (g), and (h) in

Table 5 are the representation of the 3D textured mesh delivered from the densified point clouds. Viewing pictures (c) and (h), in addition to the noise around the facilities, the roof and parapet shapes of the facility 1 and the corridor and roof shapes of the facility 2 were very undistinguishable and inaccurate. The mesh receives the point cloud as input. So, if the point cloud is noisy, the mesh also noisy. If the quality of the images is not high, the 3D Textured Mesh generated shows tendency of having holes or not being planar in planar surfaces due to the low quality of the point clouds.

It was discussed that before generating the 3D mesh, the students should have performed necessary actions for improving the quality of both the point clouds and the 3D textured mesh. Picture (d) in

Table 5 is much clearer than any other pictures. The students in the group that worked on the picture (d) indicated they operated the processing options provided in the Pix4D mapper to edit and filter the noise in the point clouds and to improve the quality of 3D textured mesh, e.g., the noise filter processing option to furnish cleaner point clouds for datasets with oblique images and the sky filter processing option to remove points in a dense point cloud associated with sky.

On the contrary to the laser scanner, a drone could easily capture the rooftop images of the stand using a top-down angle. However, when taking images under the roof of the stand shown in pictures (f) and (g), a certain limitation was found caused by a gimbal configuration of the drones. The 3-axis gimbal provides a steady platform for the attached camera, allowing for smoothly moving and capturing clear, stable images and video [

56]. The gimbal installed in the drones can tilt the camera within a 120

° range consisting of up to 30

° upward and 90

° downward from the horizontal line [

52,

53]. Due to the upward sloping limit of the gimbal, it was very difficult to capture the images in the ranges bigger than the limit. The difficulty leaded to shadowy images that caused noise in the point cloud and blurry shapes of the 3D textured mesh. A supplementary technique was considered necessary for managing the problem.

5. Lessons Learned & Discussion

The main objective of this research includes identifying lessons learned from incorporating a drone operation with LS as a preliminary experiment to promote the UAV-to-BIM curriculum for construction engineers. In the process of the experiment, the participants empirically recognized the pros and cons of the two technologies in restructuring the as-built of the two facilities in the SNUST campus.

To meet the research objective, the authors conducted a FGI based workshop with the two drone education professionals and 7 graduates who participated in the experiment. In the workshop, the 9 participants were solicited to describe their opinion on the following questions: (1) Is it necessary for developing the drone education curriculum in the universities for construction engineers? (2) What contents are essentially embraced in the curriculum? and (3) What formats and supports are desirable to successfully develop and implement the curriculum? The following are the lessons acknowledged from the workshop:

The Need for the Curriculum: All the workshop participants agreed that the formal drone curriculum should be prepared the sooner the better for the construction industry to keep up with the current digitalized market trend. While both a drone and a laser scanner allow for digitally restructuring accurate as-built models, the technologies include unique pros and cons respectively as shown in the experiment. The technologies need to go hand in hand to successfully function construction quality monitoring. Compared to the LS, drone application is still in infancy level in all life-cycle stages of built environments. Educating how to collaborate a drone with a laser scanner will support the construction engineers to be confident and insightful in challenging construction operation.

The Contents of the Curriculum: The participants argued that hovering a drone is 20% of the drone job and the other 80% is data processing. Although there have been a number of drone schools in Korea, the goal of the schools is not to deliver the suitable capacity of managing the drone data such as point clouds, 3D textured mesh, and others, but simply to instruct how to fly a drone and get a license. The participants emphasized that the contents of the curriculum should focus on acquiring, processing, analyzing, and improving the drone data rather than on flying a drone. There are diverse commercial applications to handle the digital data captured with a drone such as Pix4D Mapper, PhotoScan, DroneDeploy, Precision Hawk, and 3D Robotics. The curriculum needs to figure out and deliver the common procedures and techniques involved in each of the applications.

The Contents of the Curriculum: The participants emphasized that the contents of the curriculum also need to deal with drone risk. Flying a drone is very challenging. Especially when people are first getting started. As shown in the experiment, accidents are too easy to happen. Drone risk embraces physical as well as non-physical, threatening safety, privacy, intellectual property, and operational security [

61]

. The curriculum must include how to establish safety protocols in the use of a drone. Rather than a manual flight, it was insisted to use best practices with flight automation.

The Contents of the Curriculum: As shown in the experiment, even beginners in drone flight easily tend to regard drones as a

toy and feel like flying them faster. Time, practice, and experience are required to be a skillful operator. Very few studies have explored the human aspects of drone flight such as drone operators’ cognitive capabilities and task performance [

62]. The curriculum should address human factors and human performance in drone flight in combination with safety, experience, and a risk management plan. Human factors indicates the variables that influence a human’s capability such as external, i.e., light or noise, or internal, e.g., fatigue. Human performance, which is a function of human factors, denotes the human capability to successfully accomplish tasks and meet the job requirements [

63].

The Desirable Formats of the Curriculum: There are generally two types of curriculum models: the product model and the process model [

64]. The product model focuses on outcomes of the curriculum while the process model centers on how learning develops over time. The workshop participants discussed that since the drone curriculum aims at generating very clear digital outcomes by teaching trainees specific step-by-step procedures to do so, the product model would be a proper setting to pursue. As well, among three curriculum design methodologies widely accepted in the field of curriculum development, i.e., subject-centered, problem-centered, and learner-centered, the subject-centered approach is appropriate to the drone curriculum because the curriculum will be the basic one on which the problem-centered and learner-centered ones can be developed in the graduate study level.

The Desirable Formats of the Curriculum: The two drone professionals suggested that since flying a drone in the campus is very risky due to lots of students, traffics, and buildings, dividing the curriculum into two modules, i.e., a drone flight module and a data processing module, can be a reasonable approach to manage the risk. Through industry-academia collaboration, the drone flight module is then requested to the off-campus private drone schools licensed by the MOLIT. Doing so, faculties can focus more on teaching drone data processing disciplines while mitigating the drone operation risk and the burden of hiring a qualified pilot for the curriculum.

7. The Desirable Formats of the Curriculum: Instead of dividing the curriculum, a different option was discussed, that is, to require students for a certain prerequisite to register the drone class. The prerequisite can be having a drone license or taking on-line training courses. Some workshop participants were, however, skeptical to the option, pointing that it will not be workable because the option imposes extra load to the students. They insisted that before inventing the option, the suitable format of the curriculum to the entire CE&M program, i.e., a core course or elective course; the duration of the curriculum; the correlation of the curriculum with other courses in the program should be contemplated in the first place. There are three different curriculum formats to introduce drones into the CE&M education [

41]: arrange students to conduct a capstone project with drones, incorporate a drone education module into an existing course, or create an entire course on drones. The authors targeted to develop the curriculum with the second format in combination with the LS as an elective course.

The Desirable Formats of the Curriculum: Developing and implementing the curriculum require diverse resources from the school to be ready for drones, insurance, industry-academia collaboration and outsourcing drone flight education, and hiring full-time or part-time drone pilots. It was recommended that school administrative workforce should be consulted to secure the budget for the items, thereby making the curriculum realistically reasonable. In parallel with this consultation, checking for other departments in the campus to be supposed to use drones in lectures and willing to work with to form a drone video lab was recommended as well. In case where a drone access is limited due to lack of resources or regulatory barriers, drone education can be taught in an online format through video simulations and exercises although actual field flight is desirable.

The limitation of this study is that the lessons learned was identified on the basis of the opinion and discussion of the 9 workshop participants. While it is expected that the findings from the study are reasonable and beneficial for the CE&M faculties to refer to when preparing a drone curriculum in universities, more comprehensive industry-wide opinions, possible barriers, and suggestions to get over the barriers are needed in future research to establish rationale for developing a realistic drone education curriculum for construction engineers. Apart from the research on the curriculum development, it is necessary in the future research to investigate the limitations that hinder spreading drone applications to construction projects and to definitize directions and specific methodologies to surmount them thereby keeping on upgrading construction engineers.

6. Conclusions

The construction industry has been considered as a key industry that devotes to economic development of a nation. Construction professionals recognize that digitalization cannot be avoidable and digital technologies as an essential tool for survival. Among diverse digital technologies, a drone has been recently well acknowledged as a significant technique for collecting valuable data and insights in diverse construction processes. The MOLIT, Korea announced the plan to utilize the drones and the LS for monitoring construction operation quality in major public projects by 2025. Whereas contractors need to train their engineers to be competitive in the projects, the two technologies are not so popular in construction projects in Korea and very few experts are available.

The Korean universities implementing the CE&M were requested to develop the curriculum for providing education of the technologies for the contractors. Developing a curriculum is the multi-step process of creating and improving a learning objective, teaching strategies, materials, and assessment. To avoid trial and error in progressing the drone and LS curriculum and successfully implementing it later on, it is very essential to perform a preliminary study to identify the needs for the curriculum. The main objective of this study is to carry out the preliminary study through the experiment of drone and LS applications to the beginners in the construction industry and identify valuable lessons that would be beneficial to promote the curriculum.

The authors arranged 19 students, 12 seniors in undergraduate and 7 part-time graduates in the CE&M program at the SNUST in Korea as the participants of the experiment. Two facilities with different shapes and sizes in the campus were selected as the subject facilities to be experimented, i.e., a power plant with one story and 360m2 and a playground stand with 1,600m2. The authors incorporated a drone education module into one of the existing CE&M classes, called FFE in the SNUST. Two drone education professionals were invited from a private drone flight training institution to help the experiment.

In the experiment, Faro Focus 3D-X330 TOF scanner as well as two quadcopter drones including DJI Mavic 2 Pro and DJI Phantom 4 professional were utilized. The experiment consisted of six steps: (1) a theory and equipment-learning session; (2) a laser scanning operation; (3) a laser-scanned data development; (4) a drone flight operation; (5) a drone-flown data exploitation; and (6) an experiment results presentation. Based on the experiment results, the experiment participants figured out the pros and cons of the two technologies, the good or bad outcomes from the technologies in the experiment, and analyze the usability of the technologies in conjunction with the distinct features of the facilities.

After the experiment, the authors conducted a FGI based workshop with the two drone education professionals and 7 graduates who participated in the experiment. In the workshop, the 9 participants were solicited to describe their opinion on the needs for the curriculum, the contents of the curriculum, and the desirable formats of the curriculum as the lessons learned from the study that are beneficial to develop the comprehensive drone education curriculum later on.

The lessons learned include: drones and laser scanners need to go hand in hand to successfully function construction quality monitoring; the contents of the curriculum should focus on processing drone data rather than on flying a drone; also need to address drone risk and human factors as well as human performance in drone flight in combination with safety, experience, and a risk management plan; the product model and subject-centered curriculum design are suitable to the curriculum, separating a drone flight module from a data processing module in the curriculum and utilizing industry-academia collaboration can be a reasonable approach to manage the drone risk.

Acknowledgments

This study was supported by the Research Program funded by the SeoulTech (Seoul National University of Science and Technology), Korea.

Abbreviations

The following abbreviations are used in this manuscript:

| BIM |

Building Information Modeling |

| IoT |

Internet of Things |

| DT |

Digital Twins |

| AI |

Artificial Intelligence |

| UAS |

Unmanned Aerial System |

| LS |

Laser Scanning |

| RE |

Reverse Engineering |

| MOLIT |

The Ministry of Land, Infrastructure and Transport, Korea |

| CE&M |

The Construction Engineering and Management Program |

| SNUST |

The Seoul National University of Science and Technology, Seoul, Korea |

| FFE |

Free-form Facade Engineering |

| KASA |

Korean Aviation Safety Act |

| FGI |

Focus-group Interview |

| GFG |

The German Federal Government |

| FIEC |

The European Industry Construction Federation |

| AR |

Augmented Reality |

| MR |

Mixed Reality |

| CCET |

Civil and Construction Engineering Technology |

| YSU |

Youngstown State University, Ohio, USA |

| FAA |

Federal Aviation Administration |

| CCEC |

The Construction Capacity Evaluation Criteria |

| KOSTA |

The Korean Transportation Safety Authority |

| KASA |

Korean Aviation Safety Act |

| TOF |

Time of Flight |

| GPS |

Global Positioning System |

References

- McKinsey & Company. Executive Summary: The Next Normal in Construction: How Disruption is Reshaping the World’s Largest Ecosystem, June 2020.

- www.mckinsey.com/capabilities/operations/our-insights/imagining-constructions-digital-future (accessed on 1 December 2022).

- Construction Leadership Council (CLC). Smart Construction, A Guide for Housing Clients, UK, 2018, www.constructionleadershipcouncil.co..co.uk.

- Korea Express Corporation, Smart Construction Global Insight: Construction Automation and Robotics, Vol. 1, Center for Smart Construction Technology, Korea Express Corporation, Seoul, Korea, August 2021.

- Taher, G. Industrial Revolution 4.0 in the Construction Industry: Challenges and Opportunities, Management Studies and Economic Systems (MSES), 6 (3/4), 109-127, Summer & Autumn 2021.

- Forcael, E.F., Ferrari, I., Opazo-Vega, A., and Pulido-Arcas, J.A. Construction 4.0: A Literature Review, Sustainability 2020, 12,9755, MDPI.

- Sawhney, A., Riley, M., Irizarry, J., and Perez, C.T. A Proposed Framework for Construction 4.0 Based on Review of Literature, EPiC Series in Built Environment, Volume 1, 2020, pp 301-309 Associated Schools of Construction Proceedings of the 56소 annual international Conference.

- Karmarka, A. and Delhi, V.S.K. Construction 4.0: What We Know and Where We Are Headed?, Journal of Information Technology in Construction, ITCON, Vol.26, 526-545, 2021.

- Roslan, A.F., Aminudin, E., Lau, S.E.N., and Abidin, N.I. Construction 4.0 to Transform the Malaysian Construction Industry, The INGENIEUR, Magazine of the Boarc of Engineers Malaysia, Vol. 88, 6-23, October-December 2021.

- Jazzar, M.E., Urban, H., Schranz, C., and Nassereddine, H. Construction 4.0: A Roadmap to Shaping the Future of Construction, 37th international Symposium on Automation and Robotics in Construction (ISARC), 2020, 1316-1321.

- DroneDeploy, The Rise of Drones in Construction, June 2018, www.dronedeply.com/blog/rise-drones-construction (accessed on January 2023).

- Allied Market Research, Commercial Drones Market Expected to Reach $21.69 Billion by 2030, www.alliedmarketresearch.com/press-release/commencial-drone-market.html (accessed on 24 November 2022).

- Adhikary, R. and Parikh, K. Drone Mapping Versus Terrestrial Laser Scanning for Building Mapping and Assessment, Journal of Remote Sensing & GIS, Vol. 10, Iss.3, No:1000283, 1-4.

- Ock, J.H. Testing As-Built Quality of Free-Form Panels: Lessons Learned from a Case Study and Mock-up Panel Tests, Applied Science, MDPI, Appl. Sci. 2021, 11, 1439. [CrossRef]

- Kwen, S.H.; Shim, H.W.; Jang, H.S.; Ock, J.H. A Fundamental Study on the Comparison of As-Planned with As-Built of Free-form Building Skins Using Laser Scanning Technology. J. Comput. Des. Eng. 2011, 2, 126–136.

- www.linkedin.com/pulse/from-uav-bim-how-data-fits-scan-workflow-himani-shah/ From UAV to BIM—How UAV Data Fits into the Scan to BIM Workflow (accessed on January 14, 2023).

- Rizo-Maestre, C., González-Avilés, A., Galiano-Garrigós, A., Andújar-Montoya, M.D., and Puchol-García, J.A. UAV + BIM: Incorporation of Photogrammetric Techniques in Architectural Projects with Building Information Modeling Versus Classical Work Processes, Remote Sensing, MDPI, 2020, 12, 2329; [CrossRef]

- Park, K.J. and Ock, J.H. Structuring a BIM Service Scoping, Tendering, Executing, and Wrapping-Up (STEW) Guide for Public Owners, Appl. Sci., MDPI, 2022, 12, 3275. [CrossRef]

- CONECTech Lab—The Home for Construction 4.0 Technology Education and Research (gatech.edu).

- Overview of the Curriculum Development Process, Curriculum development Guide: Population Education for non-Formal Education programs of Out-of-School Rural Youth (fao.org).

- Howard, J. Curriculum Development, Center for the Advancement of Teaching and Learning, Elon University, Summer, 2007.

- 22. Korean Aviation Safety Act.

- Schwab. K. The Fourth Industrial Revolution, The World Economic Forum, 2016.

- Herman, M., Pentek, T., and Otto, B. 2016 Design Principles for Industrie 4.0 Scenarios. 2016 49th Hawaii International Conference on System Science (HICSS), 2016 March 3928-3937. [CrossRef]

- Kagermann, H., Wahlster, W., and Helbig, J. 2013 Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0—Final Report of Industrie 4.0 Working Group. In Industrie. Frankfurt.

- Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., Hoffman, M. Industry 4.0 Bus. Inf. Syst.Eng. 2014, 6, 239-242.

- Berger, R. Digitization in the Construction Industry: Building Europe’s Road to “Construction 4.0”; Roland Berger GMBH: Munich, Germany, 2016.

- Garcia de Soto B., Agusti-Juan I., Joss S. and Hunhevicz J. Implications of Construction 4.0 to the Workforce and Organizational Structure, The International Journal of Construction Management, 1-13, 2019.

- Rastogi, D. Construction 4.0: The 4th generation Revolution. In the Indian Lean Construction Conference, page 12, 2017.

- Kling,R. and Turk, Z. 2019 “Construction 4.0—Digital Transformation of One of the Oldest Industries,” Economic and Business Review, 21 (3), 393-410. [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0—An Innovation Platform for the Built Environment; Routledge: New York, NY, USA, 2020; ISBN 978-0-429-39810-0.

- Tatum, M.C. and Liu, J. Unmanned Aircraft System Applications in Construction, Creative Construction Conference 2017, 167-175, CCC 2017, 19-22 June, 2017, Primosten, Croatia. [CrossRef]

- Li, Y. and Liu, C. Applications of Multirotor Drone Technologies in Construction Management, International Journal of Construction Management, Vol.19, No.5, 401-412, 2019. [CrossRef]

- Mahajan, G. Applications of Drone Technology in Construction Industry: A Study 2012-2021, International Journal of Engineering and Advanced Technology (IJEAT) Vol.11, Issue 1, October 2021, 224-239.

- Maiellaro, N., Zonno, M., and Lavalle, P. Laser Scanner and Camera-equipped UAV Architectural Surveys, The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Vol. XL-5/W4, 381-686, 3D Virtual Reconstruction and Visualization of Complex Architectures, 25-27 February, 2015, Avila, Spain.

- Mader, D., Blascow, R., Westfeld, P., and Mass, H.-G. UAV-based Acquisition of 3D Point Cloud—A Comparison of a Low=Cost Laser Scanner and SFM-Tools, The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Vol. XL-3/W3, 335-341, ISPRS Geospatial Week 2015, 28 September—03 October 2015, La Grande Motte, France. [CrossRef]

- Shanbari, H.A.; Blinn, N.M.; Issa, R.R. Laser Scanning Technology and BIM in Construction Management in Education. J. Inf. Technol. Constr. 2016, 21, 204–217. 24.

- Ratajczak, J.; Marcher, C.; Schimanski, C.P.; Schweigkofler, A.; Riedl, M.; Matt, D. BIM-based Augmented Reality Tool for the Monitoring of Construction Performance and Progress. In Proceedings of the 2019 European Conference on Computing in Construction, Crete, Greece, 10–12 July 2019; pp. 467–490. 25.

- Raimbaud, P.; Lou, R.; Merienne, F.; Danglade, F.; Figueroa, P.; Hernandez, J.T. BIM-based Mixed Reality Application for Supervision of Construction. In Proceedings of the IEEE Conference on Virtual Reality and 3D User Interfaces (VR), Osaka, Japan, 23–27 March 2019; pp. 1903–1907.

- Joyce, K.E.; Meiklejohn, N.; Mead, P.C.H. Using mini drones to teach geospatial technology fundamentals. Drones 2020, 4, 57.

- AL-Tahir, R. Integrating UAV into Geomatics Curriculum. In The International Archives of the Photogrammetry, Proceedings of the Remote Sensing and Spatial Information Sciences, Toronto, ON, Canada, 30 August–2 September 2015; Copernicus Publications: Toronto, ON, Canada, 2015. 5.

- Alkaabi, K.; Abdelgadir, A. Applications of unmanned aerial vehicle (UAV) technology for research and education in UAE. Int. J. Soc. Sci. Hum. 2017, 5, 4–11.

- www.bigrentz.com/blog/drones-construction 6 Ways Drones in Construction Are Changing the Industry—BigRentz (accessed on 25 November 2022).

- Drones in construction and infrastructure—Why and how to use them | Wingtra.

- Bolick, M.M., Mikhailova, E.A., Post, C.J. Teaching Innovation in STEM Education Using an Unmanned Aerial Vehicle (UAV), Education Science, 12, 224, 2022, MDPI. [CrossRef]