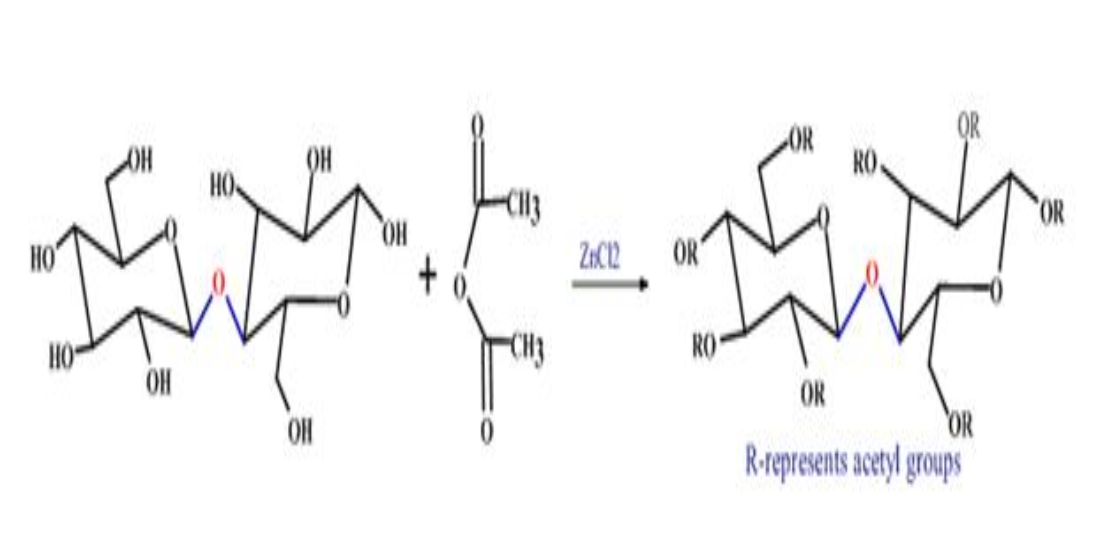

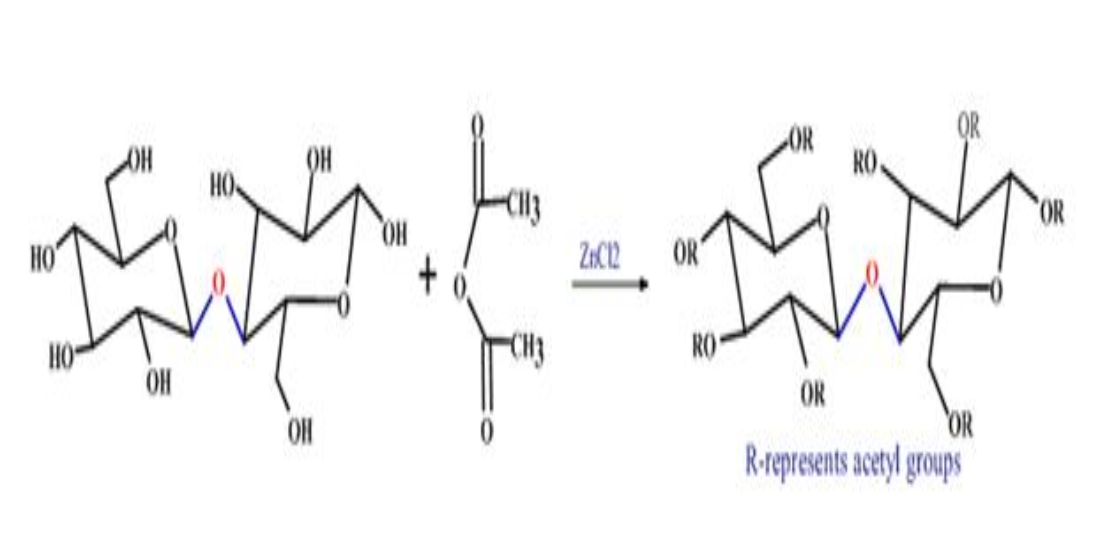

Usually, the two-bath dyeing process using disperse dyes and reactive dyes separately was employed for the dyeing of PC blends. The cost of the double bath, dyeing cycle, energy consumption and chemical consumption is quite higher than the one-step or single bath dyeing methods. In this study, the one-bath dyeing process using one kind of dye was investigated. Polyester cotton blends dyed in one-bath one-step dyeing methods with disperse dye after surface modifications of cotton by acetylation methods were studied. Surface modification of cotton was carried out using fibrous acetylation methods. The effect of acetic anhydride and time on percent acetyl content at room temperature was studied. Modified polyester/cotton was carried out in HTHP dyeing machine incorporates with different dye concentrations and dyeing temperature. Surface chemistry, thermal decomposition property and moisture regain of modified polyester/ cotton blend are evaluated. The color strength of the dyed fabrics and their fastness properties to washing, light, and rubbing as well as tear strength and abrasion resistance were evaluated. The effect of dye concentration and temperature color strength, tensile strength warp and weft direction was assessed. The optimum value for surface modification was obtained with a concentration of acetylation agent 16% and time of reaction 2.5 hours, gave percent acetylation of 34. An FTIR spectrum shows acetylation resonance. The experiment result of dyeing showed that the optimum value was obtained with dye concentration above 1% at a temperature of 120oC, warp tensile strength decreased by 12% and weft tensile strength was decreased by 9% from the control half-bleached fabric. Results of this study showed that a one-step one-bath dyed modified polyester/cotton blend with disperse dye fabric presents good fastness property compared with conventional two-bath dyed fabric as well as colour strength values.