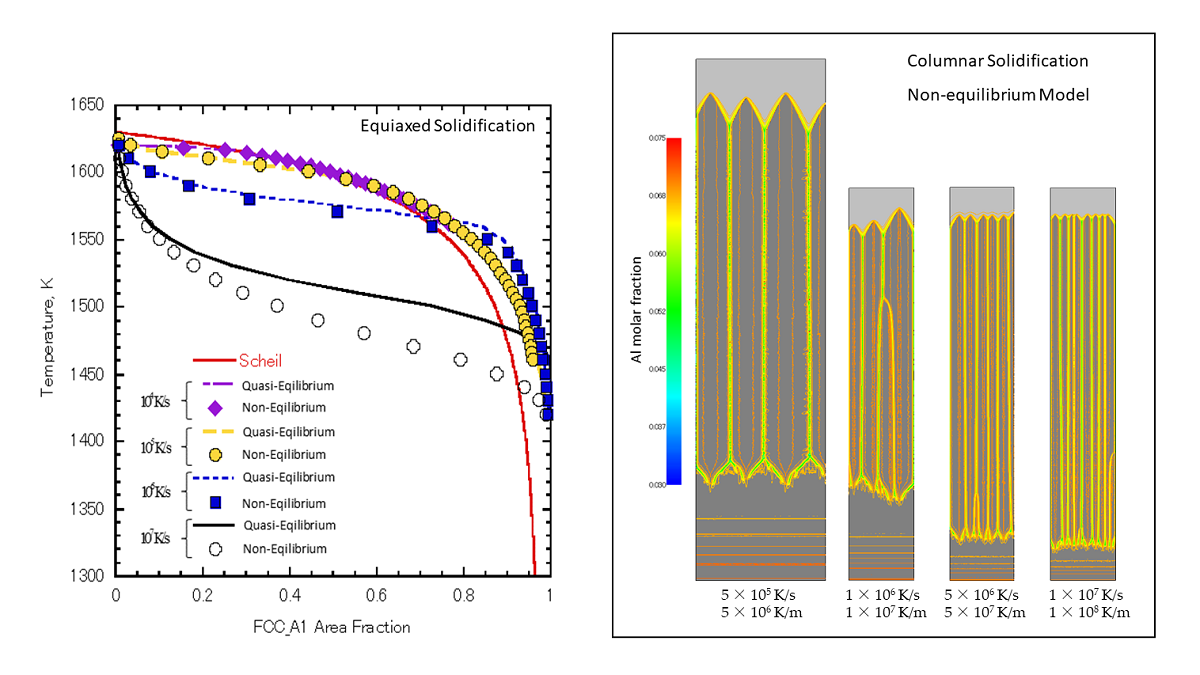

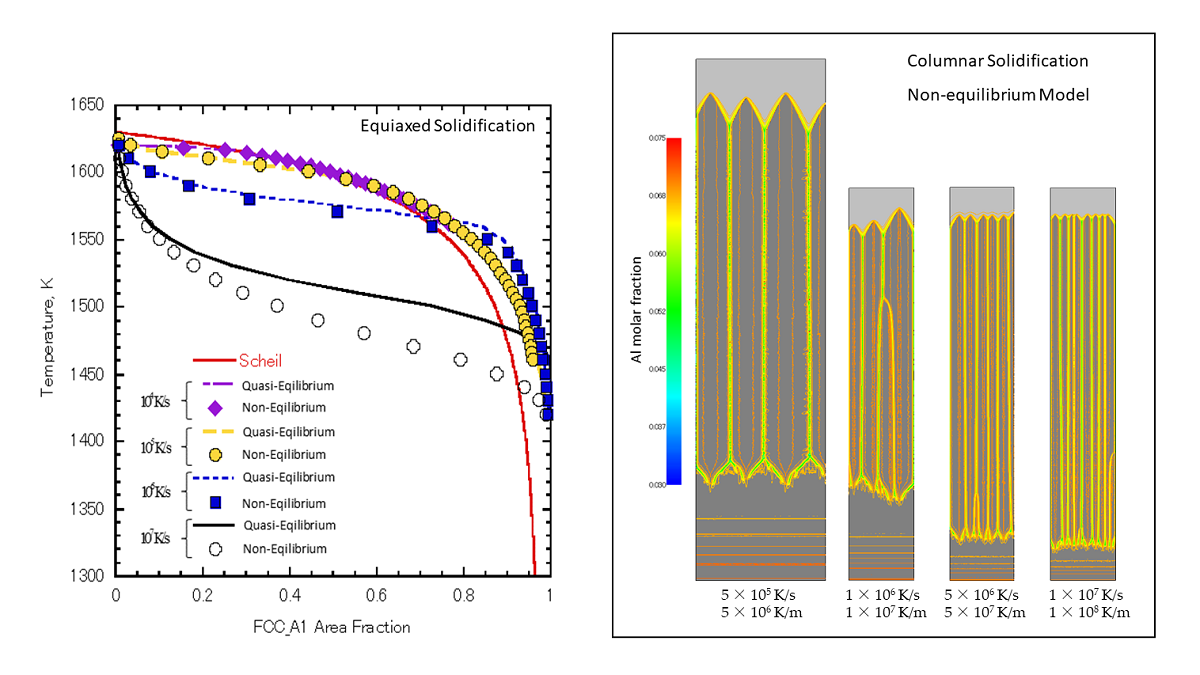

Solidification microstructure is formed under high cooling rates and temperature gradients in powder-based additive manufacturing. In this study, a non-equilibrium multi-phase field method (MPFM), which was based on a finite interface dissipation model proposed by Steinbach et. al., coupled with a CALPHAD database was developed for a multicomponent Ni alloy. A qua-si-equilibrium MPFM was also developed for comparison. Two-dimensional equiaxed micro-structural evolution for the Ni (Bal.)–Al–Co–Cr–Mo–Ta–Ti–W–C alloy was performed at various cooling rates. The temperature–γ fraction profiles obtained under 10^5 K/s using non- and qua-si-equilibrium MPFMs were in good agreement with each other. Over 10^6 K/s, the differences between non- and quasi-equilibrium methods grew as the cooling rate increased. The non-equilibrium solidification was strengthened over a cooling rate of 10^6 K/s. Colum-nar-solidification microstructural evolution was performed under cooling rates from 5×10^5 K/s to 1×10^7 K/s at various temperature gradient values under the constant interface velocity (0.1 m/s). The results showed that as the cooling rate increased, the cell space decreased in both methods, and the non-equilibrium MPFM agreed well with experimental measurements. Our results show that the non-equilibrium MPFM can simulate solidification microstructure in powder bed fusion additive manufacturing.