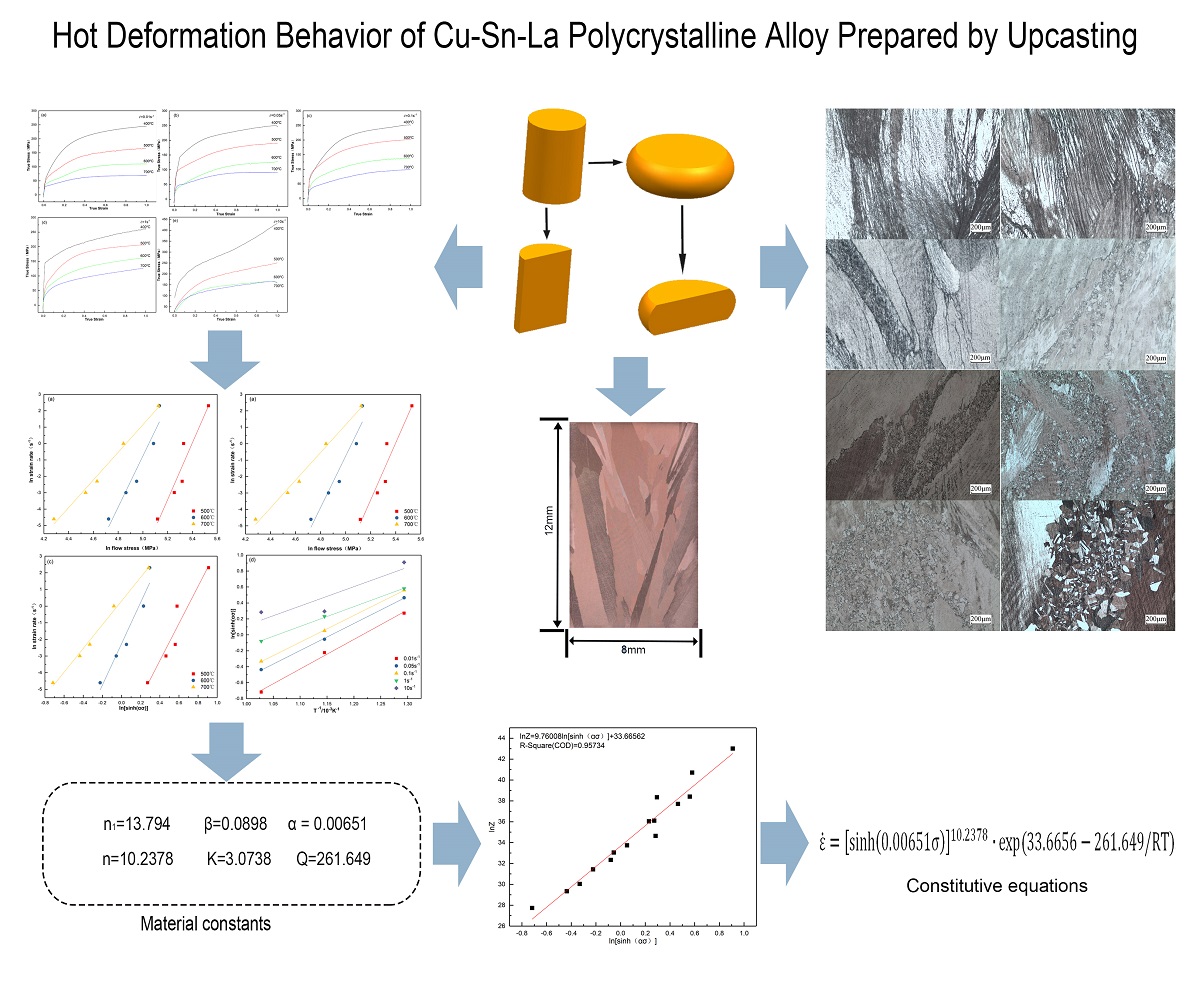

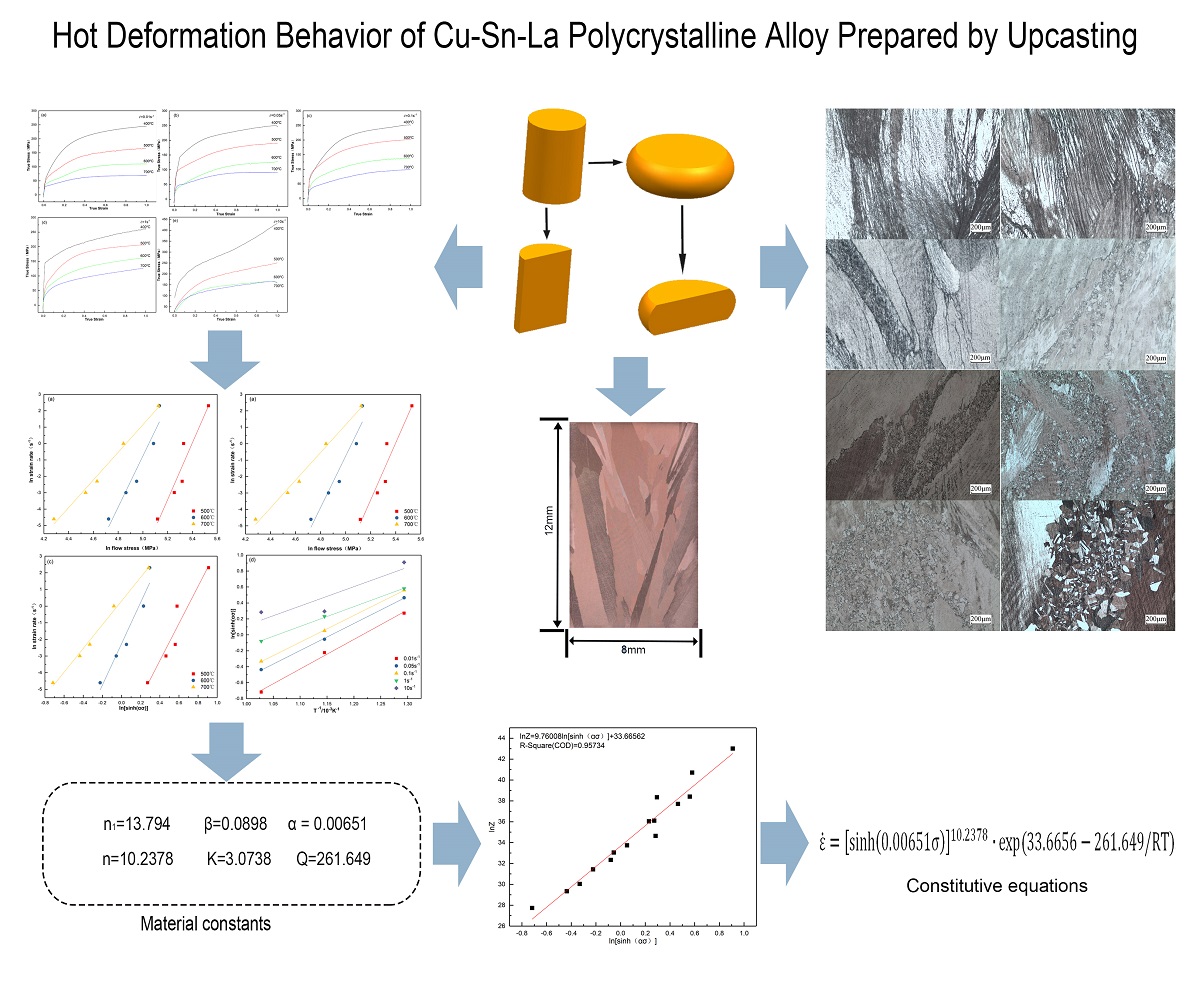

In this study, the hot deformation of Cu-0.55Sn-0.08La (wt%) alloy was studied by gleeble-3180 testing machine at deformation temperatures of 400-700oC and various strain rates. The stress-strain curve showed that the hot deformation behavior of Cu-0.55Sn-0.08La (wt%) alloy was greatly affected by work hardening, dynamic recovery, and dynamic recrystallization. The activation energy Q was calculated as 287.141 kJ/mol , and hot compression constitutive equation was determined as ε ̇=[sinh(0.006388σ)]^12.123∙exp(37.7505-287.141/RT). The microstructural evolution of the alloy during deformation at 400oC revealed the presence of both slip and shear bands in the grains. At 700oC, dynamic recrystallization grains were observed but recrystallization was incomplete. In sum, these results provided the theoretical basis for continuous extrusion process of alloys with promising future use.