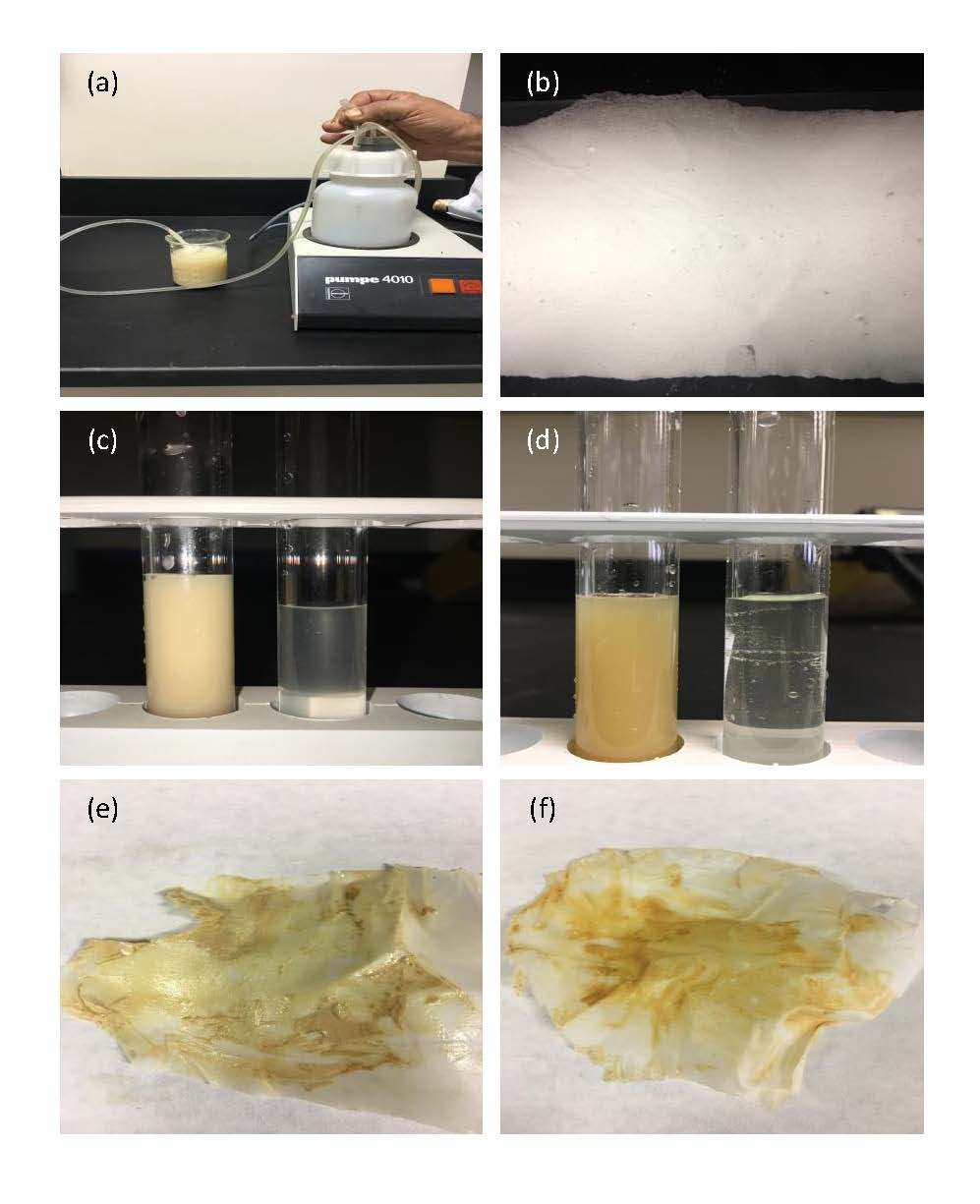

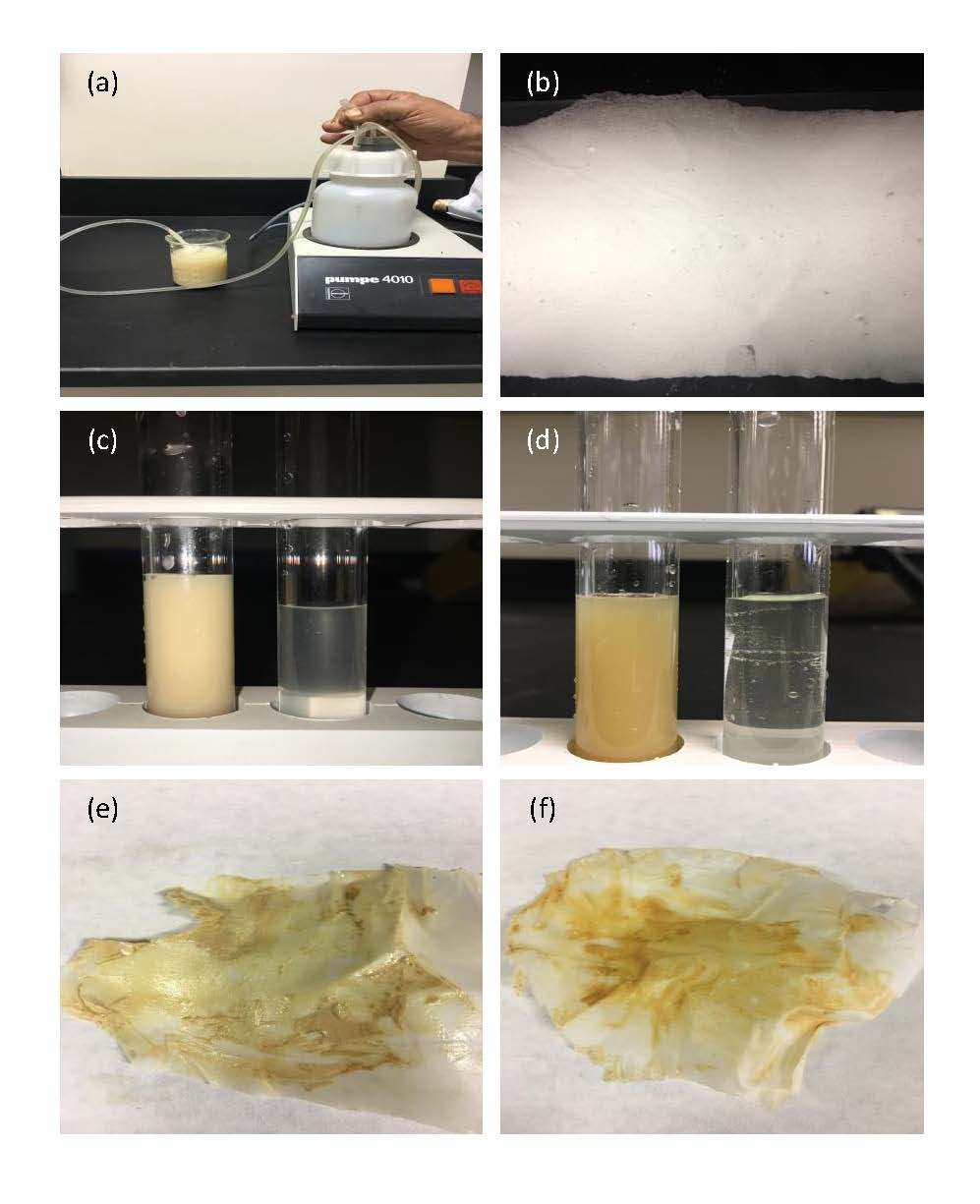

Water pollution in developing countries affects the public health of humans and the environment. It is therefore essential to develop environmentally friendly biopolymer, sustainable and low-cost membranes. Biopolymer nanofiber membranes are made by an electrospinning process of polylactic acid (PLLA) with additives. The main objective of this study is to manufacture biodegradable nanofiber membranes for use in filtering the suspended elements in wastewater at the level of drinkable or in agricultural fields. It is known that PLLA is brittle and therefore it is difficult to apply in industry. To solve this problem and enhance its flexibility. Flexible biopolymer polypropylene carbonate (PPC) and plasticizer are the addition in PLLA to reduce its glass transition and enhance its crystallization by adding Poly(3-hydroxy butyrate) PHB. In this work, 20 wt% of PPC was added to PLLA matrix to improve its elasticity and elongation at break. DSC shows that the addition of PPC, PHB, and TEC did affect the thermal properties like Tg, Tcc and Tm of the PLLA blends. The position of the Tg, Tcc, and Tm is shifting, the consequence the chain mobility is increased, therefore the crystallinity is enhanced. Electrospun fibers of PLLA/PPC/PHB/TEC were successfully manufactured. Tensile tester showed the increase in elongation at break of PLLA blend films, the elongation at break increases by 285 times. It observed with the increasing the elongation at break, a decrease in stress strength. After improving the mechanical properties with the higher elongation at break values, this blend is optimal for filtrations process.