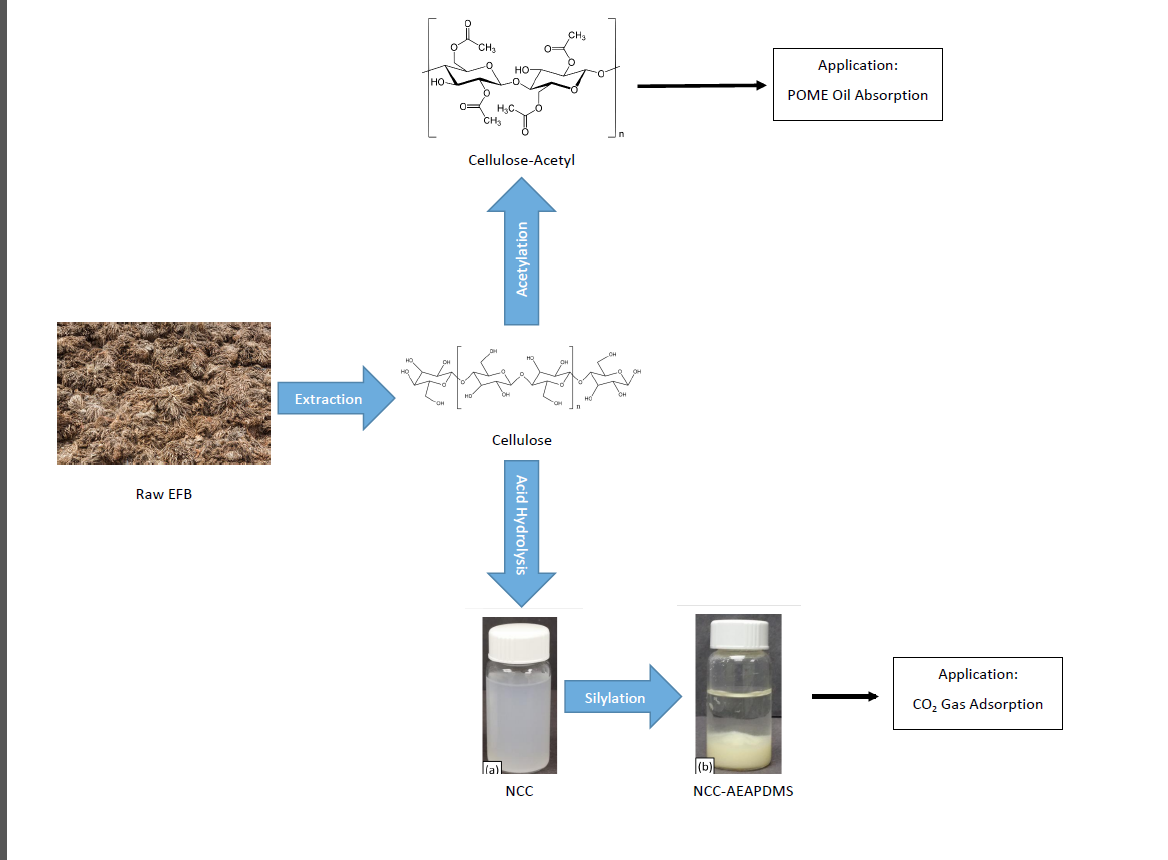

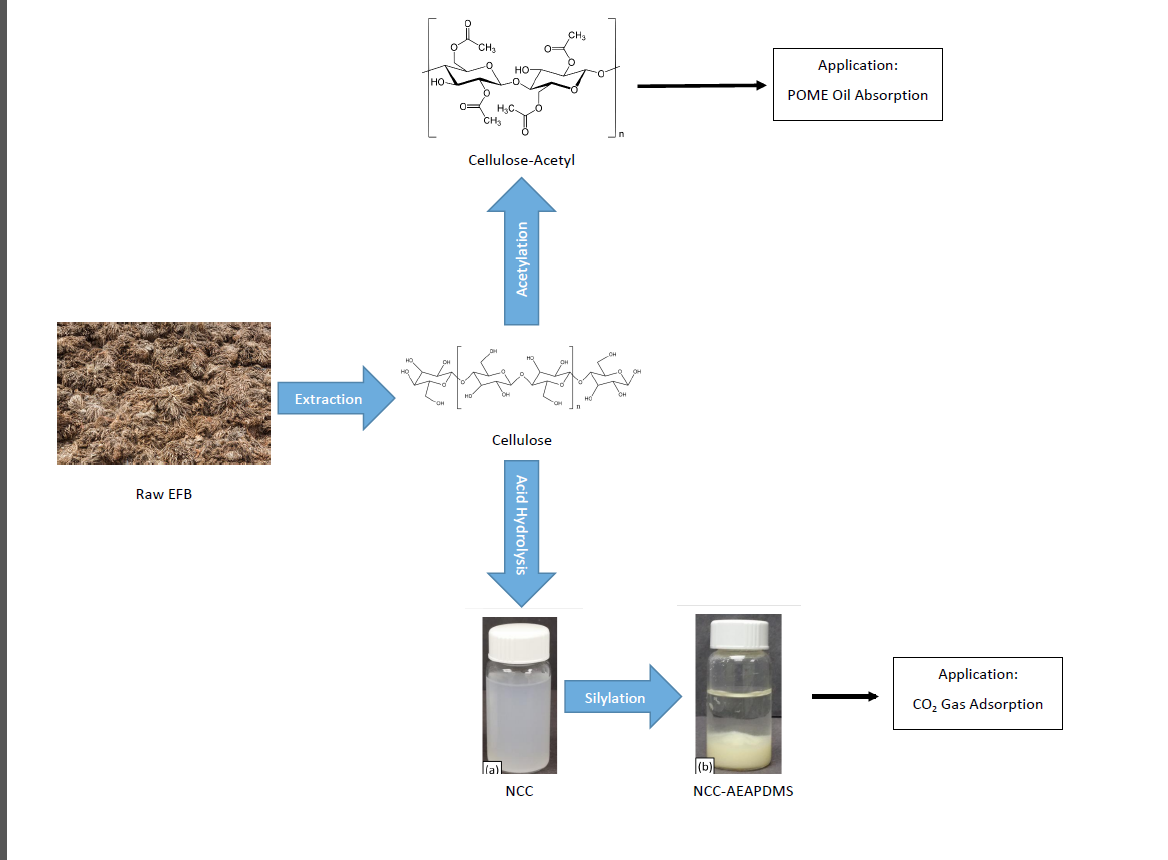

Increase demand for palm oil production has indirectly increased waste and pollution. Empty fruit bunch (EFB), which is the major solid waste from this industry, has the potential to be further treated into valuable product. In this study, cellulose will be extracted from EFB through alkali treatment and acid hydrolysis treatment with a different approach and further modified via acetylation and silylation technique. The modified samples are to be utilized to reduce pollution due to palm oil mill effluent (POME) and carbon dioxide (CO2) emission from the industry. The characterization of the extracted and modified cellulose was carried out using attenuated total reflectance-Fourier transform infrared (ATR-FTIR), thermogravimetric analysis (TGA) and scanning electron microscope (SEM). ATR-FTIR analysis revealed that the cellulose was successfully extracted from raw EFB and the cellulose-acetyl, nanocrystalline cellulose (NCC) and cellulose-2 has been successfully modified from the cellulose. TGA analysis shows that both modified cellulose have higher thermal stability compared to raw EFB and extracted cellulose. SEM morphology of the modified cellulose shows a higher surface area due to the wrinkled formation while the wax layer and cuticle pore has been diminished clearly. The modified sample gave a significant performance where cellulose-acetyl absorbed 98.5% of oil compared to unmodified cellulose-1 sample that only absorbed 5% of oil from POME. NCC-AEAPDMS adsorbed physically and chemically 3.5 cm3/g CO2 gas compared to NCC sample, which undergoes only physical adsorption with maximum capacity up to 2.4 cm3/g. Thus, modification can enhanced the performance of cellulose for industrial applications.