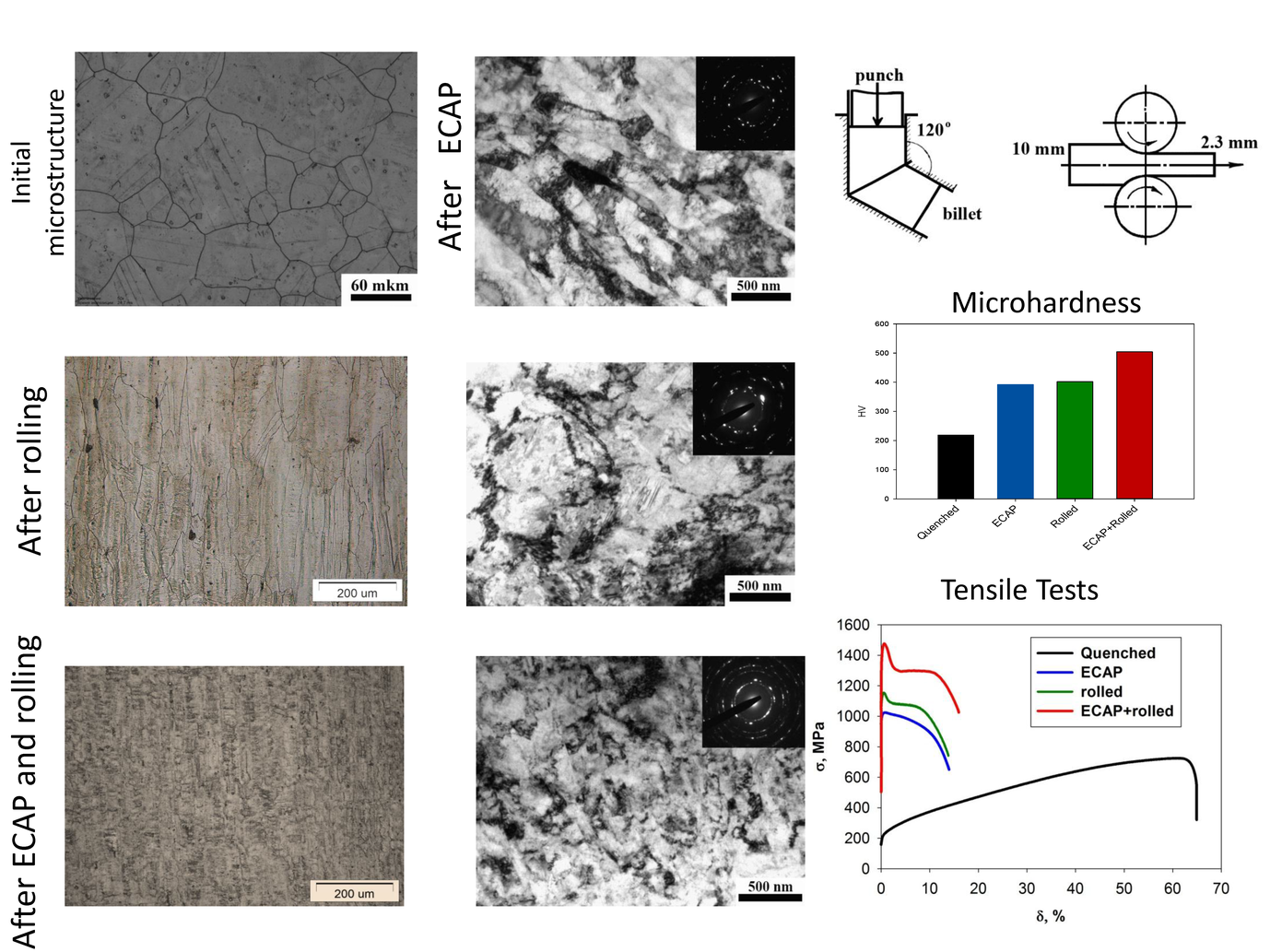

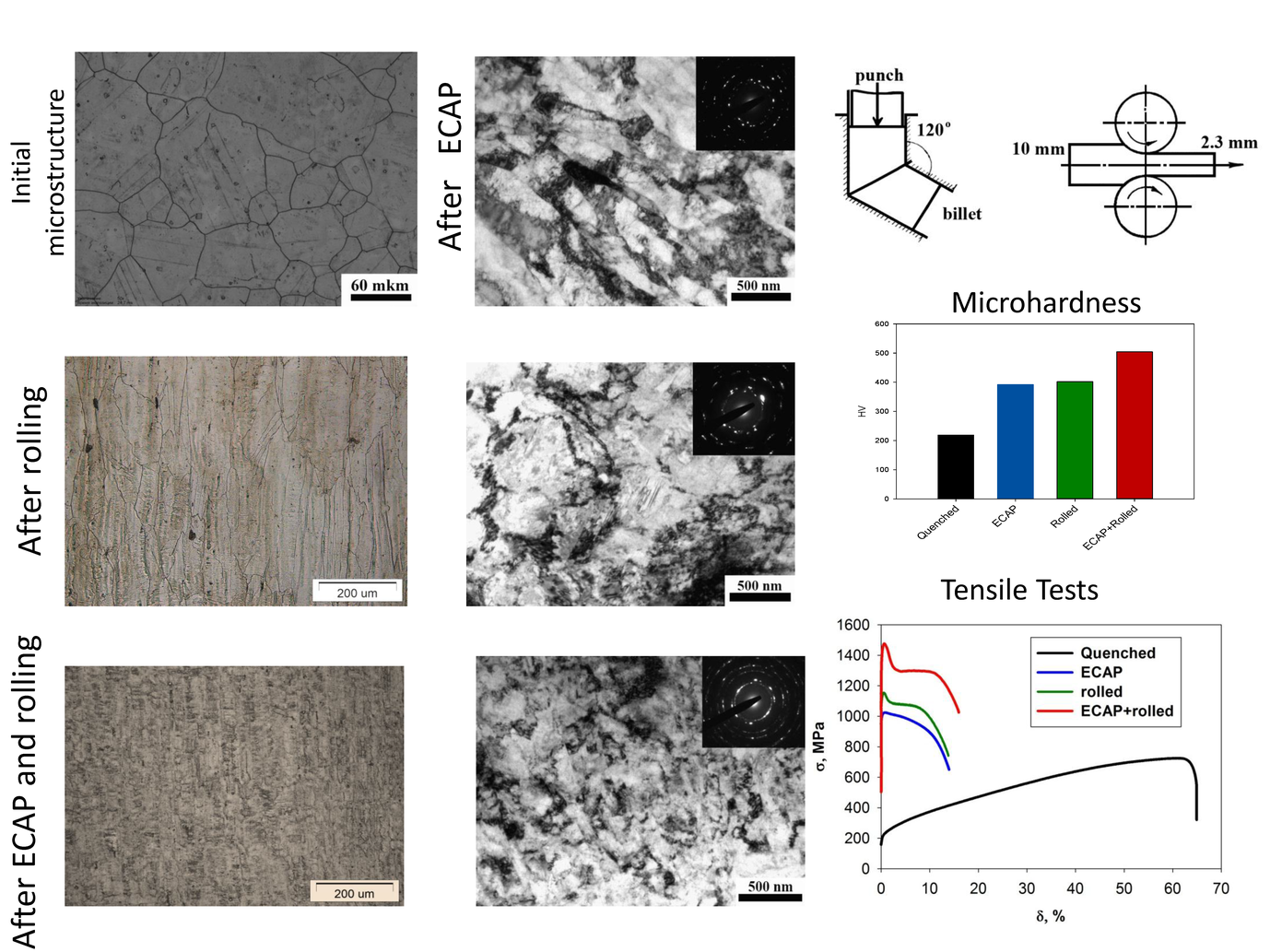

Enhancement in the strength of austenitic steels with a small content of carbon can be achieved by a limited number of methods, among which is the ultrafine-grained (UFG) structure formation, especially efficient with the use of severe plastic deformation (SPD) processing that enables increasing significantly the contribution of grain-boundary strengthening, and also involves a combination of other strengthening factors (work hardening, twins, etc.). In this paper, we demonstrate that the use of SPD processing combined with conventional methods of deformation treatment of metals, such as rolling, may lead to an additional strengthening of UFG steel. Analysis of the results of the study on the change of the microstructure and mechanical properties of the Cr-Ni stainless austenitic steel after a combined deformation reveals a substantial increase in the strength properties of this steel, resulting from a consecutive application of SPD processing via equal-channel angular pressing and rolling at a temperature of 400 С, yielding a strength more than 1.5 times higher that that produced by any of these two methods used separately.