Submitted:

13 January 2026

Posted:

13 January 2026

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

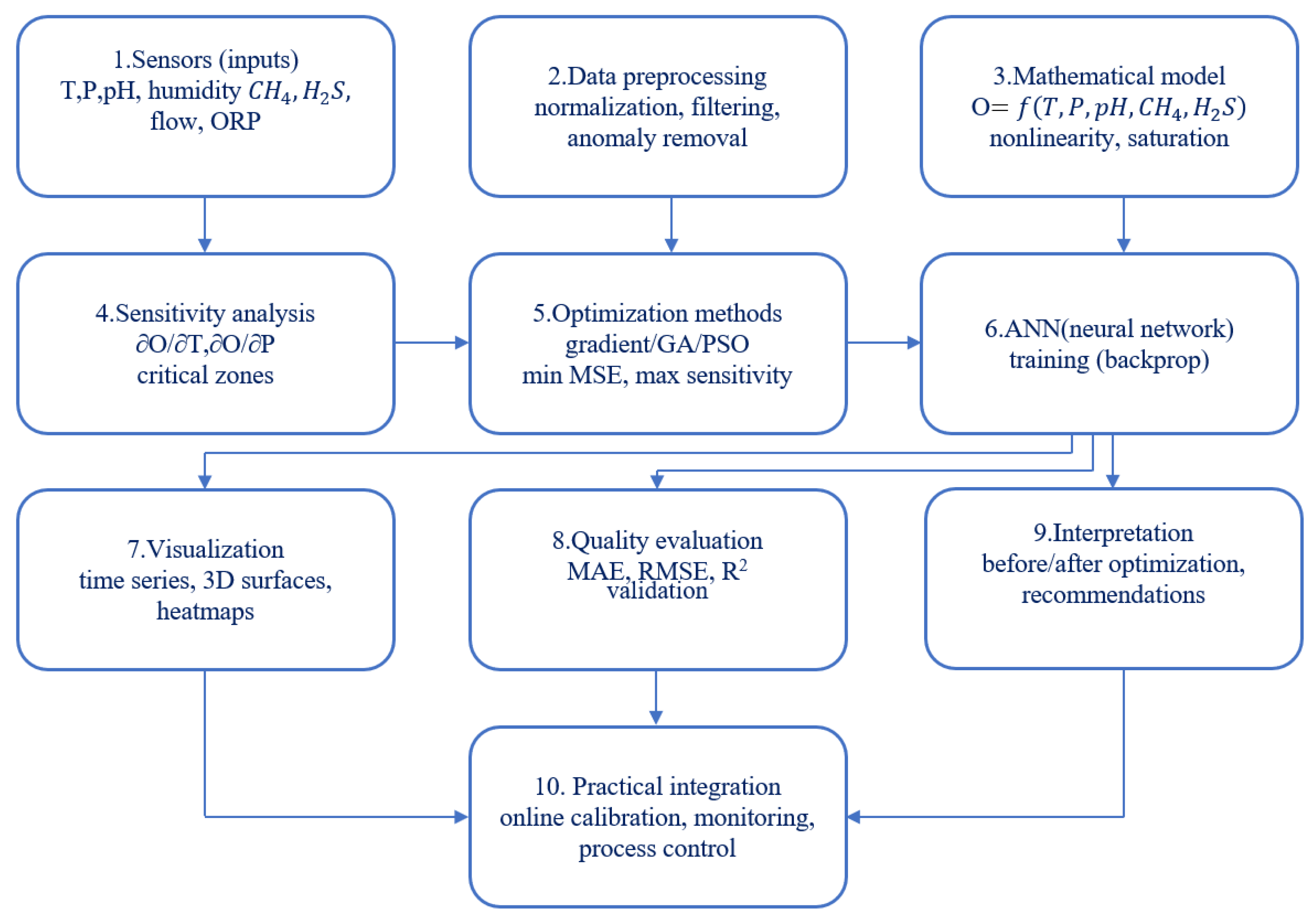

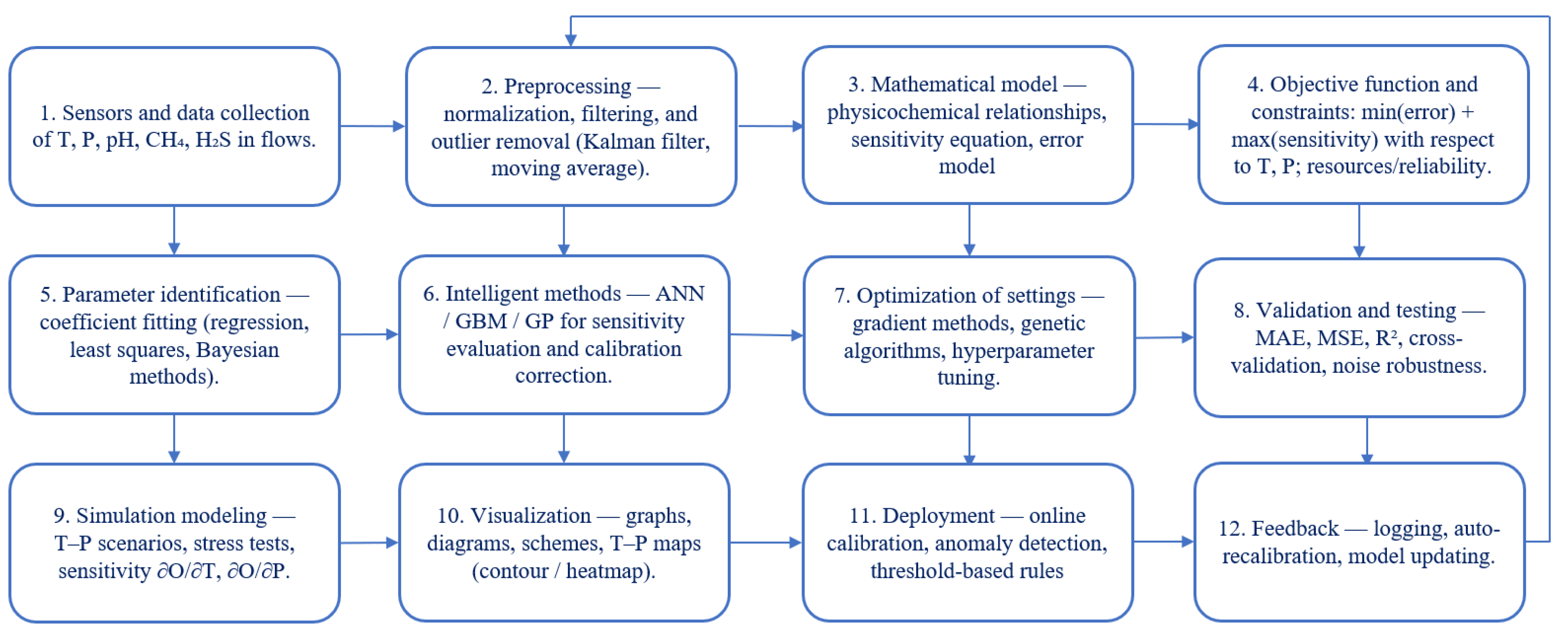

- Mathematical Modeling. To describe the relationship between environmental parameters and sensor response, a mathematical model was developed that incorporates a nonlinear relationship and output signal saturation. An approximation of the following dependences was used: as well as logical and exponential functions, taking into account nonlinear effects and saturation.

- Optimization Methods. Gradient methods, genetic algorithms, and particle swarm optimization methods were used to find optimal sensor parameters. The optimization criteria were minimizing the mean square error (MSE) and maximizing the gradient sensitivity (∂O/∂T, ∂O/∂P).

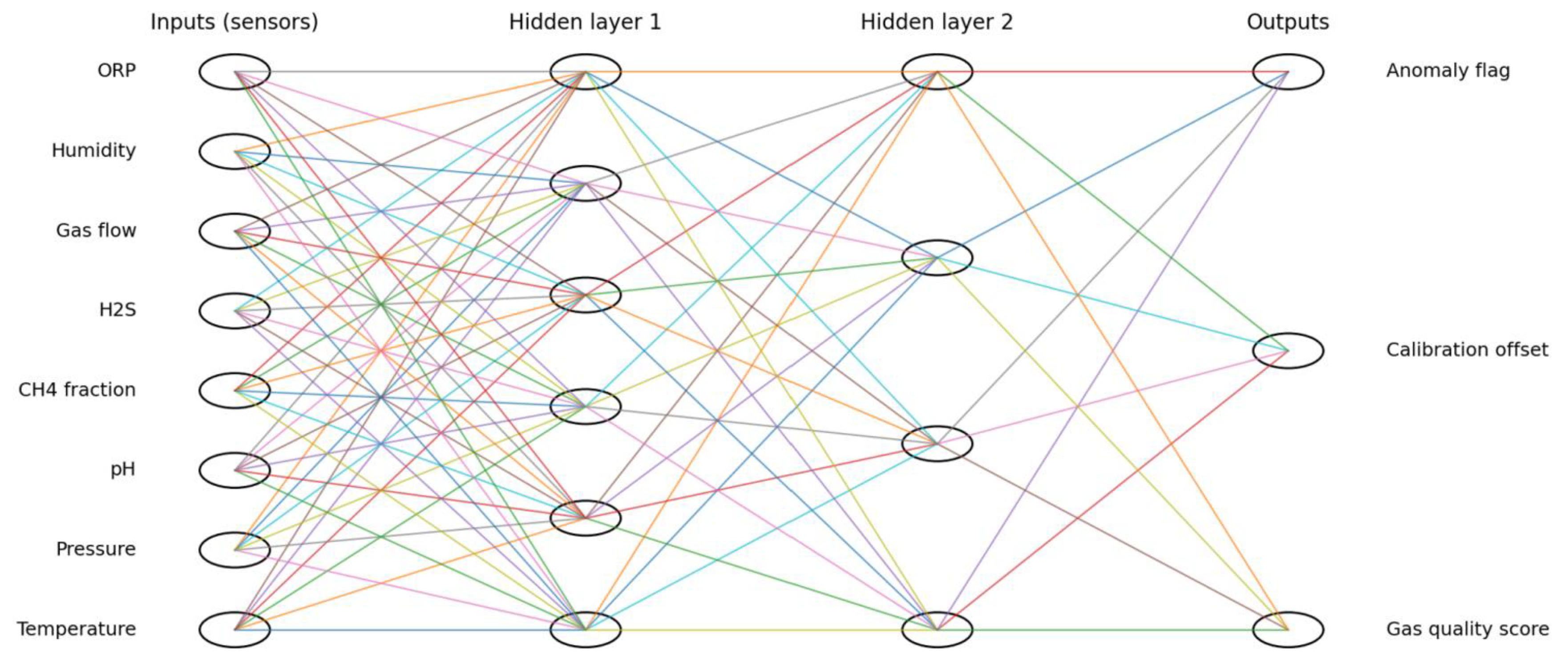

- Intelligent Data Processing Methods. An artificial neural network (ANN) was used to improve measurement accuracy and reduce noise interference. Training was performed using the backpropagation method on the training dataset [10]. Sensor readings served as input parameters for the network, and the outputs included an anomaly indicator, calibration correction factors, and integrated gas quality indicators.

- Visualization and Analysis. Modeling tools in the Python (PyCharm) environments using NumPy, SciPy, Matplotlib and TensorFlow/PyTorch libraries were used to analyses the results. Time-series graphs, 3D surfaces of dependency on external signals from temperature and pressure, and sensitivity heatmaps were built. To evaluate the performance of the sensor, the MAE, RMSE and determination coefficient (R2) indicators were used.

3. Results

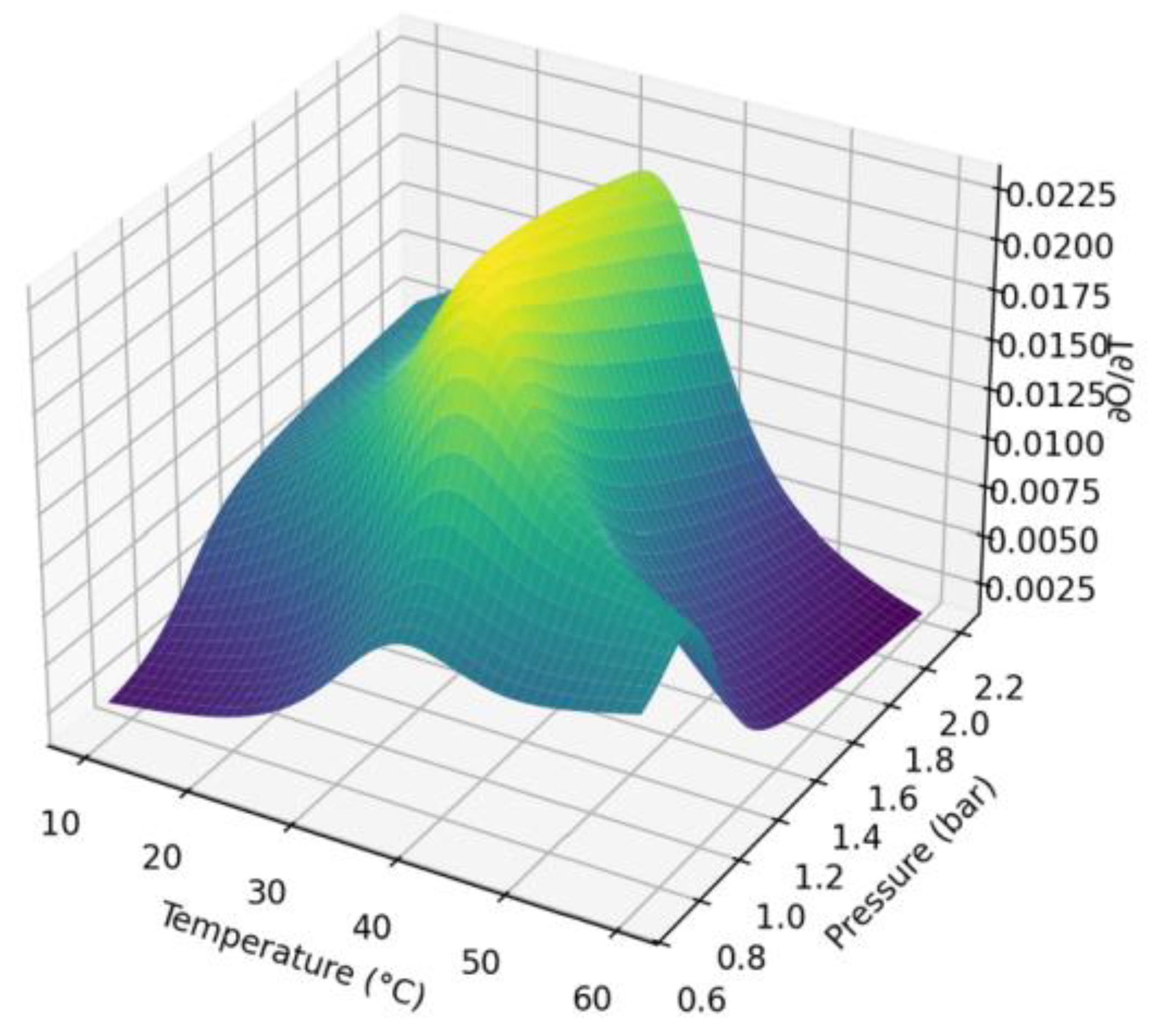

- the highest temperature sensitivity (∂O/∂T) is observed in the range of 30-45°C;

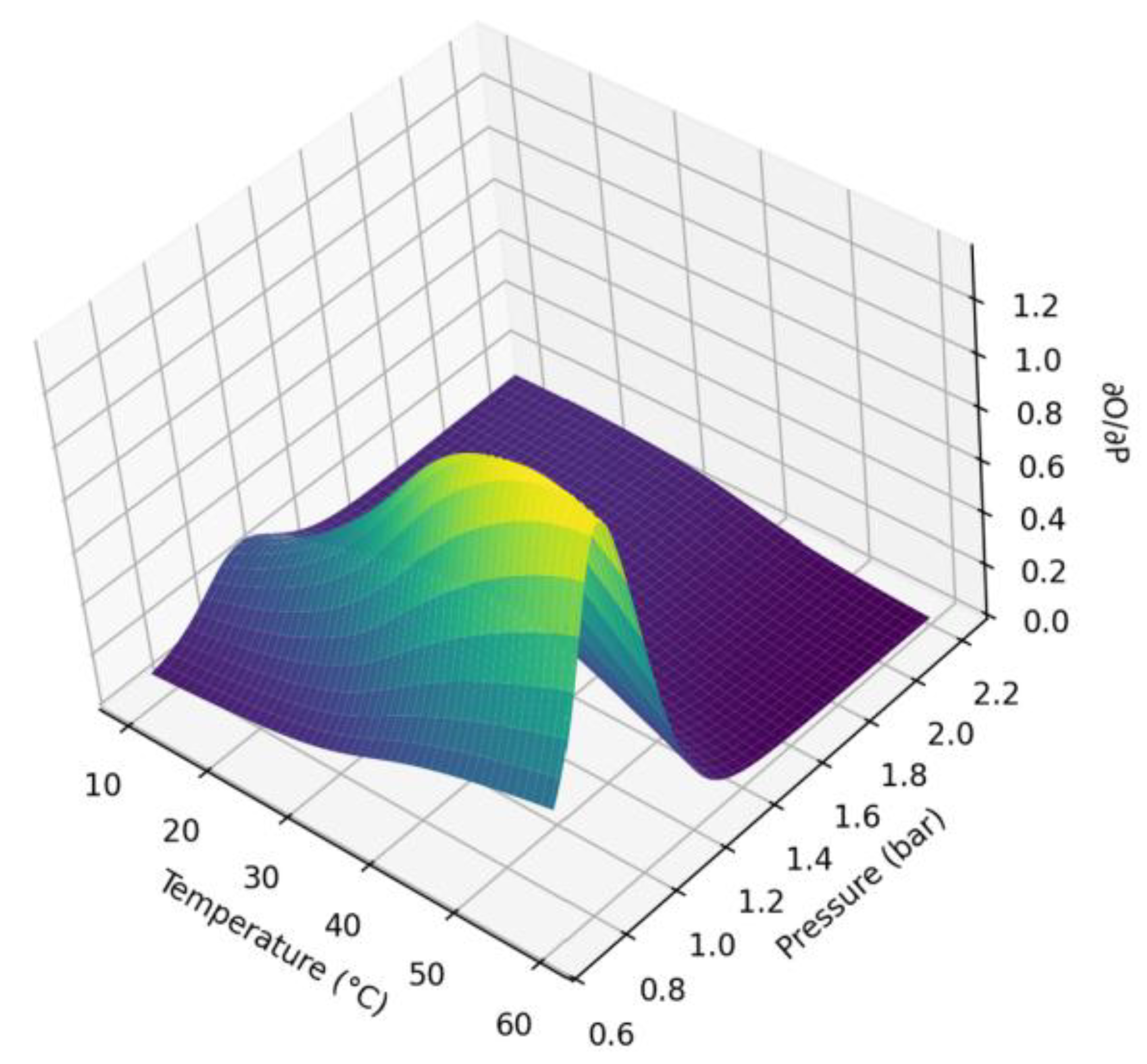

- pressure sensitivity (∂O/∂P) reaches a maximum at a pressure of 1.0-1.5 bar;

- at minimum and maximum parameter values, sensitivity decreases due to model saturation;

- as a result, the authors determined the operating ranges of sensors with higher measurement accuracy.

- minimize the mean square error (MSE) of sensor response by an average of 18-22% compared to the original data;

- increase immunity to noise through dynamic parameter correction;

- expand the range of operating conditions under which the sensors provide acceptable measurement accuracy.

- Adaptive sensor calibration was provided, taking drifts into account;

- Automatic anomaly detection with an accuracy of up to 92% was achieved;

- An integrated gas quality score (Gas Quality Score) was proposed, allowing for real-time assessment of the Ch₄ to H₂S ratio.

- 3D answer surfaces O (T, P) and derivatives ∂O/∂T and ∂O/∂P;

- Heat maps of sensitivity distribution;

- Error dynamics graphs before and after visualization.

3.1. Visualization Demonstrated

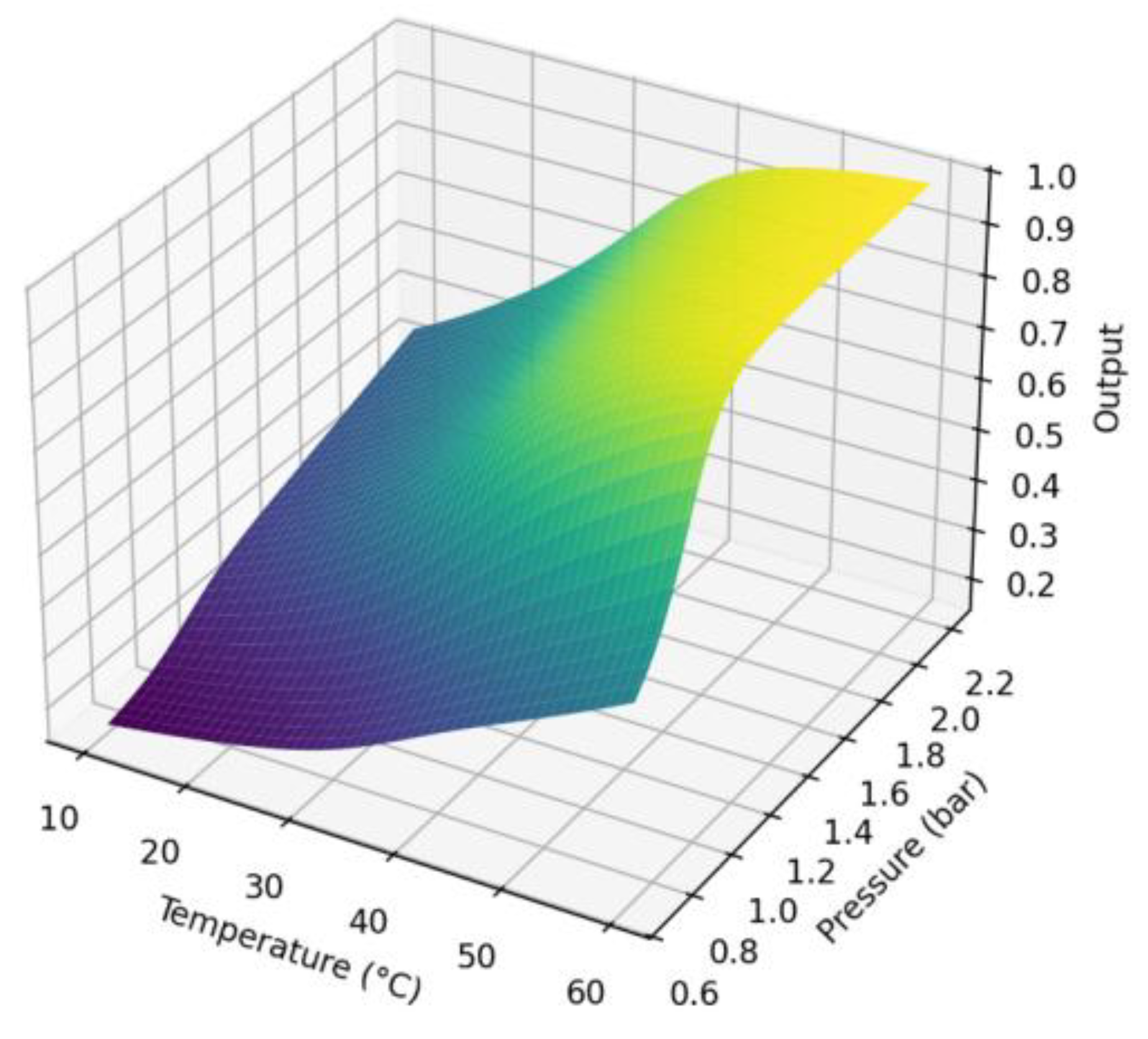

- At lower temperatures and pressures, the output signal remains close to the minimum level.

- As temperature (T) and pressure (P) increase, the response intensifies due to thermodynamic effects and pressure.

- At higher values, saturation occurs, limiting the output signal.

- In the medium temperature range, the sensitivity changes rapidly, indicating the highest sensitivity.

- At the lowest and highest temperatures, sensitivity decreases and the sensor output stabilizes.

- The surface shows the conditions under which slight fluctuations in T lead to a significant change in output, which is important for calibration and selecting the optimal range for sensor operation.

- Figure 3 shows the sensitivity of the sensor to pressure (T), which is the derivative of ∂O/∂P.

- Near the operating range (around P≈1.0-1.5 bar), sensitivity is at its maximum: slight changes in pressure significantly affect the output signal.

- At low and high pressures, sensitivity decreases due to saturation and nonlinearity.

- The surface provides an indication of the stability of measurements to pressure changes and indicates where additional correction or filtering is required.

- Regions of reduced sensitivity for both T and P.

- At lower temperatures (<20°C) and lower pressures, the sensor operates in a "quiet" mode, with changes in T and P having minimal impact on the output.

- At higher values, the sensitivity of both T and P decreases due to the saturation of the logistic function: the sensor "plateaus," resulting in a stable output.

- Application Possibilities

- In practical applications, it is necessary to consider that in certain regions, the sensor is more sensitive to temperature, while in others, it is more sensitive to pressure.

- To improve measurement accuracy, a hybrid calibration is required: temperature compensation in the mid-range of T and pressure correction in the operating range of P.

- Anomaly flag – a binary indicator for detecting anomalies and recording abnormal system operating modes;

- Calibration bias – a correction factor used to correct for dynamic bias and calibrate the sensor;

- Gas quality assessment – an integral indicator of biogas quality based on the analysis of methane and hydrogen sulfide concentrations and other key parameters.

- for Anomaly flag, sigmoid function (binary output) is appropriate;

- for Calibration offset — linear function (real value);

- for Gas quality score - sigmoid function or softmax (quality assessment/probability).

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jameel, Mohammed Khaleel; Mustafa, Mohammed Ahmed; Ahmed, Hassan Safi; Mohammed, Amira jassim; Ghazy, Hameed; Shakir, Maha Noori; Lawas, Amran Mezher; Mohammed, Saad khudhur; Idan, Ameer Hassan; Mahmoud, Zaid H.; Sayadi, Hamidreza; Kianfar, Ehsan. Biogas: Production, properties, applications, economic and challenges: A review. Results in Chemistry 2024, Volume 7. [Google Scholar] [CrossRef]

- Nagahage, I.S.P.; Nagahage, E.A.A.D.; Fujino, T. Assessment of the applicability of a low-cost sensor–based methane monitoring system for continuous multi-channel sampling. Environ Monit Assess 2021, 193, 509. [Google Scholar] [CrossRef]

- Zhao, T. “Artificial Intelligence in Mathematical Modeling of Complex Systems”. EAI Endorsed Trans e-Learn 2024, vol. 10. [Google Scholar] [CrossRef]

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of Biogas and Biomethane as Renewable Energy Sources: A Review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Boontian, N.; Yingchon, U.; Padri, M. pH and Heat Pretreatments with Zero-Valent Iron Addition to Enhance Biogas Production from Cassava Pulp Wastewater: Optimization and Comparison of Mathematical Models. Fermentation 2023, 9, 622. [Google Scholar] [CrossRef]

- Kavan Kumar, V.; Mahendiran, R.; Subramanian, P.; Karthikeyan, S.; Surendrakumar, A.; Kumargouda, V.; Ravi, Y.; Choudhary, Sharda; Singh, Ravindra; Verma, Arvind K. Optimization of biogas potential using kinetic models, response surface methodology, and instrumental evidence for biodegradation of tannery fleshings during anaerobic digestion. Open Life Sciences 2023, vol. 18(no. 1), 20220721. [Google Scholar] [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85. [Google Scholar] [CrossRef]

- Abilmazhinov, Y.; Shakerkhan, K.; Meshechkin, V.; Shayakhmetov, Y.; Nurgaliyev, N.; Suychinov, A. Mathematical Modeling for Evaluating the Sustainability of Biogas Generation through Anaerobic Digestion of Livestock Waste. Sustainability 2023, 15, 5707. [Google Scholar] [CrossRef]

- Qian, S.; Chen, L.; Xu, S.; Zeng, C.; Lian, X.; Xia, Z.; Zou, J. Research on Methane-Rich Biogas Production Technology by Anaerobic Digestion Under Carbon Neutrality: A Review. Sustainability 2025, 17, 1425. [Google Scholar] [CrossRef]

- Tsoulos, I.G.; Tzallas, A. Training Artificial Neural Networks Using a Global Optimization Method That Utilizes Neural Networks. AI 2023, 4, 491–508. [Google Scholar] [CrossRef]

- Raschka, S.; Patterson, J.; Nolet, C. Machine Learning in Python: Main Developments and Technology Trends in Data Science, Machine Learning, and Artificial Intelligence. Information 2020, 11, 193. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Y.; Wu, J.; Wang, T.; Jiang, W.; Zeng, M.; Yang, Z. Detection of Harmful H2S Concentration Range, Health Classification, and Lifespan Prediction of CH4 Sensor Arrays in Marine Environments. Chemosensors 2024, 12, 172. [Google Scholar] [CrossRef]

- Semenov, A.; Baraban, S.; Kovtun, V.; Baraban, M.; Arseniuk, I.; Rudyk, A. Development and Validation of a Mathematical Model for Pyroelectric Temperature Measurement Sensors for Application in Mobile Robotic Systems. Electronics 2024, 13, 3173. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.M.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Hannan, M.A.; Mohamed, R.; Ali, J.A.; Mekhilef, S.; Milad, A. Artificial Neural Networks Based Optimization Techniques: A Review. Electronics 2021, 10, 2689. [Google Scholar] [CrossRef]

- Ayub, HMU; Rafiq, M; Qyyum, MA; Rafiq, G; Choi, GS; Lee, M. Prediction of Process Parameters for the Integrated Biomass Gasification Power Plant Using Artificial Neural Network. Front. Energy Res. 2022, 10, 894875. [Google Scholar] [CrossRef]

- Chen, W.-Y.; Chan, Y.J.; Lim, J.W.; Liew, C.S.; Mohamad, M.; Ho, C.-D.; Usman, A.; Lisak, G.; Hara, H.; Tan, W.-N. Artificial Neural Network (ANN) Modelling for Biogas Production in Pre-Commercialized Integrated Anaerobic-Aerobic Bioreactors (IAAB). Water 2022, 14, 1410. [Google Scholar] [CrossRef]

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Fundamentals of Artificial Neural Networks and Deep Learning. In Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer: Cham, 2022. [Google Scholar] [CrossRef]

- Reisi Gahrouei, O.; McNairn, H.; Hosseini, M.; Homayouni, S. Estimation of Crop Biomass and Leaf Area Index from Multitemporal and Multispectral Imagery Using Machine Learning Approaches. Canadian Journal of Remote Sensing 2020, 46(1), 84–99. [Google Scholar] [CrossRef]

- Tang, J.; Liu, G.; Pan, Q. A Review on Representative Swarm Intelligence Algorithms for Solving Optimization Problems: Applications and Trends. IEEE/CAA Journal of Automatica Sinica 2021, vol. 8(no. 10), 1627–1643. [Google Scholar] [CrossRef]

- Goyal, M.; Mahmoud, Q.H. A Systematic Review of Synthetic Data Generation Techniques Using Generative AI. Electronics 2024, 13, 3509. [Google Scholar] [CrossRef]

- Khan, M. R.; Amin, J. M.; Hosen, M. M. Digital Twin-Driven Optimization Of Bioenergy Production From Waste Materials. Innovatech Engineering Journal 2024, 1(01), 187–204. [Google Scholar] [CrossRef]

- Nosouhian, S.; Nosouhian, F.; Kazemi Khoshouei, A. A Review of Recurrent Neural Network Architecture for Sequence Learning: Comparison between LSTM and GRU. Preprints 2021, 2021070252. [Google Scholar] [CrossRef]

- Bandara, R.M.P.N.S.; Jayasignhe, A.B.; Retscher, G. The Integration of IoT (Internet of Things) Sensors and Location-Based Services for Water Quality Monitoring: A Systematic Literature Review. Sensors 2025, 25, 1918. [Google Scholar] [CrossRef] [PubMed]

| Indictor | Before optimization | After optimization |

| Mean squared error (MSE) | high, nominal 1.00 | Reduced by 18–22%, ~0.78–0.82 |

| Temperature sensitivity (∂O/∂T) | Unstable, a peak in a narrow range of 30–40 °C | Expanded range of 30–45 °C, more consistent |

| Pressure sensitivity (∂O/∂P) | Maximum in the range of 1.0–1.2 bar, a sharp drop beyond | Maximum extension to 1.0–1.5 bar, gradual decrease |

| Noise robustness |

Low, significant impact of random perturbations |

High, error rate reduces with fluctuations ±5% |

| Sensor drift | Non-adjustable | Compensated for ANN (adaptive calibration) |

| Anomaly detection | Absent | Achieved ≈92% accuracy |

| Integral gas quality index | Not calculated | Gas Quality Score was implemented for CH₄/H₂S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).