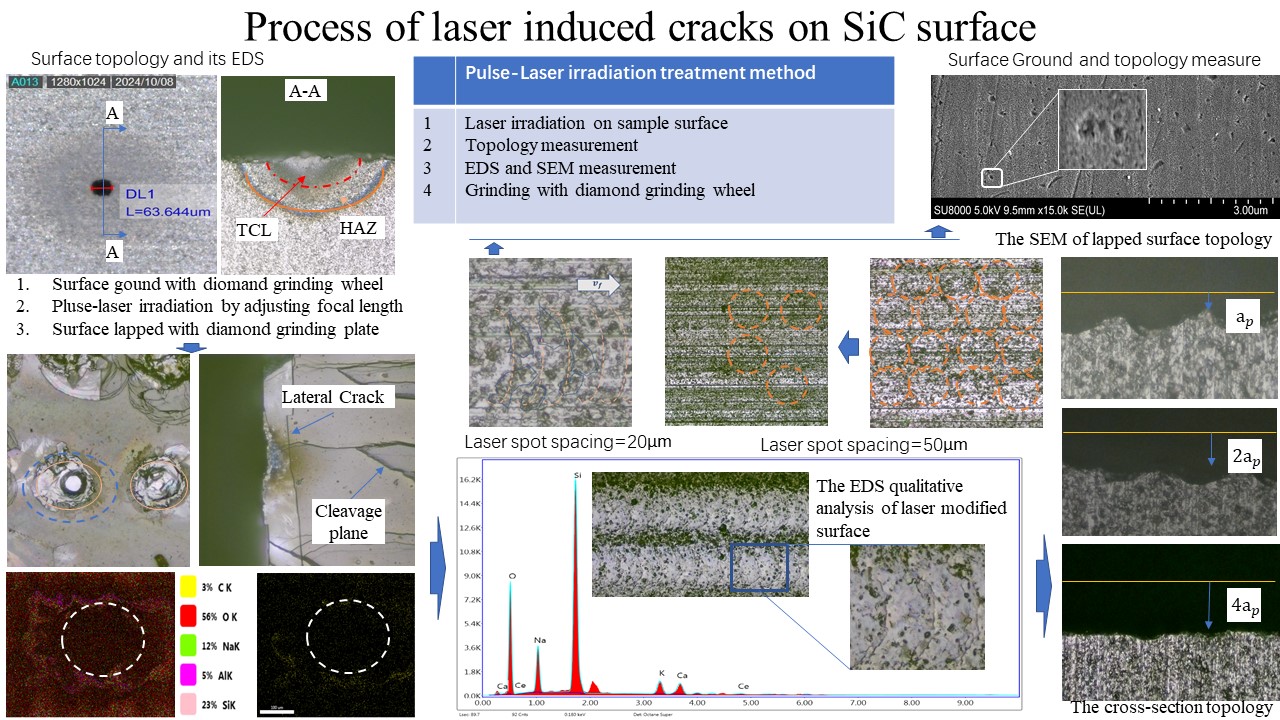

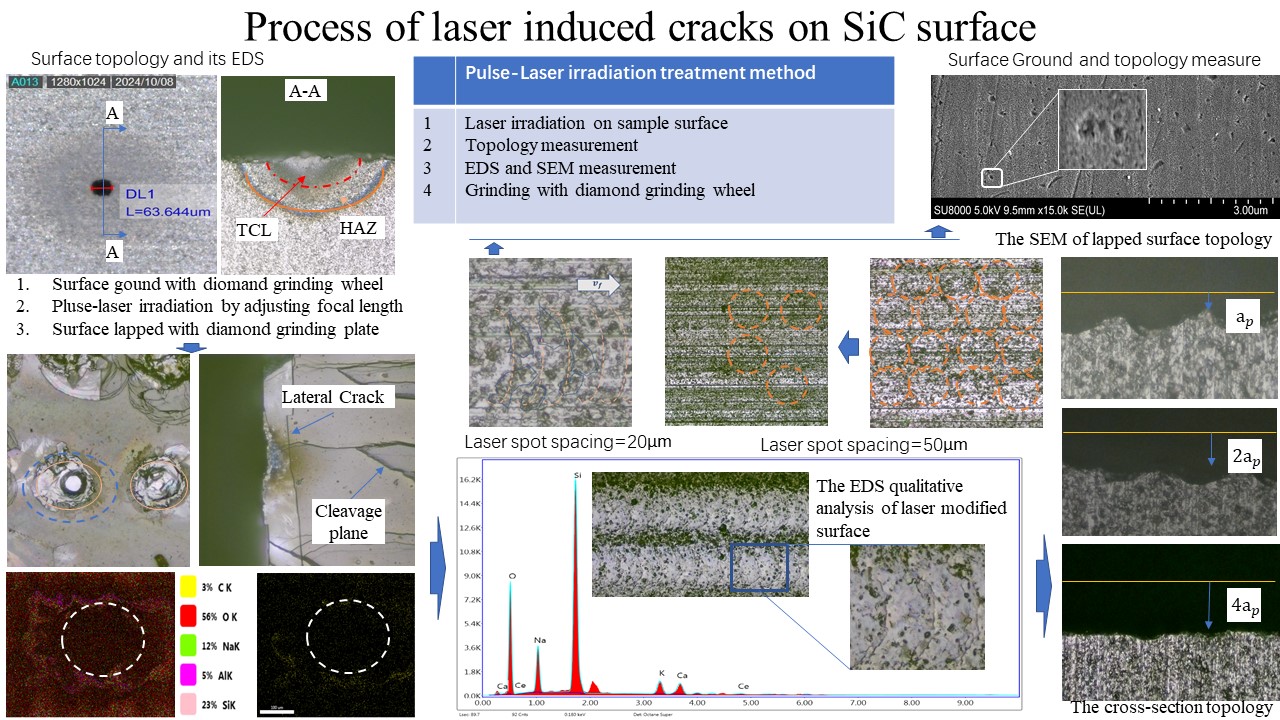

In the grinding of silicon carbide, surface and subsurface damage have a significant im-pact on the product's surface quality. A method to obtain controllable crack dimension through laser irradiation on SiC surface and its effect on the grinding process was ana-lyzed. A series of experiments were carried out based on the orthogonal experimental de-sign, with systematic adjustments made to laser parameters including pulse energy (cur-rent), laser spot spacing, scanning times as well as grinding process parameters. During the experiments, the grinding force was monitored by a dynamometer, and the specific grinding energy was calculated accordingly. Pulsed engraving laser modification could effectively reduce the hardness of the ceramic surface layer by about 20%. The median and radial crack sizes in the subsurface layer induced by laser were in the range of 20.4 μm to 54.3 μm, which could effectively inhibit the further propagation of median and radial cracks during grinding, and simultaneously reduce the tangential grinding force Ft by about 30%. These conclusions were obtained by corresponding experiments, which link the surface roughness with laser power to grinding parameters. The laser induced con-trollable crack characteristics on the grinding process are conducive to realizing the con-trol of surface and subsurface grinding damage of brittle materials.