Submitted:

19 December 2025

Posted:

22 December 2025

You are already at the latest version

Abstract

Keywords:

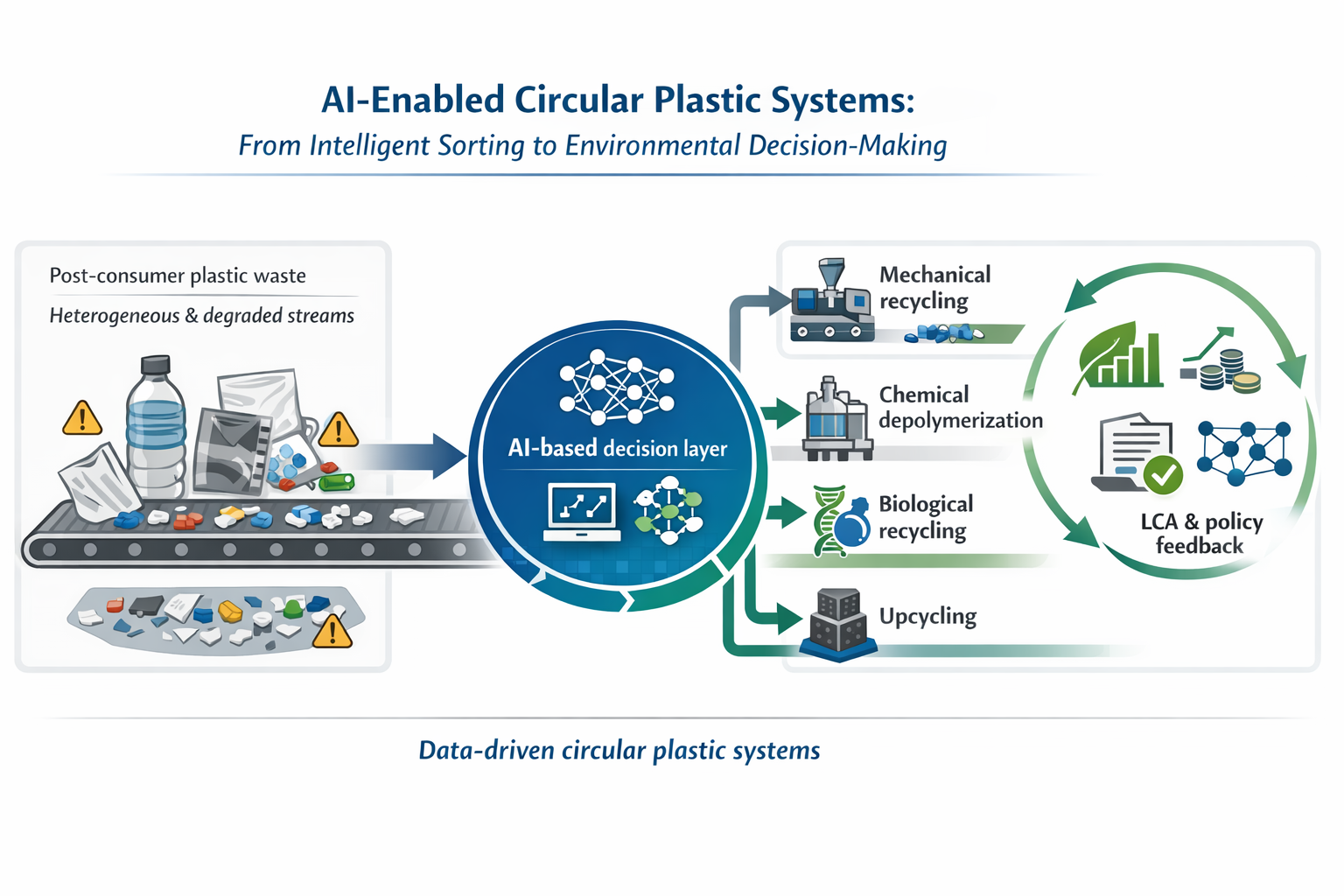

1. Circular Strategies for Plastic: Concepts and Global Context

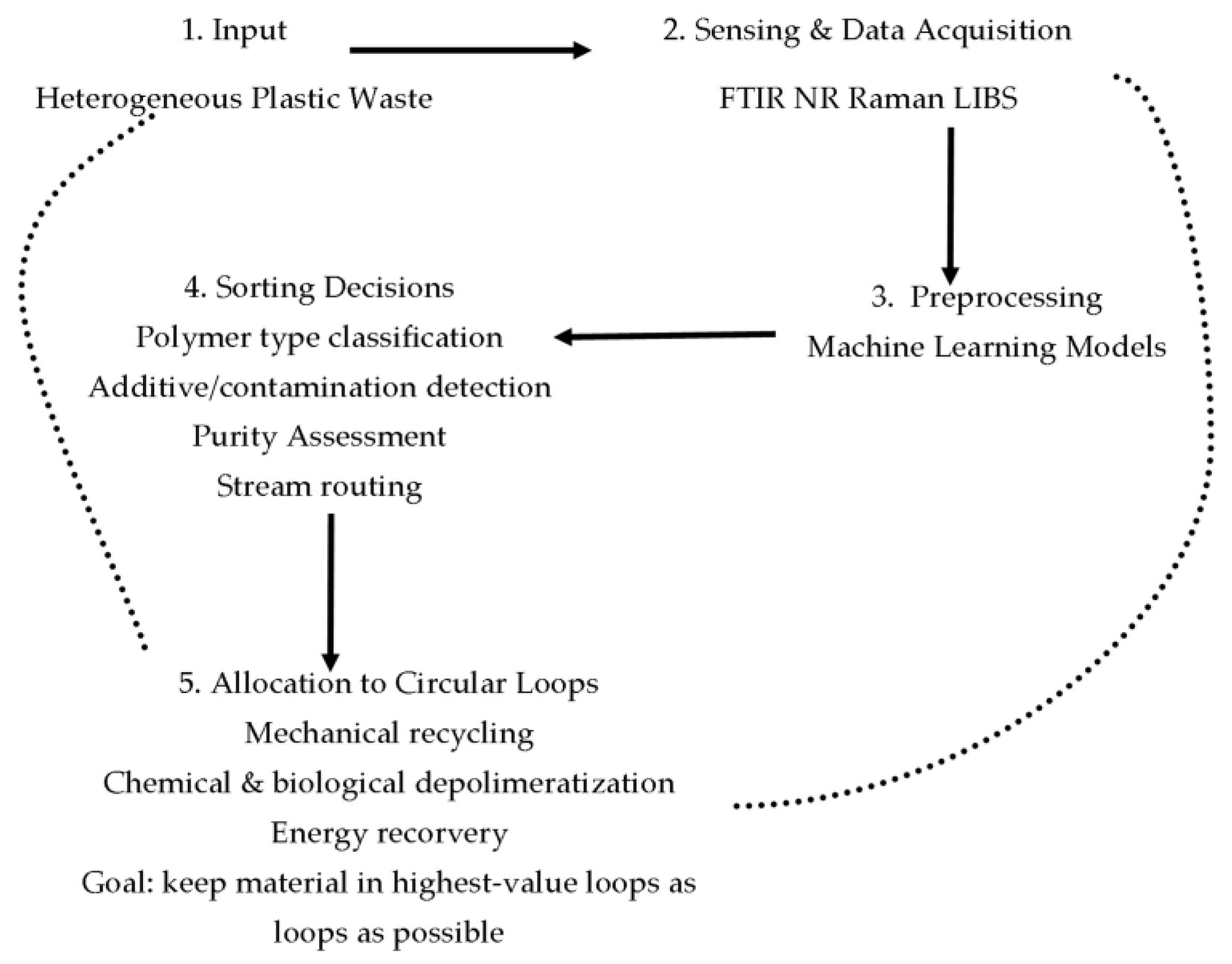

2. Advanced Sensing and Intelligent Sorting of Plastics

2.1. The Strategic Role of Intelligent Sorting in Circular Plastic Systems

2.2. FTIR Spectroscopy and AI-Enhanced Signal Separation

2.3. NIR Spectroscopy, Minuaturization, and Machine Learning and AI-Enhanced Signal Separation

2.4. Raman Spectroscopy Supported by Preprocessing and IA Algorithms

2.5. LIBS: Elemental Fingerprinting and AI for Complex Waste Stream

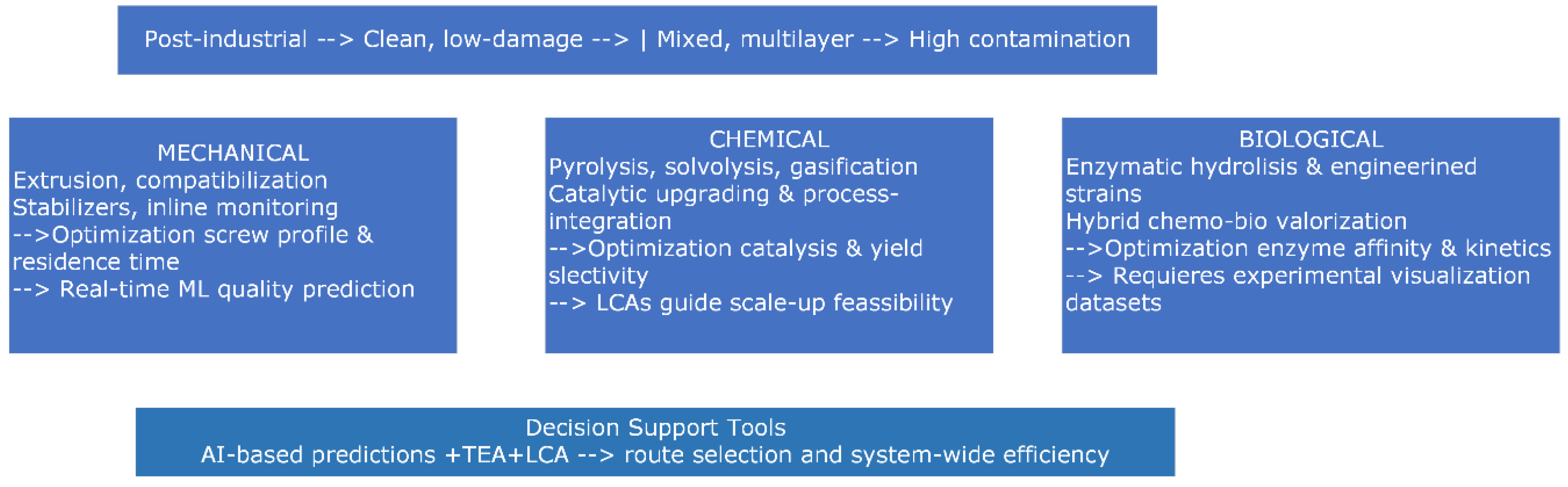

3. Optimization of Mechanical, Chemical, and Biological Recycling Routes 320.

3.1. Optimization of Mechanical Recycling

- Minimizing thermo-mechanical degradation [6],

- Enhancing inter-polymer phase compatibility,

- Minimization of mass losses along washing, melting, and filtration steps, and

- Integrating predictive extrusion-quality models.

3.2. Optimization of Chemical Recycling

- Catalyst robustness across mixed streams,

- Reduction of energy intensity per ton converted, and

- Validation of lab kinetic performance at pilot-plant scales

- Kinetic-parameter predictive models,

- Catalyst recombinations studies,

- Integrated heat-exchange schemes, and

- Selective downstream purification.

3.3. Optimization of Biological Routes

- PETase mutational libraries,

- Kinetic profiles across crystalline grades, and

- Validation of ML-guided enzyme-design workflows.

3.4. Cross-Route Optimization Perspective

- Mechanical loops maximize value when polymer memory is known, and degradation is minimal.

- Chemical loops maximize value when the waste stream is heterogeneous, multilayered, or contaminated.

- Biological loops uniquely deliver monomer-grade purity but require substrate accessibility and bio-catalyst engineering.

- ML-assisted condition prediction,

- TEA-LCA indicators, and

- Quality-based routing logic.

3.5. Integrative Resources: Comparative Table and Conceptual Diagram

4. Upcycling Pathways for High-Value Recycled Polymer Materials

4.1. Technical Pathways for Plastic Upcycling

4.1.1. Chemical Routes

4.1.2. Thermal and Thermochemical Process

4.1.3. Electrochemical Upgrading

4.1.4. Biological Upcycling

4.1.4. Polymer Blending and Compatibilization

4.2. Artificial Intelligence as an Optimization Driver in Upcycling

| Authors | Application of IA | Results |

|---|---|---|

| Wang et al. [62] | SERDA, SVR, PSO, XGBoost | Optimization of pyrolysis catalytic conditions to maximize fuels |

| Wang et al. [63] | Predictive models | Transformation of medical waste into activated carbon with high CO₂ capture performance |

| Huang & Lee [64] | Optimización estructural | Production of electrodes from PP mask |

| Cui et al. [65] | Algorithm-assisted design | Selective photocatalysts for depolymerization |

| Rezaei et al. [66] | Practical bioinformatic | Prioritization of metabolic pathways for biodegradation |

| Li et al. . [67] | Neural Networks | Porous carbon optimization with maximum CO₂ sorption |

4.3. Emerging Technological and Research Trajectories

5. Life Cycle Assessment and Environmental Metrics in Circular Plastic Systems

5.1. System Boundaries Relevant to Plastic Circularity

| System Boundary | Description | Typical Use Case | Representative Literature |

|---|---|---|---|

| Cradle-to-Gate | Covers the transformation from raw feedstock or collected waste to the production of usable recycled resin | Comparative assessments of mechanical vs chemical vs bioconversion technologies; benchmarking efficiency of pyrolysis units | Jeswani et. al.[32]; Huang et. al.[31]; Chen et. al. [78] |

| Gate-to-Gate | Focused exclusively on intra-plant processes such as washing, extrusion, catalytic depolimerization, pelletization | Optimizing specific unit operations, industrial diagnostics, and energy allocation analysis. | Martínez-Narro et. al. [79] |

| Cradle-to-Grave | Includes production, use, and end-of-life scenarios, including landfill disposal, incineration, and recycling. | Packaging evaluations; comparisons of polymer alternatives for equivalent protection performance. | Jeswani et. al.[32]; OECD [80] |

| Cradle-to-Cradle | Incorporates full circular feedback; recovered product reenters the system with a virgin equivalent | “Bottle-to-bottle” PET system; chemical recycling routes returning monomer substitutes | Tang. [30]; Uekert et al. [30] |

5.2. Performance Characterization of Chemical Recycling Routes

5.3. Life-Cycle Implications of Upcycling Processes

5.4. Digital-Twin-Based LCAs and Computational Attribution

5.5. Comparative Findings Across Recycling Pathways

- long-term regulatory planning;

- industrial-academic knowledge networks that reduce technological uncertainty;

6. Policy Instruments, Institutional Frameworks, and Circular Governance Mechanisms

6.1. Extended Producer Responsibility

6.2. Regulatory Framework for EPR Implementation

6.3. Refuse-Derived Fuel and Energy Valorization Pathways

6.4. Municipal Solid Waste (MSW) Systems in Circular Transitions

6.5. Materials Recovery Facilities (MRFs)

6.6. Supply Chain Management (SCM) for Circular Materials

7. Case Studies, Future Directions, and Framework for Circular Plastic Systems

7.1. Global Case Studies: Insights and Quantitative Evidence

7.1.1. Middle Eastern Industrial Circularity: SABIC and Aramco Initiatives

7.1.2. Thailand’s Rayong Multi-Stakeholder System: The Central Role of Informality

7.1.3. Malaysia’s P-Graph–Integrated EPR Evaluation for Circular Plastics

7.1.4. The PHOENIX Framework in the European Union: Design for Plasmix Circularity

7.1.5. PET Circularity Through LCA and MFA Integration

7.1.6. Cameroon’s Emerging Circularity Efforts

7.2. Latin America Case Studies: Policy, Socioeconomic Context, and Circularity Pathways

7.2.1. México

7.2.2. SubAmerica

7.3. Cross-Cutting Lesson from Global and Regional Experiences

7.4. Future Directions for Circular Plastic Systems

7.5. Toward a Coherent and Inclusive Framework for Circular Plastic Systems

8. Discussion

9. Conclusions

Author Contributions

Funding

Acknowledgments

Abbreviations

| AI | Artificial Intelligence |

| CE | Circular Economy |

| CED | Cumulative Energy Demand |

| GEP | Global Warming Potential |

| HDPE | High-density polyethylene |

| LCA | Life Cycle Assessment |

| LICA | Life Cycle Impact Assessment |

| LCI | Life Cycle Inventory |

| LDPE | Low-density polyethylene |

| ML | Machine Learning |

| MFA | Material Flow Analysis |

| MRFs | Material Recovery Facilities |

| MSW | Municipal Solid Waste |

| P-graph | P-graph Model |

| PHOENIX | PHOENIX Framework |

| PE | Polyethylene |

| PET | Polyethylene terephthalate |

| PLA | Polylactic Acid |

| PP | Polypropylene |

| PS | Polystyrene |

| PVC | Polyvinyl chloride |

| RDF | Refuse-Derived Fuel |

| TEA | Techno-Economic Analysis |

References

- Kara, S.; Hauschild, M.; Sutherland, J.; McAloone, T. Closed-Loop Systems to Circular Economy: A Pathway to Environmental Sustainability? CIRP Annals 2022, 71, 505–528. [Google Scholar] [CrossRef]

- Stanley, J.; Culliton, D.; Jovani-Sancho, A.-J.; Neves, A.C. The Journey of Plastics: Historical Development, Environmental Challenges, and the Emergence of Bioplastics for Single-Use Products. Eng 2025, 6, 17. [Google Scholar] [CrossRef]

- Bucknall, D.G. Plastics as a Materials System in a Circular Economy. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 2020, 378, 20190268. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci Adv 2017, 3. [Google Scholar] [CrossRef]

- Fang, Z.; Chen, D.; Hu, X.; Deng, Z.; Xu, J.; Wang, Y.; Qiao, Y.; Hu, S.; Xiang, J. Rapid Detection and Identification of Plastic Waste Based on Multi-Wavelength Laser Raman Spectroscopy Combining Machine Learning Methods. Spectrochim Acta A Mol Biomol Spectrosc 2025, 340, 126316. [Google Scholar] [CrossRef]

- Lee, J.E.; Lee, D.; Lee, J.; Park, Y.-K. Current Methods for Plastic Waste Recycling: Challenges and Opportunities. Chemosphere 2025, 370, 143978. [Google Scholar] [CrossRef]

- Sunil, M.; Pallikkavaliyaveetil, N.; MIthun., N; Gopinath, A.; Chidangil, S.; Kumar, S.; Lukose, J. Machine Learning Assisted Raman Spectroscopy: A Viable Approach for the Detection of Microplastics. Journal of Water Process Engineering 2024, 60, 105150. [Google Scholar] [CrossRef]

- Fuente-Ballesteros, A.; Ciulu, M.; Haque, S.M.; Syrgabek, Y.; Basaran, B. Honeybees as Active Bioindicators of Plastic Pollution: Environmental Exposure, Analytical Strategies, and Monitoring Perspectives. Science of The Total Environment 2025, 1003, 180722. [Google Scholar] [CrossRef]

- Deekshitha, K.; Hetman, I.; Neli, Ö.U.; Jayarama, A.; Pinto, R. AI-Accelerated Innovations in Photodegradation and Depolymerization of Waste Plastics: A Critical Review on Mechanistic Insights, Environmental Impact, and Future Perspectives. Eur Polym J 2025, 239, 114278. [Google Scholar] [CrossRef]

- King, S.; Locock, K.E.S. A Circular Economy Framework for Plastics: A Semi-Systematic Review. J Clean Prod 2022, 364, 132503. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular Economy and the Matter of Integrated Resources. Science of The Total Environment 2019, 689, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Raut, S.; Hossain, N.U.I.; Kouhizadeh, M.; Fazio, S.A. Application of Artificial Intelligence in Circular Economy: A Critical Analysis of the Current Research. Sustainable Futures 2025, 9, 100784. [Google Scholar] [CrossRef]

- Naeim, H.; Mahdavian, F.; Rodrigue, D. Review on Electrospinning of Recycled Polymer-Derived Fibers: A Road towards Sustainability, Production and Applications. J Environ Chem Eng 2025, 13, 119283. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol Rapid Commun 2021, 42. [Google Scholar] [CrossRef]

- Lubongo, C.; Bin Daej, M.A.A.; Alexandridis, P. Recent Developments in Technology for Sorting Plastic for Recycling: The Emergence of Artificial Intelligence and the Rise of the Robots. Recycling 2024, 9, 59. [Google Scholar] [CrossRef]

- Chattaraj, S.; Mitra, D.; Madan, A.; Pellegrini, M.; Choudhury, T. Conclusion of AI Technologies for Enhancing Recycling Processes. Advances in Environmental Engineering and Green Technologies Book Series 2025, 16, 531–536. [Google Scholar]

- Pasieczna-Patkowska, S.; Cichy, M.; Flieger, J. Application of Fourier Transform Infrared (FTIR) Spectroscopy in Characterization of Green Synthesized Nanoparticles. Molecules 2025, 30, 684. [Google Scholar] [CrossRef]

- Buaruk, S.; Somnuake, P.; Gulyanon, S.; Deepaisarn, S.; Laitrakun, S.; Opaprakasit, P. Membrane Filter Removal in FTIR Spectra through Dictionary Learning for Exploring Explainable Environmental Microplastic Analysis. Sci Rep 2024, 14, 20297. [Google Scholar] [CrossRef]

- van Hoorn, H.; Pourmohammadi, F.; de Leeuw, A.-W.; Vasulkar, A.; de Vos, J.; van den Berg, S. Machine Learning-Based Identification of Plastic Types Using Handheld Spectrometers. Sensors 2025, 25, 3777. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Li, W.; Wan, J. Rapid Identification of Plastic Beverage Bottles by Using Raman Spectroscopy Combined With Machine Learning Algorithm. Journal of Raman Spectroscopy 2025, 56, 381–388. [Google Scholar] [CrossRef]

- Musu, W.; Tsuchida, A.; Kawazumi, H.; Oka, N. Application of PCA-SVM and ANN Techniques for Plastic Identification by Raman Spectroscopy. In Proceedings of the 2019 1st International Conference on Cybernetics and Intelligent System (ICORIS), August 2019; IEEE; pp. 114–118. [Google Scholar]

- Das, P.; Zeng, Q.; Sirven, J.-B.; Lee, J.-M.; Gabriel, J.-C.P. AI-Enabled Spectral Classification of Plastic Resins from E-Waste via Laser-Induced Breakdown Spectroscopy for Advanced Sorting Applications. Resour Conserv Recycl 2026, 226, 108660. [Google Scholar] [CrossRef]

- Alrazen, H.A.; Aminossadati, S.M.; Mahmood, H.A.; Hussein, A.K.; Ahmad, K.A.; Dol, S.S.; Jabbar, S.; Algayyim, S.J.M.; Konarova, M.; Fattah, I.M.R. A Review of the Pathways, Limitations, and Perspectives of Plastic Waste Recycling. Mater Renew Sustain Energy 2025, 14, 50. [Google Scholar] [CrossRef]

- Nyam, T.T.; Ayeleru, O.O.; Ramatsa, Ishmael Matala; Olubambi1, P.A. Management Strategies for Plastic Wastes: A Roadmap Toward Circular Economy and Environmental Sustainability. In Plastic Waste Management; Wiley, 2024; pp. 31–54. [Google Scholar]

- Van Camp, N.; Lase, I.S.; De Meester, S.; Hoozée, S.; Ragaert, K. Exposing the Pitfalls of Plastics Mechanical Recycling through Cost Calculation. Waste Management 2024, 189, 300–313. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Management 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Edeleva, M.; De Smit, K.; Debrie, S.; Verberckmoes, A.; Marien, Y.W.; D’hooge, D.R. Molecular Scale-Driven Upgrading of Extrusion Technology for Sustainable Polymer Processing and Recycling. Curr Opin Green Sustain Chem 2023, 43, 100848. [Google Scholar] [CrossRef]

- Titone, V.; Botta, L.; La Mantia, F.P. Mechanical Recycling of New and Challenging Polymer Systems: A Brief Overview. Macromol Mater Eng 2025, 310. [Google Scholar] [CrossRef]

- Hassanian-Moghaddam, D.; Asghari, N.; Ahmadi, M. Circular Polyolefins: Advances toward a Sustainable Future. Macromolecules 2023, 56, 5679–5697. [Google Scholar] [CrossRef]

- Uekert, T.; Singh, A.; DesVeaux, J.S.; Ghosh, T.; Bhatt, A.; Yadav, G.; Afzal, S.; Walzberg, J.; Knauer, K.M.; Nicholson, S.R.; et al. Technical, Economic, and Environmental Comparison of Closed-Loop Recycling Technologies for Common Plastics. ACS Sustain Chem Eng 2023, 11, 965–978. [Google Scholar] [CrossRef]

- Huang, J.; Veksha, A.; Chan, W.P.; Giannis, A.; Lisak, G. Chemical Recycling of Plastic Waste for Sustainable Material Management: A Prospective Review on Catalysts and Processes. Renewable and Sustainable Energy Reviews 2022, 154, 111866. [Google Scholar] [CrossRef]

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life Cycle Environmental Impacts of Chemical Recycling via Pyrolysis of Mixed Plastic Waste in Comparison with Mechanical Recycling and Energy Recovery. Science of The Total Environment 2021, 769, 144483. [Google Scholar] [CrossRef]

- Paavani, K.; Agarwal, K.; Alam, S.S.; Dinda, S.; Abrar, I. Advances in Plastic to Fuel Conversion: Reactor Design, Operational Optimization, and Machine Learning Integration. Sustain Energy Fuels 2025, 9, 54–71. [Google Scholar] [CrossRef]

- Tomme, L.; Ureel, Y.; Dobbelaere, M.R.; Lengyel, I.; Vermeire, F.H.; Stevens, C. V.; Van Geem, K.M. Machine Learning Applications for Thermochemical and Kinetic Property Prediction. Reviews in Chemical Engineering 2025, 41, 419–449. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Ekici, E.; Yildiz, G.; Yang, Y.; Coward, B.; Wang, J. Applied Machine Learning for Prediction of Waste Plastic Pyrolysis towards Valuable Fuel and Chemicals Production. J Anal Appl Pyrolysis 2023, 169, 105857. [Google Scholar] [CrossRef]

- Zhan, C.; Lan, G.; Dan, Q.; Qin, N.; Pearson, A.; Mellinger, P.; Liu, Y.; Wang, Z.; Cheong, S.; Dou, C.; et al. Hybrid Biological-Chemical Strategy for Converting Polyethylene into a Recyclable Plastic Monomer Using Engineered Corynebacterium Glutamicum. Metab Eng 2025, 90, 106–116. [Google Scholar] [CrossRef] [PubMed]

- 37; Silva, R.R.A.; Marques, C.S.; Arruda, T.R.; Teixeira, S.C.; de Oliveira, T.V. Biodegradation of Polymers: Stages, Measurement, Standards and Prospects. Macromol 2023, 3, 371–399. [Google Scholar] [CrossRef]

- 38; Chen, L.; Zhao, C.; Yuan, X.; Zhang, H.; Senanayake, M.; Mašek, O.; He, C.; Ok, Y.S. Sustainable Thermochemical Plastic Valorization towards a Circular Economy: A Critical Review. Green Chemistry 2025, 27, 4867–4897. [Google Scholar] [CrossRef]

- 39; Jiang, R.; Yue, Z.; Shang, L.; Wang, D.; Wei, N. PEZy-Miner: An Artificial Intelligence Driven Approach for the Discovery of Plastic-Degrading Enzyme Candidates. Metab Eng Commun 2024, 19, e00248. [Google Scholar] [CrossRef]

- 40. Kunz, N.C. Positive Steps to Living Green The Upcycle Beyond Sustainability—Designing for Abundance William McDonough and Michael Braungart North Point Press, 2013. 254 Pp. Science (1979) 2014, 345, 258–259. [CrossRef]

- Bolus, J.J.; Platin, R.; Semisch, C. MBDC Cradle to Cradle® Product Evaluation and Certification Program. In Chemical Alternatives Assessments; The Royal Society of Chemistry, 2013; pp. 67–87. [Google Scholar]

- Wegener, C. Upcycling. In Creativity — A New Vocabulary; Palgrave Macmillan UK: London, 2016; pp. 181–188. [Google Scholar]

- Liu, X.; Park, H.; Ackermann, Y.S.; Avérous, L.; Ballerstedt, H.; Besenmatter, W.; Blázquez, B.; Bornscheuer, U.T.; Branson, Y.; Casey, W.; et al. Exploring Biotechnology for Plastic Recycling, Degradation and Upcycling for a Sustainable Future. Biotechnol Adv 2025, 81, 108544. [Google Scholar] [CrossRef]

- Habeeb, T.H.; Farooq, U. Advanced Strategies for Plastic Upcycling: Unlocking Sustainable Waste Valorization Pathways for a Green and Sustainable Environment. Catal Sci Technol 2025, 15, 5602–5634. [Google Scholar] [CrossRef]

- Alrazen, H.A.; Aminossadati, S.M.; Mahmood, H.A.; Hussein, A.K.; Ahmad, K.A.; Dol, S.S.; Jabbar, S.; Algayyim, S.J.M.; Konarova, M.; Fattah, I.M.R. A Review of the Pathways, Limitations, and Perspectives of Plastic Waste Recycling. Mater Renew Sustain Energy 2025, 14, 50. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, Y.; Zou, C.; Moon, T.S. The Current Progress of Tandem Chemical and Biological Plastic Upcycling. Biotechnol Adv 2024, 77, 108462. [Google Scholar] [CrossRef]

- Bandi, F.; Sulttan, S.; Rohani, S. Modeling and Simulation of Microwave Assisted Catalytic Pyrolysis System of Waste Plastics Polymer for Fuel Production. Finite Elements in Analysis and Design 2024, 229, 104073. [Google Scholar] [CrossRef]

- 48; Zhang, F.; Wang, F.; Wei, X.; Yang, Y.; Xu, S.; Deng, D.; Wang, Y.-Z. From Trash to Treasure: Chemical Recycling and Upcycling of Commodity Plastic Waste to Fuels, High-Valued Chemicals and Advanced Materials. Journal of Energy Chemistry 2022, 69, 369–388. [Google Scholar] [CrossRef]

- Yang, C.; Shang, H.; Li, J.; Fan, X.; Sun, J.; Duan, A. A Review on the Microwave-Assisted Pyrolysis of Waste Plastics. Processes 2023, 11, 1487. [Google Scholar] [CrossRef]

- Kim, J.; Masoumilari, S.; Park, Y.; Lee, S.; Kyung, D.; Masoumi, Z. Advancements in the Electrochemical Upcycling of Waste Plastics into High-Value Products. Crystals (Basel) 2025, 15, 293. [Google Scholar] [CrossRef]

- Xiang, D.; Zhou, K.; Huang, J.; Kang, Q.; Li, H.; Duan, Y.; Du, J.; Liu, H. Electrochemical Upgrading of Waste Polylactic Acid Plastic for the Coproduction of C2 Chemicals and Green Hydrogen. Molecules 2024, 29, 5323. [Google Scholar] [CrossRef]

- Zhou, H.; Ren, Y.; Li, Z.; Xu, M.; Wang, Y.; Ge, R.; Kong, X.; Zheng, L.; Duan, H. Electrocatalytic Upcycling of Polyethylene Terephthalate to Commodity Chemicals and H2 Fuel. Nat Commun 2021, 12, 4679. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Y.; Liu, F.; Liu, C.; Shi, R.; Chen, Y. Selective Electrocatalytic Reforming of PET-Derived Ethylene Glycol to Formate with a Faraday Efficiency of 93.2% at Industrial-Level Current Densities. Chemical Engineering Journal 2023, 473, 145292. [Google Scholar] [CrossRef]

- Ballerstedt, H.; Tiso, T.; Wierckx, N.; Wei, R.; Averous, L.; Bornscheuer, U.; O’Connor, K.; Floehr, T.; Jupke, A.; Klankermayer, J.; et al. MIXed Plastics Biodegradation and UPcycling Using Microbial Communities: EU Horizon 2020 Project MIX-UP Started January 2020. Environ Sci Eur 2021, 33, 99. [Google Scholar] [CrossRef]

- Tournier, V.; Duquesne, S.; Guillamot, F.; Cramail, H.; Taton, D.; Marty, A.; André, I. Enzymes’ Power for Plastics Degradation. Chem Rev 2023, 123, 5612–5701. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-C.; Dai, L.; Ma, L.; Guo, R.-T. Enzymatic Degradation of Plant Biomass and Synthetic Polymers. Nat Rev Chem 2020, 4, 114–126. [Google Scholar] [CrossRef]

- Yue, X.-H.; Zhang, F.-S.; Wu, L.; Zhang, C.-C.; Qian, P. Upcycling of Blending Waste Plastics as Flexible Growing Substrate with Superabsorbing Property. Chemical Engineering Journal 2022, 435, 134622. [Google Scholar] [CrossRef]

- Rajasekaran, D.; Maji, P.K. Recycling of Plastic Wastes with Poly (Ethylene-Co-Methacrylic Acid) Copolymer as Compatibilizer and Their Conversion into High-End Product. Waste Management 2018, 74, 135–143. [Google Scholar] [CrossRef]

- Titone, V.; Gulino, E.F.; La Mantia, F.P. Recycling of Heterogeneous Mixed Waste Polymers through Reactive Mixing. Polymers (Basel) 2023, 15, 1367. [Google Scholar] [CrossRef]

- Pawar, S.; Gurani, K.; -, V.O.B.; -, V.O.B. Utilization Of Plastic Waste As Construction Material. International Journal For Multidisciplinary Research 2025, 7. [Google Scholar] [CrossRef]

- Means, N.C.; Lekse, J.W.; Wang, P.; Gray, M.; Shi, F. A Big Data Analysis for Waste Plastic Recycling/Upcycling Technology: An Overview of Results and Discussions.

- Wang, J.; Li, S.; Deng, S.; Cheng, Z.; Hu, X.; Wan Mahari, W.A.; Lam, S.S.; Yuan, X. Upcycling Medical Plastic Waste into Activated Carbons toward Environmental Safety and Sustainability. Curr Opin Environ Sci Health 2023, 33, 100470. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Deng, S.; Cheng, Z.; Hu, X.; Wan Mahari, W.A.; Lam, S.S.; Yuan, X. Upcycling Medical Plastic Waste into Activated Carbons toward Environmental Safety and Sustainability. Curr Opin Environ Sci Health 2023, 33, 100470. [Google Scholar] [CrossRef]

- Huang, C.-C.; Lee, M.-H. Flexible Dry Electrocardiography Electrodes Obtained from Waste Face Masks, PEDOT:PSS, and Biosynthetic Polymers. Surfaces and Interfaces 2025, 61, 106108. [Google Scholar] [CrossRef]

- Cui, H.; Chen, X.; Lan, F.; An, B.; Zhang, X. Photocatalysis as a Tool for Upcycling of Polymers. Trends Chem 2024, 6, 392–405. [Google Scholar] [CrossRef]

- Rezaei, Z.; Dinani, A.S.; Moghimi, H. Cutting-Edge Developments in Plastic Biodegradation and Upcycling via Engineering Approaches. Metab Eng Commun 2024, 19, e00256. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Cui, H.; Sheng, Y.; Qiao, J.; Li, X.; Huang, H. Global Plastic Upcycling during and after the COVID-19 Pandemic: The Status and Perspective. J Environ Chem Eng 2023, 11, 110092. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D Printing in Upcycling Plastic and Biomass Waste to Sustainable Polymer Blends and Composites: A Review. Mater Des 2024, 237, 112558. [Google Scholar] [CrossRef]

- Qian, Q.; Ren, J. From Plastic Waste to Potential Wealth: Upcycling Technologies, Process Synthesis, Assessment and Optimization. Science of The Total Environment 2024, 907, 167897. [Google Scholar] [CrossRef]

- Khairul Anuar, S.Z.; Nordin, A.H.; Nur Husna, S.M.; Yusoff, A.H.; Paiman, S.H.; Md Noor, S.F.; Nordin, M.L.; Ali, S.N.; Nazir Syah Ismail, Y.M. Recent Advances in Recycling and Upcycling of Hazardous Plastic Waste: A Review. J Environ Manage 2025, 380, 124867. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ Sci Technol 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. The International Journal of Life Cycle Assessment 2016, 2016 22:2 22, 138–147. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol Rapid Commun 2021, 42. [Google Scholar] [CrossRef]

- Vinci, G.; Gobbi, L.; Porcaro, D.; Pinzi, S.; Carmona-Cabello, M.; Ruggeri, M. Environmental Evaluation of Chemical Plastic Waste Recycling: A Life Cycle Assessment Approach. Resources 2024, 13, 176. [Google Scholar] [CrossRef]

- Uekert, T.; DesVeaux, J.S.; Singh, A.; Nicholson, S.R.; Lamers, P.; Ghosh, T.; McGeehan, J.E.; Carpenter, A.C.; Beckham, G.T. Life Cycle Assessment of Enzymatic Poly(Ethylene Terephthalate) Recycling. Green Chemistry 2022, 24, 6531–6543. [Google Scholar] [CrossRef]

- Grant, Andy.; Cordle, Mark.; Bridgwater, Eric.; Canfora, Paolo.; Dri, Marco.; Antonopoulos, Ioannis.; Pierre, Gaudillat. Quality of Recycling - Towards an Operational Definition. 2020. [Google Scholar] [CrossRef]

- OECD Extended Producer Responsibility: Updated Guidance for Efficient Waste Management. 2016.

- Chen, G.; Li, J.; Sun, Y.; Wang, Z.; Leeke, G.A.; Moretti, C.; Cheng, Z.; Wang, Y.; Li, N.; Mu, L.; et al. Replacing Traditional Plastics with Biodegradable Plastics: Impact on Carbon Emissions. Engineering 2024, 32, 152–162. [Google Scholar] [CrossRef]

- Martínez-Narro, G.; Hassan, S.; Phan, A.N. Chemical Recycling of Plastic Waste for Sustainable Polymer Manufacturing – A Critical Review. J Environ Chem Eng 2024, 12, 112323. [Google Scholar] [CrossRef]

- OECD Towards Eliminating Plastic Pollution by 2040; Paris, France, 2023.

- Liang, H.; Dong, H.; Zhang, C.; Geng, Y.; Liu, X.; Liu, G.; Zhong, C. Combining LCA-MFA Models to Identify China’s Plastic Value Chain Environmental Impact Mitigation Pathways. iScience 2023, 26, 107701. [Google Scholar] [CrossRef]

- Go, Y.-J.; Kang, D.-H.; Park, H.-J.; Lee, J.-H.; Shim, J.-K. Meta-Analysis of Life Cycle Assessment Studies for Polyethylene Terephthalate Water Bottle System. Sustainability 2024, 16, 535. [Google Scholar] [CrossRef]

- Lin, G.; Yuan, J.; Li, X.; Zhao, S.; Wang, S.; Chang, H.; Zhao, Y. Strategic Choice of the Management of Disposable Meal Boxes from the Perspectives of Life Cycle Impact Assessment: Recycling Fossil Plastics or Promoting Biogenic Plastics. Resour Conserv Recycl 2024, 204, 107477. [Google Scholar] [CrossRef]

- van Schaick, J. Bridging Gaps with a Spatial Strategy for the Circularity Transition: Practice Review from Zuid-Holland, The Netherlands. Planning Practice & Research 2024, 1–25. [Google Scholar] [CrossRef]

- Montag, L. Roadmap to a Circular Economy by 2030: A Comparative Review of Circular Business Model Visions in Germany and Japan. Sustainability 2023, 15, 5374. [Google Scholar] [CrossRef]

- Ceroni, E. The Role Of Extended Producer Responsibility (Epr) In The Transition To A Circular Economy; 25 November 2024; pp. 293–300. [Google Scholar]

- Vermeulen, W.J.V.; Campbell-Johnston, K. Extended Producer Responsibility. In Handbook of Recycling; Elsevier, 2024; pp. 587–600. [Google Scholar]

- OECD Extended Producer Responsibility: A Policy Principle to Promote Environmental Improvements through Product Design. 2005.

- Laubinger, F.; Dubois, M.; Börkey, P. Deposit-Refund Systems and the Interplay with Additional Mandatory Extended Producer Responsibility Policies. 2022, 89. [Google Scholar]

- Chamber of Deputies Law Published in No. 299 Bis of the Official Gazette of Mexico City. CDMX 2020.

- México. Congress of the Unión General Law on Circular Economy (Ley de Economía Circular). Diario Oficial de La Federación 2021.

- Nowak, M. Features of Refuse Derived Fuel in Poland – Physicochemical Properties and Availability of Refuse Derived Fuel. Journal of Ecological Engineering 2023, 24, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Tcobanoglous, G.; Kreith, F. Handbook of Solid Waste Management, 2nd Ed. ed; 2002. [Google Scholar]

- Phogat, P. Waste- and Refuse-Derived Fuels: Circular Energy Solutions from Waste Streams. Journal of Material Science and Technology Research 2025, 12, 22–44. [Google Scholar] [CrossRef]

- Shehata, N.; Obaideen, K.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; El-Salamony, A.-H.R.; Mahmoud, H.M.; Olabi, A.G. Role of Refuse-Derived Fuel in Circular Economy and Sustainable Development Goals. Process Safety and Environmental Protection 2022, 163, 558–573. [Google Scholar] [CrossRef]

- Sarquah, K.; Narra, S.; Beck, G.; Bassey, U.; Antwi, E.; Hartmann, M.; Derkyi, N.S.A.; Awafo, E.A.; Nelles, M. Characterization of Municipal Solid Waste and Assessment of Its Potential for Refuse-Derived Fuel (RDF) Valorization. Energies (Basel) 2022, 16, 200. [Google Scholar] [CrossRef]

- Buekens, A. Refuse-Derived Fuel; 2013; pp. 71–76. [Google Scholar]

- Frankenhaeuser, M.; Manninen, H. Fuel Recovery: Valorization of RDF and PDF. In The Science of Composting; Springer Netherlands: Dordrecht, 1996; pp. 813–821. [Google Scholar]

- Ribeiro, A.; Soares, M.; Castro, C.; Mota, A.; Araújo, J.; Vilarinho, C.; Carvalho, J. Waste-to-Energy Technologies Applied for Refuse Derived Fuel (RDF) Valorisation; 2019; pp. 641–647. [Google Scholar]

- Tihin, G.L.; Mo, K.H.; Onn, C.C.; Ong, H.C.; Taufiq-Yap, Y.H.; Lee, H.V. Overview of Municipal Solid Wastes-Derived Refuse-Derived Fuels for Cement Co-Processing. Alexandria Engineering Journal 2023, 84, 153–174. [Google Scholar] [CrossRef]

- Cazares-Carrión, K.Y.; Peñafiel-Arcos, P.; Herrera-Feijoo, R.J.; Reyes-Villacrés, J. Transformación Sostenible de Residuos Urbanos En Energía: Una Evaluación de La Producción de Metano En Puyo, Pastaza. Código Científico Revista de Investigación 2024, 5, 29–48. [Google Scholar] [CrossRef]

- Okori, F.; Lederer, J.; Komakech, A.J.; Schwarzböck, T.; Fellner, J. Plastics and Other Extraneous Matter in Municipal Solid Waste Compost: A Systematic Review of Sources, Occurrence, Implications, and Fate in Amended Soils. Environmental Advances 2024, 15, 100494. [Google Scholar] [CrossRef]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal Solid Waste Generation, Composition, and Management: The World Scenario. Crit Rev Environ Sci Technol 2013, 43, 215–215. [Google Scholar] [CrossRef]

- Ramírez Ríos, L.F.; Becerra Moreno, D.; Ortega Contreras, J.Y. Potential Use of Methane Gas from the Villavicencio Sanitary Landfill, Colombia. Ingeniería y Competitividad 2024, 26. [Google Scholar] [CrossRef]

- Gonzalez Moguel, R.; Douglas, P.M.J.; Asomaning, J.; Reid, E.; Romanic, D.; Vogel, F.; Ars, S.; Gillespie, L.; Huang, Y. Four Years of Mobile Monitoring Show That Urban Waste Is the Primary Source of Large Methane Emissions Hotspots in Montreal, Canada. Environ Res Commun 2025, 7, 091002. [Google Scholar] [CrossRef]

- Díaz-Nigenda, E.; Venegas-Sandoval, A.; Vázquez-Morales, W.; Nájera-Aguilar, H.A.; Morales-Iglesias, H.; Vázquez Ovando, C. Emisiones de Metano Por La Disposición de Residuos Sólidos Urbanos: El Caso de Tuxtla Gutiérrez, Chiapas, México. Acta Univ 2022, 32, 1–14. [Google Scholar] [CrossRef]

- Aiguobarueghian, Ikponmwosa; Adanma, Uwaga Monica; Ogunbiyi, Emmanuel Olurotimi. Nko Okina Solomon Waste Management and Circular Economy: A Review of Sustainable Practices and Economic Benefits. World Journal of Advanced Research and Reviews 2024, 22, 1708–1719. [Google Scholar] [CrossRef]

- Yabbarova, R.I. Closed-cycle Economics in the Field of Municipal Solid Waste Management: Main Factors and Criteria for Evaluating Efficiency. In ecology, development; South of Russia, 2025; Volume 20, pp. 195–203. [Google Scholar] [CrossRef]

- González-Sánchez, R.; Alonso-Muñoz, S.; Medina-Salgado, M.S. Circularity in Waste Management: A Research Proposal to Achieve the 2030 Agenda. Operations Management Research 2023, 16, 1520–1540. [Google Scholar] [CrossRef]

- Cavalletti, B.; Corsi, M. By Diversion Rate Alone: The Inconsistency and Inequity of Waste Management Evaluation in a Single-indicator System. Papers in Regional Science 2019, 98, 307–330. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Lipp, A.-M.; Fellner, J.; Tischberger-Aldrian, A.; Stipanović, H.; Lederer, J. Recovery of Plastic Packaging from Mixed Municipal Solid Waste. A Case Study from Austria. Waste Management 2024, 180, 9–22. [Google Scholar] [CrossRef]

- Al-Athamin, E.A.; Hemidat, S.; Al-Hamaiedeh, H.; Aljbour, S.H.; El-Hasan, T.; Nassour, A. A Techno-Economic Analysis of Sustainable Material Recovery Facilities: The Case of Al-Karak Solid Waste Sorting Plant, Jordan. Sustainability 2021, 13, 13043. [Google Scholar] [CrossRef]

- Bradshaw, S.L.; Aguirre-Villegas, H.A.; Boxman, S.E.; Benson, C.H. Material Recovery Facilities (MRFs) in the United States: Operations, Revenue, and the Impact of Scale. Waste Management 2025, 193, 317–327. [Google Scholar] [CrossRef]

- Yu, Z.; Waqas, M.; Tabish, M.; Tanveer, M.; Haq, I.U.; Khan, S.A.R. Sustainable Supply Chain Management and Green Technologies: A Bibliometric Review of Literature. Environmental Science and Pollution Research 2022, 29, 58454–58470. [Google Scholar] [CrossRef]

- Alsolbi, I.; Shavaki, F.H.; Agarwal, R.; Bharathy, G.K.; Prakash, S.; Prasad, M. Big Data Optimisation and Management in Supply Chain Management: A Systematic Literature Review. Artif Intell Rev 2023, 56, 253–284. [Google Scholar] [CrossRef]

- Knemeyer, A.M. Logistics and Supply Chain Management: Creating Value-Adding Networks, Third Edition. Transportation Journal 2006, 45, 61–62. [Google Scholar] [CrossRef]

- Aristi Capetillo, A.; Bauer, F.; Chaminade, C. Emerging Technologies Supporting the Transition to a Circular Economy in the Plastic Materials Value Chain. Circular Economy and Sustainability 2023, 3, 953–982. [Google Scholar] [CrossRef]

- Schulte, U. Circular Systems Transitions: Industrial Models, Traceability Strategies, and Policy Stability; Springer Nature: Berlin, 2024. [Google Scholar]

- Galan-Sanchez, L.; Dittrich, C.; van Zijl, A.; Housmans, T.; Soliman, M.; Kuijpers, F. Chemical Recycling of Mixed Plastic Waste for the Production of Aromatics and Olefins as Monomers for Circular Polyolefins and Polycarbonate. SABIC TRUCIRCLE TM (Case Study). In Industrial Arene Chemistry; Wiley, 2023; pp. 2143–2162. [Google Scholar]

- Batlles-de-la-Fuente, A.; Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Abad-Segura, E. Research Trends of the Management of Solid Waste in the Context of Circular Economy. In Handbook of Solid Waste Management; Springer Nature Singapore: Singapore, 2022; pp. 37–68. [Google Scholar]

- Frączak, D. Chemical Recycling of Polyolefins (PE, PP): Modern Technologies and Products. In Waste Material Recycling in the Circular Economy - Challenges and Developments; IntechOpen, 2022. [Google Scholar]

- Samitthiwetcharong, S.; Kullavanijaya, P.; Suwanteep, K.; Chavalparit, O. Towards Sustainability through the Circular Economy of Plastic Packaging Waste Management in Rayong Province, Thailand. J Mater Cycles Waste Manag 2023, 25, 1824–1840. [Google Scholar] [CrossRef] [PubMed]

- Gutberlet, J.; Carenzo, S. Waste Pickers at the Heart of the Circular Economy: A Perspective of Inclusive Recycling from the Global South. Worldwide Waste 2020, 3, 6. [Google Scholar] [CrossRef]

- Chaiya, C.; Pinthong, P. Integrating Environmental and Socioeconomic Factors for a Sustainable Circular Economy in Thailand. Sustainability 2024, 16, 10748. [Google Scholar] [CrossRef]

- Phuang, Z.X.; Mulya, K.S.; Hoy, Z.X.; Woon, K.S. Moving towards Plastic Waste Circularity: Redefining Extended Producer Responsibility with Externality Consideration via P-Graph-Life Cycle Optimization Framework. Resour Conserv Recycl 2023, 198, 107187. [Google Scholar] [CrossRef]

- Rau, H.; Bisnar, A.R.; Velasco, J.P. Physical Responsibility Versus Financial Responsibility of Producers for E-Wastes. Sustainability 2020, 12, 4037. [Google Scholar] [CrossRef]

- Fiore, E.; Tamborrini, P. PHOENIX: Towards a Circular Economy of Plasmix Waste—A Systemic Design Approach. Circular Economy 2024, 3, 100075. [Google Scholar] [CrossRef]

- Zilia, F.; Andreottola, F.G.; Orsi, L.; Parolini, M.; Bacenetti, J. Trash or Treasure? A Circular Business Model of Recycling Plasmix. Circular Economy 2024, 3, 100089. [Google Scholar] [CrossRef]

- Berwald, A.; Dimitrova, G.; Feenstra, T.; Onnekink, J.; Peters, H.; Vyncke, G.; Ragaert, K. Design for Circularity Guidelines for the EEE Sector. Sustainability 2021, 13, 3923. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. J Ind Ecol 2019, 23, 156–168. [Google Scholar] [CrossRef]

- Gracida-Alvarez, U.R.; Xu, H.; Benavides, P.T.; Wang, M.; Hawkins, T.R. Circular Economy Sustainability Analysis Framework for Plastics: Application for Poly(Ethylene Terephthalate) (PET). ACS Sustain Chem Eng 2023, 11, 514–524. [Google Scholar] [CrossRef]

- Emmanuel, K.M. Circular Economy Approaches for Plastic Waste Management in Africa: Opportunities and Challenges. RESEARCH INVENTION JOURNAL OF ENGINEERING AND PHYSICAL SCIENCES 2025, 4, 1–6. [Google Scholar] [CrossRef]

- Nyam, T.T.; Ayeleru, O.O.; Ramatsa, Ishmael Matala; Olubambi1, P.A. Management Strategies for Plastic Wastes: A Roadmap Toward Circular Economy and Environmental Sustainability. In Plastic Waste Management; Wiley, 2024; pp. 31–54. [Google Scholar]

- Hapeman, P.; Fugh, A.; Falk, E.; Case, R.; Yeatter, D.; Balasubramanian, G.; Mehta, K. Community Approaches To Recycling Plastics. In Proceedings of the 2019 IEEE Global Humanitarian Technology Conference (GHTC), October 2019; IEEE; pp. 1–7. [Google Scholar]

- Velis, C.A.; Hardesty, B.D.; Cottom, J.W.; Wilcox, C. Enabling the Informal Recycling Sector to Prevent Plastic Pollution and Deliver an Inclusive Circular Economy. Environ Sci Policy 2022, 138, 20–25. [Google Scholar] [CrossRef]

- FEMSA Alpla Und Coca-Cola Femsa Bauen Eine Neue Recyclinganlage in Mexiko. CIRCULAR ECONOMY 2024, 43, 18–18. [CrossRef]

- Reyes Arzola, E. 5S Para El Acopio y Reciclaje Del PET En Instalaciones Públicas y Privadas En México. Ciencia Latina Revista Científica Multidisciplinar 2022, 6, 2432–2447. [Google Scholar] [CrossRef]

- Rutkowski, E.W.; Velis, C.A. Systems Analysis of Packaging HDPE Plastic Recycling Chain – an Informal Sector Circular Economy Case in Brazil; Stakeholder Dynamics, Material Quality, Rejects and Value Appropriation: Global South, 2024; Volume 138. [Google Scholar]

- Velis, C.A.; Hardesty, B.D.; Cottom, J.W.; Wilcox, C. Enabling the Informal Recycling Sector to Prevent Plastic Pollution and Deliver an Inclusive Circular Economy. Environ Sci Policy 2022, 138, 20–25. [Google Scholar] [CrossRef]

- Campelo, A.; Silva, J. LOGÍSTICA REVERSA DE EMBALAGENS PÓS-CONSUMO: IMPACTOS AO MEIO AMBIENTE. Revista VOX METROPOLITANA 2024, 140, 106–121. [Google Scholar] [CrossRef]

- Silva, U.; Baigorrotegui, G. The Chilean Regulation of Waste Electrical and Electronic Equipment (WEEE): Some of the Challenges and Opportunities to Incorporate Informal E-Waste Recyclers. In Handbook of Electronic Waste Management; Elsevier, 2020; pp. 517–531. [Google Scholar]

- Sekhri, P. Harvesting the Plastic We Have Sowed: Costs and Challenges in, and a Novel Application of Blockchain for Implementing Extended Producer Responsibility in Chile. In MASSACHUSETTS INSTITUTE; 2018; Volume 142. [Google Scholar]

- Estache, A.; Serebrisky, T. Updating Infrastructure Regulation for the 21st Century in Latin America and the Caribbean; 2020. [Google Scholar]

- Navarro Jiménez, A. Overcoming Waste Management Challenges in Costa Rica: Evaluating Practices, Government Initiatives, and Future Strategies. Preprints.org 2024. [Google Scholar]

| Mechanical | Chemical | Biological |

|---|---|---|

| Extrusion process Compatibilization Thermal stabilizaction |

Pyrolysis, solvolysis Gasification |

Enzymatic hydrolysis Microbial conversion |

| Catalytic cracking | Chemo-bio hybrids | |

| Optimization by: Screw profile Residence time Real-time ML |

Optimization by: Catalysis formulation Kinetic control Energy integration |

Optimization by: Enzyme affinity Crystallinity reduction Pathway redesign |

| Key contrainsts: Degradation Propetier loss |

Key contrainsts: | Key contrainsts: |

| High energy | Slow kinetics | |

| Complex mixtures | Lack of datasets | |

| Typical outputs: Regranulate |

Typical outputs: | Typical outputs: |

| Monomers/hydrocarbons | Monomers/intermediates | |

| ⇓ | ||

| Decision-support point (TEA+LAC+IA-based yield prediction) ⇓ Maximized circular value |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).