1. Introduction

Nickel-Titanium (NiTi) alloys are widely used in endodontic file systems due to their unique properties, such as superelasticity and shape memory [

1]. These properties allow NiTi files to navigate complex and curved root canal anatomies with greater ease compared to traditional stainless-steel files [

2]. The flexibility and durability of NiTi files reduce the risk of procedural errors such as ledge formation, transportation, and perforation, making them essential tools for effective root canal shaping [

3]. However, despite their advantageous features, NiTi files are susceptible to fracture within the root canal [

4].

Cyclic fatigue fracture occurs when a file experiences repeated tensile and compressive stresses as it rotates within a curved canal [

5]. This cyclic loading leads to the initiation and propagation of micro-cracks within the file structure, eventually causing fracture without significant plastic deformation [

6,

7]. The resistance of a file to cyclic fatigue is crucial because it directly impacts the instrument's durability and its ability to perform safe shaping during root canal treatments [

5,

8].

Meanwhile, the stresses during instrumentation by fatigue and/or torsion will crucially affect fracture resistance, especially when the files were repetitively used [

9,

10]. Related to the file size, the preloaded stress during the usage may result in different levels of stress-induced martensite (SIM) transformation, which may affect on the fatigue resistance of the files.

Manufacturers have continuously developed NiTi files with diverse designs and material properties to meet the evolving demands of endodontic treatments [

2,

11]. Advances in design have introduced variations in cross-sectional geometry and taper, optimizing file performance across varying canal anatomies [

9]. Additionally, heat treatment processes have been employed to modify the metallurgical properties of NiTi alloys, improving their flexibility and resistance to cyclic fatigue [

11,

12]. These combined advancements reflect the industry's commitment to creating durable and reliable instruments in clinical practice [

13].

Among the various NiTi file systems, the ProTaper Ultimate (PTUL; Dentsply Sirona, Ballaigues, Switzerland) represents an advanced evolution of previous systems like ProTaper Gold (Dentsply Sirona) and ProTaper Next (Dentsply Sirona) [

14]. Each file in the PTUL system undergoes a distinct heat treatment process engineered to enhance its performance, providing varying levels of flexibility and cyclic fatigue resistance [

15]. The system includes five specific files: Slider, Shaper, F1, F2, and F3, each designed to perform sequential tasks for optimal canal shaping and cleaning [

16].

Previous studies have shown that the cyclic fatigue resistance of NiTi files generally decreases with repeated use [

17,

18]. However, the rate of this decline varies significantly depending on the file’s design and the specific heat treatment it has undergone. In the PTUL system, these factors are especially crucial, as each file is uniquely engineered with distinct heat treatment properties that influence its performance under cyclic stress.

This study aimed to evaluate how repeated use affects the cyclic fatigue resistance of each file in the PTUL system. The null hypothesis is that there will be no significant difference in the reduction of cyclic fatigue resistance based on the number of artificial resin blocks shaped.

2. Materials and Methods

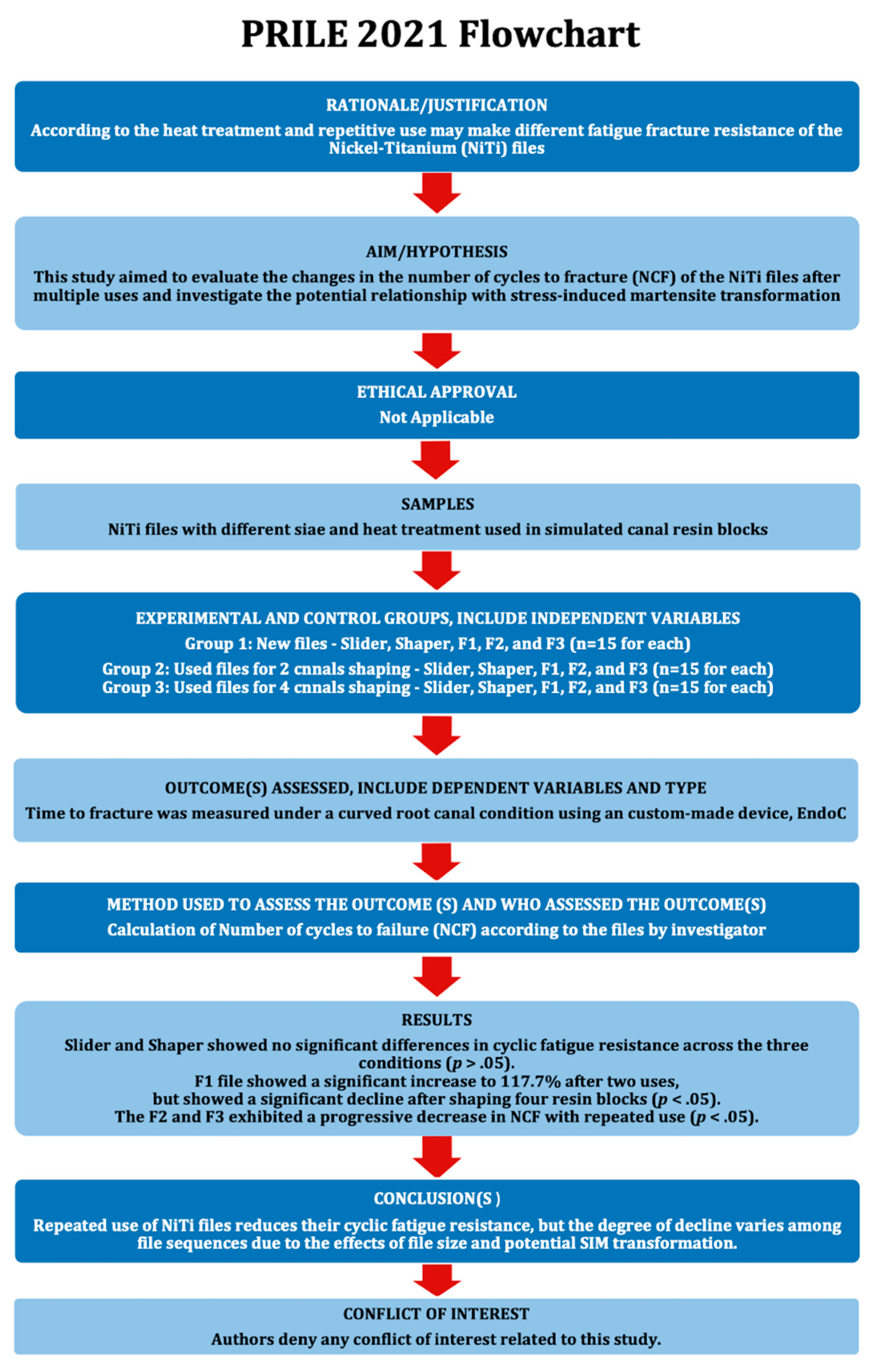

The manuscript of this laboratory study has been written and reported according to Preferred Reporting Items for Laboratory studies in Endodontology (PRILE) 2021 guidelines (

Figure 1).

2.1. Group Designation and Mechanical Loading

A total of 225 PTUL files were used in this study, allocated into three distinct groups to investigate the effects of repeated use on cyclic fatigue resistance. Each group comprised 15 files of each type (Slider, Shaper, F1, F2, and F3). Normality assumptions are commonly met in similar studies, and previous research employing fatigue resistance testing of rotary instruments has used comparable sample sizes (typically 10-15 specimens per group). This sample size is also sufficient to perform parametric statistical analyses, including variance and comparative assessments [

19].

Group 1 consisted of unused files tested in their new state, serving as the baseline for comparison. Group 2 files were used to prepare two simulated resin blocks standardized with a 16 mm long J-shaped canal and 35° curvature (Dentsply Sirona), while Group 3 files underwent shaping in four simulated resin block canals.

The shaping procedure began with the establishment of canal patency using a #10 K-file (Mani, Inc., Tochigi, Japan). Once patency was achieved, PTUL files were used sequentially, starting with the Slider, followed by the Shaper, F1, F2, and finally F3. Instrumentation was performed by a 3-year experienced postgraduate student using a 3 mm pecking motion. After every three pecks, the file was withdrawn to remove debris and irrigate the canal with saline solution. This cycle was repeated until a total of six pecks were completed, ensuring the file reached the full working length of 16 mm.

2.2. Cyclic Fatigue Test

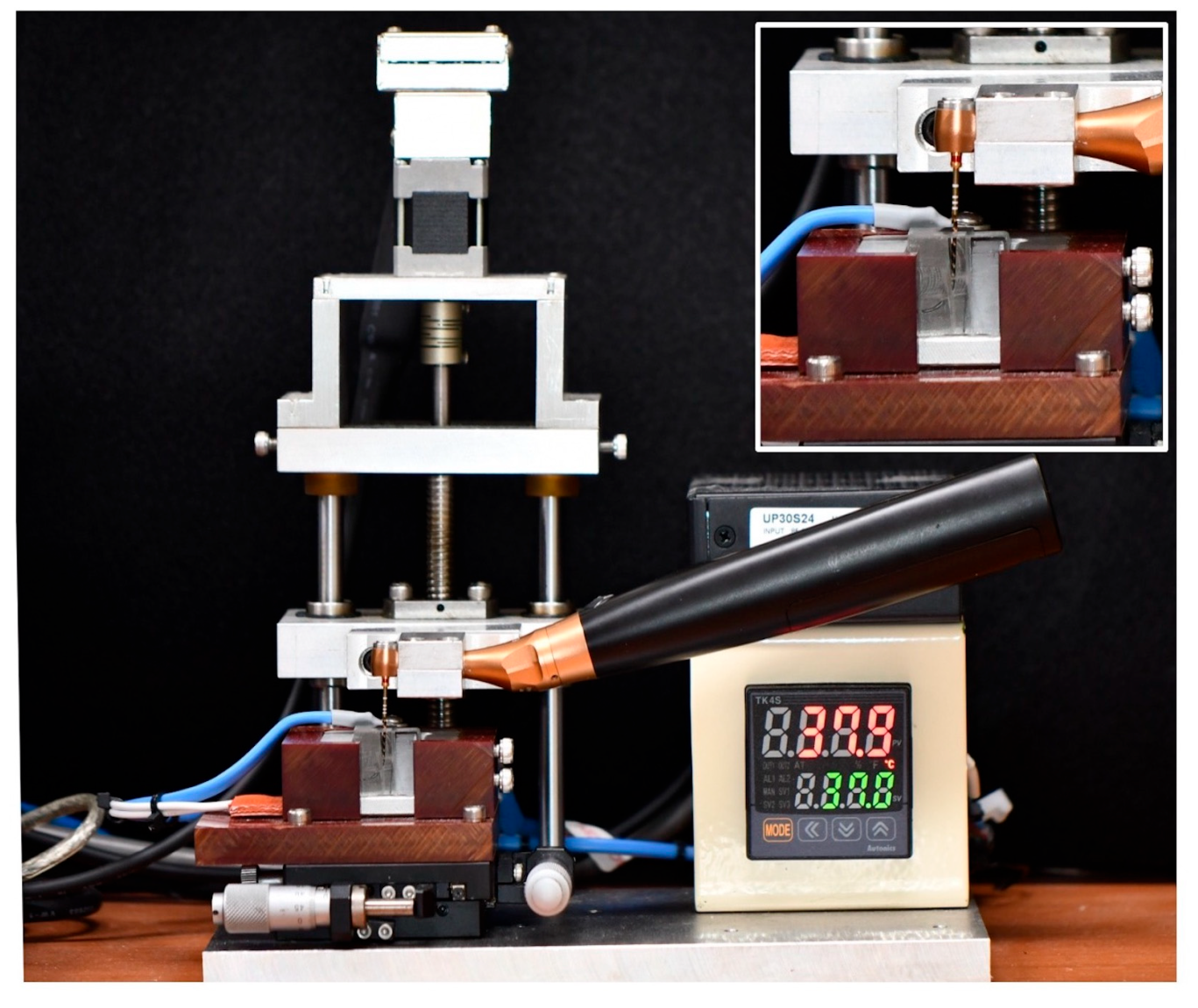

After the shaping procedures, cyclic fatigue tests were performed on all files using a custom-made device, EndoC (DMJ System, Busan, South Korea), designed to simulate the rotational motion within a curved canal environment (

Figure 2). According to the method of Schnieder, an artificial canal model made of tempered steel was used, with a 0.6 mm apical diameter, a 35° curvature, and a 6.06 mm radius [

20]. The files were rotated at 400 rpm with a maximum torque of 4.0 Ncm using an endodontic motor (Ai-Motor; Guilin Woodpecker Medical Instrument Co., Ltd, Guilin, China) and were subjected to continuous up-and-down pecking movement (4 mm in each direction at 0.5-second intervals). All procedures were performed at body temperature (37° C) controlled by an electronic heat controller (TK4N/S/SP Autonics, Busan, Korea). The time to fracture was recorded, and the number of cycles to failure (NCF) was calculated by multiplying the recorded time by the rotational speed (rpm).

2.3. Statistical Analysis

The normality of the data was assessed using the Shapiro–Wilk test, and homogeneity of variances was evaluated with Levene’s test. Based on these results, either one-way analysis of variance (ANOVA) or the Kruskal–Wallis test was applied to compare the cyclic fatigue resistance across groups (α = 0.05). One-way ANOVA followed by Tukey’s post hoc test was used for the Slider, Shaper, and F2 files, as both normality and homogeneity of variances were satisfied. In contrast, the Kruskal–Wallis test followed by Dunn’s post-hoc test with Bonferroni correction was performed for the F1 and F3 files due to violation of statistical assumptions.

3. Results

The NCF for each file type under different usage conditions is presented in

Table 1.

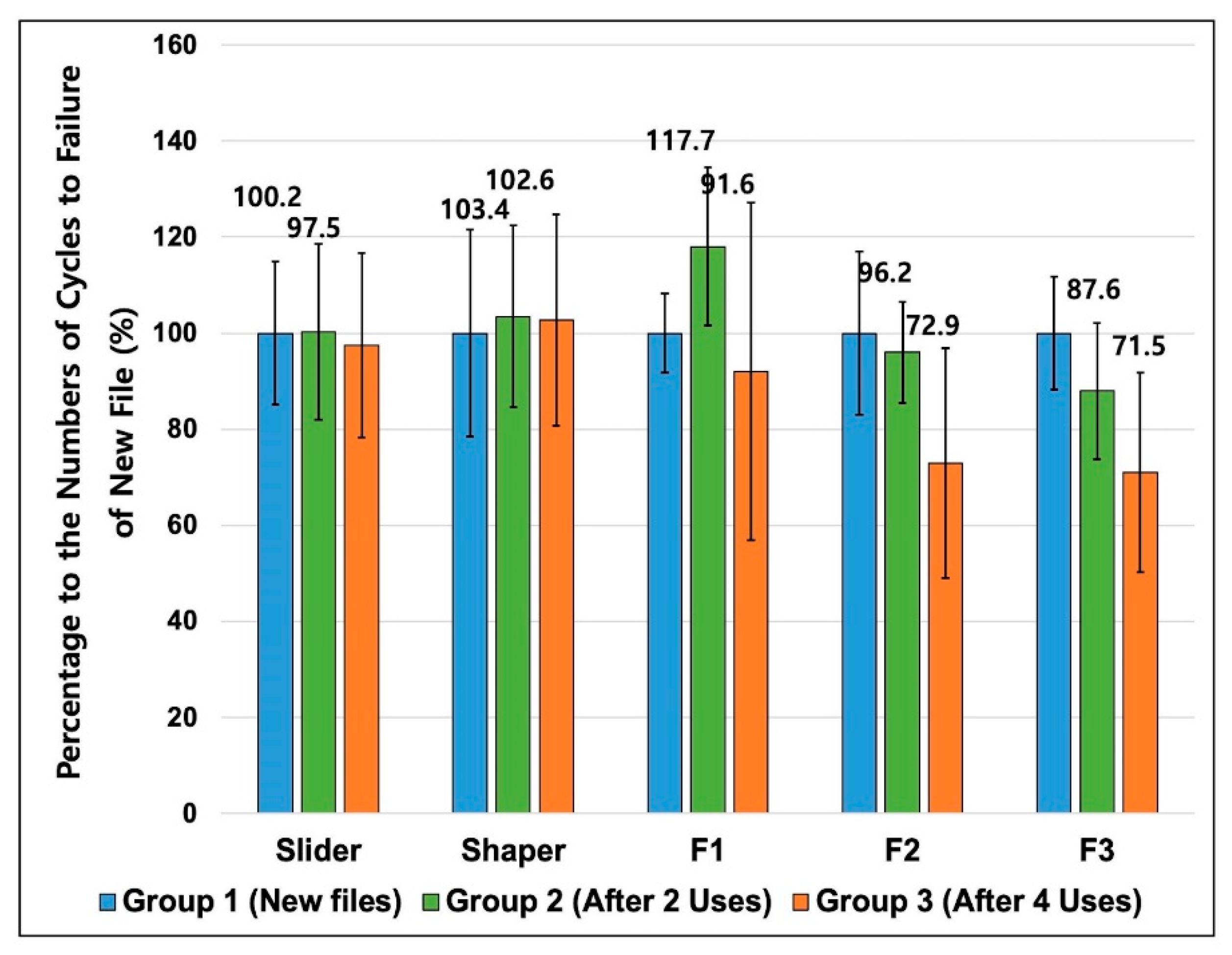

Figure 3 quantifies the changes in NCF according to the number of canals instrumented, relative to the new file (set as 100%).

The Slider and Shaper files showed no statistically significant differences in cyclic fatigue resistance across the three conditions (p > 0.05). The NCF value of the Slider remained approximately at 100% without significant reduction as 100.2% and 97.5% after two uses and four uses, respectively. The Shaper file exhibited a similar tendency with the Slider in the NCF, with the ratios of 103.4% after two uses and 102.6% after four uses compared to the new file.

In contrast, for the F1 file showed a statistically significant increase to 117.7% after two uses, but showed a statistically significant decline after shaping four resin blocks (p < 0.05). After four uses, the NCF decreased to 91.6%.

The F2 and F3 files exhibited a progressive decrease in NCF with repeated use (p < 0.05). The F2 file showed a reduction in NCF to 96.2% after two uses and to 72.9% after four uses, while the F3 file decreased to 87.6% after two uses and to 71.5% after four uses. The F3 file exhibited the most pronounced reduction in cyclic fatigue resistance, with significant differences between all three groups conditions (p < 0.05).

4. Discussion

Stress-induced martensite (SIM) transformation in NiTi alloys occurs when mechanical stress promotes the conversion of the austenitic phase into martensite [

10,

12]. This transformation can alter the mechanical behavior of the alloy and influence its fatigue resistance [

9]. Previous studies have demonstrated that NiTi instruments subjected to torsional loading exhibited increased cyclic fatigue resistance, which was attributed to SIM transformation [

9,

10]. Therefore, the mechanical stresses applied during repeated use may not only accumulate fatigue damage but also temporarily enhance fracture resistance through SIM transformation. Furthermore, since the phase transformation behavior and mechanical performance of NiTi files are influenced by the type of heat treatment applied during manufacturing, the potential interaction between SIM transformation and heat treatment should be considered when interpreting the fatigue behavior of different file types. Therefore, this study investigated whether SIM transformation induced by repeated use could affect their cyclic fatigue resistance.

The recently developed PTUL system incorporates various types of alloys within a single sequence and features a slender shaft (1.1 mm diameter) design for minimally invasive endodontic treatment [

16,

21]. The Slider is made of M-Wire, exhibiting an austenitic plus R-phase arrangement, while the Shaper and finishing files (F1-F3) are produced with Gold-wire, showing martensitic behavior with superior flexibility and fatigue resistance. The fatigue resistance of the files may vary depending on the type of alloy used [

22]. The previous studies have shown that heat-treated NiTi alloys such as Gold- and Blue-wire instruments demonstrated superior flexibility and cyclic fatigue resistance but reduced torsional strength compared with conventional austenitic alloys [

23,

24].

Despite the Slider file exhibiting an austenite finish (A

f) temperature above body temperature, its martensite peak temperature lies below body temperature, allowing the instrument to exhibit superelastic behavior under clinical [

16,

25]. While superelastic files generally exhibit lower NCF values compared to heat-treated files, the Slider demonstrated the highest NCF among the files tested in this study. Moreover, the NCF of the Slider remained at around 100% without significant reduction even after two and four times of reuses. These findings are consistent with previous studies indicating that NiTi files with smaller diameters and/or reduced cross-sectional volume show less decrease in NCF [

19,

26].

The Shaper file is made of Gold-wire alloy, and its A

f temperature is higher than body temperature, which contributes to its enhanced resistance to cyclic fatigue [

23]. In this study, although it was not statistically significant, the Shaper file exhibited a slight increase in the NCF, with higher values than 100% of the baseline value. This phenomenon may be attributed to the high fracture resistance conferred by the Gold-wire alloy [

24].

The F1 file, also made of Gold-wire, exhibited a different pattern of NCF changes changing with repeated use. Interestingly, the F1 file exhibited a distinct pattern compared with other instruments, showing a significant increase in NCF to 117.7% of the value of the new file after two uses. This temporary improvement may result from torsional pre-loading during canal shaping, which could enhance cyclic fatigue resistance through stress-induced martensite (SIM) transformation [

9,

10]. During the initial uses, torsional preloading could have promoted a partial transformation of the alloy from austenite to martensite, thereby enhancing the cyclic fatigue resistance. However, with repeated use, the accumulation of microstructural defects and microcracks likely counteracted this benefit. After four uses, the NCF decreased to 91.6% of the baseline, although the difference between Groups 1 and 3 was not significant. While the F1 file experienced a certain amount of torsional loading during canal preparation to induce SIM transformation, the Slider and Shaper may have not reached the stress threshold required to trigger SIM transformation, which could explain the absence of significant changes in their fatigue resistance.

However, the F2 and F3 files exhibited a progressive decrease in NCF with repeated shaping. It may implicate that the lager file could not have the SIM transformation effect further. The larger diameters or metal volumes of these files may have naturally reduced their flexibility, thereby diminishing the benefits of torsional pre-loading. Consequently, the F3 file showed a more pronounced decrease in NCF than the F1 or F2 files.

Manufacturers typically recommend single use of files; however, in many countries, files are sterilized and reused after endodontic treatment. Repeated use of files increases the risk of intracanal fracture, necessitating caution among clinicians [

27]. Understanding how cyclic fatigue changes with repeated use could help clinicians limit file reuse and mitigate fracture risks. Findings suggest that the Slider and Shaper files exhibit minimal changes in NCF even with multiple uses, while files with larger diameters show a significant decrease in NCF. Despite heat treatment, which is known to improve cyclic fatigue resistance, the reduction in NCF was more pronounced in larger diameter files than in the Slider. This indicates that file diameter may have a more substantial impact on cyclic fatigue resistance than heat treatment.

This study was conducted using artificial resin blocks with standardized canal shapes and curvatures to simulate clinical conditions. While this approach provides reproducibility, it does not fully reflect the variability and complexity of natural root canals. Additionally, the rotational force and pecking depth applied during the cyclic fatigue test may not fully represent the dynamic forces experienced in clinical settings. Although smaller instruments, such as the Slider and Shaper, showed no statistically significant reduction in cyclic fatigue under the present conditions, this should not be interpreted as evidence of clinical safety with repeated reuse, as the absence of significant changes may simply reflect insufficient fatigue accumulation; therefore, further investigations are required to clarify their behavior under more clinically relevant scenarios.

Future studies are required to investigate the behavior of PTUL files in natural teeth with varying canal morphologies and curvatures to better reflect clinical scenarios. Furthermore, the influence of other factors such as torsional fatigue, sterilization processes, and prolonged use on file performance should be explored. Especially, the SIM transformation should be evaluated in terms of NiTi phase composition through a way of metallurgical study. Although the present study did not provide direct evidence of stress-induced martensitic transformation, future investigations employing high-magnification microscopic or metallurgical analyses are expected to clarify its occurrence and role in file performance. Comparative studies involving other commercially available file systems could also provide a broader perspective on the clinical utility and limitations of PTUL files.

5. Conclusions

Within the repeated use of NiTi files reduces their cyclic fatigue resistance, but the degree of decline varies among file sequences due to the effects of size and potential SIM transformation. Clinicians should consider both mechanical and metallurgical factors to establish individualized usage protocols for each file to minimize the risk of fractures during endodontic procedures.

Author Contributions

Conceptualization, H.-C.K. and S.W.K.; Methodology, H.-C.K.; Validation, J.-H.H. and A.S.; Investigation, H.J. and S.W.K.; Resources, H.-C.K.; Data curation, H.J. and S.W.K.; Writing—original draft, H.J.; Writing—review and editing, A.S. and H.-C.K.; Visualization, H.J. and and H.-C.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a 2-Year Research Grant of Pusan National University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors deny any conflicts of interest.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| NCF |

the number of cycles to fracture |

| NiTi |

nickel–titanium |

| PTUL |

ProTaper Ultimate |

| SIM |

stress-induced martensite |

References

- Walia, H.M.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: a review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef] [PubMed]

- Kum, K.Y.; Spängberg, L.S.; Cha, B.Y.; Jung, I.Y.; Lee, S.J.; Lee, C.Y. Shaping ability of three ProFile rotary instrumentation techniques in simulated resin root canals. J. Endod. 2000, 26, 719–723. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef]

- Pirani, C.; Cirulli, P.P.; Chersoni, S.; Micele, L.; Ruggeri, O.; Prati, C. Cyclic fatigue testing and metallographic analysis of nickel-titanium rotary instruments. J. Endod. 2011, 37, 1013–1016. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.; Barbosa, I.; Scelza, P.; Russano, D.; Neff, J.; Montagnana, M.; Zaccaro Scelza, M. A new method for the assessment of the surface topography of NiTi rotary instruments. Int. Endod. J. 2017, 50, 902–909. [Google Scholar] [CrossRef]

- Jo, H.; Kwak, S.W.; Sigurdsson, A.; Kim, H.C. Correlation Between Fibrous Area Ratio and Numbers of Cycles to Fracture Resistances of Nickel-Titanium Files. J. Endod. 2025, 51, 622–626. [Google Scholar] [CrossRef]

- Capar, I.D.; Ertas, H.; Arslan, H. Comparison of cyclic fatigue resistance of novel nickel-titanium rotary instruments. Aust. Endod. J. 2015, 41, 24–28. [Google Scholar] [CrossRef]

- Cheung, G.S.; Oh, S.H.; Ha, J.H.; Kim, S.K.; Park, S.H.; Kim, H.C. Effect of torsional loading of nickel-titanium instruments on cyclic fatigue resistance. J. Endod. 2013, 39, 1593–1597. [Google Scholar] [CrossRef]

- Ha, J.H.; Kim, S.K.; Cheung, G.S.; Jeong, S.H.; Bae, Y.C.; Kim, H.C. Effect of alloy type on the life-time of torsion-preloaded nickel-titanium endodontic instruments. Scanning 2015, 37, 172–178. [Google Scholar] [CrossRef]

- Chan, W.S.; Gulati, K.; Peters, O.A. Advancing Nitinol: From heat treatment to surface functionalization for nickel-titanium (NiTi) instruments in endodontics. Bioact. Mater. 2022, 22, 91–111. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef]

- Haapasalo, M.; Shen, Y. Evolution of nickel-titanium instruments: from past to future. Endod. Top. 2013, 29, 3–17. [Google Scholar] [CrossRef]

- Ibrahim, H.A.; Ali, A.H.; Mannocci, F. Assessment of Debris Apical Extrusion, Unprepared Surface Areas, and Dentinal Crack Formation after Root Canal Preparation Using ProTaper Next, ProTaper Ultimate, and R-Motion File Systems. J. Endod. 2025, 51, 200–206. [Google Scholar] [CrossRef]

- Martins, J.N.R.; Silva, E.J.N.L.; Vieira, V.T L.; Pereira da Costa, R.; Baruwa, A.O.; Fernandes, F.M.B.; Versiani, M.A. A Comparative Analysis of ProTaper Ultimate and Five Multifile Systems: Design, Metallurgy, and Mechanical Performance. Materials 2025, 18, 1260. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.N.R.; Silva, E.J.N.L.; Marques, D.; Ajuz, N.; Rito Pereira, M.; Pereira da Costa, R.; Braz Fernandes, F M.; Versiani, M.A. Characterization of the file-specific heat-treated ProTaper Ultimate rotary system. Int. Endod. J. 2023, 56, 530–542. [Google Scholar] [CrossRef]

- Serefoglu, B.; Miçooğulları Kurt, S.; Kaval, M.E.; Güneri, P.; Kandemir Demirci, G.; Çalışkan, M.K. Cyclic Fatigue Resistance of Multiused Reciproc Blue Instruments during Retreatment Procedure. J. Endod. 2020, 46, 277–282. [Google Scholar] [CrossRef]

- El Abed, R.; Al Raeesi, D.; Alshehhi, A.; Alkhatib, Z.; Khamis, A.H.; Jamal, M.; Kim, H.C. Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel-Titanium Rotary Files. Materials 2023, 16, 2261. [Google Scholar] [CrossRef]

- Kang, Y.J.; Kwak, S.W.; Ha, J.H.; Gambarini, G.; Kim, H.C. Fracture resistances of heat-treated nickel-titanium files used for minimally invasive instrumentation. BMC Oral Health 2025, 25, 126. [Google Scholar] [CrossRef]

- Schneider, S.W. A comparison of canal preparations in straight and curved root canals. Oral Surg. Oral Med. Oral Pathol. 1971, 32, 271–275. [Google Scholar] [CrossRef]

- Ribeiro, G.; Martin, V.; Rodrigues, C.; Gomes, P. Comparative Evaluation of the Canal Shaping Ability, Pericervical Dentin Preservation, and Smear Layer Removal of TruNatomy, WaveOne Gold, and ProTaper Ultimate-An Ex Vivo Study in Human Teeth. J. Endod. 2023, 49, 1733–1738. [Google Scholar] [CrossRef] [PubMed]

- Abdellatif, D.; Iandolo, A.; Scorziello, M.; Sangiovanni, G.; Pisano, M. Cyclic Fatigue of Different Ni-Ti Endodontic Rotary File Alloys: A Comprehensive Review. Bioengineering 2024, 11, 499. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Mercadé Bellido, M.; Testarelli, L.; Gambarini, G. Influence of Temperature on Cyclic Fatigue Resistance of ProTaper Gold and ProTaper Universal Rotary Files. J. Endod. 2017, 43, 200–202. [Google Scholar] [CrossRef] [PubMed]

- Uygun, A.D.; Kol, E.; Topcu, M.K.; Seckin, F.; Ersoy, I.; Tanriver, M. Variations in cyclic fatigue resistance among ProTaper Gold, ProTaper Next and ProTaper Universal instruments at different levels. Int. Endod. J. 2016, 49, 494–499. [Google Scholar] [CrossRef]

- Song, J.; Jang, J.H.; Chang, S.W.; Chung, S.H.; Oh, S. Comparison of mechanical properties and shaping performance of ProGlider and ProTaper ultimate slider. BMC Oral Health 2025, 25, 59. [Google Scholar] [CrossRef]

- Yao, J.H.; Schwartz, S.A.; Beeson, T.J. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J. Endod. 2006, 32, 55–57. [Google Scholar] [CrossRef]

- Bird, D.C.; Chambers, D.; Peters, O.A. Usage parameters of nickel-titanium rotary instruments: a survey of endodontists in the United States. J. Endod. 2009, 35, 1193–1197. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).