1. Introduction

The global pulp and paper industry is under increasing pressure to shift toward sustainable and renewable feedstocks, motivated by the depletion of forest resources, the environmental burden of conventional chemical pulping, and the broader transition toward a circular bioeconomy [

1,

2,

3,

4]. Non-wood raw materials, particularly agricultural residues, have emerged as promising alternatives due to their annual renewability, low cost, and regional availability in countries with limited forested areas. In Asia, particularly in China and India, non-wood materials already account for nearly 70% of the raw materials used in pulp production [

2,

5].

Among such residues, lavender (

Lavandula officinalis) stands out as an underutilized crop waste. After harvesting for essential oil extraction, large quantities of woody stems remain as by-products, which are often disposed of by burning or composting. However, these stems are rich in lignocellulosic fibres that may serve as a potential raw material for paper production, thereby contributing to waste valorisation and the circular economy [

6,

7,

8,

9,

10].

Previous studies have explored the application of lavender essential oil in paper products, focusing on antibacterial and antifungal treatments [

11,

12,

13]. These studies reported that paper treated with lavender essential oil exhibited improved resistance to microbial deterioration and extended shelf life, suggesting that lavender’s bioactive compounds can add functional value to cellulose-based materials. However, few works have investigated lavender itself as a fibrous raw material for pulping and papermaking [

14,

15,

16].

This research addresses this gap by examining the chemical, mechanical, and physical properties of paper made from lavender stalks through nitrate–alkali pulping. This method has previously shown promising results for other non-wood sources such as black mustard and camelina [

17]. Furthermore, the study incorporates additional findings regarding the repellent properties of lavender-based paper, offering a broader perspective on its potential applications in functional materials and applied chemistry, such as protective packaging and archival conservation.

From a chemical perspective, the composition of lavender fibres—specifically the balance between cellulose, hemicellulose, and lignin—determines their pulping efficiency and paper quality. The moderate lignin content (approximately 20–24%) requires efficient delignification, while the cellulose fraction (around 29%) provides sufficient fibre strength for mechanical integrity. Compared to traditional wood pulps, lavender offers lower processing energy requirements and a reduced environmental impact due to its lower lignin and higher ash content, consistent with other annual plants such as wheat straw or corn stalks [

18,

19].

In addition to material properties, the repellent functionality of lavender-based paper introduces a unique chemical dimension. The residual essential oil components (linalool, linalyl acetate, camphor) exhibit volatile bioactivity that repels textile moths and other storage pests. These characteristic positions lavender pulp as a dual-purpose material—both structurally functional and chemically active—bridging the disciplines of materials science and applied organic chemistry.

The aim of this study was therefore twofold:

- i.

to produce nitrate–alkali pulp from lavender waste and evaluate the chemical and mechanical characteristics of the resulting papers; and

- ii.

to investigate their potential functional properties, especially insect-repellent activity, to assess the feasibility of lavender as a sustainable, multifunctional raw material for the paper industry

2. Materials and Methods

2.1. Raw Material

The raw material used in this study was secondary lavender biomass (Lavandula officinalis) obtained after harvesting the flowers for essential oil extraction. The material came from agricultural fields in the Central Bohemian Uplands of the Czech Republic, which is characterised by a temperate climate and calcareous soil. The lavender residues consisted mainly of woody stems stripped of flowers and leaves. The stems were air-dried to a constant moisture content of approximately 5% and then disintegrated into pieces approximately 1 cm in length prior to chemical processing.

Lavender was selected as a fibrous raw material due to its abundance as post-harvest secondary biomass, high cellulose content, and potential for utilising its bioactive components in functional paper applications. Its fibre morphology—fine, short fibres with relatively thin cell walls—suggests compatibility with wood-free pulp production techniques used for other herbaceous plants.

2.2. Chemical Composition Analysis

The chemical composition of lavender stems and flowers was determined according to TAPPI standards [

20]. Analyses were performed on air-dried samples, which were later oven-dried to determine moisture content and normalise all values to absolute dry weight.

The following standard methods were used:

All analyses were performed in triplicate, and average values with standard deviations were calculated. The results provided an overview of the chemical suitability of lavender for paper production, particularly in terms of the cellulose to lignin ratio and extract content.

2.3. Pulping Process

The pulping process used a nitrate-alkaline method, chosen for its proven effectiveness in delignifying non-wood fibres such as black mustard and camelina [

17]. Approximately 100 g of disintegrated lavender secondary material was placed in a laboratory vessel with a lye to material ratio of 10:1 (vol./wt.).

The pulping process consisted of two sequential stages:

Nitric acid cooking: The material was treated with a 6% nitric acid solution and cooked for 30 minutes, initiating oxidative delignification and partial decomposition of hemicelluloses.

Alkaline extraction: The nitric acid-treated pulp was then transferred to a sodium hydroxide (NaOH) bath for 10 minutes, dissolving the remaining lignin fragments and extracts.

After pulping, the material was thoroughly washed with distilled water, neutralised with 1% acetic acid, and separated by hand to remove uncooked residues. The Kappa number and pulp yield were determined to assess the degree of delignification and fibre quality.

The resulting pulp was ground and formed into sheets with a basis weight of 80, 100, and 120 g·m⁻² using a Rapid-Köthen forming machine. The sheets of paper were acclimatised at a temperature of 23 °C and a relative humidity of 50% for 24 hours prior to mechanical testing.

2.4. Mechanical and Physical Testing

The prepared paper sheets were tested for mechanical and physical properties using standardised methods:

Tensile strength: measured according to ČSN EN ISO 1924-2 [

24].

Burst index: determined according to ISO 2758:2014 [

25].

Air permeability: measured using the Gurley method by ISO 5636-5. [

26].

Each test was performed in ten repetitions, and the average values were calculated. In addition to mechanical tests, paper samples were observed under an optical microscope to assess fibre dispersion and bond quality.

2.5. Evaluation of Repellent Properties

To investigate the functional potential of lavender-based papers, repellent protection tests against textile moths (Tineola bisselliella) were conducted. Paper samples were placed in sealed glass chambers with three adult moths and stored for 14 days at a temperature of 25 °C and 60% relative humidity. A control sample made of pure linen paper was used for comparison.

Insect activity was recorded and quantified as the percentage of active insects near each type of paper. The presence of volatile compounds such as linalool, linalyl acetate, and camphor was thought to contribute to the repellent behaviour [

7,

27].

3. Results

3.1. Chemical Composition

The chemical composition of lavender stems and flowers is summarised in

Table 1.

The data show that lavender stalks contain 29.43% cellulose and 24.10% lignin, indicating moderate suitability for paper production. The relatively high ash content (~5%) reflects the mineral intake characteristics of annual plants. At the same time, the increased extracts, especially in the flowers, correspond to the presence of essential oils, flavonoids, and tannins. The difference between the stalks and blossoms suggests that only the stalks are suitable for pulp production.

3.2. Total Pulp Yield and Kappa Number

The nitrate-alkali method of pulping lavender stalks yielded 24.2% pulp with a Kappa number of 15.9 determined according to ČSN ISO 302 [

28]. The content of rejects (raw material) was minimal, only 0.28%, confirming effective delignification under the conditions used.

These results suggest that lavender stems, although woody, respond effectively to treatment with nitrates and alkalis and produce pulp with comparable yield and lignin removal levels to other herbaceous raw materials, such as black mustard and camelina, processed under similar conditions [

17].

3.3. Mechanical Properties

Mechanical and physical tests were performed on laboratory sheets with a basis weight of 80, 100, and 120 g·m⁻². The results are summarised in

Table 2.

Laboratory sheets with a weight of 80 g·m⁻² achieved the highest tensile index (16.76 N·m·g⁻¹) and breaking length (1.71 km). These values decreased with increasing weight per unit area, indicating that lighter sheets provided better fibre bonding and a more uniform structure.

Air permeability values (Gurley method) ranged between 1.8 and 3.9 s, indicating that higher basis weights resulted in denser and less porous papers, which could affect printing or surface properties.

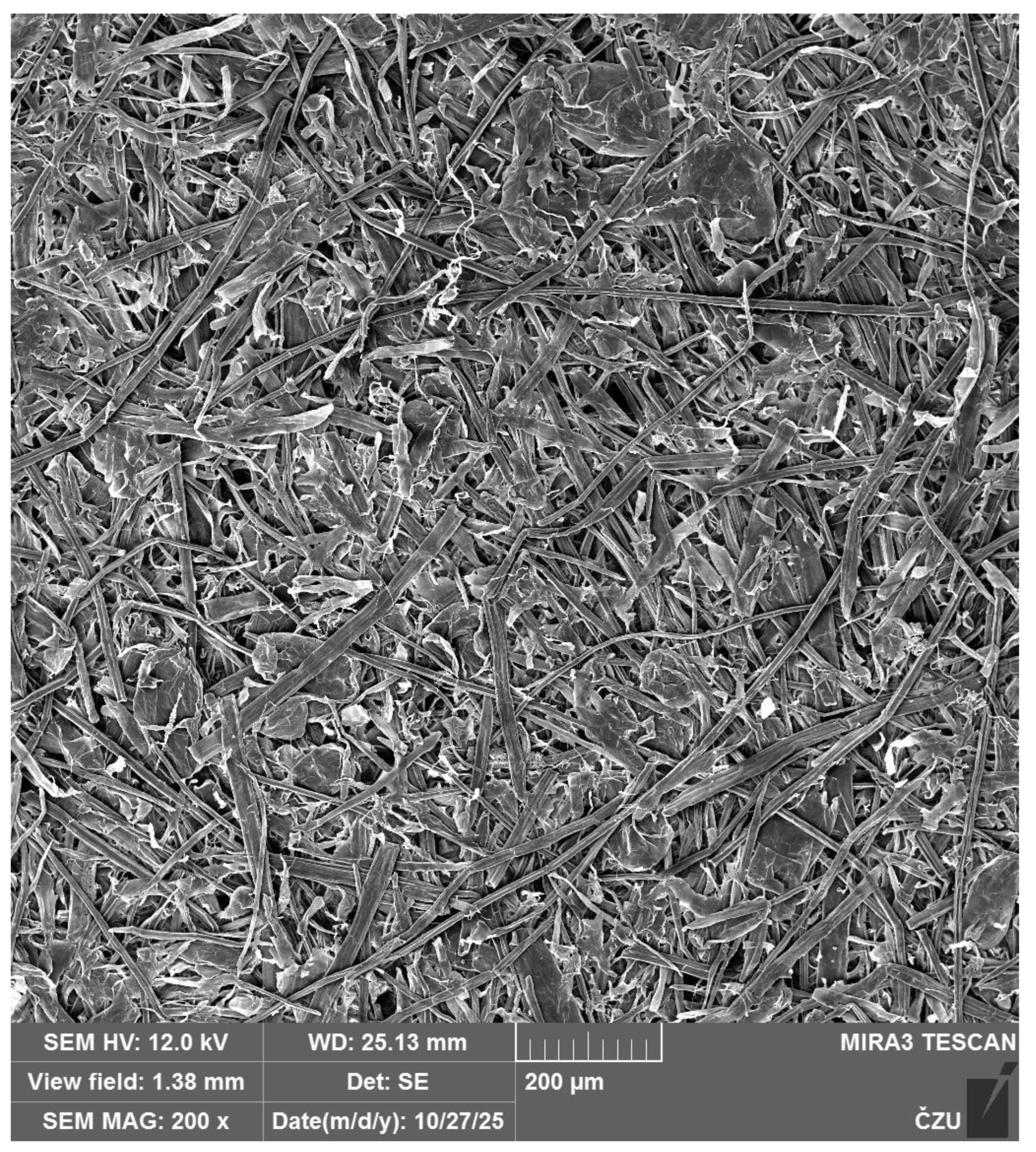

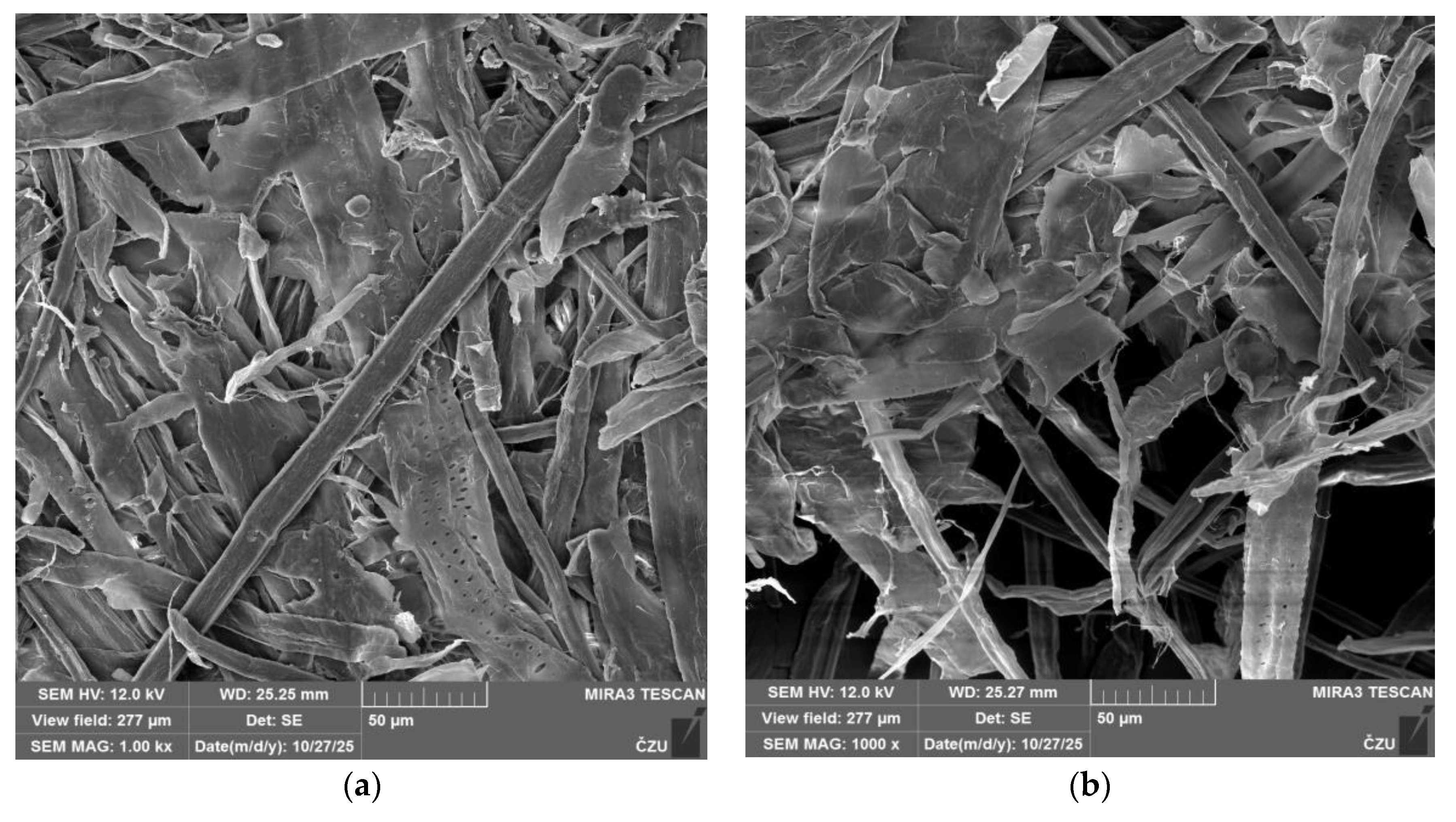

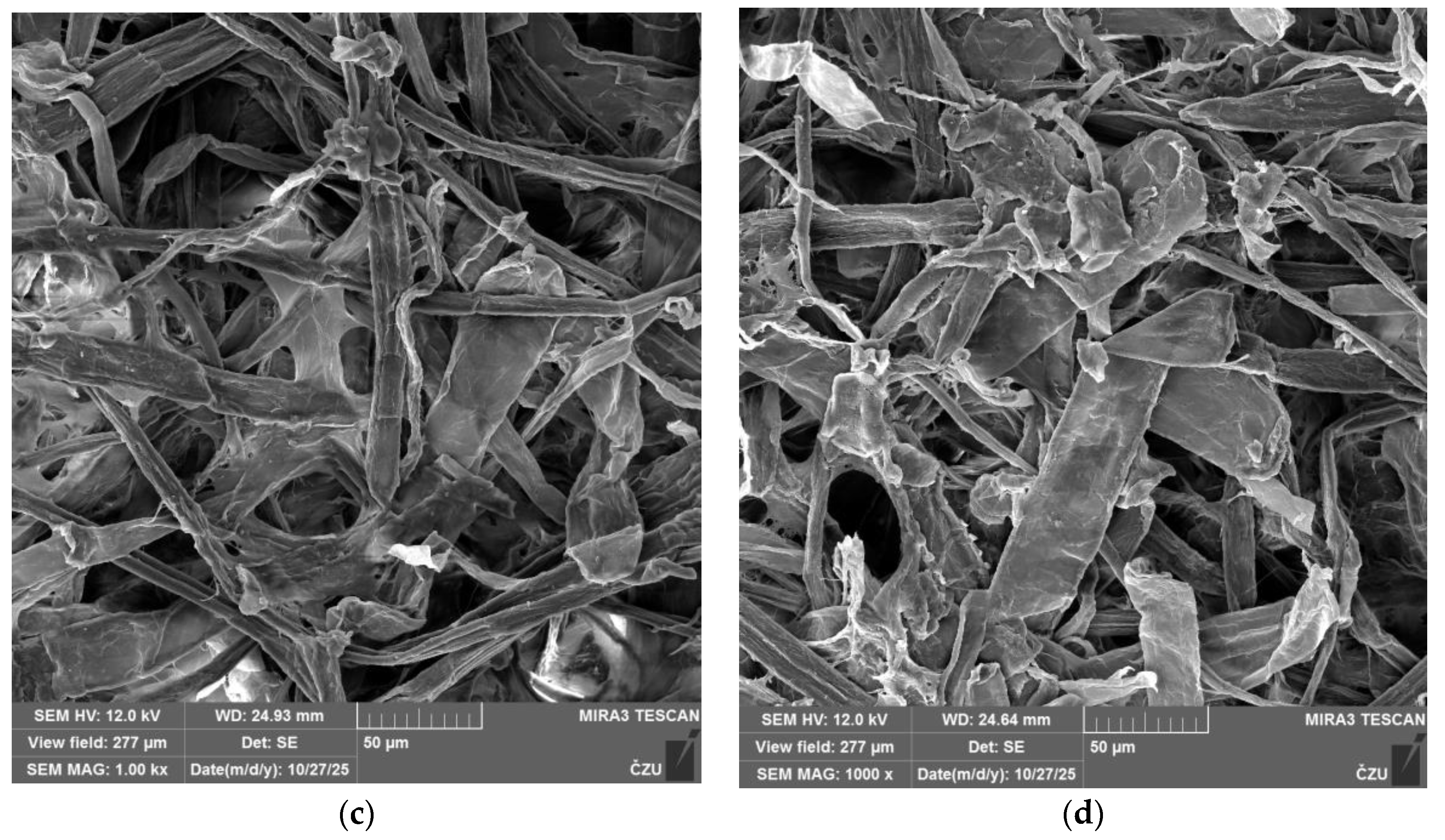

3.4. Physical Appearance and Fiber Morphology

Microscopic examination of lavender papers revealed well-connected fibres with a limited amount of fragments or unreacted particles. The fibres were relatively short and fine, which is typical for herbal raw materials. The 80 g·m⁻² sheet showed a more homogeneous surface structure, indicating better fibre distribution during sheet formation.

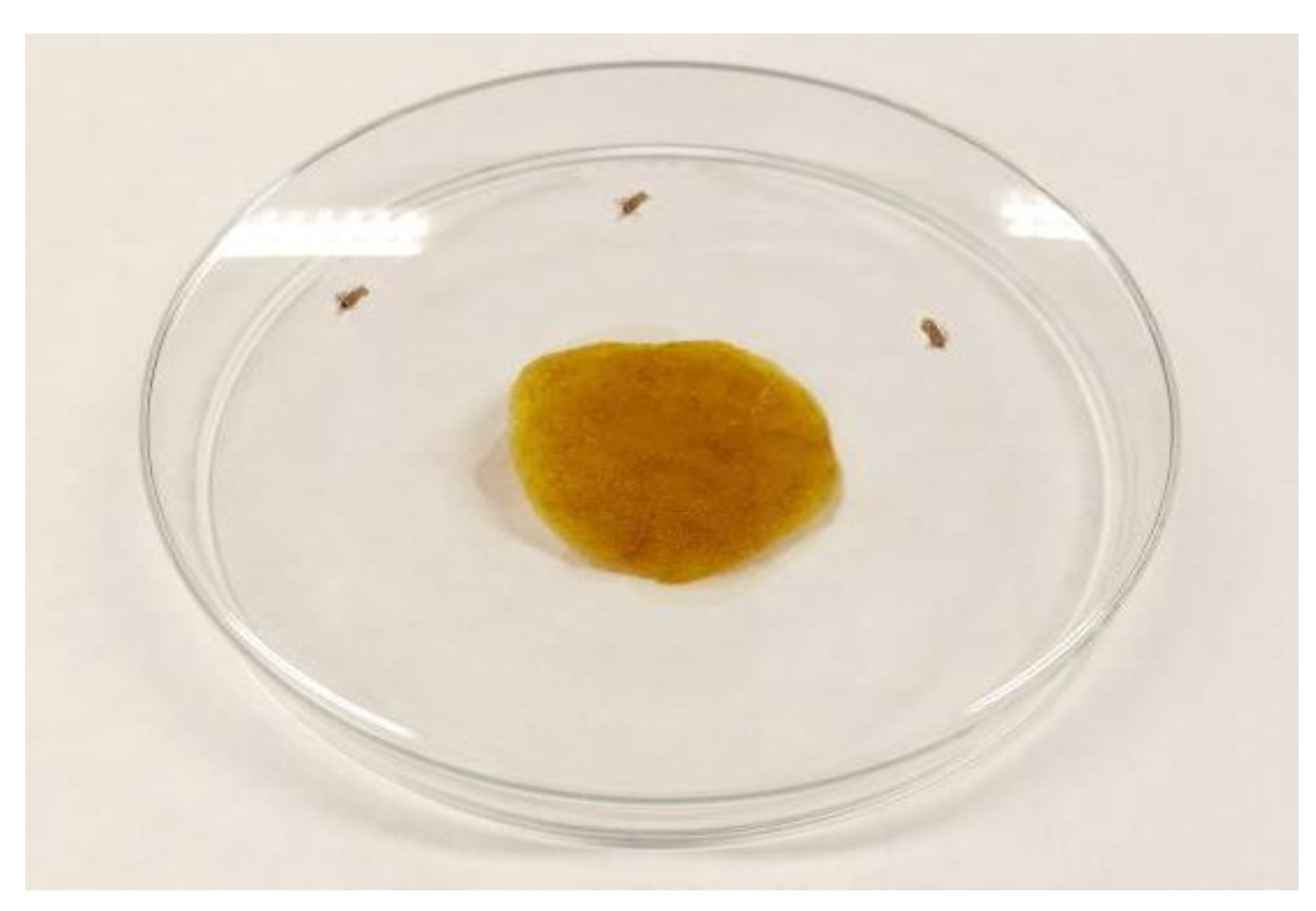

3.5. Repellent Properties

Repellent tests against clothes moths (Tineola bisselliella) showed that lavender-based paper exhibits significant natural insect repellent activity compared to control cellulose (flax) paper.

After 14 days of exposure, lavender paper reduced moth activity by approximately 70%, with a significant reduction in behaviour near lavender samples.

The effect was most substantial in samples made from sheets enriched with lavender flowers or with a percentage of lavender essential oil, probably due to higher residual concentrations of volatile organic compounds such as linalool, linalyl acetate, and camphor, which are known for their insect repellent properties [

7,

27].

Photographic documentation of the experiment is shown in

Figure 3, and the results are given in

Table 3.

4. Discussion

The chemical composition of lavender indicates a balanced lignocellulose profile, making it suitable for pulp production. The cellulose content in the stems is 29.43%, which, although lower than in typical woody plants such as birch (41%) or pine (47%) [

29], is comparable to other non-woody materials, including wheat straw (38%), rapeseed straw (37%), and sunflower stalks (36–38%) [

18,

30]. The relatively low lignin content (24.10%) facilitates delignification, reducing the need for aggressive chemical treatment. Lignin in lavender consists mainly of guaiacyl (G) and syringyl (S) units, characteristic of dicotyledonous plants, which are more susceptible to oxidative degradation during nitrate pulping. This may explain the low Kappa number (15.9) achieved after relatively mild conditions (30 minutes of nitric acid and 10 minutes of sodium hydroxide) compared to the higher values reported for cereal straw pulp (typically 20–30) [

19]. High ash and extract content is typical of herbaceous materials and is often associated with inorganic salts (K, Ca, Mg) and organic soluble substances (flavonoids, coumarins, terpenes). Although these compounds can interfere with pulp formation reactions by consuming alkalis or forming sticky residues, in this case, they contribute positively to the functional properties of the paper by imparting bioactivity and moderate hydrophobicity [

7].

The results of mechanical tests confirmed that basis weight affects tensile strength and tear strength. Sheets with a basis weight of 80 g·m⁻² showed the highest tensile strength index (16.76 N·m·g⁻¹) and length between breaks (1.71 km), surpassing the values for corn stalk pulp (5.06 N·m·g⁻¹) [

31]. This can be attributed to more effective fibre bonding and uniform fibre orientation in thinner sheets. However, with increasing basis weight to 100 and 120 g·m⁻², tensile strength and elongation decreased, probably due to imperfect bonding between layers and increased internal stress gradients during sheet formation. The tear index increased slightly with basis weight, reflecting greater thickness and resistance to compression. Compared to other nitro-alkaline pulps, the mechanical properties of lavender were intermediate: stronger than corn but weaker than black mustard or flax [

17]. These results suggest that lavender fibres possess sufficient flexibility and bonding ability; however, their relatively short length limits the ultimate strength development. Air permeability results, as determined by the Gurley test (1.8–3.9 s), indicate a dense fibre network with low porosity. Such a compact structure may be beneficial for specific applications such as barrier papers, archival packaging, or substrate surface treatments.

Microscopic observations confirmed that lavender fibres are short with smooth, thin walls and relatively wide lumens. This morphology promotes good surface bonding but limits fibre entanglement, which explains the moderate tensile strength compared to longer fibres such as kraft wood pulp [

32]. The presence of fine residual particles and extraction deposits in thicker paper sheets (120 g·m⁻²) indicates incomplete washing or partial precipitation of lignin fragments. These properties slightly increase density and tensile strength but reduce flexibility [

33,

34,

35,

36]. From a chemical engineering perspective, the process of producing lavender pulp with nitrates and alkali metals is highly selective, favouring lignin oxidation over cellulose degradation. The nitric acid stage produces nitroaromatic intermediates, which are subsequently removed during the alkali extraction process. Moderate lignin oxidation likely contributes to low Kappa numbers and high fibre brightness, which is an important advantage for further bleaching or functionalization [

37].

One of the most significant results of this study is the demonstration of the repellent properties of lavender-based paper. A ~70% reduction in textile moth activity with the addition of lavender oil and flowers compared to control samples confirms that bioactive volatile compounds partially remain in the paper matrix even after defibration. The components of lavender essential oil – linalool, linalyl acetate, camphor, and 1,8-cineole – are semi-volatile terpenoids capable of slow release from cellulose fibres [

13,

38,

39,

40]. These molecules interact with the olfactory receptors of insects, disrupting host-seeking behaviour and reducing food intake and egg laying [

27]. From a chemical perspective, these compounds are likely to be adsorbed onto the surface of cellulose or trapped in residual lignin domains. The hydrophobic aromatic network of lignin may act as a micro-reservoir for terpenoid molecules, facilitating gradual evaporation [

41,

42,

43]. This mechanism is similar to that of aroma-retaining biopolymers used in packaging films [

8]. The retention of these compounds despite acid pulping suggests that the process does not entirely remove low-molecular-weight hydrophobic molecules. This fact could be exploited in the design of biofunctional papers [

39,

44] Lavender extracts also exhibit mild antioxidant and antimicrobial properties, which may potentially enhance the paper’s resistance to ageing. This finding is consistent with earlier studies that show paper treated with lavender essential oil resists microbial damage and retains its mechanical integrity over time [

8].

Compared to other annual crops, lavender pulp exhibits a unique balance between mechanical strength, processing efficiency, and functional properties. In terms of total yield and delignification, it is comparable to camelina and black mustard [

17]. Mechanically, it outperforms corn and wheat straw pulp prepared by the sodium or peroxy-acetate method [

45]. Functionally, lavender is characterised by internal repellent properties and antimicrobial effects, which are properties that are rarely found in other agricultural residues [

13,46]. Lavender pulp could thus serve as a dual-purpose raw material, both as a structural component for fibre-based materials and as a carrier of natural bioactive molecules. Such integration exemplifies the principles of applied chemistry in circular material design, where the chemical nature of agricultural waste is utilised not only for structural restoration but also for functional enhancement.

From the perspective of applied chemistry, this study shows how the design of chemical processes and the chemistry of natural compounds can intersect in the recovery of plant residues. The method of pulp production with nitrates and alkali metals emphasises the selective oxidation of lignin and the practical preservation of cellulose. At the same time, the presence of retained volatile substances is an example of passive functionalization of the material without the need for external additives. This concept aligns with the principles of green chemistry, emphasising the minimal use of reagents, the utilisation of renewable raw materials, and the production of multifunctional outputs. Lavender pulp could be further explored as a basis for:

Active packaging materials with inherent pest resistance,

Environmentally friendly storage inserts for textiles or books,

Hybrid composites, where aromatic residues improve interfacial bonds with polymers.

This development bridges chemistry, materials science, and environmental engineering, strengthening the role of applied chemistry in circular economy solutions.

5. Conclusions

This research demonstrates that secondary biomass from lavender (Lavandula officinalis) can serve as a sustainable, non-wood raw material for paper production, aligning with the goals of applied chemistry and the circular bioeconomy. Lavender stems exhibited a favourable lignocellulosic composition with medium lignin content and high cellulose content, enabling efficient pulping and potential for functional materials.

Using a nitrate-alkali process, a pulp yield of 24.2% with a Kappa number of 15.9 was achieved. Paper with a basis weight of 80 g·m⁻² exhibited the best mechanical properties, with a tensile strength index of 16.76 N·m·g⁻¹ and a breaking length of 1.71 km, indicating its suitability for speciality rather than packaging applications.

Importantly, lavender-based papers retained partial repellent activity against Tineola bisselliella moths, reducing insect presence by approximately 70%, likely due to residual terpenoids or the addition of lavender flower or oil, such as linalool and linalyl acetate.

Overall, lavender waste offers a biodegradable and bioactive alternative for fibre production. Further optimisation of delignification and characterisation of retained volatiles could expand its use in ecological and functional paper materials.

Author Contributions

Conceptualization, K.H. and T.H.; methodology, K.H.; validation, K.H., J.B. and T.H.; formal analysis, K.H., J.B., T.H., M.F. and J.S.; investigation, K.H.; writing—original draft preparation, K.H.; writing—review and editing, K.H. and J.B.; visualization, K.H.; supervision, K.H.; project administration, K.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

We have performed all moths experiments that comply with the ARRIVE guidelines and were carried out in accordance with (Scientific Procedures) Act, 1986 and associated guidelines, EU Directive 2010/63/EU for animal experiments.

Data Availability Statement

Dataset available on request from the authors: The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

This research was supported by the Faculty of Forestry and Wood Sciences, Czech University of Life Sciences Prague (Internal Grant Agency, Project No. A_03_24).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Otieno, J.O.; Okumu, T.N.; Adalla, M.K.; Ogutu, F.O.; Oure, B. Agricultural Residues as an Alternative Source of Fibre for the Production of Paper in Kenya-A Review. Asian Journal of Chemical SciencesForest 2021, 10, 22–37. [Google Scholar] [CrossRef]

- Saijonkari-Pakhala, K. Non-Wood Plants as Raw Materials for Pulp and Paper. Agricultural and Food Science 2001, 10, 101. [Google Scholar] [CrossRef]

- Mandeep; Gupta, G. K.; Liu, H.; Shukla, P. Pulp and paper industry-based pollutants, their health hazard and environmental. Current Opinion in Environmental Science & Health 2019, 12, 48–56. [Google Scholar] [CrossRef]

- Ding, Z.; Grundmann, P. Understanding system interdependencies in sustainable paper production from residue grass biomass: Insights from fuzzy cognitive mapping. Scientific Reports 2025, 15, 1398. [Google Scholar] [CrossRef]

- El-Sayed, E.S.A.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Non-wood fibers as raw material for pulp and paper industry. Nordic Pulp and Paper Research Journal 2020, 35, 215–230. [Google Scholar] [CrossRef]

- Lesage-Meessen, L.; Bou, M.; Ginies, C.; Chevret, D.; Navarro, D.; Drula, E.; Bonnin, E.; del Río, J.C.; Odinot, E.; Bisotto, A.; Berrin, J-G. ; Sigoillot, J-C.; Faulds, C.B.; Lomascolo, A. Lavender- and lavandin-distolled straws: an untapped feedstock with great potential for the production of high-added value compounds and fungal enzymes. Biotechnology for Biofuels 2018, 11, 217. [Google Scholar] [CrossRef] [PubMed]

- Vareltzis, P.; Fotiou, D.; Papatheologou, V.; Kyroglou, S.; Tsachouridou, E.; Goula, A.M. Optimized Solid–Liquid Separation of Phenolics from Lavender Waste and Properties of the Dried Extracts. Separations 2024, 11, 67. [Google Scholar] [CrossRef]

- Greff, B.; Szigeti, J.; Varga, Á.; Lakatos, E.; Sáhó, A.; Varga, L. Effect of bacterial inoculation on co-composting of lavender (Lavandula angustifolia Mill.) waste and cattle manure. 3 Biotech 2021, 11, 306. [Google Scholar] [CrossRef] [PubMed]

- Kamperidou, V.; Terzopoulou, P. Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production. Forests 2025, 16, 1455. [Google Scholar] [CrossRef]

- Angelova, G.; Brazkova, M.; Stefanova, P.; Blazheva, D.; Vladev, V.; Petkova, N.; Slavov, A.; Denev, P.; Karashanova, D.; Zaharieva, R.; Enev, A.; Krastanov, A. Waste Rose Flower and Lavender Straw Biomass—An Innovative Lignocellulose Feedstock for Mycelium Bio-Materials Development Using Newly Isolated Ganoderma resinaceum GA1M. J. Fungi 2021, 7, 866. [Google Scholar] [CrossRef]

- Stamova, S.; Ermenlieva, N.; Tsankova, G.; Georgieva, E. Antimicrobial Activity of Lavender Essential Oil from Lavandula angustifolia Mill.: In Vitro and In Silico Evaluation. Antibiotics 2025, 14, 656. [Google Scholar] [CrossRef]

- Rungwasantisuk, A.; Raibhu, S. Application of encapsulating lavender essential oil in gelatin/gum-arabic complex coacervate and varnish screen-printing in making fragrant gift-wrapping paper. Progress in Organic Coatings 2020, 149, 105924. [Google Scholar] [CrossRef]

- Todorova, D.; Yavorov, N.; Lasheva, V.; Damyanova, S.; Kostova, I. Lavender Essential Oil as Antibacterial Treatment for Packaging Paper. Coatings 2023, 13, 32. [Google Scholar] [CrossRef]

- Marovska, G.; Vasileva, I.; Petkova, N.; Ognyanov, M.; Gandovo, V.; Stoyanova, A.; Merdzhanov, P.; Simitchhiev, A.; Slavov, A. Lavender (Lavandula angustifolia Mill.) industrial by-products as a source of polysaccharides. Industrial Crops and Products 2022, 188, 115678. [Google Scholar] [CrossRef]

- Eyupoglu, S.; Merdan, N. Physicochemical Properties of New Plant Based Fiber from Lavender Stem. Journal of Natural Fibers 2021, 19, 1–11. [Google Scholar] [CrossRef]

- Crișan, I.; Ona, A.; Vârban, D.; Muntean, L.; Vârban, R.; Stoie, A.; Mihăiescu, T.; Morea, A. Current Trends for Lavender (Lavandula angustifolia Mill.) Crops and Products with Emphasis on Essential Oil Quality. Plants 2023, 12, 357. [Google Scholar] [CrossRef] [PubMed]

- Hájková, K.; Bouček, J.; Procházka, P.; Kalous, P.; Budský, D. Nitrate-Alkaline Pulp from Non-Wood Plants. Materials 2021, 14, 3673. [Google Scholar] [CrossRef] [PubMed]

- Housseinpour, R.; Latibari, J.; Farnood, R.; Fatehi, P.; Sepiddehdam, J. Fiber Morphology and Chemical Composition of Rapeseed (Brassica Napus) Stems. IAWA Journal 2010, 31, 457–464. [Google Scholar] [CrossRef]

- González, I.; Alcalá, M.; Arbat, G.; Vilaseca, F.; Mutje, P. Suitability of rapeseed chemithermomechanical pulp as raw material in papermaking. Bioresources 2013, 8, 1967–1981. [Google Scholar] [CrossRef]

- Standard; Test Methods. Tappi Test Methods; Tappi Press: Peachtree Corners, GA, USA, 2004. [Google Scholar]

- Seifert, K. Uber ein neues Verfahren zur Schnellbestimmung Der Rein-Cellulose. Das Papier 1956, 10, 301–306. [Google Scholar]

- Wise, L.E.; Murphy, M.; D’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper Trade Journal 1946, 122, 35–43. [Google Scholar]

-

ČSN EN ISO 1924-2. (500340); Paper and Board – Determination of Tensile Properties. Czech Standard Institute: Prague, Czech Republic, 2009.

-

ISO 2758:2014; Paper – Determination of Bursting Strength. International Organization for Standardization: Geneve, Switzerland, 2014.

- Paper and Board—Determination of air Permeance (Medium Range)—Part 5: Gurley Method. ISO 5636-5; G: Organization for Standardization, 2019.

- Bidar, L.; Noohi, N.; Dehkordi, M.H. Comparative Study of Antifungal Activity of Three Herbal Essential Oil of Thymus, Lavender, and Boswellia on Paper. Journal of Research on Archaeometry 2022, 8, 101–114. [Google Scholar] [CrossRef]

-

ČSN ISO 302 (50 0258); Pulps – Determination Kappa Number. Czech Standard Institute: Prague, Czech Republic, 1993.

- Potůček, F.; Miklík, J. Chemical composition of wood and annual plant pulps. Acta Facultatis Xylologiae Zvolen 2011, 53, 49–58. [Google Scholar]

- Enayati, A.A.; Hazem, Y.; Mirshokraie, S.A.; & Molaii, M.; Molaii, M. Papermaking potential of canola stalks. Bioresources 2009, 4, 245–256. [Google Scholar] [CrossRef]

- Hájková, K.; Jurczyková, T.; Filipi, M.; Bouček, J. Chemical Pulp from Corn Stalks. Biotechnology Reports 2023, 37, e00786. [Google Scholar] [CrossRef]

- Ferdous, T.; Ni, Y.; Quaiyyum, M.A.; Uddin, M.N.; Jahan, M.S. Non-Wood Fibers: Relationships of Fiber Properties with Pulp Properties. ACS Omega 2021, 6, 21613–21622. [Google Scholar] [CrossRef]

- Urdaneta, F.; Meza, L.; Márquez, R.; Franco, J.; Vera, R.E.; Urdaneta, I.; Parrish, C.; Saloni, D.; Pawlak, J.J.; Jameel, H.; Gonzalez, R.W. Comparing the impacts of wood and APMP non-wood fibers on the properties of hygiene tissue paper. Cellulose 2025, 32, 5021–5034. [Google Scholar] [CrossRef]

- Aldroubi, S.; Kasal, B.; Yan, L.; Bachtiar, E.V. Multi-scale investigation of morphological, physical and tensile properties of flax single fiber, yarn and unidirectional fabric. Composites Part B: Engineering 2023, 259, 110732. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O. da F.M.; Silva, F. de A.; Filho, R.D.T. The effect of fiber morphology on the tensile strength of natural fibers. Journal of Materials Research and Technology 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Hindi, J.; Muralishwara, K.; Gurumurthy, B.M. Comparative analysis of physical, morphological, tensile and thermal stability characteristics of raw and alkali treated novel Tinospora cordifolia natural fiber. Scientific Reports 2025, 15, 18596. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, B.; Liang, J.; Li, J.; Liu, B.; Wang, F.; Qin, C.; Yao, S. Effects of the Preferential Oxidation of Phenolic Lignin Using Chlorine Dioxide on Pulp Bleaching Efficiency. International Journal of Molecular Sciences 2022, 23, 13310. [Google Scholar] [CrossRef]

- Türkoğlu, G.C.; Erkan, G.; Karanava, S.Y.; Sarıışık, A.M.; Bakadur, A.C.; Ütebay, B.; Popescu, A. Spray-Dried Oregano Oil and Lavender Oil Microcapsules for Antibacterial Sports and Leisurewear. AATCC Journal of Research 2023, 10, 332–345. [Google Scholar] [CrossRef]

- Kumineck Junior, S.R.; Silveira, V.F.; Silva, D.A.K.; Garcia, M.C.F.; Apati, G.P.; Schneider, A.L. dos S.; Pezzin, A.P.T. Development of bacterial cellulose incorporated with essential oils for wound treatment. Polímeros 2023, 33, e20230041. [Google Scholar] [CrossRef]

- Marshall, T.; Dosoky, N.S.; Satyal, P.; Setzer, W.N. Aroma Compounds of Carrier Oils. AppliedChem 2023, 3, 546–580. [Google Scholar] [CrossRef]

- Lisý, A.; Ház, A.; Nadányi, R.; Jablonský, M.; Šurina, I. About Hydrophobicity of Lignin: A Review of Selected Chemical Methods for Lignin Valorisation in Biopolymer Production. Energies 2022, 15, 6213. [Google Scholar] [CrossRef]

- Hu, J.; Wang, L.; Xiao, M.; Chen, W.; Zhou, M.; Hu, Y.; Zhang, Y.; Lai, M.; He, A.; Zhao, M. Insights into bacterial cellulose for adsorption and sustained-release mechanism of flavors. Food Chemistry: X 2025, 25, 102110. [Google Scholar] [CrossRef] [PubMed]

- Mishra, P.K.; Ekielski, A. The Self-Assembly of Lignin and Its Application in Nanoparticle Synthesis: A Short Review. Nanomaterials 2019, 9, 243. [Google Scholar] [CrossRef]

- Aladić, K.; Jarni, K.; Barbir, T.; Vidović, S.; Vladić, J.; Bilić, M.; Jokić, S. Supercritical CO2 extraction of hemp (Cannabis sativa L.) seed oil. Industrial Crops and Products 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Barbash, V.; Poyda, V.; Deykun, I. Peracetic acid pulp from annual plants. Cellulose Chemistry and Technology 2011, 45, 613–618. [Google Scholar]

- Srećković, N.; Mišić, D.; Gašić, U.; Matić, S.L.; Stanković, J.S.K.; Mihailović, N.R.; Monti, D.M.; D’Elia, L.; Mihailović, V. Meadow sage (Salvia pratensis L.): A neglected sage species with valuable phenolic compounds and biological potential. Industrial Crops and Products 2022, 189, 115841. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).