Submitted:

23 October 2025

Posted:

24 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Excipient Compatibility Studies

2.3. Long-Term ICH Stability Study

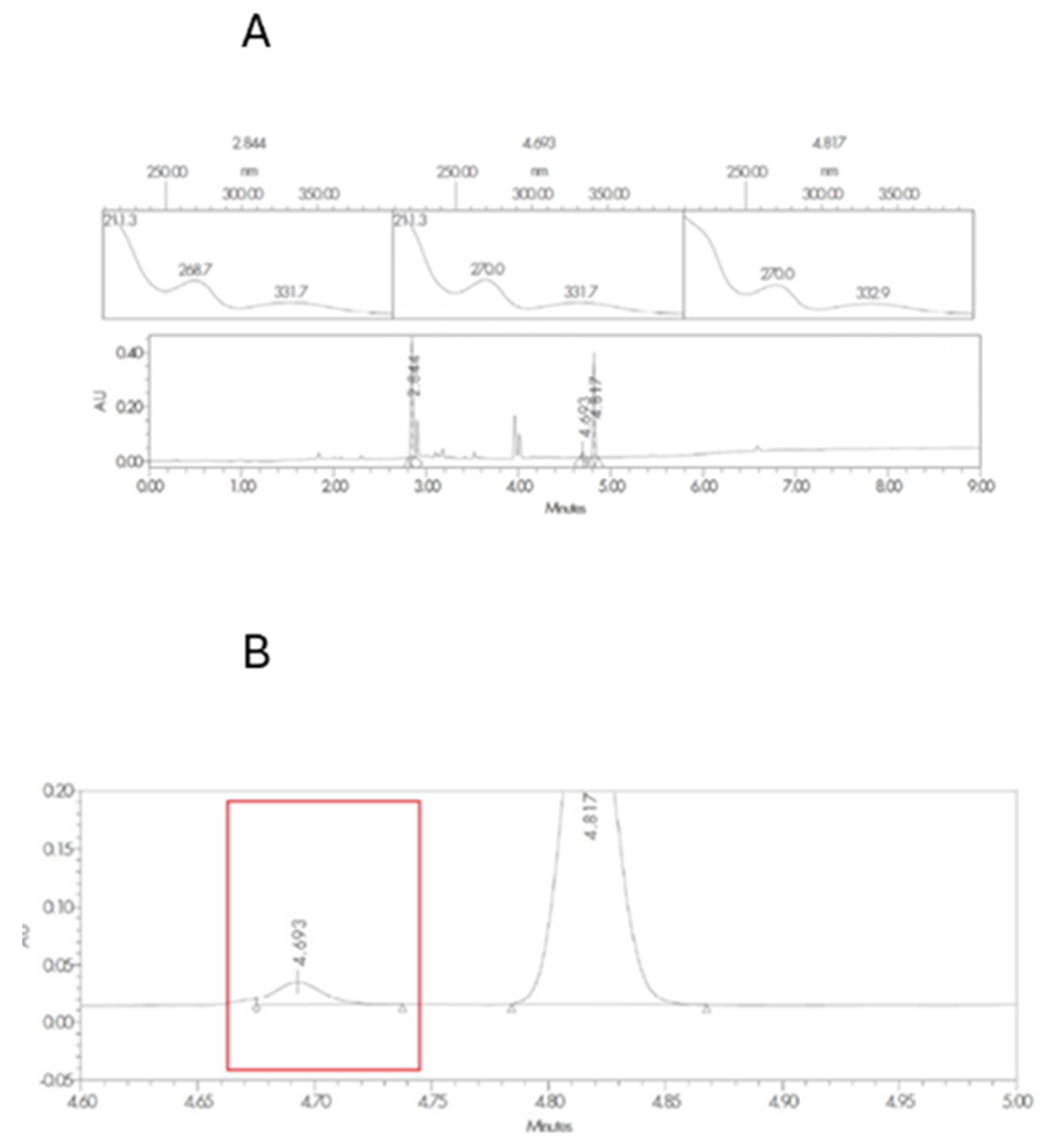

2.4. HPLC Quantification of SLD and Related Substances

2.5. Stability Modeling

2.6. Permeability of Packing Materials

3. Results and Discussion

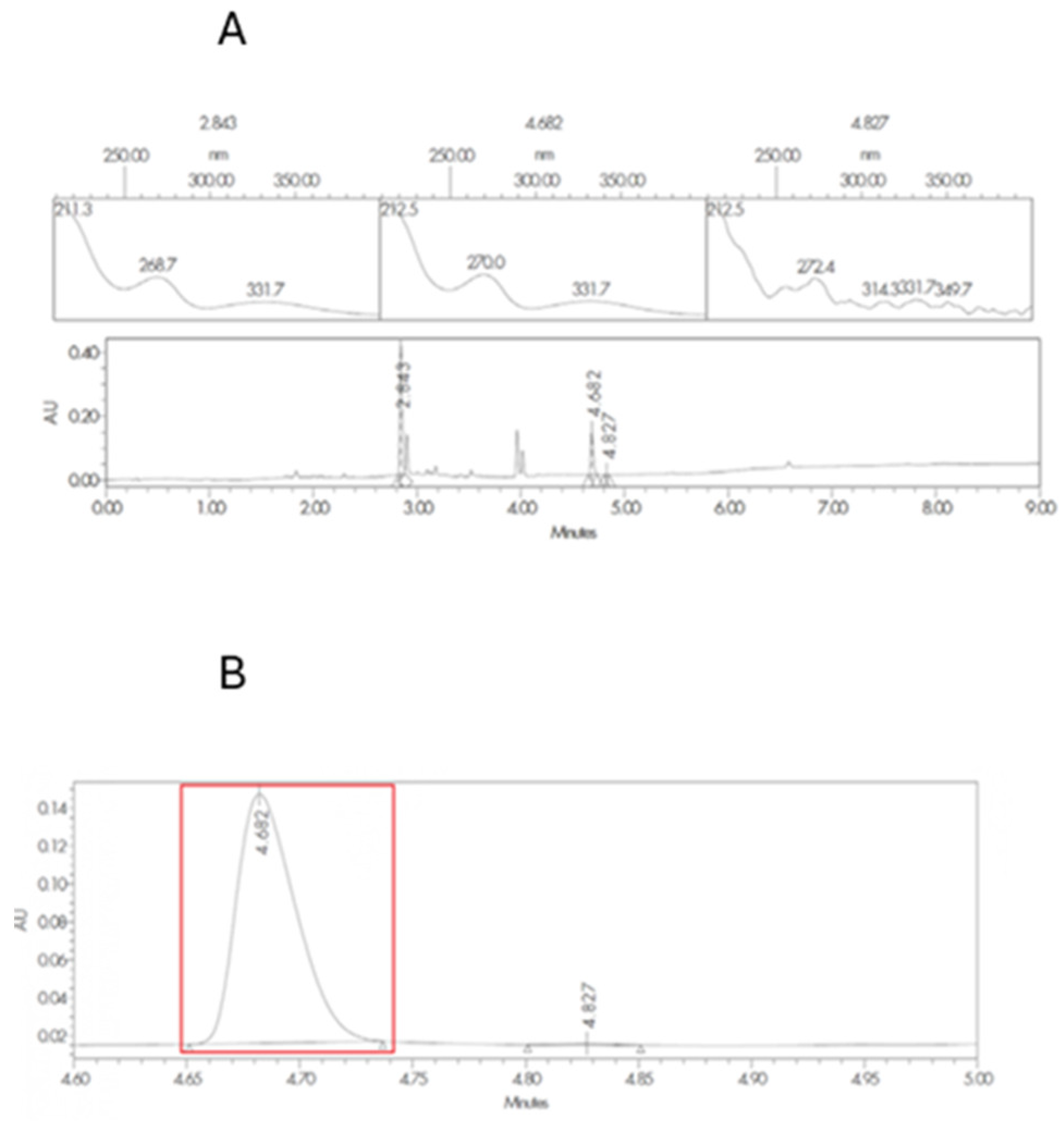

3.1. Excipient Compatibility Studies

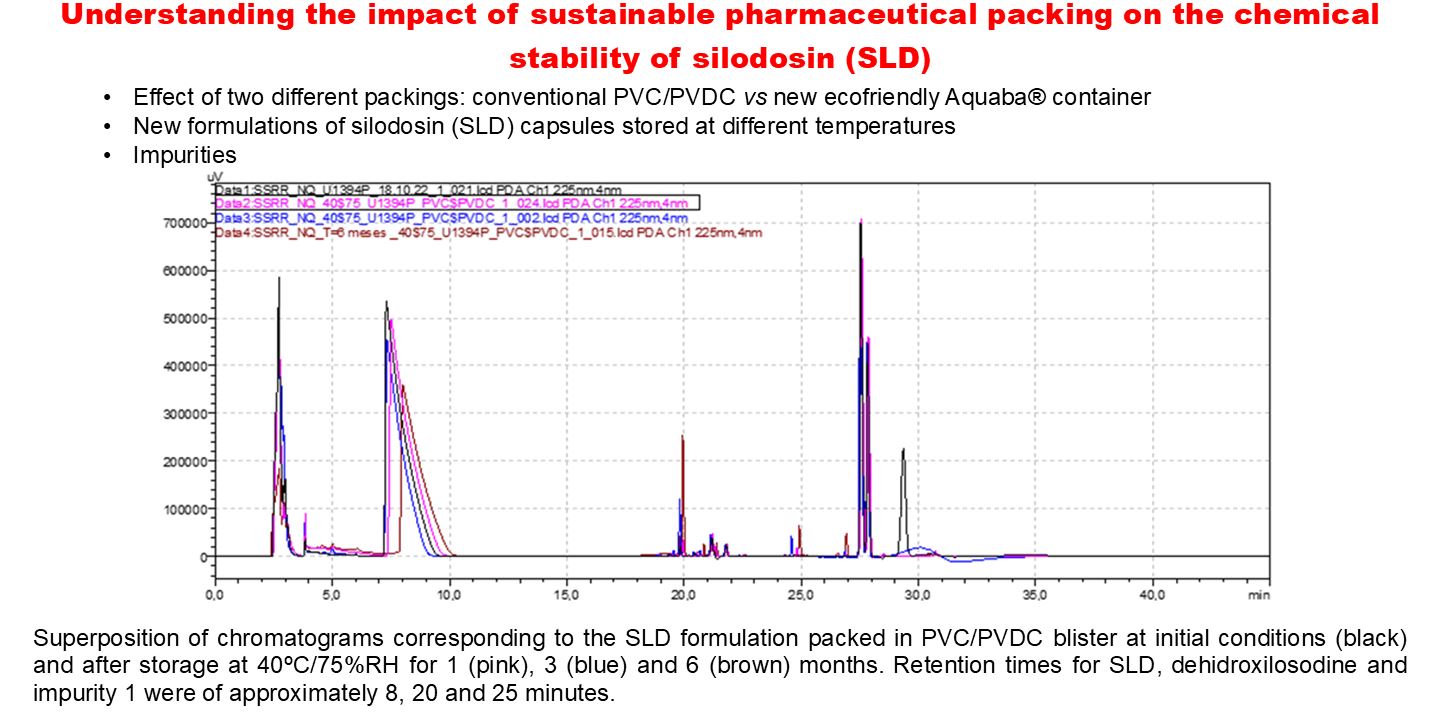

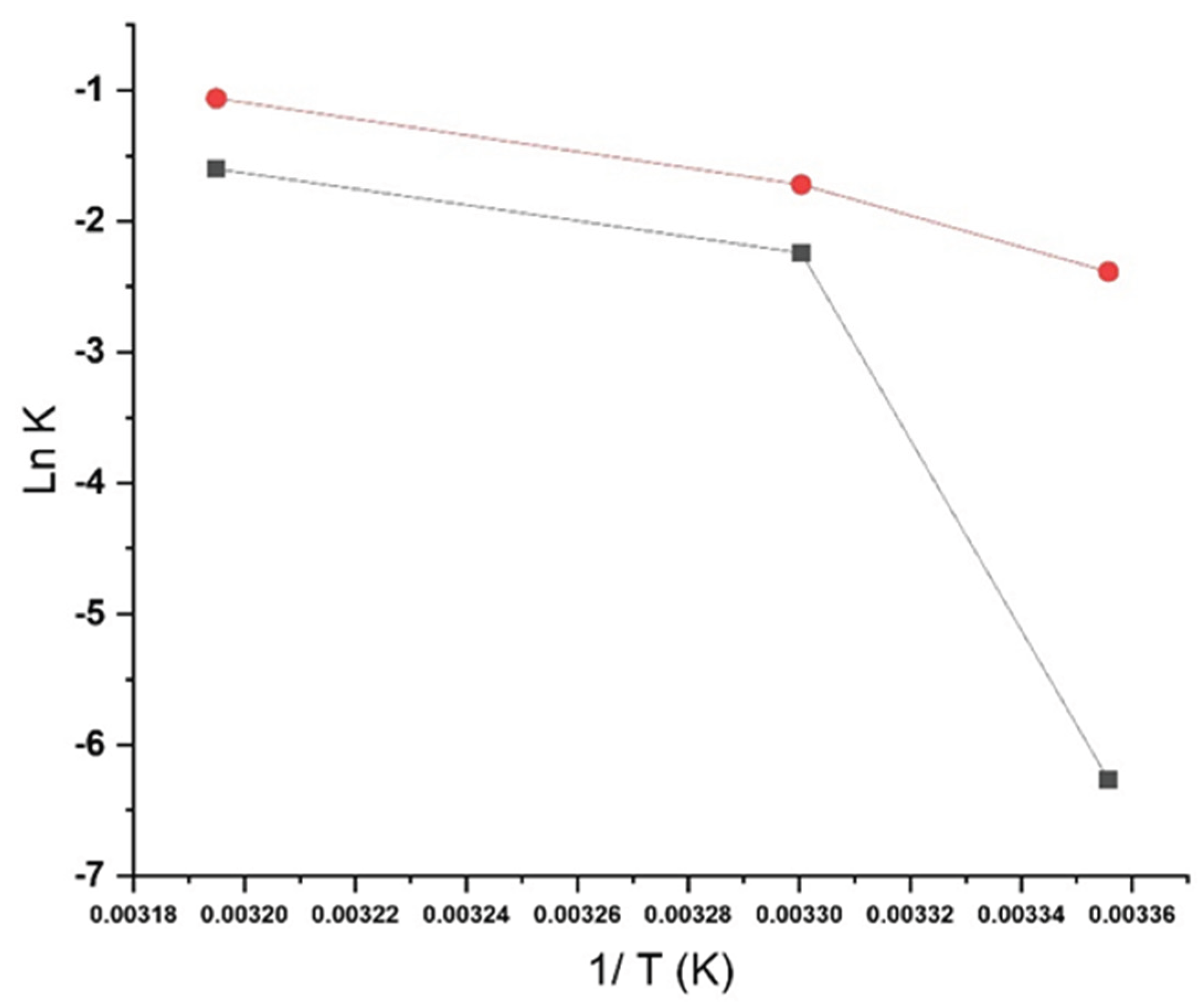

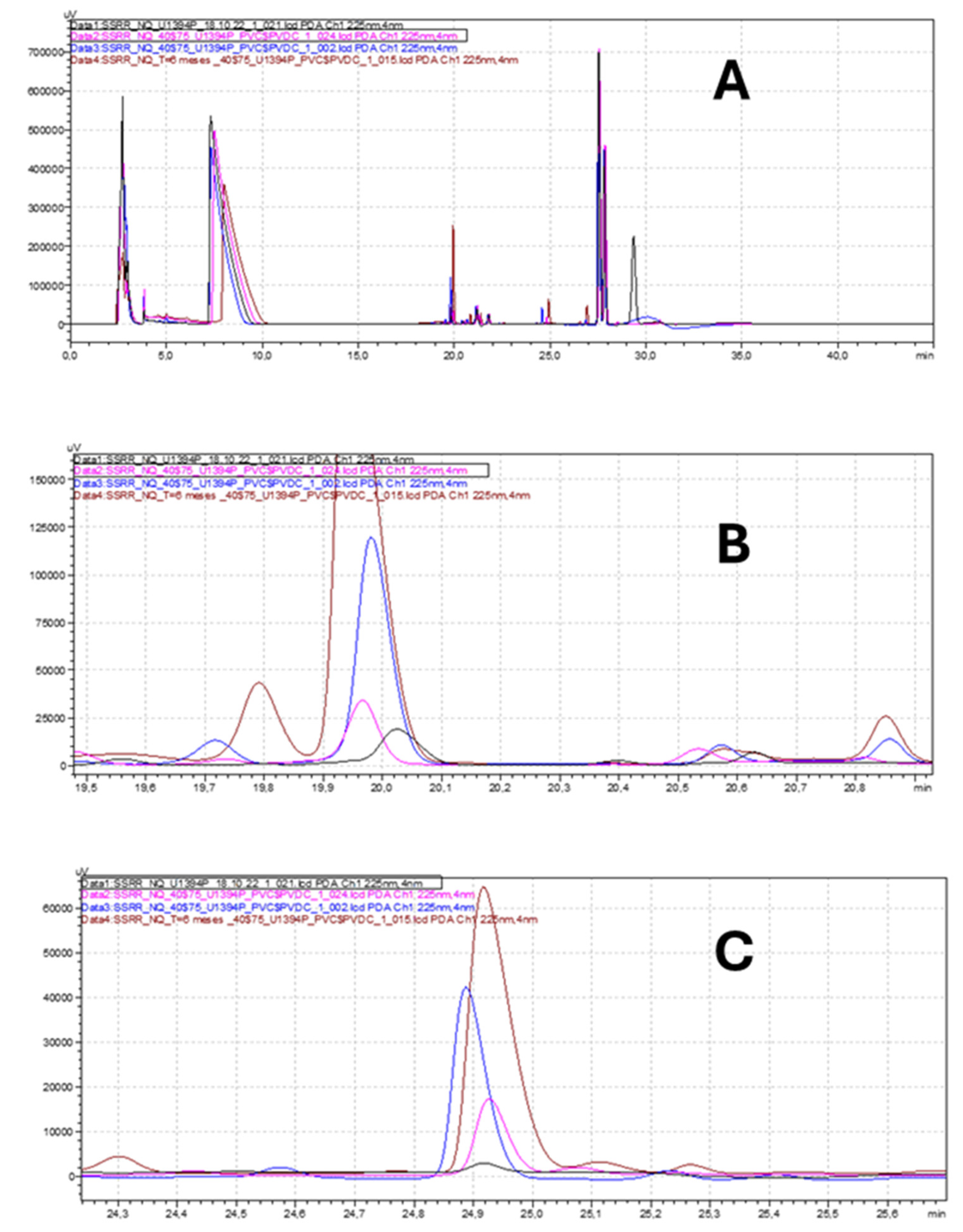

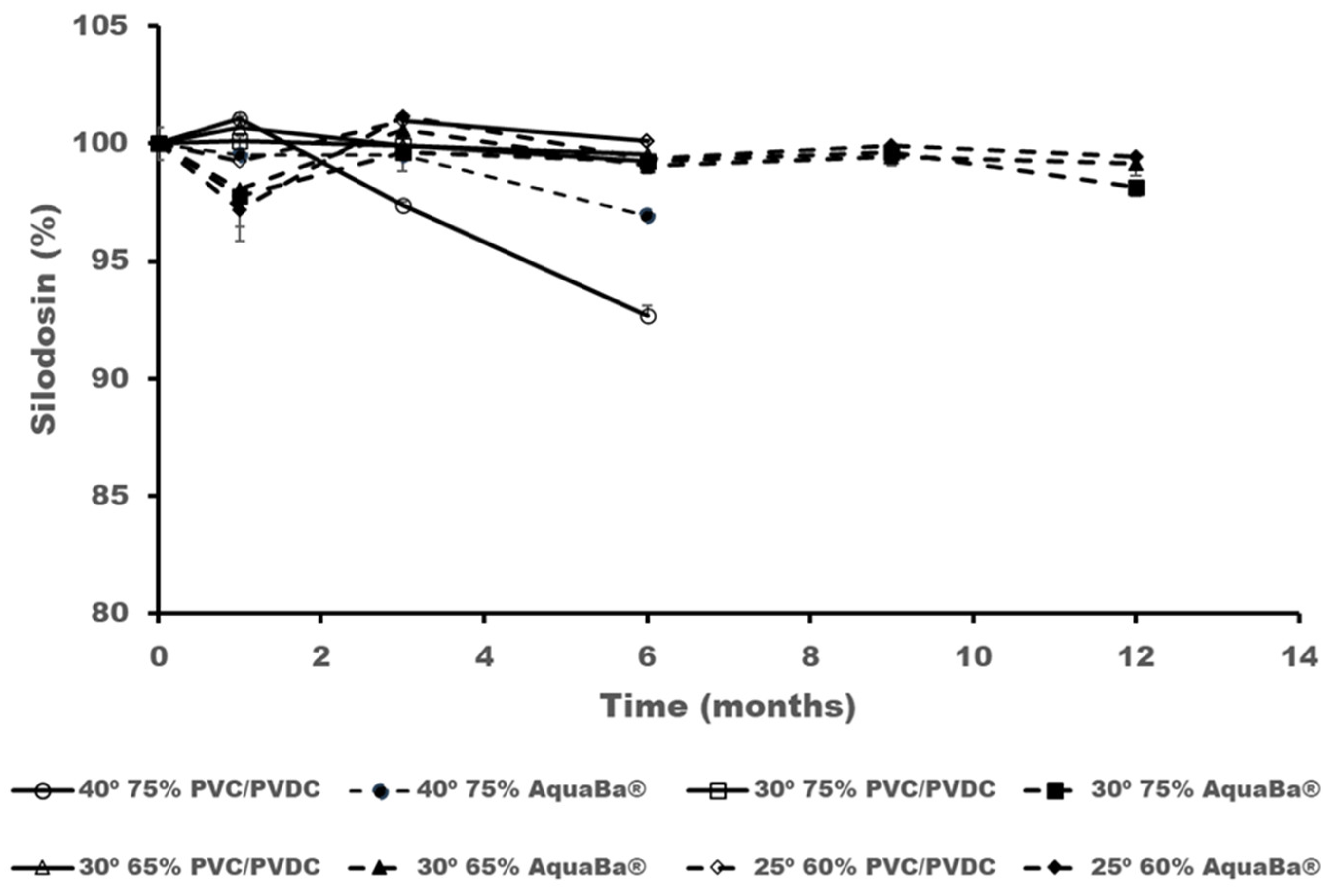

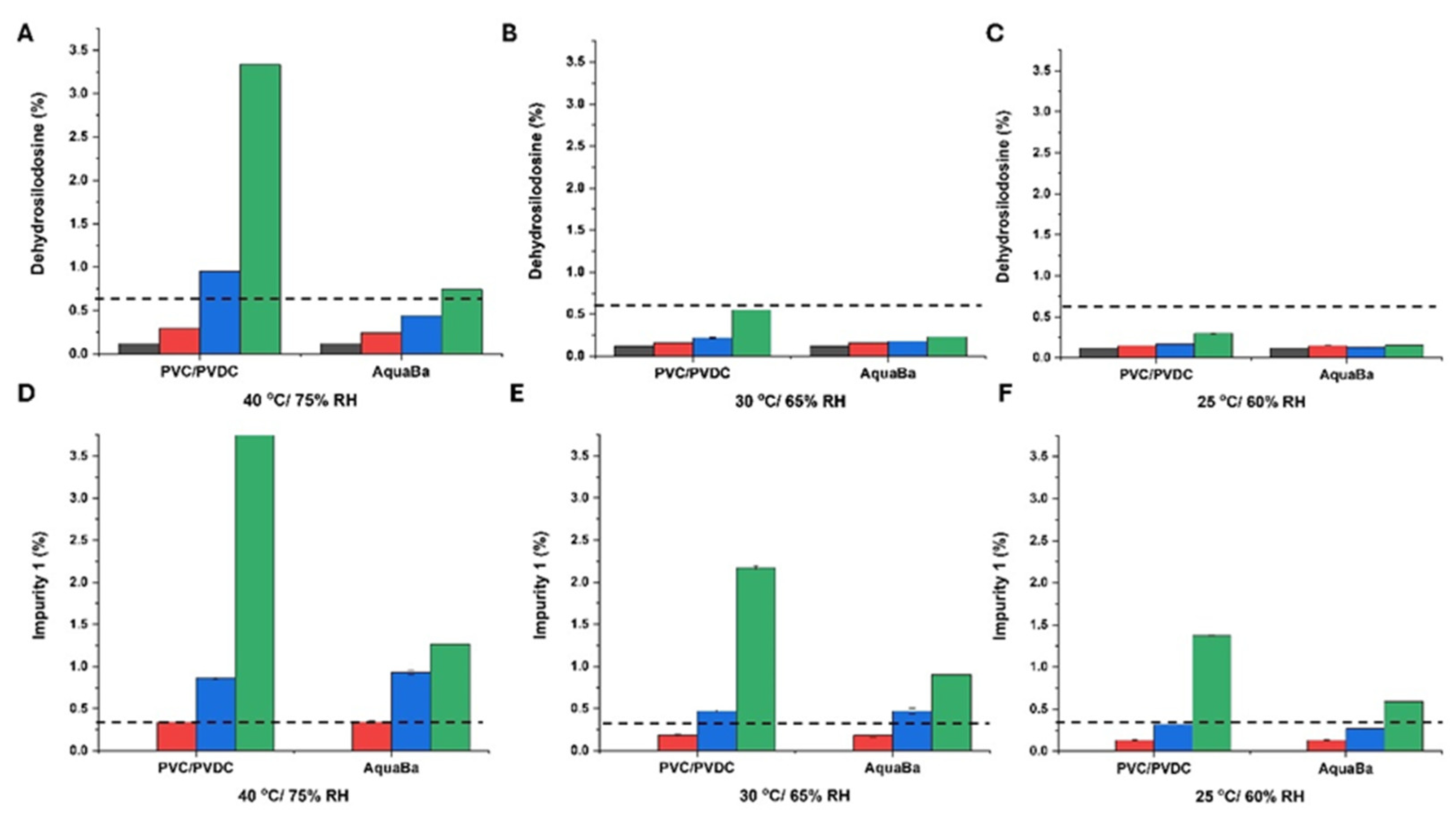

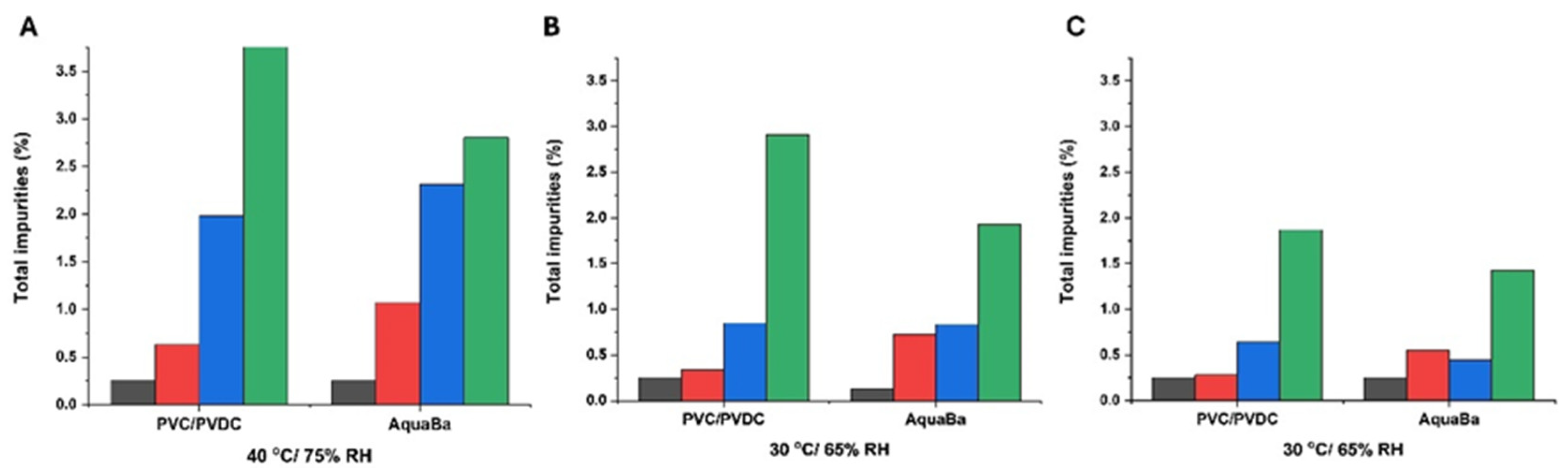

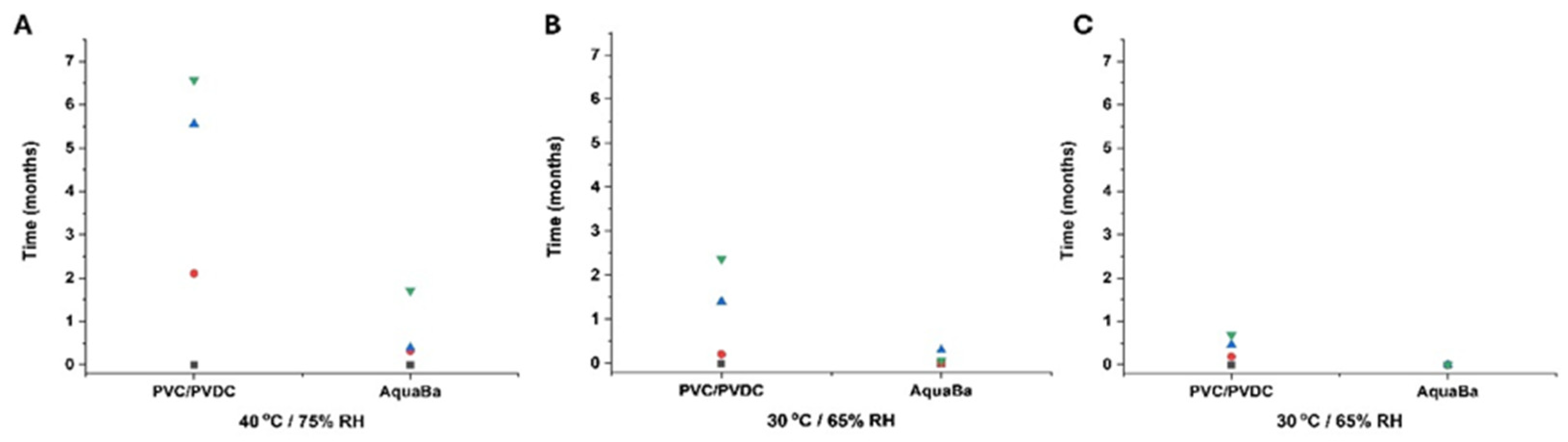

3.2. Long-Term ICH Stability Study

| Kinetic profile | 40 ºC / 75% RH | 30 ºC / 65% RH | 25 ºC / 60% RH | Average |

|---|---|---|---|---|

| Dehydrosilodosine | ||||

| Order 0 Order 1 order 2 Avrami Difussion |

0.85 1.00 0.99 0.96 0.90 |

0.87 0.88 0.87 0.75 0.85 |

0.87 0.88 0.87 0.75 0.80 |

0.86 0.92 0.91 0.82 0.85 |

|

Impurity 1 | ||||

| Order 0 Order 1 order 2 Avrami Difussion |

0.85 0.99 0.92 0.91 0.85 |

0.87 0.99 0.92 0.92 0.85 |

0.87 0.99 0.93 0.92 0.85 |

0.86 0.99 0.92 0.92 0.85 |

| Kinetic profile | 40 ºC / 75% RH | 30 ºC / 65% RH | 25 ºC / 60% RH | Average |

|---|---|---|---|---|

| Dehydrosilodosine | ||||

| Order 0 Order 1 order 2 Avrami Difussion |

0.98 0.98 0.99 0.99 0.64 |

0.84 0.96 0.92 0.86 0.72 |

* * * * * |

0.91 0.97 0.96 0.93 0.77 |

|

Impurity 1 | ||||

| Order 0 Order 1 order 2 Avrami Difussion |

0.91 0.99 0.92 0.91 0.85 |

0.9 0.99 0.93 0.92 0.85 |

0.91 0.99 0.93 0.92 0.85 |

0.91 0.99 0.93 0.92 0.85 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jindan, L., W. Xiao, and X. Liping, Evolving Role of Silodosin for the Treatment of Urological Disorders - A Narrative Review. Drug Des Devel Ther, 2022. 16: p. 2861-2884. [CrossRef]

- Gonzalez-Alvarez, I., et al., Exploring a Bioequivalence Failure for Silodosin Products Due to Disintegrant Excipients. Pharmaceutics, 2022. 14(12). [CrossRef]

- Naharros-Molinero, A., et al., Shell Formulation in Soft Gelatin Capsules: Design and Characterization. Adv Healthc Mater, 2024. 13(1): p. e2302250. [CrossRef]

- ICH Q8 (R2) Pharmaceutical Development. Reference code: EMA/CHMP/ICH/167068/2004 (2014). https://www.ema.europa.eu/en/ich-q8-r2-pharmaceutical-development-scientific-guideline. Accessed date: 15/03/2025.

- ICH: Q 1 A (R2): Stability testing of new drug substances and products. Reference code CPMP/ICH/2736/99 (2003). https://www.ema.europa.eu/en/ich-q1a-r2-stability-testing-new-drug-substances-drug-products-scientific-guideline. Accessed date: 15/03/2025.

- ICH: Q 3 A (R2): Impurities in new drug substances. Reference code: CPMP/ICH/2737/99 (2006). https://www.ema.europa.eu/en/ich-q3a-r2-impurities-new-drug-substances-scientific-guideline. Accessed daet: 15/03/2025.

- Zadbuke, N., et al., Recent trends and future of pharmaceutical packaging technology. J Pharm Bioallied Sci, 2013. 5(2): p. 98-110.

- AquaBa pahrmaceutical packing material. Available at: https://kaatimex.bg/wp-content/uploads/2015/12/Bilcare_Aquaba.pdf. Accessed date: 15/03/2025.

- Pharmaceutical Pakcing material PVC. Available at: https://www.rijerplastic.com/news/pharmaceutical-packaging-material-pvc/. Accessed date: 15/03/2025.

- Van Dooren, A.A., PVC as pharmaceutical packaging material. A literature survey with special emphasis on plasticized PVC bags. Pharm Weekbl Sci, 1991. 13(3): p. 109-18.

- Jaime, S., R. Alves, and P. Bocoli, Moisture and oxygen barrier properties of glass, PET and HDPE bottles for pharmaceutical products. Journal of Drug Delivery Science and Technology, 2022. 71( 103330).

- Pan, Z., et al., Water vapor transmission rate measurement for moisture barriers using infrared imaging. Materials Chemistry and Physics, 2023. 203(128289).

- WVTR of different packing materials. Available at: http://www.fortuneunion.net/materials-for-blister-packaging-film/. Accessed date: 16/03/2025.

- AquaBa packing material. Available at: https://kaatimex.bg/wp-content/uploads/2015/12/Bilcare_Aquaba.pdf. Accessed date: 15/03/2025.

- Serrano, D.R., et al., Designing Fast-Dissolving Orodispersible Films of Amphotericin B for Oropharyngeal Candidiasis. Pharmaceutics, 2019. 11(8).

- Serrano, D.R., et al., Optimising the in vitro and in vivo performance of oral cocrystal formulations via spray coating. Eur J Pharm Biopharm, 2018. 124: p. 13-27.

- Gonzalez-Gonzalez, O., et al., Application of Accelerated Predictive Stability Studies in Extemporaneously Compounded Formulations of Chlorhexidine to Assess the Shelf Life. Molecules, 2023. 28(23).

- Gonzalez-Gonzalez, O., et al., Drug Stability: ICH versus Accelerated Predictive Stability Studies. Pharmaceutics, 2022. 14(11).

- Fernandez-Garcia, R., et al., Targeted Oral Fixed-Dose Combination of Amphotericin B-Miltefosine for Visceral Leishmaniasis. Mol Pharm, 2025. 22(3): p. 1437-1448. [CrossRef]

- European Pharmacopoeia 11 edition. 2022.

- Vishnuvardhan, C., et al., LC-ESI-MS/MS evaluation of forced degradation behaviour of silodosin: In vitro anti cancer activity evaluation of silodosin and major degradation products. J Pharm Biomed Anal, 2017. 134: p. 1-10. [CrossRef]

- Pandeti, S., et al., Characterization of degradation products of silodosin under stress conditions by liquid chromatography/Fourier transform mass spectrometry. Rapid Commun Mass Spectrom, 2017. 31(6): p. 572-582. [CrossRef]

- Waterman, K.C. and R.C. Adami, Accelerated aging: prediction of chemical stability of pharmaceuticals. Int J Pharm, 2005. 293(1-2): p. 101-25. [CrossRef]

| Sample code | Component |

|---|---|

| 1 | SLD |

| 2 | Capryol 90 |

| 3 | Lauroyl macrogol-32 glycerides |

| 4 | BHT |

| 5 | SLD+Capryol 90 |

| 6 | SLD + Lauroyl macrogol-32 glycerides |

| 7 | SLD+BHT |

| 9 | SLD + Capryol 90+ Lauroyl macrogol-32 glycerides |

| 10 | SLD + Lauroyl macrogol-32 glycerides + BHT |

| 11 | Capryol 90 + Lauroyl macrogol-32 glycerides |

| 12 | Capryol 90 + Lauroyl macrogol-32 glycerides + BHT |

| Time (min) | % Mobile phase A | % Mobile phase B |

|---|---|---|

| 0.01 | 78 | 22 |

| 13.00 | 78 | 22 |

| 28.00 | 15 | 85 |

| 37.00 | 78 | 22 |

| 45.00 | 78 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).