3.3.1. Factorial Design

Submarine composite structures are typically manufactured using Liquid Composite Molding (LCM), a resin-based molding process. During this process, micro-voids may form due to a variety of factors, including mechanical air entrapment during resin injection, gas generation from the curing reaction, and degassing of dissolved gases in the resin [

5]. These voids not only degrade the mechanical properties of the composite but also serve as critical defects that compromise the structural reliability. Therefore, effective control of micro-void formation is not merely a matter of quality enhancement, but a fundamental requirement for ensuring the performance of high-reliability systems such as submarines.

The LCM process for composite fabrication typically involves several stages, including mold preparation, gel coating, defoaming, lay-up, resin injection, vacuum application and curing, and demolding. Among these, the defoaming step—where entrapped air is removed from the resin prior to injection—is the most directly influential in determining void formation. Despite its importance, systematic optimization of the defoaming process remains insufficiently explored.

In this study, three critical parameters of the defoaming process were selected for investigation: defoamer concentration, mixing speed, and mixing time. The defoamer facilitates the collapse of entrapped air bubbles by reducing surface tension. However, excessive use can alter interfacial properties and deteriorate the resin’s performance. Mixing speed promotes uniform dispersion of additives, but overly high speeds may introduce additional air, while insufficient speeds may cause inhomogeneity and poor curing. Likewise, mixing time must be carefully optimized; insufficient time results in uneven composition, while prolonged mixing may cause premature curing or re-bubbling of the resin [

17].

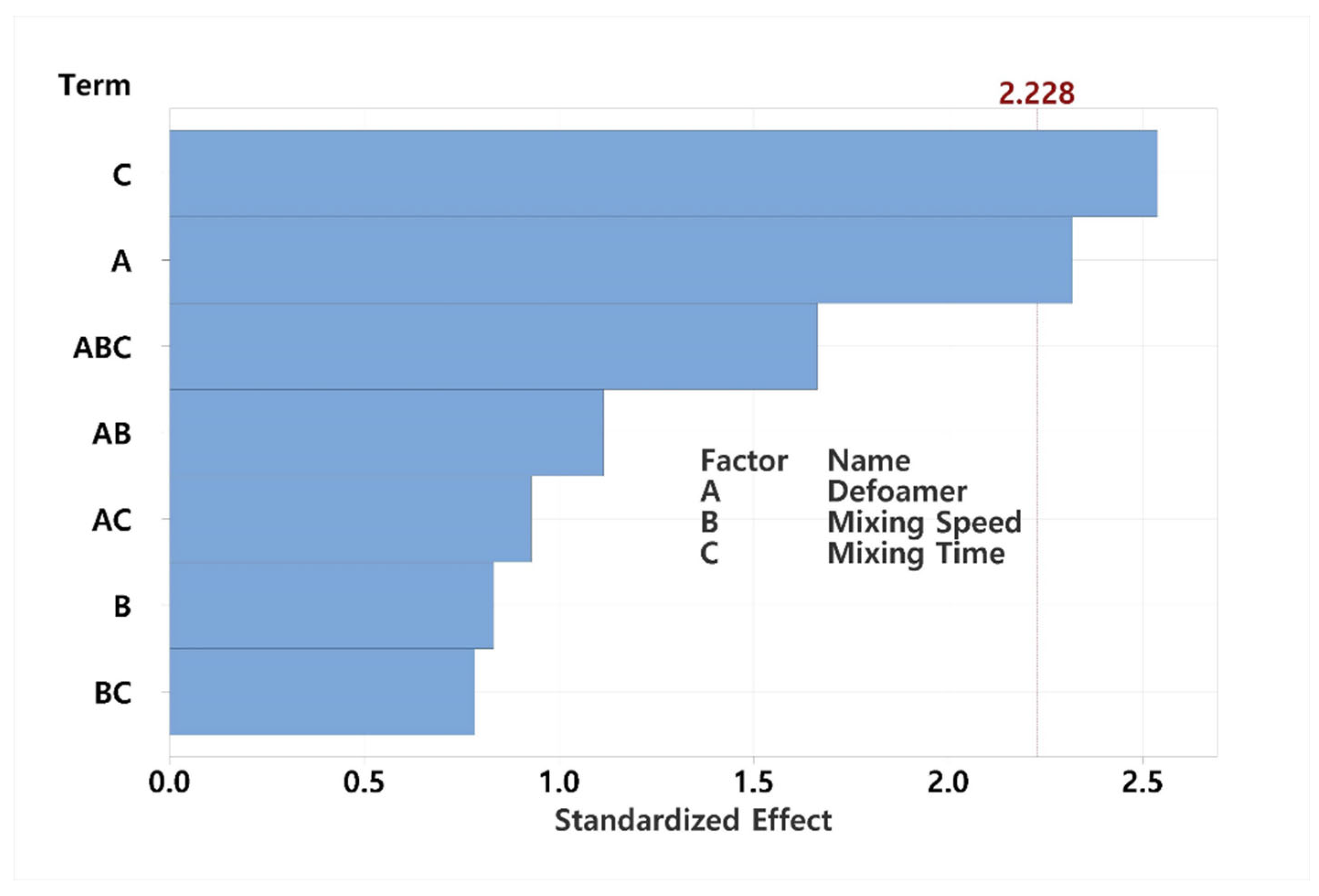

To quantitatively evaluate the effects of these process parameters and identify optimal conditions, a factorial design approach was employed. Factorial design is a statistical experimental methodology that allows simultaneous evaluation of the main and interaction effects of multiple variables on the response factor. Minitab 22 statistical software was used to construct the design matrix. The detailed design structure is summarized in

Table 1, and the relative effect sizes of the factors are visualized using a Pareto chart in

Figure 3.

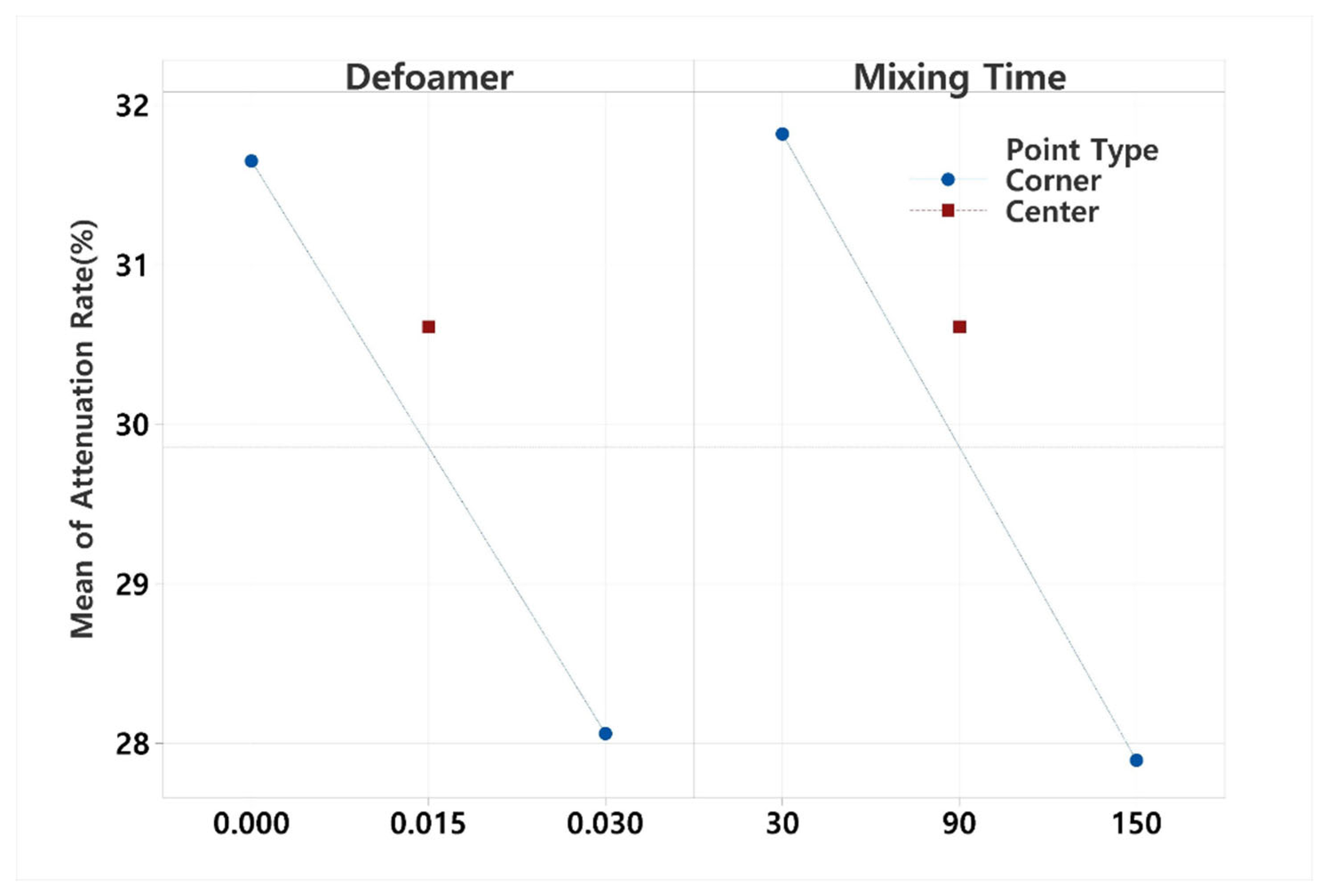

The experimental results indicated that defoamer concentration and mixing time significantly affected the attenuation rate, which served as a proxy for void content. In contrast, interaction effects and higher-order terms (second- or third-order interactions) were found to be statistically insignificant. Notably, mixing time had a greater influence than defoamer concentration, which may be attributed to the physical behavior of entrapped air—naturally escaping from the resin over time.

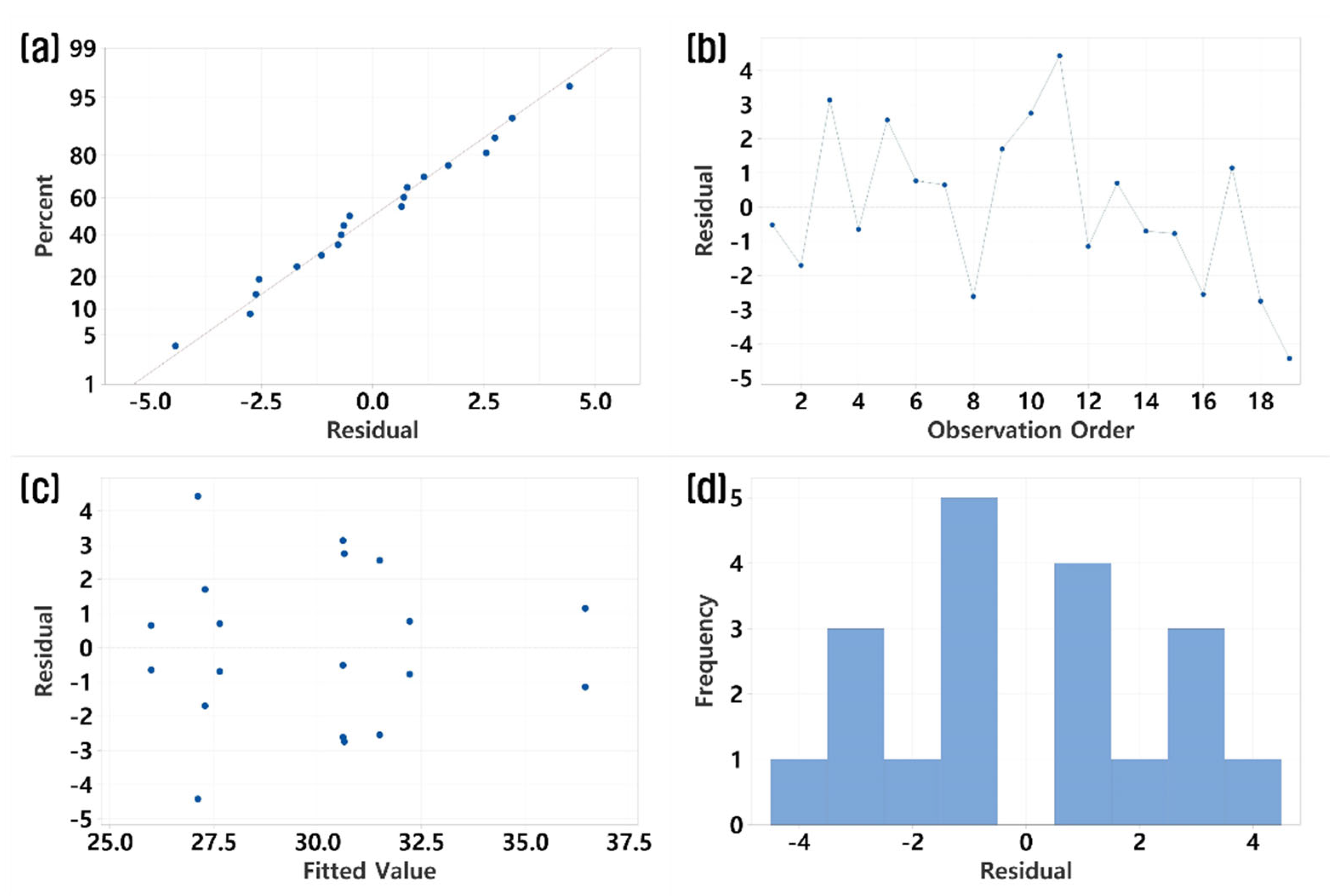

To validate the reliability of the regression model, a residual analysis was conducted. The results were as follows:

The normal probability plot of residuals (

Figure 4a) showed that the residuals approximately followed a straight line, indicating that the assumption of normality was satisfied.

The residuals versus observation order plot (

Figure 4b) revealed no discernible patterns, suggesting that the experiments were conducted in a random sequence.

The residuals versus fitted values plot (

Figure 4c) showed constant variance across the fitted values, confirming the homoscedasticity of the residuals.

The histogram of residuals (

Figure 4d) exhibited a bell-shaped normal distribution, indicating that the statistical characteristics of the data were well captured by the regression model.

Collectively, these results confirm that the regression model satisfies key statistical assumptions—normality, independence, and homoscedasticity—and that the predictive reliability of the model is sufficiently robust for subsequent optimization steps [

18].

Based on the factorial analysis results, the two primary process parameters that had statistically significant effects on ultrasonic attenuation (used as a proxy for void content) were identified as defoamer concentration and mixing time. In contrast, the second-order terms and the interaction effect between these two factors were found to be statistically insignificant, with p-values exceeding the threshold of 0.05.

Table 4 presents the results of the analysis of variance (ANOVA) considering only the significant main effects. Both defoamer concentration and mixing time exhibited p-values less than 0.05, reaffirming their statistically significant influence on attenuation rate. Notably, the lower p-value for mixing time indicates that this factor exerts a relatively greater effect on the variation in attenuation, likely due to the extended time allowing for more effective physical removal of entrapped air bubbles from the resin.

In addition, a curvature test was conducted to evaluate the existence of non-linearity in the response surface. The p-value for the curvature term was calculated as 0.714, which is significantly greater than 0.05, indicating no statistically significant evidence of curvature within the current experimental domain. This result implies that the response surface behaves in a linear manner under the tested conditions and that the global optimum may lie beyond the current design space.

Based on these results, a first-order regression model in uncoded (real-world) units was established as follows:

Attenuation rate (%) = 34.59 − 119.6 × Defoamer concentration (wt%) − 0.0327 × Mixing time (min)

Both coefficients in the regression equation are negative, suggesting that increasing the defoamer concentration and mixing time leads to a reduction in attenuation rate. This trend indicates a corresponding decrease in void content, thereby implying improved physical integrity and mechanical performance of the composite material.

Furthermore, the absence of an interaction term (i.e., the product of the two variables) in the regression model confirms that the interaction effect between defoamer concentration and mixing time was statistically insignificant within the tested range.

Figure 5 illustrates the main effects of each factor on attenuation rate. The results clearly show that attenuation reaches its minimum near a defoamer concentration of 0.03 wt% and a mixing time of 150 minutes, corroborating the findings derived from the regression model. Both parameters demonstrate a strong negative correlation with attenuation.

However, the lack of statistical significance in the curvature test indicates that the response surface remains linear within the current design domain. This suggests that the optimal conditions for minimizing void content may not yet have been reached and could exist outside the currently tested range. Accordingly, further experiments employing the Steepest Ascent Method are recommended to explore the response gradient and identify a local optimum in regions where curvature may bepresent.

3.3.2. Steepest Ascent Method

Based on the results of the factorial design analysis, defoamer concentration and mixing time were identified as statistically significant factors influencing ultrasonic attenuation. However, no curvature was observed in the response surface, suggesting that the response exhibited a linear trend within the tested experimental range. This implies that the optimal response conditions may lie outside the current design space, highlighting the need for further experimentation to explore extended process conditions.

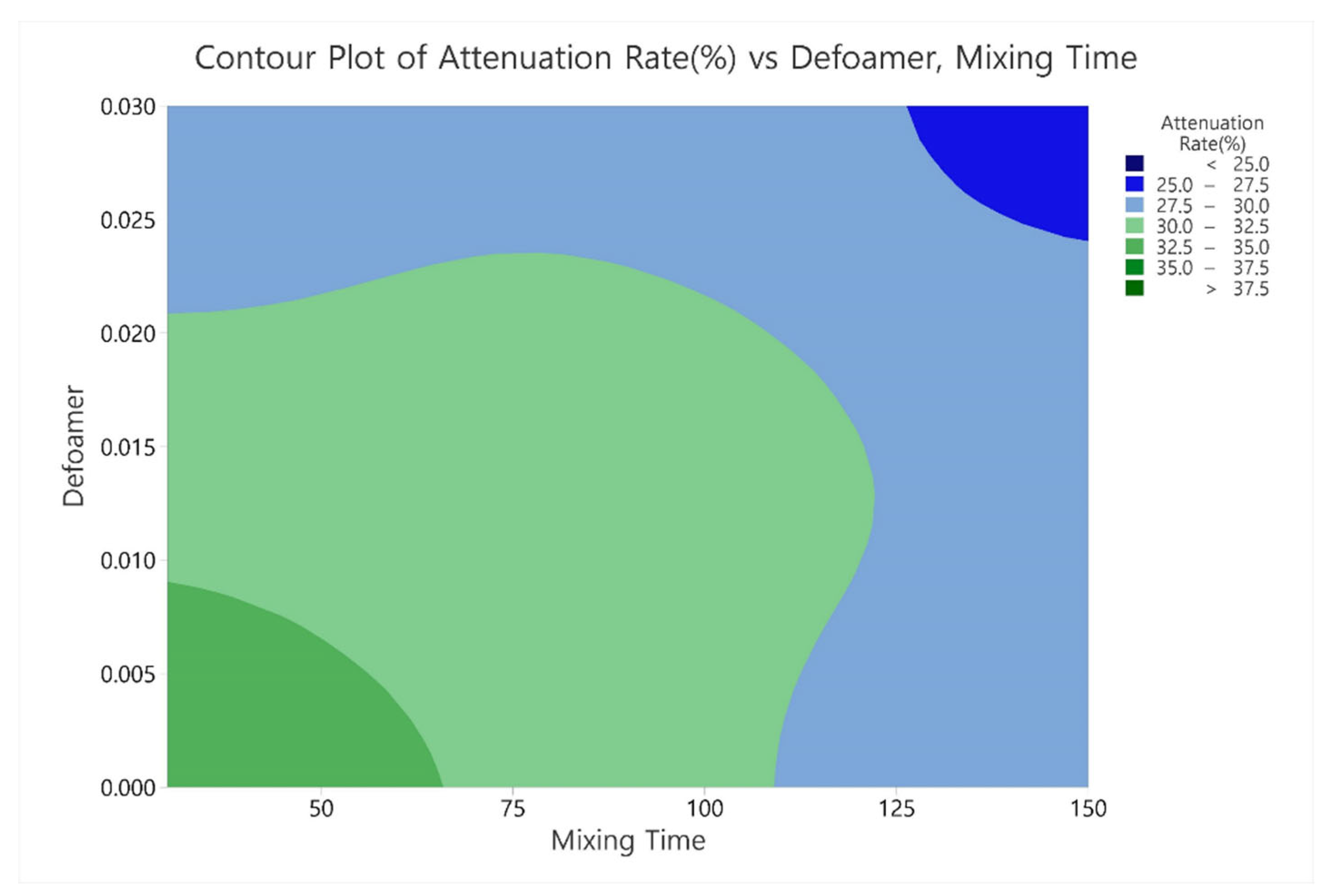

Figure 6 presents a two-dimensional contour plot showing the variation of attenuation rate with respect to defoamer concentration and mixing time. The contour distribution indicates that the lowest attenuation values occur in the upper-right region of the plot, where both variables are at their highest levels. This trend suggests that, in order to reach the optimal response, both defoamer concentration and mixing time should be increased simultaneously.

To systematically approach the optimum region, the Steepest Ascent Method was employed in this study. This method involves adjusting the experimental conditions along the direction of the gradient vector derived from the initial regression model, thereby iteratively moving toward conditions that yield improved response values [

19]. Once the progression reaches a point where no further meaningful improvement in attenuation is observed, subsequent optimization can be performed using Response Surface Methodology (RSM) to precisely identify the local optimum.

The estimated regression coefficients and their statistical significance for defoamer concentration and mixing time are summarized in

Table 5. The negative coefficients confirm that both factors contribute to reducing attenuation, with mixing time exhibiting a slightly stronger effect.

In particular, as shown in

Table 5, the defoamer concentration and mixing time yielded statistically significant p-values (0.044 and 0.029, respectively), indicating their individual influence on attenuation rate. Meanwhile, the interaction term between defoamer and mixing time was not statistically significant (p = 0.389), suggesting that the effects of each parameter are largely independent within the studied range. This supports the validity of the linear first-order model used in the steepest ascent approach.

Accordingly, the Steepest Ascent Method was applied in this study to identify the optimal processing conditions for minimizing ultrasonic attenuation. This statistical approach iteratively adjusts the experimental variables in the direction of the steepest gradient—i.e., the direction in which the response variable (attenuation rate) improves most rapidly—enabling efficient navigation toward the optimal region within the response surface.

A critical step in implementing the Steepest Ascent Method is the selection of a principal variable. Although both defoamer concentration and mixing time were found to significantly influence the attenuation rate, defoamer concentration was selected as the primary factor due to its relative ease of experimental control. Using standardized regression coefficients derived from the initial model, the gradient ratio was calculated to determine how much the mixing time should be adjusted when the defoamer concentration is increased by one coded unit. The ratio of the mixing time coefficient (−1.962) to the defoamer coefficient (1.794) yielded approximately 1.1. When converted to actual experimental units, this corresponds to an increment of 66 minutes in mixing time (i.e., 60 minutes × 1.1) for every unit increase in defoamer concentration [

17].

Based on this gradient direction, a series of experiments was conducted by progressively adjusting the process conditions. The results are summarized in

Table 6. The attenuation rate continued to decrease up to a condition of 0.045 wt% defoamer concentration and 222 minutes of mixing time, beyond which further changes in the process variables did not lead to additional improvements in the response. This indicates that these conditions are located near the optimal region for minimizing attenuation.

It is also worth noting that excessive defoamer addition can adversely alter the interfacial properties of the resin, leading to degradation in curing characteristics and mechanical performance. Similarly, overly extended mixing times may increase the resin’s viscosity or cause premature curing, compromising the processability. Therefore, the experimental results suggest that the practical optimal conditions for attenuation minimization lie near 0.045 wt% defoamer concentration and 222 minutes of mixing time. In the subsequent step, Response Surface Methodology (RSM) was employed to conduct a more precise exploration of the local optimum within the defined design space.

3.3.3. Response Surface Methodology

Following the factorial design and Steepest Ascent Method, defoamer concentration and mixing time were identified as statistically significant factors influencing the attenuation rate, and the potential presence of curvature in the response surface was suggested. Consequently, this study employed Response Surface Methodology (RSM) to perform a more refined optimization of the process parameters [

20].

The RSM experimental design was based on a Central Composite Design (CCD), with the optimal condition derived from the Steepest Ascent Method—namely, 0.045 wt% defoamer concentration and 222 minutes of mixing time—used as the center point. The design included a total of 14 additional experiments: three center points per block, four axial points, and seven factorial points from the previous design [

21]. The detailed experimental matrix and the measured attenuation rates are summarized in

Table 7.

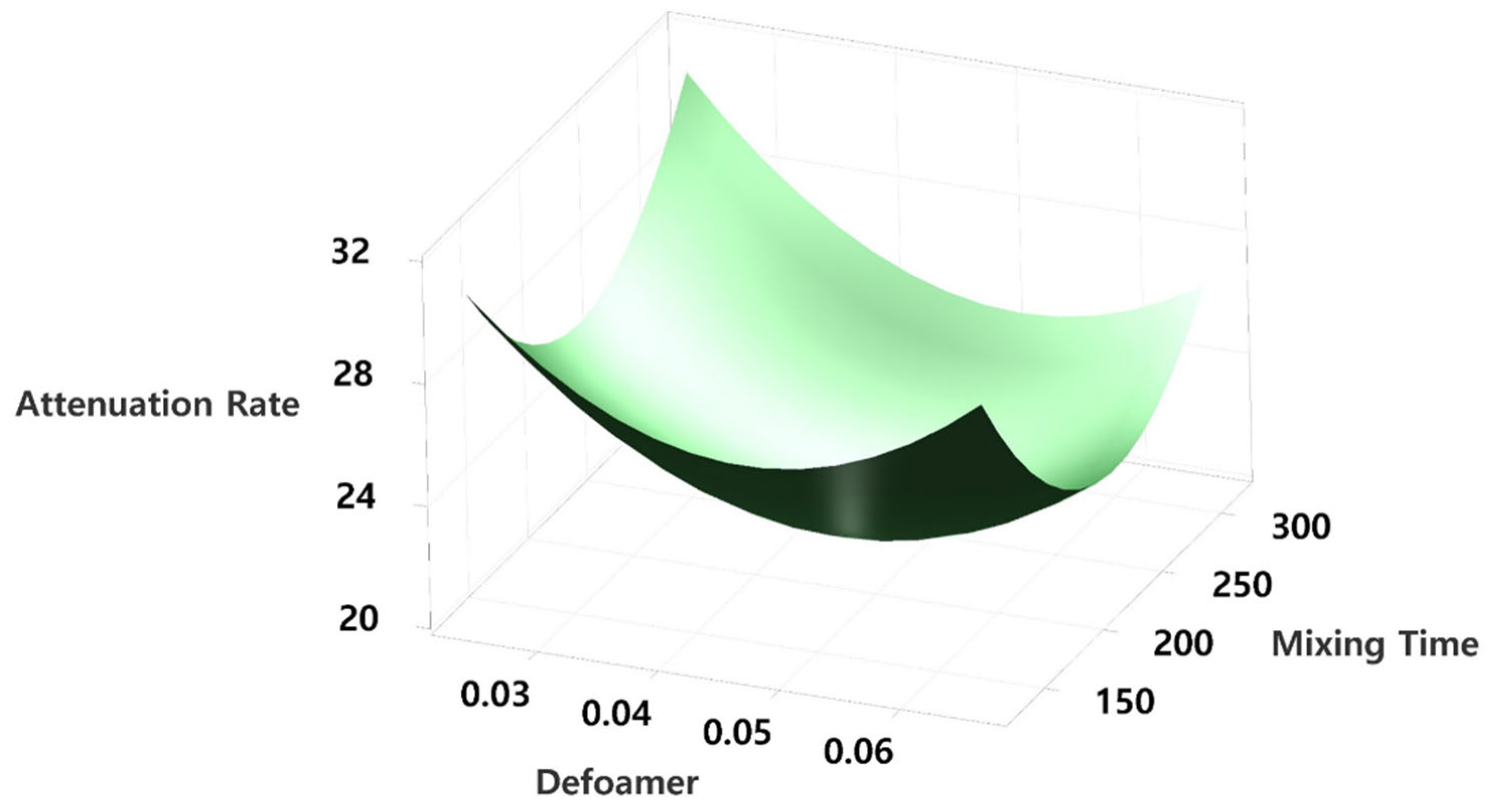

Figure 7 presents a three-dimensional contour plot of the response surface, visually confirming that the minimum attenuation rate occurs in the vicinity of 0.045 wt% defoamer concentration and 222 minutes of mixing time. Subsequently, a numerical optimization tool based on the fitted RSM model was employed to determine the precise combination of process variables that minimizes the attenuation rate.

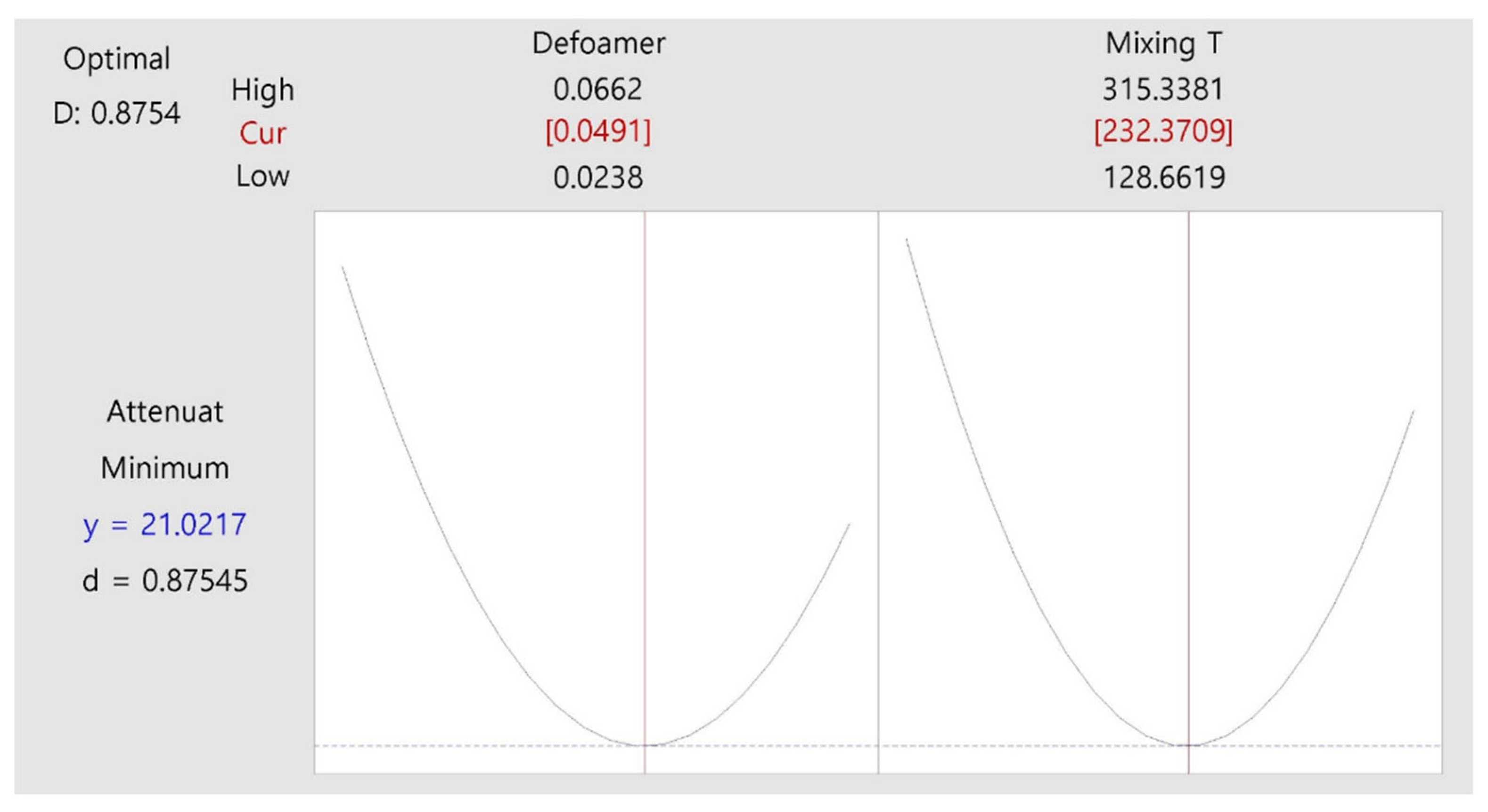

As shown in

Figure 8, the optimal condition was identified at a defoamer concentration of 0.049 wt% and a mixing time of 232 minutes, at which point the attenuation rate was minimized to approximately 21%. These findings experimentally demonstrate that fine control over defoamer concentration and mixing time significantly contributes to the reduction of micro-void content, thereby enhancing the mechanical performance of the composite material [

22].

The outcome of the response surface optimization highlights the critical impact of the defoaming process on the quality of composite structures used in submarine applications. Furthermore, it supports the effectiveness of statistical process optimization approaches in achieving consistent manufacturing quality and improving the reliability of advanced composite fabrication.