1. Introduction

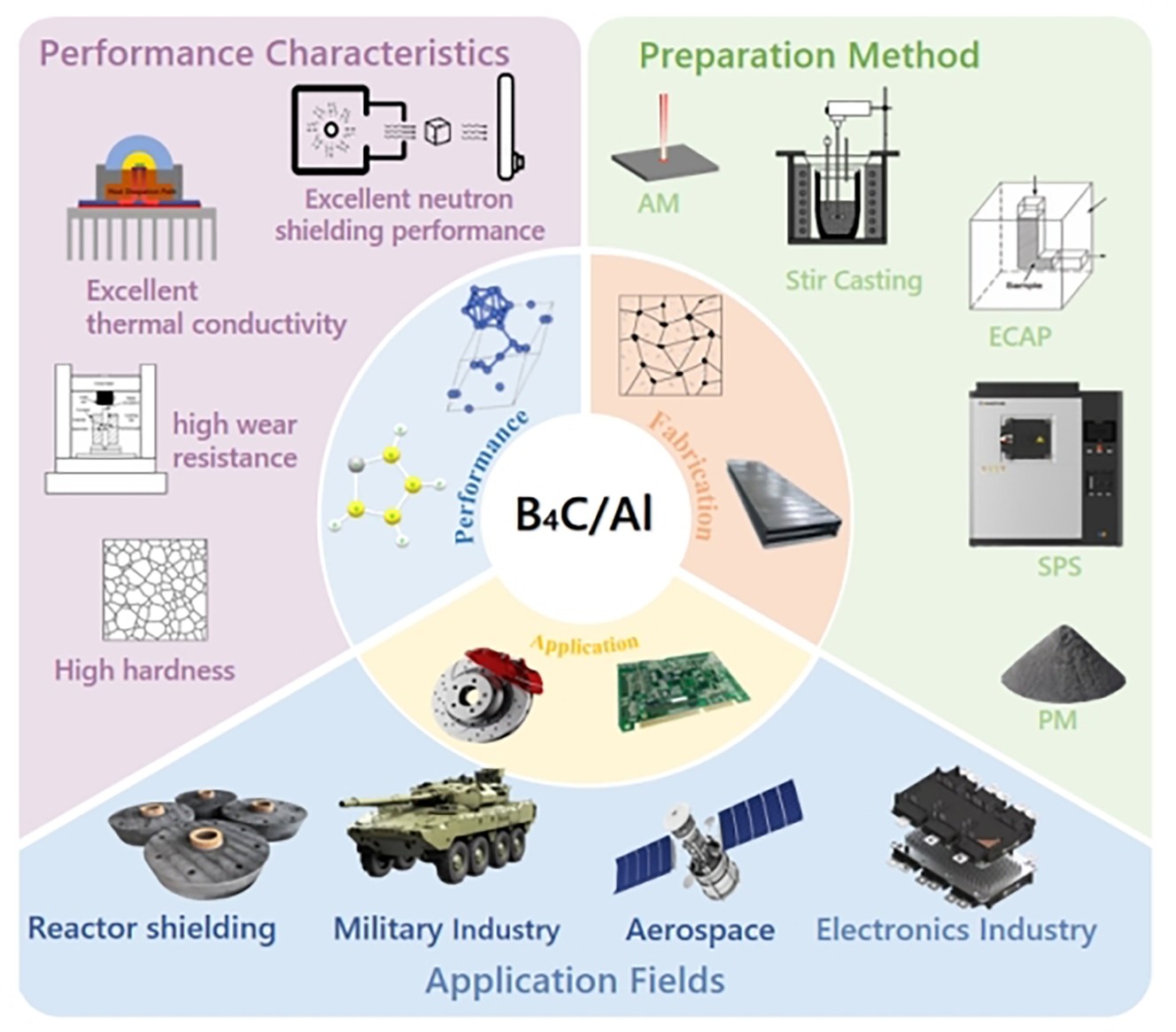

Aluminum-based boron carbide (B

4C/Al), an important branch of metal matrix composites, has received extensive attention due to its unique performance combination. The aluminum matrix endows excellent thermal conductivity, plasticity and processing performance, while the boron carbide (B

4C) reinforced phase provides extreme hardness (Mohs hardness>9.3), low density (2.52 g/cm

3)[

1]and excellent neutron absorption cross-section (up to 600 barn[

2]for thermal neutron absorption cross-section). This "strength-toughness" synergistic effect enables high mechanical properties of B

4C/Al composites while maintaining the lightweight of aluminum alloys, making them irreplaceable key materials in modern industry.

In recent years, the rapid growth of the nuclear energy and aerospace industries has driven accelerating research into B

4C/Al composites. These materials are critical for nuclear applications, including spent fuel storage and reactor shielding, because of their lightweight and neutron-absorbing properties[

3,

4]. Due to its high specific strength, it is an ideal protective material for armored vehicles in defense and military industry[

5,

6,

7]. Also, its regulating thermal expansion and excellent thermal conductivity offer unique advantages for electronic packaging applications[

8,

9]. The ongoing optimization of material properties has spurred persistent innovation in fabrication methods, progressing from conventional powder metallurgy[

10] and stir casting[

11,

12]to advanced techniques like laser additive manufacturing (AM) and equal-channel angular pressing(ECAP)[

13,

14,

15,

16].

This paper systematically reviews recent advancements in B4C/Al composites and provides a comprehensive analysis of their preparation methods, performance characteristics, and potential applications. Various synthesis techniques are evaluated, including powder metallurgy, stir casting, and AM, along with examination of material mechanical properties, thermal conductivity, and radiation shielding efficiency. Furthermore, the paper addresses critical challenges such as interfacial reactions, poor wettability and scalability issues that limit large-scale adoption. By proposing future research directions, including interface engineering, hybrid reinforcement strategies and sustainable processing, this review aims to facilitate the further development and widespread application of B4C/Al composites.

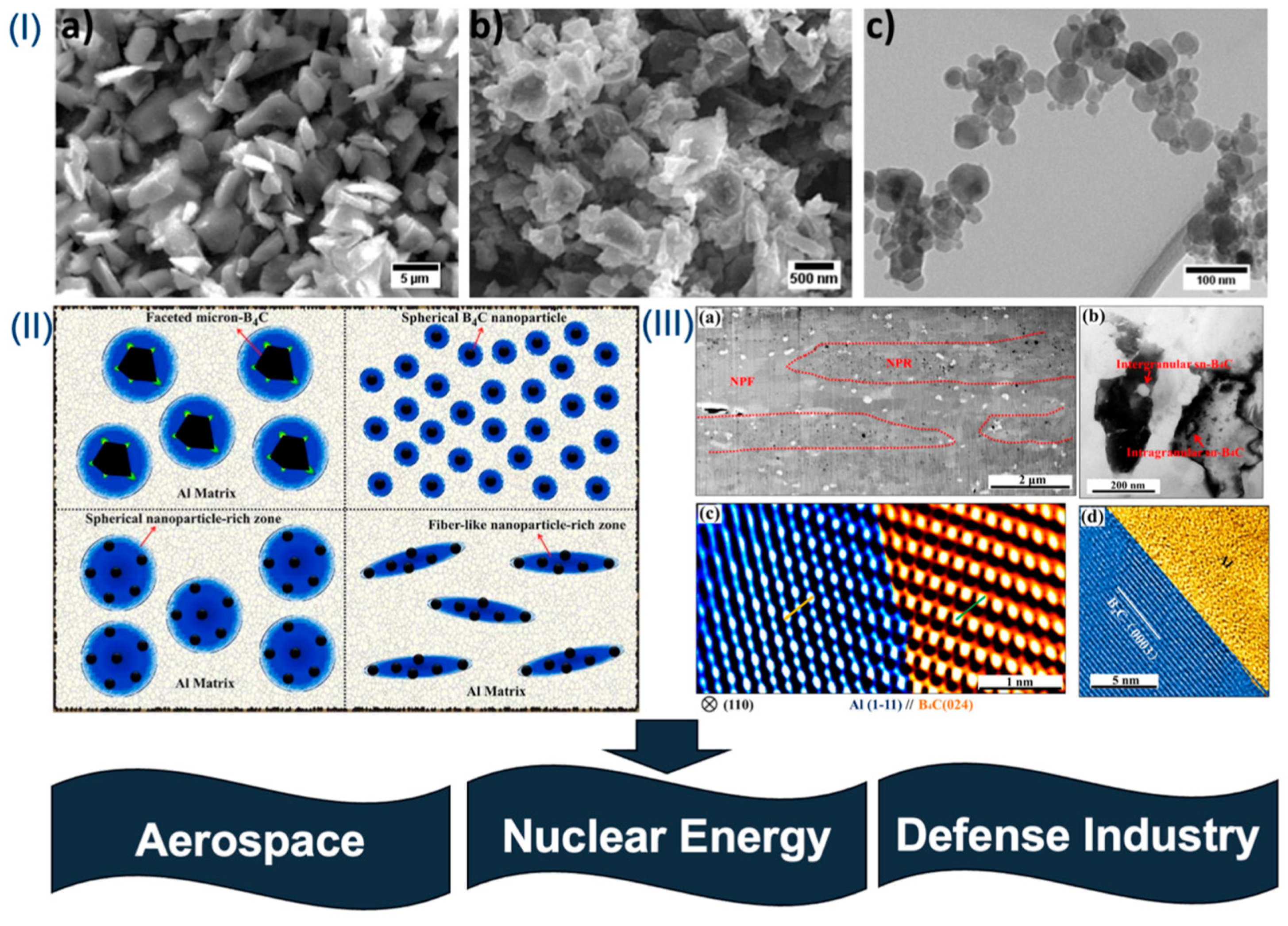

2. Material Fabrication

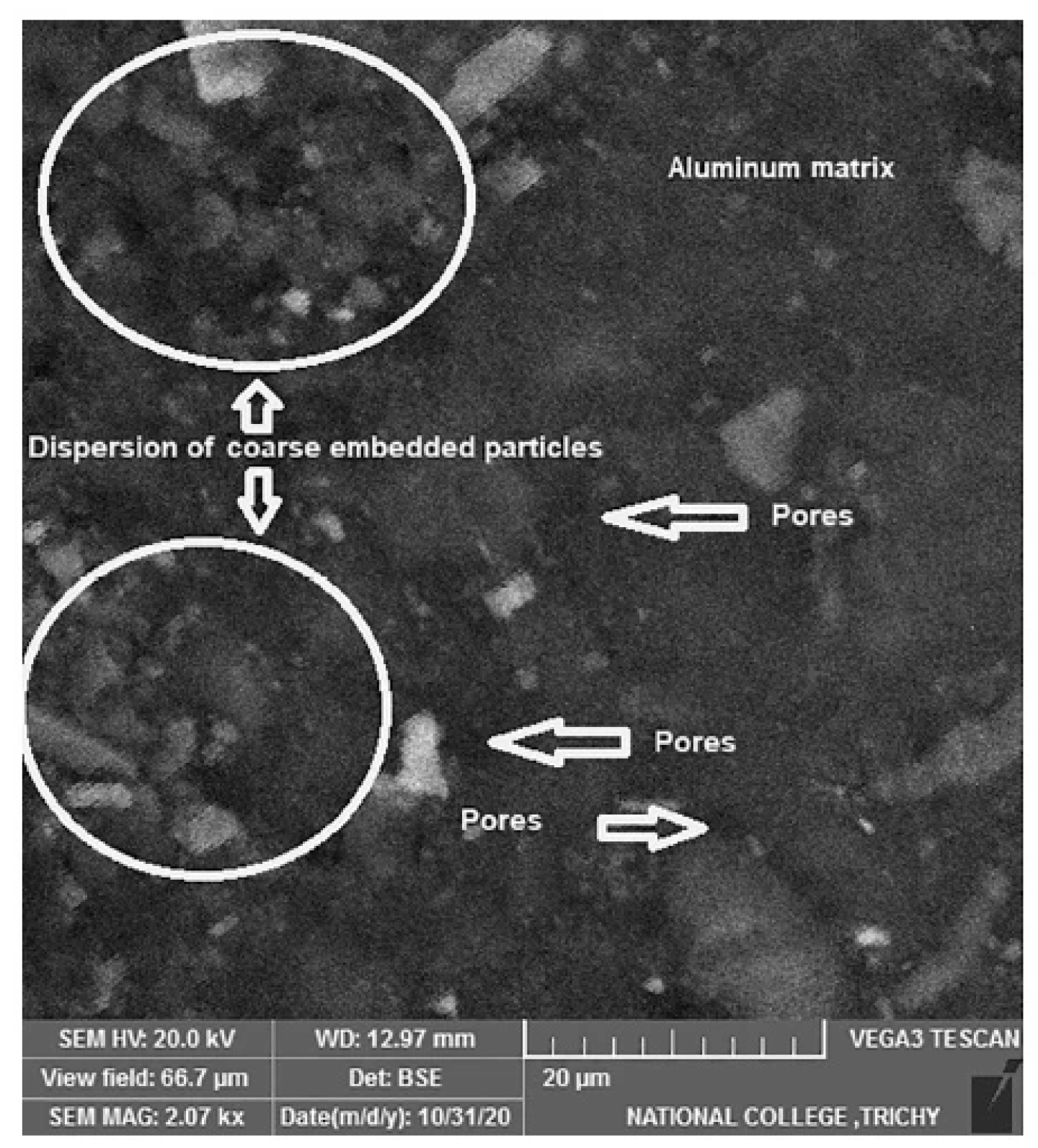

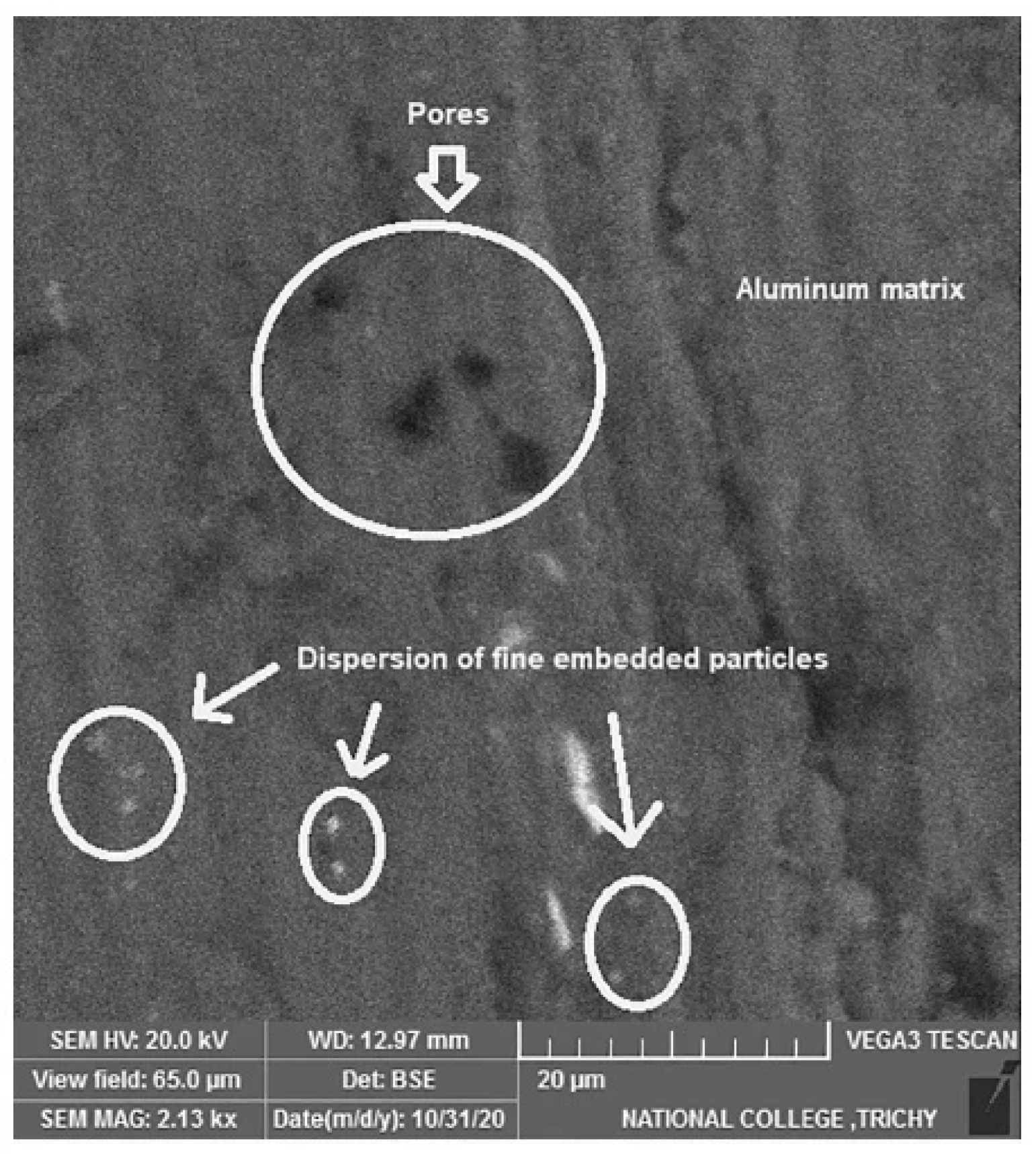

The performance of B₄C/Al composites highly depends on their preparation process. Different fabrication methods can result in significant differences in the reinforcement distribution, interfacial bonding states and microstructure, ultimately affecting mechanical, thermal and functional properties. As shown in

Figure 1(I-III) [

17,

18], the morphology and distribution of B₄C particles (from micro to nano-scale) play a critical role in determining interfacial bonding strength and dislocation interactions during powder consolidation. This section will provide a detailed overview of the current major preparation techniques and their recent advancements.

2.1. Powder Metallurgy Method

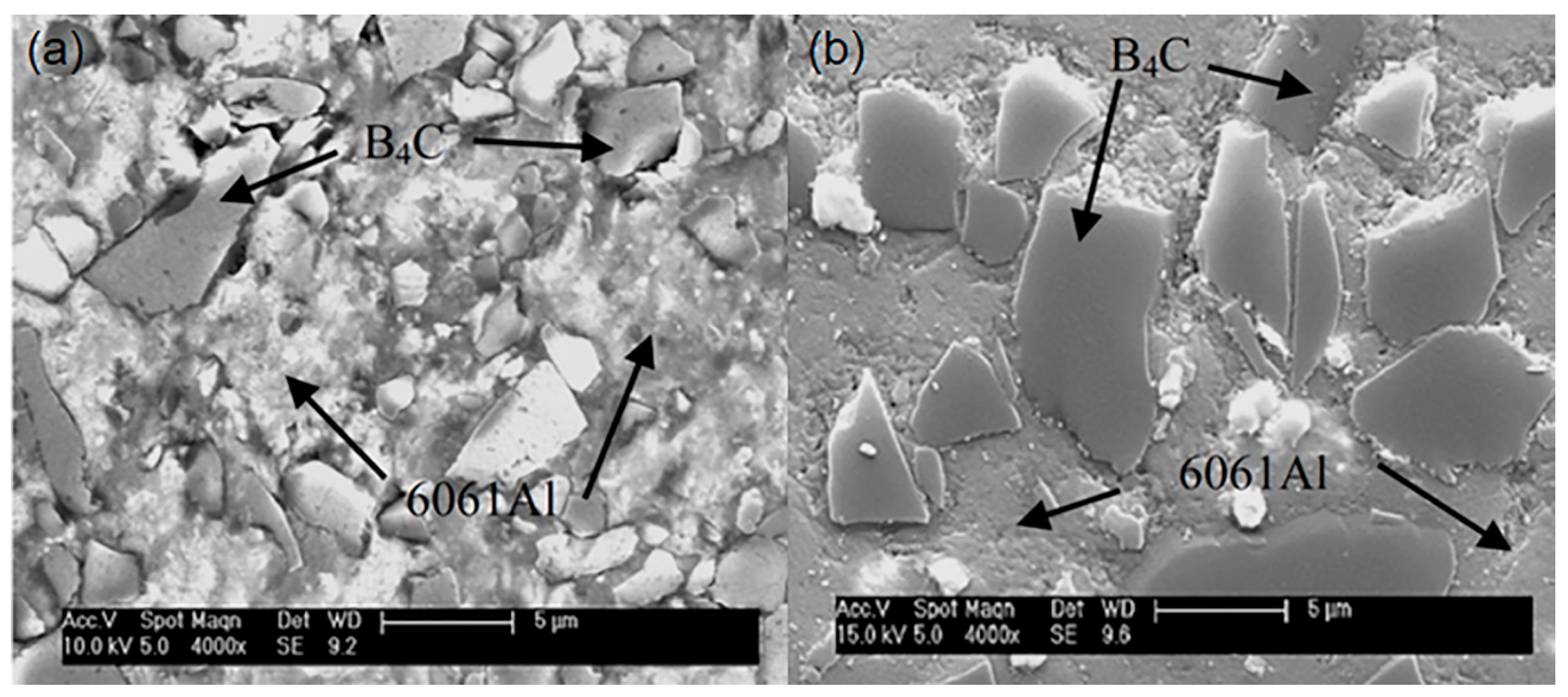

Pang et al. [

19]fabricated Al/B₄C composites with 30 wt% B

4C via semi-solid hot isostatic pressing (HIP).Research has demonstrated that, under process conditions of 650°C and 30 MPa, the 6061 Al matrix forms a 15 vol% liquid phase, effectively filling the internal pores of the material. This results in a composite material density of 99.6% of the theoretical value, significantly outperforming the traditional vacuum sintering process (91.9%). The formation of liquid-phase Al not only improves the wettability between B

4C particles and the matrix, creating a strongly bonded interface structure, but also enhances the tensile strength of the composite material to 300 MPa, more than three times that of traditional methods. It is noteworthy that the semi-solid HIP process precisely controls the temperature window (640°C-660°C), thereby avoiding interface side reactions caused by high-temperature melting while ensuring the uniform distribution of B

4C particles.This approach fundamentally addresses the issues of poor density and compositional segregation inherent in traditional processes. A microstructural analysis reveals that the liquid-phase Al, in its overflow state, uniformly coats the material surface, thereby enhancing the composite material's overall integrity. This enhancement in material performance, accomplished through high densification and microstructural optimization, offers a novel technical approach for developing high-performance neutron shielding materials based on the isotopic properties of 10B. It is particularly noteworthy that the structure, which is nearly fully densified (porosity <0.4%), and the uniform B

4C distribution obtained through this process, lay a critical material foundation for achieving stable neutron absorption performance in subsequent applications.

Thiruppathi et al.[

20]conducted a comparative study of aluminum-based brake pad composites fabricated via spark plasma sintering (SPS) and microwave sintering, revealing that SPS-processed specimens exhibited superior density and microhardness. This enhancement was attributed to two key mechanisms; localized high temperatures generated by pulsed current and plasma activation effects, which collectively accelerate particle diffusion bonding and densification (

Figure 2 and

Figure 3) Pul et al.[

6] fabricated B

4C/SiC hybrid-reinforced 7075 aluminum alloy composites via SPS, demonstrating that a 20% reinforcement ratio optimized the balance between machinability and ballistic performance. The combination of mechanical alloying and powder metallurgy has proven to be an effective approach for fabricating nanostructured B

4C/Al composites. Li et al.[

21] successfully dispersed B

4C nanoparticles within an Al5083 matrix using high-energy ball milling, with subsequent hot pressing, to produce composites of ultrahigh compressive strength (1065 MPa). This exceptional mechanical performance was attributed to synergistic strengthening mechanisms, including Hall-Petch grain refinement, Orowan strengthening and the Taylor dislocation mechanism. Further demonstrating the versatility of this approach, Zhang et al.[

22] developed tri-modal B

4C/Al composites through similar processing routes. Their work revealed that the formation of amorphous multilayer interfaces and MgO nanocrystalline regions significantly enhanced interfacial bonding strength, contributing to improved composite performance.

2.2. Liquid Preparation Technology

Liquid preparation technology primarily involves methods like stir casting and melt impregnation, which offer the advantages of low cost and scalability for mass production. However, in the preparation of B

4C-rich composite materials (>15 %), challenges such as poor wettability and particle segregation arise. Among liquid preparation methods, stirred casting remains the most widely used process. Thangadurai et al.[

23] conducted a systematic study on the fabrication and properties of AA6061-B

4C particulate composites produced via stirred casting. Their results demonstrated that as the B

4C content increased from 0 to 15 wt.%, the material hardness improved significantly while the density exhibited a decreasing trend. Notably, the composite containing 15 wt.% B

4C exhibited optimal performance under mechanical loading, showing superior axial stress, circumferential stress and hydrostatic stress resistance compared to other compositions[

23]. Bhowmik et al.[

24] identified melt temperature, stirring speed and time as critical parameters in the stirred casting that determine product quality and demand precise control. To enhance particle dispersion in Al6063-B

4C-Gr composites, Thakur et al.[

25] added K

2TiF

6 as a wetting agent during fabrication, which significantly improved interfacial bonding characteristics. Melt impregnation technology is particularly suitable for fabricating B

4C composites of high volume fraction, offering distinct advantages in achieving uniform particle distribution and dense matrix packing. Pramono et al.[

26] fabricated B

4C/Al composites through self-propagating high-temperature synthesis coupled with melt impregnation. Their results demonstrated that this hybrid approach enables effective control of interfacial reaction kinetics. Furthermore, the semi-solid processing technology employed in this work combines the advantageous characteristics of both liquid- and solid-state fabrication methods. Pang et al.[

19]systematically evaluated the mechanical properties and microstructural characteristics of B

4C/Al composites using a WANCE100 universal testing machine and SIRION200 field-emission SEM. Their results demonstrated that the semi-solid HIP can produce near theoretical density B

4C/Al composites with optimal material integrity.[

27]

Figure 4.

Microstructures of B₄C/Al composites prepared by conventional vacuum sintering-(a) and semisolid HIP-(b)[

19].

Figure 4.

Microstructures of B₄C/Al composites prepared by conventional vacuum sintering-(a) and semisolid HIP-(b)[

19].

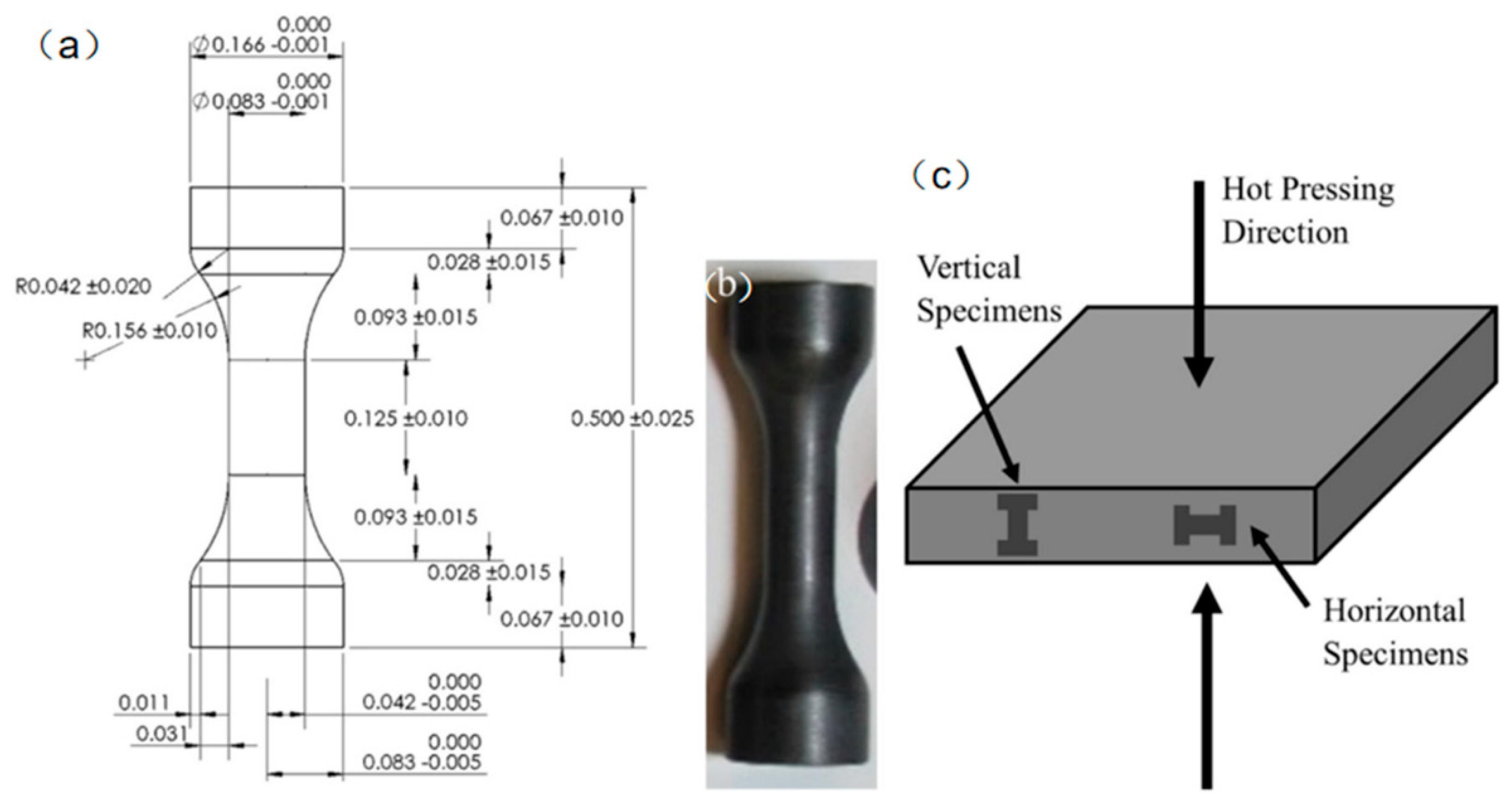

2.3. Solid-State Processing Technology

Solid-state processing technologies primarily comprise intense plastic deformation processes, including ECAP and friction stir processing (FSP), which are particularly effective for microstructural refinement and property enhancement in as-cast or sintered composite materials. Sharath et al.[

15]processed Al2618-B

4C composites via ECAP and demonstrated that increasing the number of extrusion passes led to significant improvements in both hardness and wear resistance. These enhancements were correlated with microstructural refinement and more uniform distribution of reinforcing particles. Butola et al.[

28]employed response surface methodology to optimize FSP parameters for aluminum-based surface nanocomposites. Their model predicted optimal mechanical properties (ultimate tensile strength and microhardness) at a tool rotation speed of 1300 rpm, traverse speed of 30 mm/min, and with three processing passes[

29]. Khodabakhshi et al. [

30] developed an innovative accumulative fold forging process for fabricating nanolayered AA8006-B

4C composites. Through 26 forging steps with intermediate annealing treatments, they achieved an ultrafine-grained structure (average grain size <50 nm) at room temperature. The resulting material exhibited a remarkable increase in hardness from 30 HV to 205.4 HV (

Table 1), representing one of the highest hardness values reported for Al matrix composites.

2.4. Additive Manufacturing (AM) Technology

AM technology offers a novel approach for fabricating complex-shaped B

4C/Al composite components.Xiao et al.[

31]utilized laser directed energy deposition (LDED) technology to prepare B

4C/Al composite materials and investigated the effects of varying laser powers on the microstructure, mechanical properties, and corrosion resistance of the materials. The findings of the study demonstrated that this process had the potential to yield composite materials that exhibited both exceptional ductility and moderate strength. The enhancement in performance was predominantly ascribed to dislocation formation, grain refinement, and precipitation effects. Additionally, Sun et al.[

32] developed a low-cost multi-material additive manufacturing method—wire powder arc additive manufacturing (WPA-AM)—that successfully achieved the controlled addition of ceramic particles such as B

4C, SiC, TiC, and WC/W

2C in aluminum-based composite materials. This method significantly improved the mechanical properties of the materials through optimized process parameters. Among the various additive manufacturing technologies, laser powder bed fusion (LPBF) has become one of the most widely used methods in B

4C/Al composite material research due to its ability to produce multi-material structures and functional gradient materials[

33].Yilbas et al.[

34]systematically investigated the effect of laser treatment on surface properties of B

4C/Al composites, revealing the formation of a dense sub-micron grain layer and AlN compounds on the surface. This treatment led to significant enhancements in both microhardness and surface hydrophobicity.

2.5. Surface Composite Technology

Surface composite technology can produce B

4C/Al composite coatings on substrate materials, offering both functional performance and cost efficiency. Abenojar J. et al.[

35]found that aluminum-based composites containing Fe/B exhibited reduced corrosion resistance at lower sintering temperatures of 650°C–950°C. However, mechanical alloying treatment significantly improved the corrosion resistance of boron carbide-containing aluminum alloys.However, the electrochemical potential difference between the aluminum matrix and B

4C reinforcement led to preferential interfacial corrosion, resulting in reduced corrosion resistance compared to pure aluminum[

36]. Ziani et al.[

37]employed ion beam sputtering deposition to fabricate Al/Mo/SiC tri-component periodic multilayer films, achieving reflectance of 48% and 27.5% at wavelengths of 17.3 nm and 28.2 nm, respectively. This advancement provided critical technical support for the solar orbiter mission’s extreme ultraviolet (EUV) imaging system. As illustrated in

Table 2, the process characteristics and typical performance indicators of the main preparation methods for B

4C/Al composite materials are summarized.

3. Performance Characteristics

B4C/Al composites exhibit critical performance characteristics across four key domains; mechanical properties, radiation shielding capability, thermophysical behavior, and tribological performance. These functional attributes are fundamentally governed by material composition and microstructural features. The following section provides a systematic analysis of these property relationships and their determining factors.

3.1. Mechanical Properties

The mechanical properties of B4C/Al composites represent a critical performance metric, fundamentally determining their structural application viability. Extensive research demonstrates that optimized material design and processing can produce B4C/Al composites with superior strength, hardness and wear resistance compared to conventional aluminum alloys.

3.1.1. Strength Characteristics

The strength of B

4C/Al composites is governed by several critical factors, including the matrix alloy composition, B

4C particle content and spatial distribution, and the interfacial bonding quality between reinforcement and matrix. Li et al.[

21] achieved an ultrahigh compressive strength of 1065 MPa in their B

4C-reinforced Al5083 nanocomposites. This exceptional performance was attributed to synergistic strengthening mechanisms, including Hall-Petch effect (grain boundary strengthening), Orowan strengthening (dislocations by passing particles),and Taylor mechanism (geometric necessary dislocations).Pang et al.[

19]demonstrated that the aluminum matrix undergoes a transformation into a liquid phase composed of 15 vol% under the conditions of the hot isostatic pressing (HIP) semi-solid process, which involves a temperature of 650°C and a pressure of 30 MPa. This liquid phase diffuses into the pores of the material, leading to an increase in its density to 99.6% (2.66 g/cm

3). The resultant material exhibits a tensile strength of 301 MPa, which is significantly higher than the tensile strength of 86 MPa observed in conventional vacuum sintering processes. This enhancement in tensile strength is attributed to the presence of the liquid phase, which contributes to the material's increased resistance to deformation. EDS analysis indicates that B₄C particles form strong interface bonds with the aluminum matrix, and the fracture surface exhibits a ductile dimple structure, indicating high load transfer efficiency. Notwithstanding the high B

4C content (30 wt%), which engenders a low elongation rate (<3%), the HIP process has been shown to enhance the mechanical properties of the composite material by eradicating pores and optimizing interfaces.

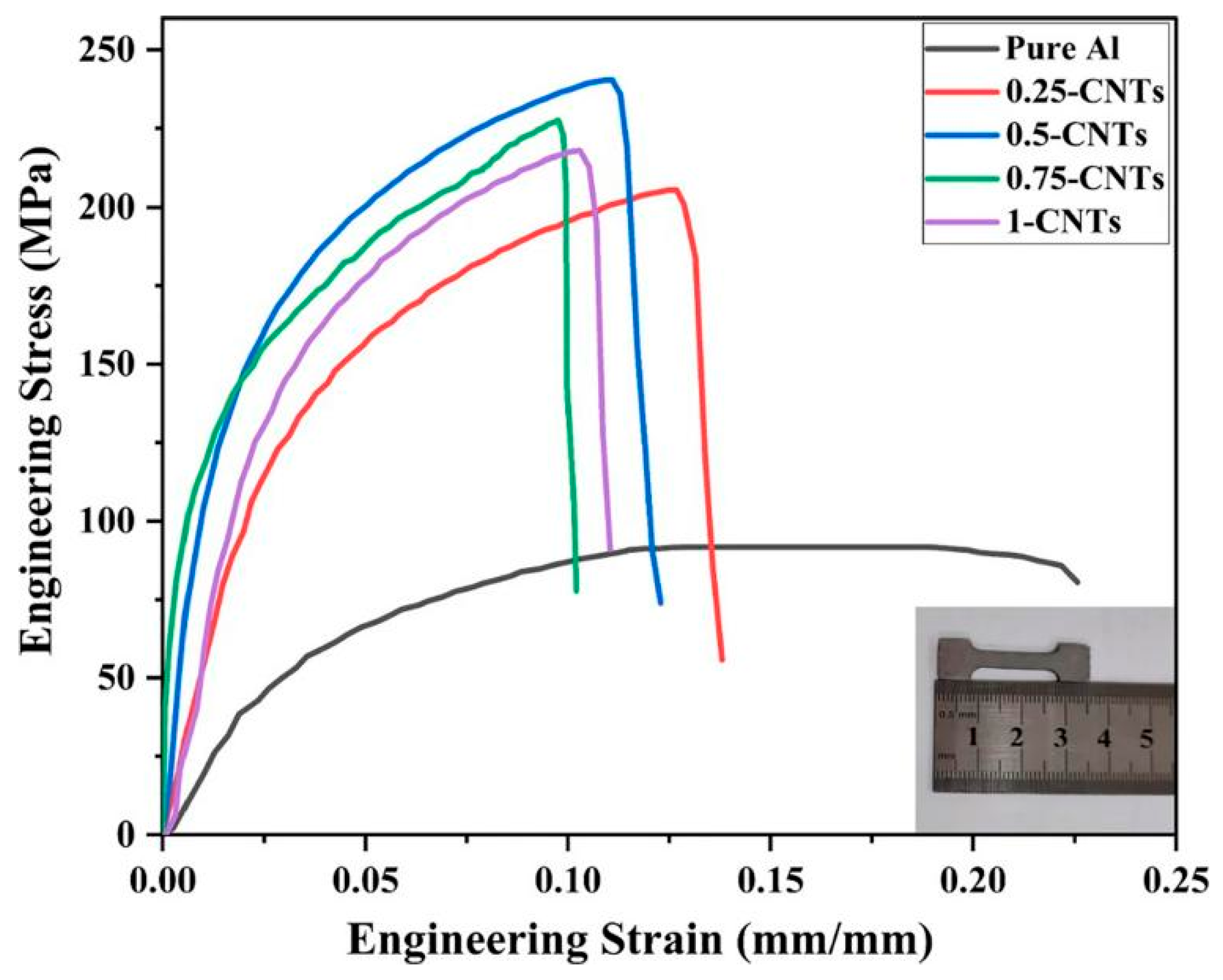

Hybrid reinforcement is an effective strategy for enhancing the overall performance of B

4C/Al composites. Khan et al.[

38]engineered a hybrid-reinforced aluminum matrix composite by incorporating both hexagonal boron nitride and multi-walled carbon nanotubes. The resulting material exhibited a remarkable 189% enhancement in tensile strength, which the researchers attributed to the homogeneous dispersion of reinforcement phases, in-situ formation of hard aluminum carbide precipitates and effective load transfer through the nanoscale reinforcement network (

Figure 5). Raja et al.[

39]engineered an Al7075 hybrid composite incorporating 9 wt.% B

4C and 3 wt.% TiB

2 reinforcements, achieving a tensile strength of 233 MPa. This performance surpassed that of composites with either reinforcement alone, demonstrating the synergistic benefits of the dual-phase reinforcement system.

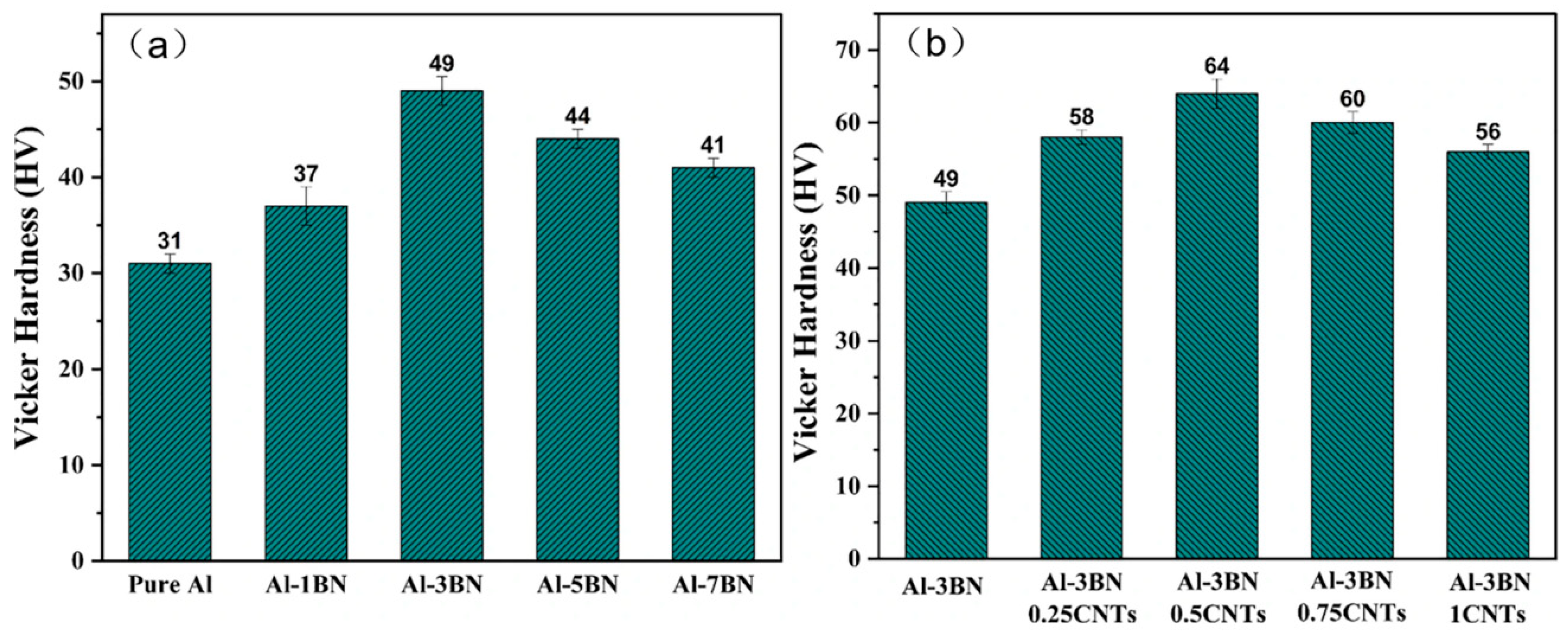

3.1.2. Hardness and Toughness

The incorporation of B

4C particles can substantially improve the hardness of the aluminum matrix. This reinforcement effect can be further enhanced in hybrid systems, as demonstrated by Khan et al.[

38], where the synergistic combination of h-BN and CNTs in aluminum matrix composites resulted in a 106% increase in Vickers hardness compared to the unreinforced matrix. Figure 6 shows the micro-Vickers hardness variations of pure aluminum, BN/Al and BN-CNTs /Al composites. As shown in Figure 6 (a), the microhardness of the aluminum matrix exhibits a significant increase from (31 ± 1) HV to (49 ± 1.5) HV with h-BN content increasing from 0 to 3 wt.%, demonstrating the effective hardening capability of h-BN reinforcement. At the optimal 3 wt.% h-BN concentration, the composite achieves peak hardness due to h-BN’s superior dispersion and significantly higher intrinsic hardness compared to pure aluminum. These results clearly demonstrate that h-BN incorporation can substantially enhance the hardness of aluminum matrix composites. Furthermore, Figure 6 (b) demonstrates the synergistic effect of CNT addition (0-1 wt.%) to the Al-3BN composite. The incorporation of 0.25 wt.% CNTs increased the microhardness from (49 ± 1.5) HV to (58 ± 2) HV (87% higher than pure aluminum). At 0.5 wt.% CNTs, the hardness further improved to 64 ± 2 HV, representing a 30.6% increase relative to the Al-3BN composite and 106.4% compared to pure aluminum. Alizadeh et al.[

40] observed a linear increase in composite hardness with rising B

4C content, accompanied by a threefold improvement in wear resistance under 20 N loading conditions. Khodabakhshi et al.[

30] fabricated AA8006-B

4C nanocomposites via accumulative fold forging, achieving a record hardness of 205.4 HV for aluminum matrix composites. However, this exceptional hardness enhancement typically comes at the expense of reduced toughness, illustrating the characteristic strength-toughness trade-off in metal matrix composites..Pandey et al.[

41] demonstrated that when Al

2O

3 content surpassed 30 wt.% and B

4C exceeded 15 wt.%, the composite’s fracture mechanism transitioned from ductile dimple rupture to brittle cleavage fracture. To achieve an optimal balance between hardness and toughness, Thakur et al.[

25]engineered an Al6063 composite co-reinforced with B

4C and graphite. The graphite’s solid lubricating effect effectively inhibited crack propagation, thereby significantly improving the material’s fracture toughness while maintaining enhanced hardness from B

4C.

Figure 6.

The micro-Vickers hardness of 3BN/Al-(a) and 3BN-CNT/Al-(b) [

38].

Figure 6.

The micro-Vickers hardness of 3BN/Al-(a) and 3BN-CNT/Al-(b) [

38].

3.2. Shielding Performance

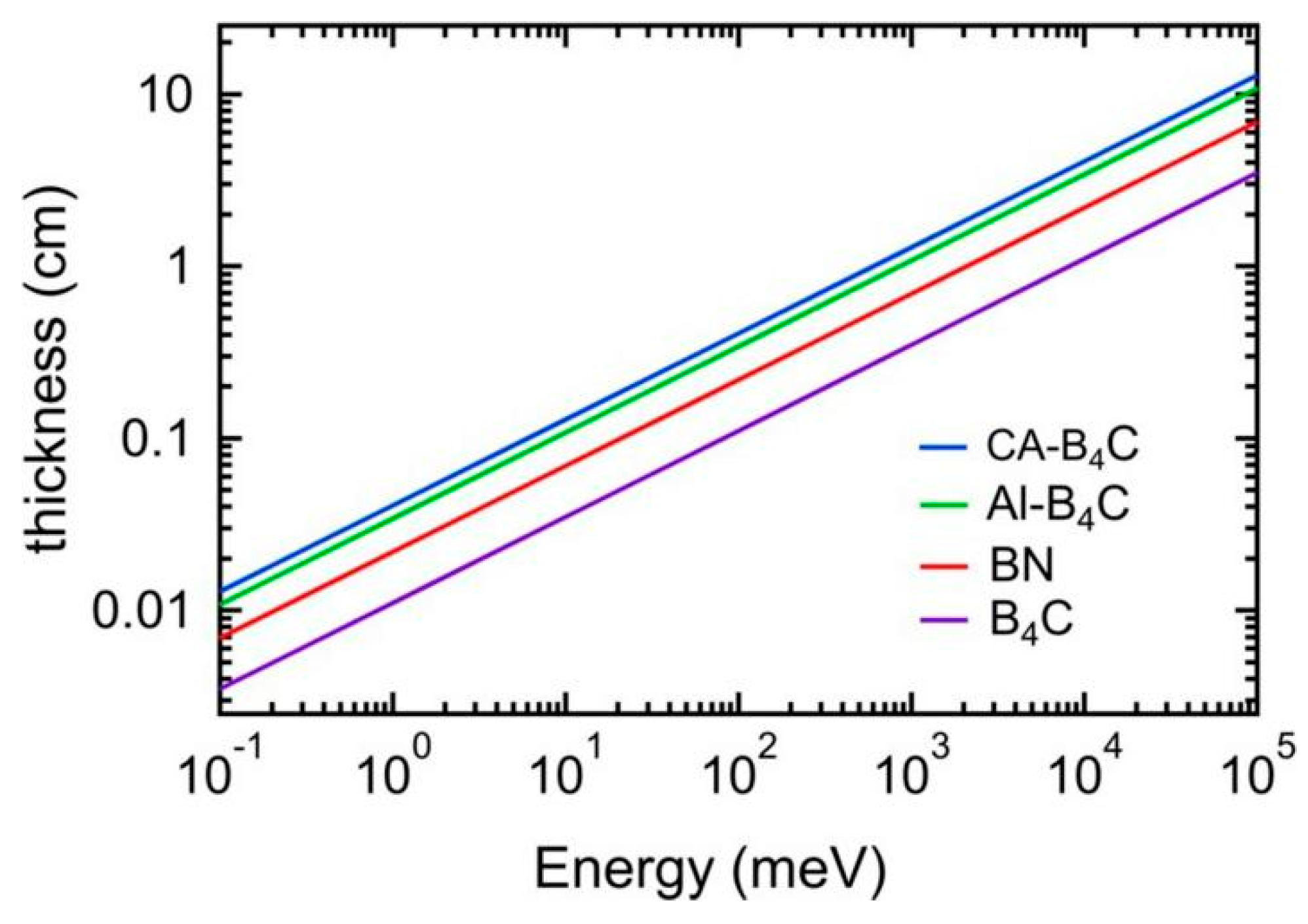

Neutron shielding performance represents the most critical functional property of B4C/Al composites, establishing their irreplaceable role in nuclear energy applications. The material’s neutron shielding effectiveness is primarily governed by three key factors; the concentration of 10B isotopes, material thickness and incident neutron energy spectrum.

3.2.1. Neutron Absorption Characteristics

Through Monte Carlo simulations, Dai et al.[

42] investigated the neutron shielding performance of B₄C/Al composites, revealing two key relationships; the neutron transmission coefficient decreased linearly with increasing B

4C content, and it exhibited exponential decay with the increase of material thickness. The absorption fraction A of the material follows the Beer–Lambert law.[

43]

where the penetration depth can be determined in terms of the unit cell volume,

V z is the material thickness,

V the unit cell volume, σ

obs absorption cross-section, ϵ packing fraction of the material, and

Nf.u. is the number of formula units. The material thickness required to achieve specific absorption rates is a critical design parameter. As shown in

Figure 7, B₄C/Al composites require only centimeter-scale thickness to achieve 99% neutron absorption in the thermal energy region (<1 keV), demonstrating their potential for compact shielding structures. This efficiency stems from the high ¹⁰B areal density (0.035 g/cm

2–0.0389 g/cm

2) and optimized packing fraction (90%) as calculated in Ref. [

44]

3.2.2. Irradiation Stability

In the domain of nuclear applications, the stability of B

4C/Al composite materials under radiation exposure is a critical performance metric. Xian et al.[

45]reported that Al6061-31vol.% B

4C composite materials prepared using the hot isostatic pressing (HIP) process at 580°C exhibited excellent microstructural stability, with B

4C particles uniformly distributed in the matrix and minimal interface reactions. This uniformity guarantees the stability of the material's mechanical properties and neutron absorption performance under irradiation conditions. Quantitative measurements of the distribution of particles in the composite material demonstrated an average B

4C content of (31 ± 0.5)%, with the standard deviation indicating optimal dispersion uniformity. This uniform distribution is critical for maintaining stable neutron shielding performance, as particle aggregation or uneven distribution may lead to localised performance degradation or reduced absorption efficiency. Furthermore, the composite material's density is nearly equal to the theoretical value (2.642 g/cm

3), exhibiting minimal porosity. This characteristic has been demonstrated to enhance the material's radiation resistance and effectively suppress defect formation caused by neutron irradiation.

3.3. Thermophysical Properties

The thermal conductivity and coefficient of thermal expansion (CTE) of B

4C/Al composites are critical performance parameters, particularly for electronic packaging applications where efficient heat dissipation and dimensional stability are essential. Ambigai et al.[

8]characterized the thermophysical properties of centrifugally cast aluminum-based B

4C functionally graded composites (FGCs). Their study revealed that incorporating 100 μm reinforcement particles enhanced thermal conductivity by 46.4% and thermal diffusivity by 27.8%, relative to the matrix material. This improvement was attributed to the formation of more continuous thermal conduction pathways through percolation of large B

4C particles. Nano-alumina reinforced B₄C/Al composites have been developed,which demonstrate exceptional thermal conductivity. These advanced materials show particular promise for defense, military, and aerospace applications where efficient heat dissipation is critical. Through first-principles calculations, Zhang et al.[

46]demonstrated that SiC and phosphorus-doped graphene form strong interfacial bonds with the Al matrix, significantly enhancing the composite’s thermal conductivity, as shown in

Table 3.

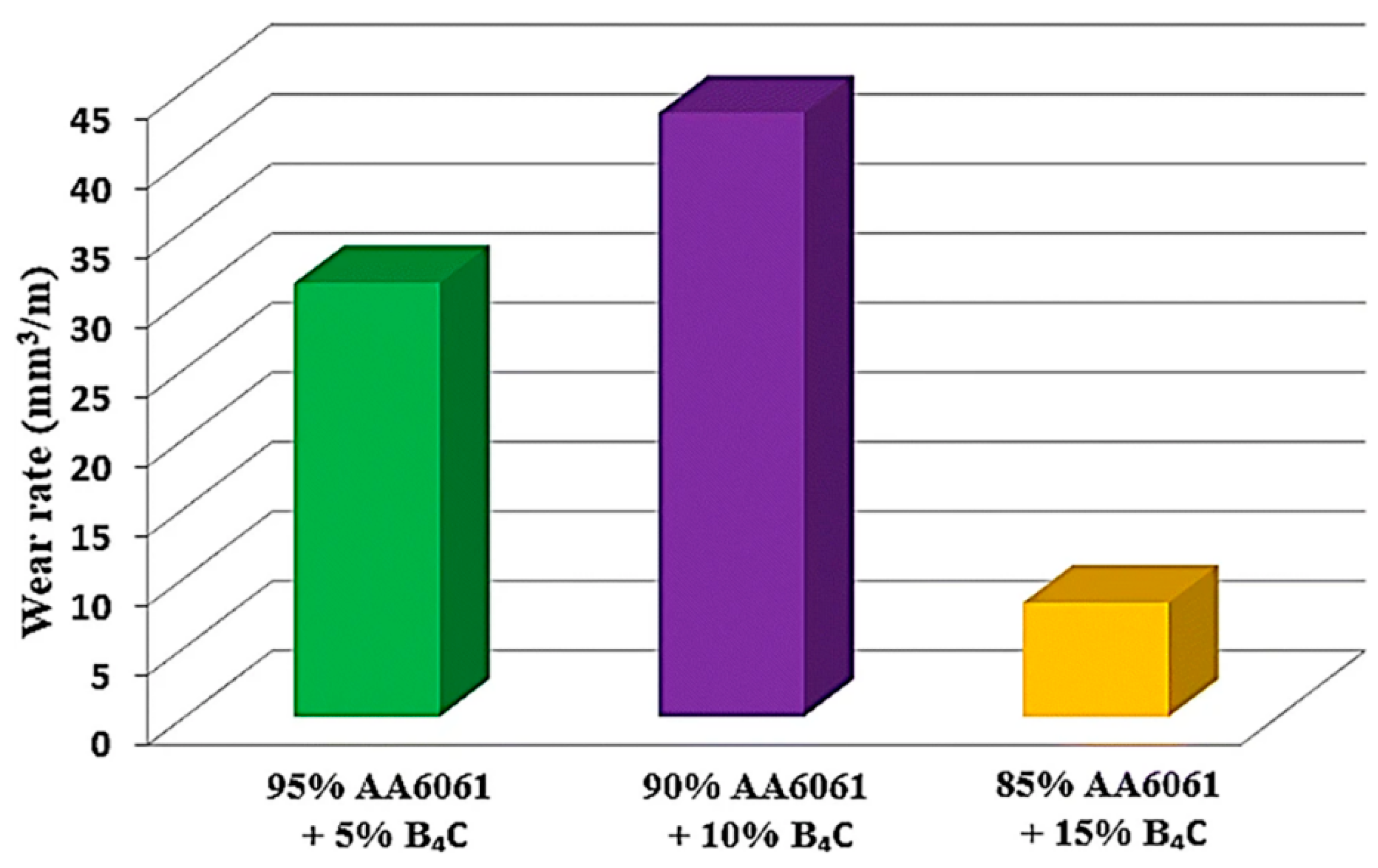

3.4. Friction and Wear Performance

B

4C/Al composites exhibit outstanding wear resistance, positioning them as promising candidates for high-performance friction components, including braking systems and bearings.Hynes et al..[

47]analyzed the wear performance of AA6061-B₄C composites with varying reinforcement content (5wt.%, 10wt.%, and 15 wt.%) and demonstrated that the wear rate decreased significantly with increasing B₄C content, as illustrated in

Figure 8. The composite with 15% B₄C exhibited the lowest wear rate, highlighting the role of hard ceramic particles in enhancing abrasion resistance and reducing surface degradation.Emiru et al.[

48]demonstrated that incorporating SiC, B

4C and MoS

2 nanoparticles into Al6061 alloy synergistically enhanced wear resistance through dual mechanisms; the solid lubrication effect of MoS

2 and in-situ formation of a protective B

2O

3 layer, enhanced the wear resistance of the multiphase reinforced composite compared to the unreinforced alloy. Ali et al.[

49]identified an optimal composition in AA6351 hybrid composites, where the synergistic combination of 1 wt.% graphite and 1 wt.% B

4C nanoparticles yielded superior tribological performance.

3.5. Other Performances

3.5.1. Corrosion Resistance

Han et al.[

50] conducted a systematic investigation of the electrochemical behavior of B

4C/Al composites, revealing an inverse correlation between B

4C volume fraction and corrosion resistance. This degradation was attributed to two primary mechanisms; galvanic coupling between the aluminum matrix and B

4C particles, and an oxygen diffusion-controlled corrosion process at the reinforcement-matrix interfaces.Huang et al.[

51] used low-pressure cold spraying technology to create an Al-30% B₄C composite coating on a 5083 aluminum alloy substrate. Friction and wear tests revealed that the coating's wear rate was one-third that of the base aluminum alloy. However, electrochemical tests showed that the coating's corrosion rate was slightly higher than that of the base material. The study revealed that the unique fragmentation and embedding behavior of B₄C particles during deposition significantly influenced the coating's microstructure, thereby determining its neutron absorption performance and wear- and corrosion-resistant properties. The residual content of B₄C particles is a key factor in the coating's functional properties.

3.5.2. Processing Performance

The processing characteristics of B

4C/Al composites critically influences their industrial applicability. Mohankumar et al.[

52]developed a predictive model for water-jet cutting angles in Al6063-B

4C composites, effectively addressing dimensional precision challenges in machining hard particle reinforced lightweight alloys. Kumaran et al.[

53] achieved significant improvements in processing quality through parameter optimization of pulsed: YAG laser machining for Al6351-B

4C composites.

Table 4 comprehensively summarizes the key performance metrics and critical influencing factors for typical B

4C/Al composite systems. The optimization of machining parameters, including cutting speed, feed rate, and cutting depth, has been demonstrated to reduce surface roughness and energy consumption during the milling process of aluminum-based composite materials (AMCs) [

54]. A thrust prediction model during drilling is imperative for the optimization of machining such composites [

55]. The utilization of acoustic emission technology in the context of monitoring wire electrical discharge machining (WEDM) has been demonstrated to yield valuable Ref. information for the machining process [

56]. In the domain of laser processing, attaining optimal surface quality necessitates meticulous selection of processing parameters [

57].

4. Application Fields

B4C/Al composites have been successfully implemented in multiple high-tech fields including nuclear energy, defense and military systems, and aerospace due to their exceptional multifunctional performance, high mechanical properties (such as specific strength, hardness, and wear resistance), excellent neutron-shielding capabilities, superior thermophysical properties (e.g. thermal conductivity and tunable coefficient of thermal expansion), and lightweight characteristics. Their application scope continues to expand into emerging technological domains, advanced electronic packaging, high-performance transportation components, and specialized tool manufacturing. This section details their principal industrial applications, along with representative case studies.

4.1. Nuclear Energy Engineering

In nuclear energy applications, B4C/Al composites serve as critical neutron absorbing materials, particularly in spent fuel storage systems and reactor shielding components. These composites offer three key advantages, including an exceptionally high neutron absorption cross-section, superior thermal conductivity and optimal mechanical strength for structural applications.

4.1.1. Spent Fuel Storage

Spent fuel storage stands as the most prominent and well-established application of B

4C/Al composites. The B

4C/Al nuclear waste storage system incorporates two key design innovations; a reinforced auxiliary structure with moisture-resistant treatment, and synergistic integration of reinforced boron (high 10B neutron absorption cross-section) and tungsten-nickel-iron alloy (excellent γ-ray shielding). This optimized configuration enables radiation reduction, long-term stability of the shielding layer and environmental resilience.Shirvanimoghaddam et al.[

58] fabricated B

4C/Al neutron absorption plates for nuclear fuel assemblies using the stir casting method.They optimized the casting temperature to improve the mechanical properties of the neutron absorption plates.

4.1.2. Reactor Shielding

Aluminium-based boron carbide (B4C/Al) composite materials have been demonstrated to have unique application value in reactor radiation shielding. This is due to their high-efficiency neutron absorption capability and comprehensive advantages in radiation safety.

With regard to the optimization of shielding performance, the neutron shielding effect of B

4C/Al composite materials is closely related to material composition and thickness. Dai et al.[

42]discovered that the neutron transmission coefficient of B₄C/Al composite materials decreases linearly with increasing boron carbide content and exponentially with increasing material thickness through Monte Carlo simulations. Furthermore, the samples demonstrated heightened sensitivity in terms of energy response characteristics within the thermal neutron energy range. This superior performance in shielding is a notable advantage over conventional shielding materials.

In the context of irradiation safety verification, ensuring the stability of the material under reactor irradiation conditions is of paramount importance. Mi et al.[

59] conducted a thermal safety analysis using computational fluid dynamics (CFD) simulations to verify the structural integrity and thermal stability of B₄C/Al composite materials under in-core irradiation conditions. This analysis ensured the safety of the materials as reactor shielding materials.

4.2. National Defense and Military Industry

Boron carbide (B₄C) reinforced aluminum matrix composites have emerged as an ideal new-generation armor material due to their high hardness, low density and excellent ballistic resistance. The aluminum matrix provides lightweight characteristics, while the B4C reinforcement phase endows the material with outstanding impact resistance capabilities.

Boron carbide has unique advantages in armor applications, with exceptional comprehensive properties such as extremely high hardness (Mohs hardness 9.3), low density (2.52 g/cm

3) , and excellent thermochemical stability.[

1]These characteristics establish B

4C as an indispensable material for advanced armor systems. Pul et al.[

6] systematically investigated the ballistic performance of 7075 aluminum alloy composites reinforced with SiC and B

4C particles. Their study demonstrated that increasing the reinforcement ratio progressively improves ballistic resistance, with an optimal 20% reinforcement content achieving the ideal balance between ballistic protection and machinability. Moorehead et al.[

60] identified that microstructural defects (such as aggregates and carbonaceous thin sheets) in hot-pressed B

4C ceramics, significantly degrade mechanical performance. Through high-resolution micro-CT characterization (

Figure 9), they quantitatively mapped the size distribution and spatial arrangement of these mesoscale defects, establishing a critical foundation for optimizing armor material properties through defect engineering. Zhang et al.[

22] engineered three-modal B

4C/Al composites featuring amorphous multilayer interfaces, which demonstrated significantly improved impact resistance showing 40% increase in fracture toughness and 30% higher energy absorption compared to conventional composites under ballistic testing.Kumar et al.[

61] demonstrated that garnet and B

4C-reinforced aluminum matrix composites exhibit superior tensile strength and hardness, while significantly reducing the wear rate properties, making them highly suitable for high-stress military vehicle transmission components.

4.3. Aerospace

B

4C/Al composites are ideal for aerospace due to their lightweight, high strength, and excellent high-temperature resistance. Their low density, reinforced stiffness, and thermal stability make them suitable for aircraft and spacecraft components. The h-BN and CNTs co-reinforced aluminum matrix composites developed by Khan et al.[

38] exhibit outstanding properties, achieving a high relative density of 97.7%. These composites demonstrate a remarkable 106% increase in Vickers hardness, and a 189% enhancement in tensile strength (

Figure 5,

Table 5), making them highly promising for aerospace applications. Their superior strength to weight ratio and enhanced mechanical performance position them as ideal candidates for high strength, lightweight structural materials in the aerospace industry. Ma et al.[

62] emphasized that particle-reinforced Al matrix composites offer significant advantages for aerospace lightweight applications. Their research highlights that the size and spatial distribution of both matrix grains and reinforcing particles play a crucial role in determining the material’s mechanical properties, making these composites highly suitable for high- performance aerospace structures. Through optimized friction stir welding process parameters, Jamaludeen[

63] achieved a significant reduction in wear rate to 154.21×10⁻⁵ mm

3/m for AA6092/B

4C composites, substantially improving their reliability for aviation applications. Sekhar et al.[

64] developed a sustainable high-performance composite by reinforcing recycled aluminum can matrix with granite particles and B

4C. The material exhibited exceptional, mechanical properties, achieving compressive strength of 1124 MPa along with 28% enhanced wear resistance, successfully combining resource recycling with superior performance. Ambigai et al.[

8] developed a centrifugally cast Al-based B

4C FGCs with remarkable thermomechanical properties. Their study revealed that a 50 μm reinforcing phase improved the tensile strength by 31%, while the 100μm reinforcing phase enhanced the thermal conductivity by 46.4% and the thermal diffusivity by 27.8%. These tailorable properties make the composite ideal for aerospace thermal management systems, particularly for graded heat exchangers and heat sinks accommodating variable thermal loads.

4.4. Transportation

B4C/Al composites are highly competitive for automotive and rail transport applications due to their optimal combination of lightweight properties, excellent wear resistance, and cost efficiency. The low-density aluminum matrix enables significant weight reduction, while the B4C reinforcement enhances surface durability. These advantages, along with competitive manufacturing costs, make B4C/Al composites particularly suitable for high-performance moving components where reducing mass and extending service life are critical requirements.

4.4.1. Automobile Parts

Chandel et al.[

65] demonstrated that Al matrix composites incorporating both hard ceramic particles and soft reinforcements achieve optimal performance-significantly enhancing strength, hardness and wear resistance while reducing brittleness. This balanced approach effectively meets automotive industry requirements for lightweight materials with high strength and superior wear resistance. Thakur et al.[

25] developed an Al6063-B

4C-Gr hybrid composite with optimized reinforcement ratios, demonstrating superior wear resistance for high-speed applications. Madhu et al.[

11] innovatively incorporated rubber ash and B

4C in varying ratios into Al-based FGCs, achieving both cost reduction and enhanced tensile strength through synergistic reinforcement-offering a novel solution for automotive lightweight applications. Aabid et al.[

66] enhanced the dry sliding wear performance of aluminum hybrid composites, offering potential for developing lubricant-reduced automotive braking systems.

4.4.2. Rail Transit

Venkatesan et al.[

67] developed an optimized die contour technology combining cosine and cubic polynomial profiles, which significantly reduced extrusion loads while ensuring uniform metal flow in B

4C/Al composites. This advancement provides an efficient new manufacturing process for producing large structural components in rail transit applications.

4.5. Electronics Industry

In electronics industry, B

4C/Al composites have become essential materials for electronic packaging and thermal management systems, owing to their tunable CTE and superior thermal conductivity. These tailored thermophysical properties enable optimal heat dissipation while minimizing thermal stresses in sensitive electronic components. Ziani et al.[

37]developed an Al/Mo/SiC tri-component periodic multilayer film exhibiting high EUV reflectivity (48% at 17.3 nm), which has been successfully implemented in the solar orbiter mission’s EUV imager. Zhang et al.[

46] demonstrated that strong interfacial bonding between SiC/P-doped graphene and Al matrix can simultaneously enhance the composite’s mechanical strength and thermal performance, offering a novel design strategy for advanced electronic packaging materials. The laser surface treatment of B

4C/Al composites by Yilbas et al.[

34] significantly enhanced both surface microhardness and hydrophobicity through the formation of a dense sub-micron grain layer containing AlN compounds, making these modified composites particularly suitable for electronic device enclosure applications. Alattar et al.[

68] demonstrated that incorporating 5% B

4C particles into Al matrix composites yields a uniform fine-grained microstructure, optimizing both hardness and ultimate tensile strength, properties particularly advantageous for heat-sensitive electronic components requiring efficient thermal dissipation.

4.6. Other Applications

Beyond these primary applications, B

4C/Al composites are also utilized in specialized domains such as tool manufacturing and sports equipment. Mironovs et al.[

69] developed a powder metallurgy recycling process for aluminum-based B-W fiber composites, enabling the reuse of high-strength fiber waste in cutting tool manufacturing. Panneerselvam et al.[

70] demonstrated that AA6063-B

4C-ZrSiO

4 hybrid composites exhibit superior wear resistance and a reduced coefficient of friction in tribological tests, rendering them ideal as high-performance sports equipment materials.

Table 6 summarizes the key performance metrics and representative applications of B

4C/Al composites across different application fields.

5. Summary and Outlook

After decades of development, significant advancements of B4C/Al composites have been achieved in processing techniques, performance optimization, and engineering applications, yet critical challenges remain. This section summarizes current research milestones, analyzes persistent limitations, and outlines future development priorities.

5.1. Summary of Research Progress

From a material system perspective, B

4C/Al composites have progressed from simple binary formulations to advanced multi-component hybrid architectures. Khan et al.[

38]developed an Al matrix composite co-reinforced with h-BN and CNTs, achieving 97.7% theoretical density while significantly enhancing mechanical properties. Raja et al.[

39] developed a multi-scale Al7075 composite reinforced with hybrid B

4C-TiB

2 particles, achieving optimal comprehensive performance. This multi-component design strategy has emerged as a critical approach for advanced material optimization. Regarding fabrication methods, conventional processing techniques continue to undergo refinement while novel approaches are rapidly advancing. Chen et al.[

3]optimized the HIP process for manufacturing large-scale B

4C/Al composite plates.Sun et al. [

31,

32,

33]were the first to develop additive manufacturing (AM) technology, which facilitates the economical and precise fabrication of aluminum-based composite structures. The implementation of wire powder arc additive manufacturing (WPA-AM) methodologies enabled the effective incorporation of ceramic particles, including B

4C, SiC, TiC, and WC/W

2C, into the aluminum matrix. Through the optimization of process parameters, a substantial enhancement in the mechanical properties of the material was attained.The following text is intended to provide a comprehensive overview of the subject matter. Khodabakhshi et al.[

30] pioneered an innovative accumulative fold-forging process to fabricate ultrafine-grained nanocomposites. This breakthrough in processing technology establishes a robust foundation for enhancing material properties. Performance investigations have progressively advanced from macroscopic mechanical characterization to comprehensive understanding of microscopic deformation mechanisms. Li et al.[

21] elucidated the synergistic reinforcement mechanisms in Al-based composites, demonstrating enhanced performance through multi-scale strengthening effects. Dai et al.[

42]established quantitative composition-performance relationships for radiation shielding applications. Collectively, these studies provide fundamental theoretical guidance for advanced material design. The engineering applications of these composites have significantly expanded beyond traditional nuclear shielding to emerging fields including armor protection systems and high-performance electronic packaging, reflecting their versatile property portfolio. The diverse applications of B

4C/Al composites, including nuclear waste storage tanks [

71], high-performance armor systems[

6] and EUV optical components [

37] demonstrate their exceptional versatility across multiple engineering domains[

49].

5.2. Key Issues

Despite significant advancements, critical challenges still exist for B4C/Al composites.

5.2.1. Interface Response Control

Interface control remains a critical research challenge in B

4C/Al composites. Excessive formation of brittle phases at the B

4C/Al interface significantly reduces both fracture toughness and plastic deformation capacity. However, systematic methodologies for precisely regulating interfacial reaction products through process optimization remain largely underdeveloped. Han et al.[

50] demonstrated that higher B

4C content exacerbates galvanic corrosion in B

4C/Al composites, revealing the critical role of interface stability in corrosion resistance [

35]. Future research must address three key priorities; elucidating the thermodynamic and kinetic mechanisms of interfacial reactions, establishing quantitative structure-property relationships at interfaces, and developing universal interface engineering strategies.

5.2.2. Process Repeatability

Process repeatability remains the critical bottleneck limiting large-scale industrial adoption. As Bhowmik et al.[

24] demonstrated, both controlled and uncontrolled variables in stir casting processes significantly impact final product quality. However, comprehensive quantitative models correlating process parameters with material properties remain underdeveloped [

52]. Butola et al.[

28] optimized FSP parameters using response surface methodology, demonstrating that theory-guided process design is essential for ensuring material property consistency. To achieve precise process control, future efforts should focus on developing real-time monitoring and intelligent control systems.

5.2.3. Irradiation Damage Mechanism

The limited understanding of irradiation damage mechanisms remains a critical barrier for nuclear applications.Tthe long-term irradiation effects on microstructure evolution and performance degradation require further investigation [

72]. Although the graphitized nanocarbon helium-absorption method [

46] demonstrates effectiveness, a more comprehensive irradiation damage mitigation strategy is still required. Future research should integrate advanced characterization techniques with multiscale simulations to develop predictive irradiation damage models.

5.3. Future Development Direction

To address these challenges, future research on B4C/Al composites can focus on the following key directions.

5.3.1. Multi-Scale Interface Design

Future research can develop multiscale interface design methodologies to precisely control interfacial performance in B

4C/Al composites. By integrating atomic-scale first-principles calculations[

46], nanoscale interface engineering, and macroscale alloy design, this hierarchical approach enables the construction of gradient functionalized interfaces that simultaneously enhance strength, fracture toughness and environmental stability. Critical implementation strategies will leverage surface modification, nano-coating technologies[

73] and precision microalloying to optimize reinforcement-matrix compatibility and bulk property uniformity.

5.3.2. Intelligent Preparation process

Future study can focus on developing intelligent manufacturing processes to improve property consistency and repeatability in B

4C/Al composites. By integrating machine learning and digital twin technologies, a quantitative process-structure-property prediction model can be established, enabling real-time process optimization[

74]. Advanced digital manufacturing techniques including AM and cold spraying will play increasingly critical roles in achieving these objectives.

5.3.3. Prediction of Extreme Environmental Behaviors

To enhance the prediction and evaluation of material behavior in extreme environments, future research should focus on developing multi-physics coupled irradiation damage models. By integrating artificial intelligence with these models, one can accurately predict material performance evolution under complex conditions, including long-term irradiation, high-temperature, and high-pressure exposures, thereby providing reliable guidance for engineering applications[

75].In-situ characterization techniques and accelerated testing methodologies will be critical to validating these predictive frameworks.

5.3.4. Sustainable Development

Future work on Al-based composites must prioritize sustainable development and closed-loop material cycles. As demonstrated by Mironovs et al.[

69], developing energy-efficient fabrication processes with minimal emissions, along with establishing robust recycling protocols, will be critical for reducing environmental impact [

76]. These efforts should be complemented by advanced design strategies such as functional gradient architectures and structure-function integration, which optimize material utilization efficiency across multiple lifecycles. The integration of these approaches combining green manufacturing techniques, effective end of life recovery methods, and intelligent material design represents a comprehensive pathway toward sustainable composite technologies.

Author contributions

Caixia Chen: Conceptualization, Data curation, Formal analysis, Investigation, Writing-original draft.Baocheng Li,Investigation,Writing-original draft. Wang Yun: Project administration, Writing- review & editing.Bian Ming: Investigation, Methodology.Xiaomin Kang: Project administration and Supervision.Xun Yang: Data curation and Investigation.

Ethical approval

Not required.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Data availability

All data generated or analyzed during this study are included in this published article.

Acknowledgments

C Chen thanks "National New Materials Testing and Evaluation Platform-Main Center" Project, Ministry of Industry and Information Technology (TC170A5SU-2) for financial support. Y Wang thanks UCI CORCLOR award for partial support.X Kang acknowledges the partial support provided by the project(S202410555214).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence.

References

- Shen, Q.; Li, P.; Li, C.; Wang, S.; Wang, L.; Zhang, Q. Microstructure and mechanical properties of Al-7075/B₄C composites fabricated by plasma activated sintering. J. Alloys Compd. 2014, 588, 265–270.

- Dai, L.; Wang, X.; Zhang, X.; Liu, Y.; Wang, J. Shielding property calculation of B₄C/Al composites for spent fuel transportation and storage. Acta Phys. Sin. 2013, 62, 108–113.

- Chen, H.; Zhang, L.; Liu, Y.; Li, J. Research Progress and Development of Neutron-absorbing Materials. Rare Met. Eng. 2020, 49, 4358–4364.

- Cherdyntsev, V.V.; Gorshenkov, M.V.; Kaloshkin, S.D.; Tcherdyntsev, V.V. Metal-matrix radiation-protective composite materials based on aluminum. Met. Sci. Heat Treat. 2013, 55, 14–18. [CrossRef]

- Bommana, D.; Rao, C.S.; Kumar, B.N. Effect of 6 wt.% Particle (B₄C+SiC) Reinforcement on Mechanical Properties of AA6061 Aluminum Hybrid MMC. Silicon. 2022, 14, 4197–4206. [CrossRef]

- Pul, M.; Ayar, K.B.; Akin, B. Investigation of Mechanical Properties of B₄C/SiC Additive Aluminum Based Composites and Modeling of Their Ballistic Performances. J. Polym. Politeknik Dergisi. 2020, 23, 383–392. [CrossRef]

- Vats, A.; Bharti, S.; Gupta, M. Mechanical and Erosive Wear Analysis of Boron Carbide Reinforced Scrap Aluminium Composites. Int. J. Metalcast. 2025, 19, 1–21. [CrossRef]

- Ambigai, R.; Prabhu, S. Characterization and thermo-mechanical analysis of centrifugally fabricated aluminium-boron carbide functionally graded composites. Proc. Inst. Mech. Eng. Part N-J. Nanomater. Nanoeng. Nanosyst. 2024, 238, 1–16. [CrossRef]

- Vijay, S.; Raja, V.K.B.; Raguraman, M.; Murugan, D. A comparative investigation of hardness and compression strength of Nickel coated B4C reinforced 601AC/201AC selective layered functionally graded materials. Mater. Res. Express. 2020, 7, 016527.

- Senel, M.C.; Gürbüz, M.; Koç, E. Reciprocating sliding wear properties of sintered Al-B4C composites. Int. J. Miner. Metall. Mater. 2022, 29, 1261–1269.

- Madhu, B.; Rao, C.S.; Seshu Bai, V. Effect of rubber ash on mechanical properties of Al6061 based hybrid FGMMC. Mater. Res. Express. 2020, 7, 096522.

- Srivastava, A.K.; Maurya, N.K.; Manoj, M.; Saxena, A.; Dwivedi, S.P. Investigation of micro-structural and mechanical properties of metal matrix composite A359/B4C through electromagnetic stir casting. Mater. Today: Proc. 2023, 23, 171–180.

- Chandla, N.K.; Yashpal; Kant, S.; Goud, M.M.; Jawalkar, C.S. Mechanical, tribological and microstructural characterization of stir cast Al-6061 metal/matrix composites-a comprehensive review. Sadhana. 2021, 46, 1–38.

- Madhukar, P.; Selvaraj, N.; Rao, C.S.P.; Kumar, G.B.V. Influence of Ultrasonic Vibration towards the Microstructure Refinement and Particulate Distribution of AA7150-B4C Nanocomposites. Coatings. 2022, 12, 1–15. [CrossRef]

- Sharath, B.N.; Jeevan, T.P.; Kumar, A.; Gowrishankar, M.C.; Gajakosh, A. Wear behaviour of aluminium-based hybrid composites processed by equal channel angular pressing. Proc. Inst. Mech. Eng., Part J: J. Eng. Tribol., 2024, 238, 1079–1090. [CrossRef]

- Jayendra, B.; Kumar, S.S.; Singh, V. Mechanical Characterization of Stir Cast Al-7075/B4C/Graphite Reinforced Hybrid Metal Matrix Composites. Mater. Today: Proc. 2020, 21, 1104–1110.

- Nieto, A.; Yang, H.; Jiang, L.; Schoenung, J.M. Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 2017, 390-391, 228–235.

- Jiang, L.; Yang, H.; Yee, J.K.; Mo, X.; Topping, T.; Lavernia, E.J.; Schoenung, J.M. Toughening of aluminum matrix nanocomposites via spatial arrays of boron carbide spherical nanoparticles. Acta Mater. 2016, 103, 128–140. [CrossRef]

- Pang, X.; Li, Y.; Zhang, T.; Bian, X.; Mi, J. Liquid Phase Flow Behavior and Densification Mechanism of Al/B4C Composites Fabricated via Semisolid Hot Isostatic Pressing. Rare Met. Mater. Eng. 2019, 48, 3102–3107.

- Thiruppathi, K.; Aravindan, S.; Gupta, M. Densification Studies on Aluminum-Based Brake Lining Composite Processed by Microwave and Spark Plasma Sintering. Powder Metall. Met. Ceram. 2021, 60, 44–51. [CrossRef]

- Li, Y.; Zhao, Y.H.; Ortalan, V.; Liu, W.; Zhang, Z.H.; Vogt, R.G.; Browning, N.D.; Lavernia, E.J.; Schoenung, J.M. Investigation of aluminum-based nanocomposites with ultra-high strength. Mater. Sci. Eng. A. 2009, 527, 305–316. [CrossRef]

- Zhang, X.; Li, S.; Yang, B.; Zhang, J.; Li, H.; Lei, H.; Wang, W.; Pan, D. Metal/ceramic interface structures and segregation behavior in aluminum-based composites. Acta Mater. 2015, 95, 254–263. [CrossRef]

- Thangadurai, K.R.; Ramesh, T. Synthesis and cold upsetting behavior of stir casted AA6061-B₄Cp composites. J. Sci. Ind. Res. 2014, 73, 394–399.

- Bhowmik, A.; Kumar, D.; Dey, D.; Biswas, A. Casting of particle reinforced metal matrix composite by liquid state fabrication method: A review. Res. Eng. 2024, 24, 1–16. [CrossRef]

- Thakur, A.; Kumar, A.; Purohit, R. Characterization, Strength and Wear Optimization of Aluminium Based Boron Carbide/Graphite Hybrid Composite by TOPSIS for Dry Condition. ECS J. Solid State Sci. Technol. 2023, 12, 127005. [CrossRef]

- Pramono, A.; Kolev, I.; Dimitrova, R.; Ilinkina, A. The Aluminum Based Composite Produced by Self Propagating High Temperature Synthesis. Mater. Sci.(Medžiagotyra). 2016, 22, 41–43. [CrossRef]

- Singh, H.; Brar, G.S.; Kumar, H.; Aggarwal, V. Evaluation of mechanical performance on a developed AA 6061matrix-Mg/0.9-Si/0.68 reinforced with B4C based composites. Funct. Compos. Struct. 2021, 3, 01154. [CrossRef]

- Butola, R.; Kumar, R.; Pratap, S.; Walia, R.S. Experimental analysis and optimization of process parameters using response surface methodology of surface nanocomposites fabricated by friction stir processing. Proc. Inst. Mech. Eng. Part N-J. Nanomater. Nanoeng. Nanosyst. 2024, 238, 119–129. [CrossRef]

- Butola, R.; Kumar, R.; Singh, S.; Walia, R.S. Fabrication and multi-objective optimization of friction stir processed aluminium based surface composites using Taguchi approach. Surf. Topogr.: Metrol. Prop. 2021, 9, 025044. [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Chekhonin, P.; Hafiz, M.H.; Pradeep, K.G. Fabrication and characterization of a high strength ultra-fine grained metal-matrix AA8006-B4C layered nanocomposite by a novel accumulative fold-forging (AFF) process. Mater. Des. 2018, 157, 211–226. [CrossRef]

- Xiao, W.; Zhang, Z.; Zhang, Y.; Zhang, S.; Li, R.; Cai, C.; Wang, H. Microstructure, mechanical, and corrosion properties of B₄C/Al composites with excellent ductility fabricated by laser-directed energy deposition. Virtual Phys. Prototyp. 2025, 20, e2505991. [CrossRef]

- Sun, J.; Yan, Q.; Zhang, Y.; Chen, W.; Huang, W.; Huang, S. Wire-powder-arc additive manufacturing: A viable strategy to fabricate carbide ceramic/aluminum alloy multi-material structures. Addit. Manuf. 2022, 51, 102637. [CrossRef]

- Karabulut, Y.; Gökmen, U.; Çinici, H. Additive manufacturing of ceramic particle-reinforced aluminum-based metal matrix composites: a review. J. Mater. Sci. 2022, 57, 19212–19242. [CrossRef]

- Yilbas, B.S.; Ali, H.; Khaled, M.M.; Al-Aqeeli, N.; Said, S.A.M. Laser surface treatment of aluminum based composite mixed with B4C particles. Opt. Laser Technol. 2015, 66, 129–137. [CrossRef]

- Abenojar, J.; Velasco, F.; Bautista, A.; Campos, M.; Martínez, M.A. Study through Potentiodynamic Techniques of the Corrosion Resistance of Different Aluminium Base MMC´s with Boron Additions. Mater. Sci. Forum. 2010, 660-661, 203–208.

- Vairamuthu, J.; Senthil Kumar, B. Synthesis and electrochemical behaviour of TiC- and B₄C-reinforced Al-based metal matrix composite. Emerg. Mater. Res. 2021, 10, 24–32. [CrossRef]

- Ziani, A.; Frassetto, F.; Minesso, A.; Garoli, D.; Pelizzo, M.G. Ion beam sputtered aluminum based multilayer mirrors for extreme ultraviolet solar imaging. Thin Solid Films. 2014, 552, 62–67. [CrossRef]

- Khan, M.A.; Alam, S.; Ali, A.; Alrobei, H.; Umer, M.A. Synergistic Effects of Carbon Nanotubes (CNTs) and White Graphite (h-BN), on the Microstructure and Mechanical Properties of Aluminum Matrix Composites. Arab. J. Sci. Eng. 2024, 49, 9611–9624. [CrossRef]

- Raja, M.V.; Kumar, S.R.; Babu, B.S.; Kumar, A.S.; Reddy, K.S. Mechanical and tribological characteristics of aluminium hybrid composites reinforced with boron carbide and titanium diboride. Ceram.-Silik. 2022, 66, 396–406. [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E.; Khosroshahi, R.A. Creep behavior and wear resistance of Al 5083 based hybrid composites reinforced with carbon nanotubes (CNTs) and boron carbide (B4C). J. Alloys Compd. 2015, 650, 783–793. [CrossRef]

- Pandey, V.K.; Kumar, R.; Dwivedi, S.P. Role of ceramic particulate reinforcements on mechanical properties and fracture behavior of aluminum - based composites. Mater. Sci. Eng. A. 2019, 745, 252–264. [CrossRef]

- Dai, C.; Wang, X.; Zhang, X.; Liu, Y.; Wang, J. The Monte Carlo simulation of neutron shielding performance of boron carbide reinforced with aluminum composites. Acta Phys. Sin. 2013, 62, 131–135. [CrossRef]

- Stone, M.B.; Chakoumakos, B.C.; Rawn, C.J. Characterization of shielding materials used in neutron scattering instrumentation. Nucl. Instrum. Methods Phys. Res. A. 2019, 946, 162708.

- Stone, M.B.; Kunc, V.; Hassen, A.A.; Kimber, M.; Ozcan, S. Characterization of aluminum and boron carbide based additive manufactured material for thermal neutron shielding. Mater. Des. 2024, 237, 112463. [CrossRef]

- Xian, Y.; Li, Y.; Wang, J.; Zhang, T.; Bian, X.; Mi, J. Microstructure and mechanical properties of Al6061-31vol.%B4C composites prepared by hot isostatic pressing. J. Mater. Eng. Perform. 2015, 24, 4044–4053. [CrossRef]

- Zhang, E.; Li, Z.; Zhang, S.; Wang, C.; Wang, G. Reinforcement of aluminum metal matrix composites through graphene and graphene-like monolayers: a first-principles study. Mater. Adv. 2024, 5, 9596–9603. [CrossRef]

- Hynes, N.R.J.; Sankaranarayanan, R.; Tharmaraj, R.; Pruncu, C.I. Mechanical and tribological characteristics of boron carbide reinforcement of AA6061 matrix composite. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 155. [CrossRef]

- Emiru, A.A.; Ayalew, E.A.; Sinha, D.K. Fabrication and characterization of hybrid aluminium (al6061), metal matrix composite reinforced with sic, B4C and MoS₂ via stir casting. Int. J. Metalcast. 2023, 17, 801–812. [CrossRef]

- Ali, S.; Abdul Rani, A.M.; Baig, M.; Aliyu, A.A.A.; Hastuty, S.; Rao, T.V.V.L.N.; Subramaniam, K. Synergetic Effect of Gr-B4C Reinforcement on the Structural and Mechanical Properties of AA6351 Hybrid Metal Matrix Composites. ECS J. Solid State Sci. Technol. 2023, 12, 067002. [CrossRef]

- Han, Y.M.; Chen, X.; Li, D.Y. Electrochemical Behavior of Al-B4C Metal Matrix Composites in NaCl Solution. Materials. 2015, 8, 6455–6470. [CrossRef] [PubMed]

- Huang, G.; Wang, H.; Li, X.; Wang, Z.; Li, C.; Wang, J. Cold spraying B4C particles reinforced aluminium coatings. Surf. Eng. 2019, 35, 772–783. [CrossRef]

- Mohankumar, V.; Rajeshkannan, A.; Sureshkannan, G. A Hybrid Design of Experiment Approach in Analyzing the Electrical Discharge Machining Influence on Stir Cast Al7075/B4C Metal Matrix Composites. Metals. 2024, 14, 1–23. [CrossRef]

- Kumaran, S.T.; Uthayakumar, M.; Kumar, S.S. Mmicro-grooving of aluminum-based composites using nd:yag laser machining. Surf. Rev. Lett. 2023, 30, 2350078. [CrossRef]

- Saini, P.; Singh, I.; Kumar, R.; Kumar, H.; Kumar, S. Experimental investigation on microstructure, mechanical and machining properties of Al-4032/granite marble powder (GMP) composite produced through stir casting. Mater. Sci. Eng. Technol. 2022, 53, 1450–1467. [CrossRef]

- Taskesen, A.; Kutay, D. Analysis of thrust force in drilling B₄C-reinforced aluminium alloy using genetic learning algorithm. Int. J. Adv. Manuf. Technol. 2014, 75, 237–245. [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P.; Mohandas, E. Performance Monitoring of WEDM Using Online Acoustic Emission Technique. Silicon. 2018, 10, 2635–2642. [CrossRef]

- Selvarasu, S.; Murugan, M.; Suresh, R.; Kumar, S.S. An effect of nano-SiC with different dielectric mediums on AZ61/7.5% B4C nanocomposites studied through electrical discharge machining and Taguchi based complex proportional assessment method. Matéria (Rio J.). 2023, 28, e20230058. [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Akbari, M.K.; Pakseresht, A.H.; Abdi, F.; Abbasi, A.; Naebe, M. Boron carbide reinforced aluminium matrix composite: Physical, mechanical characterization and mathematical modelling. Mater. Sci. Eng. A, 2016, 658, 135–149. [CrossRef]

- Mi, X.; Li, Y.; Zhang, T.; Pang, X.; Bian, X. Thermal Safety Analysis of Aluminum Matrix B4C In-Pile Irradiation. At. Energy Sci. Technol. 2012, 46, 454–458.

- Moorehead, C.A.; Karthikeyan, S.; Odegard, G.M. Meso-scale microstructural agglomerate quantification in boron carbide using X-ray microcomputed tomography. Mater. Charact. 2018, 141, 177–185. [CrossRef]

- Kumar, R.A.; Devaraju, A.; Arunkumar, S. Mechanical properties and microstructure of stir casted Al/B₄C/garnet composites. Mater. Test. 2017, 59, 338–343. [CrossRef]

- Ma, K.; Li, T.; Li, X.; Li, M.; Ma, Y.; Ji, Z.; Wang, H. Particulate reinforced aluminum alloy matrix composites - a review on the effect of microconstituents. Rev. Adv. Mater. Sci. 2017, 48, 91–104.

- Jamaludeen, U.M.; Ramabalan, S. Analysis and Multi-Response Optimization of Friction Stir Welding Parameters for Stir-Cast AA6092/B4C/ ZrO2 Hybrid Composites. Mater. Res. 2025, 28, 20250185. [CrossRef]

- Sekhar, R.A.; Singh, D.; Patnaik, A.; Kumar, R. Enhanced mechanical and wear properties of aluminium-based composites reinforced with a unique blend of granite particles and boron carbide for sustainable material recycling. J. Alloys Compd. 2023, 963, 171165. [CrossRef]

- Chandel, R.; Sharma, N.; Bansal, S.A. A review on recent developments of aluminum-based hybrid composites for automotive applications. Emergent Mater. 2021, 4, 1243–1257. [CrossRef]

- Aabid, A.; Baig, M.; Khan, S.A.; Sebaey, T.A. Optimization of dry sliding wear behavior of aluminium-based hybrid MMC's using experimental and DOE methods. J. Mater. Res. Technol. 2022, 16, 743–763. [CrossRef]

- Venkatesan, R.; Xavior, M.A. Analytical, numerical and experimental approach for design and development of optimal die profile for the cold extrusion of B4C DRMM Al 6061 composite billet into hexagonal section. J. Mech. Sci. Technol. 2014, 28, 5117–5127. [CrossRef]

- Alattar, A.L.; Hamzah, M.K. Increase in the Physicomechanical Properties of Aluminum Alloys Reinforced with Boron Carbide Particles. Russ. Metall. 2023, 2023, 688–694. [CrossRef]

- Mironovs, V.; Lisicins, M.; Boiko, I.; Koppe, T.; Glushenkov, A.; Sergienko, A. Recycling of Aluminum-Based Composites Reinforced with Boron-Tungsten Fibres. Materials. 2022, 15, 3207. [CrossRef] [PubMed]

- Panneerselvam, T.; Senthil, P.; Raghuraman, S. Tribological study on hybrid reinforced aluminium-based metal matrix composites. Int. J. Surf. Sci. Eng. 2018, 12, 449–466. [CrossRef]

- Soundararajan, R.; Ramesh, A.; Sivasankaran, S.; Vignesh, M. Modeling and Analysis of Mechanical Properties of Boron Carbide Reinforced Aluminum Alloy (A413) Using Artificial Neural Network Models and Statistical Techniques through Extrusion Casting Process. Mater. Today: Proc. 2017, 4, 2008–2030.

- Chen, Z.; Wang, J.; Li, S.; Wang, H.; Liu, Y. Neutron shielding properties of TPX/B4C composites based on Monte Carlo method. In Asia Conference on Geological Research and Environmental Technology (GRET), Electr Network. 2020, 632, 052037. [CrossRef]

- Ramasubramanian, K.; Arumugam, P.R.; Sankaran, S. Investigation on tribological behaviour of boron doped diamond coated cemented tungsten carbide for cutting tool applications. Surf. Coat. Technol. 2017, 332, 332–340. [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P. Parametric optimization of wire electrical discharge machining on aluminium based composites through grey relational analysis. J. Manuf.Processes. 2015, 20, 33–39. [CrossRef]

- Tjong, S.C.; Ma, Z.Y. High cycle fatigue response of in-situ Al-based composites containing TiB₂ and Al₂O₃ submicron particles. Compos. Sci. Technol. 2005, 65, 1537–1546. [CrossRef]

- Khatkar, S.K.; Suri, N.M.; Kant, S.; Singh, G. A review on mechanical and tribological properties of graphite reinforced self lubricating hybrid metal matrix composites. Rev. Adv. Mater. Sci. 2018, 56, 1–20. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).