1. Introduction

Gravity current (GC) is a generic name for the buoyancy-driven flow of a fluid of one density,

, into an ambient fluid of a different density,

, mostly in horizontal direction

x (to be distinguished from the mostly vertical buoyancy-driven flows called plumes); see [

11] and the references therein. The interpretation of the driving buoyancy mechanism is as follows: the hydrostatic pressure fields

produce a horizontal pressure gradient

, where

g is the gravitational acceleration,

z is the vertical upward coordinate,

j denotes the ambient and current, and

is the reduced gravity. The buoyancy is balanced by inertial or viscous effects. Here we focus attention on the so called viscous GC, dominated by a buoyancy–viscous dynamic balance, relevant to flows at a small Reynolds number. Viscous GCs have numerous applications in nature and industry. The systems of interest belong to various prototypes, such as Newtonian or non-Newtonian fluids, two-dimensional (2D) or cylindrical axisymmetric (AXI) propagation, fixed or time varying (influxed) volume, liquid or porous medium. An important distinction is between unconfined and confined (gap) domain into which the GC propagates. Geostrophic and environmental GCs are often unconfined (e.g., spread of lava or oilspills), and have received significant attention.The confined GC occur often in a gap where one viscous fluid displaces another viscous fluid particular in the context of porous layers (e.g., [

2,

4,

10,

14] and the review [

15]).

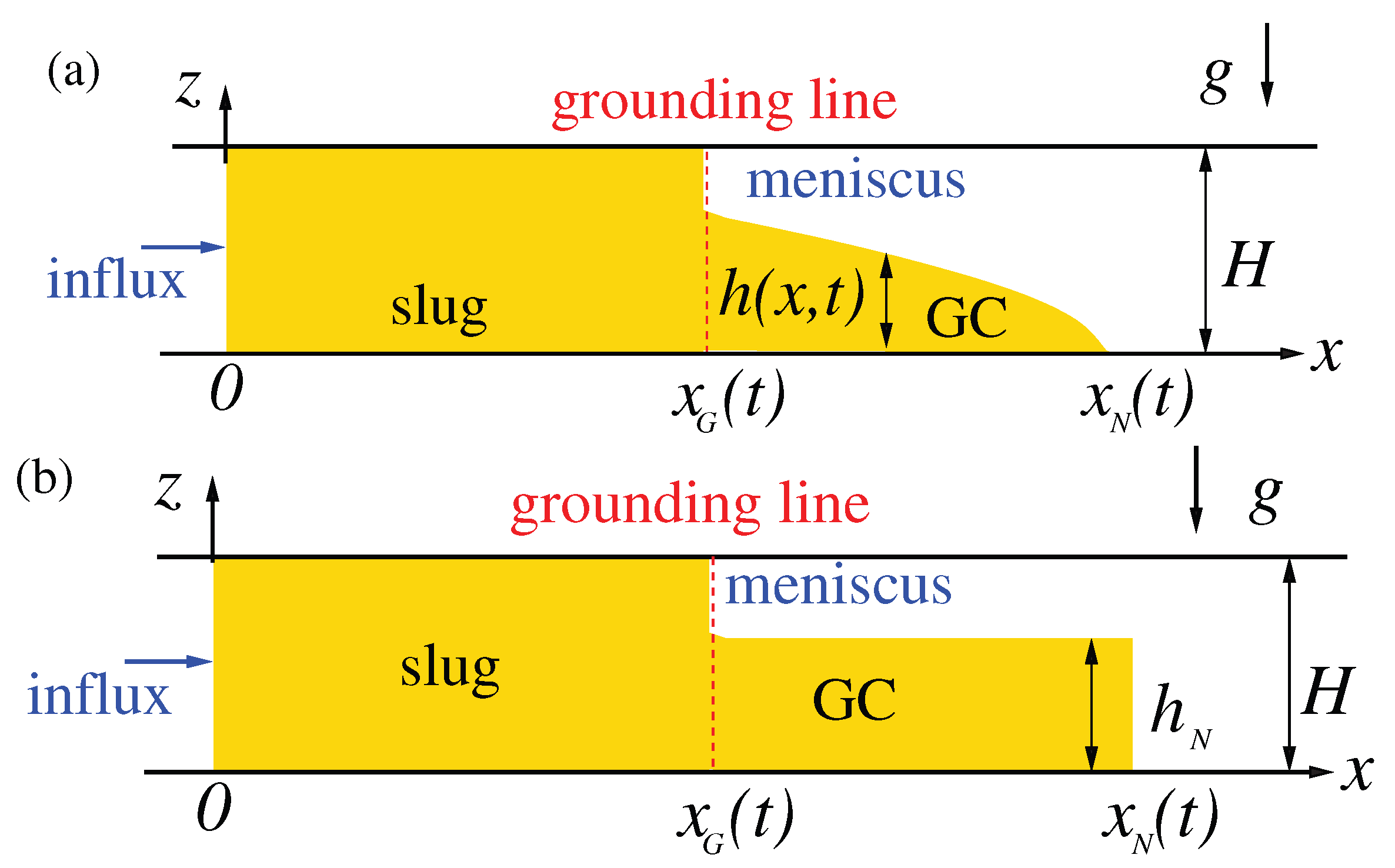

Recent investigations addressed the flow of confined viscous GCs, relevant to injection molding (see [

5]), see

Figure 1(a). Consider the two dimensional (2D) propagation of a viscous fluid injected into a small gap of height

H between two horizontal plates. This is a simplification of a rectangular channel of width

. Assume that the ambient fluid, displaced from the gap by the injected fluid, is less dense and significantly less viscous than the injected one (e.g., oil injected into air). In this case, the following type of flow may appear: the dense fluid forms a slug which fills the gap in

while the fluid ahead of the slug, in

, forms a viscous GC on the bottom, while the interface is detached from the gap. The subscripts

G and

N denote the “grounding line” and the nose of the GC. Moreover, when the injected volume is

, such flows may be self-similar, in the sense that the GC elongates like

while the slug elongates as

, where

are positive constants and

t is time. (The details of the source at

are outside the scope of this study. In the laboratory and industry, the influx is supplied by a pump or similar mechanical device, which provides the volume rate and the pressure necessary for the flow in the

domain. There is evidence that such systems work well, i.e., [

8].)

The stringent task is to determine the values of and K for a given physical system. Moreover, it is important to suggest a convenient scaling, to determine the governing dimensionless parameters, and predict the trends of the flow upon the variation of the input conditions. In particular, it is clear that for a sufficiently large H, the confined GC can be considered unconfined; a sharp criterion for this transition is of interest. The need for an efficient prediction method motivated our study.

[

8] considered the confined axisymmetric (AXI) flow of a Newtonian fluid (theoretically and experimentally). They used a lubrication-theory model (with no surface tension effects) to show that a constant influx,

, produces self-similar propagation with power

, and the only governing dimensionless parameter is

, where

l is the typical height of the corresponding unconfined GC. The associated experiments (using golden syrup in a gap of about 1 cm filled initially with air), supported the theory (with some small discrepancies). [

13] (referred to below as U25) extended the theory to cover also two-dimensional (2D) and non-Newtonian power-law fluids with exponent

n (the Newtonian fluid is recovered for

). The lubrication-theory framework indicates that a self-similar flow develops for select values of

, determined by

n; the power

is equal to

in 2D case and

in AXI case. The detached interface of the GC displays an inclined profile, see

Figure 1(a), is defined by a second-order ordinary differential equation subjected to boundary conditions at the nose and at the grounding line, which in general must be solved numerically. When surface-tension effects are discarded, for a given fluid (specified by the viscosity exponent

n) the scaled solution depends on only one dimensionless parameter,

J. The theory provides a convenient scaling of variables, and a sharp prediction of the threshold value

below which the confinement is irrelevant (the GC with the select

propagates on the bottom without touching the top of the gap).

The paper [

7] revisits the system of [

8], and demonstrates that the discrepancies between theory and experiment can be attributed (mainly) to surface-tension (

) effects between the current and the ambient fluids at the grounding line. The Young-Laplace formulation predicts the existence of a meniscus at the grounding line of height of the order of the capillary length

, but the details and boundary conditions are complicated and hence an accurate solution of the meniscus in practical systems is not feasible. However, by modelling this meniscus as a vertical jump of height

, see

Figure 1, (where

is a constant) the surface-tension effect was added conveniently to the original lubrication-model. The main point is that the similarity behaviour is maintained, with unchanged

and

. The dependencies between

and

K are affected by

. The theoretical solutions with small

show better agreement with experiments than the original

predictions. Although the exact value of

is not known a-priori, this model provides valuable insights and can be applied with tentative theoretical or empirically estimated values. The study of [

7] suggests that

is a fair approximation. This promising extension of the original lubrication model similarity solution was derived and tested in [

7] only for the a Newtonian fluid in AXI system (

). Here we show that the

contribution can be implemented conveniently also in the theory of confined GCs of power-law fluids in both 2D and AXI systems.

The advantage of these published theories, based on the lubrication simplification, is the rigor of the governing equations and of the mathematical solution. The similarity solution predicts analytically the time behaviour, but the spatial profiles must be compiled numerically. The numerical task is straightforward. The disadvantage of this solution is that the needed mathematical manipulations are cumbersome and the results lack analytical description. This precludes straightforward extraction of trends and obscures the physical insights. This difficulty is exacerbated for the confined flow of power-law fluids in presence of surface-tension effects, which is dependent on three major parameters, , and the geometry (2D and AXI). (An additional parameter, , associated with the nose meniscus, will be introduced later.) For example, the value (for a given ) is obtained from the numerical integration of a second-order ODE; a change of requires a new integration. This motivated the search for a simpler mathematical model for the same physical problem.

A simpler model is expected to be beneficial for both research and applications. For this objective, in this paper, we develop and test a box-model solution. The box-model approximation makes bold assumptions about the details of the local behaviour of the flow field, and applies integral balances of volume and momentum on the entire mass (the box) of the GC. Box models have been used successfully for influxed viscous GCs, but, to our knowledge, only for unconfined systems (e.g., [

1,

3,

6,

9,

11,

12]). A widely-used simplification (also implemented here) is that the interface of the GC is horizontal, see

Figure 1(b); this eliminates the calculation of the profile of the inclined interface, which is the major challenge in the lubrication model.

The present work is a significant extension of the improved box-model presented in [

12]. The previous model considers GCs in a very deep environment, i.e., the height of the container,

H, is much larger than the height

h of the current. In this configuration, called “unconfined,” the GC which propagates on the bottom is not influenced by the top boundary. In the present system, the GC is confined by the top. Moreover, here we take into account the surface-tension effect, because there is evidence ([

7]) that the meniscus about the grounding line in the confined flow affects the motion (see

Figure 1). In other words, the present box model incorporates two novel physical effects: confinement and surface tension. The present paper demonstrates that the box-model for the self-similar confined flow provides explicit simple and insightful results for both 2D and AXI systems with Newtonian and non-Newtonian power-law fluids, including surface tension effects.

The surface tension is expected to generate, in addition to the meniscus at the grounding line, also a meniscus at the nose, i.e., a modification of the tip of the GC at the bottom position

in

Figure 1(a). This effect can be incorporated in both the lubrication and box models with an additional small parameter

. However, the typical influence of this meniscus is significantly smaller than that of the grounding-line meniscus, and hence the main analysis and discussion of the paper ignore this detail. The quantitative justification will be given in

Appendix A.

The structure of the paper is as follows. The box-model governing equations are developed, and some useful analytical results are derived for the general system (including surface tension), for the 2D and AXI in §

Section 2.2 and §

Section 2.3, respectively. Results for the special (basic state) with excluded surface tension,

, are presented in §

Section 3. At the end of each section we perform stringent quantitative comparisons with the more rigorous lubrication-model solution and show that there is good agreement for a wide range of parameters. A brief comparison with published data is discussed in §

Section 4. Concluding remarks are given in §

Section 5. The effect of the nose meniscus (not included in the main text) is estimated in

Appendix A. The method of solution of the lubrication model, which is compared with the box-model predictions, is briefly presented in

Appendix B.

4. Comparison with Data

A useful test for the validity of the box model is provided by a comparison of the present predictions with the experimental data presented in the papers of [

8] and [

7]. The laboratory system is AXI, the GC fluid is Newtonian (

) golden syrup, the ambient fluid is air (hence

), the gaps

H are 0.71, 1.07, and 1.48 cm. The viscous fluid was influxed at a constant rate (

) by a piston pump via a hole of 5.5 cm diameter in the bottom plate and spread out in a quite axisymmetric pattern (the maximum

was 27 cm). For sufficiently large influx rates, a clear separation between the slug and the GC, i.e. a clear grounding line, was observed. The propagation of the nose

and grounding line

(when present) were recorded for various constant volume fluxes. The absence of the grounding line indicates a free (unconfined) GC.

[

8] and [

7] use the same scaling as here for length, velocity and time, see (

23), but employ the notations

and

, as follows

In terms of our scaled solution, see (

40), the correspondence is:

,

,

.

The definition of

J here ((

37)) for

recovers the definition of

J in these papers.

The box model predicts that for

a self-similar propagation of the type (

46) appears in the AXI system for

. The experiments confirmed this prediction: the measured

and

fitted very well that pattern. This allowed the calculation of the experimental

and

(the estimated error is

; the error of the experimental

is 22 %.)

Table 1 of [

8] provides values of the experimental

and

as functions of

J for three different gaps,

H. [

7], using available experimental values of the surface tension

, pointed out that the three different gaps

H also imply three different values of the parameter

. The suggestion is to use the approximation

in the models.

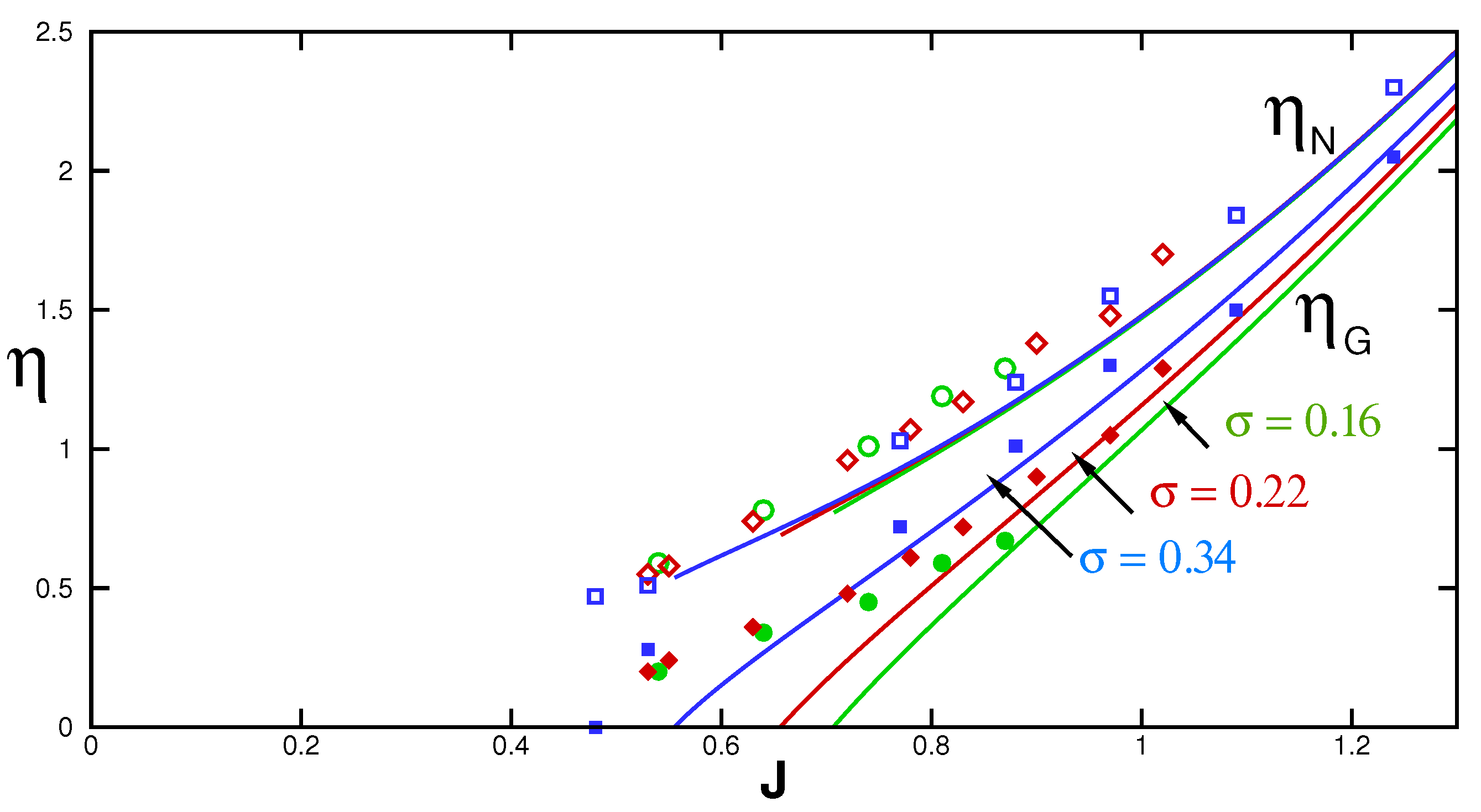

Figure 4 of [

7] shows the experimental points

and

vs.

J (symbols), and the corresponding predictions (curves) of the lubrication model which takes into account the surface tension effect.

The box-model predictions for the tested flows are straightforward. For the AXI system with

, we obtain

, (see (

27)) and (

33)). For a given

, the algebraic equation (

34) and (

40) provide values of

and

for various

J of interest. Using these results and the conversion

, we present in

Figure 11 a similar plot to Fig. 4 of [

7]. The the lines are box-model predictions. There is a fair agreement of the predictions with the data. We see that the model predicts correctly the behaviors of

and

. There is strong decay of

as

J decreases from 1.2 to 0.5 (approximately). However, the effect of

on this variable is remarkably small: the theoretical lines for the three values of

almost overlap, and the open symbols for the three values of

collapse on a smooth (imaginary) line.

decreases faster than

as

J decreases.

increases with

, as seen in the prediction lines and in the filled symbols. (For

the comparison with data is irrelevant because the GC is unconfined.)

The box model provides the physical interpretation of these trends. The parameter

J is proportional to

. When the influx rate decreases and/or the gap increases, the parameter

J decreases, and in the physical system the coefficients

and

of the propagation of the fronts, see (

46), are expected to decrease due to volume conservation. A larger

cause a smaller effective thickness

, see

Figure 1(b), and a smaller buoyancy force

. This allows a reduction of the bottom drag of the GC which is

. Consequently, at a fixed

J, a larger

appears for a larger

. The behaviour of

is subtle. For a fixed

J (fixed influx) a larger

renders a smaller effective thickness

; this would suggest an increase of

to accommodate the volume. Here enters the second front. The larger

increases

, which means an increase of the radius of the slug. The larger slug absorbs a larger portion of the influxed fluid, and counteracts the expected increase of

. The resulting flow displays a value of

which is little affected by the variations of

in these data.

The quantitative discrepancies between the data and the theoretical predictions observed in our

Figure 11 are, roughly, of the same magnitude for the present box model and the lubrication model used by [

7] (Fig. 4 in that paper). It is not possible to determine how much of the discrepancy is attributable to the box-model simplifications, because of the restricted data set, experimental errors, and uncertainty of the parameter

. Taking into account the fact that the box model predicts correctly the values of

and

of the experimental system, the overall predictions of the box model in this test seem to capture well the physical balances of the flow under consideration. In our opinion, this comparison provides support to the box-model as a predictive tool for realistic systems, and motivates further tests in other systems, in particular power-law fluids.

5. Conclusions

We presented a box-model analysis of the flow of a viscous fluid injected into a horizontal gap of height H in rectangular 2D and cylindrical AXI geometries, for a power-law non-Newtonian fluid (). When the displaced (ambient) fluid is less dense and significantly less viscous than the injected one (a typical occurrence in molding industry), and the influx is sufficiently strong, the leading part of the flow is a GC while the tail fills the gap. We focused attention on the influxed volume . We showed that for certain values of (depending on n) the flow is self-similar: the propagation of the nose and of the grounding line are like and . In general, in 2D and in AXI. We recall that the unconfined GCs display self-similar propagation for any . The confinement restricts the similarity flow to and in 2D and AXI flows, respectively. We obtained explicit formulas for the stringent features of the flow field, like . All the results are in good agreement with the more rigorous lubrication-model solution (which does not assume a horizontal interface). In particular, we note identical prediction for the time-power coefficients and , and a surprisingly small discrepancy for the dimensionless prefactor .

In general, the flow under consideration depends on four parameters: and . The box-model demonstrates that the dependencies are strongly coupled and non-linear, and hence a simple model is helpful for understanding the physical influence of each of the parameters.

The box model reveals that the main surface tension effects, , are: (a) for a fixed J, the position increases; and (b) for maintaining a fixed , J must be reduced. The effects of a nose meniscus are in the same direction, but .

The restriction of the solution to special values of the influxed volume coefficient

reproduces a physical condition, not a mathematical simplification. We argue that the similarity behaviour corresponding to this

is essential in the present problem; influx with a different

is bound to produce a very different flow pattern. The present

keeps the grounding line between the inlet and the nose (

). In this case the GC elongates, but maintains a constant average thickness. When

is reduced, the GC tends to become thinner with

t, the grounding line moves toward the inlet, and an unconfined GC appears on the bottom of the gap. When

is increased, the GC tends to become thicker with

t, the grounding line moves toward the nose, and all the injected fluid behaves like a slug in contact with both boundaries of the gap. It is remarkable that the similarity solution is robust: for a given geometry, the time powers

and

depend on

n, and are unaffected by the presence of surface tension effects represented by

and

. This interesting prediction has been verified experimentally for the AXI system and

([

7]), and further tests will be beneficial.

We recall that the accurate value of the surface-tension parameter

is not available for practical systems. The comparisons of predictions with data, performed by [

7] and here in §

Section 4, suggests that

is a fair approximation. This is a good starting point for the practical use of the present models. However, we must keep in mind that the data set of [

7] covers only AXI flow of a Newtonian fluid. For the assessment and improvement of the extended theory, a much wider experimental study is necessary. We hope that this will be reported in the near future.

The advantage of the box model is in the simplicity of the derivation and the predictions. We straightforwardly gain the insight that the kinematic (volume continuity) balances determine the relation between and , and the coefficient K; the dynamic force balance determine the values of and . The interconnections between the dimensionless variables are expressed in explicit formulas, without any adjustable constants. The description of the flow has been reduced to a set of basic algebraic-substitution formulas. The influence of the surface tension meniscus at the grounding line (parameter ) is well elucidated. The box model also clarifies that the effect of the nose meniscus (parameter ) is typically negligible. These simplifications are expected to facilitate the analysis and design of various applications. Needless to say, the same information can be extracted from the more rigorous lubrication model, but this requires a more significant effort of programming, data processing, and interpretation.

We emphasize that, in general, the box model is an unreliable prediction tool, unless subjected to stringent verification against some more accurate results over a significant range of parameters. The present box model can be recommended because it has passed such tests (without using any adjustable constants), and we have reliable information about the expected error concerning the sign (under/over prediction) and order of magnitude. However, we keep in mind that this paper compares mostly between two theories based on simplifications (such as thin layer, hydrostatic pressure, sharp meniscus, well-controlled influx). The convincing assessment of the models requires critical comparison with experimental data. (The comparison with the data of [

7] is in §

Section 4 is encouraging, but covers a restricted domain, in particular

.) In view of the large number of involved parameters, this is a challenging experimental task. We are confident that the present quite sharp theoretical predictions will facilitate the experimental verification.

Figure 1.

Sketch of the confined system: (a) lubrication model for the GC with inclined interface, and (b) box model with horizontal interface . The height of the meniscus at the grounding line is . The volume (per unit width) is . In the self similar flow, , , and depends on the parameter J. In the axisymmetric geometry, r replaces x and is per radian. are constants.

Figure 1.

Sketch of the confined system: (a) lubrication model for the GC with inclined interface, and (b) box model with horizontal interface . The height of the meniscus at the grounding line is . The volume (per unit width) is . In the self similar flow, , , and depends on the parameter J. In the axisymmetric geometry, r replaces x and is per radian. are constants.

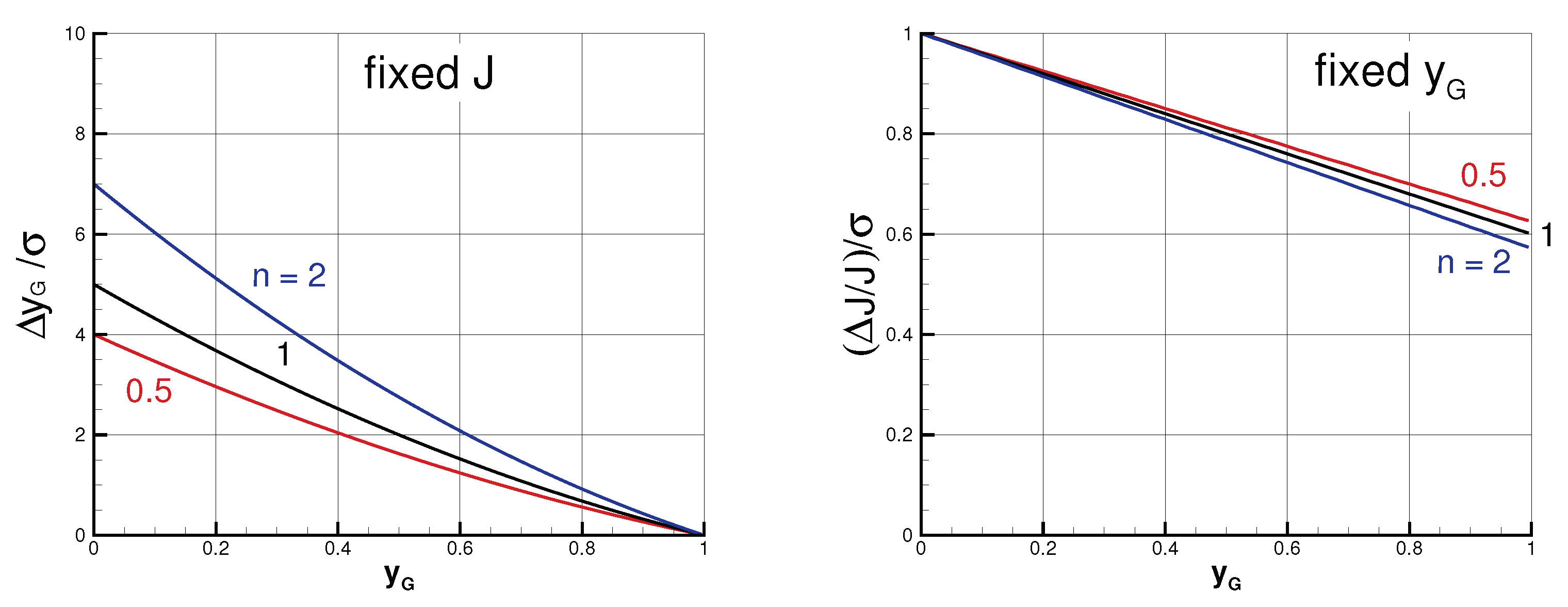

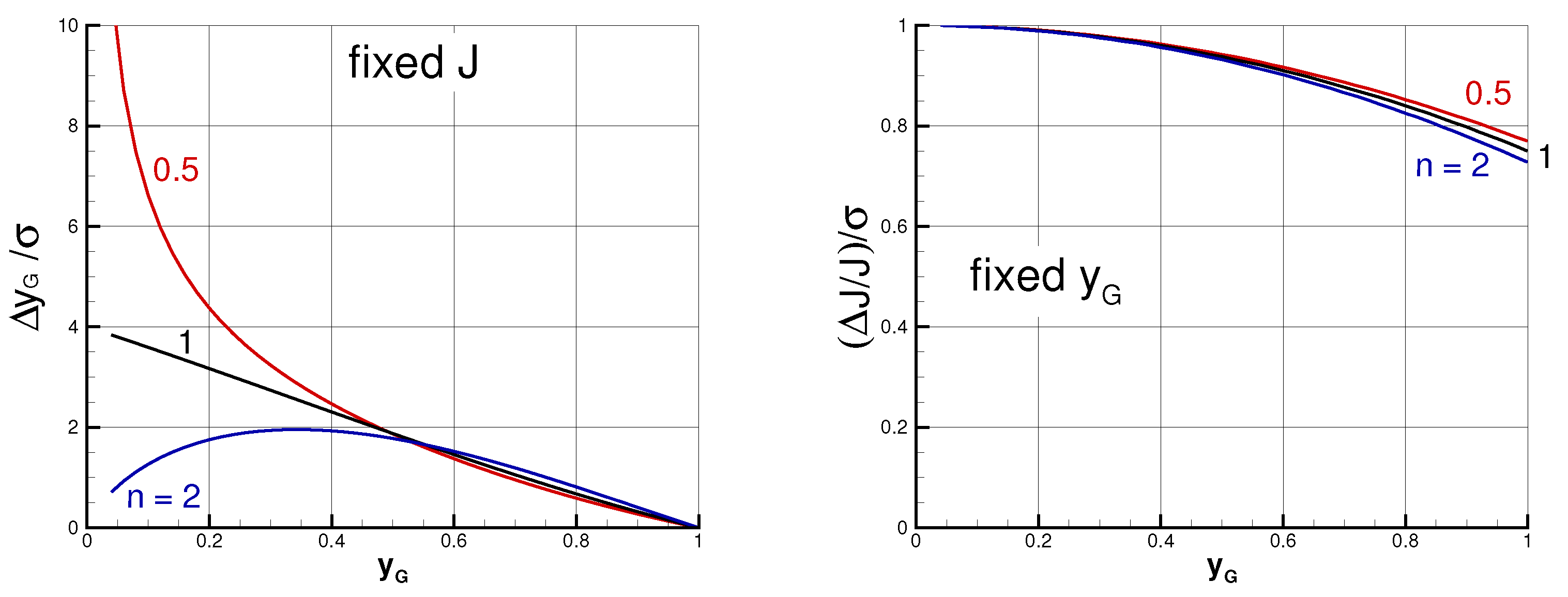

Figure 2.

2D case. The slopes and as functions of for various n.

Figure 2.

2D case. The slopes and as functions of for various n.

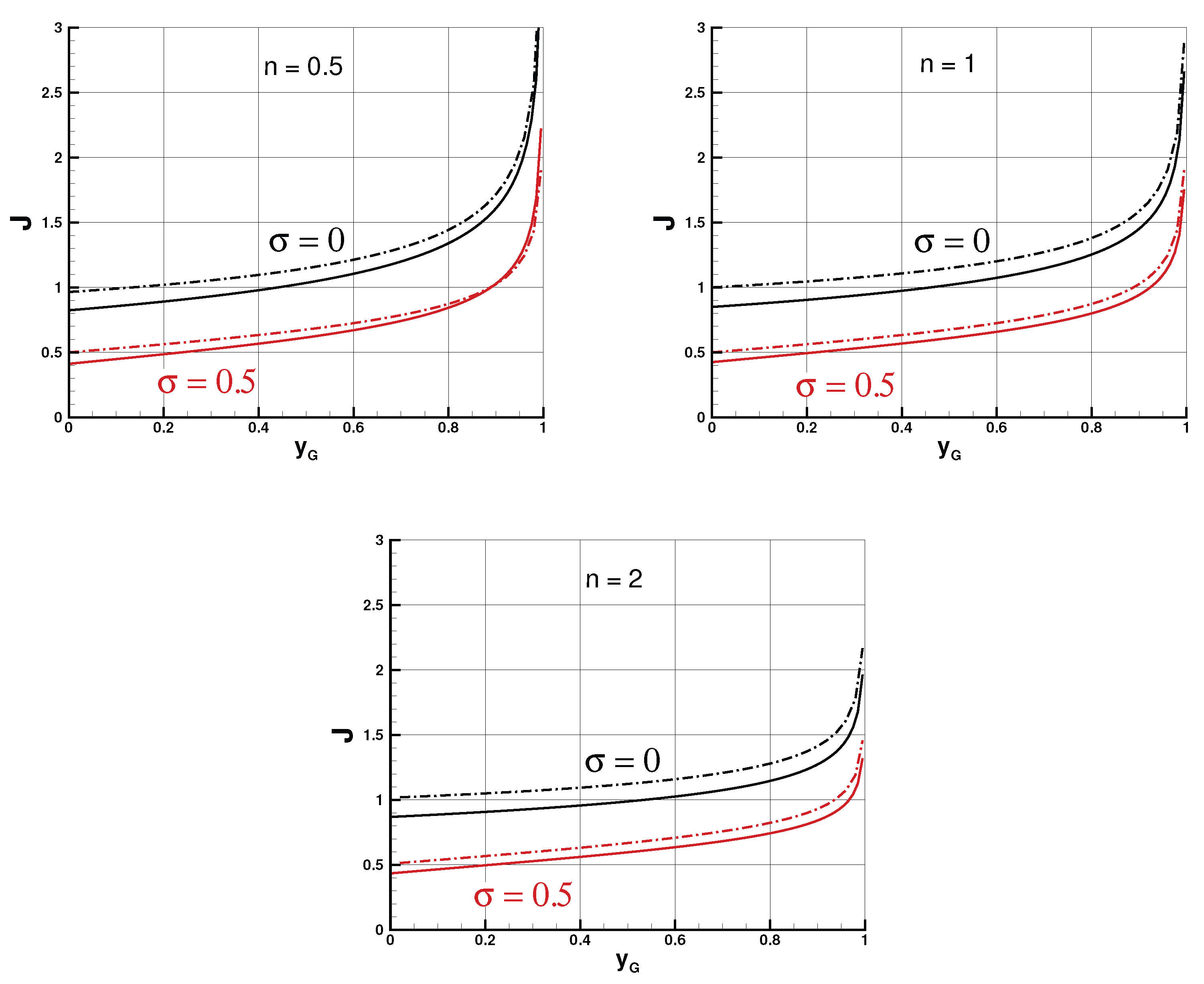

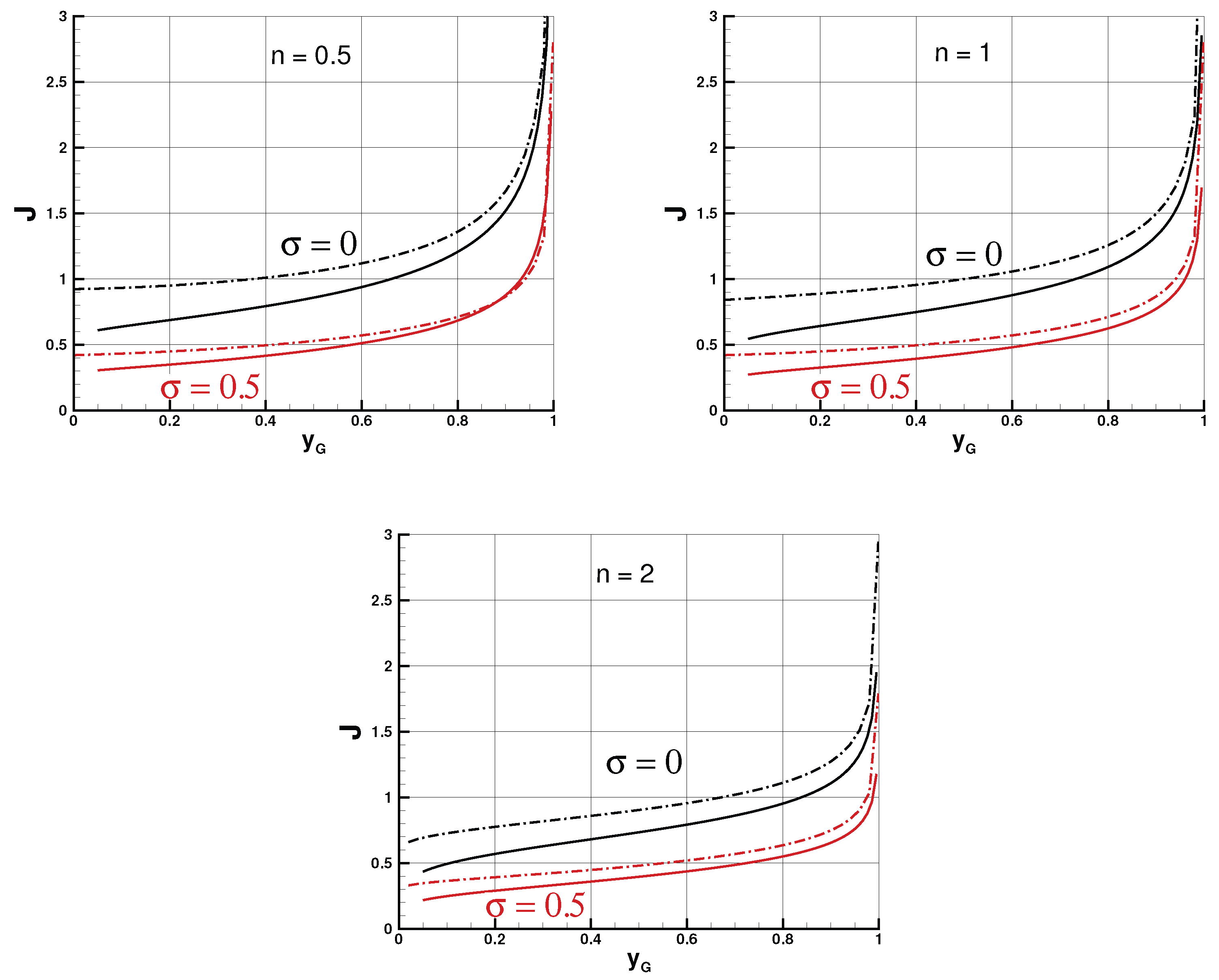

Figure 3.

Box model (dash-dot line) and lubrication model (solid line) results J vs. yG. for σ = 0 (black lines) and σ = 5 and (red lines) for 2D system. The frames are for n = 0.5, 1, 2.

Figure 3.

Box model (dash-dot line) and lubrication model (solid line) results J vs. yG. for σ = 0 (black lines) and σ = 5 and (red lines) for 2D system. The frames are for n = 0.5, 1, 2.

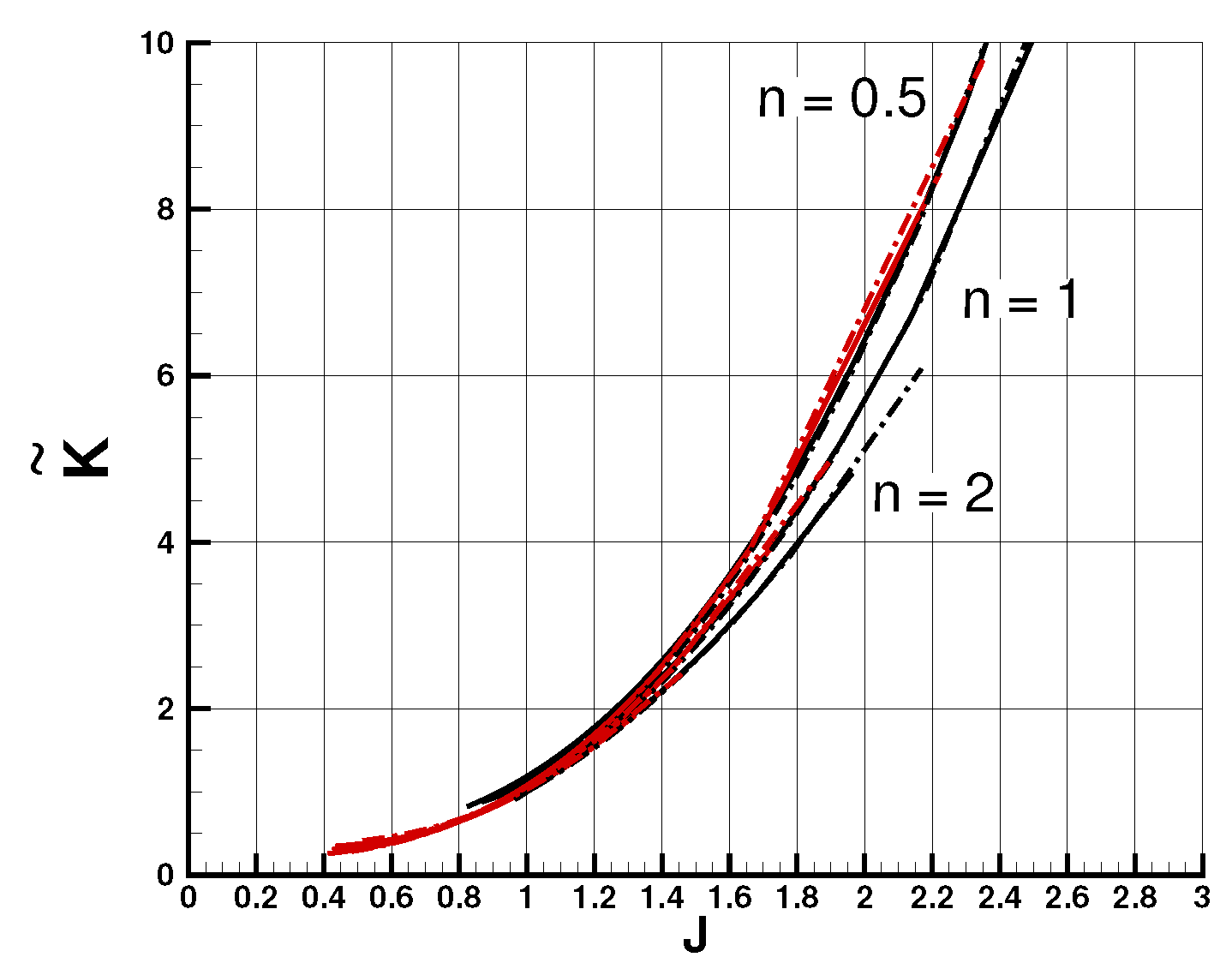

Figure 4.

vs. J for the systems of previous figure.

Figure 4.

vs. J for the systems of previous figure.

Figure 5.

AXI case. The slopes and as functions of for various n.

Figure 5.

AXI case. The slopes and as functions of for various n.

Figure 6.

Box model (dash-dot line) and lubrication model (solid line) results J vs. yG. for σ = 0 (black lines) and σ = 5 and (red lines) for AXI system. The frames are for n = 0.5, 1, 2.

Figure 6.

Box model (dash-dot line) and lubrication model (solid line) results J vs. yG. for σ = 0 (black lines) and σ = 5 and (red lines) for AXI system. The frames are for n = 0.5, 1, 2.

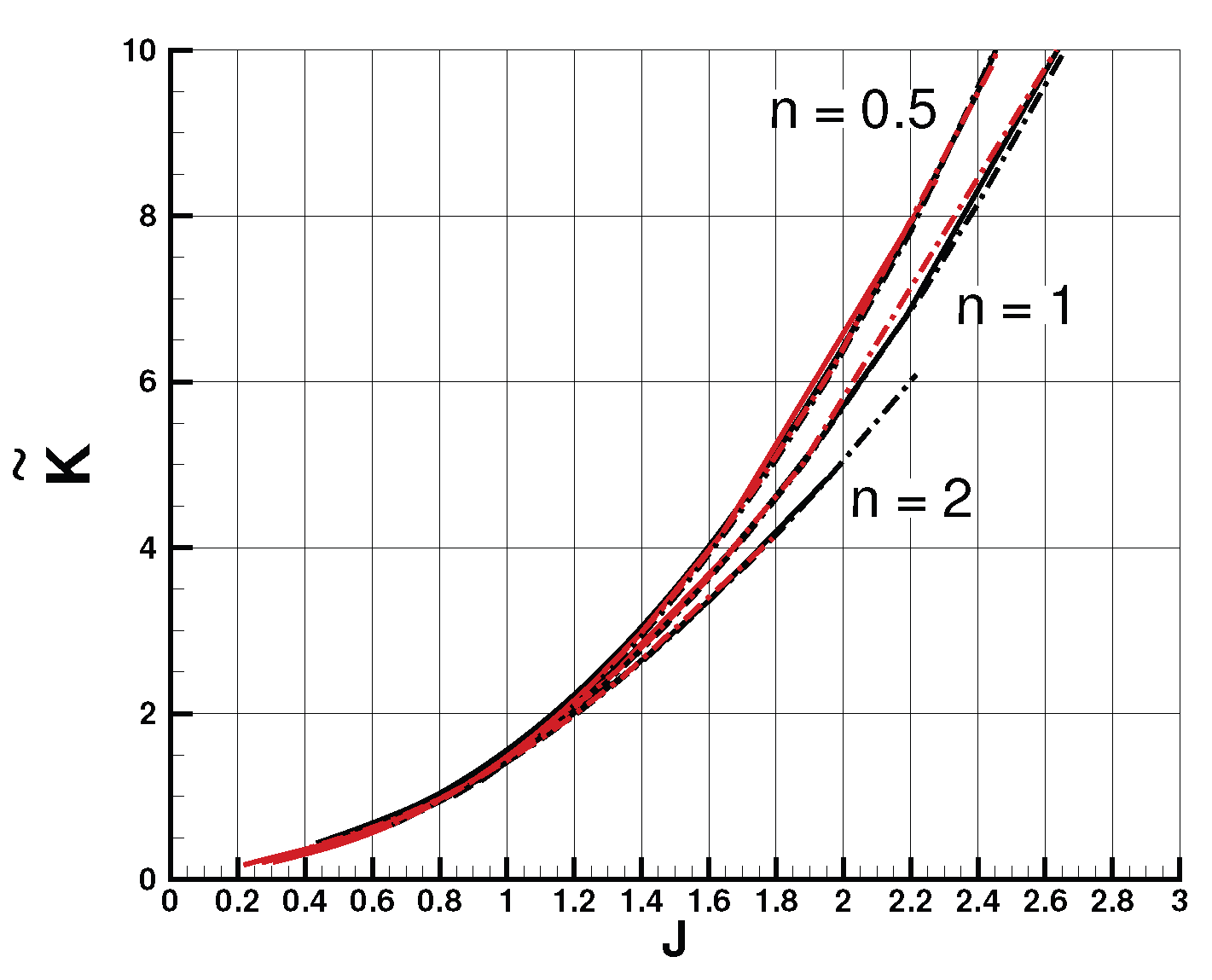

Figure 7.

vs. J for the systems of previous figure.

Figure 7.

vs. J for the systems of previous figure.

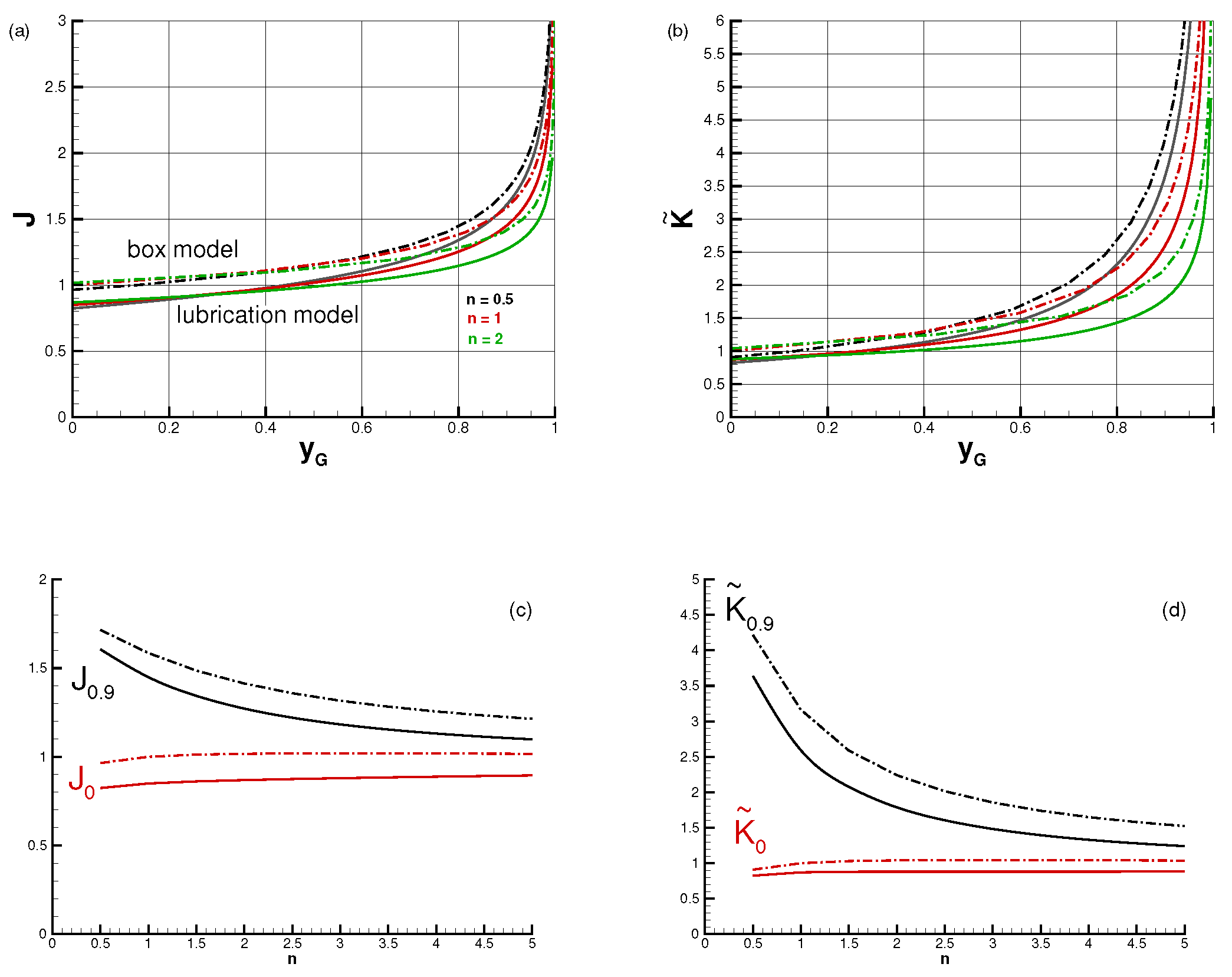

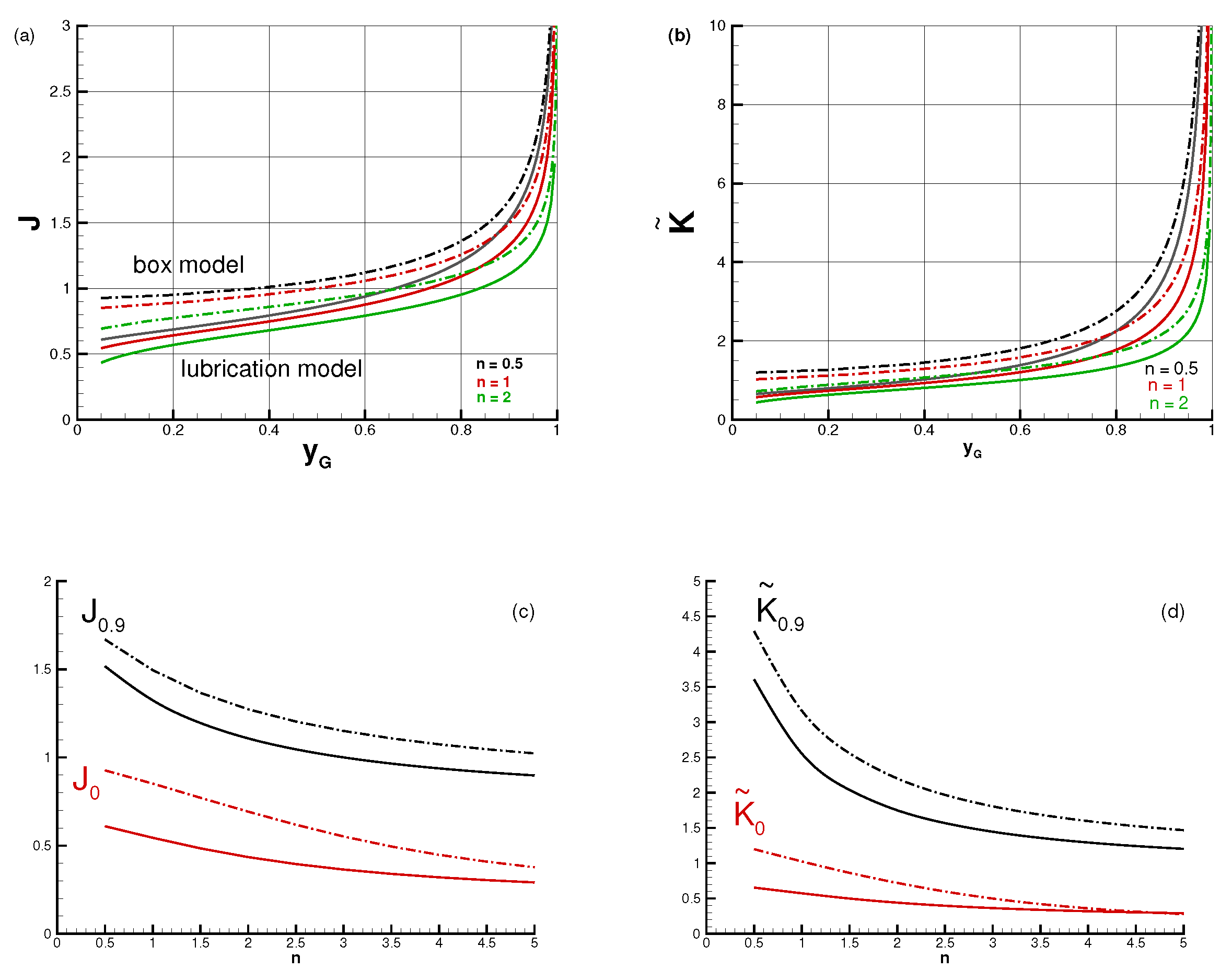

Figure 8.

Box model (dash-dot line) and lubrication model (solid line) results for 2D system for . (a,b) J and as functions of for various n (0.5, black; 1, red, 2, green). (c,d) as functions of n.

Figure 8.

Box model (dash-dot line) and lubrication model (solid line) results for 2D system for . (a,b) J and as functions of for various n (0.5, black; 1, red, 2, green). (c,d) as functions of n.

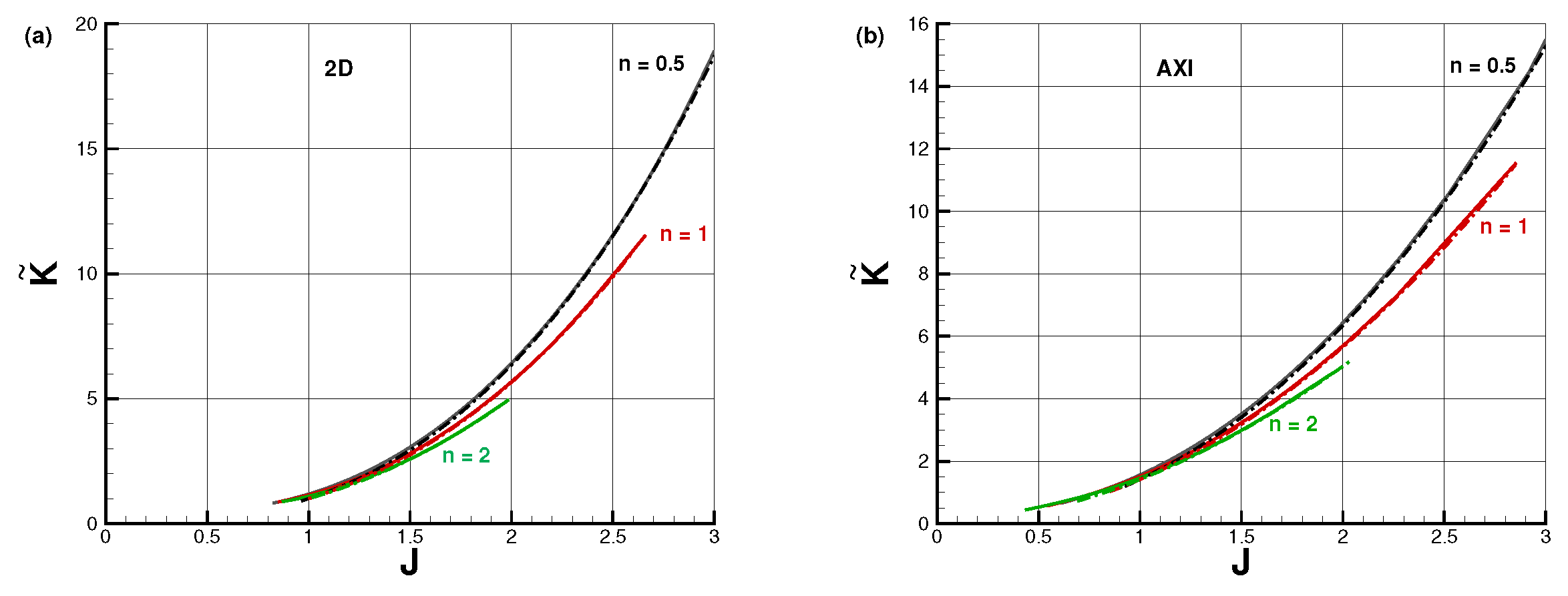

Figure 9.

vs. J for , various n. Box model (dash-dot line) and lubrication model (solid line). (a) 2D and (b) AXI system. The red and green lines end at the value of J for which .

Figure 9.

vs. J for , various n. Box model (dash-dot line) and lubrication model (solid line). (a) 2D and (b) AXI system. The red and green lines end at the value of J for which .

Figure 10.

Box model (dash-dot line) and lubrication model (solid line) results for AXI system for . (a,b) J and as functions of for various n. (c,d) as functions of n.

Figure 10.

Box model (dash-dot line) and lubrication model (solid line) results for AXI system for . (a,b) J and as functions of for various n. (c,d) as functions of n.

Figure 11.

and

as functions of

J for

(green, red, blue). Box model (lines) and data of [

7] (open symbols for

, filled symbols for

). (For

the GCs are typically unconfined, and outside the scope of our model.)

Figure 11.

and

as functions of

J for

(green, red, blue). Box model (lines) and data of [

7] (open symbols for

, filled symbols for

). (For

the GCs are typically unconfined, and outside the scope of our model.)