1. Introduction

The growth trends in the number of buildings stories of urban development for a long time are defined by the limited land resources and transport communications. The placement of multi-floor manufacturing and logistics facilities in the residential area of a smart sustainable city is associated with the development of innovative, green technologies and products [

1,

2]. City multifloor manufacturing clusters (CMFMCs) and their supply chain ecosystem (SCE) are developing actors of the smart sustainable city, which uses information and communications technologies (ICTs) and human-cyber-physical systems to co-create value [

3,

4]. The CMFMC includes a group of multi-floor manufacturing buildings and a city logistics node (CLN) as their lead ser-vice provider, which are located in a residential area of the smart sustainable city. The variety of sizes, forms and types of CMFMC enterprises, the balance of production and pricing policy are defined by competitive conditions and the capacity of the smart sustainable city market [

4,

5]. City manufacturing is a more general term that covers both traditional production (mass, craft and mass-customized production) located in a residential area and urban manufacturing with modern types of production organization (personalized production, social and share manufacturing). Traditional productions do not just exist within the urban manufacturing environment, but also develop and interact with them, utilizing shared production capacity within smart sustainable CMFMCs [

6,

7]. The integration of city manufacturing into the urban environment has been made possible by their modern trans-formation, with an emphasis on sustainability and the use of industry 4.0 (I4.0) technologies [

8,

9]. Energy sources, manufacturing and its products, transport system and information support of CMFMC must meet the smart sustainable city criteria and are focused on meeting the needs of the population and various enterprises of the mega-polis in innovative products and goods [

1,

10]. Depending on the current and future consumer demand, CMFMC uses various types of production process organizations and their corresponding modular lightweight equipment that implement additive and traditional manufacturing technology [

11,

12].

Freight transport service (FTS) provides delivery and shipment of cargo and finished products within the CMFMC [

13,

14]. Intra-cluster cargo transportation is carried out mainly through the CLN, which implements a set of logistics operations (including fulfilment service operations) for further shipment of goods to consumers both within and outside the CMFMC [

4]. Loading-unloading and sorting of cargo operations in the CMFMC and transported cargo location are carried out using Internet of Things (IoT), Blockchain technology, Global Positioning System (GPS), Wireless Fidelity [

15,

16]. The SCE of the smart sustainable CMFMC are based on a platform approach to create innovative products as well as get suppliers and customers various services that fulfil their needs. The platform service supply chain (PSSC) strategy within SCEs aims at enabling its users with cloud-based technologies that foster their innovative relationships along with providing various services [

17,

18]..

The main actors in the CMFMC are small and medium-sized enterprises (SMEs) that are embedded in an “open collective innovation system” with consideration of energy conservation (EC) policies within the framework of SCE for the purpose of knowledge management (KM) in the market conditions of a smart sustainable city [

10,

19]. Transfer of knowledge and innovative technologies is a key aspect of sustainable development of SMEs within CMFMCs [

20].. A key actor in the SCE is its orchestrator, who manages knowledge flows in open innovation (OI) among all stakeholders both inside and outside the CMFMC [

21,

22]. Usually, the orchestrator of the SCE is the University Innovation Centres, which have different names depending on the country and even the university [

23,

24]. For example, at the Maritime University in Szczecin (Poland) it is the University Centre for Projects and Innovation. In the same city at the West Pomeranian University of Technology in Szczecin (Poland) it is the Regional Centre for Innovation & Technology Transfer. In this study, to clearly identify such SCE orchestrator, we will refer to them as the University Centre for Projects and Innovation (UCPI).

The purpose of this paper is to develop a conceptual framework for KM based on OI with consideration of EC policies within SCE of a smart sustainable CMFMC. To achieve the objective, this paper suggested four specific research questions:

RQ1: What is the spatial configuration and key actors of a SCE of a CMFMC for KM based on OI and EC?

RQ2: What role does the UCPI play in OI-based KM in SCE of a CMFMC to bolstering innovation?

RQ3: What role can the UCPI play in boosting innovation activities in the SCE of a CMFMC under KM based on OI and EC?

RQ4: What is the role of the UCPI in overcoming the barriers associated with the CMFMCs organization in large cities and KM based on OI and EC in them?

To achieve the research objective and answer the research questions, a case study method using qualitative studies and to carry out research based on “how” and “why” questions was adopted (Yin, 2018). This paper provides information on how SCE can play a role in smart sustainable CMFMCs startups development by analysing the KM based on OI and EC perspective.

The paper is structured as:

Section 2 present the theoretical background relatively to the current literature on SCE and KM based on OI and EC for city manufacturing.

Section 3 presents a conceptual model of spatial configuration of a SCE of a CMFMC for KM based on OI and EC.

Section 4 provides the methodology in our research.

Section 5 presents the results of this study.

Section 6 discusses the research findings and managerial implications.

Section 7 are the conclusion, research limitations and future research issues.

2. Literature Review

2.1. Supply Chain Ecosystem for City Manufacturing

The SCE is defined as a network of actors implementing a set of interrelated processes between suppliers and end users to create innovative products and services from order receipt to its implementation [

3,

25]. The process of creating innovative products and services is based on the creative collaboration of all actors in the SCE. Such cooperation is carried out both by direct actors in the implementation of the order and the creation of value, and by other actors in the SCE who generate new ideas and knowledge, improve and implement innovative products and services [

18,

26]. Mutual enrichment of knowledge and skills of SCE participants at the stage of value creation occurs at the network level through continuous self-learning and mutual learning using e-resources and with the involvement of third-party actors, which can be represented by University and UCPI [

4,

27].

The SCE is defined as a network of actors implementing a set of interrelated processes between suppliers and end users to create innovative products and services from order receipt to its implementation [

3,

25]. The process of creating innovative products and services is based on the creative collaboration of all actors in the SCE. Such cooperation is carried out both by direct actors in the implementation of the order and the creation of value, and by other actors in the SCE who generate new ideas and knowledge, improve and implement innovative products and services [

18,

26]. Mutual enrichment of knowledge and skills of SCE participants at the stage of value creation occurs at the network level through continuous self-learning and mutual learning using e-resources and with the involvement of third-party actors, which can be represented by University and UCPI [

4,

27].

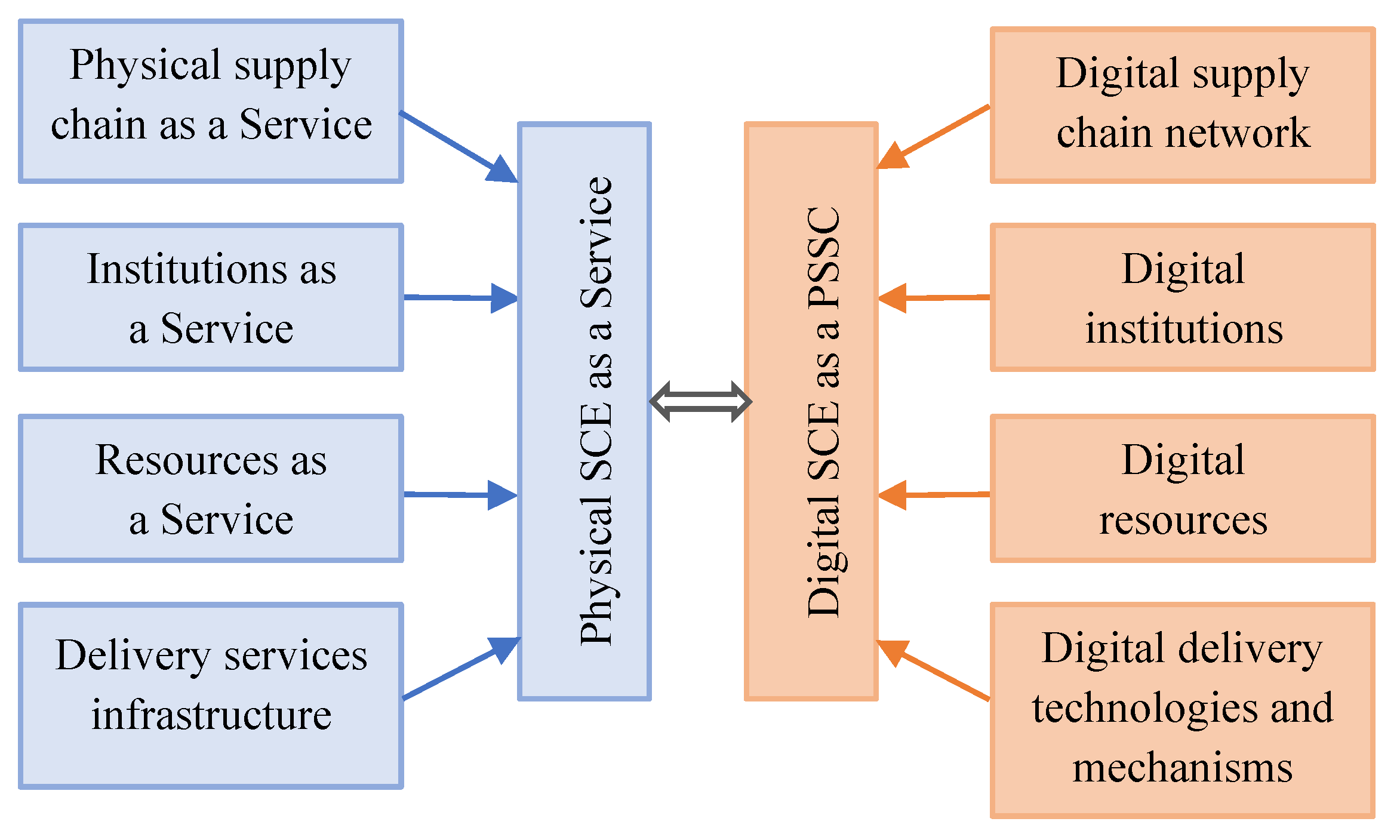

The SCE framework is shown in

Figure 1. Physical SCE as a Service consists of four subsystems: 1. Physical supply chain as a Service; 2. Institutions as a Service: Governmental and Social; 3. Resources as a Service including Human, Natural, Financial and CMFMC; 4. Delivery services infrastructure [

3,

16]. Digital SCE as a PSSC also consists of four subsystems: 1. Digital supply chain network; 2. Digital institutions: Governmental and Social; 3. Digital resources including Customer integration, Smart sustainable CMFMC, Payments and financial flows, Dynamic service composition, Fulfilment coordination; 4. Digital delivery technologies and mechanisms [

16,

28]. Thus, the SCE includes physical and digital assets, the integration of which is aimed at making mechanisms and processes for creating innovative products and services within the cloud supply chain approach [

16,

28]. Some researchers distinguish the following main contributors in the SCE framework: the ecosystem orchestrator, complementors, users and external actors of the ecosystem that contribute to its development and legitimacy [

22,

29]. The difference in approaches to the SCE framework emphasizes the need for its further study within the CMFMC in terms of innovation orientation.

The key network instrument of the SCE is the PSSC, which is usually owned by the focal firm [

18,

30]. The purpose of the focal firm is to form a digital SCE of the CMFMC by creating a PSSC, constantly expanding the range of its users and services provided, creating conditions for innovation and prudent use of the available resources of the cluster [

30]. The PSSC within the CMFMC integrates the processes of digital production and logistics, and the creative interaction of all stakeholders in order to maintain a balance of their interests under competitive environment and the sustainable development of SCE [

18,

21]. The SCE activation within the GMFMC is based on a platform-based approach and is aimed to increase innovation capability in stakeholder relations in the creation of products and services [

17,

31]. UCPI is the orchestrator of knowledge flow in OI environment and formation of partnership creative relations between individual coalitions of SCE participants at all stages of innovation and service delivery, and PSSC is the communication tool. Thus, one of the main tasks of UCPI within the SCE of the CMFMC is to provide innovative services and create innovative value using PSSC. The development of interactions within the formed virtual coalitions is not limited to the SCE, as a result of which innovations are created and realized both inside and outside of it [

18]. Such interaction of SCE participants extends to all aspects of their activities and is aimed at successful innovative solutions to economic, social and environmental issues at various levels within the CMFMC. It is obvious that the communication of stakeholders within the SCE both through PSSC and directly requires appropriate competencies not only in the field of ICT, but also in the field of professional competencies, continuous training and self-education, and the development of the creative potential of its participants [

27]. The formation of innovations is based on new knowledge that is created in the process of creative communication and continuous self-education of all interested participants [

18,

25]. Training, self–education, creativity, and a focus on success are the main components of successful renewal processes within CMFMC and its SCE [

4]. Obviously, the use of PSSC also for the provision of educational services is a key element in accelerating innovation within the framework of SCE of the CMFMC.

One of the key tasks of the CNFNC’s SCE is to create OIs, transfer knowledge and technologies in the field of logistics services aimed at increasing the sustainability and mobility of urban freight transportation. This is due to the commonality of logistics services for all participants in the SCE, regardless of their main activity, and the uncertainty of supply-delivery realization, considering the intensity of urban traffic and restrictions imposed on cargo transportation [

4]. This explains the emergence of innovative logistics solutions in large cities related to the location of logistics facilities directly in the urban environment, the use of intelligent and sustainable vehicles and equipment, and various digital logistics platforms [

4,

30]. Cloud supply chain is a new service-oriented networked business model that includes physical and digital assets for supply chain implementation and is based on the “Supply Chain as a Service” paradigm using human-cyber-physical system, cloud-based design, manufacturing and materials handling systems, cloud computing, 5G, IoT, Blockchain, artificial intelligence, digital twins, big data and augmented reality [

16]. The proposed business model is based on I4.0 technologies, a platform approach within the digital ecosystem and is aimed to shape the “supply chain as a service”. It integrates all the processes and stakeholders involved in manufacturing and logistics based on the material, financial and information flows of service supply chains [

30]. Cloud supply chain based on a platform approach allows to dynamically manage the physical supply chain in real time, focusing on customer needs [

16] and can be considered as one of the important subsystems of the SCE for city manufacturing.

2.2. Knowledge Management Based on OI and EC Through a Platform Service Supply Chain

Knowledge management based on OI and EC is one of the important aspects of sustainable development of the SCE of a CMFMC within a large city.

Sá et al., [

32] defined the OI as “an innovation strategy in which organizations use internal and external knowledge to leverage their business value, thus maintaining a sustainable competitive advantage”. The development of the SCE of smart sustainable cities is accelerating as all aspects of the life of individuals and legal entities are covered by digital platform support. The active involvement of the population of a smart sustainable city in innovative processes in SCE of CMFMs is based on openness and mutual trust and is associated with a personal interest in products and services that meet their needs [

33]. Therefore, deliberate inflows and outflows of useful knowledge in the CMFMC become the property of society, which excludes the monopoly of knowledge and innovation of the SCE actors [

34,

35]. Thus, the paradigm of OI in SCEs of CMFMCs is becoming a generally accepted model of entrepreneurship and city manufacturing development in smart sustainable cities, and the socialization of its population [

13,

34].

A key role in the selection of OI products is played by the limitations of energy and resource consumption in each SME of the CMFMC, which are determined by the smart contrast with their suppliers within the large city [

9,

10]. Obviously, the energy and resource consumption of new technologies and products being introduced by enterprises should not exceed the established limits of energy and resource consumption. Nevertheless, within each production building of the CMFMC, SMEs can redistribute electricity consumption by mutual agreement within the limits allocated to the building, taking into account current production plans [

10].

The spatial proximity of all participants in the SCE of a CMFMC contributes to the collective OI activity, which is a continuous and dynamic flow of knowledge through the PSSC [

7,

35]. Effective management of the knowledge flow in OI is an important aspect of the successful development of CMFMCs and the key tasks of SCEs orchestrator and the focal firms (owners of the PSSCs) [

30,

36].

The orchestrator of digital SCE is the focal firm, owner of the PSSC. The role of the orchestrator of the physical SCE as a Service as a knowledge broker, its legitimacy, and its place in the spatial configuration have not been sufficiently studied. It is unclear whether the orchestrator of the physical SCE as a Service belongs to government or university or cluster structures, what tasks and mechanisms of their resolution are in the scope of its activities, how interaction with the main actors of the SCE, including the focal firm (owner of the PSSC) is carried out. These issues are important from the point of view of organizing an effective centralized innovation environment, in which the role of the orchestrator of the physical SCE as a Service is to organize the flow of knowledge in the SCE, and the role of the orchestrator of the digital SCE is to ensure the knowledge flow through the PSSC for all its participants.

Digital platforms are the most important online resource that determines the economic, social, environmental aspects of human activity in a smart sustainable city [

28,

37]. In logistics, at the initial stage of development, digital platforms were used by service providers to demand logistics services under uncertainty with the ability to visualize supply processes for all stakeholders [

38,

39]. The further development of high-tech I4.0 has led to the emergence of PSSC with a significant expansion of the range of opportunities provided to their customers [

40]. According to Lin et al., 2021 [

30], the PSSC is 'a service supply chain with a platform providing not only logistics services as core offerings, but also other value-added services that support logistics services'. The owner of the PSSC using digital transformation and Internet technologies provides a software resource for information support and meeting the needs of suppliers and customers with service supply chains without physical participation in their implementation [

16,

30]. The main service provided by PSSC within the CMFMCs is the logistics service related to the cargo delivery from suppliers to customers [

30]. The logistics service includes a supply chain of sub-services such as the selection of rational transportation routes, vehicles, loading-unloading, warehousing and distribution operations in CLNs, and real-time monitoring of the transported cargo [

41,

42]. The supply chain of ancillary services through PSSC in KM based on OI and EC is aimed at ensuring the implementation of the main service in the shortest possible time and is associated with the provision of services such as banking, accounting, tax, innovation, education, etc. services [

13,

18]. The PSSC is a digital platform with an open architecture, which is based on cloud and network (IoT, Blockchain) technologies and has the ability to integrate with other platforms of services of various orientation, ownership forms, consumer coverage levels (from local to transnational) in case of need of interested actors. The involvement of a large number of service providers within the PSSC based on the balance of supply and demand contributes to the innovative development of CMFMC based on its SCE [

4,

18].

Cooperation based on a platform-based approach is especially important in crisis situations, e.g., during the COVID-19 pandemic, as it allows you to quickly respond to emerging challenges and effectively manage innovation processes under uncertainty [

37]. The PSSC integration with Not-for-Profit Entities (NFPEs) applications, e.g., crowdsourcing applications, facilitates the involvement of a large number of people in an innovative approach to solving various environmental, social and ecological problems of CMFMC. Participation in crowdsourcing allows all stakeholders to attract innovation providers both inside the CMFMC (spawned startups) and outside it (university spin-offs), and thereby improve the cluster’s infrastructure and more effectively reconfigure its supply chain of products and services, including educational services [

43,

44].

Lin et al. 2021 [

30] proposed 'a conceptual structure of a PSSC, which highlights a triadic relationship among suppliers, customers, and the focal firm. According to this simplified approach, all participants in a digital SCE formed by a focal firm through a PSSC can be classified as either service providers or clients, and the roles of service provider and client can change dynamically [

16,

30]. The triadic structure of the PSSC platform does not distinguish between suppliers of innovative services, which makes it difficult to understand the importance and role of startups in the development of the SCE of a CMFMC. Therefore, the allocation of the ecosystem orchestrator as a conductor of startups and accelerators of their implementation in the structure of the PSSC is justified. The PSSC could also focus on innovation processes related to improving production, products and services [

18,

30]. Thus, the PSSC structure and its innovative orientation is not sufficiently studied, including within the SCE of a CMFMC, considering the actors operating in it. The following section presents a conceptual framework for KM based on OI and EC in SCE of a CMFMC to effectively create collective knowledge flow.

3. A Conceptual Model of Spatial Configuration of the SCE within CMFMC for KM Based on OI and EC

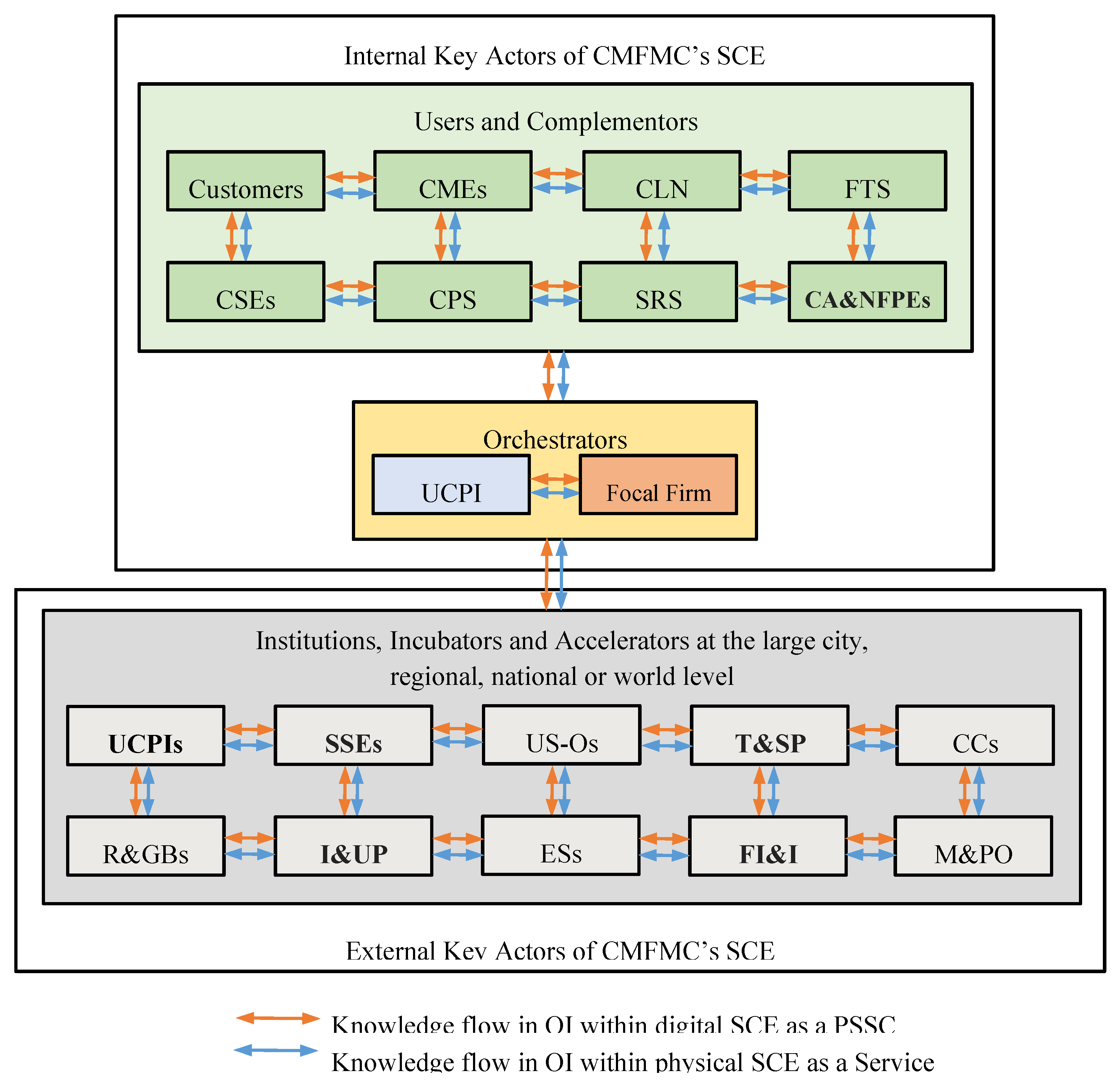

A spatial configuration and key actors of the SCE within CMFMC for KM based OI and EC are shown in

Figure 2. The SCE is represented by internal and external key actors of the CMFMC. The internal key actors of the SCE of a CMFMC are users, complementors and orchestrators that are directly involved in the supply chain, and the external key actors that are not directly involved in the supply chain, but influencing it by contributing to its legitimacy and sustainability [

22,

29]. It is rather difficult to unambiguously identify the key actors of the SCE of a CMFMC, to which of the presented groups they belong, due to the fact that the same actors can change their affiliation to a particular group of actors or even represent them simultaneously [

22,

45]. Nevertheless, the differentiation of key actors into four groups is necessary for a better understanding of their role in innovation processes and KM based OI and EC within the CMFMC.

Users are the main actors in the SCE of a CMFMC as their beneficiaries or end-consumers who are directly involved in the innovation processes of creating products and services within the KM based OI and EC. They include:

1. Customers: CMFMC residents (individuals and legal entities) who use its products, services and the PSSC, participate in their improvement, and benefit from smart mobility, clean energy, sustainable products, circular economy practices, etc., and non-resident of CMFMC within in the large city (municipal entities who apply cluster-tested innovations to urban infrastructure and services related to public transport, renewable energy sources, municipal and industrial waste, hospitals, and public engagement [

2,

46], Advanced Technology and Educational Parks (ATEPs) who use the SCE for applied research and development (R&D), training, prototyping and engage with cases study to test and refine innovations and Industrial and Technology Parks who apply cluster-tested innovations to improve its efficiency [

4,

47].

2. Cluster manufacturing enterprises (CMEs) who adopt innovations for smart sustainable product and service development, serve as testbeds or scale partners for city manufacturing technology using PSSC [

7].

3. Cluster startup enterprises (CSEs) who use shared CM spaces (e.g., FabLabs, coworking and other collaborative spaces) and digital tools (artificial intelligence, computer-aided technology, 3D printing, IoT, Blockchain, PSSC, etc.) to create innovative products and services [

27,

48].

Complementors as supplementary actors are not part of the main supply chain of innovation, but ensure its operation by providing additional products and services, such as:

1. Cluster procurement service (CPS) is a network of enterprises providing services in the field of procurement of raw materials and components for the cluster's needs [

7,

16].

2. Sales and return service (SRS) is a smart sustainable channels for the distribution of cluster products to users (e.g., cluster shopping centres, parcel lockers, and delivery, couriers, moving, and crowdshipping services for last mile delivery, etc.), their after-sales service, return, reuse and recycling [

13,

49].

3. CLN is a logistics facility within the CMFMC (usually located near the shopping centre), which serves as a lead sustainability and smart service provider; receives, sorts, temporarily stores and ships of cargo to users, CPS and SRS with the provision of fulfilment services and using the PSSC [

4].

4. FTS of a CMFMC includes delivery, couriers, moving, and crowdshipping services using enterprises, public and individual vehicles such as intelligent reconfigurable trollies, autonomous mobile robots, freight elevators, light e-trucks, and buses, trams, trolleybuses, subways, pickups, cars, light commercial vehicles, motorcycles, bicycles, and drones [

13,

50].

5. Cluster associations & NFPEs (CA&NFPEs) promoting equal access to manufacturing careers, ethical practices, sustainability and compliance, maker spaces and cooperatives, reducing barriers to innovators [

13,

29].

The external actors of the SCE within CMFMC are divided into two categories, one of which is involved in the innovation supply chain and KM based OI and EC, and the other has an impact but is not directly involved in the innovation supply chain. The first category of external actors of the SCE includes:

1. UCPIs of other CMFMCS in the large city [

13].

2. Spawned startup enterprises (SSEs) [

18].

3. University spin-offs (US-Os) are enterprises that use the know-how based on university scientific and applied research, knowledge and technology to accelerate the creation of innovative products and service using leverage capital and entrepreneurial talent [

51,

52].

4. Technology & startups providers (T&SP) offer innovation designs, technologies, equipment, software, services, and innovation hubs for CM (e.g., 3D printing, Computer-aided technology, Manufacturing Execution System, Enterprise Resource Planning, cloud-based design, manufacturing and materials handling systems, cloud computing, 5G, IoT, Blockchain, artificial intelligence, digital twins, big data, FabLabs, Shared factories, Coworking, Makerspaces, PSSC, etc.) [

16,

48].

The second category of external actors of the SCE includes:

1. Regulators & government bodies (R&GBs) are the regulators of trade policies, environmental laws, labour standards, certification and ESG (Environmental, Social, and Governance) initiatives, and provide preferences for smart sustainable innovative technologies within the city manufacturing development strategy [

3].

2. Municipal infrastructure & utility provider (I&UP) offer renewable energy and natural resources, communications, public transport, green technologies including facility and waste management, and support the physical and digital basis of CM using the PSSC [

9,

53]. The I&UP set and regulate utility resources consumption limits, including electricity, for each production building in the CMFMC [

10].

3. External suppliers (ESs) of raw materials, components, services.

4. Financial institutions & investors (FI&I) provide financing, subsidies and grants, venture capital, crowdfunding and crowdlending, public-private partnerships, financial analysts, and insurance services to fund pilot projects, scale innovations, and support risk-taking and experimentation.

5. Media & Public Opinion (M&PO) as actor shaping consumer perceptions and CMFMC reputation.

6. Cluster competitors (CCs): other CMFMCs in the same city that influence the supply chain innovation strategy and market conditions [

7,

22].

The two orchestrators of the cluster’s SCE are the UCPI and focal firm, owner of the PSSC, which respectively co-ordinate innovation activities as a Physical SCE as a Service and Digital SCE as a PSSC [

7,

21].

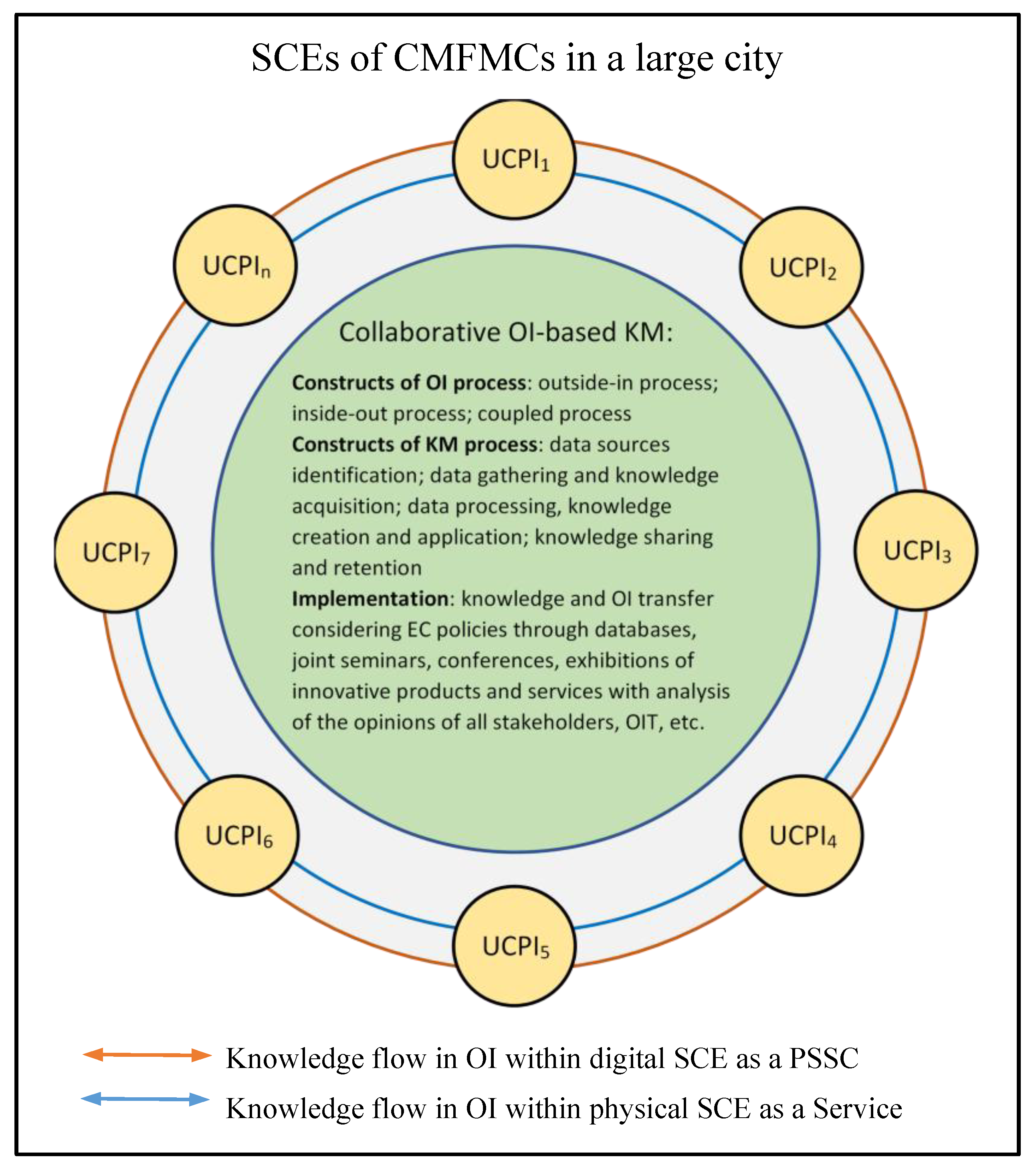

Knowledge flow in OI within physical SCE as a Service and digital SCE as a PSSC encompasses all its key actors and flows through the orchestrators of the SCE of a CMFMC. The nineteen key actors in the SCE go through UCPI, three OI process (outside-in process, inside-out process, coupled process) and four KM processes (data sources identification; data gathering and knowledge acquisition; data processing, knowledge creation and application; knowledge sharing and retention) [

36,

42]. These KM based OI and EC and knowledge flows through the UCPI to all actors in the SCE of a CMFMC and the UCPI role as a SCE’s orchestrator are the subject of our study that is presented in the following sections.

4. Methodology

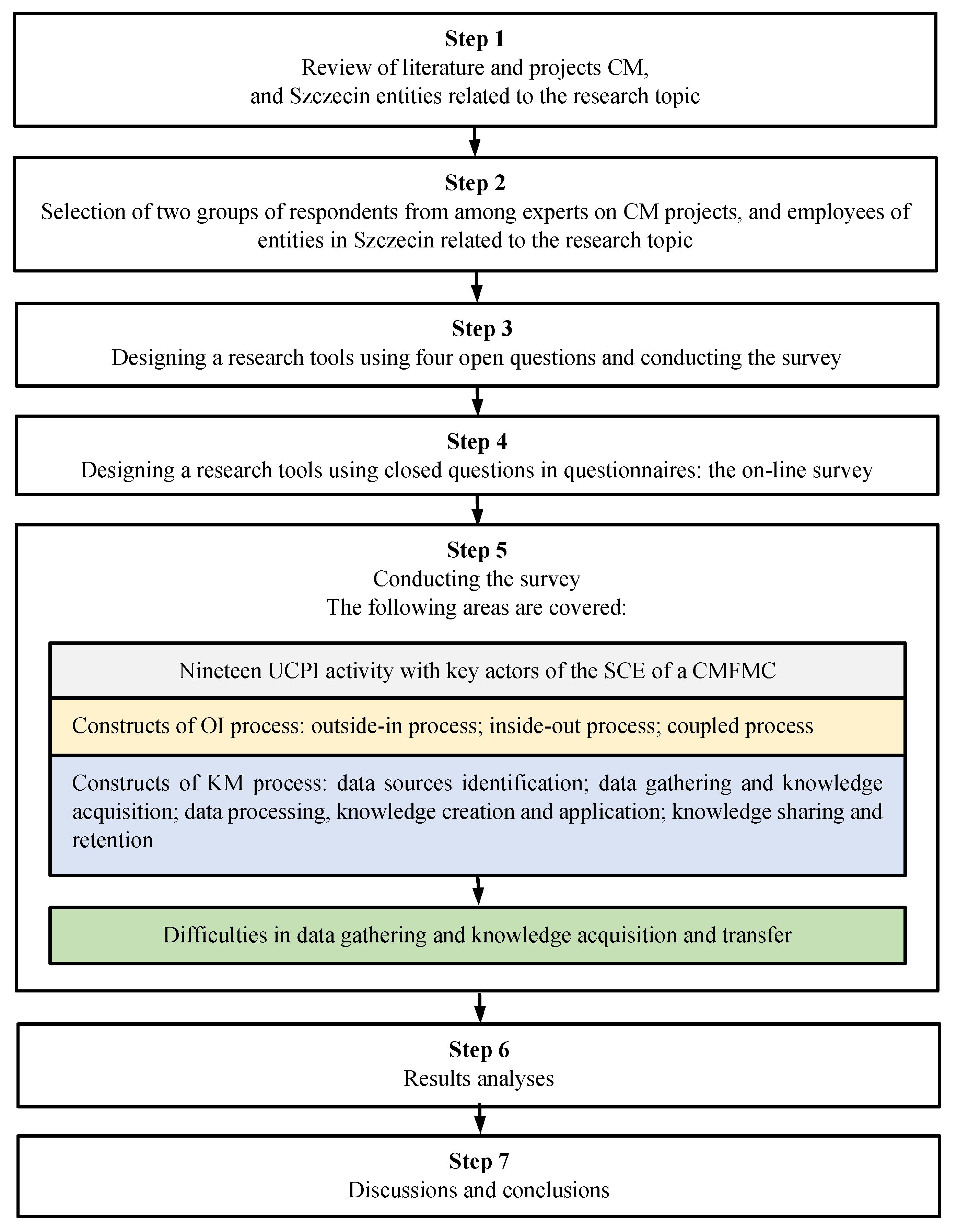

4.1. Methodological Approach

The paper presents the concept of spatial configuration and key actors of the SCE of a CMFMC for KM based OI and EC, among which the role of the orchestrator of the physical SCE as a Service is assigned to the UCPI. In accordance with the purpose of the research, the UCPI is considered as a driver of OI in the SCE and an orchestrator implementing KM in it. Based on this concept, we adopted a qualitative approach to explore in depth the role of the UCPI in KM based OI and EC within the SCE of a CMFMC. Case study is effective in situations where not enough is known about the object of study or the phenomenon under consideration [

54]. The data collection and data analysis using the case study method allows to form an understanding of the phenomena occurring in the studied object of a complex system, which can be attributed to UCPI as the orchestrator of the SCE of a CMFMC implementing KM based OI and EC. The case study method is useful both at the initial stage of studying an object in an unformed theory, and in an in-depth study of already formed theoretical concepts [

4,

55]. Following this methodological approach, we carried out this study by setting up a seven-stages research framework including concepts (nineteen UCPI activity, OI process and KM process) and its constructs as shown in

Figure 3 [

36,

42].

In this study, we assumed that the use of qualitative methodology presupposes the presence of a sufficient number of respondents with experience in the research area [

55]. The authors of this paper had experience of participating in research and projects related to the topic of CM, which determined the involvement of experts with academic and project experience in this field from various European countries as interviewees. Experts with academic and design experience in the field of CM are also regional consultants on the selection and implementation of new smart sustainable solutions in the urban environment, which was an important reason for their involvement in the survey [

42]. As the next group of interviewees, we involved in the survey specialists from Szczecin (Poland) entities, who can be classified among the nineteen key actors from among those proposed by us in the spatial configuration of the SCE of a CMFMC. Several boundary conditions were applied when selecting enterprises and organizations of Szczecin and interviewed specialists. The study considered only specialists of enterprises located in the residential area of the city, including both traditional CMEs and new generation from among SMEs, FabLabs, SSEs, etc., and using 3D printers, coworking and other collaborative spaces to organize and stimulate innovation activities. The number of personnel at such enterprises (including urban divisions of major production and logistics operators) in the vast majority of cases did not exceed 100 employees. Each interviewee had the opportunity to participate in the survey both as an employee of the Szczecin entity and as a consumer of city products and services. As representatives of UCIPs and their managers, the UCIP of the Maritime University in Szczecin and the Regional Centre for Innovation and Technology Transfer of the West Pomeranian University of Technology in Szczecin were considered.

4.2. Data Collection Procedures

The preliminary literature review formulated four specific research questions that became the starting point of the present study. To uncover the role, nature of the UCPI's capabilities and linkages as an orchestrator of the SCE of a CMFMC with its nineteen key actors activities, we applied case study and qualitative analysis methodology [

55,

56]. A review of projects related to CM identified a first group of 32 experts with academic experience who were invited to participate in the surveys. The second group of 76 interviewed participants were engineers, managers, investors, journalists and government officials representing commercial and non-commercial entities in Szczecin (Poland) from the key actors of the SCE of s CMFMC identified in the literature review phase.

This approach was supported by two interviews with two groups of survey participants. The first survey was conducted face-to-face and on-line using four open-ended questions formulated as the specific research questions of this study, supplemented by an indication of the OI and KM process constructs. The questions were supported by references to publications on the topic of this study. The first face-to-face surveys with the second group of interviewees were conducted for at least 40 min with leading questions and transcripts with the promise that they would be used only for this study. The purpose of such approach was to minimize the difference in professional background and perception bias of the second group interviewers, and broaden and deepen the analysis to overcome the lack of qualitative methodology [

35]. Face-to-face surveys of participants in the second group of interviewees with leading questions facilitated the qualitative construction of inductive concepts and factors that could explain UCPI's ability to overcome barriers related to organizing CMFMC in large cities and KM based OI and EC. After categorizing the responses, a questionnaire with fifteen closed-ended questions was developed using Computer Assisted Web Interview to conduct an online survey of participants from the first and second survey groups who participated in the first interview. Participants in the two survey groups were interviewed in 2025 with their written consent. At the final stage of the survey, the number of participants in the first and second groups of interviewees was to 32 and 56 people, respectively. The characteristics of the participants of the two groups of interviewees are presented in

Table 1 and

Table 2.

4.3. Data Analysis

The theoretical understanding of KM based on OI and EC within the SCE of a CMFMC was based on a three-level abstraction using an inductive approach [

56,

57]. Initially, we analysed the respondents of all participants in the first survey of the third stage of the research (see

Figure 2). We analysed key words, text fragments, ideas and categories contained in the transcripts and answers of interviewed respondents and related to the research topic. As a result of coding and sorting the responses, we identified 15 themes that illustrated the type of problem, the spatial configuration and key actors of the SCE of a CMFMC, the operational aspects of KM based on OI and EC within it, the role of the UCPI in OI-based KM to bolstering and boosting innovation and startups, and to overcoming the barriers associated with the CMFMCs organization in large cities. Aspects related to the concepts of KM based on OI and EC, and their constructs, were taken into account. The identification of patterns in the categories of the third stage made it possible to identify 15 themes and accompanying thoughts and ideas, which served as the basis for formulating 15 closed-ended questions and five possible answers for each on the 5-point Likert scale. The fifth stage of the research involved the online survey of the first and second groups of interviewees using 15 closed-ended questions.

The fifth and sixth stages of research were aimed at identifying patterns at a higher level, which made it possible to identify the main difficulties in data gathering and knowledge acquisition and transfer and to substantiate theoretically the ways of overcoming them, as well as their theoretical implications. A critical view of the performed research was supported by discussions of the obtained theoretical and practical results, including answers to four specific research questions. As a last step we substantiated theoretical and practical conclusions, limitations and future research directions.

5. Results

The analysis of the answers to open-ended questions in our third research stage revealed two groups of suggestions. The suggestions common to both groups are the understanding that the UCPI acts as a knowledge broker, its custodian, provider and evaluator, and an orchestrater, connecting innovation processes and SCE of a CMFMC [

52,

58].

The first group of interviewees’ suggestions is related to improving the current activities of the UCPI and includes such traditional aspects as: promoting the scientific activities of the university in accordance with its profile; supporting research by scientists and students (e.g., in scientific circles); registration, submission of applications, monitoring the implementation of projects, R&D, patents and reporting documents; development of scientific and technical cooperation with regional, national and transnational stakeholders; preparation and holding of scientific and educational events (conferences, seminars, courses, etc.); provision of databases of digital platforms (including PSSC) of legal, commercial, marketing and patent information related to innovation activities; advertising of innovative achievements, prototypes at exhibitions and fairs to attract US-Os, CMEs, investors, etc. [

4,

47,

59].

The second group of interviewees’ suggestions identified the following 15 topics to bolstering and boosting innovation that significantly expand the capabilities of the UCPI as an orchestrator of the SCE of a CMFMC:

1. Formation of spatial configuration and key actors of the SCE of a CMFMC for KM based on OI and EC: one of the main prerogatives of the SCE orchestrator.

2. Involving students in the innovation process based on OI-based KM: creation of FabLabs, coworking spaces in the university environment equipped with smart sustainable technological equipment for the development of innovative products and services.

3. Organization of training for young people from lyceums and technical schools: involvement of students from among those who have mastered smart sustainable technological equipment (primarily 3D printers) to train young people living in the CMFMC area.

4. Formation of databases of 3D projects of innovative products of the CMFMC: the creation of an innovative product within the SCE for OI-based KM implies free access to its detail design via the PSSC.

5. Organization of associations that promote smart sustainable development of the SCE of a CMFMC: training, retraining, monitoring compliance with ethical standards and certification of members of various associations.

6. Creation of an advisory council at the UCPI: formation of a strategy for the smart sustainable development of the SCE of a CMFMC for OI-based KM by involving scientists, innovators, students, associations heads of the SCE entities, etc. in its activity.

7. Attracting investors to innovative projects of the CMFMC: participation in the creation and advisory support of crowdfunding and crowdlending associations of the SCE, attracting domestic and foreign investments to support startups, US-Os and business incubators.

8. Formation of student design association and bureau: development of student design groups and bureaus, training in design using advanced computer aid design software and product scanning.

9. Creation of a register of technological equipment of enterprises with an indication of existing limitations on the consumption of utility resources, including electricity, and the throughput capacity of freight elevators in the production buildings of the CMFMC: formation of the structure of the smart sustainable technological equipment fleet, its rational grouping in the buildings using PSSC to organize network production of innovative products and services.

10. Performing marketing research in the CMFMC: contributes to the expansion of the range of manufactured products, flexibility of production services, and allows to forecast the needs for technological equipment.

11. Adherence to priorities of digital knowledge transfer and open innovation: it is more sustainable to digital transfer knowledge and OI than to transport finished innovative goods from other regions, countries and continents.

12. Organizing knowledge transfer through OI tourism (OIT): attracting mature startups with good scalability to the OIT contributes to the rapid development of CM and filling the local market with innovative products and services.

13. Familiarization of OIT representatives with the cultural values of the city: immersion in a new cultural environment contributes to the generation of new ideas, the formation of new knowledge and innovative solutions.

14. Interethnic communication within the framework of OIT: enriches knowledge and creates opportunities for generating new ideas due to immersion in a other ethnic and cultural environment, and familiarization with local traditions, folklore, cuisine and everyday life.

15. Familiarization of OIT representatives with local businesses products and services: broadens the horizons and knowledge of stakeholders, which contributes to boost of innovations activities.

Table 3 presents the results of the fifth stage of the research (see

Figure 3).

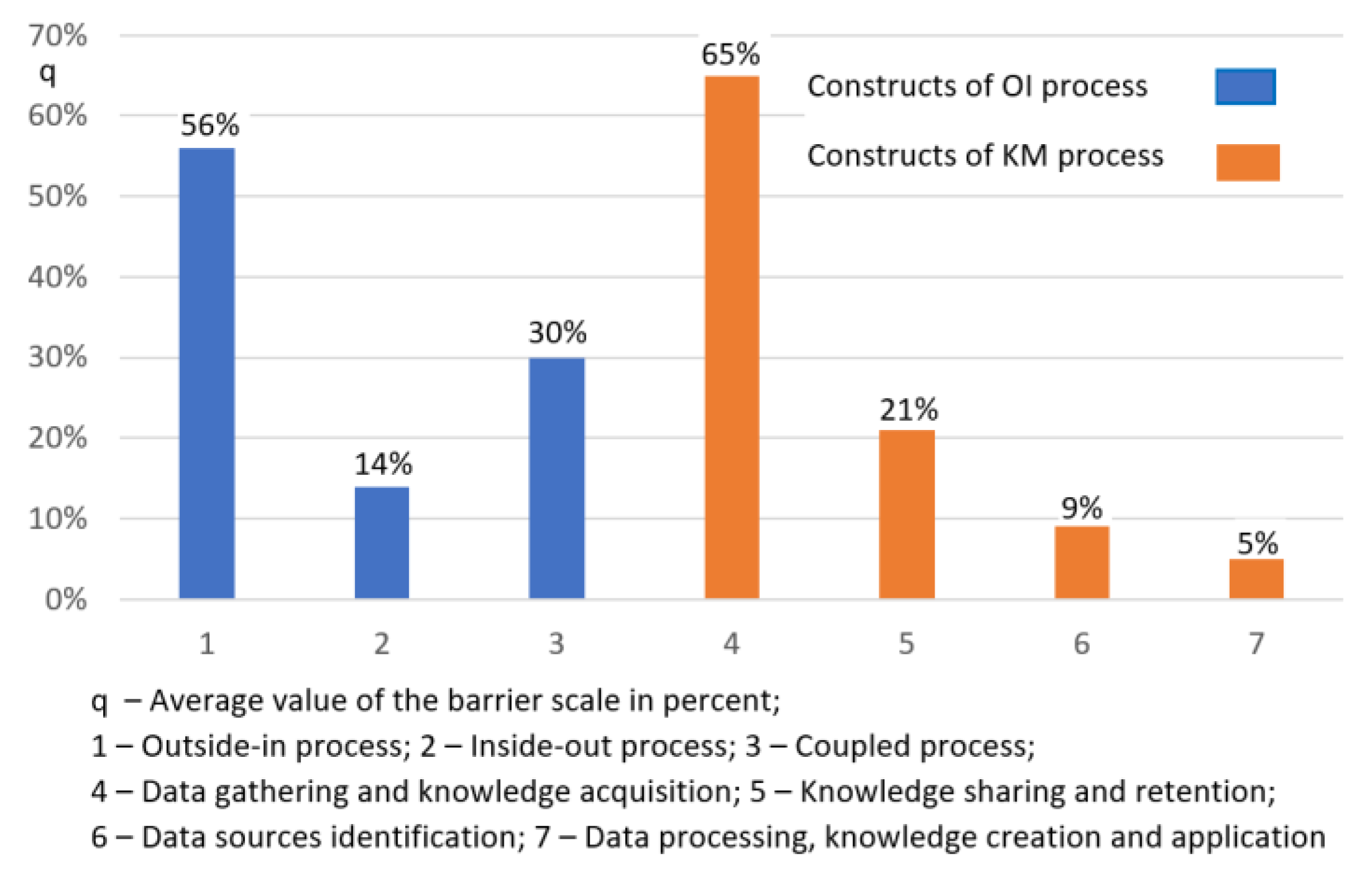

The mean values of the questionnaire results presented in the

Table 3 columns with the heading “Keys Actors of the SCE within a CMFMC for KM based OI and EC by the UCPI are obtained from the survey of representatives of Szczecin entities. The remaining columns show the integrated statistical results of the survey of all interviewees, both project experts and interviewed representatives of Szczecin entities.

The second survey of two representative groups of interviewees revealed barriers in the implementation of OI and KM processes constructs for key actors in the SCE (see

Figure 4). The greatest challenges for key actors in the SCE of a CMFMC are the outside-in process in OI and the data gathering and knowledge acquisition in KM, which is consistent with findings from other studies [

36,

42].

6. Discussion

According to the overwhelming majority of interviewees (89%), the SCE of a CMFMC self-organizes as the population and SMEs (including family enterprises) accumulate technological equipment and, above all, 3D printers, and as they understand that value for themselves can be created jointly within the framework of network production and KM based on OI and EC [

10,

22,

35]. The organization of network production begins with small steps, which, in the context of market relations, develop into a well-structured and balanced SCE of a CMFMC [

7,

60]. At the stage of SCE emergence, it is important for its orchestrators to be recognized as a conductor of innovations and an effective broker of knowledge and technology. It is important to understand that in the context of self-organization of the ecosystem, the role of UCPI in making innovative decisions is limited and cannot be ultimatum-like, but only advisory. The final decision is made by the users of SCE of a CMFMC, taking into account the recommendations received, the experience of other users and the market situation. Therefore, the orchestrator can only partially manage knowledge flows and technology transfer, which is also confirmed by previous studies. However, some of interviewees from among the expert researchers emphasized the importance of the organizing role of the UCPI in the formation and legitimization of the SCE of a CMFMC [

22].

The conceptual model of spatial configuration and key actors of the SCE of a CMFMC for KM based on OI and EC that we proposed was generally positively assessed by the interviewees. Most respondents believe that it is important to continue research on this topic and to refine the results obtained as CM develops in large cities. The strategic role of the UCPI in the legitimization of the new economic logic and the sustainable development of the SCE largely depends on the breadth of its range of actions, effective bolstering and boosting of the innovative activity of the key actors of the CMFMC. It is important not only to lead the innovative component of the development of the SCE of a CMFMC, but also to maintain the position of its orchestrator, making effective decisions on KM based on OI and EC [

22].

The use of OI in the SCE of a CMFMC is widespread and therefore is a priority condition for its sustainable development. However, based on the understanding that the concept of CM is broader than urban manufacturing and logistics due to the fact that it covers both traditional and network (and individual) production, closed innovations can also be implemented in the CMFMC (e.g., in CMEs with traditional production). At the same time, these same CMEs can also utilize OI. Thus, there are two types of innovations in the SCE of a CMFMC - OI and closed innovations, which are also supported by the UCPI. According to the interviewees, as the clustering of CM in large cities deepens, the share of closed innovation will decrease and can lose its importance as society socializes, giving way to OI. Such a phenomenon is also characteristic of smart sustainable megacities [

35].

The implementation of OI based on the use of energy-consuming and high-performance technologies is limited by the established bounds of utility resource consumption, including electricity, and the throughput capacity of freight elevators in the production buildings of the CMFMC. Additive technologies are energy-intensive technologies with relatively low performance. Therefore, the limiting parameter for the application of additive technologies at the CMFMC enterprises is the restrictions on electricity consumption set by the energy supply providers [

7]. The use of automatic lines for the implementation of OI is limited by the established bounds on utility resource consumption (primarily electricity) and the throughput capacity of freight elevators in the production buildings of the CMFMC [

2,

10].

Some respondents noted the potential for a synergistic effect resulting from the joint KM based on OI and EC process carried out by all orchestrators of the SCE of CMFMCs of a large city as a unified team.

Figure 5 shows how the interaction of UCPIs through knowledge transfer and implemented OIs engages representatives of SCEs key actors from all CMFMCs of the large city in a continuous collective innovation process.

In the opinion of the interviewees, the implementation of constructs OI processes as inside-out and coupled does not contain significant barriers to innovation. Nevertheless, the innovative activity of these processes is insufficient. Bolstering and boosting of innovation processes is associated with the creation of a favorable university environment for KM based on OI and EC through specialized laboratories with modern technological equipment and the involvement of students and young people in scientific and innovative activities. This is an important aspect of the policy of the each university and their UCPIs. The acquisition of skills in operating smart sustainable technological equipment and in particular 3D printers by students is an important aspect in involving youth in the CMFMC's business activities. At the same time, the motto of the training is: Learn yourself, teach all family members, including grandparents. This approach promotes the development of family businesses within the framework of a smart sustainable approach to CMFMCs development [

61].

The establishment of student design bureaus, the identification and involvement in their work of talented young people from among students and pupils of lyceums participating in competitions to solve design and graphic problems using modern computer aid design software products is one of the priority conditions for the development of the SCE of a CMFMC. The conduct of marketing research are integral parts of creating innovative products and services. 3D models and prototypes of innovative items can be presented at local exhibitions and fairs, and through media channels. An OI is considered implemented when its detail design is included in the UCPI’s database and is freely accessible for use by key actors within the SCE of a CMFMC via the PSSC. When developing manufacturing technologies for innovative products and establishing a production network for their creation, respondents emphasized the importance of creating a registry of the CMFMC’s technological equipment and tracking its real-time utilization status. The presence of such a registry allows for effective management of the equipment’s structure, composition, and location, as well as for forecasting the need for its modernization [

7].

An advisory board can play a significant role in the development strategy of the SCE of a CMFMC for KM based on OI and EC. Although its recommendations are not mandatory for the leadership of entities of the CMFMC, the knowledge, experience, and competencies of advisory board members across a wide range of issues can contribute to the smart sustainable development of the SCE. The role of the advisory board is especially important in the creation of CA&NFPEs, which help enhance the overall efficiency of the CMFMC. This includes the establishment of associations such as: Associations Owners of CMEs; Associations Crowdsourcing for OI [

62]; Associations Crowdshipping Networks to engage the public in last-mile delivery of finished products to consumers within the CMFMCs and the surrounding area of same large city [

13]; Associations Crowdfunding or Crowdlending to support innovative projects; Investment Associations to attract domestic and foreign investments in support of startups, US-Os, and business incubators [

63,

64], and other associations.

The barriers identified by this study in implementing the constructs of OI and KM processes in the SCE of a CMFMC have shown the need to improve outside-in and data gathering and knowledge acquisition processes while prioritizing digital knowledge transfer and OI, strategies and business models [

65]. On the other hand, it is known that the collaboration of key actors in the SCE with external actors has a positive impact on the effectiveness of OI creation and KM [

66,

67]. In this regard, it is important to organize OIT as another effective mechanism for the transfer of knowledge, technology and OI. The analysis of the survey results (No of topics 11–15, see

Table 3) showed that OIT is, in the opinion of interviewees, one of the most promising areas of KM, support and stimulation of knowledge transfer and OI.

The OIT provides for the temporary departure of OI representatives from their place of permanent residence at the invitation of the SCE entities (including the UCPI) to combine the exchange and transfer of OI and technology, professional knowledge, skills and competencies with tourism purposes at the expense of the host party and without receiving income. The OIT is not limited to the exchange or transfer of knowledge, technologies and OI. It is primarily aimed at the generation of new ideas, mutual enrichment with new knowledge and competencies and is beneficial to all stakeholders. The consequence of such communication is not only the exchange of OI tourist practices, but also the involvement of the host party in the processes related to OIT in other regions. The invitation to colleagues in the framework of OIT is aimed at attracting mature startups with good scalability and begins with the search for innovative products and services, and enterprises that provide them on various information platforms. The selection of mature startups helps to reduce barriers to their implementation, and the use of proven practices, methods, techniques and tools for KM based on OI and EC [

68]. The OIT implies expanding the boundaries of innovative cooperation, involving representatives of different countries and nationalities without any restrictions within the legal framework of the host country. The successful inflow and implementation of knowledge into the SCE of a CMFMC as a result of OIT requires certain abilities and skills of international communication from its recipients [

69]. Cross-national communication as an element of OIT contributes to the creation of multinational enterprises in CMFMCs, increasing the absorptive capacity of people to perceive and use new knowledge from their environment [

70]. In this sense, KM based on OI and EC in the SCE provides opportunities for mutual learning and enrichment with new knowledge for all stakeholders as a result of OIT implementation, while at the same time allowing them to focus their activities primarily on creating truly new value both within and outside the CMFMC [

27].

7. Conclusions

SCE of the CM system is a new paradigm of innovative development of a smart sustainable city. CM clustering in large cities is a consequence of its smart sustainable development within the framework of I4.0 technologies and is aimed at rapidly meeting the needs of their residents in products and services and reducing both urban and global traffic [

4,

13]. The increase in the share of urban manufacturing in the total volume of CM due to the development of SMEs has led to the reengineering of traditional city manufacturing, the prevalence of the OI as a new approach to the creation of innovative products and services [

35]. The SCE of each CMFMC is an integral part of smart sustainable cities and aims to ensure effective innovation activities based on OI-based KM in order to meet the local market needs for new products and services [

7,

18,

36]. This study aimed to develop a conceptual model of the SCE of a smart sustainable CMFMC for KM based on OI and EC and to answer the four research questions posed. As a result of the qualitative study, we derive a new model of the spatial configuration and key actors of SCE of a CMFMC for KM based on OI and EC. The place and role of the UCPI as a physical orchestrator as a service of the SCE in bolstering and boosting the innovative activity of the CMFMC through KM based on OI and EC are shown. The barriers to the implementation of the constructs of OI and KM processes for the key actors of the SCEs of CMFMCs are identified and the role of the UCPIs in overcoming them is considered. Theoretical and practical implications are provided to enhance the understanding of the SCE of a CMFMC and the UCPI role as its physical orchestrator in bolstering and boosting innovation activities under OI-based KM, and in overcoming barriers in the implementation of OI and KM processes constructs. Finally, important limitations are identified to motivate the future research of KM based on OI and EC within the SCE of a CMFMC.

7.1. Theoretical Implications

The theory of the ecosystem of smart sustainable CM has been further developed. First, we clarified that the term SCE of CM is a broader concept in comparison with the SCE of urban manufacturing and logistics due to the fact that it covers all types of production, from traditional mass and serial production to urban network and individual manufacturing within the residential area of a smart sustainable city [

6,

7]. Next, we extend previous studies that have shown that ecosystems can self-organize, but also have emphasized the role of the orchestrator in accelerating this process [

22,

29]. Here we have found out the conditions for the self-organization of the SCEs of CMFMCs, which are associated with the mass training of the population in the skills of working with modern technological equipment, primarily on 3D printers, and on this basis, the formation of their need for their purchase. We also found that this initial process of forming the SCE of a CMFMC is positively influenced by the creation of professional and technical associations of 3D printer users and heads of CMEs, primarily from among SMEs. Next, we found out that as the city's population accumulates 3D printers and creates their registry based on a platform approach, conditions are created for organizing individual and network production within the framework of the created SCE associations. At this stage of clustering of CM, the size of its SCE has not yet been fully formed and will be clarified as it develops. We also found out that involving users in the creation of innovative products and services is another important component of the SCE development. At the same time, in continuation of previous studies [

35,

36], we found out that OI will be in demand in the cluster ecosystem, while closed innovation and, partially, OI will prevail in traditional manufacturing enterprises. Secondly, in continuation of ecosystem research [

3,

22,

29], including CM ecosystems [

16], we proposed a conceptual model of the spatial configuration of a CMFMC's SCE, identified its key actors from among users, complementors, orchestrators and external actors, and channels of materials, knowledge, information, etc. flows. Here we also reveal the role and functions of the key actors of the SCE of a CMFMC in its innovation activities. The theory of the ecosystem of CM has been further developed in the form of its physical and digital model, covering all entities of its key actors, and all operational processes, material, information and financial flows [

16]. We hereby expand prior studies by proposing in the SCE of a CMFMC two orchestrators responsible for physical and digital supply chain of knowledge, technology, products and services within the constructs of OI and KM processes. We further specify that the orchestrators of the SCE of a CMFMC are the UCPI and the focal firm that owns the PSSC, which respectively perform the roles of the physical orchestrator as a service and the digital orchestrator as a PSSC. Thirdly, we specify the role of the UCPI as a physical orchestrator in bolstering and boosting innovation activities in the CMFMC through KM based on OI and EC We found that issues related to the role of the digital orchestrator of the ecosystem represented by the focal firm as the owner of the PSSC have been studied quite well [

30]. However, very little attention has been paid in the scientific literature to the role of the UCPI as a physical orchestrator of the SCE of a CMFMC. We have tried to eliminate this gap in the present study. In addition to the traditional role of the UCPI as an orchestrator of the SCE within the constructs of OI and KM process, we have identified 15 topics, the development of which helps to bolstering and boosting OI in the CMFMC. We theoretically justified such approaches and tools within the framework of OI and KM as: the formation of the spatial configuration of the SCE by the UCPI and the selection of its key actors, training the population in the use of 3D printers and involving them in the innovation process; the formation of databases of 3D projects of innovative products; the organization of separate professorial and technical associations within the CMFMC; the creation of an advisory council to identify promising areas of innovative development; the attraction of investors to innovative projects, creating and consulting crowdfunding and crowdlending associations, and the attraction of domestic and foreign investments to support startups, US-Os and business incubators; the formation of student design bureaus; the creation of a technological equipment register in the CMFMC; the conduction of marketing research; following the priorities of digital knowledge transfer and OI; organizing international knowledge transfer through the OIT in order to immersing its participants in a new environment of communication, and acquaintance with the products and services of local businesses. Fourth, we expand prior studies related to barriers in constructs of OI and KM processes and their overcoming [

35,

36,

42]. Our research confirmed that the main barriers in the implementation of OI and KM processes constructs for key actors in the SCE are the outside-in of OI process and the data gathering and knowledge acquisition of KM process. We associate the overcoming of these barriers with our proposed approach to the use of external resource provision by entities of the SCE of a CMFMC in the form of OIT, which is an extension of the theory of external resource provision for SMEs in the context of limitations in conditions of limited internal innovation resources [

20,

67]. We have shown that OIT reduces these barriers and promotes knowledge transfer, and attracts mature startups with good scalability, rapid development of CM and filling the local market with innovative products and services. An important feature of OIT is the possibility of international participation of representatives of different countries in it, which contributes to the generation of new ideas, the formation of new knowledge and innovative solutions through immersion in a different ethnic and cultural environment, acquaintance with local traditions, folklore, cuisine and everyday life, and products and services of local businesses. Fifth, we expand prior studies related to the external innovative resource provision of SMEs at the regional level [

67]. Here we clarified the understanding that mutual resource provision of the SCE entities in the form of knowledge, technology and OI transfer through UCPIs is possible within a large city. The involvement of all SCEs of a large city and their UCPIs in a continuous collective OI process helps to boosting innovation in each CMFMC.

7.2. Practical Implications

Our research has some practical implications for managers of entities representing key actors in SCE of a CMFMC within the smart sustainable city concept. First, we have proposed a spatial configuration of the SCE and identified its key actors, which allows to outline the range of stakeholders in the CMFMC’s innovation activities. Managers can use our research to better understand the roles of key actors of SCE and its physical and digital orchestrators in enhancing innovation activities in the CMFMC and specify the functions of the UCPI as a physical orchestrator to ensure effective KM based on OI and EC. Secondly, we found out that at the initial stage of SCEs development, the main role in the formation of their spatial configuration and key actors are played by managers of the UCPIs, to whom we offered a comprehensive approach to involving the population (primarily students and youth of lyceums and technical schools) in individual and network production through training in advanced technologies in university laboratories, coworking spaces, creating associations of 3D printer users for mutual exchange of knowledge and skills, involvement in innovative activities within the framework of university scientific circles, creation of databases of projects of OI products and services and a register of technological equipment of the cluster, exchange of experience and best practices of SMEs of CMFMCs of a large city. Thirdly, our findings show that the managers of the UCPI, in order to bolstering and boosting innovative activities in the SCE of a CMFMC within the framework of the constructs of OI and KM processes, can use a set of practical recommendations from among 15 topics identified as a result of the survey and related to the involvement of students in the innovation process based on OI-based KM, professional and technical training and certification of the population and members of their associations from among users and complementors, the use of the scientific and professional potential of the advisory board at UCPI to identify areas of innovative development, attracting investors to innovative projects, using the potential of the student design bureaus, conducting marketing research, adhering to the priorities of digital knowledge transfer and OI. Fourth, our findings show how managers from among the entities of users, complementors and orchestrators of the SCE of a CMFMC can overcome existing barriers in the constructs of OI and KM processes. In particular, to overcome barriers in the outside in process in OI and the data gathering and knowledge acquisition in KM, it is advisable to use OIT with the involvement of mature startups with good scalability from different countries of the world. Multiculturalism, interethnic communication, immersion in a new cultural environment contribute to the generation of new ideas, the formation of new knowledge and innovative solutions. Fifth, our findings provide managers of UCPIs of a large city with tools for the legalization of a continuous collective innovation process by knowledge and OI transfer through PSSC, databases, joint seminars, conferences, courses, exhibitions of prototypes of innovative products and services with analysis of the opinions of all stakeholders, etc. Collection, analysis and implementation of best OI-based KM practices by UCPIs managers is one of the factors of successful innovation activities in the SCEs of CMFMCs of a large city [

42].

7.3. Limitations and Future Research

This study expands the understanding of the SCE of a CMFMC and its physical orchestrator as a service represented by the UCPI implementing KM based on OI and EC. However, as with any study, some limitations should be highlighted, which can be overcome in future research. The first limitation is related to the choice of Szczecin as the object of research of key actors of the SCE of a CMFMC. While Szczecin is a major city in Poland, it does not belong to the category of large European megapolises such as Warsaw or Berlin, and even less so to the group of densely populated megacities in Asia. In addition, Szczecin is at an early stage of clustering in terms of CM. This limitation was partially mitigated by the participation of project experts from various large cities across the European Union. Nevertheless, this research is still at a relatively early stage, and the applicability of its findings to megapolises with well-developed CM systems requires further verification in future studies. Participation of the authors in such studies, in collaboration with researchers representing such megapolises, would be of great interest. Another limitation is related to the use of qualitative research methodology, which reflects although representative opinions of project experts from different countries of the European Union and interviewed stakeholders from Szczecin entities, but does not allow for generalization of the findings to other large cities or megapolises with their own historical, cultural, and national characteristics. Another limitation lies in the assessment of OIT as an effective tool for knowledge and technology transfer, and a generator of new business ideas and a multidimensional approach to mutual knowledge enrichment at different levels, ranging from professional to cultural and language exchange. Although the idea of such OIT seems intuitive, and we conducted a survey among entrepreneurs from Szczecin who traveled to other regions of Poland and the European Union with this mission, the evaluation of its possible international nature and effectiveness as a OI-based KM tool within the SCE of a CMFMC requires further research.

Author Contributions

Conceptualization, T.D., K.K. S.I. and K.D.; methodology, T.D., K.K. and S.I.; software, T.D., K.K. and K.D.; validation, T.D., K.K. and S.I.; formal analysis, K.K. and S.I.; resources, T.D., K.K. and S.I.; data curation, K.K. and K.D.; writing—original draft preparation, T.D. and S.I.; writing—review and editing, T.D., K.K. and S.I.; supervision, K.K. and S.I.; funding acquisition, T.D., K.K. and S.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research outcome has been founded by the research project no 1/S/KRiZR/2025 financed by Maritime University of Szczecin from subsidy of the Ministry of Science and Higher Education.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| CLN |

city logistics node |

| CM |

city manufacturing |

| CMFMC |

city multifloor manufacturing cluster |

| CA&NFPE |

cluster associations & not-for-profit entity |

| CC |

cluster competitor |

| CME |

cluster manufacturing enterprise |

| CPS |

cluster procurement service |

| CSE |

cluster startup enterprise |

| ES |

external supplier |

| FTS |

freight transport service |

| GPS |

global positioning system |

| ICT |

information and communications technologies |

| I4.0 |

industry 4.0 |

| IoT |

internet of things |

| KM |

knowledge management |

| FI&I |

financial institutions & investor |

| MI&UP |

municipal infrastructure & utility provider |

| NFPE |

not-for-profit entity |

| OI |

open innovation |

| OIT |

open innovation tourism |

| PSSC |

platform service supply chain |

| R&GB |

regulators & government body |

| R&D |

research and development |

| SRS |

sales and return service |

| SCE |

supply chain ecosystem |

| SME |

small and medium-sized enterprise |

| SSE |

spawned startup enterprise |

| T&SP |

technology & startups providers |

| UCPI |

university Centre for Projects and Innovation |

| US-O |

university spin-of |

References

- Lom, M.; Pribyl, O.; Svitek, M. Industry 4.0 as a Part of Smart Cities. Proceedings of the SCSP 2016. Smart City Symposium, Prague, Czech Republic, 2016.

- Dzhuguryan, T.; Deja, A. Sustainable waste management for a city multifloor manufacturing cluster: A framework for designing a smart supply chain. Sustainability 2021, 13, 1540. [CrossRef]

- Viswanadham, N.; Samvedi, A. Supplier selection based on supply chain ecosystem, performance and risk criteria. Int. J. Prod. Res. 2013, 51:21, 6484-6498. [CrossRef]

- Deja, A.; Dzhuguryan, T.; Dzhuguryan, L.; Konradi, O.; Ulewicz, R. Smart sustainable city manufacturing and logistics: A framework for city logistics node 4.0 operations. Energies 2021, 14, 8380. [CrossRef]

- Dudek, T.; Dzhuguryan, T.; Wiśnicki, B.; Pędziwiatr, K. Smart Sustainable Production and Distribution Network Model for City Multi-Floor Manufacturing Clusters. Energies 2022, 15(2):488. [CrossRef]

- Mourtzis D.; Doukas M. Design and planning of manufacturing networks for mass customisation an personalisation: Challenges and Outlook, Robust Manufacturing Conference (RoMaC 2014), Procedia CIRP 2014, 19, 1–13. [CrossRef]

- Deja, A.; Ślączka, W.; Dzhuguryan, L.; Dzhuguryan, T.; Ulewicz, R. Green technologies in smart city multifloor manufacturing clusters: A framework for additive manufacturing management. Prod. Eng. Arch. 2023, 29(4), 428-443. [CrossRef]

- Amjad, M.S.; Diaz-Elsayed, N. Smart and sustainable urban manufacturing for a circular economy. Environ Dev Sustain. 2024, 26, 31789–31815. [CrossRef]

- Davydenko, L.; Davydenko, N.; Bosak, A.; Bosak, A.; Deja, A.; Dzhuguryan, T. Smart Sustainable Freight Transport for a City Multi-Floor Manufacturing Cluster: A Framework of the Energy Efficiency Monitoring of Electric Vehicle Fleet Charging. Energies 2022, 15, 3780. [CrossRef]

- Gevorkyan, E.; Chmiel, J.; Wiśnicki, B.; Dzhuguryan, T.; Rucki, M.; Nerubatskyi, V. Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology. Energies 2022, 15(17), 6443. [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 1-21. [CrossRef]

- Bai, C.; Zhou, H.; Sarkis, J. Evaluating Industry 4.0 technology and sustainable development goals – a social perspective. Int. J. Prod. Res. 2023. [CrossRef]

- Deja, A.; Ślączka, W.; Kaup, M.; Szołtysek, J.; Dzhuguryan, L.; Dzhuguryan, T. Supply Chain Management in Smart City Manufacturing Clusters: An Alternative Approach to Urban Freight Mobility with Electric Vehicles. Energies 2024, 17(21), 5284. [CrossRef]

- Wiśnicki, B.; Dzhuguryan, T.; Mielniczuk, S.; Petrov, I.; Davydenko, L. A Decision Support Model for Lean Supply Chain Management in City Multifloor Manufacturing Clusters. Sustainability 2024, 16(20), 8801. [CrossRef]

- Cai, Y.-J.; Choi, T.-M.; Zhang, J. Platform supported supply chain operations in the blockchain era: supply contracting and moral hazards. Decision Sciences 2021, 52 (4), 866–892. [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud supply chain: Integrating Industry 4.0 and digital platforms in the “Supply Chain-as-a-Service”. Transp. Res. E Logist. Transp. Rev. 2022, 160, 102676. [CrossRef]

- Liu, G.; Aroean, L.; Ko, W.W. A business ecosystem perspective of supply chain justice practices: A study of a marina resort supply chain ecosystem in Indonesia. Int. J. Oper. Prod. Manag. 2019, 39(9/10), 1122-1143. [CrossRef]

- Wagner, S.M. Startups in the supply chain ecosystem: an organizing framework and research opportunities. Int. J. Phys. Distrib. Logist. Manag. 2021, 51(10), 1130-1157. [CrossRef]

- Ingaldi, M.; Ulewicz, R. Problems with the Implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability 2020, 12, 217. [CrossRef]

- Scuotto, V.; Alfiero, S.; Cuomo, M.T.; Monge, F. Knowledge management and technological innovation in family SMEs context. J. Knowl. Manag. 2024, 28(3), 789-798. [CrossRef]

- Iansiti, M.; Levien, R. The Keystone Advantage: What the New Dynamics of Business Ecosystems Mean for Strategy, Innovation, and Sustainability. Harvard Business School Press, Boston, Massachusetts, 2004. [CrossRef]

- Thomas, L.D.W.; Ritala, P. Ecosystem legitimacy emergence: a collective action view. J. Manag. 2021, 48(3), 515-541. [CrossRef]

- Franco, M.; Pinho, C. A case study about cooperation between University Research Centres: Knowledge transfer perspective. J. Innov. Knowl. 2019, 4(1), 62-69. [CrossRef]

- Kulkarni, P.; Tigadi, B.; Gokhale, P.; K., L. University incubators performance through the lens of institutional theory. Vilakshan - XIMB Journal of Management 2024. [CrossRef]

- Magliocca, P.; Herold, D.; Canestrino, R.; Temperini, V.; Albino, V. The role of start-ups as knowledge brokers: a supply chain ecosystem perspective. J. Knowl. Manag. 2023, 27(10), 2625-2641. [CrossRef]

- Ketchen, D.J.; Crook, T.R.; Craighead, C.W. From supply chains to supply ecosystems: implications for strategic sourcing research and practice. J. Bus. Logist. 2014, 35 (3), 165-171. [CrossRef]

- Wang, C.; Hu, Q. Knowledge sharing in supply chain networks: Effects of collaborative innovation activities and capability on innovation performance. Technovation 2020, 94-95, 102010. [CrossRef]

- Viswanadham, N. Ecosystem model for healthcare platform. Sādhanā 2021, 46, 188. [CrossRef]

- Shipilov, A.; Gawer, A. Integrating research on interorganizational networks and ecosystems. Acad. Manag. Ann. 2020, 14(1), 92-121. [CrossRef]

- Lin, Y.; Chen, A.; Yin, Y.; Li, Q.; Zhu, Q.; Luo, J. A framework for sustainable management of the platform service supply chain: An empirical study of the logistics sector in China. Int. J. Prod. Econ. 2021, 235, 108112. [CrossRef]

- Chen, L., Tong, T. W., Tang, S., & Han, N., Governance and design of digital platforms: a review and future research directions on a meta-organization. J. Manag. 2022, 48(1), 147-184. [CrossRef]

- Sá, T.; Ferreira, J.J.M.; Jayantilal, S. Open innovation strategy: a systematic literature review. Eur. J. Innov. Manag. 2025, 28(2). 454-510. [CrossRef]

- Ogink, R.H.A.J.; Goossen, M.C.; Romme, A.G.L; Akkermans, H. Mechanisms in open innovation: A review and synthesis of the literature. Technovation 2023, 119, 102621. [CrossRef]

- Chesbrough, H.W. Open Innovation Results; Going Beyond the Hype and Getting Down to Business. Oxford University Press, London, 2020.

- Han, J. Open innovation in a smart city context: the case of Sejong smart city initiative. Eur. J. Innov. Manag. 2024. [CrossRef]

- Wu, I.-L.; Hu, Y.-P. Open innovation based knowledge management implementation: a mediating role of knowledge management design. J. Knowl. Manag. 2018, 22(8), 1736-1756. [CrossRef]

- Strulak-Wójcikiewicz, R.; Deja, A. A concept for an IT platform to assess the impact of transport infrastructure investments on ecological safety and security. Procedia Comput. Sci. 2022, 207, 4258-4267. [CrossRef]

- Shen, B.; Xu, X.; Chan, H.L.; Choi, T.-M. Collaborative innovation in supply chain systems: value creation and leadership structure. Int. J. Prod. Econ. 2021, 235, 108068. [CrossRef]

- Iwan, S.; Jedliński, M.; Sosik-Filipiak, K.; Osypchuk, O.; Nürnberg, M. Analysis of contemporary scientific achievements in the field of Urban Freight Transport in terms of the use of knowledge-based management. Transp. Res. Proc. 2023, 23, 4388-4395. [CrossRef]

- Peng, Y.; Chen, B.; Veglianti, E. Platform Service Supply Chain Network Equilibrium Model with Data Empowerment. Sustainability 2022, 14, 5419. [CrossRef]

- Bereznoy, A.; Meissner, D.; Scuotto, V. The intertwining of knowledge sharing and creation in the digital platform based ecosystem. A conceptual study on the lens of the open innovation approach. J. Knowl. Manag. 2021, 25(8). 2022-2042. [CrossRef]