1. Introduction

According to the “2023 Annual Report of China’s Ecological Environment Statistics” issued by the Ministry of Ecology and Environment, in 2023, the production of general solid waste in the country will be 4.27 billion tons, the comprehensive utilization will be 2.58 billion tons, the disposal will be 8.3 billion tons, and the annual increment will be 8.6 billion tons. Among them, the production of coal mining and washing industry accounts for 13.5 %, and about 116 million tons of coal gangue will be added in 2023. Moreover, the amount of coal gangue produced in coal mining and washing for many years is huge. Shanxi, Inner Mongolia, Hebei, Shandong and Liaoning, the top five regions in the country in terms of the production of general solid waste, happen to be the main producing areas of coal in China. The annual production of general solid waste totals 1.83 billion tons, accounting for 42.8 % of the national production.

In the coal mining and washing land, the disposal of coal gangue mainly adopts landfill measures. Domestic and foreign scholars have carried out research on the resource utilization of coal gangue. According to the different components or regions of coal gangue, power generation [

1], production of chemical fertilizer [

2], firing of cement [

3], improvement of soil [

4,

5], brick making [

6], sand making [

7], concrete making [

8], production of energy storage materials [

9], extraction of chemical raw materials and metals [

10,

11,

12], firing of ceramsite [

13], etc., provide a variety of ways for coal gangue in resource utilization, but the amount of disposal or reduction is limited.

With the people ‘s yearning for a better life, the requirements for building comfort and durability are gradually increasing, but there are few types of assembled exterior wall panels suitable for modern buildings [

14], such as glass curtain walls, metal curtain walls, and ALC panels. According to the information released by the National Bureau of Statistics, the construction area of real estate houses in China will be 733,247 square meters in 2024, which shows that the demand for exterior wall panels in the construction market is huge. If the appropriate coal gangue can be used to produce prefabricated exterior wall panels, it will realize the resource utilization of coal gangue. It can also improve the relevant performance by adjusting the mix ratio of coal gangue concrete, coal gangue board composite rock wool, and the assembly of exterior wall panels to meet the requirements of ‘ good house ‘ for heat preservation, heat insulation, sound insulation, durability and efficient construction, so as to expand the resource utilization rate of coal gangue.

In recent years, the research group has carried out experimental research on the feasibility of producing building wall panels, concrete mix ratio, wall panel design and related performance for spontaneous combustion coal gangue, and has carried out practical application in combination with specific projects.

2. Spontaneous Combustion Gangue

When the combustion value of coal gangue is high and the thickness of open-air stacking is large, spontaneous combustion often occurs. The coal gangue after spontaneous combustion will increase the oxide content of aluminum, calcium, iron and magnesium, and improve the activity as a cementitious material. After the spontaneous combustion of coal gangue, it changes from the original combustible or combustible to the non-combustible or non-combustible. The outer wall panel made of spontaneous combustion coal gangue can meet the requirements of Class A fire protection grade. The spontaneous combustion coal gangue selected by the research group comes from the gangue yard of a coal mine in Yangquan, Shanxi.

2.1. Selecting and Using Principles

The first principle is that the radioactivity of spontaneous combustion coal gangue should meet the limits of relevant standards or specifications [

15]. Shanxi Boao Scientific Research and Testing Co., Ltd.was entrusted to use PGs-6000 low-background multi-channel γ energy spectrum BAOKY-302 to measure the selected spontaneous combustion coal gangue samples, and their radioactivity met the requirements, as shown in

Table 1.

Secondly, due to the different building types, heights and use scenarios, the requirements for the fire resistance of building wallboards are different. The combustion performance of spontaneous combustion coal gangue used for processing and making exterior wallboards should not be lower than grade B

1 [

16].

Furthermore, as coarse and fine aggregate, it should meet the relevant requirements of “pebbles and gravels for construction” [

17]. Before crushing, the mud content of spontaneous combustion coal gangue should not be more than 1.5%, the sulfide and sulfate content should be less than or equal to 1.0 %, and the organic matter content should be qualified. The chemical composition of the selected spontaneous combustion coal gangue was measured and analyzed by SEM scanning electron microscopy. The contents of silicon, aluminum, calcium, iron, magnesium, potassium, sodium, oxygen and sulfur were 16.01%, 8.79%, 4.20%, 7.40%, 0.71%, 1.19%, 0.60%, 61.70% and 0.09%, respectively. The main components are shown in

Table 2.

2.2. Crushing and Screening

The massive spontaneous combustion coal gangue was selected from the gangue yard. After crushing, screening and particle gradation adjustment, the coarse aggregate with particle size of 5-10 mm and the fine aggregate with particle size of ≤ 3 mm were obtained, which were used to make 20 mm thick spontaneous combustion coal gangue plate, as shown in

Figure 1 and

Figure 2. The particle gradation of aggregate is shown in

Table 3 and

Table 4.

In order to make the spontaneous combustion coal gangue composite exterior wall panel, the coarse aggregate with particle size ≤10 mm is specially selected, so there is no coarse aggregate with particle size ≥16.0 mm after standard sieve screening.

The relevant data of

Table 4 are calculated and analyzed. The fine aggregate of spontaneous combustion coal gangue corresponds to the medium sand in the 2 area of machine-made sand.

2.3. Basic Performance

The basic physical properties of the spontaneous combustion coal gangue coarse aggregate after crushing and screening are shown in

Table 5, which meets the requirements of the specification.

The basic physical properties of the spontaneous combustion coal gangue fine aggregate after crushing and screening are shown in

Table 6, which meets the requirements of the specification.

3. Spontaneous Combustion Coal Gangue Fine Stone Concrete

Using the above-mentioned spontaneous combustion coal gangue coarse and fine aggregates, mixed with cement, fly ash, additives, and water, the mix ratio of the fine stone concrete required for the outer wall panel is determined.

3.1. The Basic Requirements of Fine Stone Concrete

As a public building or residential wallboard, it should have good fire resistance [

18],durability, crashworthiness, impermeability, sound insulation, thermal conductivity, mechanical properties and so on. C20 spontaneous combustion coal gangue fine stone concrete is planned to be used in this assembled exterior wall panel. The fluidity of concrete should meet the production requirements of exterior wall panel and have appropriate initial setting and final setting time.

3.2. Raw Materials of Fine Stone Concrete

1. Aggregate

After crushing and screening, the coarse and fine aggregates of spontaneous combustion coal gangue that meet the requirements of particle gradation in

Table 3 and

Table 4 are selected.

2. Cement

The cement is ordinary Portland cement P.O 42.5 from Taiyuan. The bulk density is 1037 kg/m3, the specific surface area is 320 m2/kg, the initial setting time is 70 min, the final setting time is 242 min, the loss on ignition is 1.65%, and the volume stability is qualified.

3. Fly ash

Taiyuan grade II fly ash was selected, and its bulk density was 632 kg/m3. The dosage of fly ash is 10%.

4. Additives

The naphthalene superplasticizer is selected as the water reducer, and the water reducer is dissolved in the mixing water in advance and then added to the mixer.

In order to improve the crack resistance and impact resistance of the concrete, 1-2kg polypropylene short fiber is added to each cubic meter of concrete. The fiber length is 12mm and the diameter is 48μm.

5. Mixing water

The water used for mixing fine stone concrete is tap water, and the water absorption rate of spontaneous combustion coal gangue aggregate should be considered when calculating the water consumption.

3.3. The Mix Proportion of Fine Stone Concrete

In the formula: is the strength of concrete preparation (MPa); is the standard value of concrete cube compressive strength (MPa); is the standard deviation of concrete strength (MPa).

According to the procedure [

16] take σ=4.0, calculated:

=26.58MPa

In the formula:

is the water-binder ratio of concrete;

,

is the regression coefficient, according to the procedures [

19] look-up table:

;

is the compressive strength (MPa) of 28 d mortar of cementitious material.

In the formula:

and

are the influence coefficient of fly ash and the influence coefficient of granulated blast furnace slag powder, taking [

20]

;

is the 28 d compressive strength of cement mortar (MPa).

In the formula: is the surplus coefficient of cement strength grade value, look up the table to take ; is the strength grade of cement (MPa).

According to the formula (4), is calculated, is brought into the formula (3) to calculate , and is brought into the formula (2) to calculate the water-binder ratio of fine stone concrete . According to the limit of the maximum water-binder ratio in the “Code for Design of Concrete Structures”, take 0.60.

3. Water consumption

According to the production requirements of spontaneous combustion coal gangue exterior wallboard, the slump of spontaneous combustion coal gangue fine stone concrete is selected as 35~50mm.Combined with the water absorption rate of spontaneous combustion coal gangue aggregate, according to the regulation of water consumption of plastic concrete in the regulation [

19],

; when the fine stone concrete is prepared, the naphthalene superplasticizer is added, and the water reduction effect is 15%. Finally, the water consumption is determined to be

.

4. The amount of cement

The amount of cementitious material in fine stone concrete:

Bring and into Formula (5) to get , which meets the requirement of minimum cementitious material dosage. When the content of fly ash is 10%, the cement content of fine stone concrete is .

5. Sand rate

The slump of fine stone concrete is 35~50mm.According to the water-binder ratio of , the maximum nominal particle size of coarse aggregate, and the fine aggregate belongs to artificial sand, the sand rate is .

6. Aggregate dosage

The mass method is used to determine the amount of aggregate, which is calculated according to the following formula:

In the formula: , is the amount of mineral admixtures and cement per cubic meter of fine aggregate concrete (); , is the amount of coarse aggregate and fine aggregate per cubic meter of fine aggregate concrete (); is the water consumption per cubic meter of fine stone concrete (); is sand ratio (%); is the assumed mass () of fine aggregate concrete mixture per cubic meter.

Taking , taking the values of , , into formula (6), the total amount of aggregate in fine stone concrete per cubic meter can be obtained as 1851.33; according to Formula (7), , .

According to the mix ratio calculated by the above theory, the mixing test of spontaneous combustion coal gangue fine stone concrete is carried out. According to the workability and slump of the mixture, the mix ratio used to make the outer wall panel is determined. See

Table 7 below.

3.4. The Performance of Fine Stone Concrete

According to the mix ratio of

Table 7, the STWJ-60 concrete horizontal mixer is used in the laboratory to mix the spontaneous combustion coal gangue fine stone concrete in batches, and after the test, the plate vibration table is used to vibrate and compact. After 24 hours of indoor standing, the test block was disassembled, and the number and standard maintenance were randomly carried out. 48 test blocks of 150×150×150mm, 24 test blocks of 150×150×300mm, 27 test blocks of 100×100×400mm and 21 test blocks of 100×100×100mm were made, which were used for the test of compressive strength and splitting tensile strength, axial compressive strength and elastic modulus, flexural strength and freeze-thaw cycle, carbonation test. In three of the 100×100×400 mm test blocks, the temperature measuring rods were embedded in advance for the temperature measurement in the subsequent freeze-thaw test.

3.4.1. Mechanical Property

The mechanical properties of spontaneous combustion coal gangue fine stone concrete were tested by WAW-1000kN testing machine with loading rate of 7kN/s.

1. Compressive strength

When the test block is cured to 3d,7d, 14d and 28d, three150×150×150mm test blocks are taken respectively, and the measured compressive strength is shown in

Table 8.

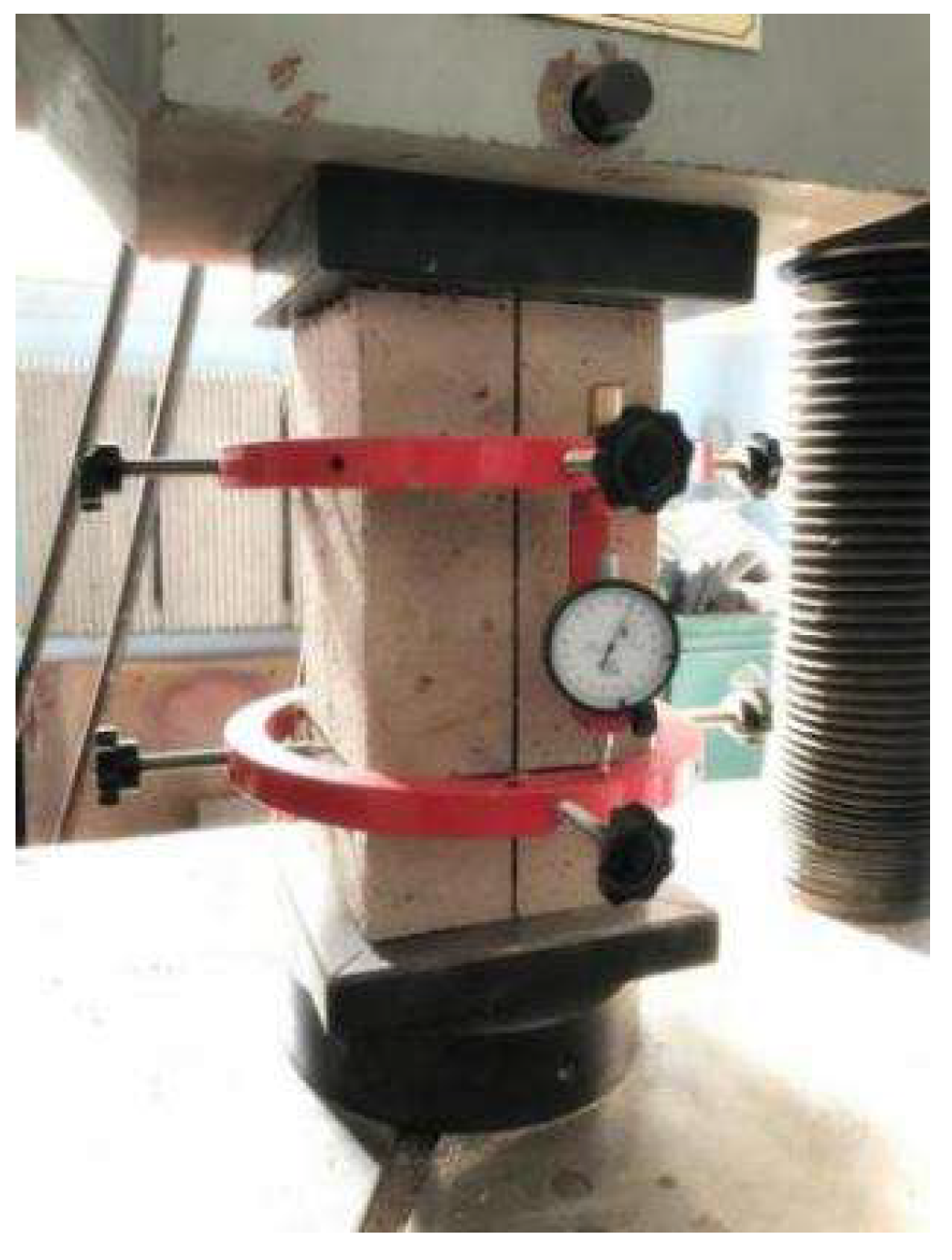

2. Axial compressive strength and elastic modulus

Six 150×150×300mm test blocks were taken after the curing age of the test blocks reached 28 days. Three of them were used to test the axial compressive strength and the other three were used to test the elastic modulus of static compression.The test process is shown in

Figure 3 and

Figure 4. In the test, the lower part adopts the ball hinge + steel plate to support the test block. Before loading, the upper loading steel plate of the test machine is adjusted to 5-10 mm on the top surface of the test block to ensure that the test block is centered and the test is started.

The measured values of the axial compressive strength of the test block are 17.2 MPa, 18.5 MPa, 18.3 MPa, and the average value is 18.0 MPa.

The midline is marked on the side of the elastic modulus test block and the deformation measuring device is installed symmetrically. The elastic modulus was tested by using the results of axial compressive strength test. According to the strength of the test block, take

, and take

as the corresponding pressure value when the test block reaches 1/3 of its axial compressive strength. The deformation values of each measuring point were completed within 30 s after loading

,

at a constant speed for 60 s. When the pressure is increased to, the deformation increment difference of each measuring point is less than or equal to 20 %, the test is effective, otherwise the retest is adjusted. When the test is effective, the pressure is uniformly unloaded to

,

, and then completely unloaded, each holding for 60 s. After two cycles, it was officially loaded to

,

.After holding the load, the deformation values of each measuring point were recorded, the deformation measuring device was removed, and the specimen was pressurized at a constant speed until it was destroyed and the maximum pressure was recorded.

In the formula: is the elastic modulus of concrete (MPa); A is the cross-sectional area (mm) of the concrete test block; is the initial pressure (N) of the concrete test block; is the corresponding pressure (N) when the compressive strength of concrete reaches 1/3 of the axial compressive strength.; L is the distance between the deformation measuring points of the test block (mm); is the average value (mm) of the deformation increment of the three test blocks when the pressure reaches .

According to the measured results of three test blocks and formula (8), is calculated.

3. Splitting tensile strength

After the curing age of the test block reaches 28 days, three 150×150×150mm test blocks are taken to carry out the splitting tensile strength test. The test loading is shown in

Figure 5. According to the measured data, the splitting tensile strength of the three test blocks is calculated to be 1.84MPa, respectively. 1.66MPa,1.78MPa, with an average of 1.76MPa.

4. Flexural strength

After the curing age of the test block reached 28 days, three 100×100×400mm test blocks were taken for flexural strength test. The test loading is shown in

Figure 6. According to the measured data, the flexural strength of the three test blocks was calculated to be 3.7MPa,4.1MPa and 3.7MPa, respectively, with an average of 3.8MPa.

The compressive strength, elastic modulus, splitting tensile strength and flexural strength of spontaneous combustion coal gangue concrete are lower than those of ordinary concrete. The main reason is that the compressive strength of spontaneous combustion coal gangue as aggregate is lower than that of gravel or pebble. The section of the test block mainly occurs in the coarse aggregate itself rather than the combination of aggregate and cementitious material. The elastic modulus of concrete will also be low, but as a material for exterior wall panels, it can meet its mechanical performance requirements.

3.4.2. Freeze-Thaw Test

After the curing age of the test block reaches 28 days, three 100×100×400mm test blocks are taken from the curing pool as a group, a total of three groups. The surface moisture of the test block was wiped, and the weight was recorded as

, and the dynamic elastic modulus of the test block was measured by the dynamic elastic modulus DT-20 tester as

; after the freeze-thaw cycle, the surface moisture of the test block was wiped, the weight of the test block was weighed and recorded as

, and the dynamic elastic modulus of the test block was recorded as

. The freeze-thaw cycle test adopts the fast freeze-thaw test method in the “long-term performance and durability of ordinary concrete “, and uses the SRTDR-16 concrete fast freeze-thaw test machine of Beijing Shourui Company. The maximum temperature is set to +5°C, the minimum temperature is-18°C, and the cycle time is 3h. When the mass loss of the test block is more than 5% or the loss of its dynamic elastic modulus is more than 40%, the test is terminated. The test process is shown in

Figure 7a and

Figure 7b, and the test results are shown in

Table 9.

After 25 freeze-thaw cycles, the average dynamic elastic modulus loss rate of the test block did not reach or exceed 40 %, but the average mass loss rate was 7%>5%, and the freeze-thaw test was terminated. In order to explore the influence of freeze-thaw cycles on the dynamic elastic modulus of spontaneous combustion coal gangue concrete, the effects of increasing 3 and 4 cycles are shown in

Table 9. As a building in the northern region, the outer wall with frost resistance grade of F25 cannot have the same life as the main body of the structure. Because there are many voids in the spontaneous combustion coal gangue aggregate, it will reduce the frost resistance of the concrete. In practical application, the hydrophobic agent can be sprayed on the surface of the spontaneous combustion coal gangue plate to improve its frost resistance.

3.4.3. Carbonization Test

After the test block was cured for 28 days, twelve 100×100×100mm test blocks were taken and dried in an oven at 60°C for 48 hours. After drying, only one surface of the test block is exposed and the remaining is sealed with melted paraffin. The carbonation test of 3d, 7d, 14d and 28d is carried out by carbonization box. The average measured carbonation depth is 20.0mm, 23.0mm, 28.5mm and 32.5mm respectively. Compared with ordinary concrete, the carbonation depth of spontaneous combustion coal gangue concrete is larger, which will affect the durability of spontaneous combustion coal gangue wallboard in the whole life cycle of buildings. Spraying hydrophobic agent on the surface of spontaneous combustion coal gangue board can prevent the carbonization of spontaneous combustion coal gangue concrete from expanding internally and improve its frost resistance.

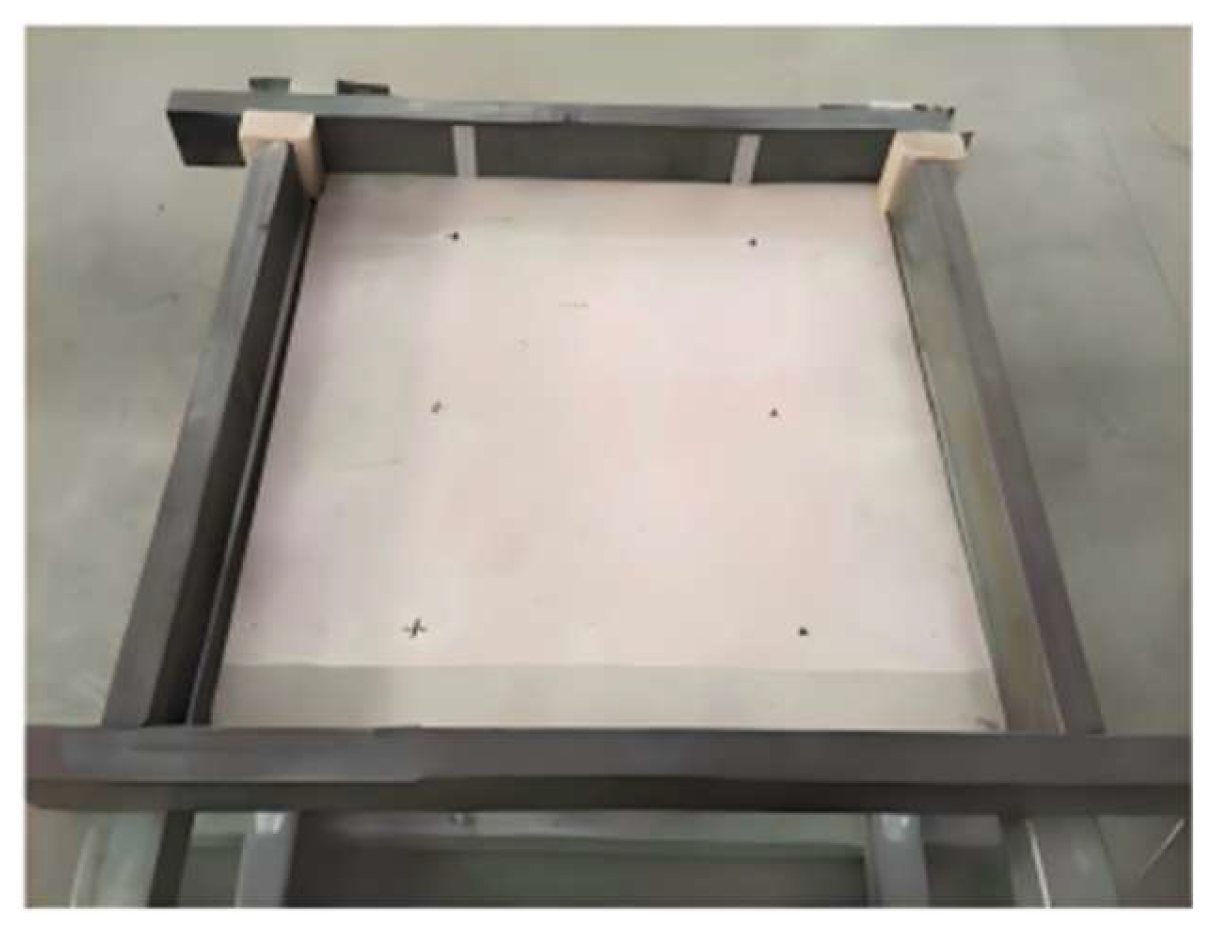

4. Spontaneous Combustion Coal Gangue Board

Using the spontaneous combustion coal gangue fine stone concrete with the above workability, fluidity, strength, frost resistance and carbonation resistance to design and manufacture the panel of composite exterior wall-thickness of 20 mm, short side length ≤1200 mm, long side size≤1500 mm. When the long side size of the spontaneous combustion coal gangue board is greater than 1500 mm, in order to reduce the shrinkage stress and cracks of the concrete, it can be disconnected near the midpoint of the long side and set the keel here. Considering the mass production in practical application, the spontaneous combustion coal gangue board specimens are manufactured and maintained in the factory. Concrete mixing using JS500 forced mixer, see

Figure 8, strict measurement and control of spontaneous combustion of coal gangue concrete raw material consumption.

4.1. Design and Maintenance

1. Reinforcement

In order to improve the integrity and bending resistance of 20 mm thick spontaneous combustion coal gangue plate, a cold drawn steel wire mesh with a grade of CDW

550 is configured at a distance of 10 mm from the surface of the plate. The two-way spacing is 65 mm, and the steel wire intersection is welded by resistance welding. The thickness of the protective layer is controlled by a special pad, as shown in

Figure 9. The plate is equipped with two-way steel wire mesh. When the load on the outer wall is

, the bearing capacity of the spontaneous combustion coal gangue plate meets the requirements, and the deformation is less than 1/250 of its short side length.

2. Anti-cracking measures

In order to prevent dry shrinkage cracks during non-standard maintenance, a 75g / m2, 5m×5m crack-resistant glass fiber mesh cloth is laid on the surface of the plate, and it is wrapped in the cementitious material after being compacted and polished.

3. Panel fixed

The spontaneous combustion coal gangue board is a concrete product. In order to fix it on the keel-galvanized rectangular steel pipe of the composite exterior wall board, a 1.0 mm thick galvanized steel plate is welded on the steel wire mesh before pouring and extends 100 mm out of the board surface, which is used for the connection fixation of the spontaneous combustion coal gangue board and the keel-core-pulling rivet or welding.

4. Maintenance

The specimens of spontaneous combustion coal gangue board are made in summer. Combined with the age strength measured in the laboratory, the plastic film is covered immediately after the spontaneous combustion coal gangue concrete is poured, compacted and polished. After 12 hours, the water is sprinkled once a day, and the mold is removed after 3 days.

4.2. Performance Test

1. Surcharge test

The size of the panel for stacking is 900mm×900mm×20mm, and the opposite side is fixed. Using the 100mm×32mm×1mm galvanized steel plate connector embedded in the panel, three 4×6 core-pulling rivets are fixed to the test bracket, as shown in

Figure 10 and

Figure 11. Weighing sandbags and weights are used for step-by-step loading [

18], as shown in

Figure 12 and

Figure 13.

Surcharge to 300kg (out-of-plane), 150kg (in-plane) When the load is held for 5 min, the panel is not cracked and the deflection is less than 1/250 of the short side length of the panel. After removing the heaped load, the galvanized steel plate fixed on the panel has a relative displacement of 1mm, and the core-pulling rivet has not changed. Through the stacking test, it can be determined that the bearing capacity and deformation of the panel meet the requirements, and the anchorage of the galvanized steel plate connector and the connection between the panel and the keel are reliable and effective.

2. Impact test

According to the requirements of “building wallboard test method” [

21]. A 500 mm×400mm×20mm panel specimen was cut. The standard sand with a thickness of 100 mm is paved in the range of 700mm×700mm on the test bench, and the panel specimens are placed on the sand cushion and fully contacted. The steel ball with a mass of 500 g falls freely at a height of 1.4 m from the center of the upper surface of the specimen, and each specimen is repeated three times. At the end of the test, there were visible dents in the impact position, no cracks in the impact point and its corresponding reverse. In order to further explore the impact resistance of the panel, the mass of the steel ball was increased to 1000g.After three times of impact from the same height, the dent at the impact point was aggravated, but no crack was found. The test results show that the impact resistance of the panel is good, and it is not necessary to increase the anti-collision measures when it is used for the outer wall panel of general buildings.

3. Impermeability test

Three square specimens of 250mm×250mm were cut from the spontaneous combustion coal gangue board [

18], and a PVC pipe with a length of 300mm and

was bonded with AB structural adhesive in the center, as shown in

Figure 14. Injecting 250mm high water into the PVC pipe, the liquid level did not drop after standing for 2h. After standing horizontally for 24h, 48h and 72h, there were no water marks or water droplets on the opposite side of the specimen, as shown in

Figure 15.

The test results show that the impermeability of spontaneous combustion coal gangue board meet the requirements.

4. Hanging test

As the outer wall panel of the building, there are often installation or fixed air conditioning units, electronic display screens, solar panels and other use requirements outdoors. There are often installation or fixed air-conditioning hanging machine, TV or display, water heater, range hood and other use requirements in the room. At this time, the outer wall panel should be able to provide sufficient hanging force. The force of the installation or fixed point is usually subjected to shear force or tension, and the shear and tensile tests of the hanging point are carried out respectively.

For 20 mm thick panel, M6 plastic expansion plug and M4 self-tapping screw are used to fix shear or tensile connectors. The experiments of 1, 2 and 3 fastener fixed connectors were carried out respectively, with 3 test points for each connection.

In the shear test, see

Figure 16, when the relative displacement of the connector is 2mm, it is considered to reach the normal use limit state of the connection. The average shear bearing capacity of the three test points is 366.7kN, 583.3kN and 1016.7kN respectively when one, two and three fasteners are fixed. At this time, although the connectors have relative displacement, they are all loose. The removal of the self-tapping screw does not see its plastic deformation, and the plastic expansion plug hole is complete.

In the tensile test, see

Figure 17, when the connector pulls out the plastic expansion plug, it is considered to reach the bearing capacity limit state of the connection. The average tensile ultimate bearing capacity of the three test points is 466.7kN, 1000.0kN and 1866.7kN respectively when one, two and three fasteners are fixed. At this time, the connector is separated from the panel, and the panel corresponds to a complete hole.

Through the shear and tensile test of the hanging point, different hanging bearing capacity schemes can be provided to meet the actual needs. The test results show that the layout of grid cloth on the two surfaces of the panel has a significant effect on the improvement of local pressure and local punching shear performance at the hanging place.

5. Application of Spontaneous Combustion Coal Gangue Composite Exterior Wallboard

The external wall area of a building is usually several times the building area. In order to facilitate the production and installation, a large area of the wall needs to be divided into small units. As the external wall of the building, in addition to the above performance, it should also have good thermal insulation, heat insulation and sound insulation performance. Therefore, 20mm thick spontaneous combustion coal gangue board composite rock wool is used to improve its related performance for building exterior walls.

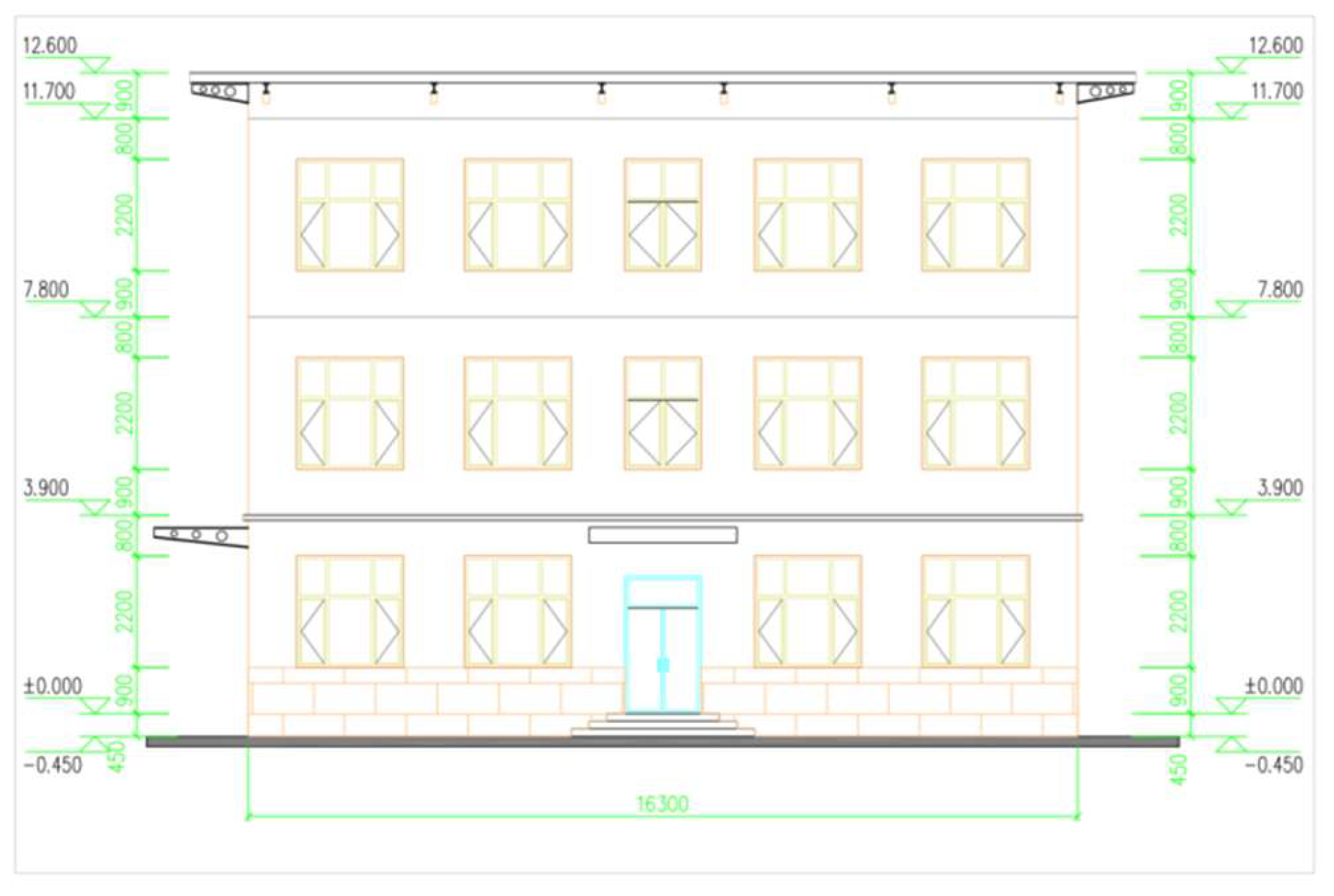

5.1. Segmentation of Building Exterior Wall

The exterior wall of the building has doors and windows due to the requirements of lighting, ventilation and traffic organization. During the construction of the exterior wall, holes will be reserved for this purpose, as shown in

Figure 18 and

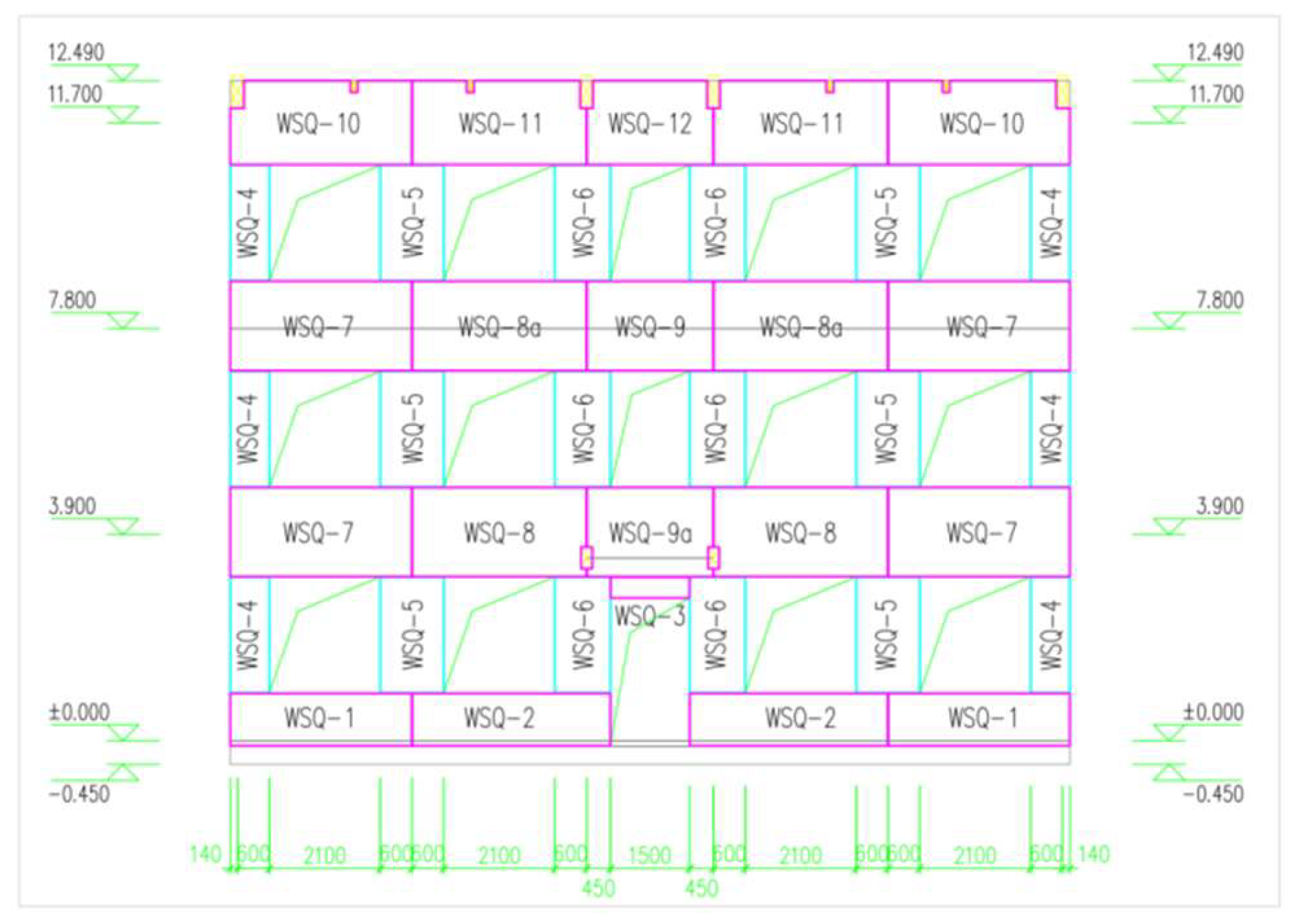

Figure 19. Taking the gable of a demonstration project office building in Datong City, Shanxi Province as an example, the wall segmentation is shown in the figure.

The wall surface segmentation is to divide the larger wall surface into units suitable for construction considering factors such as structural deformation, force transmission path, processing and installation. The wall segmentation shown in

Figure 19 is based on the building elevation map, bounded by the upper and lower sides of the window hole, adjacent wall frame columns or frame columns, as a wall panel unit, such as WSQ-1, 2, 7, 8, etc.; the unit is usually a regular rectangle, which can directly transmit force to the wall frame column or frame column, and the force transmission is direct and reliable.After the split, the wall between the windows will naturally become an independent unit, supported by the first split unit; the unit is located near the high point of the layer, and the reasonable fixation method can better adapt to the structural water. The characteristics of large flat deformation.According to the above method, there are 12 kinds and 41 wallboard units after the gable wall is divided.

5.2. Spontaneous Combustion Coal Gangue Composite Board

Through the above segmentation method, all the exterior walls can be divided into wallboard units. Using 20mm thick spontaneous combustion coal gangue board composite rock wool to make prefabricated coal gangue exterior wall panels that meet the requirements of building energy conservation and sound insulation.

A demonstration project in Datong City, Shanxi Province is located in the northern cold region. The building function is community office and activity center. According to the “Design Standard for Energy Efficiency of Public Buildings” [

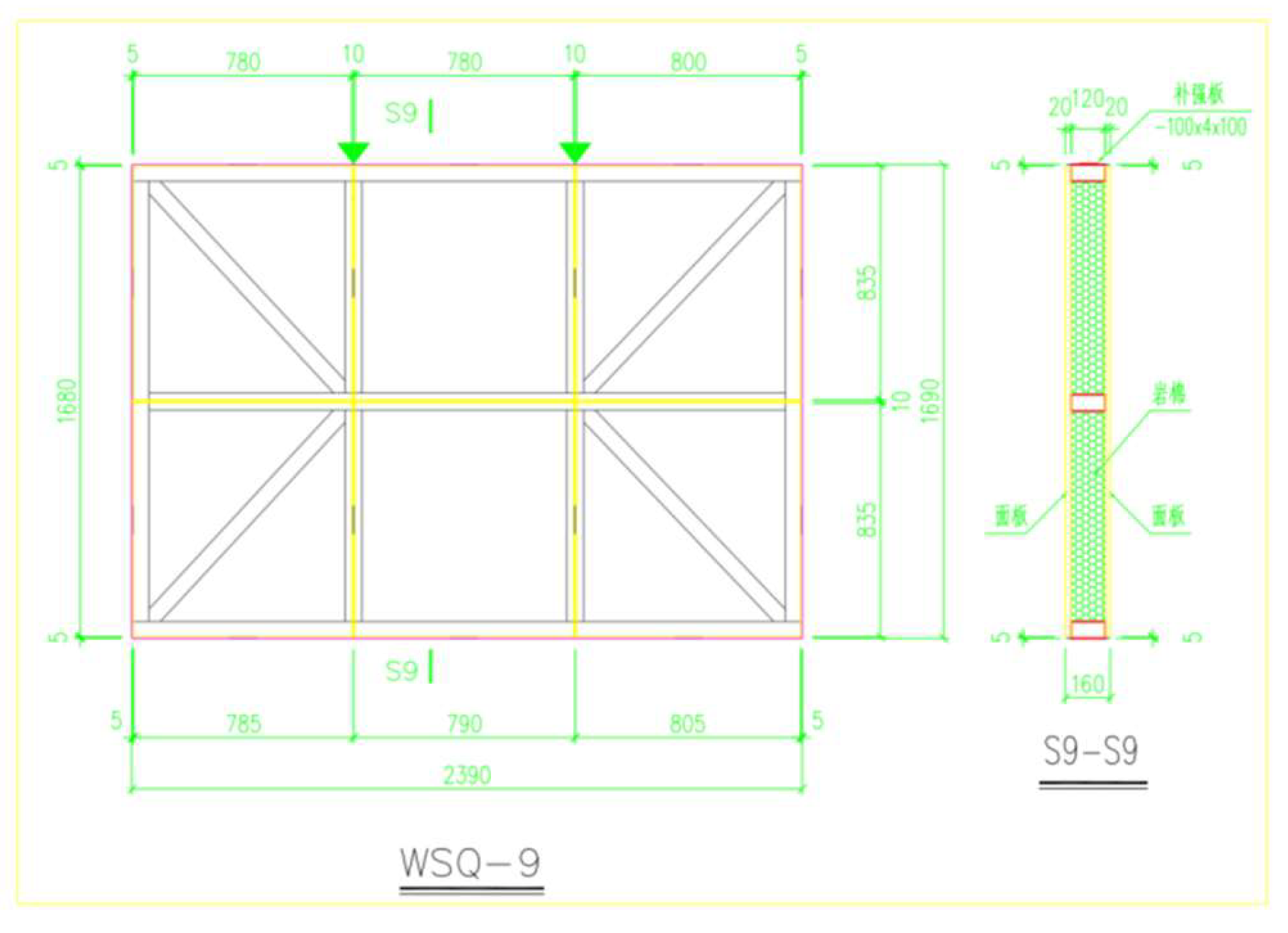

22], when 30 mm thick B1 flame retardant extruded polystyrene board and 120 mm thick rock wool are used, the external wall can meet the energy saving requirements of public buildings in cold C area. On both sides of each 20mm thick spontaneous combustion coal gangue board, 120 mm thick rock wool in the middle; the

galvanized rectangular tube was selected for the keel, and the spontaneous combustion coal gangue plate composite plate was prefabricated in the factory. After the installation of the composite board of the spontaneous combustion coal gangue board is completed, the 30 mm thick polystyrene board and the real stone paint wall surface are constructed on site. The sound insulation of the wallboard meets the requirements of public buildings. Taking WSQ-9 as an example, the wallboard composite method is shown in

Figure 20.

As shown in the diagram, in order to ensure the safe and orderly construction process, lifting points are set up in each wall panel unit.

5.3. On-Site Installation

Before installing the general wall panel unit on site, the fixed connector T 120×120×6×6 at the lower elevation of the wall panel unit is welded at the corresponding position of the wall frame column or the frame column, and the connector is made of Q235-B steel. After lifting the wall panel unit in place and adjusting the position correctly, the fixed connector at the elevation of the wall panel unit is welded. After the installation of the general wall panel unit is completed, the installation of the window wall panel unit is carried out. The keel of the window wall panel unit is welded and fixed with the keel of the general wall panel unit by using a 100mm long,

connector. At this time, only the weld at the tip of the angle steel is welded to adapt to the horizontal deformation of the structure. The on-site installation process of the external wall of the demonstration project office building is shown in

Figure 21, and the photos after the completion of the office building are shown in

Figure 22.

6. Conclusions

Through the experimental research and practice of spontaneous combustion coal gangue, spontaneous combustion coal gangue concrete, spontaneous combustion coal gangue board and spontaneous combustion coal gangue composite board, the main conclusions are as follows:

1. Spontaneous combustion coal gangue was selected as aggregate, and 26.58 MPa was used to prepare strength. Fine stone concrete meeting the performance requirements of workability and slump was obtained, and the relevant mechanical properties were measured.

2. Using spontaneous combustion coal gangue concrete, a 20mm thick spontaneous combustion coal gangue plate with a surface load of was designed. The test verified that its bearing capacity, deformation, connection structure, impermeability and impact resistance meet the requirements.

3. The shear and tensile bearing capacity of the hanging point under different fastener connections are obtained, which can provide a basis for practical engineering applications.

4. Through the combination of spontaneous combustion coal gangue board and rock wool, the spontaneous combustion coal gangue composite wallboard which meets the requirements of building energy saving and sound insulation is made and applied in the demonstration project.

The research results provide a new way for the resource utilization of coal gangue in prefabricated buildings.

Author Contributions

Conceptualization, Y.Y.; methodology, Y.Y. and P.W.; validation, J.Y. and P.W.; formal analysis, L.Y. and Q.Z.; investigation, J.Y. and Q.Z.; resources, J.W.; data curation, L.Y. and Q.Z.; writing—original draft preparation, J.Y. and J.W.; writing—review and editing, Y.Y., P.W, and J.Y.; visualization, Y.Y. and L.Y.; supervision, Y.Y. and P.W; funding acquisition, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (No. 51208332) and Scientific research project of Ministry of Construction (No. 01-2-079).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Yajie Yan was employed by Shanxi University of Electronic Science and Technology and Taiyuan University of Technology, he is one of participants the funded projects. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict.

References

- Zhu, L.; Gu, W.Z.; He, Z.W.; Liu, C.Y.; Zhao, M.Y. Current situation of comprehensive utilization of coal gangue and exploration of ways of high-value utilization: A case study of china national coal group corporation. Coal Science and Technology 2025, 53, 104–124. [Google Scholar]

- Liu, X.P; Wu, S.W; Zhang, C. Activation of Se-enriched coal gangue and the efficient use of coal gangue Se fertilizer. Journal of Plant Nutrition and Fertilizers 2020, 26, 1526–1535. [Google Scholar]

- Wang, A.G.; Liu, P.; Sun, D.S.; Liu, K.W.; Fang, L.A. Research progress in activity evaluation methods of calcined coal gangue powder materials. Materials Reports 2018, 32, 1903–1909. [Google Scholar]

- Zhang, J.J; Song, H.P; Feng, Z.J.; Munkhbat, B.; Jin, D.P.; Wei, J.J. Study on the effect of coal gangue particle size and ratio on desertified soil improvement. Journal of Environmental Engineering Technology 2025, 15, 780–787. [Google Scholar]

- Yang, Y., Hu; Zhang, X.Y.; Gao, T.; Wang, S.J. Experimental study on compressive properties of modified raw soil mixed with coal gangue powder and mineral powder. Building structure 2022, 52, 2202–2206. [Google Scholar] [CrossRef]

- Liu, H. Study on aerated concrete block preparation used with fly ash and coal gangue of fuxin. Bulletin of the Chinese Ceramic Society 2013, 32, 1932–1935. [Google Scholar] [CrossRef]

- Yi, Q.; Gu, J.; Chen, W.J.; Xiang, H.; Guo, Z.H. Effect of coal gangue fine aggregate modification treatment on mortar performance. Bulletin of the Chinese Ceramic Society 2025, 44, 2193–2200. [Google Scholar] [CrossRef]

- Mao, M.J.; Huang, B.; Chen, H.X.; Zhang, D.S. Research on damage of unburned coal gangue coarse aggregate concrete after high temperature. Building structure 2022, 52, 1566–1570. [Google Scholar] [CrossRef]

- Sun, Z.H.; Wang, Y.B.; Ma, S.X.; Li, M. Energy storage modification of coal gangue and its application inhigh-specific-energy batteries. Coal Science and Technology 2025, 53, 318–326. [Google Scholar]

- Zhu, L.; Gu, W.Z.; He, Z.W.; Liu, C.Y.; Zhao, M.Y. Current situation of comprehensive utilization of coal gangue and exploration of ways of high-value utilization: A case study of china coal [J/OL]. Coal Science and Technology, 1–20 [2025-08-10]. https://link.cnki.net/urlid/11.2402.TD.20250424.1434.002.

- Zhao, L.Y.; Zhai, H.B.; Zhang, J.W.; Yan, K.Z.; Yang, F.L. Mineral occurrence and acid leaching characteristic of aluminum forcoal gangue in shanxi province. Coal Science and Technology 2025, 53, 434–444. [Google Scholar]

- Li, G.M.; Su, N.J.; Zhu, B.S.; Liang, L.P.; Tian, Y.M. Fe3O4 and Fe loaded composites as microwave absorbents by recycling of gangue. Bulletin of the Chinese Ceramic Society 2021, 40, 2998–3004. [Google Scholar] [CrossRef]

- Wu, X.G.; Tao, X.K.; Yu, S.Y.; Li, S.S.; Zhang, R.H. Research progress on the application of high-performance composite sandwich exterior wall panels. Building structure 2020, 50, 611–616. [Google Scholar] [CrossRef]

- Zhang, J.H.; Meng, F.H.; Wang, L.N.; Dai, L.F.; Yao, L.F. Preparation and properties of coal gangue-based foamed ceramics. Bulletin of the Chinese Ceramic Society 2023, 42, 960–969. [Google Scholar] [CrossRef]

- GB 6566-2010 “Limits of Radionuclides in Building Materials” [S]. Beijing: China Standards Press, 2010.

- GB 8624-2012 “Classification for Burning Behavior of Building Materials and Products” [S]. Beijing: China Standards Press, 2012.

- GB/T 14685-2022 “Pebble and Crushed Stone for Construction” [S]. Beijing: China Standards Press, 2022.

- GB 50016-2014 “Code for Fire Protection Design of Buildings” [S]. Beijing: China Planning Press, 2014.

- JGJ 55-2011 “Specification for Mix Proportion Design of Ordinary Concrete” [S]. Beijing: China Architecture & Building Press, 2011.

- GB/T 50010-2010 “Standard for Design of Concrete Structures” [S]. Beijing: China Architecture & Building Press, 2010.

- GB/T 30100-2013 “Test Methods for Building Panels” [S]. Beijing: China Standards Press, 2013.

- GB/T 30100-2013 “Test Methods for Building Panels” [S]. Beijing: China Standards Press, 2013.

Figure 1.

Coarse aggregate.

Figure 1.

Coarse aggregate.

Figure 2.

Fine aggregate.

Figure 2.

Fine aggregate.

Figure 3.

Axial compressive strength test.

Figure 3.

Axial compressive strength test.

Figure 4.

Elastic modulus measurement.

Figure 4.

Elastic modulus measurement.

Figure 5.

Splitting tensile strength test.

Figure 5.

Splitting tensile strength test.

Figure 6.

Flexural strength test.

Figure 6.

Flexural strength test.

Figure 7.

Freeze-thaw test. (a)Temperature control equipment for freeze-thaw test; (b)Environmental chamber of freeze-thaw test.

Figure 7.

Freeze-thaw test. (a)Temperature control equipment for freeze-thaw test; (b)Environmental chamber of freeze-thaw test.

Figure 8.

Factory JS500 mixer.

Figure 8.

Factory JS500 mixer.

Figure 9.

Mould for pouring.

Figure 9.

Mould for pouring.

Figure 10.

Fixation of panel.

Figure 10.

Fixation of panel.

Figure 11.

Blind riveted connection.

Figure 11.

Blind riveted connection.

Figure 12.

Surcharge test of panel(out-of-plane).

Figure 12.

Surcharge test of panel(out-of-plane).

Figure 13.

Surcharge test of (in-plane).

Figure 13.

Surcharge test of (in-plane).

Figure 14.

Impermeability test of panel.

Figure 14.

Impermeability test of panel.

Figure 15.

The reverse side of specimen.

Figure 15.

The reverse side of specimen.

Figure 16.

Shear test of hanging point.

Figure 16.

Shear test of hanging point.

Figure 17.

Tensile test of hanging point.

Figure 17.

Tensile test of hanging point.

Figure 18.

The wall of an office building.

Figure 18.

The wall of an office building.

Figure 19.

Wall partition of an office building.

Figure 19.

Wall partition of an office building.

Figure 20.

Spontaneous combustion coal gangue board composite board.

Figure 20.

Spontaneous combustion coal gangue board composite board.

Figure 21.

Installation of outer wall panel.

Figure 21.

Installation of outer wall panel.

Figure 22.

An office building after completion.

Figure 22.

An office building after completion.

Table 1.

The measured radioactivity value of spontaneous combustion coal gangue.

Table 1.

The measured radioactivity value of spontaneous combustion coal gangue.

Detection

Project

|

Radioactivity Specific Activity (Bq/kg) |

Internal Exposure |

External Exposure |

standard |

| Ra-226 |

Th-232 |

K-40 |

| index |

94.23 |

71.56 |

509.74 |

0.45 |

0.61 |

Ir<1.0 |

Table 2.

Main components of spontaneous combustion coal gangue.

Table 2.

Main components of spontaneous combustion coal gangue.

| Essential Component |

Al2O3

|

SiO2

|

CaO |

Fe2O3

|

MgO |

K2O |

| Content(%) |

14.8 |

54.1 |

14.2 |

12.4 |

2.4 |

1.1 |

Table 3.

Particle gradation of coarse aggregate.

Table 3.

Particle gradation of coarse aggregate.

Square hole sieve size

(mm) |

Screen oversize

(kg) |

Retained

(%) |

Cumulative retained

(%) |

| 16.0 |

0 |

/ |

/ |

| 9.5 |

0.05 |

2.8 |

2.8 |

| 4.75 |

1.03 |

54.3 |

57.1 |

| 2.36 |

0.79 |

38.7 |

95.8 |

Table 4.

Particle gradation of fine aggregate.

Table 4.

Particle gradation of fine aggregate.

| Square hole sieve size |

Screen oversize

(g) |

Retained

(%) |

Cumulative retained(%) |

Standard(%) |

| 4.75mm |

0 |

0 |

0 |

10~0 |

| 2.36mm |

23 |

4.6 |

4.6 |

25~0 |

| 1.18mm |

123 |

24.6 |

29.2 |

50~10 |

| 600μm |

120 |

24 |

53.2 |

70~41 |

| 300μm |

12 |

18.4 |

71.6 |

92~70 |

| 150μm |

52 |

10.4 |

82 |

94~80 |

Table 5.

Physical properties of coarse aggregate.

Table 5.

Physical properties of coarse aggregate.

Physics

Indicators |

grain size(mm) |

Molded cylinder compressive strength

(MPa) |

Apparent Density(kg·m-3) |

Bulk Density(kg·m-3) |

Water Absorption(%) |

Coarse

Aggregate |

5~10 |

2.5 |

2440 |

1132 |

9.6 |

Table 6.

Physical performance index of spontaneous combustion coal gangue fine aggregate.

Table 6.

Physical performance index of spontaneous combustion coal gangue fine aggregate.

Physics

Indicators |

Apparent Density(kg·m-3) |

Aggregate Size(mm) |

Bulk Density(kg·m-3) |

Fineness Modulus |

Type |

Fine

Aggregate |

2441 |

<3mm |

1209 |

2.41 |

medium sand |

Table 7.

Mix proportion of spontaneous combustion coal gangue fine stone concrete (kg).

Table 7.

Mix proportion of spontaneous combustion coal gangue fine stone concrete (kg).

| Cement |

Fine Aggregate |

Coarse Aggregate |

Fly Ash |

Water

Reducing

Admixture |

Water |

Short Fiber |

| 280 |

326 |

1525 |

31 |

4.5 |

338 |

2.0 |

Table 8.

Strength of spontaneous combustion coal gangue fine stone concrete at different ages.

Table 8.

Strength of spontaneous combustion coal gangue fine stone concrete at different ages.

| Age(d) |

3 |

7 |

14 |

28 |

Compressive strength

Measured value(MPa) |

1 |

7.0 |

13.7 |

16.9 |

21.7 |

| 2 |

6.6 |

13.4 |

16.8 |

20.8 |

| 3 |

6.5 |

12.8 |

15.9 |

20.5 |

| Average Value |

6.7 |

13.3 |

16.5 |

21.0 |

Table 9.

Freeze-thaw cycle test results.

Table 9.

Freeze-thaw cycle test results.

Test Grou-

ping |

Number of Speci-

mens |

Before the freeze-thaw cycle |

Loop

Number of times |

After the freeze-thaw cycle |

Average mass loss rate(%) |

Average dynamic elastic modulus loss rate(%) |

Quality mean

(kg) |

Mean value of dynamic elastic modulus(GPa) |

Quality mean

(kg) |

Mean value of dynamic lastic modulus(GPa) |

| Ⅰ |

3 |

8.20 |

16.65 |

25 |

7.56 |

11.83 |

7 |

30 |

| Ⅱ |

3 |

8.28 |

17.40 |

28 |

7.56 |

10.85 |

8 |

37 |

| Ⅲ |

3 |

8.14 |

17.33 |

29 |

7.35 |

10.72 |

9 |

38 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).