Submitted:

14 August 2025

Posted:

14 August 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Identification and classification of new technological solutions and their roles in enabling Industry 4.0 and SM ecosystems.

- Evaluation of existing industrial IT frameworks based on flexibility, scalability, interoperability, and sustainability.

- Development of a new framework for industrial digitalization through the transformation of a variety of business processes such as design creation, manufacturing processes, warehouse operations, and maintenance management.

- Analysis and assessment of major challenges and future perspectives in digital transformation, with particular emphasis on enhancing adaptability, growth potential, seamless integration, and long-term viability in the context of Industry 4.0 and Industry 5.0 technologies.

2. Methodology

-

Scopus:((digitalization OR digitization OR "digital transformation") AND "industry" AND "smart manufacturing") AND (("Internet of Things" OR IoT) OR ("artificial intelligence" OR AI) OR (robotics OR automation) OR ("big data" OR "cloud computing")) AND PUBYEAR > 2019 AND PUBYEAR < 2026 AND (LIMIT-TO (OA, "all")) AND (LIMIT-TO (LANGUAGE, "English")) AND (LIMIT-TO (DOCTYPE, "ar") OR LIMIT-TO (DOCTYPE, "re"))This search returned n = 4,029 articles.

-

WoS:TS = (("digital transformation" OR digitalization OR digitization) AND "smart manufacturing" AND "industry" AND ("Internet of Things" OR IoT OR "Artificial Intelligence" OR AI OR robotics OR automation OR "big data" OR "cloud computing")) AND PY = (2020-2025) AND LA = (English) AND DT = (Article OR Review)An additional manual Open Access filter was applied, yielding n = 87 articles.

- 7 articles that did not meet full Open Access criteria (e.g., paid access or restricted institutional access);

- 7 articles with a primarily economic, managerial, or educational focus and insufficient discussion of technological aspects.

- 17 review articles providing consolidated insights and thematic syntheses;

- 44 original research articles presenting empirical findings or technological developments.

3. Related Work

3.1. State-of-the-Art in Industrial Transformation According to Review Articles

- Strategic alignment frameworks are seen in Serey et al. [18], who emphasize that digital transformation in industrial firms must align technological investments with business models, workforce reskilling, and integrated digital ecosystems, and Isoko et al. [21], who propose an operational roadmap for bioprocessing 4.0.

- Technical and architectural frameworks appear in Onaji et al. [13] and Wang & Jiao [25]. Onaji et al. present a layered DT architecture combining physical systems, data infrastructure, and decision-making analytics, while Wang & Jiao introduce a framework for merging smart in-process inspection with human–automation symbiosis, supporting real-time defect identification and adaptive task allocation. Performance evaluation framework is outlined by Kamble et al. [23], who validate a multi-dimensional SM Performance Measurement System (SMPMS) for SMEs, linking Industry 4.0 investments to outcomes such as flexibility, real-time analytics, and sustainability.

3.2. State-of-the-Art in Widely Used Technologies in Smart Manufacturing According to Research Articles

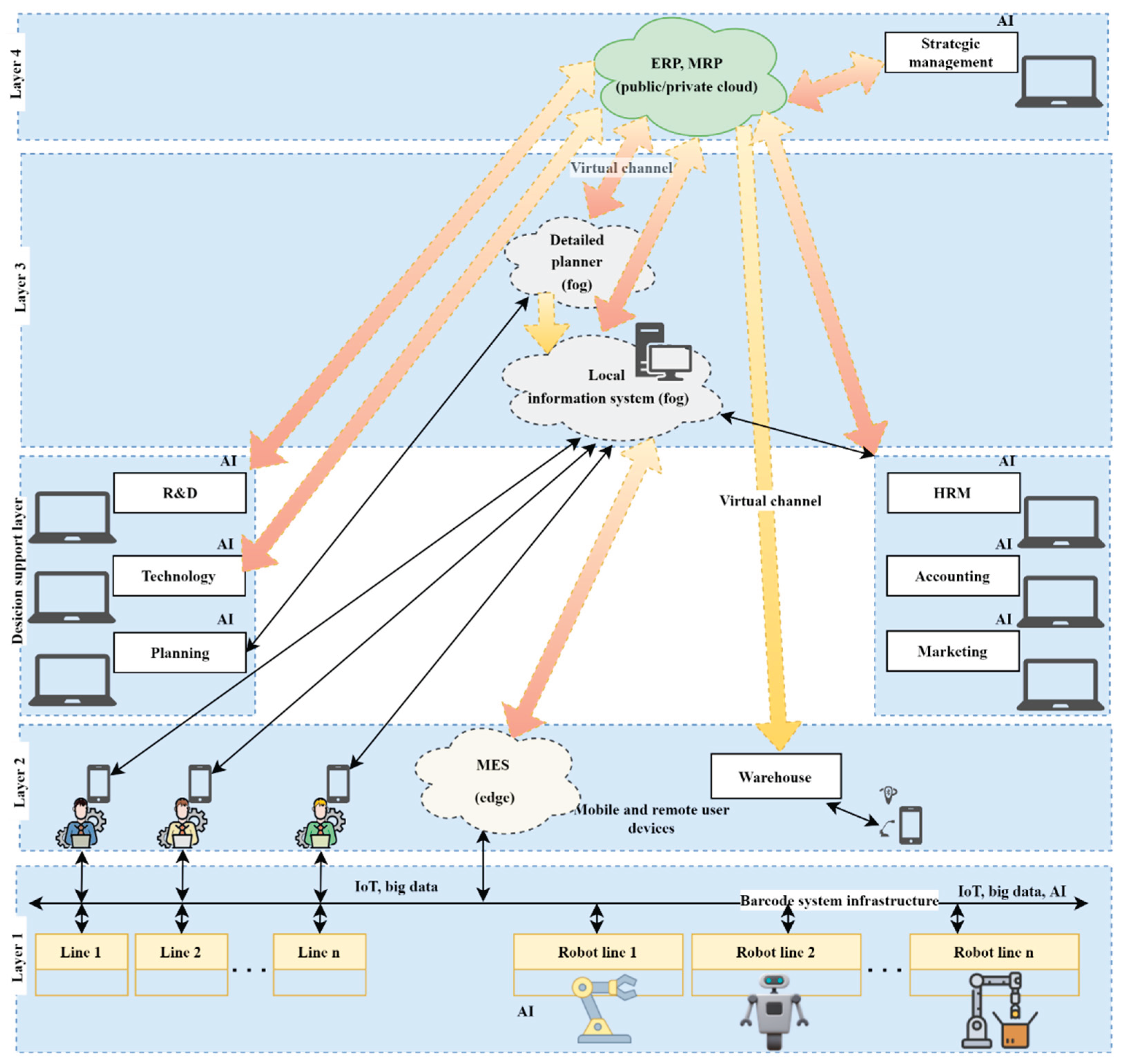

4. Conceptual Framework for Industrial Digitalization

4.1. Framework Design and Structure

4.2. Framework Verification

5. Discussion

6. Conclusions

- Revealing interdependencies among technologies, resources, and organizational capabilities across time and layers (shop-floor, MES/ERP, enterprise level).

- Enabling dynamic orchestration of IT, showing when and how to integrate automated systems, cloud computing and AI to reinforce one another rather than operate in isolation.

- Avoiding fragmented digitalisation, where isolated projects and siloed technology stacks cause inefficiencies and duplicate costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The Rise of Industry 4.0 in 5 Stats. Available online: https://iot-analytics.com/industry-4-0-in-5-stats/ (accessed on 31 July 2025).

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Madrid-Guijarro, A.; Maldonado-Guzmán, G.; Rodríguez-González, R. Unlocking resilience: The impact of Industry 4.0 technologies on manufacturing firms' response to the COVID-19 pandemic. Manag. Decis. 2025, 63, 126–154. [Google Scholar] [CrossRef]

- Federal Ministry for Economic Affairs and Energy. Industrie 4.0. Available online: https://www.bundeswirtschaftsministerium.de/Redaktion/EN/Dossier/industrie-40.html (accessed on 31 July 2025).

- People's Republic of China State Council. Made in China 2025 (English translation). Available online: http://english.www.gov.cn/policies/latest_releases/2015/05/19/content_281475110703534.htm (accessed on 31 July 2025).

- Zhou, K.; Liu, T.; Zhou, L. Industry 4. In 0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar] [CrossRef]

- Canavese, D.; Mannella, L.; Regano, L.; Basile, C. Security at the edge for resource-limited IoT devices. Sensors 2024, 24, 590. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzla, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Burzyńska, A.; Review of data-driven decision support systems and methodologies for the diagnosis of casting defects. Arch. Foundry Eng. 2024. Available online: https://journals.pan.pl/Content/133780/AFE%204_2024_17.pdf (accessed on 31 July 2025).

- Gargalo, C.L.; Malanca, A.A.; Aouichaoui, A.R.N.; Huusom, J.K.; Gernaey, K.V. Navigating industry 4.0 and 5.0: The role of hybrid modelling in (bio)chemical engineering’s digital transition. Front. Chem. Eng. 2024, 6, 1494244. [Google Scholar] [CrossRef]

- Ghosh, S.; Knoblauch, R.; El Mansori, M.; Corleto, C. Towards AI driven surface roughness evaluation in manufacturing: A prospective study. J. Intell. Manuf. 2024. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital twin in manufacturing: Conceptual framework and case studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, X.; Chen, Z. A survey of digital twin techniques in smart manufacturing and management of energy applications. Green Energy Intell. Transp. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Escobar, C.A.; McGovern, M.E.; Morales-Menendez, R. Quality 4.0: A review of big data challenges in manufacturing. J. Intell. Manuf. 2021, 32, 2319–2334. [Google Scholar] [CrossRef]

- Benslimane, T.; Benabbou, R.; Mouatassim, S.; Benhra, J. Understanding the relationship, trends, and integration challenges between lean manufacturing and industry 4.0: A literature review. Int. J. Prod. Manag. Eng. 2024, 12, 195–209. [Google Scholar] [CrossRef]

- Suuronen, S.; Ukko, J.; Eskola, R.; Semken, R.S.; Rantanen, H. A systematic literature review for digital business ecosystems in the manufacturing industry: Prerequisites, challenges, and benefits. CIRP J. Manuf. Sci. Technol. 2022, 37, 414–426. [Google Scholar] [CrossRef]

- Serey, J.; Alfaro, M.; Fuertes, G.; Vargas, M.; Ternero, R.; Duran, C.; Sabattin, J.; Gutierrez, S. Framework for the strategic adoption of industry 4.0: A focus on intelligent systems. Processes 2023, 11, 2973. [Google Scholar] [CrossRef]

- Voinea, G.D.; Girbacia, F.; Duguleană, M.; Boboc, R.G.; Gheorghe, C. Mapping the emergent trends in industrial augmented reality. Electronics 2023, 12, 1719. [Google Scholar] [CrossRef]

- Salierno, G.; Leonardi, L.; Cabri, G. The future of factories: Different trends. Appl. Sci. 2021, 11, 9980. [Google Scholar] [CrossRef]

- Isoko, K.; Cordiner, J.L.; Kis, Z.; Moghadam, P.Z. Bioprocessing 4.0: A pragmatic review and future perspectives. Digit. Discov. 2024, 3, 1662–1681. [Google Scholar] [CrossRef]

- Qiu, F.; Kumar, A.; Hu, J.; Sharma, P.; Tang, Y.B.; Xu Xiang, Y.; Hong, J. A review on integrating IoT, IIoT, and Industry 4.0: A pathway to smart manufacturing and digital transformation. IET Inf. Secur. 2025, 1, 9275962. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Ghadge, A.; Raut, R. A performance measurement system for industry 4. 0 enabled smart manufacturing system in SMMEs—A review and empirical investigation. Int. J. Prod. Econ. 2020, 229, 107853. [Google Scholar] [CrossRef]

- Reyes Domínguez, D.; Infante Abreu, M.B.; Parv, A.L. Main trend topics on industry 4.0 in the manufacturing sector: A bibliometric review. Appl. Sci. 2024, 14, 6450. [Google Scholar] [CrossRef]

- Wang, S.; Jiao, R.J. Smart in-process inspection in human–cyber–physical manufacturing systems: A research proposal on human–automation symbiosis and its prospects. Machines 2024, 12, 873. [Google Scholar] [CrossRef]

- Ilieva, G.; Yankova, T.; Staribratov, P.; Ruseva, G. Industrial digitalization technologies and their applications (2020–2025). Mendeley Data 2025, V1. [Google Scholar] [CrossRef]

- Kahveci, S.; Alkan, B.; Mus’ab H, A.; Ahmad, B.; Harrison, R. An end-to-end big data analytics platform for IoT-enabled smart factories: A case study of battery module assembly system for electric vehicles. J. Manuf. Syst. 2022, 63, 214–223. [Google Scholar] [CrossRef]

- Sverko, M.; Grbac, T.G.; Mikuc, M. SCADA systems with focus on continuous manufacturing and steel industry: A survey on architectures, standards, challenges and industry 5.0. IEEE Access 2022, 10, 109395–109430. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, A.; Díez-González, J.; Verde, P.; Ferrero-Guillen, R.; Perez, H. Hyperconnectivity proposal for smart manufacturing. IEEE Access 2023, 11, 70947–70959. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a smart factory based on cyber-physical systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Ahn, D.-J.; Jun, C.; Song, S.; Baek, J.-G. Production system maturity model (PSMM) for assessing manufacturing execution system. IEEE Access 2024, 12, 123459–123475. [Google Scholar] [CrossRef]

- Ryalat, M.; Franco, E.; Elmoaqet, H.; Almtireen, N.; Al-Refai, G. The integration of advanced mechatronic systems into industry 4.0 for smart manufacturing. Sustainability 2024, 16, 8504. [Google Scholar] [CrossRef]

- Nagy, M.; Lăzăroiu, G.; Valaskova, K. Machine intelligence and autonomous robotic technologies in the corporate context of SMEs: Deep learning and virtual simulation algorithms, cyber-physical production networks, and Industry 4.0-based manufacturing systems. Appl. Sci. 2023, 13, 1681. [Google Scholar] [CrossRef]

- Khalil, E.; Akter, M. Prediction of seam strength of cotton canvas fabric using fuzzy logic. Results Control Optim. 2024, 17, 100502. [Google Scholar] [CrossRef]

- Kim, B.; Shin, M.; Hwang, S. Design and development of a precision defect detection system based on a line scan camera using deep learning. Appl. Sci. 2024, 14, 12054. [Google Scholar] [CrossRef]

- Mu, H.; He, F.; Yuan, L.; Commins, P.; Ding, D.; Pan, Z. A digital shadow approach for enhancing process monitoring in wire arc additive manufacturing using sensor fusion. J. Ind. Inf. Integr. 2024, 40, 100609. [Google Scholar] [CrossRef]

- Singh, M.; Kapukotuwa, J.; Gouveia, E.L.S.; Fuenmayor, E.; Qiao, Y.; Murry, N.; Devine, D. Unity and ROS as a digital and communication layer for digital twin application: Case study of robotic arm in a smart manufacturing cell. Sensors 2024, 24, 5680. [Google Scholar] [CrossRef]

- Lee, C.K.; Huo, Y.Z.; Zhang, S.Z.; Ng, K.K. Design of a smart manufacturing system with the application of multi-access edge computing and blockchain technology. IEEE Access 2020, 8, 28659–28667. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Improving transactional data system based on an edge computing–blockchain–machine learning integrated framework. Processes 2021, 9, 92. [Google Scholar] [CrossRef]

- Dakhnovich, A.D.; Moskvin, D.A.; Zegzhda, D.P. Approach for securing network communications modelling based on smart multipath routing. Nonlinear Phenom. Complex Syst. 2020, 23, 386–396. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Xanthakis, E. Digital transformation of production planning and control in manufacturing SMEs—The mold shop case. Appl. Sci. 2022, 12, 10788. [Google Scholar] [CrossRef]

- Saha, A.; Airehenbuwa, B.; Jahangir, J.B.; Ndoye, M.; Akasheh, F.; Kim, E.; Fiock, T.; Van Meter, Z.; Alam, M.A.; Shakouri, A. Part fingerprinting-based productivity monitoring of CNC machines with low-cost current sensors. Int. J. Adv. Manuf. Technol. 2025, 137, 5913–5926. [Google Scholar] [CrossRef]

- Tanane, B.; Bentaha, M.-L.; Dafflon, B.; Moalla, N. Bridging the gap between Industry 4.0 and manufacturing SMEs: A framework for an end-to-end Total Manufacturing Quality 4.0’s implementation and adoption. J. Ind. Inf. Integr. 2025, 45, 100833. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Lopes, S.I.; Fernández-Caramés, T.M. Green IoT and edge AI as key technological enablers for a sustainable digital transition towards a smart circular economy: An industry 5.0 use case. Sensors 2021, 21, 5745. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Salah, B.; Habib, T. Utilizing industry 4.0-related technologies and modern techniques for manufacturing customized products—Smart yogurt filling system. J. Eng. Res. 2024, 12, 468–475. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, A.; Díez-González, J.; Ferrero-Guillén, R.; Verde, P.; Álvarez, R.; Perez, H. Digital twin for automatic transportation in Industry 4.0. Sensors 2021, 21, 3344. [Google Scholar] [CrossRef]

- Bianchini, A.; Savini, I.; Andreoni, A.; Morolli, M.; Solfrini, V. Manufacturing execution system application within manufacturing small–medium enterprises towards key performance indicators development and their implementation in the production line. Sustainability 2024, 16, 2974. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and identification of current research trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Asghar, M.Z.; Memon, S.A.; Hämäläinen, J. Evolution of wireless communication to 6G: Potential applications and research directions. Sustainability 2022, 14, 6356. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Zhang, S.; Song, L.; Tao, F. Artificial intelligence-enhanced digital twin systems engineering towards the industrial metaverse in the era of Industry 5.0. Chin. J. Mech. Eng. 2025, 38, 40. [Google Scholar] [CrossRef]

- Stojadinovic, S.M.; Majstorovic, V.D.; Gąska, A.; Sładek, J.; Durakbasa, N.M. Development of a coordinate measuring machine—Based inspection planning system for Industry 4.0. Appl. Sci. 2021, 11, 8411. [Google Scholar] [CrossRef]

- Gellert, A.; Sorostinean, R.; Pirvu, B.-C. Robust assembly assistance using informed tree search with Markov chains. Sensors 2022, 22, 495. [Google Scholar] [CrossRef]

- Chen, T.; Sampath, V.; May, M.C.; Shan, S.; Jorg, O.J.; Aguilar Martín, J.J.; Stamer, F.; Fantoni, G.; Tosello, G.; Calaon, M. Machine Learning in Manufacturing towards Industry 4.0: From ‘For Now’ to ‘Four-Know’. Appl. Sci. 2023, 13, 1903. [Google Scholar] [CrossRef]

- Chinnathai, M.K.; Alkan, B. A digital life-cycle management framework for sustainable smart manufacturing in energy intensive industries. J. Clean. Prod. 2023, 419, 138259. [Google Scholar] [CrossRef]

- Hozdić, E.; Makovec, I. Evolution of the human role in manufacturing systems: On the route from digitalization and cybernation to cognitization. Appl. Syst. Innov. 2023, 6, 49. [Google Scholar] [CrossRef]

- Chiang, A.H.; Trimi, S.; Kou, T.C. Critical factors for implementing smart manufacturing: A supply chain perspective. Sustainability 2024, 16, 9975. [Google Scholar] [CrossRef]

- Bezerra, N.R. de A.; Marchisotti, G.G.; Bezerra, M.J.S.; Farias Filho, J.R. de. Digital transformation in naval industry. Braz. J. Oper. Prod. Manag. 2024, 21, 2210. [Google Scholar] [CrossRef]

- Demeter, K.; Szász, L.; Rácz, B.-G.; Györfy, L.-Z. Fourth industrial (r)evolution? Investigating the use of technology bundles and performance implications. J. Manuf. Technol. Manag. 2024, 35, 1–23. [Google Scholar] [CrossRef]

- Sofic, A.; Rakic, S.; Pezzotta, G.; Markoski, B.; Arioli, V.; Marjanovic, U. Smart and Resilient Transformation of Manufacturing Firms. Processes 2022, 10, 2674. [Google Scholar] [CrossRef]

- Popan, I.A.; Cosma, C.; Popan, A.I.; Bocăneț, V.I.; Bâlc, N. Monitoring Equipment Malfunctions in Composite Material Machining: Acoustic Emission-Based Approach for Abrasive Waterjet Cutting. Appl. Sci. 2024, 14, 4901. [Google Scholar] [CrossRef]

- Walas, F.; Redchuk, A. IIoT/IoT and Artificial Intelligence/Machine Learning as a Process Optimization driver under industry 4.0 model. J. Comput. Sci. Technol. 2021, 21, e15. [Google Scholar] [CrossRef]

| Reference | Research Objective |

IT Technologies |

Key Findings and Suggestions |

|---|---|---|---|

| Çınar et al. (2020) [9] |

To review of ML in PdM by classifying existing studies according | ML for PdM in smart factories, highlights popular supervised ML | Finds that RF is the most widely applied ML technique in PdM, used across many industrial assets. Suggests ensemble approaches to improve prediction accuracy and robustness. |

| Kamble et al. (2020) [23] |

To develop and validate a performance-measurement system for SMEs auto-component manufacturing | Robotics and semi-autonomous systems, CPS, IoT, cloud computing, big data analytics, AI, AM, AR/VR, blockchain | Empirically selected 59 measures into ten validated dimensions (cost, quality, flexibility, time, integration, optimized productivity, real-time diagnosis & prognosis, computing, social & ecological sustainability) |

| Escobar et al. (2021) [15] |

To chart the shift to Quality 4.0 by integrating real-time data and AI into shop-floor quality control | IoT sensor networks, cloud/edge analytics platforms, ML/DL | Classical SPC and Six Sigma must be enhanced by AI-driven predictive analytics and corresponding explainability |

| Salierno et al. (2021) [20] |

To compare major approaches for factory digitalization under the I4.0 and ‘MIC2025’ initiatives | CPS to integrate physical and digital factory components (enabling DT), IoT, 3D simulation | European “digital factory” and Chinese “cloud manufacturing” paradigms share the goal of smarter, digitalized production but focus on different levels (intra-factory processes vs. inter-factory collaboration). Interoperability is a critical challenge. |

| Onaji et al. (2022) [13] |

To propose a conceptual framework for assessment of DT applications and validate it via manufacturing case studies | CPS, IoT, cloud computing, big data analytics, AI, simulation tools | DT enables PdM, real-time optimization, and enhanced decision-making; integration complexity and infrastructure needs are key barriers to broader adoption. |

| Suuronen et al. (2022) [17] |

To review DBEs in manufacturing and outline challenges, benefits, and future research trends | IoT/IIoT, cloud computing and platform technologies, AI and data analytics | DBEs offer innovation and market agility but face challenges like interoperability and cybersecurity. The study identifies key enablers, barriers, and benefits, and outlines future research directions and managerial implications. |

| Wang et al. (2022) [14] |

To develop an agent-based framework that enhances SM through AI, DT, and real-time decision-making | AI, intelligent agents, DT, real-time analytics | The framework improves manufacturing flexibility, responsiveness, and autonomy; includes recommendations for implementing decentralized systems in dynamic production environments. |

| Serey at al. (2023) [18] |

To create a strategic framework integrating I4.0 and AI to guide industrial organizations through DX | I4.0 technologies, digital ecosystems, intelligent systems. | Strategic alignment with I4.0 requires mindset shifts, workforce reskilling, business model innovation, and integrated data-driven ecosystems for sustainable competitiveness. |

| Voinea et al. (2023) [19] |

To map emergent trends in industrial AR (IAR) through a scientometric review of literature from 2018–2022 | SM, AR, IoT, AI, DT, Human–Robot Interaction, visualization | Identifies key growth areas in IAR, with AI as fastest-growing and I4.0 as most published; notes industrial benefits and challenges like high cost, usability, and integration. |

| Benslimane et al. (2024) [16] |

To analyse the relationship, trends, and challenges in integrating Lean Manufacturing with I4.0 through a systematic literature review | Robotics, CPS, IoT, RFID, AM, cloud, big data, AI, DTs, analytics tools | Reveals mutual reinforcement between LM and I4.0, identifies key trends (productivity, sustainability, I5.0), and challenges (culture, technology, skills). |

| Burzynska (2024) [10] |

To systematically review of data-driven DSS for diagnosing casting defects | AI/ML/DL methods; DTs; case-/rule-based reasoning; and analytical tools |

AI-based models often achieve high accuracy; challenges include imbalanced defect data and limited deployment in real factories; calls for further research to enable reliable, real-time predictive |

| Gargalo et al. (2024) [11] |

To investigate hybrid modelling integrating mechanistic and AI/ML methods to accelerate digitalization in chemical and biochemical industries, enabling credible DTs and I4.0/I5.0 transition | Cloud, ML/AI, hybrid models, DTs, data integration, advanced analytics, real-time monitoring systems feeding process optimization and decision support | Hybrid models improve optimization, cost efficiency, and sustainability but face data, integration, and skill challenges; proposed pathway positions them as foundation for DX. |

| Ghosh et al. (2024) [12] |

To survey and synthesize AI/ML methods for predicting surface quality (surface roughness) in manufacturing | Pd ML/DL models, edge/IoT computing | Most studies use sensor/experimental data to train AI models. DL models often achieved the highest accuracy, while tree-based/SVM methods were used on tabular data. |

| Isoko et al. (2024) [21] |

To assess the integration of I4.0 technologies into complex manufacturing environments and propose a roadmap for DX | CPS and DT frameworks, connectivity, ML, data-driven modelling, predictive analytics, immersive technologies for operations | Identifies key integration challenges, especially lack of standards; proposes operating models and guiding principles for scalable, interoperable smart factory systems. |

| Reyes Domínguez et al. (2024) [24] |

To analyse IoT and AI/ML integration under I4.0 for industrial process optimization through bibliometric analysis | SM, IoT/IIoT, AI/ ML, process optimization | AI and ML significantly optimize industrial processes, though complexity remains a barrier; greater focus on integrated frameworks is recommended. |

| Wang and Jiao (2024) [25] |

To propose a conceptual framework for integrating smart in-process inspection with human–automation symbiosis in CPS in manufacturing | Smart in-process inspection, cognitive task allocation, human–automation interfaces, and adaptive decision support in CPPS | Integration enhances quality, resilience, and adaptability; key barriers are inspection accuracy, adaptive task allocation, and nudging design. |

| Qiu et al. (2025) [22] |

To review IIoT integration within I4.0 for SM, highlighting differences from traditional IoT | CPS, 5G, IIoT, AI/ML, big data, blockchain, cybersecurity | Effective IIoT deployment improves operational efficiency; addressing interoperability and cybersecurity via encryption/blockchain is critical. |

| Framework layer | Current company capabilities | Implementation status | Potential improvements |

|---|---|---|---|

| Layer 1 | Modern machinery, partial automation |

Partial | Expand robotics, add more sensors |

| Layer 2 | Some PLCs and IoT devices |

Partial | Implement edge AI for predictive maintenance |

| Layer 3 | Limited local data aggregation |

Low | Deploy MES and integrate DTs |

| Layer 4 | ERP in place, limited analytics |

Partial | Add cloud-based AI for demand forecasting |

| Decision support | Skilled workforce, manual dashboards |

Partial | Implement XAI interfaces |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).