1. Introduction

Chemical sensors play a central role in modern analytical science, offering real-time, selective, and sensitive detection of chemical species across gas, liquid, and solid phases. These devices typically consist of three key components: a recognition element (such as a nanostructured material), a transduction system (electrical, optical, thermal, or piezoelectric), and a signal-processing module. The fundamental operation involves capturing a molecular interaction or binding event and converting it into a measurable output. Over the past two decades, a significant transformation has occurred in the field, driven largely by the development of novel nanomaterials and their integration into compact, portable, and often wearable sensing platforms [

1,

2].

Historically, chemical sensors were dominated by metal oxide semiconductors such as SnO₂, ZnO, and TiO₂, especially for gas detection [

3]. These materials are still widely used today but have been surpassed in performance by nanostructured materials with higher specific surface areas, tunable surface chemistries, and advanced electronic or photonic properties. Carbon nanotubes (CNTs), for instance, have been implemented in chemiresistive and field-effect transistor (FET) sensor architectures, demonstrating parts-per-billion (ppb) detection limits for NO₂, NH₃, and volatile organic compounds (VOCs) [

4]. Graphene-based materials—including graphene oxide and reduced graphene oxide—have shown exceptional promise for both chemical and biosensing, particularly when modified with functional groups or metallic nanoparticles [

5,

6]. More recently, metal–organic frameworks (MOFs) have emerged as a class of crystalline, porous materials with high surface area and chemical tunability. Their potential in gas sensing is increasingly recognized, especially when integrated with transducers like QCM, SPR, or electrochemical cells [

7,

8,

9]. MOFs such as ZIF-8, HKUST-1, and MIL-101 have been used to detect CO₂, SO₂, H₂S, and various VOCs under ambient conditions, often outperforming conventional sensors in selectivity and stability [

10,

11,

12]. Meanwhile, two-dimensional (2D) materials like MoS₂, WS₂, and MXenes have shown promise in flexible sensing applications due to their high electronic mobility and mechanical robustness [

5,

13,

14]. In the United States, sensor technologies are considered strategic across environmental, healthcare, industrial, defense, and infrastructure sectors. The Environmental Protection Agency (EPA), for example, supports the deployment of low-cost air quality sensors to monitor ozone, particulate matter, and NO₂ in urban and rural environments, as part of its “Air Sensor Toolbox” initiative [

15,

16]. The National Institutes of Health (NIH) and National Science Foundation (NSF) have funded numerous projects focusing on wearable sensors for health diagnostics, such as glucose, lactate, cortisol, and hydration levels from sweat and interstitial fluid [

17,

18]. These sensors are also finding applications in early disease detection, remote patient monitoring, and pandemic preparedness.

The integration of chemical sensors into smart infrastructure is advancing rapidly. Cities such as New York, Los Angeles, and San Francisco are incorporating networks of air quality and environmental sensors to manage urban mobility, public health, and emergency response systems [

19]. Furthermore, smart homes and industrial facilities now include embedded chemical sensors for detecting gas leaks, VOC emissions, or equipment degradation in real-time, feeding data into machine learning platforms for predictive maintenance [

20]. The global chemical sensors market reflects this expansion. Recent market analyses estimate the 2024 market value at USD 24.9 billion, with projections exceeding USD 55 billion by 2034 [

21]. North America holds a substantial share (~35%), and within the United States, the sector is growing at a compound annual rate of 8.6%, driven by environmental regulations, healthcare diagnostics, and industrial automation [

22]. Notably, startups and academic spinoffs in Boston, San Diego, and the Bay Area are at the forefront of commercializing chemical sensor technologies for portable and personalized use. Another major trend is the shift toward flexible, stretchable, and biodegradable sensor platforms. Advances in additive manufacturing—such as aerosol jet printing, inkjet printing, and extrusion-based 3D printing—have enabled the fabrication of low-cost, scalable sensor arrays on substrates like polyimide, PDMS, and paper [

23]. These developments facilitate mass production of wearable devices that conform to the human body, essential for next-generation medical diagnostics, athletic performance tracking, and military applications [

23]. Simultaneously, artificial intelligence (AI) and machine learning are increasingly integrated into sensor systems, improving signal classification, drift correction, and real-time decision-making. AI-enhanced “electronic nose” systems, for example, are used for complex odor and VOC pattern recognition in environmental and food quality monitoring [

24,

25]. In healthcare, AI algorithms are being applied to predict dehydration, blood glucose fluctuations, or infectious disease onset from multivariate sensor datasets. A crucial element supporting these developments is the use of advanced characterization techniques. Methods such as Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and electrochemical impedance spectroscopy (EIS) are routinely employed to understand material–analyte interactions, sensor surface chemistry, and degradation mechanisms. These insights are vital for rational sensor design and reliability under diverse operating conditions.

Despite these advances, challenges remain. Sensor drift over time, reproducibility across batches, power consumption, cross-sensitivity to interferents, and calibration under variable conditions all require further study. Moreover, regulatory frameworks for wearable chemical sensors, particularly in healthcare applications, are still evolving and can delay commercialization. Sustainability is also emerging as a key concern, with increasing interest in green synthesis methods, biodegradable substrates, and recycling of spent devices [

26]. This review aims to provide a comprehensive analysis of recent progress (2019–2025) in U.S.-led chemical sensor technologies, focusing on four main dimensions: (1) novel sensing materials, (2) advanced fabrication methods, (3) characterization and performance evaluation, and (4) real-world applications in healthcare, environment, food safety, and industrial systems. We highlight synergies between nanomaterial science, engineering design, data science, and translational research. Furthermore, we outline future perspectives and technological bottlenecks that must be addressed to enable wide-scale deployment of smart, robust, and sustainable sensor platforms. This convergence of application-driven demand and materials innovation sets the stage for a detailed examination of the nanomaterials that underpin state-of-the-art chemical sensors.

2. Material for Advanced Chemical Sensors

The performance of chemical sensors is intimately linked to the properties of the materials used in their construction. Over the past decade, the discovery and engineering of nanostructured materials have led to major breakthroughs in sensitivity, selectivity, response time, and device stability. This section reviews the main classes of sensing materials that have shaped the evolution of next-generation chemical sensors, highlighting their structural features, functional advantages, and integration potential.

2.1. Carbon-Based Nanomaterials

Carbon-based nanomaterials have emerged as one of the most prominent platforms for advanced chemical sensor development due to their exceptional physicochemical properties, tunable electronic structure, high specific surface area, and versatile functionalization capabilities [

27]. Among these, graphene, reduced graphene oxide (rGO), and carbon nanotubes (CNTs) are the most extensively explored materials in the field of chemical sensing.

Graphene, a single-atom-thick two-dimensional (2D) sheet of sp²-hybridized carbon atoms arranged in a hexagonal lattice, exhibits outstanding electrical conductivity, mechanical strength, and thermal stability [

28]. Its high electron mobility at room temperature (~200,000 cm²/Vs) makes it particularly attractive for electronic sensing applications where rapid and sensitive transduction of molecular interactions is required [

29]. The large specific surface area of graphene (~2630 m²/g) provides abundant sites for analyte adsorption, thus enhancing sensor response [

30]. Furthermore, the zero bandgap of pristine graphene can be tuned via chemical doping, defect engineering, or hybridization with other materials to improve its sensitivity and selectivity towards target analytes [

31].

Reduced graphene oxide (rGO), derived from the chemical or thermal reduction of graphene oxide (GO), combines some of the electrical conductivity of pristine graphene with residual oxygen-containing functional groups that facilitate chemical modification and functionalization [

32]. These functional groups (e.g., hydroxyl, epoxy, carboxyl) not only impart hydrophilicity, enabling stable aqueous dispersions, but also serve as active sites for covalent or non-covalent immobilization of recognition elements such as enzymes, antibodies, or aptamers [

33]. Consequently, rGO-based sensors have demonstrated superior performance in detecting gases [

34], heavy metal ions [

35], and biomolecules [

36] compared to unmodified graphene-based platforms, due to the synergy between conductive domains and functional anchoring sites.

Carbon nanotubes (CNTs), both single-walled (SWCNTs) and multi-walled (MWCNTs), represent another widely explored class of carbon nanostructures for chemical sensing applications. CNTs are quasi one-dimensional materials with extraordinary mechanical strength, chemical stability, and electrical conductivity, enabling efficient electron transfer between analytes and electrodes [

37]. SWCNTs, in particular, possess tunable electronic properties (metallic or semiconducting) depending on their chirality and diameter, which can be exploited to design sensors with tailored performance characteristics [

38]. The hollow tubular morphology of CNTs provides internal and external adsorption sites for analytes, thereby enhancing their sensitivity [

39].

A critical aspect in the design of high-performance chemical sensors based on carbon nanomaterials is surface functionalization to improve both sensitivity and selectivity. For instance, functionalization of graphene or rGO with metal nanoparticles (e.g., Au, Pt, Pd) enhances catalytic activity towards specific analytes and facilitates charge transfer between the nanomaterial and the target molecules, resulting in improved sensing performance [

40,

41]. Non-covalent functionalization using π-π stacking interactions with aromatic compounds or surfactants preserves the conjugated electronic structure of graphene while introducing specific recognition capabilities [

42]. Covalent functionalization, although potentially disrupting the sp² network, enables strong attachment of molecular recognition elements, which is essential in biosensor designs [

43,

44]. In the case of CNTs, functionalization strategies include acid treatment to introduce carboxyl and hydroxyl groups on the surface, enabling further conjugation with biomolecules or polymers [

45]. Additionally, decorating CNTs with conducting polymers such as polyaniline (PANI) or polypyrrole (PPy) has been shown to enhance selectivity towards gases like ammonia and nitrogen dioxide by synergistically combining the redox responsiveness of polymers with the conductive properties of CNTs [

46,

47]. Recent advancements also involve the development of hybrid nanocomposites, where carbon-based nanomaterials are combined with metal oxides (e.g., ZnO, TiO₂, SnO₂) to achieve enhanced sensitivity, stability, and selectivity towards a broad range of analytes [

48,

49]. Such hybrid systems leverage the high surface area and conductive network of carbon nanomaterials with the inherent catalytic or adsorption capabilities of metal oxides, resulting in superior sensing performance in terms of response time, limit of detection (LOD), and operational stability [

50]. For example, a graphene/ZnO nanocomposite-modified electrode has been reported to exhibit remarkable sensitivity towards hydrogen peroxide with a low detection limit and rapid response time due to the synergistic catalytic activity of ZnO nanoparticles and the high conductivity of graphene sheets [

51]. Similarly, rGO-TiO₂ composites have been employed in photoelectrochemical sensors, where rGO enhances charge separation and transport under illumination, thereby improving the photocurrent response upon analyte binding [

52].

In summary, carbon-based nanomaterials, particularly graphene, rGO, and CNTs, offer a versatile platform for chemical sensor development due to their intrinsic electronic properties, high surface area, and amenability to surface functionalization. Ongoing research focuses on optimizing functionalization strategies to tailor their surface chemistry towards specific analytes while maintaining or enhancing their electrical properties. Moreover, the integration of these nanomaterials into flexible, wearable, and miniaturized sensor devices is opening new avenues for their application in environmental monitoring, healthcare diagnostics, and industrial process control [

53,

54].

2.2. Metal and Metal Oxide Nanostructures

Metal and metal oxide nanostructures form a cornerstone of modern chemical sensing technologies due to their intrinsic physicochemical properties, versatile morphologies, and well-established synthesis methods that facilitate integration into practical devices. Their widespread use arises from their high surface-to-volume ratios, tunable electronic structures, catalytic activity, and chemical stability, which collectively enable highly sensitive and selective detection of a broad spectrum of chemical analytes, including gases, ions, and biomolecules. Among these materials, zinc oxide (ZnO) has emerged as one of the most widely studied metal oxides for chemical sensors. ZnO is an n-type semiconductor with a wide bandgap of 3.37 eV and a large exciton binding energy (~60 meV), properties that confer high electron mobility and strong optical absorption in the UV region [

55]. The ability to synthesize ZnO in various nanostructured morphologies, such as nanorods, nanowires, nanosheets, nanobelts, hollow spheres, and hierarchical flower-like assemblies, has been pivotal in tuning its sensing performance [

56]. For example, ZnO nanorods and nanowires provide one-dimensional electron transport pathways, enhancing charge carrier mobility, while hierarchical flower-like structures formed by radially oriented nanorods dramatically increase the surface area available for analyte adsorption. This combination of structural features enables ZnO-based sensors to achieve high sensitivity, rapid response, and low detection limits for target gases such as NO₂, ethanol, and volatile organic compounds (VOCs) [

57,

58]. Similarly, tin dioxide (SnO₂) is a prominent n-type semiconducting metal oxide extensively employed in gas sensing applications. Its wide bandgap (~3.6 eV) and high conductivity modulation in the presence of adsorbed gases make it ideal for detecting reducing gases like CO, H₂, CH₄, and various alcohol vapors [

59]. The fundamental sensing mechanism in SnO₂ involves chemisorption of oxygen species on the surface, which creates electron depletion layers; upon exposure to reducing gases, these oxygen species are removed via surface reactions, leading to an increase in electrical conductivity [

60]. The fabrication of SnO₂ into nanostructures such as nanorods, nanowires, hollow spheres, and mesoporous architectures enhances the density of active sites, promotes efficient gas diffusion, and improves the kinetics of adsorption–desorption processes [

61]. Moreover, doping SnO₂ with noble metals such as Pt, Pd, or Au (see

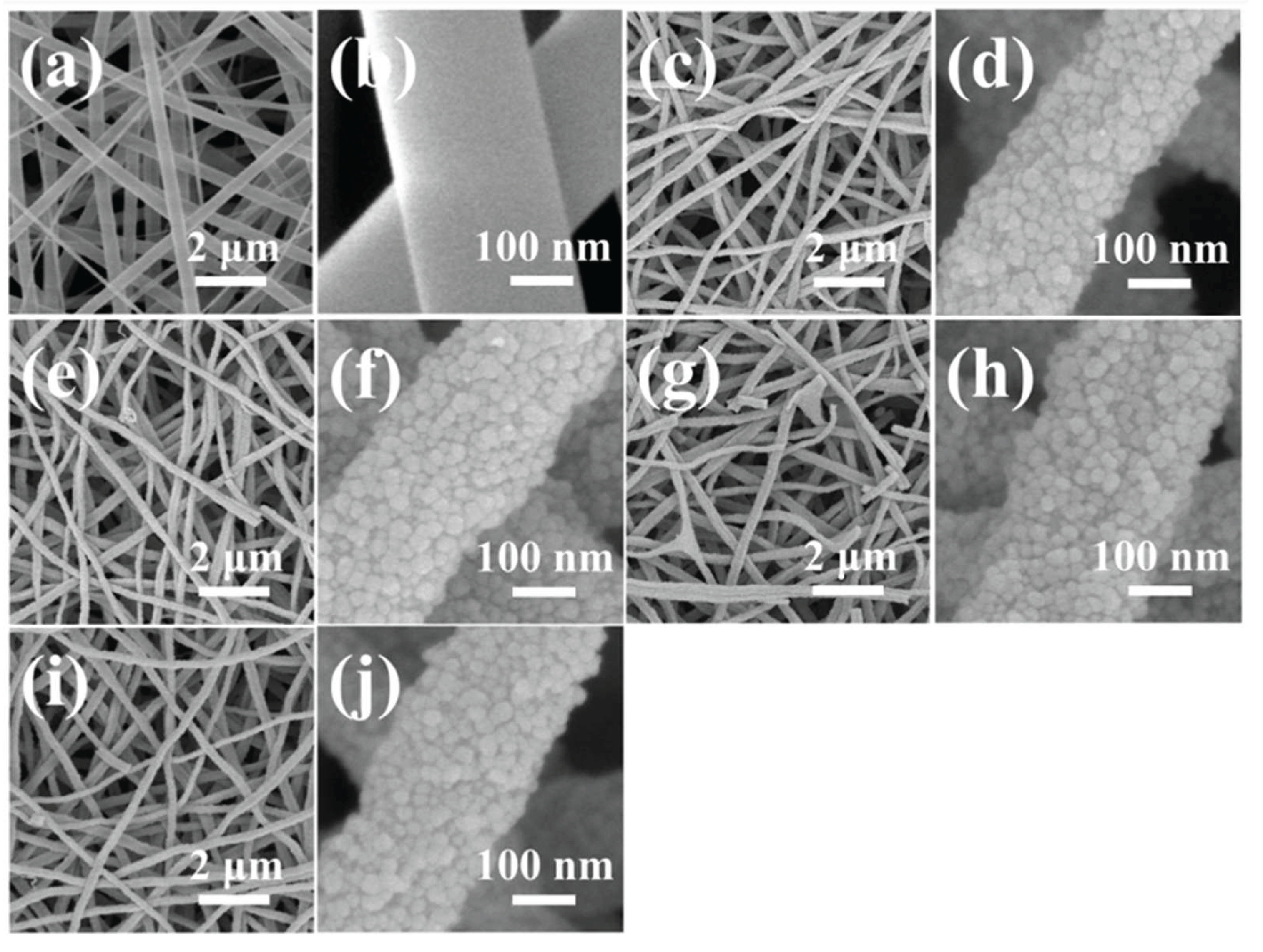

Figure 1), can significantly lower the operating temperature of sensors while enhancing selectivity and catalytic activity towards specific analytes, an aspect critical for energy-efficient and targeted sensing applications [

62].

Another noteworthy example is copper oxide (CuO), a p-type semiconductor with a narrow bandgap (~1.2 eV). CuO’s sensing capabilities stem from its strong surface adsorption and redox reactivity, enabling effective detection of gases such as H₂S, NH₃, and NO₂ [

63]. The synthesis of CuO nanostructures, including nanoflakes, nanorods, nanoplatelets, and porous microspheres, further amplifies its sensing performance by increasing the availability of reactive sites and facilitating rapid analyte diffusion within the sensor matrix. Additionally, combining CuO with other metal oxides to form heterojunctions, such as CuO–ZnO or CuO–TiO₂, improves sensor performance through the formation of p–n junctions that facilitate charge separation and modulate conductivity upon analyte exposure [

64,

65].

Titanium dioxide (TiO₂) is another metal oxide widely used in chemical sensing, particularly in photo-assisted applications due to its strong photocatalytic activity and chemical inertness. TiO₂ exists in three crystalline phases (anatase, rutile, brookite), with anatase being preferred for sensing applications because of its higher electron mobility and photocatalytic efficiency [

66,

67]. Nanostructured TiO₂, fabricated as nanotubes, nanorods, nanobelts, mesoporous films, or hierarchical assemblies, offers enhanced analyte adsorption and fast charge transport [

68]. Under UV illumination, TiO₂ generates electron-hole pairs that can participate in surface redox reactions, enabling photoelectrochemical sensing with improved sensitivity and minimal interference from ambient conditions [

9]. This characteristic is particularly advantageous for the detection of organic vapors, toxic gases, and biomolecules in aqueous environments [

69]. Beyond metal oxides, noble metal nanoparticles such as gold (Au) and silver (Ag) play a crucial role in chemical sensor development due to their unique localized surface plasmon resonance (LSPR) properties [

70]. LSPR results in strong absorption and scattering of light at characteristic wavelengths, which are highly sensitive to changes in the surrounding dielectric environment. This forms the basis of various optical sensing strategies, including colorimetric and refractive index-based detection [

71,

72]. Gold nanoparticles are particularly attractive for biosensing applications due to their excellent chemical stability, ease of functionalization with thiol-linked biomolecular recognition elements, and biocompatibility. They have been widely used in sensors for detecting proteins, nucleic acids, and small biomolecules with high sensitivity and selectivity [

73]. Silver nanoparticles, on the other hand, exhibit stronger plasmonic enhancement effects, making them ideal substrates for surface-enhanced Raman scattering (SERS) sensors capable of detecting analytes down to single-molecule levels [

1]. A defining feature that underpins the superior performance of metal and metal oxide nanostructures in sensing applications is their structural design, which directly influences material–analyte interactions, charge transfer processes, and sensor stability. For example, hierarchical morphologies, such as flower-like assemblies of nanorods or hollow sphere structures, provide exceptionally high surface areas and facilitate rapid mass transport of analytes, resulting in enhanced sensitivity and faster response-recovery cycles [

74]. In ZnO nanoflower-based sensors, the radial arrangement of nanorods not only increases active site availability but also creates open diffusion pathways that promote efficient gas molecule adsorption and desorption [

75]. Core–shell architectures represent another powerful design strategy to combine complementary material properties in a single nanostructure. In such systems, the core material often imparts desirable electronic or optical properties, while the shell material governs surface reactivity and analyte selectivity. For instance, Au@TiO₂ core–shell nanoparticles leverage the high conductivity and LSPR effects of gold with the photocatalytic activity of TiO₂, leading to enhanced charge separation and improved photoelectrochemical sensing performance [

76]. Similarly, SnO₂@SiO₂ core–shell structures have been shown to improve selectivity by modulating surface chemistry and preventing interference from non-target species, a feature critical for accurate detection in complex matrices [

77]. Moreover, facet engineering and shape control of nanostructures can significantly influence their sensing properties. Different crystal facets exhibit distinct atomic arrangements and electronic densities, affecting the adsorption energy and catalytic activity towards analytes. For example, SnO₂ nanocubes exposing <100> facets have demonstrated higher CO sensing performance than nanorods exposing <101> facets due to increased surface oxygen vacancy densities and lower activation energies for gas adsorption reactions [

78].

Finally, the design of porous and hollow nanostructures enhances analyte accommodation within internal voids while preserving structural integrity. This leads to improved sensitivity, faster analyte diffusion, and reduced sensor fouling, all essential for prolonged sensor operation with minimal degradation in performance [

1]. In summary, metal and metal oxide nanostructures offer a rich design landscape for chemical sensing applications. Their inherent electronic and catalytic properties, coupled with sophisticated structural engineering strategies such as hierarchical morphology construction, core–shell formation, facet control, and porosity tuning, enable the development of sensors with superior sensitivity, selectivity, and operational stability. These materials serve as an essential foundation for integrating advanced functionalities into miniaturized, flexible, and wearable sensor devices, facilitating real-time and accurate detection in environmental monitoring, healthcare diagnostics, food safety assurance, and industrial process control – domains that will be explored in subsequent sections of this review.

2.3. Silicon Nanowires and Semiconductor Materials

Silicon-based nanostructures, particularly silicon nanowires (SiNWs), represent a cornerstone in the development of next-generation chemical sensors due to their superior electronic properties, high surface-to-volume ratios, and compatibility with established semiconductor fabrication technologies. These attributes make SiNWs ideal candidates for highly sensitive, label-free, and real-time detection platforms applicable to environmental monitoring, biomedical diagnostics, and industrial process control. Silicon nanowires are one-dimensional semiconductor structures with diameters ranging from a few to hundreds of nanometers and lengths extending to several micrometers. Their high aspect ratio dramatically increases the density of surface atoms relative to bulk silicon, enabling substantial modulation of their electronic properties upon adsorption of target analytes [

79]. The ability to tailor their electrical characteristics through controlled doping further enhances their versatility for sensor design. A particularly impactful integration strategy involves incorporating SiNWs into field-effect transistor (FET) platforms. In such configurations, the nanowire acts as the semiconducting channel bridging source and drain electrodes, while the gate potential is modulated by the adsorption of charged analytes or biomolecules on the nanowire surface. This surface-induced field effect alters the carrier density within the channel, leading to measurable changes in current that directly correlate with analyte concentration [

80]. This principle enables label-free detection, eliminating the need for fluorophores or enzymatic amplification, thus simplifying device architecture and facilitating real-time analysis. Seminal work by Cui et al. in 2001 demonstrated the first SiNW-FET biosensor capable of detecting streptavidin through biotin functionalization with high sensitivity [

79]. Since then, extensive advances have been made in device architectures, including back-gated, top-gated, and electrolyte-gated FETs. Electrolyte-gated configurations have proven especially suitable for biosensing applications due to their high gate capacitance and direct exposure of the nanowire surface to the analyte-containing solution [

81,

82]. The fabrication of SiNW-based sensors benefits from both top-down and bottom-up approaches. Top-down fabrication involves defining nanowire structures from silicon-on-insulator (SOI) wafers using lithographic patterning and etching techniques such as electron-beam lithography and reactive ion etching. This method offers precise control over nanowire dimensions, alignment, and doping profiles, and is fully compatible with CMOS processing, enabling large-scale production and integration into microelectronic circuits [

81]. However, it requires advanced facilities and is cost-intensive. Bottom-up synthesis, primarily achieved via vapor–liquid–solid (VLS) growth mechanisms using metal nanoparticle catalysts (typically Au), enables the production of single-crystalline SiNWs with excellent electronic properties and tunable dimensions [

83]. These nanowires can be assembled onto pre-patterned electrodes using techniques such as dielectrophoresis or contact printing, although challenges remain in achieving precise large-scale alignment for device integration. Advances in microfabrication have also facilitated the incorporation of SiNWs into microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS). These hybrid devices combine electrical and mechanical sensing modalities, enabling enhanced performance and multifunctionality. For example, MEMS cantilever arrays coated with SiNWs allow for mass-based sensing through deflection or resonance frequency shifts upon analyte binding, providing high sensitivity and multiplexed detection capabilities [

84]. NEMS devices employing ultra-thin SiNWs can achieve attogram-level mass resolution, enabling the detection of individual virus particles or nanoparticles by monitoring resonance frequency shifts as target analytes adsorb onto the nanowire surface [

85]. Additionally, integration of SiNW sensors with on-chip microfluidic systems and wireless readout electronics has led to the development of portable diagnostic devices capable of rapid, real-time analysis of biomarkers, pathogens, and environmental pollutants [

86]. The combination of SiNWs with plasmonic nanoparticles or quantum dots has also been explored to create hybrid optoelectronic sensors with enhanced sensitivity and tailored spectral responses for specific analytes [

87].

Despite these advances, challenges remain in the large-scale and reproducible manufacturing of SiNW-based sensors, long-term operational stability, and biocompatibility for in vivo applications. Strategies such as optimized surface passivation, antifouling coatings, and system-level packaging are under active investigation to address these limitations. Overall, silicon nanowires and related semiconductor nanomaterials provide a versatile and scalable platform for chemical sensing, enabling the development of highly sensitive, miniaturized, and integrable devices essential for future applications in environmental monitoring, healthcare diagnostics, food safety, and industrial process surveillance.

2.4. Metal–Organic Frameworks (MOFs) and Hybrid Composites

Metal–organic frameworks (MOFs) have emerged as a powerful class of materials in chemical sensing due to their exceptionally high surface areas, tailorable pore structures, and versatile chemical functionalities. MOFs are crystalline porous materials formed by the self-assembly of metal ions or clusters (nodes) with organic linkers (ligands), resulting in frameworks with well-defined pore sizes and tunable chemical environments [

88]. This structural modularity enables precise control over adsorption selectivity, molecular recognition, and catalytic activity, which are critical for the design of high-performance chemical sensors. A key advantage of MOFs is their tailorable pore structures, which can be engineered to achieve size- and shape-selective sensing of target analytes. For instance, modification of organic linkers or choice of metal centers allows tuning of pore dimensions to match specific gas or vapor molecules, enhancing both selectivity and adsorption capacity [

89]. Furthermore, the incorporation of functional groups within the framework, such as amine, thiol, or carboxyl moieties, introduces specific chemical affinities, facilitating selective detection via strong host–guest interactions or coordination chemistry [

90]. This tunability enables MOFs to act as molecular sieves and pre-concentration layers in sensor architectures, improving sensitivity and lowering detection limits.

Despite these advantages, the intrinsic insulating nature of many pristine MOFs initially limited their direct use as transducer materials. Recent strategies to overcome this limitation include the synthesis of electrically conductive MOFs, incorporation of redox-active metal centers or ligands, and formation of hybrid composites with conductive materials such as graphene, carbon nanotubes, or metal nanoparticles [

91]. For example, conductive 2D MOFs based on metal bis(dithiolene) or bis(dithiolene diimine) motifs have demonstrated electrical conductivities up to 100 S/cm, enabling their direct integration into chemiresistive sensor devices [

92].

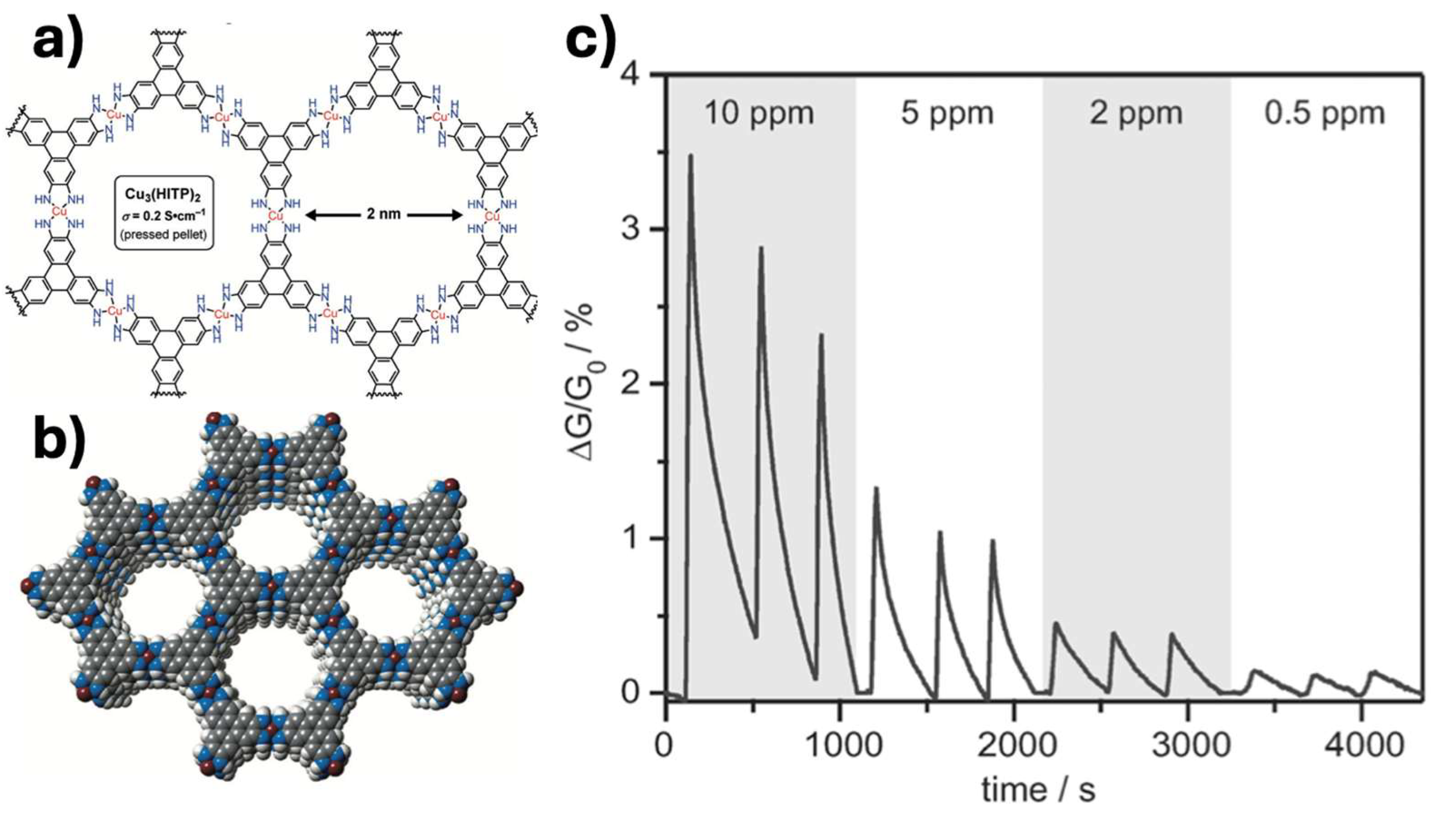

A recent U.S.-based study by Campbell et al. demonstrated the development of a Cu₃(HHTP)₂ (HHTP = 2,3,6,7,10,11-hexahydroxytriphenylene) conductive MOF thin film sensor for ammonia detection [

93]. The device exhibited a linear and reversible response to NH₃ at parts-per-million levels with rapid response times (< 30 s), attributed to the strong interaction between NH₃ molecules and open copper sites within the MOF structure combined with its intrinsic electrical conductivity (see

Figure 2). This represents a significant advance towards practical MOF-based gas sensors operable at room temperature with low power consumption. Hybrid composites combining MOFs with other functional nanomaterials have further enhanced sensor performance by leveraging synergistic effects. For instance, the integration of MOFs with graphene oxide (GO) or reduced graphene oxide (rGO) improves electrical conductivity and mechanical stability while maintaining the high porosity and selective adsorption properties of MOFs [

94]. An example is the ZIF-8/rGO composite sensor developed for VOC detection, where ZIF-8 provides selective adsorption of target vapors while rGO enables efficient charge transport, resulting in enhanced sensitivity and rapid response [

95,

96,

97]. Moreover, MOF–metal nanoparticle composites have been utilized for catalytically assisted sensing. The encapsulation or deposition of noble metal nanoparticles (e.g., Au, Pt, Pd) within MOF structures facilitates catalytic decomposition or redox reactions of analytes, producing measurable electrical or optical signals [

90]. For example, a recent study reported Au@MIL-101 composites for hydrogen peroxide sensing, where the Au nanoparticles catalyze the decomposition of H₂O₂ while MIL-101 ensures high dispersion and accessibility of active sites [

98]. The integration of MOFs with microfabrication and printing techniques has also advanced rapidly in the United States. Researchers have successfully fabricated MOF thin films via layer-by-layer deposition, spray-coating, and inkjet printing, enabling scalable production of flexible and miniaturized sensors compatible with wearable and portable devices [

99,

100]. For example, microfabricated MOF-coated quartz crystal microbalance (QCM) sensors have demonstrated highly selective and sensitive detection of aromatic VOCs such as benzene, toluene, and xylene (BTX) through size-selective adsorption within the MOF pores [

101].

Additionally, the development of MOF-derived materials, where MOFs serve as sacrificial templates for synthesizing porous metal oxides, carbons, or metal–carbon composites, has expanded the range of functional sensing materials. These MOF-derived structures often retain the high porosity and tunable morphology of the parent MOF while exhibiting enhanced conductivity and stability, making them suitable for electrochemical and gas sensing applications [

102]. MOFs and hybrid composites offer unique opportunities for chemical sensor development due to their structural tunability, high porosity, and versatile functionalization strategies. Recent U.S.-based research continues to drive innovations in conductive MOF design, integration with electronic transducers, and scalable fabrication approaches, paving the way for next-generation sensors with high sensitivity, selectivity, and operational stability suitable for environmental monitoring, industrial safety, and biomedical diagnostics.

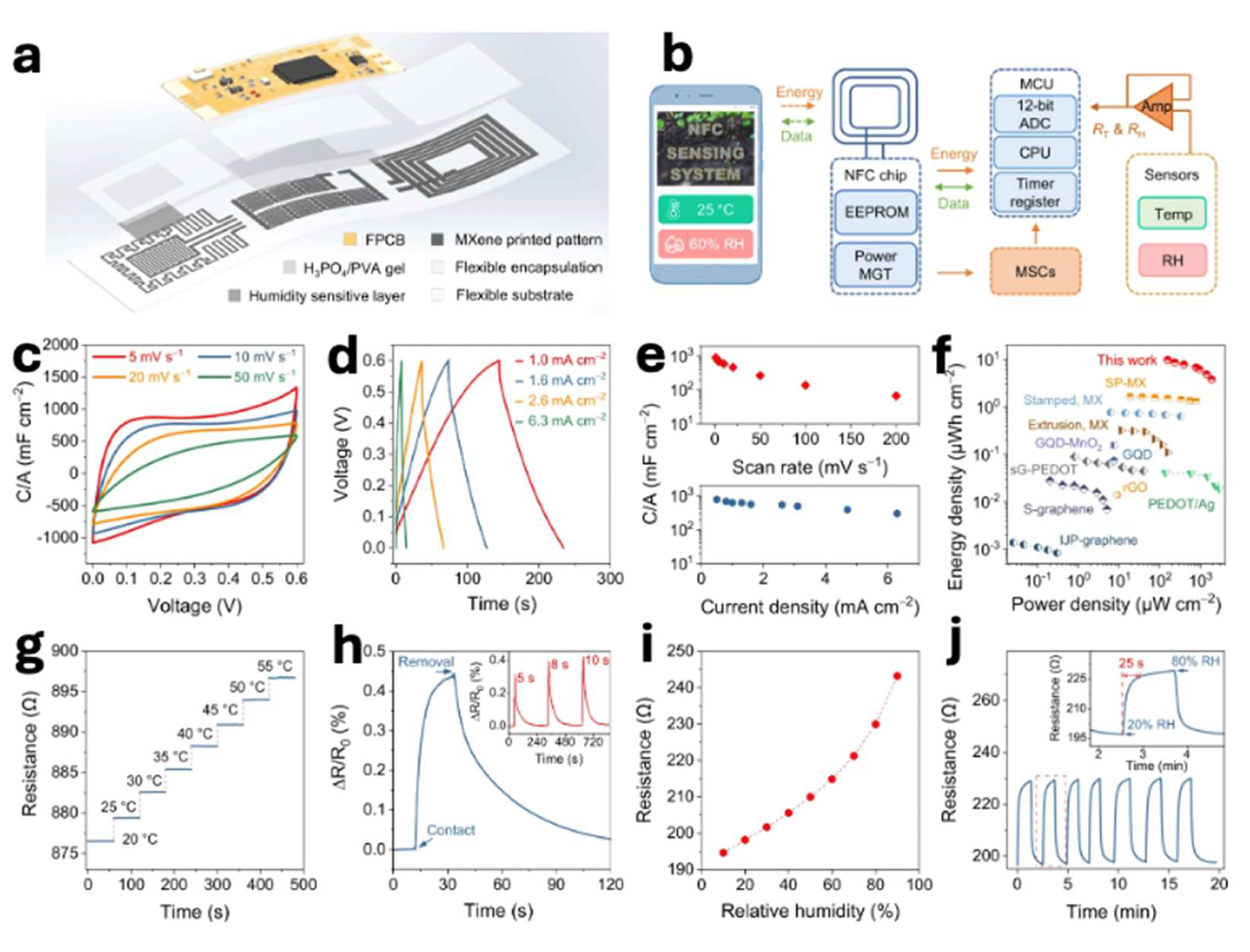

2.5. Emerging Materials

In recent years, the exploration of emerging materials for chemical sensing applications has expanded beyond traditional semiconductors and noble metals, with a focus on advanced two-dimensional (2D) materials, conductive polymers, and bioinspired platforms. Among 2D materials, graphene was the initial focus due to its exceptional surface area, mechanical strength, and electronic properties. However, research has rapidly diversified towards other 2D materials such as transition metal dichalcogenides (TMDs), MXenes, and black phosphorus, which offer tunable band gaps, rich surface chemistries, and synergistic functionalities that are highly attractive for chemical sensor development [

103].

Molybdenum disulfide (MoS₂), a prototypical TMD, exhibits a direct band gap in its monolayer form (~1.8 eV), high on/off current ratios in field-effect transistors (FETs), and significant chemical sensitivity due to abundant edge sites and defect-mediated interactions with analytes. Recent studies have demonstrated MoS₂-based FET sensors with femtomolar detection limits for biomolecules such as dopamine, enabled by surface functionalization with aptamers or metal nanoparticles to enhance specificity and electronic transduction efficiency [

104,

105].

MXenes, a class of early transition metal carbides and nitrides with general formula Mₙ₊₁XₙTₓ, have emerged as highly promising candidates for chemical sensing due to their metallic conductivity, hydrophilic nature, and surface termination versatility (–OH, –F, –O groups). For example, Ti₃C₂Tₓ MXene-based sensors have exhibited rapid response times (<1 s) and low detection limits (ppb range) towards volatile organic compounds (VOCs) such as ethanol and acetone, attributed to strong analyte adsorption and high carrier mobility [

106,

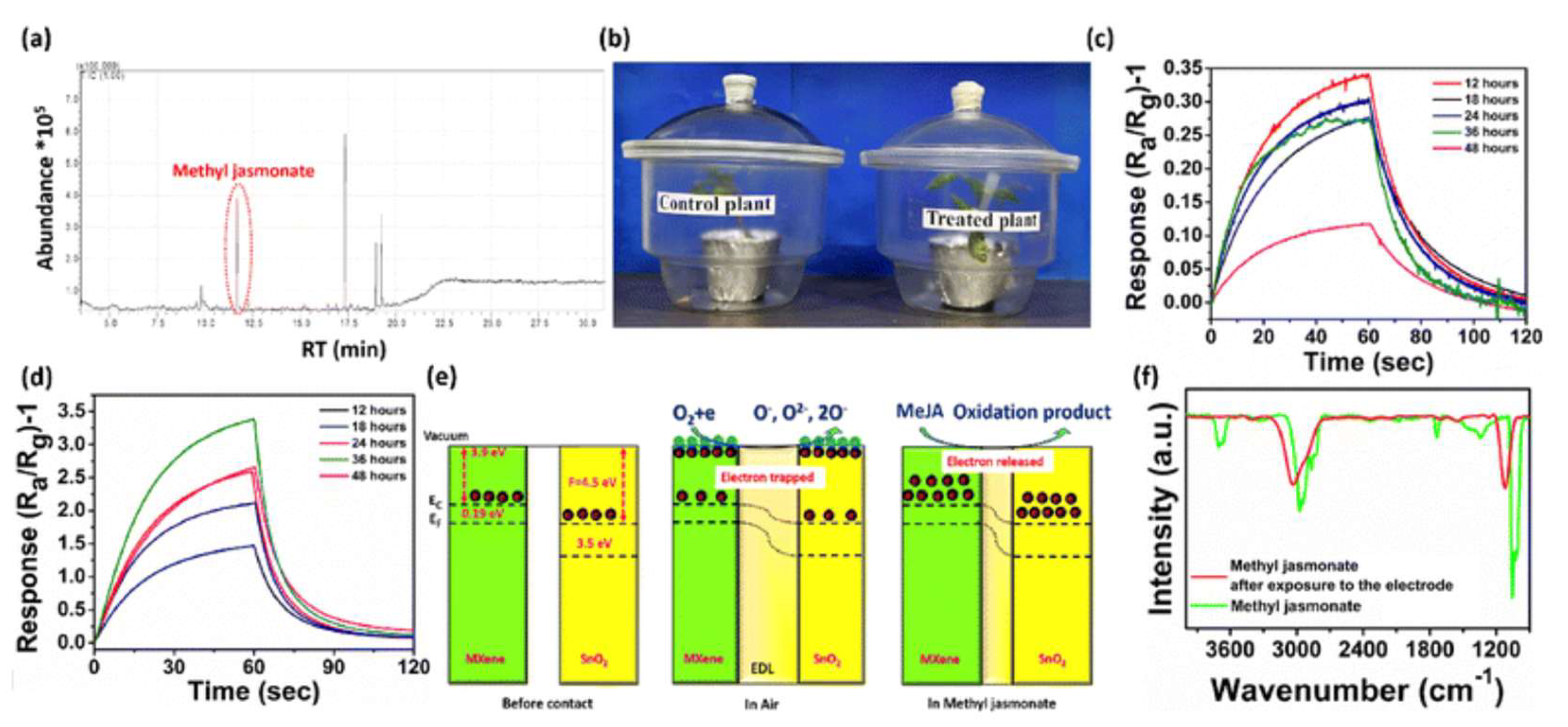

107]. Recent advances have demonstrated the potential of MXene-based hybrids in agricultural sensing. For instance, Kumar

et al. [

108] developed a chemoresistive sensor combining SnO₂ nanoparticles with Ti₃C₂Tₓ MXene sheets to detect methyl jasmonate (MeJA), a volatile ester released by plants under insect attack. The SnO₂/MXene nanocomposite formed a p–n heterojunction, enhancing charge separation and catalytic oxidation of MeJA, achieving a detection limit as low as 120 ppb with high selectivity and rapid response even at 125°C (

Figure 3). Remarkably, real-time testing on tomato plants infested with

Tuta absoluta revealed sensor responses 10 times higher than uninfested controls, underscoring its applicability in precision agriculture and early pest detection systems [

108].

Additionally, recent approaches integrate MXenes with conductive polymers or metal-organic frameworks (MOFs) to achieve synergistic enhancements in sensitivity, selectivity, and environmental stability [

109]. Conductive polymers such as polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene) (PEDOT) remain versatile platforms due to their tunable conductivity, facile synthesis, and ability to incorporate functional dopants or biomolecular recognition elements [

110,

111]. Recent innovations include the fabrication of PANI nanofiber networks for ammonia sensing with detection limits down to sub-ppm levels [

112], and PPy-based nanocomposites integrated with carbon nanomaterials for electrochemical detection of heavy metal ions with enhanced preconcentration and electron transfer capabilities [

113,

114]. Beyond synthetic materials, bioinspired and biomimetic sensing platforms are gaining momentum, leveraging natural recognition mechanisms and hierarchical architectures. For instance, silk fibroin and peptide-functionalized nanostructures have been employed to detect volatile analytes and biomolecules with high selectivity under ambient conditions [

115,

116]. Additionally, the incorporation of natural enzymes or synthetic enzyme-mimicking nanozymes into sensor architectures provides catalytic amplification and specificity, enabling ultrasensitive detection of glucose, organophosphates, and other clinically or environmentally relevant targets [

117]. The integration of these emerging materials with microfabrication technologies, flexible substrates, and wireless readout systems is paving the way for next-generation wearable, implantable, and environmental monitoring devices with unprecedented sensitivity, selectivity, and real-time data acquisition capabilities. Continued progress in controlled synthesis, interfacial engineering, and scalable processing remains essential to translate the intrinsic advantages of these novel materials into robust, commercially viable chemical sensor platforms [

103,

118].

The rich variety of nanomaterials explored for chemical sensing—ranging from carbon-based structures and metal oxides to MOFs and emerging 2D systems—has opened unprecedented opportunities for performance enhancement. However, the successful deployment of these materials in real-world sensing platforms critically depends on the development of suitable fabrication technologies and device architectures that preserve material functionality while enabling integration, scalability, and mechanical adaptability.

3. Fabrication Technologies and Sensor Architectures

The translation of novel sensing materials into practical devices requires equally innovative fabrication strategies. Advances in micro- and nanofabrication techniques, combined with the emergence of flexible and biodegradable substrates, have enabled the development of miniaturized, stretchable, and wearable sensor architectures with enhanced functionality and user adaptability. This section discusses the main fabrication approaches and design strategies that underpin the next generation of chemical sensors, with emphasis on scalable production, structural integration, and compatibility with real-world applications.

3.1. Miniaturization Techniques

The progressive miniaturization of chemical sensors has been a fundamental driver in advancing analytical performance, integration capabilities, and application versatility. Key fabrication strategies enabling miniaturization include soft lithography, nanoimprint lithography, and self-assembly, each offering distinctive advantages in resolution, scalability, and cost-effectiveness.

Soft lithography encompasses a suite of techniques that utilize elastomeric stamps, molds, or conformable photomasks, typically fabricated from polydimethylsiloxane (PDMS), to pattern features at micro- and nanoscale dimensions [

119]. It includes microcontact printing (µCP), replica molding, and microtransfer molding, among others. Soft lithography allows for high-throughput patterning of organic, inorganic, and biological materials onto diverse substrates under relatively mild conditions, enabling the fabrication of flexible, stretchable, and biointegrated sensors. For instance, microcontact-printed gold or SAM-based patterns have been used to define electrode architectures in electrochemical sensors with submicron resolution [

120].

Nanoimprint lithography (NIL) is a high-resolution, high-throughput patterning technology that relies on mechanical deformation of a resist material using a rigid mold to replicate nanoscale features down to sub-10 nm [

121]. Thermal NIL involves heating the resist above its glass transition temperature before imprinting, while UV-NIL uses photocurable resists under ambient conditions. NIL offers advantages over conventional photolithography, such as bypassing diffraction limits and achieving cost-effective patterning without expensive optics or masks. Its applications in sensor fabrication include the creation of periodic nanostructures for surface-enhanced Raman scattering (SERS) substrates, photonic crystals for optical sensors, and nanofluidic channels for molecular detection [

122].

Self-assembly leverages the spontaneous organization of molecules, nanoparticles, or block copolymers into ordered structures driven by non-covalent interactions such as van der Waals forces, electrostatic interactions, and hydrogen bonding [

123]. This bottom-up approach enables the formation of well-defined architectures without external patterning tools. For example, self-assembled monolayers (SAMs) of alkanethiols on gold provide molecularly precise functionalization layers in electrochemical and optical sensors, imparting selectivity towards specific analytes [

124]. Additionally, block copolymer micelles and colloidal nanoparticle arrays have been utilized to fabricate nanostructured sensing films with tunable porosity and surface area, enhancing analyte diffusion and binding capacity [

125]. The convergence of these miniaturization techniques with advanced materials and flexible substrates underpins the development of next-generation wearable, implantable, and portable chemical sensors. Future directions include hybrid approaches that integrate top-down lithographic precision with bottom-up self-assembly to achieve hierarchical multiscale architectures with optimized sensing performance and manufacturability.

3.2. Additive Manufacturing and Printing Technologies

Additive manufacturing (AM) and printing technologies have revolutionized the fabrication of chemical sensors by enabling rapid prototyping, design versatility, and direct integration on flexible and unconventional substrates. These techniques are especially attractive for low-cost, scalable production of customized sensor architectures tailored for wearable, implantable, and environmental monitoring applications.

Inkjet printing is a non-contact, digitally controlled technique that deposits picoliter droplets of functional inks onto substrates with high precision [

126]. It is compatible with a wide range of materials including metallic nanoparticle inks, carbon nanomaterials, conductive polymers, and biomolecule solutions. Inkjet printing has been employed to fabricate interdigitated electrodes, conductive traces, and sensing films for applications such as glucose sensing, heavy metal ion detection, and gas sensing. For instance, inkjet-printed silver nanoparticle electrodes have enabled flexible amperometric biosensors with low detection limits and stable operation [

127].

Aerosol jet printing offers higher resolution (down to ~10 μm) and greater versatility in ink viscosity compared to inkjet printing, by focusing an aerosolized ink stream with a sheath gas before deposition [

128]. This allows for conformal printing onto 3D or uneven surfaces, critical for integrating sensors onto complex geometries or flexible substrates. Aerosol jet printing has been utilized to produce highly sensitive gas sensors based on printed networks of carbon nanotubes or graphene, as well as to fabricate microelectrode arrays for electrochemical biosensing [

129].

3D printing, including techniques such as fused deposition modeling (FDM), stereolithography (SLA), and direct ink writing (DIW), enables layer-by-layer construction of three-dimensional sensor platforms [

130]. DIW, in particular, allows printing of viscoelastic inks containing conductive fillers or biomolecules to create functional microstructures with embedded sensing capabilities. Applications include fully printed electrochemical cells, microfluidic-integrated sensors, and customizable wearable patches for sweat analysis [

131,

132].

A key advantage of these AM technologies is their compatibility with flexible and unconventional substrates, such as polyethylene terephthalate (PET), polyimide (PI), textiles, paper, and biodegradable polymers. Printing on flexible substrates enables the development of conformal sensors capable of monitoring physiological parameters with minimal discomfort, such as epidermal sensors for electrolytes or metabolites [

133]. Furthermore, printing on biodegradable or eco-friendly substrates supports sustainable sensor technologies, critical for disposable environmental monitoring devices [

134]. Despite their potential, challenges remain in ensuring ink-substrate compatibility, maintaining functional stability under mechanical deformation, and achieving high-resolution multilayer structures without cross-contamination. Ongoing advances in ink formulation, printer design, and hybrid integration strategies are expected to address these limitations, paving the way for the widespread adoption of additive manufacturing in the scalable production of next-generation chemical sensors.

3.3. Wearable and Stretchable Sensor Designs

The development of wearable and stretchable chemical sensors has revolutionized personalized healthcare, real-time physiological monitoring, and human-machine interfaces. These sensors are designed to conform to the dynamic surfaces of the human body while maintaining reliable performance under mechanical deformation.

Electronic skin (e-skin) refers to sensor systems that mimic the tactile sensing capabilities and mechanical properties of human skin, integrating arrays of pressure, temperature, and chemical sensors onto ultrathin, flexible substrates [

135]. For chemical sensing, e-skin platforms incorporating pH sensors, sweat electrolyte analyzers, and gas sensors have been demonstrated. For example, graphene-based e-skin devices have been fabricated to detect ammonia and volatile organic compounds (VOCs) relevant to skin health and environmental exposure [

136]. These systems often utilize stretchable interconnects, serpentine-patterned electrodes, or intrinsically stretchable materials to accommodate strains exceeding 20%, enabling robust operation during body movements.

Textile-based sensors integrate conductive fibers, yarns, or printed patterns into fabrics, offering a seamless interface with clothing for unobtrusive monitoring [

137]. Techniques such as embroidery with metallic threads, dip-coating with conductive polymers, or direct inkjet printing of nanomaterial-based inks have been used to fabricate textile sensors for analytes such as sweat metabolites (e.g. glucose, lactate) and respiratory gases. Recent studies demonstrated knitted textile sensors incorporating carbon nanotube fibers for continuous ammonia sensing with high mechanical durability under bending and washing cycles [

138].

Implantable and on-body sensing platforms extend wearable sensor capabilities to invasive and minimally invasive configurations for continuous monitoring of internal biochemical markers [

139]. Implantable electrochemical sensors, often fabricated using biocompatible polymers, flexible electronics, and microfabricated electrodes, have been developed to detect analytes such as glucose, lactate, oxygen, and electrolytes within tissues or bodily fluids. For example, microneedle-based electrochemical sensors enable minimally invasive interstitial fluid analysis, providing real-time glucose monitoring with reduced patient discomfort compared to traditional needle-based methods [

140]. Similarly, flexible implantable sensors based on polyimide or PDMS substrates integrated with enzyme-functionalized electrodes have demonstrated stable operation for days to weeks with minimal tissue inflammation [

141].

Wearable and stretchable sensor designs demand materials and fabrication strategies that balance mechanical compliance, biocompatibility, electrical performance, and long-term stability. Future directions include integrating multifunctional sensing (e.g. combined chemical, electrophysiological, and mechanical monitoring), wireless data transmission, and energy harvesting modules to achieve fully autonomous, closed-loop healthcare systems. These fabrication strategies, when combined with the latest advances in nanomaterials, are enabling the creation of highly integrated, flexible, and multifunctional sensor platforms. However, to fully exploit their potential and ensure reliable operation across diverse applications, it is essential to employ advanced characterization techniques that can elucidate material properties, interface behavior, and sensing mechanisms.

4. Advanced Characterization and Performance Evaluation

The development of high-performance chemical sensors critically depends on a deep understanding of the structural, chemical, and electronic properties of sensing materials and interfaces. As sensor architectures become increasingly complex—incorporating nanocomposites, flexible substrates, and bioinspired layers—advanced characterization techniques play a pivotal role in guiding rational design, optimizing performance, and ensuring reproducibility. This section provides an overview of the main experimental tools used to probe material properties at multiple scales, elucidate transduction mechanisms, and validate sensor behavior under real-world conditions.

4.1. Spectroscopic and Microscopic Tools

Comprehensive characterization of sensor materials, surfaces, and interfaces is indispensable for elucidating structure–function relationships, optimizing fabrication processes, and ensuring reproducibility in chemical sensing performance. Spectroscopic and microscopic techniques provide complementary insights across length scales ranging from atomic to macroscopic levels.

X-ray photoelectron spectroscopy (XPS) is a powerful surface-sensitive analytical tool that probes the elemental composition, oxidation states, and chemical environments within the top ~5–10 nm of materials [

142]. It has been widely applied to verify surface functionalization of sensing layers, confirm successful immobilization of recognition elements such as enzymes, aptamers, or antibodies, and evaluate the oxidation states of metal or metal oxide nanoparticles used as catalytic or transducing elements in sensors. For instance, XPS has confirmed thiol-based self-assembled monolayers (SAMs) on gold electrodes to ensure molecular orientation and packing density critical for biosensor selectivity [

143]. Additionally, in gas sensors based on metal oxides (e.g. SnO₂, ZnO), XPS reveals oxygen vacancy concentrations and surface hydroxylation levels, which govern adsorption and sensing behavior [

144].

Raman spectroscopy provides vibrational fingerprints of materials, enabling non-destructive assessment of chemical bonding, molecular structure, crystallinity, and defect density [

145]. In carbon-based sensing materials, Raman is indispensable to analyze graphene oxide reduction (ID/IG ratios), layer number (2D peak shape), and functional group changes after surface modification. For example, reduced graphene oxide-based electrochemical sensors utilize Raman to confirm partial restoration of sp² carbon networks, correlating with enhanced electrical conductivity and sensor performance [

146]. For semiconductor nanostructures (e.g. MoS₂, WS₂), Raman modes (E²g and A₁g) reveal layer thickness, strain, and doping effects, which influence electronic sensing mechanisms [

147].

Fourier-transform infrared spectroscopy (FTIR) identifies characteristic vibrational modes of functional groups and molecular interactions, serving as a versatile tool for verifying surface modifications, polymer composition, and analyte binding [

148]. In polymer-based sensors, FTIR detects incorporation of dopants, cross-linking degrees, or incorporation of nanoparticles. Moreover, FTIR has been used to study adsorption of VOCs or biomolecules onto metal-organic frameworks (MOFs) and porous sensing films, revealing specific interaction sites that dictate selectivity and response kinetics [

149].

Scanning electron microscopy (SEM) provides high-resolution topographical and compositional imaging, essential for visualizing surface morphology, nanostructured architectures, and film uniformity [

150]. For printed or coated sensors, SEM ensures homogenous deposition and reveals crack formation or delamination risks. In chemiresistive sensors, SEM characterizes percolation networks of nanomaterials such as carbon nanotubes or metal nanoparticle assemblies, influencing electron transport pathways and sensitivity [

151].

Transmission electron microscopy (TEM) enables atomic-resolution imaging and crystallographic analysis through selected area electron diffraction (SAED) or high-resolution TEM (HRTEM) [

152]. TEM characterizes nanoparticle size distributions, core-shell structures, and lattice fringes in catalytic nanomaterials, providing insights into active sites for sensing reactions. For instance, in electrochemical sensors employing Pt or Pd nanoparticles, TEM elucidates particle dispersion on carbon supports, which determines electroactive surface area and detection limits [

153].

Atomic force microscopy (AFM) offers nanoscale surface topography mapping with sub-nanometer vertical resolution, as well as mechanical property and electrical property measurements using specialized modes [

154]. Tapping-mode AFM characterizes roughness and morphology of thin-film sensors, crucial for analyte diffusion and surface interactions. Conductive-AFM maps local conductivity variations, identifying grain boundaries or defects affecting sensor response. Kelvin probe force microscopy (KPFM) measures surface potential, relevant for semiconductor-based FET sensors to understand work function modulations upon analyte adsorption [

155].

Integrated application of these tools allows holistic characterization of sensor materials, correlating chemical composition, structure, morphology, and functional properties to sensing performance. For instance, combining XPS and Raman provides chemical state and structural information on graphene derivatives, while SEM and AFM collectively elucidate micro- and nanoscale surface morphology. Such comprehensive analyses are critical to rationally design high-performance, stable, and selective chemical sensors for diverse applications in environmental monitoring, healthcare, and industrial process control.

4.2. Electrochemical and Impedance-Based Techniques

Electrochemical techniques are fundamental to characterizing and understanding the sensing mechanisms, analytical performance, and interfacial processes of chemical sensors. Among these, electrochemical impedance spectroscopy (EIS), voltammetry, and amperometry remain the most widely employed methodologies, each offering unique insights into sensor behavior.

Electrochemical impedance spectroscopy (EIS) is a versatile frequency-domain technique that applies a small alternating voltage perturbation to an electrode while measuring the resulting current over a range of frequencies [

156]. This enables the deconvolution of interfacial processes such as charge transfer resistance, double-layer capacitance, and diffusional impedance, which collectively govern the sensor’s response characteristics. EIS is particularly powerful for probing the kinetics of redox reactions at sensor surfaces, as well as for evaluating the properties of thin films, modified electrodes, and nanostructured interfaces. In biosensing applications, for instance, EIS has been widely used in label-free detection platforms, where the binding of analytes such as proteins or DNA strands to recognition elements like aptamers or antibodies induces measurable changes in the charge transfer resistance and capacitance at the electrode–electrolyte interface [

157]. This principle underpins many modern impedimetric biosensors that achieve detection limits down to the femtomolar range for biomarkers relevant to cancer diagnosis or infectious disease monitoring [

157]. Moreover, EIS is essential for evaluating the stability and reproducibility of sensing interfaces, providing insights into degradation mechanisms under repeated analyte exposure or mechanical stress, particularly in wearable sensors [

158].

Voltammetry, encompassing cyclic voltammetry (CV), differential pulse voltammetry (DPV), and square-wave voltammetry (SWV), is extensively employed to characterize the redox behavior of sensing materials and quantify analyte concentrations [

159]. CV is particularly useful for obtaining qualitative information regarding redox reversibility, diffusion coefficients, and electron transfer kinetics. For example, it allows the evaluation of the electroactive surface area of modified electrodes, which directly correlates with sensitivity in amperometric detection [

160]. DPV and SWV, on the other hand, offer enhanced analytical sensitivity by minimizing capacitive background currents, making them suitable for trace detection of analytes such as heavy metals, pharmaceuticals, and neurotransmitters [

161]. In chemical sensors employing carbon-based nanomaterials, voltammetry provides crucial evidence of successful material functionalization, as observed through shifts in peak potentials or enhanced current densities corresponding to increased electron transfer rates [

133]. Furthermore, voltammetry is instrumental in evaluating selectivity by enabling the simultaneous detection of multiple analytes based on their distinct oxidation or reduction potentials, a feature particularly valuable in complex biological or environmental matrices [

162].

Amperometry remains a cornerstone technique for chemical sensors due to its simplicity, rapid response, and suitability for real-time continuous monitoring [

163]. By applying a constant potential and measuring the resulting current, amperometry directly quantifies analyte concentrations based on Faradaic processes at the electrode surface. This approach underpins classic enzymatic biosensors, such as glucose sensors, where the enzymatic reaction produces an electroactive species (e.g. H₂O₂) that is oxidized at the electrode, generating a current proportional to glucose concentration [

159]. Recent developments in amperometric sensors have leveraged nanostructured electrodes incorporating materials like gold nanoparticles, carbon nanotubes, and graphene to enhance electron transfer kinetics, increase electroactive surface area, and lower detection limits [

158]. The integration of amperometric sensors into flexible and stretchable platforms has enabled their use in wearable devices for non-invasive monitoring of biomarkers in sweat, tears, or interstitial fluid, with demonstrated applications in personalized healthcare and fitness tracking [

139].

Key performance metrics evaluated using these electrochemical techniques include limit of detection (LOD), selectivity, and response/recovery time. The LOD defines the lowest analyte concentration that can be reliably distinguished from noise, often determined using DPV or EIS due to their high signal-to-noise ratios [

157]. Recent advances in nanomaterial-modified electrodes and surface engineering have enabled electrochemical sensors to achieve LODs in the picomolar to femtomolar ranges, supporting ultra-sensitive detection of biomarkers or environmental pollutants [

157]. Selectivity, essential for sensor reliability in complex matrices, is assessed by comparing responses to target analytes against potential interferents. This is achieved through material functionalization strategies that incorporate selective recognition elements, tuning of operating potentials to minimize interference, or leveraging the distinct electrochemical signatures provided by voltammetric methods [

162]. Response time, defined as the interval required to reach 90% of the steady-state signal upon analyte exposure, and recovery time, representing the duration for the sensor to return to baseline after analyte removal, are critical for real-time monitoring applications. Rapid response and recovery are particularly valued in wearable and environmental sensors where dynamic changes in analyte concentrations must be captured accurately [

139]. Electrochemical characterization not only validates sensor functionality but also guides rational design and optimization by revealing fundamental insights into material properties, interface stability, and transduction mechanisms. The integration of electrochemical methods with microfabrication, flexible electronics, and wireless data acquisition systems is accelerating the development of next-generation wearable, implantable, and portable chemical sensors with high sensitivity, selectivity, and operational stability. Future directions are expected to focus on the combination of electrochemical techniques with optical, spectroscopic, and mass-based transduction in hybrid multimodal platforms, further enhancing analytical performance for diverse applications in health, environmental monitoring, and industrial process control [

139].

4.3. In-Field and Real-Time Validation

The ultimate goal of chemical sensor development lies in their successful deployment for in-field and real-time applications, which requires rigorous validation under operational conditions. Laboratory-based characterization provides fundamental insights into sensor behavior; however, translation to real-world environments necessitates additional assessments of robustness, reliability, and practicality. Deployment protocols are crucial to ensure standardized testing and reliable performance data across diverse field conditions. These protocols typically include pre-deployment calibration using known standards, validation against established analytical techniques (e.g. ICP-MS for metal ion sensors, HPLC for organic analytes), and controlled exposure tests under simulated field environments. For environmental monitoring sensors, deployment often involves integration into flow systems, drones, buoys, or wearable patches, depending on target analytes and application contexts [

164]. For example, heavy metal ion sensors designed for river monitoring are commonly tested within flow-through cells or directly submerged, with periodic sampling for laboratory validation [

165].

Environmental robustness is a critical parameter determining sensor suitability for real-time deployment. Sensors must maintain performance under fluctuating temperature, humidity, light exposure, and mechanical stresses. In the case of wearable chemical sensors, mechanical deformation such as bending or stretching during body movements can affect signal stability. Strategies to enhance robustness include encapsulation with permeable protective coatings, use of intrinsically flexible substrates (e.g. PDMS, Ecoflex), and integration of strain-insensitive electrode architectures [

166]. For environmental sensors, robustness also entails resistance to biofouling, sediment accumulation, and chemical interferences from complex matrices, often addressed by incorporating antifouling coatings or selective membranes [

167,

168].

Calibration methods are indispensable for accurate and reproducible measurements in the field. Traditional calibration approaches involve laboratory-based standard curves, which may not account for matrix effects or environmental variabilities. To address this, in situ calibration methods such as standard addition protocols, internal standards, or automatic on-board calibration using stored standards have been employed [

169]. Calibration methods, including on-chip standard addition and drift correction strategies, are critical for ensuring accuracy and stability in field-deployed and wearable sensor platforms [

170]. Recent advances in real-time calibration leverage machine learning models trained on large datasets to dynamically adjust calibration curves, compensating for environmental factors such as temperature, humidity, or pH variations, thereby enhancing measurement accuracy under variable conditions [

171].

Successful in-field validation also requires assessment of sensor response and recovery times under realistic analyte concentration changes, long-term stability over operational periods ranging from days to months, and evaluation of power consumption and data transmission reliability in wireless or remote sensing platforms [

136]. For instance, wearable sweat sensors must demonstrate continuous operation over multiple hours with minimal signal drift, while environmental VOC sensors deployed on drones require rapid stabilization times to enable spatial mapping of analyte distributions during flight [

172].

Finally, deployment studies often include user feedback and operational feasibility analysis, particularly for wearable and point-of-care devices, to ensure ergonomic design, user comfort, and minimal interference with daily activities or workflows. The integration of sensors with data processing units, wireless transmission modules, and user interfaces further determines their practical utility in real-world settings [

139]. In-field and real-time validation bridges the gap between laboratory innovation and impactful application, requiring interdisciplinary approaches that combine materials science, device engineering, data analytics, and user-centered design to ensure that chemical sensors fulfill their intended societal and environmental roles effectively. These insights not only support the rational design of advanced sensors but also enable their successful deployment in critical real-world scenarios. The following section explores how these technologies are currently being applied across major sectors in the United States.

5. Application Domains in the United States

The practical impact of chemical sensors is ultimately measured by their performance in real-world settings. In recent years, the United States has led numerous efforts to translate advances in materials, fabrication, and characterization into field-deployable sensing systems. These systems address critical national priorities such as environmental protection, public health, food safety, industrial optimization, and smart infrastructure. This section highlights the major application domains where chemical sensors are currently being implemented across the U.S., providing representative examples of how cutting-edge technologies are shaping decision-making, regulatory compliance, and societal outcomes.

5.1. Environmental Monitoring

Environmental monitoring represents a critical and expanding application domain for chemical sensors in the United States, driven by the need to assess and manage risks associated with anthropogenic and natural sources of pollution. Chemical sensors provide real-time, in situ, and often low-cost alternatives or complements to traditional analytical techniques such as gas chromatography-mass spectrometry (GC-MS) or inductively coupled plasma mass spectrometry (ICP-MS), enabling continuous monitoring across wide geographic areas.

Air quality monitoring has seen substantial integration of chemical sensors to detect gaseous pollutants such as nitrogen oxides (NOₓ), sulfur dioxide (SO₂), ozone (O₃), carbon monoxide (CO), and volatile organic compounds (VOCs), as well as particulate matter (PM) fractions including PM₁₀ and PM₂.₅ [

173]. The traditional paradigm relies on fixed-site regulatory monitoring stations equipped with highly accurate reference analyzers, which, while providing robust data, suffer from limited spatial resolution due to installation and maintenance costs [

174]. To address this, low-cost sensor networks based on electrochemical, metal oxide semiconductor (MOS), or optical sensing principles are being deployed to provide high-resolution pollutant mapping. For instance, MOS-based NO₂ and O₃ sensors have been mounted on public transport vehicles and bicycle fleets to map urban air quality with unprecedented spatial granularity [

175]. Similarly, VOC sensors based on photoionization detection and metal oxide arrays have been utilized for monitoring industrial emissions and detecting hazardous leaks.

Particulate matter monitoring has also advanced significantly through optical particle counters (OPCs) employing light scattering techniques. These sensors, while requiring frequent calibration and correction for humidity effects, offer compact and energy-efficient solutions for personal exposure monitoring, enabling epidemiological studies linking PM exposure to cardiovascular and respiratory diseases [

176]. Portable PM₂.₅ sensors have been validated for personal exposure assessments and indoor air monitoring, although calibration and drift correction remain critical challenges [

177]. Integration of PM sensors into UAVs has further expanded their application, enabling aerial mapping of smoke plumes, assessment of pollutant dispersion models, and optimization of emergency response efforts [

172].

Water quality monitoring employs chemical sensors to detect a broad spectrum of contaminants including heavy metals such as lead (Pb), arsenic (As), mercury (Hg), and cadmium (Cd), as well as nitrates, phosphates, and organic micropollutants such as pesticides, pharmaceuticals, and endocrine disruptors [

178]. Electrochemical sensors based on anodic stripping voltammetry (ASV) with bismuth or gold nanoparticle-modified electrodes have demonstrated high sensitivity and low detection limits for trace metal analysis, facilitating rapid on-site measurements that are critical in contamination events such as lead leaching in municipal water systems [

179]. Citizen sensing initiatives have transformed environmental monitoring by empowering communities with low-cost sensors, though challenges in calibration and data interpretation remain [

173].

Structured citizen science frameworks and participatory environmental monitoring programs have greatly enhanced public engagement and expanded data collection for air quality assessments in the United States [

180]. These platforms are designed for long-term deployment in surface waters, stormwater systems, and wastewater treatment facilities, supporting regulatory compliance, pollutant source identification, and assessment of remediation efficacy.

Recent advances in low-cost air quality monitoring tools have facilitated their adoption in community-based sensing programs, bridging research and public engagement for environmental health assessments [

181]. Socioeconomic disparities in air pollution exposure highlight the importance of integrating environmental justice considerations into sensor deployment and monitoring strategies [

182].

Wildfire monitoring represents a rapidly growing area of sensor application due to the health impacts of smoke exposure, which include exacerbation of asthma, cardiovascular events, and increased mortality rates [

183]. Chemical sensors deployed during wildfire events measure smoke-associated pollutants such as VOCs, CO, and PM₂.₅, providing real-time exposure data for public health agencies and supporting epidemiological studies on respiratory outcomes [

184]. Integration of sensors into autonomous platforms such as drones and stationary sensor networks facilitates rapid mapping of pollutant dispersion, identification of fire hotspots, and evaluation of containment strategies [

185]. Additionally, research initiatives are exploring the deployment of chemical sensors for early detection of wildfire ignition through monitoring of combustion gases and thermal signatures, contributing to rapid response systems [

186,

187].

The deployment of chemical sensors for environmental monitoring in the United States is further supported by interdisciplinary collaborations involving federal agencies, academic institutions, private companies, and community organizations. These collaborations facilitate technology transfer, ensure adherence to quality standards, and accelerate the adoption of sensor data in regulatory frameworks and environmental management practices [

188].

Future directions in environmental monitoring include the development of calibration-free or self-calibrating sensors that maintain accuracy under variable environmental conditions, integration of sensor data streams with artificial intelligence and machine learning models for predictive pollution mapping, and expansion of sensor networks into underserved and rural areas to address environmental justice disparities. Advances in material science, nanotechnology, and data analytics will continue to drive innovation in sensor sensitivity, selectivity, and durability, enhancing their impact on public health protection, ecosystem conservation, and climate resilience.

5.2. Healthcare and Biomedical Diagnostics

The application of chemical sensors in healthcare and biomedical diagnostics has advanced significantly over the past decade, driven by the demand for rapid, non-invasive, and personalized monitoring tools that enable early disease detection, therapy optimization, and improved patient outcomes. Among the biological fluids targeted for chemical sensing, breath, sweat, and saliva have emerged as attractive matrices due to their accessibility, minimal invasiveness, and rich biochemical information reflective of systemic health status.

Breath analysis has attracted substantial interest for the detection of volatile organic compounds (VOCs) and gaseous biomarkers associated with metabolic and respiratory diseases [

189]. Exhaled nitric oxide (NO) is an established biomarker for airway inflammation in asthma, measured using chemiluminescent and electrochemical sensors to guide corticosteroid therapy adjustments [

190]. Furthermore, acetone detection in breath has been explored as a non-invasive diagnostic for diabetes mellitus, as breath acetone levels correlate with blood ketone bodies produced during altered glucose metabolism [

191] The clinical potential of exhaled breath analysis for diabetes mellitus. Metal oxide semiconductor (MOS) sensors, quartz crystal microbalance (QCM) devices, and colorimetric sensor arrays have been developed for these applications, with recent advances focusing on enhancing selectivity through nanostructured sensing films, molecularly imprinted polymers, or catalytic filters that minimize cross-interferences from humidity and other VOCs [

192].

Sweat analysis offers another promising avenue for continuous health monitoring. Sweat contains electrolytes such as sodium, potassium, and chloride, as well as metabolites including glucose, lactate, and urea, which reflect hydration status, metabolic activity, and renal function [

193]. Flexible electrochemical sensors integrated onto wearable platforms, including epidermal patches and textile-based devices, have enabled real-time monitoring of sweat analytes during exercise, occupational tasks, or daily activities [

194]. For instance, lactate sensors based on enzyme-functionalized electrodes provide insights into anaerobic threshold and muscle fatigue, relevant for athletic performance optimization [

136]. Glucose sensors for sweat have been investigated as potential non-invasive alternatives to blood glucose monitoring in diabetes management, although challenges remain due to the low and variable concentrations of glucose in sweat compared to blood [

195]. Strategies such as sweat induction via iontophoresis, signal amplification using nanomaterials, and incorporation of microfluidic sweat collection channels are being developed to improve detection limits and sampling efficiency [

196].

Saliva-based sensing has gained attention for its potential in monitoring a wide range of analytes, including hormones (e.g., cortisol), electrolytes, metabolites, and pathogens [

197]. In the United States, saliva has been validated as a reliable and non-invasive matrix for SARS-CoV-2 detection, supporting its integration into diagnostic and surveillance protocols [

198]. Additionally, saliva offers a medium for rapid viral detection, as demonstrated during the COVID-19 pandemic, where lateral flow assays and electrochemical sensors were adapted for SARS-CoV-2 antigen and antibody detection [

199]. The integration of saliva sensors into mouthguards or intraoral devices has further expanded their application prospects for continuous monitoring in sports medicine and chronic disease management [

200].

The broader paradigm of non-invasive biosensing aligns with the principles of personalized medicine, enabling tailored healthcare interventions based on an individual's real-time biochemical profile [

201]. Wearable and implantable sensors capable of continuously tracking physiological and biochemical parameters can inform early diagnosis, optimize drug dosing, and detect adverse responses before clinical symptoms manifest [

202]. For example, wearable platforms integrating sweat glucose sensors with transdermal insulin delivery modules represent a closed-loop system for diabetes management under investigation [