Submitted:

30 July 2025

Posted:

31 July 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

2.1. Maintenance Versus Key Performance Indicators (KPIs)

2.2. Fleet and Reserve Fleet Dimensions

3. Cases Studies

3.1. Trevim Fire

3.2. Case of the Serra da Estrela Fire

3.3. Semide 2017, Fire

3.4. Crash of a Poorly Fixed Element Boeing CH-47 Chinookum

3.5. Crash of the FireHawk Helicopter in Florida

3.6. Crash of the Helicopter in Douro, 2024

4. Analysis of the Availability Time of the Helicopters of Firefighting and Maintenance Fleet Management

4.1. Helicopter Operational Fleet Management

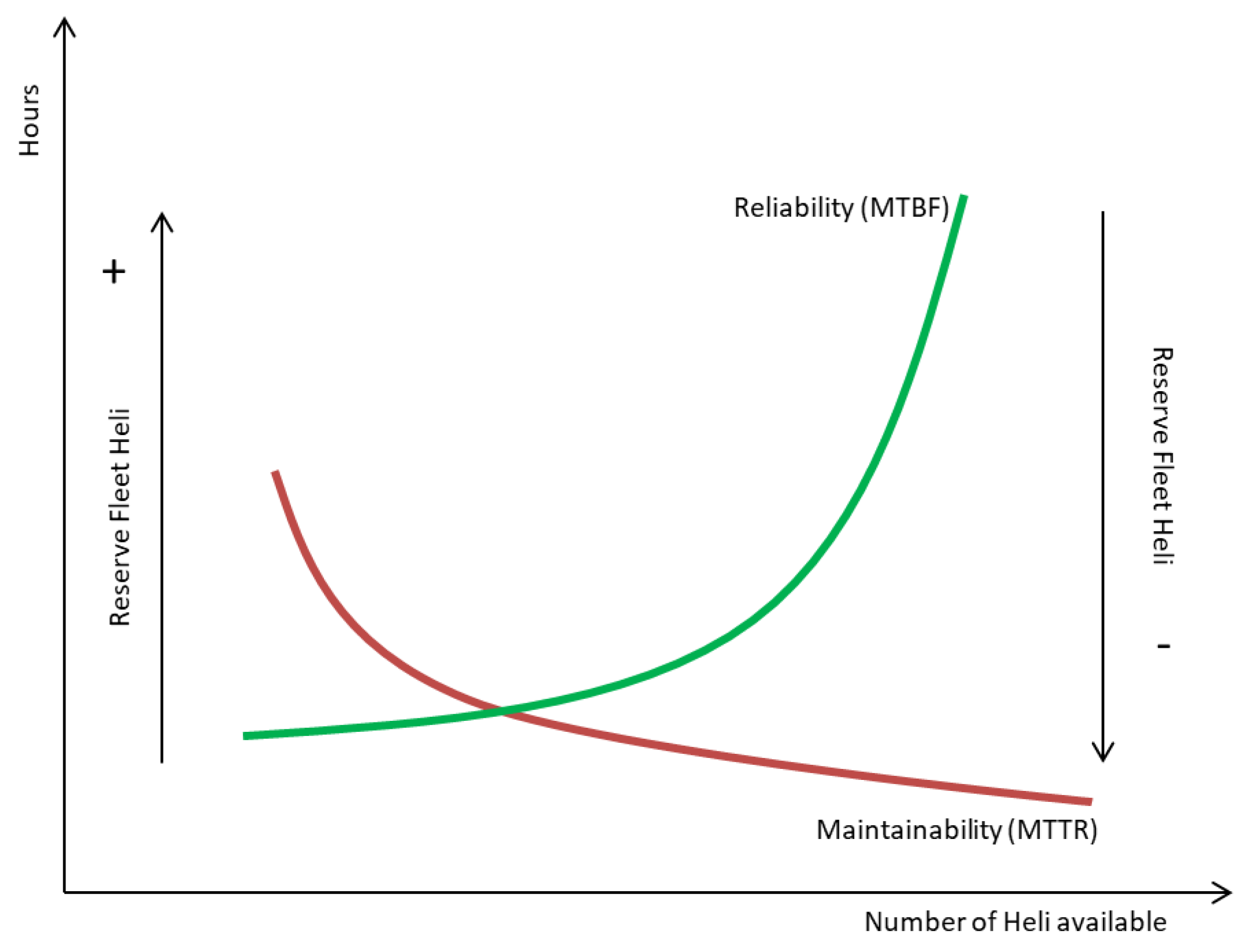

4.2. Maintenance Versus Reserve Fleet Helicopters

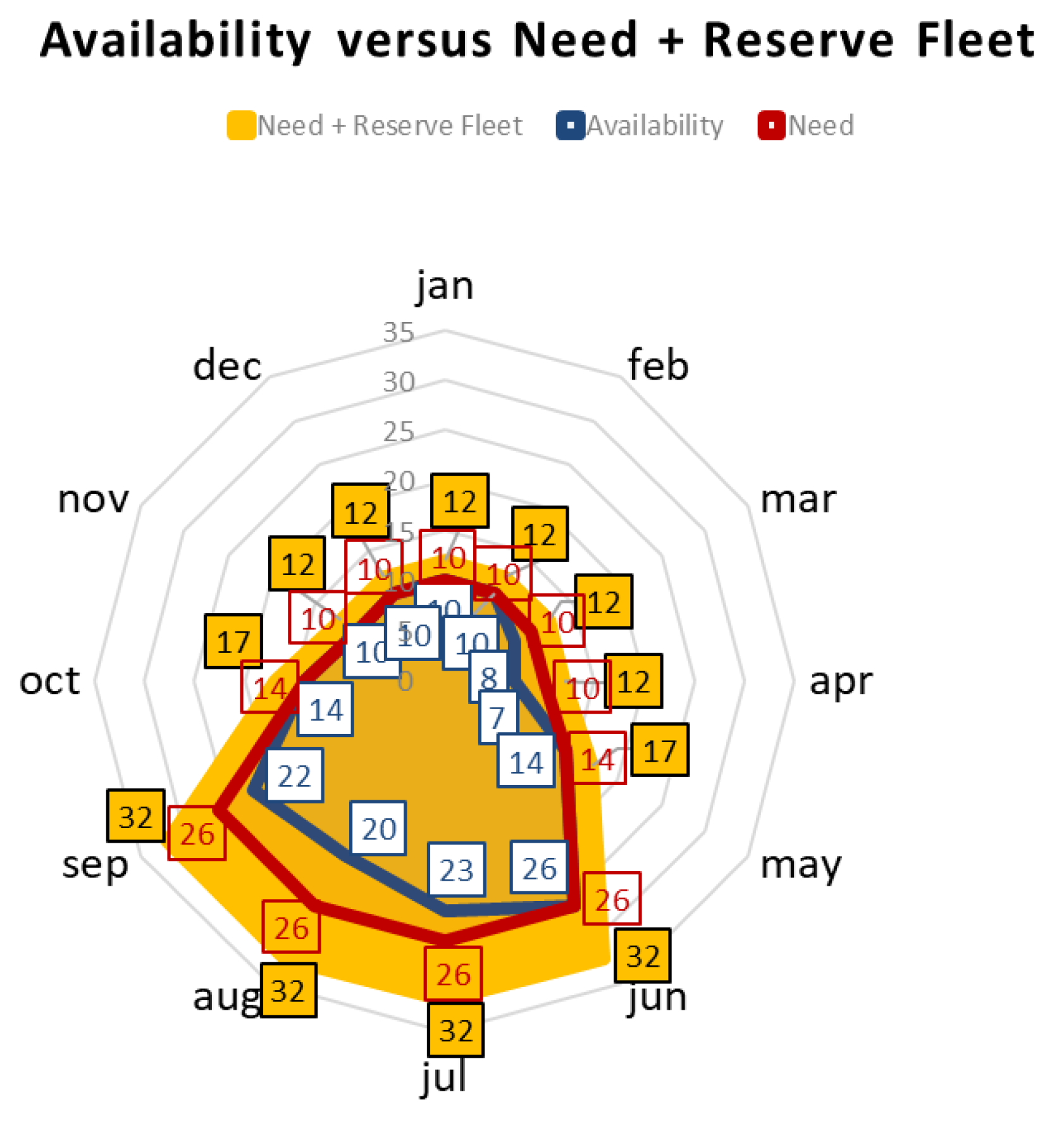

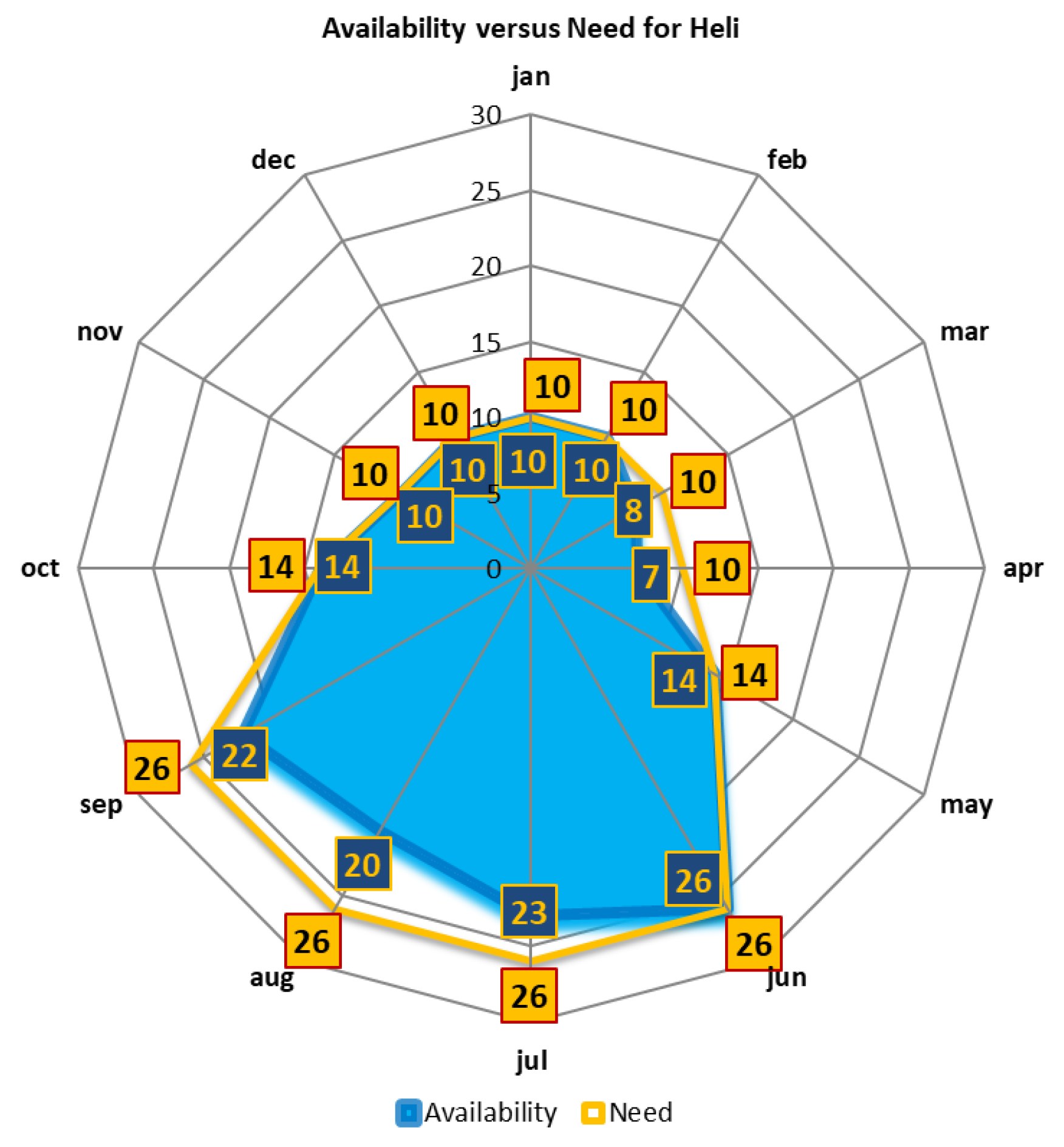

- Helicopters Available will change from 10 to 26 helicopters depending on the periods of the year , depending also from maintenance and from the need due to the danger of fire.

- Firefighting helicopter repair times can vary depending on the type of maintenance required. Here are some examples: Line/Baseline Inspections: These inspections are typically quick and can be completed in a few hours to a day.

- Preventative Maintenance: Includes regular checks and replacement of worn parts, which can take from a few days to a week.

- Component Repairs: When major components such as engines or hydraulic systems need to be replaced or repaired, repair times can range from one to several weeks.

- Biennial Inspections: Full inspections, such as those performed, can take approximately 10 weeks to complete.

- Parts Availability: How quickly replacement parts can be obtained can significantly impact repair time.

- Problem Complexity: More complex problems or extensive damage may require more time to resolve.

- Workshop Capacity: The capacity and efficiency of the maintenance workshop also influences the time required to complete repairs.

- These times are estimates and may vary depending on the specific circumstances of each repair.

-

Operating costs may vary, but based on previous contracts we can make an estimate. For example, HeliBravo [31] supplied four light helicopters for 350 000 euros for 25 flight hours per aircraft. If we apply this cost to the 26 helicopters:

- ○

- 350 thousand euros / 4 helicopters = 87.5 thousand euros per helicopter

- ○

- 87.5 thousand euros x 7 helicopters = 612,5 thousand euros for 25 flight hours for each of the 10 helicopters

- ○

- 87.5 thousand euros x 11 helicopters = 962,5 thousand euros for 25 flight hours for each of the 10 helicopters

- ○

- 87.5 thousand euros x 26 helicopters = 2.275 million euros for 25 flight hours for each of the 26 helicopters.

- These values are estimates and may vary depending on specific operating and maintenance conditions.

5. Conclusions

References

- Viegas, D.X.; Raposo, J.R.; Davim, D.A.; Rossa, C.G. Study of the jump fire produced by the interaction of two oblique fire fronts. Part 1. Analytical model and validation with no-slope laboratory experiments. Int. J. Wildland Fire 2012, 21, 843–856. [Google Scholar] [CrossRef]

- Raposo, J.R.; Viegas, D.X.; Xie, X.; Almeida, M.; Figueiredo, A.R.; Porto, L.; Sharples, J. Analysis of the physical processes associated with junction fires at laboratory and field scales. Int. J. Wildland Fire 2018, 27, 52–68. [Google Scholar] [CrossRef]

- Trincão, M. O que é a gestão da manutenção? Em Cegid Primavera, 2021. https://pt.primaverabss.com/pt/blog/gestao-da-manutencao/.

- Pereira, P. M. de S. Planos de Manutenção Preventiva Manutenção de Equipamentos Variáveis na BA Vidro, SA. Faculdade de Engenharia da Universidade do Porto, 2009.

- Xanthopoulos, G.; Mariano Delogu, G.; Leone, V.; Correia, F.J.M.; Magalhães, C. Firefighting approaches and extreme wildfires. firefighting-approaches-and-extreme-wildfires, 2020, 9780128157213.

- Zhou, T.J.; Lu, J.Z.; Wu, C.P. Numerical Calculation and Analysis of Water Dump Distribution Out of the Belly Tanks of Firefighting Helicopters. Safety 2022, 8, 69. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Fonseca, I.; Ferreira, L.A. Condition monitoring with prediction based on diesel engine oil analysis: A case study for urban buses. Actuators 2019, 8, 14. [Google Scholar] [CrossRef]

- Alander, J.; Honkasilta, L.; Saastamoinen, K. Simulating the Aerial Ballet: The Dance of Fire-Fighting Planes and Helicopters. Eng. Proc. 2024, 68, 54. [Google Scholar] [CrossRef]

- Raley, K.; Hamilton, J. Radiant Heat in Wildland Fire Suppression Operations Area of Concern: Flight Safety, 2020. OAS-43A (12/12).

- Longline, Vs. Shortline—Helicopters Magazine, n.d. Available online: https://www.helicoptersmagazine.com/longline-vs-shortline-148/ (accessed on 19 July 2024).

- NP EN 13306:2021: Terminologia da Manutenção. Instituto Português da Qualidade (IPQ), 2021.

- Farinha, J.M.T. Asset Maintenance Engineering Methodologies, (In English). Printed in USA, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018; ISBN -13: 978-1138035898. [Google Scholar]

- Silva, F.; Raposo, J.; Farinha, J.T.; Raposo, H.; Reis, L. Study of the Condition of Forest Fire Fighting Vehicles. Fire 2023, 6, 274. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Ferreira, L.; Galar, D. An integrated econometric model for bus replacement and determination of reserve fleet size based on predictive maintenance. Eksploatacja i Niezawodnosc 2017, 19, 358–368. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Ferreira, L.; Galar, D. Reserve Fleet Indexed to Exogenous Cost Variables. Transport 2019, 34, 437–454. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Ferreira, L.; Galar, D. Dimensioning reserve bus fleet using life cycle cost models and condition based/predictive maintenance: a case study. Public Transport 2018, 10, 169–190. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Pais, E.; Galar, D. An Integrated Model for Dimensioning the Reserve Fleet based on the Maintenance Policy. WSEAS Trans. Syst. Control 2021, 16, 43–65. [Google Scholar] [CrossRef]

- Negi, P.; Pathani, A.; Bhatt, B.C.; Swami, S.; Singh, R.; Gehlot, A.; Thakur, A.K.; Gupta, L.R.; Priyadarshi, N.; Twala, B.; et al. Integration of Industry 4.0 Technologies in Fire and Safety Management. Fire 2024, 7, 335. [Google Scholar] [CrossRef]

- Lu, J.; Zhou, T.; Wu, C.; Ou, Y. Dropping Fire Retardants by Helicopter and Its Application to Wildfire Prevention near Electrical Transmission Lines. Fire 2023, 6, 176. [Google Scholar] [CrossRef]

- Xia, Y.; Guo, Q.; Lei, L.; Wu, J.; Su, X.; Wu, J. Research on Fuzzy Comprehensive Evaluation of Fire Safety Risk of Battery Pack Production Process Based on DEMATEL-ANP Method. Fire 2025, 8, 31. [Google Scholar] [CrossRef]

- Alkhammash, E.H. Leveraging Large Language Models for Enhanced Classification and Analysis: Fire Incidents Case Study. Fire 2025, 8, 7. [Google Scholar] [CrossRef]

- Freixo, V. Scientific Methodology: Fundamentals, Methods and Techniques, 3rd ed.; Instituto Piaget: Lisboa, 2011. [Google Scholar]

- NP EN 15341:2019; Manutenção—Indicadores de desempenho da manutenção (KPI). Instituto Português da Qualidade (IPQ), 2019.

- Raposo, H.; Farinha, J.T.; Fonseca, I.; Galar, D. Predicting condition based on oil analysis—A case study. Tribol. Int. 2019, 135, 65–74. [Google Scholar] [CrossRef]

- Pediram socorro durante 20 minutos e MAI está a investigar: a história do incêndio que matou um bombeiro e deixou outros quatro feridos—Expresso. Available online: https://expresso.pt/sociedade/2020-07-11-Pediram-socorro-durante-20-minutos-e-MAI-esta-a-investigar-a-historia-do-incendio-que-matou-um-bombeiro-e-deixou-outros-quatro-feridos. (accessed on 8 April 2024).

- Manobra de helicóptero fez ‘perder controlo’ do fogo na Serra da Estrela no verão passado. Available online: https://www.dn.pt/sociedade/manobra-de-helicoptero-fez-perder-controlo-do-fogo-na-serra-da-estrela-no-verao-passado-16172286.html/ (accessed on 8 April 2024).

- iPad caído derrubou helicóptero que combatia incêndios nos EUA. (n.d.). Available online: https://aeroin.net/ipad-caido-derrubou-helicoptero-que-combatia-incendios-nos-eua/ (accessed on 22 July 2024).

- Snorkel hitting rotor blades was likely cause of fatal helicopter crash—Fire Aviation. (n.d.). Available online: https://fireaviation.com/2021/06/10/snorkel-hitting-rotor-blades-was-likely-cause-of-fatal-helicopter-crash/ (accessed on 23 July 2024).

- GPIAAF. Nota informativa de acidente com aeronave—aircraft accident information notice unidade de aviação civil, 2024. https://www.gpiaa.gov.pt/upload/membro.id/ficheiros/i007382.pdfDisclaimer/Publisher’s.

- Strategic analysis of the aviation capacity for the Integrated Management System of Rural Fires in Portugal from 2025, 2024.

- Serviços—Helibravo. (n.d.). Available online: https://helibravo.com/servicos/ (accessed on 27 March 2025).

| Designation | Formulas | Variables |

|---|---|---|

| Availability (A) |

MTBF Mean Time Between Failures MTTR Mean Time to Repair MWT Mean Waiting Time |

|

| Mean Time Between Failures (MTBF) |

|

TBF Good Operating Time |

| Mean Time to Repair (MTTR) |

|

TTR Technical Repair Time. |

| Mean Waiting Time (MWT) | WT Average Waiting Time |

| Designation | Formulas | Variables |

|---|---|---|

| Reserve Fleet (RF) |

|

RF Reserve Fleet; m Number of vehicles that make up the fleet; MTBF Mean Time Between Failure; A Availability; TTR Technical Repair Time; i i=0,1,2,3…n k Number of days/years (365 days). |

| Helicopters Total HEBL |

Period | |||

| Rest of the Year | 15/05—31/05 | 01/06—15/10 | 16/10—31/10 | |

| 10 | 14 | 26 | 14 | |

| 2024 | ||||

| Months | Availability | Need | Maintenance | Reserve Fleet |

| jan | 10 | 10 | 0 | 12 |

| feb | 10 | 10 | 0 | 12 |

| mar | 8 | 10 | -2 | 12 |

| apr | 7 | 10 | -3 | 12 |

| may | 14 | 14 | 0 | 17 |

| jun | 26 | 26 | 0 | 32 |

| jul | 23 | 26 | -3 | 32 |

| aug | 20 | 26 | -6 | 32 |

| sep | 22 | 26 | -4 | 32 |

| oct | 14 | 14 | 0 | 17 |

| nov | 10 | 10 | 0 | 12 |

| dec | 10 | 10 | 0 | 12 |

| MTTR [Hours] | Heli Fleet [m] | Reserve Fleet [RF] | Interval [RF] |

| 8 | 26 | 0 | [1,1] |

| 15 | 26 | 0 | [1,1] |

| 23 | 26 | 1 | [1,2] |

| 39 | 26 | 1 | [1,2] |

| 83 | 26 | 2 | [2,3] |

| 132 | 26 | 3 | [3,4] |

| 188 | 26 | 5 | [4,5] |

| 250 | 26 | 7 | [6,7] |

| 300 | 26 | 8 | [7,8] |

| Type | Guide suggestion |

|---|---|

| Deployment of heli-transported teams | Caution! The indraft of air of the helicopter. Do not fly in way to interact with the fire behavior which can affect the teams in the ground. it is recommended that the team be recovered in an area far enough away from the fire front. |

| Helicopters in moop-up | Warning! These operations are not the suitable for this type of machines. |

| Equipment that is incorporated in the helicopters | Attention! It is recommended that operators and management discuss the use of these devices with the maintenance teams and mechanics to discuss the best way and place to attach them safely and the best way of performing the maintenance |

| Training | Consider the lack of training offered to the pilots and crew for the specific exercise of firefighting activity and for safety issues. |

| Availability versus maintenance | Helicopters Available will change depending on the periods of the year due to maintenance and from the need demanded by the danger of fire. Firefighting helicopter repair times can vary depending on the type of maintenance required. When major components such as engines or hydraulic systems need to be replaced or repaired, repair times can range from one to several weeks and this will demand larger RF. RF (fleet reserve) refers to helicopters that are available for operations and cannot be considered assets. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).