Introduction

Supply Chain Management (SCM) is widely acknowledged as a foundational support of organizational performance, sustaining the seamless integration of activities across suppliers, manufacturers, distributors, and end customers. In an increasingly globalized and volatile business environment, firms face increasing pressure to streamline their supply chain processes to sustain competitiveness, enhance agility, and respond effectively to shifting market dynamics (Yasmin, 2023; Hernández, 2023). Furthermore, sustainable logistics practices are increasingly reinforced by the integration of information systems. Recent studies (Stroumpoulis et al., 2024) (Stroumpoulis et al., 2021) show that aligning digital technologies such as IOS and B2B integration with sustainability strategies enhances traceability—particularly in reverse logistics— and contributes to more efficient resource utilization. This alignment supports the development of environmentally responsible, economically viable, and socially equitable supply chains. Therefore, embedding sustainability into digital transformation efforts is not only a value-driven initiative but also a strategic necessity for building long-term resilience and competitive advantage

Among the key enablers of high-performing supply chains is effective collaboration between partners. Collaborative relationships enhance efficiency, facilitate risk sharing, and improve responsiveness to shifting market demands (Baah et al. 2022). Achieving such collaboration necessitates a foundation of mutual trust, open communication, and a shared commitment to common objectives (Moatari-Kazerouni, Antonucci, and Kirchmer, 2025). To enable and support this level of collaboration, firms are increasingly leveraging digital technologies—most notably, Inter-Organizational Systems (IOS). IOS are digital platforms that facilitate real-time data exchange between business partners, improving coordination, visibility, and strategic decision-making. As highlighted by Zhang and Cao (2017), IOS plays a pivotal role in reducing operational costs and improving overall supply chain efficiency. These systems enable firms to monitor, manage, and optimize supply chain operations with greater precision, thereby supporting long-term sustainability. By ensuring the timely and accurate flow of critical information, IOS improves responsiveness and strengthens the strategic competitiveness of supply networks. In this regard, the adoption of IOS contributes significantly to Supply Chain Performance (SCP) by streamlining coordination, minimizing errors, and optimizing inventory management (Anwar, 2022).

In addition to IOS, Business-to-Business (B2B) integration serves as a complementary technological enabler that translates digital connectivity into operational outcomes. While IOS provides the infrastructure for real-time data exchange and inter-firm visibility, B2B integration focuses on embedding this connectivity into core business processes, such as invoicing, procurement, inventory management, and logistics coordination. Through standardized data formats and automated workflows, B2B integration enhances the accuracy, speed, and reliability of inter-organizational transactions (Penttinen et al., 2018).

Moreover, B2B integration strengthens the collaborative potential of IOS by facilitating synchronized planning, joint decision-making, and shared access to critical information. This creates a more agile and responsive supply chain ecosystem in which partners can quickly align operations and adapt to disruptions.

By promoting seamless communication and real-time information sharing, IOS enhances collaboration across the supply chain, while B2B integration complements this by increasing transactional transparency and enabling real-time order tracking. Together, these technologies streamline operations, foster responsiveness, and build lasting customer trust and satisfaction (Kowalkowski and Ulaga, 2024).

In light of the strategic impact of IOS and B2B integration, this study is anchored in the Resource-Based View (RBV), which posits that firms gain sustainable competitive advantage by leveraging internal resources that are valuable, rare, inimitable, and non-substitutable (Asamoah et al., 2019). Within this framework, IOS and B2B integration are not merely tools, but strategically embedded capabilities that—when integrated with organizational routines and partner relationships—offer firms distinctive advantages that are difficult for competitors to imitate.

Anchoring the study in RBV not only emphasizes the role of IOS and B2B integration as sources of operational efficiency but also underscores their potential as unique strategic assets, especially in emerging markets such as Palestine. The Palestinian automotive spare parts sector plays a vital role in vehicle maintenance and after-sales services, yet it faces significant challenges, including economic instability, overdependence on international suppliers, and fragmented supply chain operations. These issues are compounded by inefficient coordination among sales, warehousing, and procurement functions, often resulting in delays, inventory shortages, and reduced customer satisfaction.

Despite these challenges, the sector has experienced notable growth. According to the Palestinian Central Bureau of Statistics (PCBS, 2022), the number of vehicles in Palestine has increased by 115% over the past decade, directly fueling the demand for maintenance and replacement parts. This growth underscores the critical role of the automotive spare parts industry in supporting the broader automotive sector.

To address these challenges and capitalize on sector growth, the strategic adoption of IOS and B2B integration is vital. These technologies reduce inefficiencies, improve visibility, and enhance customer satisfaction—cornerstones of supply chain performance. When deeply embedded, these technologies promote transparency and coordination—two pillars essential for gaining customer trust and maintaining a competitive edge.

This study aims to address the following questions:

How does IOS adoption impact Supply Chain Performance (SCP)?

What is the effect of IOS adoption on B2B integration within the supply chain?

How does B2B integration influence SCP?

Does B2B integration mediate the relationship between IOS adoption and SCP, and if so, how?

By addressing these questions, this study aims to provide actionable insights for practitioners, policymakers, and scholars. The findings aim to guide strategic decisions related to digital adoption and collaboration, ultimately supporting more resilient and competitive supply chains in Palestine’s automotive spare parts industry.

2. Theoretical framework

2.1. Supply Chain Management (SCM)

Supply Chain Management (SCM) has been defined in various ways across the literature. For instance, Kain and Verma (2018, p. 3813) describe SCM as "a system of organizations, people, activities, information, and resources moving a product or service from supplier to customer," emphasizing the transformation of natural resources, raw materials, and components into finished products delivered to end customers. Similarly, Ramos et al. (2020, p. 119) define SCM as “an internal process that drives the firm toward future integrations.” Lambert and Enz (2017, p. 5) provide a broader definition, viewing SCM as “the management of relationships in the network of organizations, from end customers through original suppliers, utilizing key cross-functional business processes to create value for customers and other stakeholders.”

For this study, we adopt Ramos et al.’s (2020) definition, emphasizing SCM as an internal process that fosters integration within the firm—an approach aligned with our focus on integration as a key factor in effective SCM. SCM aims to ensure end-to-end integration across organizational functions, optimizing both internal and external interactions, and thus enhancing customer experience and overall performance (Asamoah et al., 2019). A critical capability under SCM is supply chain flexibility, defined as the firm’s ability to swiftly adjust operations—for example, by adopting flexible production systems to swiftly adapt to changing market demands (Gupta et al., 2019; Richey et al., 2022). Moreover, real-time visibility into demand and inventory data plays an essential role in improving forecasting accuracy and delivery performance (Somapa et al., 2018).

In recent years, there has been a growing emphasis on Sustainable Supply Chain Management (SSCM), especially due to increased societal awareness and the impacts of global events such as the COVID-19 pandemic. Stakeholders now expect companies and their partners to adopt environmentally and socially responsible practices throughout the supply chain. SSCM can offer numerous benefits, including cost savings, enhanced environmental performance, and competitive advantage. However, while much research has focused on environmental and economic aspects of sustainability, the social dimension remains underexplored. Furthermore, customers increasingly prefer products from eco-friendly and socially responsible firms, highlighting the importance of sustainability at every level of the supply chain. As a result, leading companies are expected to ensure that their affiliates and suppliers uphold sustainability standards, as their actions directly affect the reputation of the entire supply chain. (Stroumpoulis et al., 2021)

2.2. Supply Chain Performance (SCP)

Supply Chain Performance (SCP) refers to ensuring the timely and accurate delivery of the right product in the right quantity and condition to the intended customer. It is measured using metrics such as delivery reliability, responsiveness, flexibility, cost-effectiveness, and overall operational efficiency (Vern et al., 2024). In the automotive sector, emerging technologies like additive manufacturing (3D printing) enhance supply chain flexibility and responsiveness, especially during early-stage prototyping (Delic & Eyers, 2020).

Key SCP metrics include delivery reliability, responsiveness, flexibility, cost-effectiveness, and customer satisfaction—all fundamental to building customer trust and loyalty (Vern et al., 2024; Achetoui et al., 2019). For example, Al-Doori’s (2019) study on Pakistan's automotive industry found that information systems (IS), joint decision-making (JDM), and electronic data interchange (EDI) significantly improved operational performance by enhancing coordination and efficiency across the supply chain.

2.3. Interorganizational System (IOS)

Information Systems (IS) consist of interconnected components designed to efficiently collect, process, store, and disseminate information. They empower decision-making, facilitate coordination, enforce controls, support analysis, and provide visualization within organizations (Saani, 2019). Patanjal Kumar et al. (2023) argue that digital coordination mechanisms significantly improve sustainable supply chain performance, mirroring our findings in the auto spare parts context. By integrating these functions, IS enhances operational efficiency, strategic planning, and overall performance.

IS plays a crucial role in supporting sustainable capabilities across logistics and supply chain operations. As highlighted by (Stroumpoulis et al., 2024)digital transformation and IS adoption enable logistics providers to improve traceability, resource efficiency, and responsiveness to environmental requirements. These systems facilitate data integration and visibility, which are essential for implementing green logistics and closed-loop supply chains. Thus, IS not only enhances operational performance but also contributes significantly to environmental sustainability in the supply chain context.

Interorganizational Systems (IOS) extend IS by integrating processes across multiple organizations, enabling seamless resource sharing and performance optimization (Anwar, 2022). Zhou et al. (2024) define IOS as “automated information systems shared by two or more organizations designed to link business processes.” IOS supports real-time ordering and interaction among trading partners—such as manufacturers ordering parts from suppliers or retailers requesting inventory from manufacturers (DeLone, McLean & Sedera, 2022).

IOS also supports standardized data formats like XML and JSON. This capability improves coordination, speeds response times, and enhances efficiency across sectors like healthcare and government (Zhou et al., 2024; Anwar, 2022; Cannavale et al., 2022; Chen et al., 2019). In marketing, IOS fosters integrated communication across digital and social media platforms, enabling continuous dialogue and collaboration with partners (Tsou et al., 2019).

Asamoah et al. (2021), drawing on the Resource-Based View (RBV), demonstrate that IOS adoption directly enhances supply chain capabilities and SCP. Specifically, IOS improves coordination, flexibility, responsiveness, and real-time data sharing—capabilities that lead to better supply chain outcomes, such as faster delivery, lower costs, and higher customer satisfaction. From an RBV perspective, these capabilities are valuable, often rare in developing supply chains, and embedded in firm-specific routines—making them difficult to replicate by competitors. Supply chain capabilities thus mediate the relationship between IOS adoption and SCP, meaning IOS boosts SCP not only directly, but also indirectly by enhancing these internal capabilities.

In the automotive parts sector, IOS provides additional benefits such as cost reduction, improved customer relations, and greater operational efficiency. By reducing paper-based processes and administrative burdens, IOS accelerates information flow and enhances responsiveness to customer needs. Automated transaction processing supports continuous production replenishment, reduces data entry errors, and improves data quality and auditability (Tsuguio et al., 2019).

2.4. Business-to-Business (B2B) Integration

Business-to-Business (B2B) platforms facilitate connectivity among trading partners by enabling critical transactions such as invoicing, payments, and data exchange (Filosa et al., 2025). These platforms improve transaction accuracy, reduce procurement costs, accelerate processing times, and optimize inventory management (Loro & Mangiaracina, 2022). B2B platforms cater specifically to companies that sell products or services to other businesses rather than end consumers (Soumena et al., 2024).

B2B Integration is defined as a set of capabilities and resources that enable firms to effectively collaborate and communicate with their trading partners, enhancing the flow of information and resources across the supply chain. Chohan et al. (2023) show that social capital enhances supply chain performance via quality integration mechanisms, shedding light on the relational processes underlying IOS and B2B integration effects. These capabilities include indicators such as:

Trust: Trust forms the cornerstone of business-to-business relationships by creating a cooperative environment that reduces transaction risks and promotes open information sharing (Haghkhah et al., 2020).

Loyalty: Loyalty reflects the commitment of partners to maintain long-term relationships, which supports continuity and joint strategic planning (Hossain et al., 2024; Kim et al., 2024).

Coordination: The ability of parties to organize their joint activities in a synchronized manner to avoid conflicts and improve operational performance (Haghkhah et al., 2020).

Information Exchange: Represents the level of transparency and open communication that allows for timely and data-driven decision making (Alavi et al., 2020; da Silva et al., 2024).

Customer Service: The support provided before, during, and after sales to enhance customer satisfaction and build sustainable relationships (Turban et al., 2015; Bone et al., 2015).

Together, these indicators form a coherent theoretical framework that captures the complex structure of B2B Integration, which is a critical factor for improving supply chain efficiency and effectiveness.

B2B integration plays a critical role in modern supply chain operations by enabling seamless, real-time communication between businesses (Zighan, Al-Salhi & Dwaikat, 2023). It facilitates alignment of internal functions to better understand and meet customer needs. Additionally, B2B integration enhances visibility, allowing firms to track goods flow, monitor inventory levels, and gather production schedule data, thereby improving planning and coordination (Sundram, Chhetri & Bahrin, 2020).

While IOS primarily refers to the technological platforms and information systems that enable seamless data exchange and coordination across organizational boundaries, B2B Integration encompasses a broader scope. B2B Integration includes not only the technological infrastructure provided by IOS but also the relational, organizational, and process-oriented capabilities that facilitate effective collaboration between business partners. In this sense, IOS can be viewed as the foundational technology that supports B2B Integration, whereas B2B Integration represents the strategic utilization of these technologies to build trust, loyalty, coordination, and transparency among partners. Therefore, although IOS and B2B Integration are closely related and interdependent, they are conceptually distinct constructs, with IOS focusing on the technological enablers and B2B Integration emphasizing the organizational and relational outcomes of these technological implementations.

In the automotive sector, B2B platforms revolutionize parts distribution by linking suppliers directly with distributors and workshops, covering pre-sale, ordering, logistics, and after-sales services. Features such as smart catalogs, secure payments, rapid delivery, and responsive support improve efficiency and reach. Furthermore, these platforms add value through data analytics, knowledge sharing, and microcredit facilities (Kosaka et al., 2021).

According to RBV, effective B2B integration constitutes a complex organizational capability—based on trust, loyalty, coordination, and information exchange—that is socially embedded and not easily imitable. These intangible relational resources, once developed, provide a strategic advantage by fostering deeper customer integration and long-term cooperation. In this way, B2B integration acts as a capability that channels the benefits of IOS adoption into measurable supply chain performance improvements.

B2B integration improves supply chain performance in the automotive industry by accelerating invoicing, deliveries, and order fulfillment. IDC highlights that integrated networks enhance efficiency via synchronized operations and seamless data flow. To succeed, manufacturers must pursue market expansion and build more resilient supply chains. They should also adopt advanced IT solutions such as cloud computing and big data analytics. Integration of B2B systems with ERP platforms is critical to fostering collaboration and improving performance (Veronesi, 2017).

While prior studies have examined the impact of IOS adoption on supply chain performance (SCP), the role of B2B integration in this relationship has received limited attention. In particular, the direct effect of IOS adoption on B2B integration lacks sufficient research, and a comprehensive framework linking IOS adoption, B2B integration, and SCP is missing. Accordingly, this study seeks to bridge this research gap by empirically examining the effect of IOS adoption on B2B integration and its subsequent impact on SCP, with a focused application in the Palestinian automotive spare parts industry. The findings are expected to offer valuable theoretical and managerial implications.

2.5. Hypothesis Development

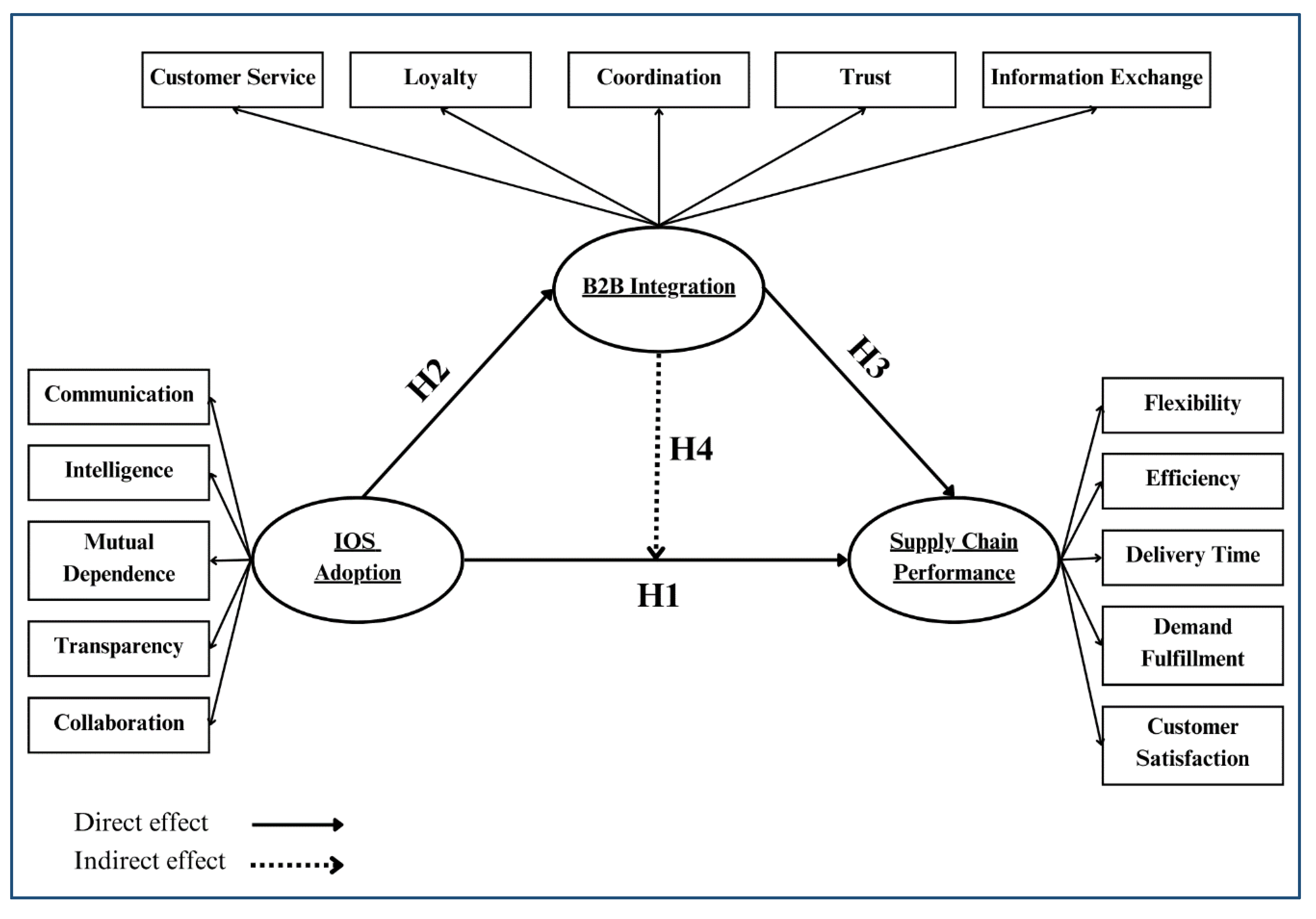

In this regard, Alavi et al., (2020) validate that IOS adoption enhances operational efficiency and strategic advantages in realizing SCP. Besides, Asamoah et al., (2021), evidenced that IOS use directly improves SCP by allowing the development of critical capabilities, such as flexibility, responsiveness, and coordination. Sundram et al., (2020) discussed issues with how IT, IS, and SCP are interconnected; effective use of these technologies, including IOS, significantly improves SCP. All these studies together provide strong empirical evidence to support the hypothesis that IOS adoption significantly improves SCP. Consequently, the adoption of IOS helps to enhance SCP. As a result, hypothesis H1 is formulated:

H1: The adoption of IOS has significant and positive impacts on Supply Chain Performance.

IOS has a significantly positive influence on B2B integration due to the improved communication and cooperation of trading partners. While there is an acknowledgment of the benefits derived from IOS in improving customer integrations, no prior study has explicitly examined the relationship between IOS adoption and B2B integration. Thus, the subsequent hypothesis is proposed:

H2: IOS adoption has a significant and positive effect on the B2B integration

Veronesi (2017) explains that the integration of B2B is effective in enhancing SCP both in the manufacturing and automotive industries. He lists several key improvements, including invoice processing speed, customer order delivery time, and order fulfillment, among others. The implication derived is that the SCP has been observed to be higher when there is greater integration of B2B networks, where the product operation becomes more synchronized and the flow of information is effective. Therefore, the following hypothesis was derived:

H3: B2B integration is positively related to Supply Chain Performance.

Organizations stand a better chance of taking advantage of the B2B integration, with the adoption of IOS, for better collaboration with the supply chain partners, hence performance. Since B2B integration may bring extra benefits by complementing the IOS-adopting firms, it is expected that B2B integration mediates the relationship between IOS adoption and SCP.

H4: B2B integration mediates the impact of IOS adoption on Supply Chain Performance

This study draws on the RBV theory to investigate the IOS adoption, B2B Integration, and their combined effect on the overall performance of the supply chain.

Figure 1 below depicts the conceptual model which explains the constructs and hypotheses.

The main variables establishing this research are explained in detail: IOS adoption, B2B integration, and SCP:

An operationalization table outlines the specific indicators or measurement items used to assess each construct within a conceptual model.

Table I outlines the indicators used to assess each construct within the conceptual model, drawing from previous studies and references detailed in the study.

Table I.

Operationalization of Variables.

Table I.

Operationalization of Variables.

| no. |

Indicator |

Based on references |

Construct |

| IOSA1 |

Communication |

(de Mattos and Laurindo, 2017)

(Zhang and Cao, 2017) (Kurnia et al., 2019) |

|

| IOSA2 |

Intelligence |

(Abou et al., 2023) (Zhang and Cao, 2017)

(Asamoah et al., 2021), (Anwar, 2022) |

IOS

Adoption |

| IOSA3 |

Mutual

Dependence |

(Kurnia et al., 2019) |

| IOSA4 |

Transparency |

(Cho, Ryoo and Kim, 2017) |

| IOSA5 |

Collaboration |

(Leppikorpi, 2018) (Alavi et al., 2020) |

| BI1 |

Trust |

Haghkhah et al., (2020) |

B2B Integration |

| BI2 |

Loyalty |

Haghkhah et al., (2020) (Kim et al., 2024). |

| BI3 |

Coordination |

Haghkhah et al., (2020) |

| BI4 |

Information Exchange |

(Alavi et al., 2020) (da Silva et al., 2024) |

| BI5 |

Customer Service |

(Turban et al., 2015) (Bone et al., 2015) |

| SCP1 |

Flexibility |

(Asamoah et al., 2021),

(Delic and Eyers, 2020) (Anwar, 2022)(Delic and Eyers, 2020) (Anwar, 2022)

|

SCP |

| SCP2 |

Efficiency |

(Asamoah et al., 2019) (Anwar, 2022) (Alavi et al., 2020) |

| SCP3 |

Delivery Time |

(Delic and Eyers, 2020), (Asamoah et al., 2019) (Anwar, 2022) (Alavi et al., 2020) |

| SCP4 |

Demand Fulfillment |

(Delic and Eyers, 2020). |

| SCP5 |

Customer Satisfaction |

(Delic and Eyers, 2020). (Achetoui, Mabrouki and Mousrij, 2019b) |

Table II summarizes the model focus, key variables, and main findings of the key models discussed in the theoretical framework, along with the model being proposed in this paper.

Table II.

Summary of key models in the theoretical framework and proposed study model.

Table II.

Summary of key models in the theoretical framework and proposed study model.

| Study |

|

Model Focus |

Key Variables |

Main Findings |

| (Veronesi, 2017) |

|

How B2B Integration Drives Superior Supply Chain Performance (SCP) |

B2B Integration and SCP |

The study underscores the critical role of B2B integration in driving superior SCP |

| Sundram et al., (2020) |

|

Impact of IT and IS on SCI, SCP, and firm performance |

IT, IS, SCI, firm performance |

Effective use of IT and IS enhances SCI and SCP, improving overall firm performance by better integrating internal and external value chains. |

| Rahman et al., (2023) |

|

Role of supply chain resilience and customer engagement in SCP |

Supply chain resilience, adaptive capability, customer engagement, sustainable SCP |

Supply chain resilience positively impacts sustainable SCP, especially with high customer engagement, underscoring the role of engagement in adaptive capabilities. |

| Asamoah et al., (2019) |

|

IOS adoption and its effects on SCP and supply chain capabilities |

IOS, flexibility, responsiveness, coordination, SCP |

IOS adoption directly improves SCP by enhancing flexibility, responsiveness, and coordination. Supply chain capabilities mediate the relationship between IOS adoption and SCP. |

| Alavi et al., (2020) |

|

Impact of environmental uncertainty on IOS adoption in supply chains |

IOS, environmental uncertainty, trust, information sharing, operational efficiency |

Environmental uncertainty hinders IOS adoption due to trust issues and reluctance to share information. However, effective internal resource management can still result in better operational efficiency and competitive advantage. |

| The current study |

|

IOS adoption, B2B integration, and SCP in the automotive spare parts industry |

IOS, B2B integration, SCP |

IOS adoption and B2B integration improve SCP in the Palestinian automotive sector by enhancing key supply chain capabilities such as flexibility, responsiveness, and coordination. |

2.6. Resource-Based View (RBV) as Theoretical Foundation

This study is grounded in the Resource-Based View (RBV), a theory that explains how firms can achieve competitive advantage by leveraging valuable, rare, inimitable, and non-substitutable (VRIN) resources (Barney, 1991). According to RBV, internal resources and capabilities form the basis for sustained performance, provided they are strategically utilized.

IOS and B2B Integration are conceptualized as strategic resources within this framework. IOS adoption enhances firm capabilities such as coordination, responsiveness, and real-time data access—features that are valuable, rare in many local contexts, and difficult to imitate due to technological and relational complexities (Asamoah et al., 2021). Similarly, B2B integration reflects organizational routines and partner-specific processes that enable trust, loyalty, and seamless collaboration, making them embedded and hard to replicate (Hossain et al., 2024; Kim et al., 2024).

By embedding these capabilities into supply chain operations, firms in the automotive sector can enhance flexibility, efficiency, and customer satisfaction—key dimensions of SCP. The integration of IOS and B2B platforms aligns with RBV’s emphasis on leveraging internal capabilities and inter-firm relationships to achieve superior performance.

Thus, RBV not only justifies the selection of IOS and B2B integration as focal constructs in this study but also supports the mediating role of B2B integration as a capability that channels the impact of IOS on supply chain outcomes.

3. Materials and Methods

This study investigates the IOS adoption, B2B Integration, and their collective influence on the overall performance of the supply chain within the automotive spare parts sector. It adopts a quantitative approach using survey methodology for data collection and analysis. Quantitative research categorizes data into measurable units, facilitating analysis through graphs and tables (Dehalwar et al., 2024).

3.1. Sampling and Data Collection

3.1.1. Sample Selection

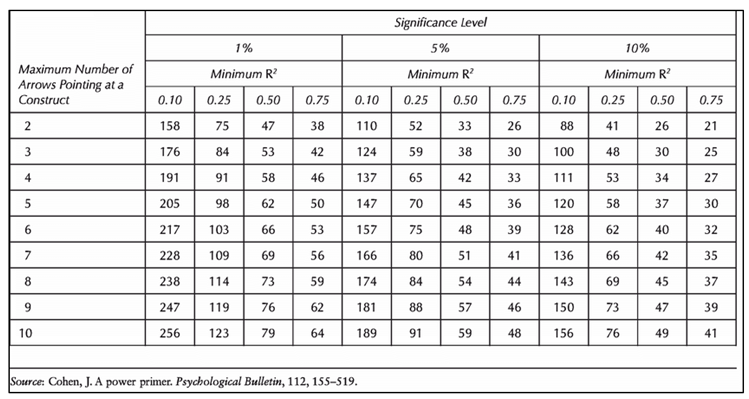

The target population for this study comprises companies involved in the automotive spare parts sector in Palestine, encompassing distributors, retailers, and workshops. According to recent statistics from the Palestinian Central Beurue of Statistics (PCBS, 2023), the estimated population size of these entities within the sector is approximately 1,953. The sample size for this study was determined using recommendations outlined in the PLS-SEM book (Hair et al., 2013). Several key factors were considered to calculate the appropriate sample size:

Minimum R-squared Value: The assumption was made based on achieving a minimum R-squared value of 25%, indicating the desired level of explained variance in the model.

Maximum Number of Arrows Pointing at a Construct: In the conceptual model used for this study, each construct is associated with 5 arrows, representing the number of indicators linking to each construct.

Significance Level (α): A significance level of 5% (0.05) was chosen, which represents the acceptable risk of making a type I error (false positive) in hypothesis testing.

Based on these criteria, a sample size of 70 respondents was deemed adequate (see

Table III).

Table I.

Sample size recommendation (Source: Cohen, J. A power primer, Psychological Bulletin, 112, 155-519).

Table I.

Sample size recommendation (Source: Cohen, J. A power primer, Psychological Bulletin, 112, 155-519).

The snowball sampling method was chosen due to the network-based nature of the industry. Initial participants referred other firms, leading to the identification of 70 companies, including wholesalers, retailers, and workshops. Questionnaires were accompanied by cover letters explaining the study’s objectives and emphasizing the importance of participation. Through persistent outreach efforts, a 100% response rate was achieved, resulting in a robust dataset for analysis.

3.1.2. Data Collection Method

The questionnaire was initially sent via email, but due to limited responses, a multi-channel approach was adopted, including paper-based versions and online distribution through social media and site visits. This approach ensured a wider reach and higher engagement.

3.2. Survey Instrument

3.2.1. Questionnaire Design

This questionnaire was developed based on validated constructs from prior literature about IOS adoption, B2B integration, and SCP. The introductory paragraph introduces the importance of this study in understanding the needs of automotive spare parts customers.

To measure the perception and attitude of the respondents regarding study variables, a five-point Likert scale (1=strongly disagree, 5=strongly agree) was used to measure respondents’ attitudes toward these variables.

3.2.2. Questionnaire Validation

The questionnaires were put through a series of validation procedures in terms of content validity and reliability. The questionnaire items were developed based on previous studies related to the present study, and expert views of specialists in the area of interest informed their refinement. Content validity is very important because it gives confidence to the questionnaire by measuring the intended constructs of IOS adoption, B2B integration, and SCP. A validated questionnaire strengthens the credibility and reliability of research findings by offering an appropriate and robust measurement instrument that corresponds with the intended goals of the study and the theoretical framework (Lim and Koay, 2024).

3.3. Data Analysis

Structural Equation Modeling (SEM) is widely used in social sciences and business research for analyzing complex relationships among multiple variables (Vukovi´c, 2024). Traditional SEM techniques, such as Covariance-Based SEM (CB-SEM), require large sample sizes and assumptions of multivariate normality, which may be restrictive in practical applications.

Partial Least Squares SEM (PLS-SEM) is a nonparametric alternative that relaxes these assumptions and is suitable for smaller sample sizes and non-normal data distributions (Al Mahdy, Khodeir and Gadelhak, 2025). It supports both reflective and formative measurement models, enhancing its applicability (Goktas and Dirsehan, 2024).

Given the sample size of 70, which aligns with the minimum thresholds recommended for PLS-SEM based on model complexity (Hair et al., 2019). PLS-SEM was selected as the analytical method. The approach is particularly advantageous for prediction and exploratory research aims.

However, it is important to note that the relatively small sample size limits the ability to establish strong causal inferences. PLS-SEM does not inherently address potential endogeneity issues such as omitted variable bias or reverse causality. Consequently, the results should be interpreted with caution as indicative of associations rather than definitive causal relationships. Future studies with larger samples and advanced methodological controls for endogeneity are recommended to reinforce causal claims.

The proposed model and hypotheses were tested using SmartPLS 3 software, widely recognized for its capability in handling complex models with relatively small samples in social sciences and business research (Dwaikat, 2023; (Mahdi et al., 2024).

4. Results

4.1. Analysis of Respondents' Demographic Profiles

The analysis in this study is based on a dataset comprising 70 completed questionnaires, offering valuable insights into the participant demographics and characteristics.

Table IV.

Respondents' profile.

Table IV.

Respondents' profile.

| Demographic |

Item |

Frequency |

Percentage (%) |

| Company Size |

Small |

23 |

32.9% |

| Large |

9 |

12.9% |

| Medium |

38 |

54.3% |

| Company Scope of Business |

Others |

2 |

3% |

| Workshop |

33 |

47% |

| Retailer |

25 |

36% |

| Wholesaler |

10 |

14% |

| Type of Required Goods |

Oils and Lubricants |

5 |

7.1% |

| Others |

10 |

14.3% |

| Accessories |

7 |

10.0% |

| Spare Parts |

48 |

68.6% |

| Job Title |

Top Management |

24 |

34.3% |

| Others |

12 |

17.1% |

| Marketing and Sales |

16 |

22.9% |

| Purchasing |

18 |

25.7% |

| Company Age (years) |

15 and more |

14 |

20.0% |

| Less than 1 |

1 |

1.4% |

| 1-5 |

28 |

40.0% |

| 6-14 |

27 |

38.6% |

| Current Use of Websites |

20% -50% |

11 |

15.7% |

|

20% or less |

54 |

77.1% |

|

50% and more |

5 |

7.1% |

Table IV provides a detailed profile of the respondents, illustrating the composition of the study sample in terms of company size, type of required goods, job titles, company age, and current use of websites (all terms are in Appendix B). Concerning the scope of business for the companies studied, the breakdown indicated that 47% of the companies were workshops, 36% were retailers, and 14% were wholesalers. It demonstrates that the study encompassed 70 companies, representing nine large-sized companies. It can be identified that the majority of these companies require spare parts, while 77.1% reported less than 20% usage of current websites. Furthermore, a significant number of the respondents were holding top management positions amounting to 34.3%. These demographic features give full knowledge of the structure of the respondents included in the research.

4.2. Measurement Model Assessment

The measurement model assessment focused on evaluating the reliability and validity of the constructs using Partial Least Squares Structural Equation Modeling (PLS-SEM), the study followed the guidelines recommended by Hair et al., (2019) using Smart PLS version 4 – PLS Algorithm with default settings (300 iterations and Path Analysis as the weighting scheme).

In this study, all constructs—IOS adoption, B2B integration, and SCP—are modelled reflectively based on theoretical rationale and prior research (e.g., Asamoah et al., 2021; Alavi et al., 2020). Each of these constructs is conceptualized as a latent variable that drives the variation in its indicators.

For instance, SCP is considered a higher-order construct that reflects various aspects of supply chain success, such as flexibility, delivery time, efficiency, demand fulfillment, and customer satisfaction. A change in SCP is expected to cause corresponding changes in these indicators, and removing one indicator (e.g., flexibility) would not redefine the construct itself, as others would still represent the performance concept.

Similarly, IOS adoption is conceptualized as a managerial and technological posture that manifests through transparency, collaboration, mutual dependence, and intelligence. These indicators are expected to move together when IOS adoption increases or decreases, supporting a reflective structure.

Finally, B2B integration is modeled as a strategic orientation toward inter-organizational alignment, which is reflected in trust, loyalty, coordination, and customer support. These elements are not causes of B2B integration but rather outcomes or reflections of it. Therefore, the reflective specification aligns with both the conceptual definition and previous empirical modeling.

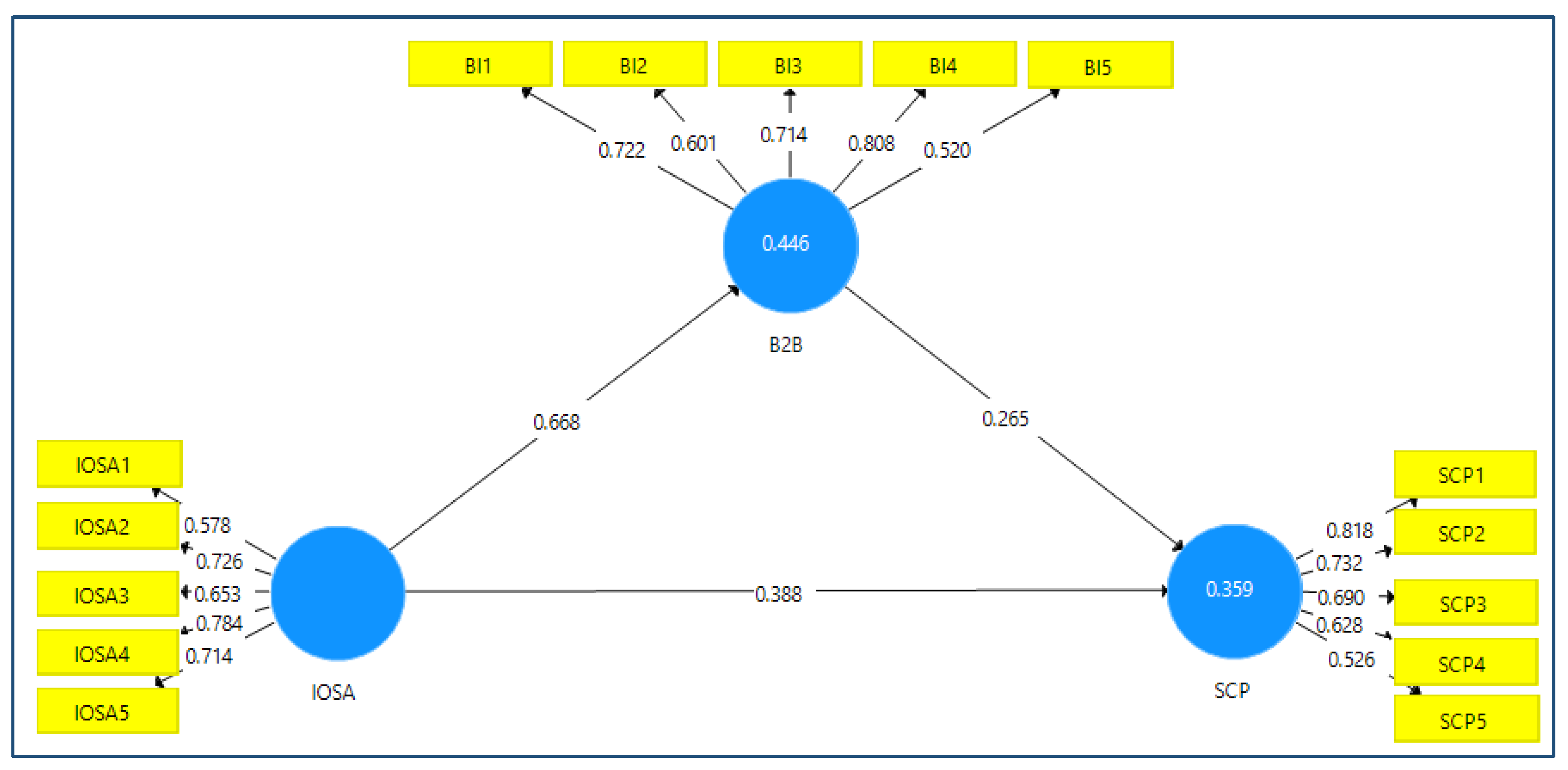

Figure 2.

PLS path modeling estimation of the research model.

Figure 2.

PLS path modeling estimation of the research model.

4.2.1. Indicator Loadings and Item Reliability

Initial assessment of indicator loadings against a minimum criterion of 0.708 as recommended by Hair et al., (2019) indicated that certain items did not meet the threshold. As a result, items with factor loadings below 0.708 (BI5: Customer Service, IA1: Communication, SCP4: Demand Fulfillment, and SCP5: Customer Satisfaction) were removed from the analysis. However, IA3 (Mutual Dependence), SCP3 (Delivery Time), and BI2 (Trust) were retained due to their statistical significance.

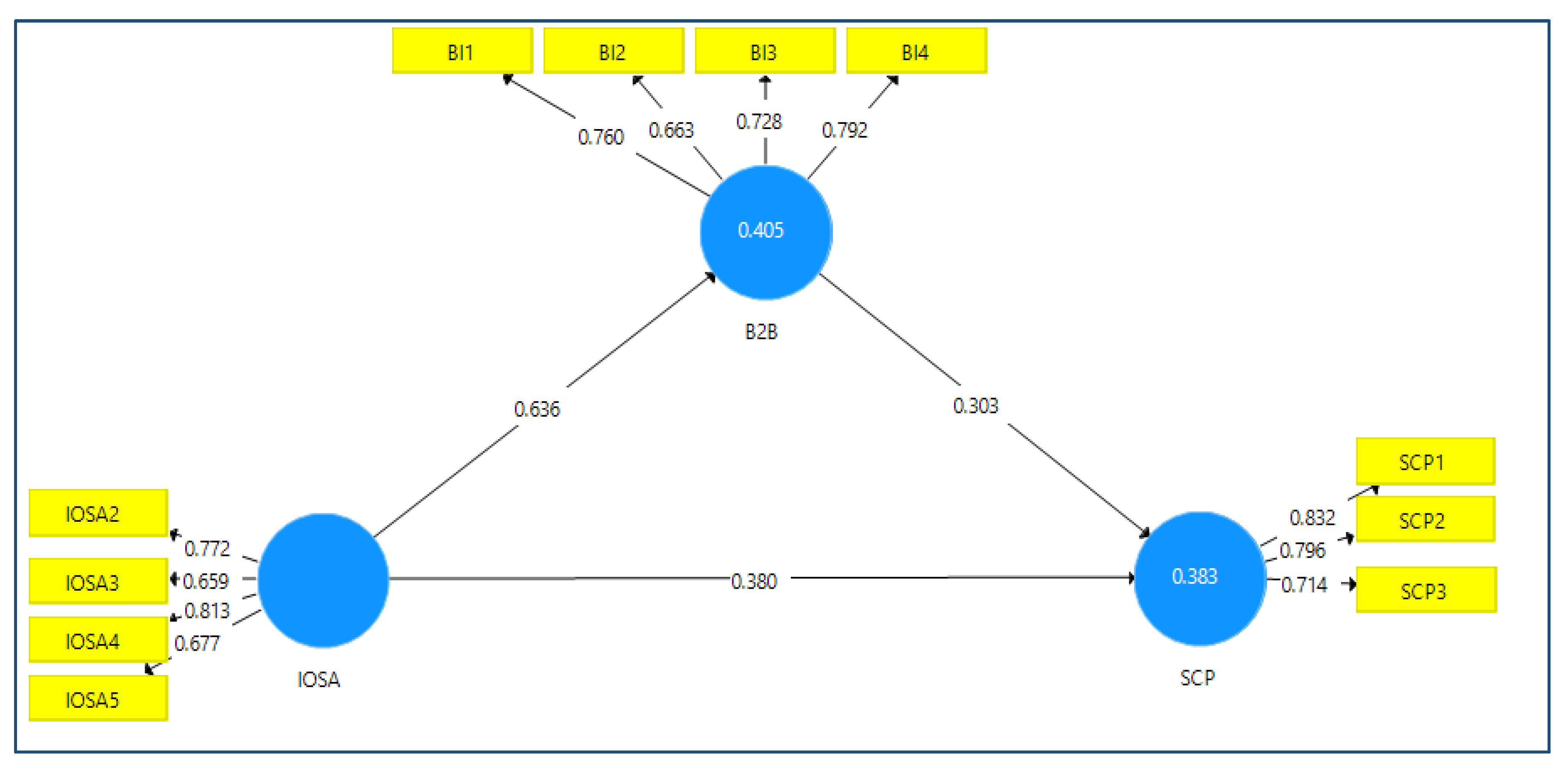

Following item removal, the PLS algorithm was recalculated, and updated results of the outer loadings are shown in Table Table V and

Figure 3.

Table V.

Results of outer loading.

Table V.

Results of outer loading.

| Indicator |

Point estimation |

T-values |

P-values |

| B2B |

B2B Integration |

|

|

|

| BI1 |

Trust |

0.760 |

9.732 |

0.000 |

| BI2 |

Loyalty |

0.663 |

7.195 |

0.000 |

| BI3 |

Coordination |

0.728 |

8.660 |

0.000 |

| BI4 |

Information Exchange |

0.792 |

14.541 |

0.000 |

| IOSA |

IOS Adoption |

|

|

|

| IOSA2 |

Intelligence |

0.772 |

12.044 |

0.000 |

| IOSA3 |

Mutual Dependence |

0.659 |

7.381 |

0.000 |

| IOSA4 |

Transparency |

0.813 |

22.107 |

0.000 |

| IOSA5 |

Collaboration |

0.677 |

7.562 |

0.000 |

| SCP |

Supply Chain Performance |

|

|

|

| SCP1 |

Flexibility |

0.832 |

20.493 |

0.000 |

| SCP2 |

Efficiency |

0.796 |

17.508 |

0.000 |

| SCP3 |

Delivery Time |

0.714 |

5.628 |

0.000 |

T-values are statistical measures used to determine the significance of the indicators in the variables in a model. The t-values are obtained through a bootstrapping procedure with 5000 subsamples as the default setting in the software. Table V shows the updated outer loading results, indicating significant factor loadings (T-values exceeding 1.96 at the significance level of 5% and P-values less than 0.05 as recommended by Hair et al., (2019).

4.2.2. Reliability and Validity Assessment

The study conducted a comprehensive assessment of the internal consistency reliability and convergent validity of the constructs using metrics recommended by Hair et al., (2019).

Internal Consistency Reliability:

The Internal consistency reliability could be measured by Cronbach's Alpha and values of Composite Reliability. As shown in Table VI, the levels of Cronbach's Alpha have been 0.690 to 0.722 while Composite Reliability was from 0.822 to 0.826. Following Hair et al., (2019), all the values for Cronbach's Alpha and Composite Reliability should be greater than 0.7 to establish good internal consistency among constructs. The result is shown in Table VI, it was established that Cronbach's Alpha and Composite Reliability values met the threshold level and represented good internal consistency across the constructs except for SCP, where Cronbach's Alpha value was 0.690.

Convergent Validity:

Convergent validity is the degree to which a construct can explain the variance of its items. It is measured by calculating each construct's Average Variance Extracted (AVE). High AVE values signify that the constructs successfully capture the variance of their respective items, confirming the adequacy of the measurement model. Results in Table VI present that the constructs have acceptable levels of convergent validity: B2B integration with AVE = 0.544; IOS Adoption with AVE = 0.537; SCP has an AVE = 0.612, meeting the acceptable threshold 0.5 recommended by Hair et al., (2019), hence confirming convergent validity.

Table III.

Convergent validity test.

Table III.

Convergent validity test.

| |

R2

|

Cronbach Alpha |

Composite Reliability |

Average Variance Extracted (AVE) |

| B2B integration |

0.405 |

0.722 |

0.826 |

0.544 |

| IOS Adoption |

|

0.714 |

0.822 |

0.537 |

| SCP |

0.383 |

0.690 |

0.825 |

0.612 |

4.2.3. Discriminant Validity Assessment

Discriminant validity refers to the degree to which indicators of a particular construct are much more highly correlated with each other rather than with indicators of other constructs in the research mode. It reflects the distinctiveness of each construct regarding checking the magnitude of the correlation between its indicators and various constructs' indicators.

Discriminant validity can be confirmed, according to Fornell and Larcker, discriminant validity is assessed by comparing the square root of the Average Variance Extracted (AVE) for each factor with the correlations among constructs. The square root value should be higher than the correlation values between the latent variables (Asamoah et al., 2021b). The findings presented in Table VII support that all constructs demonstrate robust discriminant validity.

In addition to the Fornell-Larcker test, HTMT was used to further verify the discriminant validity. The HTMT examines relationships between various constructs and has been considered a superior option to the Fornell-Larcker criterion when assessing discriminant validity in partial least squares SEM. As presented in Table VII, the HTMT values suggest satisfactory discriminant validity since all these values are well below the recommended threshold of 1.0 as recommended by (Henseler, Ringle and Sarstedt, 2015). The HTMT values for B2B-IA, B2B-SCP, and IA-SCP pairs are 0.844, 0.741, and 0.763, respectively. Consequently, discriminant validity has been validated, which infers that each construct in this research model is different from others.

Table IV.

Discriminant validity tests.

Table IV.

Discriminant validity tests.

| Fornell-Larcker |

|---|

| |

B2B |

IA |

SCP |

| B2B |

0.737 |

|

|

| IOSA |

0.636 |

0.733 |

|

| SCP |

0.545 |

0.573 |

0.782 |

| HTMT |

| |

B2B |

IA |

SCP |

| B2B |

|

|

|

| IOSA |

0.844 |

|

|

| SCP |

0.741 |

0.763 |

|

The outcomes of both the Fornell-Larcker test and HTMT analysis provide robust indications that the constructs in the research model differ from one another. This confirms that through each construct, a unique latent variable is measured.

4.3. Structural Model Analysis Results

4.3.1. VIF Analysis

Assessing multicollinearity among independent variables is crucial before testing the proposed model to ensure the accuracy and stability of the results. The Variance Inflation Factor (VIF) is a widely used metric for evaluating collinearity. Typically, a VIF value of 5 or higher suggests significant multicollinearity problems. However, even lower VIF values, around 3 or more, can indicate potential issues. Ideally, VIF values should remain close to or below 3 to maintain model stability and reduce the risk of multicollinearity impacting the findings. In this study, as presented in Table VIII, the VIF values range from 1.259 to 1.450, which are well within the acceptable range, demonstrating that there are no multicollinearity issues among the variables (Hair et al., 2019).

Table II.

The result of the VIF test.

Table II.

The result of the VIF test.

| Indicator |

VIF |

The result |

| Trust |

BI1 |

1.562 |

meeting the requirement |

| Loyalty |

BI2 |

1.259 |

meeting the requirement |

| Coordination |

BI3 |

1.45 |

meeting the requirement |

| Information Exchange |

BI4 |

1.348 |

meeting the requirement |

| Intelligence |

IOSA2 |

1.351 |

meeting the requirement |

| Mutual Dependence |

IOSA3 |

1.295 |

meeting the requirement |

| Transparency |

IOSA4 |

1.512 |

meeting the requirement |

| Collaboration |

IOSA5 |

1.292 |

meeting the requirement |

| Flexibility |

SCP1 |

1.319 |

meeting the requirement |

| Efficiency |

SCP2 |

1.374 |

meeting the requirement |

| Delivery Time |

SCP3 |

1.335 |

meeting the requirement |

4.3.2. Model Fit Assessment

The coefficient of determination (R²) is a statistical metric used to show what part of the changes in the dependent variable (outcome) we can attribute to independent variables. It is expressed as a percentage and ranges between 0% and 100%. Higher R² values suggest a stronger relationship, where the independent variables effectively explain the variability in the outcome. As shown in Table VI, the R² results for SCP is 0.383 and the R² for B2B integration is 0.405 which means the R² indicated that 38.3% of the variance in SCP was explained by B2B integration and IOS adoption, and 40.5% of the variance in B2B was explained by IOS adoption (Hair et al., 2019).

Furthermore, the predictive relevance (Q²) of the model reflects how effectively the independent variables predict the dependent variables. The blindfolding procedure is commonly used to assess predictive relevance, with a general guideline that Q² values should be greater than 0.00. As indicated in

Table 9, all dependent variables in this study show Q² values exceeding zero, confirming that the model has predictive accuracy for each specific endogenous construct (Hair

et al., 2019).

Table III.

Predictive Relevance (Q²).

Table III.

Predictive Relevance (Q²).

| |

SSO |

SSE |

Q² = 1- SSE/SSO |

| B2B |

280 |

222.749 |

0.204 |

| SCP |

210 |

168.652 |

0.197 |

Path Coefficient Analysis

Path coefficient analysis involves examining the standardized path coefficients (B values) derived from a structural equation model to understand the magnitude and significance of relationships between latent variables (constructs). The path coefficients represent the strength and direction of these relationships. In SEM, path coefficients indicate how much the dependent variable changes in standard deviation units for a one standard deviation increase in the independent variable.

Standardized Path Coefficients (B values): These coefficients quantify the impact of one variable (construct) on another within the structural model. Values of 0.1 or higher are typically considered significant, indicating a substantial effect size based on recommendations by Eggert and Serdaroglu (2011). Regarding the effects of individual independent variables as shown in

Figure 3:

IOS Adoption ' (β=0.380): This beta coefficient represents the standardized effect size of 'IOS Adoption ' on 'SCP'. A beta coefficient of 0.380 indicates that a one-unit increase in 'IOS Adoption ' is associated with a 0.380 standard deviation increase in 'SCP'.

B2B Integration' (β=0.303): This beta coefficient represents the standardized effect size of 'B2B Integration' on 'SCP'. A beta coefficient of 0.303 indicates that a one-unit increase in 'B2B Integration' is associated with a 0.303 standard deviation increase in 'SCP'.

The higher beta coefficient for 'IOS Adoption ' (β=0.380) compared to 'B2B Integration' (β=0.303) suggests that 'IOS Adoption ' has a stronger positive effect on 'SCP' in this study, as it explains a larger proportion of the variance in the dependent variable relative to 'B2B Integration'.

Statistical Significance: Path coefficients are evaluated using associated t-values and p-values. A significant p-value (usually < 0.05) indicates that the observed relationship between variables is unlikely to be due to random chance, based on recommendations by Eggert and Serdaroglu, (2011).This test will be done when calculating bootstrapping with default settings.

Table 10 provides a comprehensive summary of the path coefficient analysis, including the original sample estimates, standard deviations, T-statistics, and p-values.

Table X.

The results of the hypothesis.

Table X.

The results of the hypothesis.

| Relationship |

Coefficient (Original Sample) |

Standard Deviation |

T-statistics |

P values |

Conclusion |

| IOS Adoption → Supply Chain Performance |

0.380 |

0.110 |

3.443 |

0.001 |

H1 is supported |

| IOS Adoption → B2B Integration |

0.636 |

0.072 |

8.877 |

0.000 |

H2 is supported |

| B2B Integration → Supply Chain Performance |

0.303 |

0.129 |

2.354 |

0.019 |

H3 is supported |

| IOS Adoption → B2B Integration → Supply Chain Performance |

0.193 |

0.081 |

2.374 |

0.018 |

H4 is supported |

Observing the path coefficients, t-values, and p-values of the inner model, the results confirm that the path coefficient analysis confirms the following:

IOS Adoption also has a statistically significant positive impact on 'SCP' (β=0.380, t=3.443, p=0.001), supporting Hypothesis 1 (H1).

IOS Adoption has a statistically significant positive impact on 'B2B Integration' (β=0.636, t=8.877, p=0.000), supporting Hypothesis 2 (H2).

B2B Integration' has a statistically significant positive impact on 'SCP' (β=0.303, t=2.354, p=0.019), supporting Hypothesis 3 (H3).

Mediation effect (indirect effect): IOS Adoption ' has a statistically significant positive impact on 'B2B Integration’ and 'SCP' (β=0.193, t=2.374, p=0.018). This mediation effect supports Hypothesis 4 (H4).

In conclusion, the path coefficient analysis validates the structural model by demonstrating significant relationships between constructs, providing robust evidence in support of the formulated hypotheses. These findings provide strong empirical support for the theoretical framework posited in this study. The validated structural model underscores the critical roles of IOS Adoption and B2B Integration in enhancing SCP within the automotive spare parts sector in Palestine.

5. Discussion

The empirical results support all four hypotheses: H1 shows that IOS adoption significantly enhances Supply Chain Performance (SCP) by improving information flow, coordination, and inventory management (Lee et al., 2014b; Asamoah et al., 2019; Alavi et al., 2020). H2 confirms that IOS adoption also drives stronger B2B integration by automating transactions and fostering real-time data sharing (Sundram et al., 2020). In turn, H3 establishes that B2B integration further boosts SCP through faster order and invoice processing, reduced errors, and enhanced transparency, leading to shorter lead times and greater customer satisfaction (Veronesi, 2017; Rahman et al., 2023). Finally, H4 demonstrates that B2B integration mediates the IOS–SCP link, indicating that the full performance gains from IOS are realized only when firms leverage these systems to deepen collaboration with their supply chain partners.

B2B integration also furthers transparency and trust among partners since they can easily access critical information; this strengthens relationships, enhances customer satisfaction, reduces lead times and operational costs due to automation, and smooths out internal and external communications. Moreover, these improvements contribute to the sustainability of supply chains by enabling more transparent and efficient use of resources, reducing redundancies and waste, and supporting environmentally friendly practices such as green logistics and circular economy initiatives. The integration of IOS and B2B systems thus enhances operational and financial performance and aligns with the growing global emphasis on SSCM, meeting both economic and ecological objectives.

The four hypotheses of this study have been supported and matched with the literature base from which the hypotheses were generated. Simultaneously, the newly proposed hypothesis in the course of this study has been supported, too. These all together prove to be significantly beneficial for the growing body of literature based on how technology and process integration drive strategic supply chain advantages.

This study is important because it reinforces prior research and underlines some very crucial knowledge gaps; for example, the direct link between IOS adoption and B2B integration also shows the critical role of B2B integration as a mediator between IOS adoption and SCP. In this way, the research underlines deep dimensions of how these technological and process innovations work in applying supply chain performance improvements, bringing new light into the field.

5.1. Theoretical Contribution

From a theoretical standpoint, this study offers valuable insights into how technology adoption and inter-organizational integration interact to influence supply chain outcomes.

The findings of this research represent significant theoretical contributions in the fields of SCM and technology adoption. This research provided a fresh theoretical lens from which to analyze how IOS adoption and B2B integration interact in enhancing SCP, with particular emphasis on the automotive spare parts industry in Palestine. The present study contributes to the literature by providing empirical evidence and a structural model that embeds industry-specific knowledge into general technology adoption frameworks.

Some works study the relation between IOS adoption and SCP, such as Lee et al., (2014b), Asamoah et al., (2021) and, Alavi et al., (2020), found that IOS adoption has a positive effect on supply chain efficiency. The contribution of this study is to further support these findings and expand their generalizability to the automotive industry in Palestine, a very significant sector that faces unique challenges in this context. Because of the limited number of studies that have so far focused on this industry in the region, the present study offers fresh insight and covers the existing knowledge gap, hence, it is a new contribution.

One of the greatest theoretical contributions of this study involves how B2B integration mediates the relationship between IOS adoption and SCP. This finding represents an important in the extant literature and indicates that the advantages of IOS adoption are enhanced if organizations use these systems to develop a closer collaborative relationship with their supply chain partners. This mediating role of B2B integration suggests that organizations should adopt technological adoption and process integration strategically to have optimized supply chain outcomes. This knowledge is valuable in building a more holistic theoretical framework for the interplay of technology and collaboration in SCM.

This study extends RBV-based SCM theory by showing that IOS adoption directly improves SCP and that B2B integration mediates this effect.

5.2. Practical Implications

From a business perspective, the findings of this study provide actionable insights for firms aiming to improve their supply chain performance through digital integration.

In the automotive spare parts business, IOS and B2B integration technologies enhance the aggregate SCPs in cost reductions, improved delivery accuracy, competitive advantage, and increased sales and profitability.

The key practical implications of this study are:

Firstly, increasing supply chain flexibility: Using technology such as IOS and B2B can allow real-time sharing of information amongst supply chains. IOS views the availability of a product's inventory and automatically updates the order schedule, making inventory management more efficient. The visibility of customers' demands in real time enables rapid response to market changes in a dynamic environment. IOS improves communication and collaboration with suppliers, allowing for enhanced decision-making capabilities in quicker responses in cases of changes in demand or disruption to supply.

Secondly, higher efficiency: Automation of tasks such as order processing, inventory management, and tracking of orders minimizes the chances of human error, accelerates the process of order processing, and hence reduces lead times. Integration of B2B with ERP systems ensures optimization of the deployment of resources and reduction of operational bottlenecks for enhancing overall efficiency.

Thirdly, building Up Customer Trust and Loyalty: By analyzing the demand contributed by different sources, IOS enables a business to anticipate the needs of its customers and ensures timely delivery of service. B2B integration also raises the level of responsiveness throughout the supply chain, with close collaboration with suppliers and distributors for inventory optimization and fast order fulfillment. Thus, increased coordination and efficiency also translate to higher customer satisfaction. Customers' trust and loyalty are further improved with the adoption of IOS and B2B integration through increased transparency and responsiveness, hence strengthening the relationships and giving an edge over the competition, which translates to increased sales.

Finally, maximization of Technological Benefit: The features of B2B can be used as a tool for effective marketing. A detailed display of information about the product to the customers reduces costs as less sales effort and time is required to inform the customer about the product. Secondly, automation decreases human dependence on operation manuals. This saves money by reducing some of these operations. Consequently, maximization of the benefits from technology will lead to ease of operations, increased market positioning, and overall sales and profits.

Practical Examples for Implementation in Palestinian Firms

To better illustrate how these insights can be implemented within Palestinian automotive spare parts companies, several practical scenarios are proposed:

Automated Ordering Systems: Establishing IOS-enabled automatic inventory monitoring and replenishment between suppliers and distributors can significantly reduce stockouts and overstock situations, improving operational efficiency.

Digital Invoice and Payment Processing: Implementing B2B platforms for electronic invoicing and payment can shorten payment cycles, minimize manual errors, and enhance financial transparency among partners.

ERP-B2B Integration: Linking internal ERP systems with external B2B platforms allows real-time visibility of orders, shipments, and inventory levels, enabling better coordination across departments and supply chain partners.

Data Analytics for Demand Forecasting: Sharing sales and inventory data via IOS can empower firms to analyze customer demand patterns collaboratively, leading to optimized inventory levels and distribution planning.

Online Customer and Partner Support Portals: Creating digital platforms integrated with B2B systems to provide real-time communication, issue resolution, and service tracking improves relationships and trust with supply chain partners and customers alike.

By adopting such practical applications, Palestinian companies can improve their supply chain flexibility, responsiveness, and overall performance, thereby strengthening their competitive position in a challenging market environment.

6. Conclusion

This study confirms that IOS adoption and B2B integration play a pivotal role in enhancing Supply Chain Performance (SCP) by enabling real-time information sharing, operational efficiency, and closer collaboration among partners. IOS offers the technological infrastructure for data visibility across the supply chain, while B2B integration automates transactions and improves communication, trust, and responsiveness. Together, these technologies enhance forecasting, inventory management, and customer satisfaction.

Using a quantitative approach with 70 valid responses from Palestinian auto spare parts firms, the research employed a structured, literature-based questionnaire and analyzed results using PLS-SEM. The findings demonstrate significant improvements in flexibility, coordination, lead times, and cost reduction due to the use of IOS and B2B systems.

Importantly, B2B integration partially mediates the relationship between IOS and SCP, highlighting that the full benefits of IOS are realized only when combined with strong collaborative processes. B2B serves as the bridge that translates digital capabilities into tangible performance gains, boosting transparency, trust, and decision-making speed across the supply chain.

The study offers both theoretical and practical contributions by extending technology adoption frameworks with industry-specific insights, emphasizing the strategic alignment of digital tools with collaborative practices. It shows that integrating technology and processes leads to greater resilience, operational excellence, and profitability.

For firms in the auto spare parts sector, the adoption of IOS and B2B integration is essential for maintaining competitiveness. These innovations reduce operational costs, improve responsiveness to market changes, and drive long-term success. As such, industry leaders and policymakers must actively support digital transformation through infrastructure, regulation, and training to unlock the full potential of supply chain digitalization.

Therefore, to remain competitive in such an evolving landscape, industry leaders must take decisive steps toward embracing digital transformation. Strategic investments in Inter-Organizational Systems and B2B integration are critical not only for achieving operational excellence but also for securing a sustainable competitive advantage in the Palestinian automotive spare parts sector.

Furthermore, by enhancing visibility, reducing lead times, and minimizing inefficiencies, IOS and B2B integration also contribute to environmental and operational sustainability. These systems enable better resource planning, reduce overproduction and waste, and support green logistics practices. In this sense, digital transformation not only enhances performance but also aligns with global sustainability goals, contributing to more responsible and transparent supply chain management.

7. Future Research Directions

Future research should address the limitations of the current study by employing larger sample sizes to enhance statistical power and enable stronger causal inferences. Additionally, the incorporation of advanced methodological approaches to control for potential endogeneity issues—such as omitted variable bias and reverse causality—will improve the robustness and validity of the findings. Beyond methodological improvements, future studies should explore the generalizability of these findings across diverse industries, such as electronics and pharmaceuticals, and geographical contexts with varying levels of digital infrastructure and regulatory complexity. Cross-industry and cross-regional investigations can uncover sector-specific dynamics and enhance external validity. Furthermore, longitudinal research designs are essential to capture the evolving nature of Inter-crm size, digital maturity, or supply chain turbulence—that may influence the trajectory of supply chain performance outcomes. Moreover, future research should explore the role of IOS and B2B integration in enabling Sustainable Supply Chain Management

Acknowledgment

The authors would like to thank An-Najah National University (

www.najah.edu) for the technical support provided to publish the present manuscript. This manuscript was proofread using ChatGPT 4.5, an advanced language model developed by OpenAI, to enhance clarity, coherence, and readability. The researchers care-fully reviewed the entire manuscript after the AI-assisted proofreading to ensure the accuracy of the content, interpretation of findings, and correctness of all references. The authors take full responsibility for the final version of the manuscript, including all analyses, conclusions, and cited materials

References

- Abou, E. E., Osman, I. E., and Awaad, S. M. (2023). Antecedents and enablers of inter-organizational systems on Firm Performance: The Mediation Effect of Supply Chain Capabilities. In Asian Journal of Social Science and Management Technology (Vol. 5, Issue 1). www.ajssmt.com.

- Achetoui, Z., Mabrouki, C., and Mousrij, A. (2019a). A review of spare parts supply chain management. Jurnal Sistem Dan Manajemen Industri, 3(2), 67. [CrossRef]

- Achetoui, Z., Mabrouki, C., and Mousrij, A. (2019b). Performance Measurement System for Automotive Spare Parts Supply Chain: A Categorization. Journal of Transportation and Logistics, 31–50. [CrossRef]

- Al Mahdy, S. M., Khodeir, L. M., and Gadelhak, M. I. (2025). Investigating organizational agility in Egyptian architecture firms. HBRC Journal, 21(1), 1–36. [CrossRef]

- Alavi, S. N. Alavi, S. N., Abdolvand, N., Harandi, S. R., and Alavi, S. N. (2020). A model for studying the value of the inter-organisational information systems’ implementation-case study: tourism industry. In Int. J. Networking and Virtual Organisations (Vol. 23, Issue 2).

- Al-Doori, J. A. (2019). The impact of supply chain collaboration on performance in automotive industry: Empirical evidence. Journal of Industrial Engineering and Management, 12(2), 241–253. [CrossRef]

- Anwar, M. F. A. (2022). The Influence of Inter-Organizational System Use and Supply Chain Capabilities on Supply Chain Performance. South Asian Journal of Operations and Logistics, 20–38. [CrossRef]

- Asamoah, D., Agyei-Owusu, B., Andoh-Baidoo, F. K., and Ayaburi, E. (2021a). Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. International Journal of Information Management, 58. [CrossRef]

- Asamoah, D., Agyei-Owusu, B., Andoh-Baidoo, F. K., and Ayaburi, E. (2021b). Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. International Journal of Information Management, 58. [CrossRef]

- Asamoah, D., Agyei-Owusu, B., Kofi Andoh-Baidoo, F., Ayaburi, E., and Effect, E. A. (2019). Effect of Inter-Organizational Systems Use on Supply Chain Capabilities and Performance. 293–308. [CrossRef]

- Baah, C., Opoku Agyeman, D., Acquah, I. S. K., Agyabeng-Mensah, Y., Afum, E., Issau, K., Ofori, D., and Faibil, D. (2022). Effect of information sharing in supply chains: understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking, 29(2), 434–455. [CrossRef]

- Bone, S. A., Fombelle, P. W., Ray, K. R., and Lemon, K. N. (2015). How Customer Participation in B2B Peer-to-Peer Problem-Solving Communities Influences the Need for Traditional Customer Service. Journal of Service Research, 18(1), 23–38. [CrossRef]

- Cannavale, C., Esempio Tammaro, A., Leone, D., and Schiavone, F. (2022). Innovation adoption in inter-organizational healthcare networks – the role of artificial intelligence. In European Journal of Innovation Management (Vol. 25, Issue 6, pp. 758–774). Emerald Group Holdings Ltd. [CrossRef]

- Chen, Y. C., Hu, L. T., Tseng, K. C., Juang, W. J., and Chang, C. K. (2019). Cross-boundary e-government systems: Determinants of performance. Government Information Quarterly, 36(3), 449–459. [CrossRef]

- Cho, B., Ryoo, S. Y., and Kim, K. K. (2017). Interorganizational dependence, information transparency in interorganizational information systems, and supply chain performance. European Journal of Information Systems, 26(2), 185–205. [CrossRef]

- Chohan, A., Hussain, G., & Shafique, I. (2023). Does social capital affect supply chain performance? Establishing an underlying mechanism and a boundary condition. International Journal of Productivity and Performance Management, 73(9), 423–439.

- da Silva, R. M., Tarigan, Z. J. H., and Siagian, H. (2024). The influence of supplier competency on business performance through supplier integration, vendor-managed inventory, and supply chain collaboration in Fuel Station: An evidence from Timor Leste. Uncertain Supply Chain Management, 12(1), 207–220. [CrossRef]

- de Mattos, C. A., and Laurindo, F. J. B. (2017). Information technology adoption and assimilation: Focus on the suppliers portal. Computers in Industry, 85, 48–57. [CrossRef]

- Dehalwar, K., Shashikant, and, and Sharma, N. (2024). Exploring the Distinctions between Quantitative and Qualitative Research Methods. 27(7). [CrossRef]

- Delic, M., and Eyers, D. (2020). The effect of Additive Manufacturing adoption on supply chain flexibility and performance: an empirical analysis from the automotive industry.

- DeLone, W., McLean, E., and Sedera, D. (2022). Future of information systems success: Opportunities and challenges. In Computing Handbook: Two-Volume Set (pp. 1–19). CRC Press. [CrossRef]

- Dwaikat, N. (2023), The impact of job stress and job satisfaction on employee performance: The case of the Software Companies in Palestine, An-Najah University Journal for Research - B (Humanities), Vol. 37 No. 4, pp. 775-803. [CrossRef]

- Eggert, A., and Serdaroglu, M. (2011). Exploring the impact of sales technology on salesperson performance: A task-based approach. Journal of Marketing Theory and Practice, 19(2), 169–186. [CrossRef]

- Filosa, C., Jovanovic, M., Agostini, L., and Nosella, A. (2025). Pivoting B2B platform business models: From platform experimentation to multi-platform integration to ecosystem envelopment. International Journal of Production Economics, 280. [CrossRef]

- Goktas, P., and Dirsehan, T. (2024). Using PLS-SEM and XAI for casual-predictive services marketing research. Journal of Services Marketing. [CrossRef]

- Gupta, S., Drave, V. A., Bag, S., and Luo, Z. (2019). Leveraging Smart Supply Chain and Information System Agility for Supply Chain Flexibility. Information Systems Frontiers, 21(3), 547–564. [CrossRef]

- Haghkhah, A., Rasoolimanesh, S. M., and Asgari, A. A. (2020). mrp.ase.ro Effects of customer value and service quality on customer loyalty: the mediation role of trust and commitment in a business-to-business context.

- Hair, J. F., Risher, J. J., Sarstedt, M., and Ringle, C. M. (2019). When to use and how to report the results of PLS-SEM. In European Business Review (Vol. 31, Issue 1, pp. 2–24). Emerald Group Publishing Ltd. [CrossRef]

- Henseler, J., Ringle, C. M., and Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. Journal of the Academy of Marketing Science, 43(1), 115–135. [CrossRef]

- Hernández, M. S. (2023). Beliefs and attitudes of canarians towards the chilean linguistic variety. Lenguas Modernas, 62, 183–209. [CrossRef]

- Hossain, M. A., Islam, S., Rahman, M. M., and Arif, N. U. M. (2024). Impact of Online Payment Systems on Customer Trust and Loyalty in E-Commerce Analyzing Security and Convenience. Academic Journal on Science, Technology, Engineering and Mathematics Education, 4(3), 1–15. [CrossRef]

- Jia, F. (Jeff), Seuring, S., Chen, L., and Azadegan, A. (2024). Guest editorial: Supply chain transparency: opportunities, challenges and risks. In International Journal of Operations and Production Management (Vol. 44, Issue 9, pp. 1525–1538). Emerald Publishing. [CrossRef]

- Kain, R., and Verma, A. (2018). Logistics Management in Supply Chain - An Overview. Materials Today: Proceedings, 5(2), 3811–3816. [CrossRef]

- Kim, J. W., Rhee, J. H., and Park, C. H. (2024). How Does Digital Transformation Improve Supply Chain Performance: A Manufacturer’s Perspective? Sustainability (Switzerland), 16(7). [CrossRef]

- Kosaka, M., Wu, J., Ke, ·, Shiyong, X. ·, and Editors, Z. (2021). Business Innovation with New ICT in the Asia-Pacific: Case Studies.

- Kowalkowski, C., and Ulaga, W. (2024). Subscription offers in business-to-business markets: Conceptualization, taxonomy, and framework for growth. Industrial Marketing Management, 117, 440–456. [CrossRef]

- Kurnia, S., Parker, C., Ali, M., and Karnali, R. (2019). The impact of multilevel contextual factors on is adoption at the inter-organizational level. Communications of the Association for Information Systems, 44(1), 421–459. [CrossRef]

- Lambert, D. M., and Enz, M. G. (2017). Issues in Supply Chain Management: Progress and potential. Industrial Marketing Management, 62, 1–16. [CrossRef]

- Lee, H., Kim, M. S., and Kim, K. K. (2014a). Interorganizational information systems visibility and supply chain performance. International Journal of Information Management, 34(2), 285–295. [CrossRef]

- Lee, H., Kim, M. S., and Kim, K. K. (2014b). Interorganizational information systems visibility and supply chain performance. International Journal of Information Management, 34(2), 285–295. [CrossRef]

- Leppikorpi, T. (2018). Utilizing information systems in inter-organizational collaboration and information sharing.

- Lim, W. M., and Koay, K. Y. (2024). So, you want to publish in a premier journal? An illustrative guide on how to develop and write a quantitative research paper for premier journals. In Global Business and Organizational Excellence (Vol. 43, Issue 3, pp. 5–19). John Wiley and Sons Inc. [CrossRef]

- Loro, C., and Mangiaracina, R. (2022). The impact of e-marketplace on the B2b relationships. Industrial Management and Data Systems, 122(1), 37–54. [CrossRef]

- Mahdi, S., Ratnasari, D., Purwani, S., Herawati, T., Budiono, R., Subartini, B., and Sukono, S. (2024). Analysis of Factors Affecting Barriers to Learning English for Students Using SEM-PLS. International Journal of Instruction, 17(2), 419–438. [CrossRef]

- Mittal, V., Han, K., Lee, J. Y., and Sridhar, S. (2021). Improving Business-to-Business Customer Satisfaction Programs: Assessment of Asymmetry, Heterogeneity, and Financial Impact. Journal of Marketing Research, 58(4), 615–643. [CrossRef]

- Mittal, V., and Sridhar, S. (2020). Customer based execution and strategy: Enhancing the relevance and utilization of B2B scholarship in the C-suite. Industrial Marketing Management, 88, 396–409. [CrossRef]

- Mukhamedjanova, K. A. (2020). Concept of supply chain management. Journal of Critical Reviews, 7(2), 759–766. [CrossRef]

- Radhakrishnan, A., Davis, J. S., Sridharan, S. V., Moore, D. W., and David, D. (2018). The impact of inter-organizational information systems-enabled external integration on capabilities of buyer–supplier dyads. European Management Journal, 36(4), 558–572. [CrossRef]

- Rahman, M. S., Gani, M. O., Fatema, B., and Takahashi, Y. (2023). B2B firms’ supply chain resilience orientation in achieving sustainable supply chain performance. Sustainable Manufacturing and Service Economics, 2, 100011. [CrossRef]

- Ramos, E., Pettit, T. J., Flanigan, M., Romero, L., and Huayta, K. (2020). Inventory Management Model Based on Lean Supply Chain to Increase the Service Level in a Distributor of Automotive Sector. In Int. J Sup. Chain. Mgt (Vol. 9, Issue 2).

- Richey, R. G., Roath, A. S., Adams, F. G., and Wieland, A. (2022). A Responsiveness View of logistics and supply chain management. Journal of Business Logistics, 43(1), 62–91. [CrossRef]

- Saani, J. I. (2019). Management Information Systems. https://www.researchgate.net/publication/340647719.

- Somapa, S., Cools, M., and Dullaert, W. (2018). Characterizing supply chain visibility – A literature review. International Journal of Logistics Management, 29(1), 308–339. [CrossRef]