1. Introduction

Pipeline facilities act an essential aspect of moving materials like oil, gas, and even water from one region to another. This is because failure of these pipelines poses serious consequences on environment, economy and safety of the people (Wu et al., 2023). Normally, inspection and maintenance are carried out in a traditional way, which is to repair or replace the failed components. In this regard, predictive control methodologies that define probable faults before their criticality has emerged as highly important. Of these, the Magnetic Flux Leakage (MFL) system was particularly highlighted as a powerful and efficient approach to NDT as well as pipeline condition assessment (Peng et al., 2020).

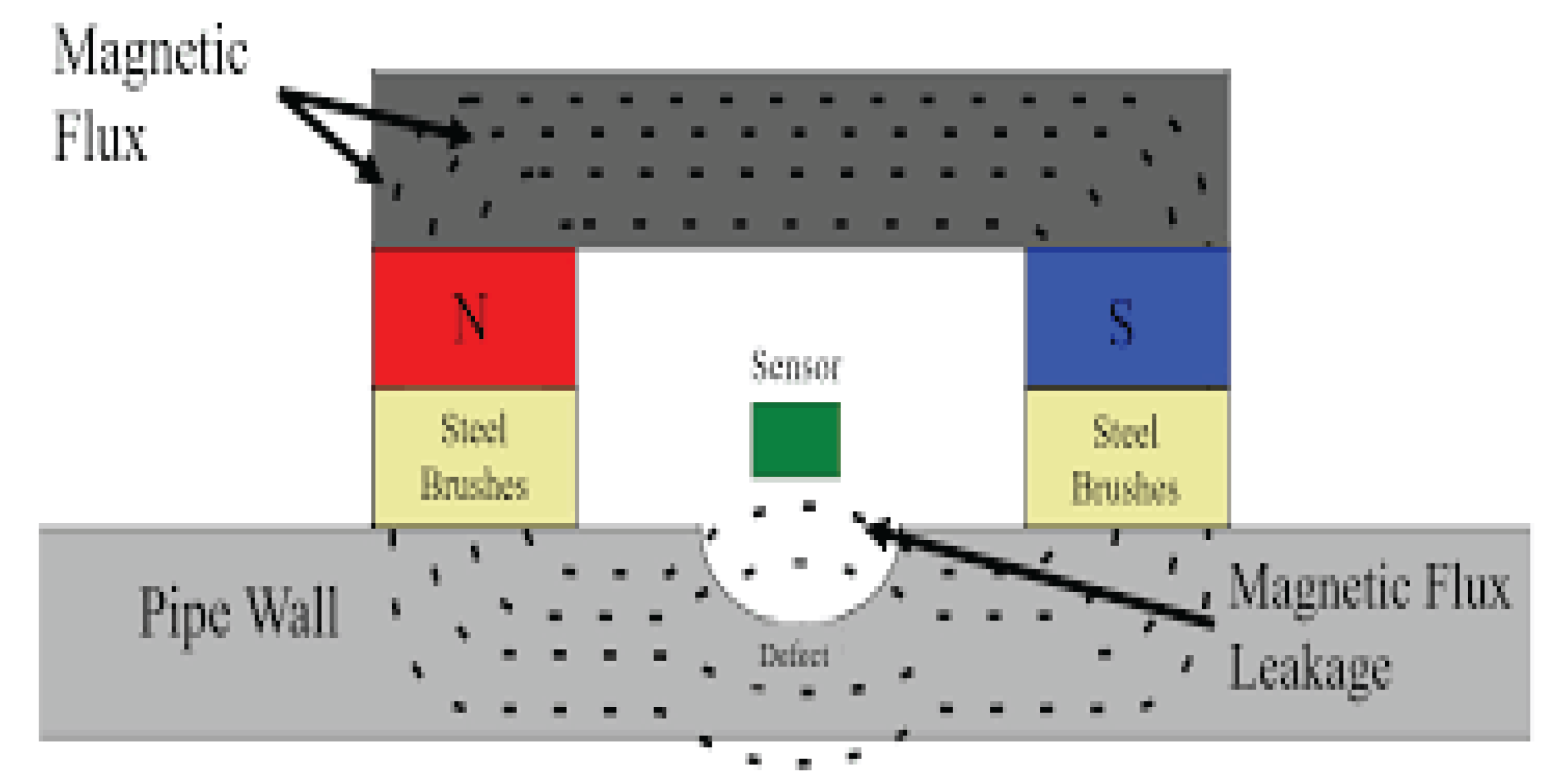

MFL technology is based on the magnetic flux distortion method. When a magnetic field is introduced into a pipeline, the presence of defects including cracks, corrosion or material degradation distorts the magnetic field from the desired path (Piao et al., 2020). With the help of these leakages, which are captured and analyzed with MFL system and its specialized sensors, flaws could be detected with great accuracy (Tang et al., 2021). The technique has an advantage of offering real-time data, and can cover large pipeline areas within a short time, and can identify both topographical and subterranean irregularities.

Applying the MFL system as a predictive controlling method helps operators switch from reactive to preventive approaches to maintaining assets (Peng, 2021). It helps identify any site-related problems and address them while they are still at infancy to avoid translating them into expensive problems. In addition, combining MFL data with subsequent analysis and machine learning improves its prognostic characteristics, revealing the evolution of defects and pipeline durability (Wang et al., 2024). This paper focuses on use of MFL system in context of its use as a predictive tool, its technical considerations, benefits, and contribution towards the longevity of pipelines.

2. Predictive Control in Pipeline Management

In 2021, Ma et al proposed several non-destructive testing (NDT) methods. Eddy current testing (EC), electromagnetic acoustic technology (EMAT), ultrasonic testing (UT), and magnetic flux leakage (MFL) testing were some of the methods. It has been possible to construct un-piggable robotic inspection systems or a single modality or many types of integrated NDT systems called Pipeline Inspection Gauge (PIG). This investigation looks into several inspection techniques in relation to non-destructive testing. Additionally, failure prediction, maintenance, categorization, and defects measurement are all done with data structures and management. Ultimately, the difficulties, issues, and advancements in pipeline inspection and data management have been identified and examined.

In 2021, Sun et al developed an enhanced dragonfly technique, the fuzzy surfacelet neural network was tuned to raise the pipeline's integrity management assessment level. The first is a summary of the pipeline integrity management research advancements, both domestic and international. Additionally, the system for evaluating pipeline integrity management is built depend on the technological and managerial features of pipeline integrity management. The updated inertia weight and population initialization strategies form the basis of the enhanced dragonfly method. Simulation outcomes demonstrate the usage of fuzzy Surfacelet neural networks optimized by improved dragonfly algorithms has shorter convergence times than other assessment designs, achieving convergence after 500 iterations. Compared to previous assessment models, the suggested model has a lower mean square error, ranging from 0.79 to 1.02%.

In 2021, Yongsheng suggested the "two major risks" of complex geological changes as well as regular human activity, along with the "three problems" of inadequate application of legislation, rules, and standards, low construction as well as management cost estimation, Furthermore, depend on actual business situation of mountainous pipeline company, the general concept of digital transformation with "five longitudinal + two transverse pipelines and two systems" was proposed.

In 2024, Wang et al examined a design of a data-driven online model system for urban water pipeline networks that utilizes GIS in order to address problems like one-way information flow, challenges with GIS data interchange, the inability to accomplish cross-departmental data sharing, and growing data silos. In order to accomplish network topology relationship management, pipeline inspection and operation, pipeline leakage control, and water supply schedule simulation, this employs a service-oriented SOA architecture and makes extensive use of Internet of Things, big data, and WebGIS technologies. The investigation carried out related testing and analysis on the system's operational efficacy. 86% of the marketing water volume could be fixed within the secondary partition water meter in order to control pipeline leaks. Water supply schedule simulations make up the highest percentage about 60% of pipeline network online models that support business processes.

In 2023, Wu et al offered the most inexpensive and effective method of transporting oil is by pipeline, and pipeline safety management serves as a useful tool for preventing pipeline accidents as well as guaranteeing the safe and reasonable operation of pipelines. One of the most important aspects of pipeline integrity management is timely and accurate pipeline leakage monitoring, that significantly lessens the effects of accidents. Lastly, the future advancement trend of pipeline leakage monitoring techniques has been boiled up and forecasted: the integrating of information systems, the integration of hardware and software.

In 2022, Chen et al discussed the tensile strain capacity of an X80. The tensile strain capacity (TSC) concept became utilized extensively to pipelines which undergo expectable plastic strain to both configuration and services. Nevertheless, certain stress-based designed pipelines encountered unforeseen plastic strain with last ten years, leading to failure. The beginning of stable tearing is represented by this limit condition, which often offers a rather conservative estimate.

In 2019, Dakheel

et al explored the viability of developing a comprehensive intrusion detection system for the gas pipeline sector, which makes use of current artificial intelligence (AI)-based systems to alert a gas controller to unforeseen modifications with pipeline characteristics, such as weight, delta pipeline PSI, time interval, and stream rate. It might be developed into an engaging crack-checking method, but testing in real-world, intricate structure configurations with the help of suitable AI demonstrating experts is also anticipated to increase the likelihood that the true usefulness of this adjustment-mechanized innovation will be understood. For instance, backfeeding and by-passing, as well as other explicit structural requirements that call for redesigned arrangements using AI. The Automation trends in pipeline management has been illustrated by

Figure 1.

In 2020, Lu et al have determined the strain-based design (SBD) technology. This approach has garnered increased interest from the industry for evaluating the strain capacity of in-service stress-based pipelines, particularly those which experience ground movement. Stress-based pipelines must have their strain capability evaluated in order to maintain their structural soundness and operational security. The PRCI-CRES TSC model and the CSA Z662-11 Annex C technique are the two primary publicly available approaches used to forecast the TSC. TSC assessments occur using real pipeline information and construction data whenever feasible.

In 2020, Levy investigated a multisensory technique which involves sophisticated GIS technologies. Real-time geospatial disaster management as well as decision-making are supported by the suggested system construction, which also incorporates incident reports and thematic maps. This novel offers a practical response towards the expanding issue of pipeline accidents. This has been demonstrated that the network's structure could mitigate the effects of pipeline incidents within the larger environmental, regulatory, socioeconomic, and physical contexts, in addition to emergency response times.

In 2022, Fang

et al explained a prediction technique that could be used in fluorine chemical pipeline locations that have been prone to erosion. The fluorine chemical industry's typical working environments have been compiled in order to create a computational fluid dynamics (CFD) technique to industrial pipelines. With regard to the findings, the pipeline's erosion-prone sections are anticipated. The technique appears to be used in numerous sizable petrochemical businesses and is universally applicable. This accomplishes the goal of accurately and scientifically identifying the regions where pipeline erosion is most extreme. The

Table 1 represents the analysis on Predictive Control in Pipeline Management.

3. Magnetic Flux Leakage (MFL) Technology

In 2020, Peng et al introduced in-line inspection (ILI) is performed to evaluate the pipeline's integrity and identify and measure metal loss. The MFL signal and data analysis aid in the prediction and quantification of corrosion. Signal processing techniques and descriptive methods that are intended to improve measurement and characterize corrosion have been defined and examined in relation to corrosion quantification. Throughout this work, researchers explore several MFL data matching methods for corrosion prediction which align flaws by consecutive ILI runs. Following that, simulations of corrosion growth were developed with the goal of forecasting the corrosion situation in the future. The corroded pipeline's evaluation of reliability is also examined. The possibility of combining MFL with additional non-destructive testing (NDT) methods is also investigated.

In 2022, Durai et al presented the floor faults of a petrochemical storage tank have been analysed using the magnetic flux leakage (MFL) approach. Due to the materials being housed, tank floors are more susceptible to various types of harm. The MFL approach is recommended for inspecting tank floors, which are primarily composed of ferromagnetic materials. Since flux leakage enhances health and safety inspection in dangerous work conditions, a robotic MFL system is used here to examine the flaws. The power and detection units are the two main components of this system. The power unit regulates the robot's movement, while the detection unit handles the investigation of defects. Two kinds of flaws, including holes and grooves, have been added to the low carbon steel plate. Plotting of the collected data is done using an Arduino connected to the computer. Additionally, the computed error percentage for the measured signal was within 10%.

In 2021, Peng et al provided the benefits of magnetic flux leakage (MFL) testing technique include modest requirements on the surface of the detected workpiece, easy technical implementation, and a straightforward principle. As a result, it is frequently utilized for testing long-distance pipelines and has been one of the research hotspots with field of non-destructive testing (NDT). The evolution of MFL testing technology was discussed in this study by the perspectives of fundamental theory, influencing variables, magnetization technology, signal processing, etc.

In 2022, Hao

et al proposed the quality of magnetic flux leakage (MFL) signal, which signifies the leaking of magnetic field lines close to the magnetized specimen's fault, is essential to non-destructive quantitative testing method. Although the magnetic shielding (MS) method is intended to improve the quality of the MFL signal, its use is limited by the discrepancy with modeling findings and current trials. To analyse the experimental outcomes quantitatively, researchers created a finite element modeling approach for the MS effect. The

Figure 2 represents the Principles of Magnetic Flux Leakage system.

In 2021, Javed et al developed the magnetic flux leakage (MFL) technique were detected as a promising non-destructive testing method for detecting metal loss in external post-tensioned tendons and stay-cables. The constructed system shows that the magnetization of steel strands which is buried at a depth of 8 inches was feasible. Furthermore, a set of user interfaces has also been improved in a programming language in order to enhance data handling and representation. To detect defects in the embedded tendons, this method starts with near surface magnetization followed by far surface reading. Surface scans of the bridge spans for the coupler bar showed irregular areas that may be suggestive of a failure or structural defect.

In 2020, Piao et al proposed that the pipeline sector employs the magnetic flux leakage (MFL) inspection technology frequently to locate defects and ensure pipeline integrity. While the high-speed inspection, there was relative motion with the steel pipe wall and the PIG, which resulted in motion-induced eddy current (MIEC). This study employs finite-element method (FEM) simulations in three dimensions (3D) with inspection speeds ranging from 0 to 8 m/s and wall thicknesses between 8 and 15 mm. Both thick-wall thickness and high-speed inspection will reduce the magnetization of steel pipes, according to simulation studies. Three-axis MFL signals are severely distorted, and the signal-to-noise ratio (SNR) is less than 6 dB, when the steel pipe exits a magnetic saturation zone along with the magnetic field strength is less than 2 kA/m at a speed of 8 m/s and a thickness of 15 mm.

In 2020, Zhang et al examined the detection of magnetic flux leakage (MFL) is the most popular technique in the field of non-destructive testing (NDT) of wire rope. The high weight, poor sensitivity, low recognition rate, and big volume are the drawbacks of the conventional single-dimensional MFL detection method. After noise reduction, transformed the three-dimensional MFL signals into RGB space to make it possible to image with colour. Colour photos of broken wire flaws had been then cropped using the localisation and segmentation technologies. Also, the identification rate of broken wires could be effectively enhanced by the application of three-dimensional MFL colour imaging.

In 2023, Yousaf et al offered the 2D MFL signals (Bx, By) in D19 rebars under different defect conditions. This work also sought to enhance the capacity to assess the defect aspects like spread, depth, and area from the MFL signals (Bx, By). The experimental and numerical outcomes represent a high cross-correlation with a mean of 0.860 and the median coefficient of 0.920. The width and depth of the two-dimensional flaws in this two-dimensional MFL signal examination were at times entangled and could not be measured individually. The total fluctuation for signal amplitude of magnetic flux leakage signals with an x-component (Bx) has been used to quantify the defect area.

In 2021, Wu et al discussed MFL testing is mostly utilized in inspection of steel structures as a promising NDT method using a considerable number of times. However, the identification of internal defects in MFL testing is still relatively challenging. Most of the present MFL course studies are confined to surface-breaking crack, while little emphasis is placed on internal flaw. Through the development of magnetic circuit designs, the performance of numerical simulations and MFL tests, the study explores the MFL process of interior flaws. This is found which the near-surface wall improves the MFL course since steel has higher permeability than air. In addition to increasing the observable depth of interior flaws, this paper develops a high sensitivity MFL testing technique that employs an induction coil with a high permeability core and Helmholtz coil magnetization.

In 2021, Tang

et al explored ways to prevent the wearing of magnetic sensors, an air or non-ferromagnetic wear-resistant layer is applied in the conventional MFL detection. On the other hand, the MFL signal amplitude and the detection sensitivity will reduce with the increase in the lift-off. An innovative MFL detection technique using the ferromagnetic lift-off layer is then presented. The ferromagnetic lift-off layer is provided with a via groove so that there is space for air under the sensor. The local magnetization intensity around the fracture on the sample is enhanced by the leakage magnetic field (LMF) enabled by the through groove while the lift-off layers through groove is also made more magnetized by the LMF enabled by the crack. Therefore, a higher MFL signal is obtained by the magnetic sensor placed above the through groove. The assessment on Magnetic Flux Leakage (MFL) Technology has been illustrated by

Table 2.

4. Evolution of MFL in Pipeline Inspection

In 2020, Blanco determined a number of defect sizing techniques developed based on MFL signal. Improvements in reliability are still called for by the industry, however. In the current concept, a calibration curve-based approach for reconstructing defects using MFL signals is proposed. These correlations with defect size and MFL signal features might be explained by considering the various factors considered in the different investigations. This paper employs a conceptual, mathematical, and experimental model to give a reliable three-dimensional system for this study. The calibration curves for the inner and outer fault configurations are also available. The computations and the analyses indicate superposition of the MFL signal.

In 2023, Pan & Gao investigated the interior examination of oil and gas pipelines, the most utilized non-destructive method is Magnetic Flux Leakage (MFL) testing. One of the most significant issues that have remained constant in the pipeline leakage detection is the measurement of faults. As a result, scientific defects marking and classification is a prerequisite for precise quantification. Segmented pipelines are scanned to identify the number and location of defects by utilizing an improved CLIQUE approach to tag the defect areas. Next, the characteristic signals for 3D MFL of designated areas are checked and obtained. They are categorized by training the SSA_BP neural network of the seven flaws. The outcomes prove that the approach is superior in the detection of defects and superior in the extent of detection of areas.

In 2024, Chen et al explained the lift-off value for detection probe and the vibration response of a multi-sealing disc pipeline inspection robot when crossing a girth weld is investigated using co-simulation under different design parameters. The fluid-structure interactions simulation technique of MSC/ADAMS and MATLAB/SIMULINK is developed with consideration of the coupling with the fluid and the robot. The results prove that the dynamic reaction is sensitive to the variations of the running speed and sealing disc interval. The degree of reciprocating oscillation with time history curve and the extreme value of the vertical acceleration decreases significantly when the running speed increases. Lift-off correction and structural fatigue analysis are two areas that gain from the evaluation that is offered.

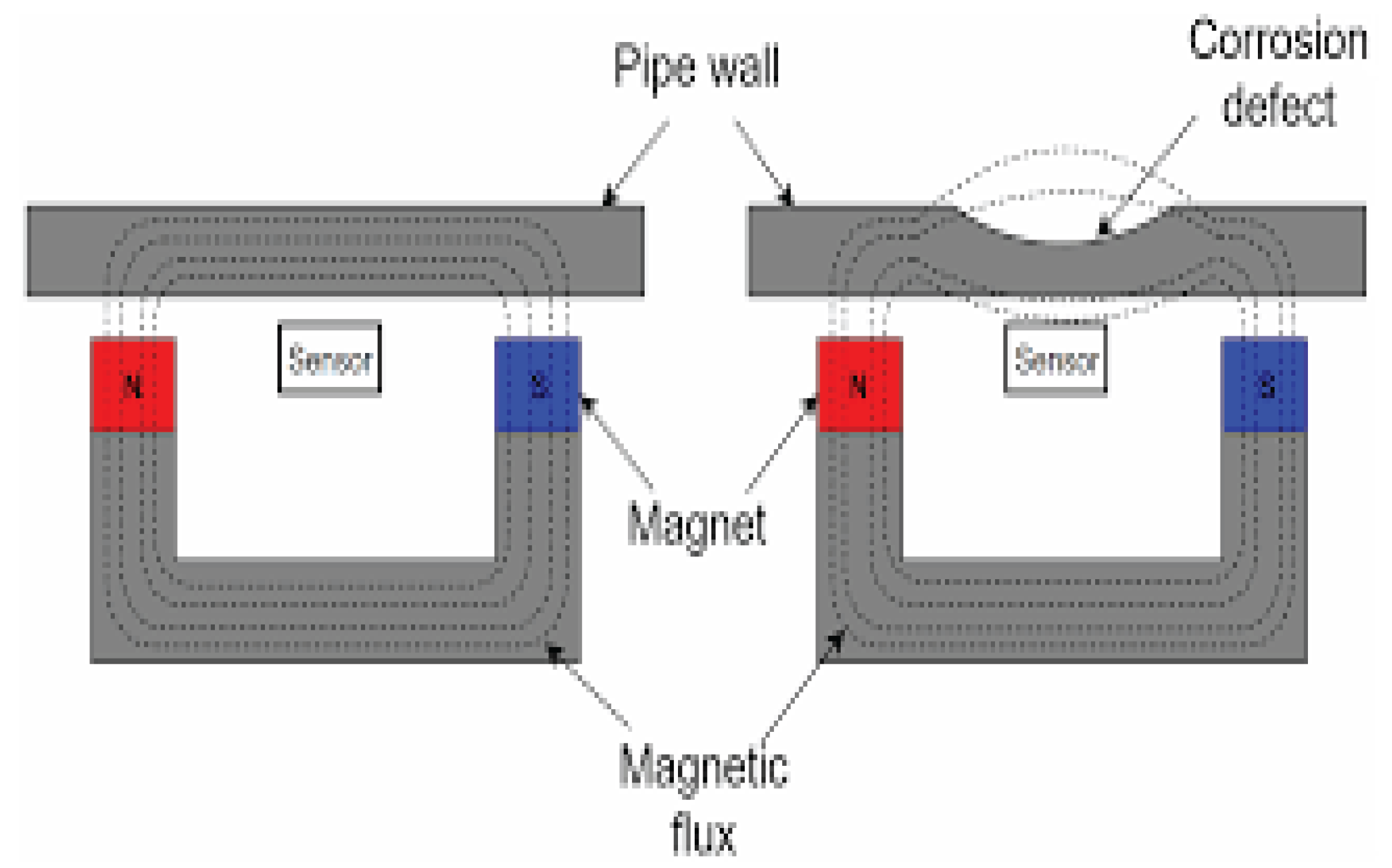

In 2021, Peng introduced the pipeline industry regularly performs in-line inspections (ILI) utilizing the magnetic flux leakage (MFL) technology. The pipeline integrity management (PIM) program, which makes decisions about pipeline integrity maintenance, depends heavily on the ILI data. The goal of this thesis project is to use MFL evaluation of data to help the PIM program's decision-making process. To get a contextual representation of the corrosion flaws, the parameterization notion is first proposed. Similar corrosion difficulties which might severely compromise the integrity of the pipeline might be retrieved by structural engineers with the aid of this high-level representation within the PIM program. The suggested method aligns the coordinate systems of two data sets using a Gaussian mixture model and a sliding window searching technique. Additionally, the POD of their combination is studied by integrating the inspection data from several tools. The in-line inspection of MFL has been depicted by

Figure 3.

In 2023, Parlak & Yavasoglu presented many smart pigs utilized in steel oil and gas pipelines and groups them according on their application regions, anomaly-detection capabilities, functioning principles, and pipeline structure. There is discussion of the benefits and drawbacks of every sensor method which could be utilized with a smart pig for in-line inspection (ILI). The following sensors were examined in this context: mechanical contact (MC), eddy current (EC), electromagnetic acoustic transducer (EMAT), magnetic flux leakage (MFL), as well as ultrasonic testing (UT). A thorough examination for the growing history of these sensors in the literature is also included in this article. Furthermore, the accuracy of various sensor technology configurations in determining the depth, length, and width of anomalies is compared. ILI is crucial for preserving pipeline dependability and safety; however, it might also be advantageous for the surroundings.

In 2024, Beairsto et al provided the assessment of metal loss in steel pipelines using passive magnetic flux density (MFD). The ferromagnetic characteristics of steel pipes were used to assess pipeline condition from the early invention of MFL techniques in the 1960s, and ongoing advancements have improved the tools' resolution. Nevertheless, nothing is known about how low resolution MFD analysis might be employed to examine pipeline conditions. This method offers a pipeline integrity evaluation that is as least as accurate as hydrostatic testing and has enough resolution to comprehend pipeline wall status. That then shows how the Pipers® solution could be used as a low-resolution inline inspection tool to ensure that pipelines are managed safely and legally by using this knowledge of the passive MFD. Finally, the method is justified by comparing with an MFL inspection.

In 2024, Zhu et al developed the resources for offshore oil and gas are crucial to the energy requirements of the human society. Being crucial facilities for storage as well as transportation of offshore gas and oil, the system of subsea pipelines, interconnected with each other, should be inspected and maintained on a regular basis to ensure safe functioning and exclude the negative impact on the environment. It has been noted that the processes of possible risks identification and examination inside the pipeline network have widely used in-line inspection (ILI) procedures. In this work, an overview of ILI approaches that have been used in subsea pipelines has been presented, in addition to a discussion of their advantages, disadvantages, appropriate application, and effectiveness. It might be useful for those involved in managing pipelines and planning, and the authors aim at providing useful information to engineers that select ILI technology.

In 2024, He et al developed the Oil and gas pipeline defects are often detected using magnetic flux leakage (MFL), among the major utilized non-destructive testing techniques. By detecting the variety and shape of pipeline faults based on the MFL signals of various problems is a very important and difficult work, which has attracted much attention of engineering and academic circles. To investigate the signal features and distinguish inner and outer defects simultaneously, the framework establishes a finite element method (FEM) technique for the MFL signal of nearby issues based on Maxwell theory. When the distance with neighboring defects increases, the interference is less strong. An interference distance concept is defined using the rate of variation in the peak value of MFL signals for assessing the interference caused by different faults. As a result, this research might reduce the errors brought on by nearby flaws by supporting the use of MFL technology to identify adjacent faults on steel pipelines.

In 2019, Simon et al suggested, a high-density polyethylene (HDPE) walled sour gas pipeline owned by Shell Canada (Shell) experienced internal corrosion failure. As a result of that breakdown, Shell closed all of its lined sour gas pipelines until the internal corrosion process had been monitored and each pipeline's integrity could be confirmed. The pipelines had a non-metallic liner, which made full in-line inspections (ILI) difficult. This became common practice to finish such ILI using magnetic flux leakage (MFL) smart pigs by removing and reinstalling liners, but this was impractical in this instance. Industry has utilized the existing remote field testing (RFT) ILI equipment to examine cement mortar lined (CML), reinforced concrete, and unlined pipelines. Following the success of the HDPE-lined pipeline examination, Shell recently inspected a 28-year-old CML-produced water pipeline using a similar technique. On the pipeline, external corrosion at disbonded coating areas has been determined to be active. The successful implementation of RFT ILI technology, which became a crucial component of Shell's pipeline integrity management program, is summed up in this report along with the lessons learned.

In 2021, Roslee

et al suggested the second-biggest producer of natural gas and oil in Southeast Asia and among one of the world's top three exporters of liquefied natural gas, Malaysia has demonstrated that its oil and gas sector has developed quickly, which has led to a rapid evolution in the use of steel pipes. When it comes to moving fluids, such as gas, water, steam, petroleum, etc., steel pipe is crucial and frequently used. The two biggest issues facing the oil and gas sector are corrosion and obstruction. When thorough care is not taken, this procedure is too risky. Ironically, the actual pipeline inspection procedure carried out by oil and gas companies is not fully depicted by the execution. Steel pipe is employed in this study to simulate the actual pipeline inspection scenario. Ultrasonics were used as the primary sensors in a simulation utilizing the finite element analysis approach, and the results demonstrate which ultrasonic may successfully enter the steel pipe. The assessment on Evolution of MFL in pipeline inspection is represented by

Table 3.

5. Types of Pipeline Defects Identified by MFL

In 2024, Chen et al examined the need for fossil fuels rises, long-distance oil and gas pipelines has emerged as the primary means of moving these resources. Long-distance pipelines were vulnerable to surface flaws due to their complex environment, that presents a serious safety risk. One non-destructive testing (NDT) technique for mapping and tracking pipeline flaws is magnetic flux leakage (MFL) detection. Nevertheless, the data processing and analytics techniques employed can seriously impair the precision and dependability of MFL detection. YOLOv5 and Vision Transformer (ViT), two well-known computer vision computations, are combined in this study to create a novel hybrid approach for pipeline defect identification that allows for simultaneous, precise pipeline defect detection along with categorization. The database includes the modified pipeline faults, such as metal corrosion, geometrical defects, loss of metal material, and geometrical structures, among others.

In 2024, Wang et al examined Data-driven methods were successfully studied for MFL defect identification, and magnetic flux leakage (MFL) testing is frequently utilized to get MFL signals in order to identify pipeline flaws. Nevertheless, present techniques are limited by inadequate information by single modal data, that do not meet detection criteria, and pipeline problems are becoming more complex. In order to identify defects, multi-modality hierarchical attention networks (MMHAN) are suggested. The suggested MMHAN was evaluated by extensive tests on multimodal pipeline datasets. The experimental findings validate MMHAN's remarkable performance by showing that it obtains a better identification accuracy.

In 2020, Chen

et al offered the simulation error in the feature depth as well as length estimation from the in-line inspection tool is one of the common sources of uncertainty which must be taken into account while predicting pipeline burst pressure. For instance, for the Common kind of corrosion, a frequently stated corrosion depth sizing parameter is ±10% of pipe wall thickness with 80% confidence. The burst pressure computation will then take into account the distribution's shape, mean, and standard deviation as constants. But for a sample of real-world flaws, these variables are never consistent. Actually, they should be variables based on individual features. An illustration of such a method might involve feature-specific error tolerance, where a feature's estimated depth is 36%wt with 80% confidence with an interval of [30%, 48%] of wall thickness.

Figure 4 determines the Corrosion defects on pipelines.

In 2021, Liu et al discussed the most popular and successful technique for long-distance online detection of oil and gas pipelines is pipeline magnetic flux leakage (MFL) internal detection technique. The impact of stress on the MFL signal has received increasing attention as the precision of data quantization has increased. This work introduces the J-A theory-based link with stress and saturation magnetization. The MFL detection signal analytical framework for pipeline composite faults has been developed. Composite flaws' MFL signal properties have been calculated quantitatively. Stress's impact on the MFL signal is investigated. Findings from excavation and experiments validate the theoretical analysis. According to the studies, in a strong magnetic field, ferromagnet saturation magnetization drops exponentially as stress increases. Comparing composite problems to volumetric flaws for the same dimension, the MFL signal is weaker.

In 2022, Feng et al discussed a nondestructive testing technique that are used extensively in pipeline maintenance is magnetic flux leakage (MFL) inspection. Defect identification, evaluating the locations of defect MFL signals in MFL heat maps, is an essential step in pipeline MFL data processing. Due to noise and interference, MFL signals obtained by the pipeline were not optimal. The identification procedure must be coordinated with the upgrading process in order to overcome this obstacle. Through task-oriented joint training, the gray value contrast with pipe wall signal locations and defect signal areas in MFL heat maps is improved by roughly 10 to 48. A unique loss function is also devised. The recognition accuracy is increased to 97.3% and the suggested strategy obtains an average precision (AP) of 0.967.

In 2023, Liu et al explored the best techniques for evaluating long-distance gas and oil pipelines is internal magnetic flux leakage (MFL) detection. To check the applicability of the statistical model, systematic experiments have been conducted on X70 pipes with different wall thickness. The results proved that due to thickness of pipe wall, the signals of exterior flaws of the MFL were reduced. The MFL signals increased with a first order exponential fashion up to a maximum error of 18.8% and a minimum error of 2.0% as the defect depth increases by 0.6 to 7.2 mm. The present research helped in quantifying the outer surface defects by giving a clear description of the propagation characteristics of MFL signals of outer surface defects.

In 2024, Yigzew et al established that one of the most effective non-destructive techniques for detecting flaws in steel construction is magnetic flux leakage (MFL). In this work, the authors introduce a new MFL based 3D visualization technique for the identification and characterization of metal loss flaws, which are a major concern in a number of industrial applications where specimen reliability is critical. One popular non-destructive method for identifying flaws in steel constructions is magnetic flux leakage (MFL). In this work, researchers explore a 3D visualization method depend on magnetic flux leakage (MFL) for detecting and assessing metal loss flaws, that are a significant issue in a number of industrial domains where specimen structural integrity is essential.

In 2023, Liu et al investigated the standard methodology for global oil and gas pipeline safety maintenance is magnetic flux leakage (MFL), an internal pipeline detection method. It is suggested to use the contour plot technique to visually assess the extent of flaws. Experiments had been carried out methodically on the X70 pipeline using internal MFL technologies in order to contrast the inaccuracy with uniform and non-uniform models and confirm the accuracy of the theoretical representation. Near the surface and edge, the magnetic charge density rises sharply as the defect breadth and depth increase.

In 2022, Chen et al explained the main challenges impacting magnetic flux leakage (MFL) internal inspection technologies are the capacity to characterize corrosion and gouging related to metal loss as well as capacity to distinguish between different forms of gouge and metal loss defects. A two-stage finite element (FE) model is constructed to forecast magnetic flux leakage caused by two different kinds of defects. By empirically correlating the properties of the MFL signals for every defect type, it was confirmed that the MFL approach could be used to detect and identify corrosion and gouge at low-level magnetization.

In 2022, Zhang et al introduced a unique direct inversion method depend on cascading abstract features to address the aforementioned issue. Initially, a stacked multipath denoising sparse autoencoder (sMPDS-AE) adaptive abstract defect feature extraction network is built, along in a number of additional feature transmission channels. Secondly, the sMPDS-AE framework is strengthened and abstract feature dimensions are unified through the use of multifeature fusion and sparsity rules. Thirdly, a new ensemble-backed predictor is created to investigate the intricate nonlinear correlation among defect sizes and abstract attributes. With the structure described above, the suggested approach might effectively extract abstract aspects of pipeline problems from MFL signals and more precisely differentiate between defects of varying magnitude. Lastly, a pipeline network with MFL signals is used for a number of comparison tests. The superiority of this approach is confirmed by extensive study and experimental findings with other popular inversion techniques.

In 2022, Lang, X., Han presented a multilayer feature fusion multiscale GhostNet (MFMSGN)-based technique is suggested to increase the precision of magnetic flux leakage (MFL) image identification of corrosion flaws in pipelines. Lastly, an approach that is both efficient and lightweight has been suggested. According to the experiment's findings, the eight-layer MFMSGN to MFL corrosion defect identification has a slightly lower accuracy than ResNet101 and a higher accuracy than ResNet50, but it requires a significantly lower amount of computing power.

In 2021, Zhou et al provided the varieties of tubing flaws are broken down in this study into three categories: pit-like, through-hole, and strip-like defects. Additionally, compound problems are created by superimposing the three categories of single faults. After modeling the tubing with various defect kinds using the 2D finite element technique, the variance in MFL brought on by changes in the depth, width, and other parameters for a single defect has been simulated and examined, and a fitting formula and corresponding quantitative relationship curve are produced. According to simulation studies, magnetic flux leakage varies similarly in single defects and compound defects in varying defect parameters.

In 2024, Zhao et al studied the magnetic flux leakage internal inspection, this study conducts internal inspection and identifies weld flaws in oil and gas pipelines Researchers examine how to characterize the circumferential weld's leakage signal and develop a system for categorizing and diagnosing flaws utilizing the leakage signal's peak characteristics. The technique offers technical assistance for the automatic detection of weld flaws and could be applied to identification and assessment for weld defects in non-excavation settings, significantly lowering the expense of excavations inspection.

In 2023, Katser et al developed the number of industrial domains has recently focused on using computer vision for anomaly detection. Defect identification in oil pipelines is a significant example. A single oil pipeline collapse could result in a widespread breakdown or stop the entire transportation system from operating. But when it comes to doing this work, there is a lack in the relevant literature. The goal of this work is to mitigate these problems. Furthermore, in order to achieve good performance when taking into account the relevant parameters, researchers suggested robust techniques and took advantage of contemporary convolutional neural network architectures. Real-world data was used to validate the suggested methods and their suitability.

In 2024, Jiang et al suggested the main problems with MFL signal processing is defect detection. Magnetic flux leakage (MFL) testing is an efficient non-destructive testing (NDT) technique to pipeline safety operation. Because of a lack of defect specimens, MFL defect detection is currently difficult. Heterogeneous signals are gathered in the MFL process to provide more useful information, however fully utilizing these signals remains a challenging task. This work proposes the heterogeneous signal fusion approach (IHSF), an end-to-end MFL fault detection architecture with insufficient training samples. Firstly, axial and radial sensors gather heterogeneous inputs from the same pipeline. Secondly, the features are made broader and more flexible by fusing the characteristics from pre-trained models that have been fine-tuned and those that have not. Lastly, MFL flaw detection experiments are carried out, and IHSF is contrasted with the most advanced techniques. The outcomes confirm the effectiveness of the suggested approach. Attention, Practitioners

In 2022, Zhang et al examined the safety detection of oil and gas pipeline using a two-axis magnetic flux leakage detection system. The detection findings are examined and evaluated. Several simulation computations have been used to optimize the number of network layers. Lastly, experiments are conducted using the information gathered on-site. According to the outcomes, the testing accuracy is 97.38% and the training accuracy is 99.19%.

In 2020, Fu et al examined the most practical and affordable way to transport natural gas and petroleum is via pipeline. It is difficult to precisely identify abnormalities with defined borders due to the complicated corrosion environment. By include the STLR, the model increases the disparity with the two components and boosts anomaly detection efficiency. In order to gather the measures with high saliency, the raw MFL measurements were at first processed using profile and filter transformations as part of an anomaly detection architecture that is suggested. Secondly, the modified measurements were splitted into certain blocks and all detection outcomes were combined utilizing a measurement fusion algorithm.

In 2019, Yu et al given the damaged pipeline defect inversion has widely employed magnetic flux leakage (MFL) inspection in nondestructive testing (NDT). The size estimation of defects in the inversion problem has been a challenge due to the dynamic environment that the MFL signal presents. In this research, a novel stacking learning-based pipeline defect inversion technique known as the WT-STACK is developed. This approach has two parts. Firstly, radial, axial, and circumferential signals are employed to construct a multi-domain feature extraction model. Secondly, an iterative stacking estimate network is constructed with dynamic multi-domain features as input to explore the complicated nonlinear mapping relationship with the feature and defect size. The network achieves adaptive learning, that improves generalization for various defect inversion problem sample sets. Lastly, tests utilizing simulation signals and MFL signals gathered by the experimental platform are used to assess the approach.

In 2024, Ren et al discussed the safety risks in oil and gas pipelines are increased by complex multiphase flow. Nevertheless, motion-induced eddy currents (MIECs) are created by the fast motion of MFL inspection instruments, making it more difficult to identify and measure flaws. This work uses these coefficients to investigate how the magnetizer arrangement and defect size affect these velocity-induced effects. A drop in peak-to-peak values is suggested by the amplitude deformation coefficients to porosity, internal corrosion, along with lack of penetration, which range between 0.86 to 0.98 for as well as -0.01 to 0.1 for Bx. Other faults, on the other hand, show a rise in peak-to-peak values, suggesting in which an MFL signal might be strengthened by the velocity effect.

In 2022, Geng et al explored the construction of long-distance gas and oil pipelines in recent years, there has been a steady rise in accidents, the majority that's where have had major repercussions. Statistics show that girth weld issues are responsible for a significant amount of pipeline cracking. Following training, 156 test samples are classified using the deep learning network, with a 78% prediction accuracy. The

Table 4 represents the analysis on Types of Pipeline Defects Identified by MFL.

6. Integration of MFL with Predictive Maintenance Frameworks

In 2019, Xie determined clever pigging instruments, in-line inspections (ILI) are conducted on a regular basis to find pipeline flaws such corrosion and cracks. Based on ILI data, this thesis offers a thorough analysis and foundational knowledge of pipeline integrity management. There is discussion of data-driven approaches and physics-based models for forecasting the evolution of flaws in pipelines with various defect types. An integrated prognostics model for a pipeline with a fatigue fracture is suggested as part of the more sophisticated prognostics approach in order to improve prediction accuracy. A simulation-based method is created to assess the cost of pipelines having corrosion flaws. Rather than using a fixed inspection interval, the input random variable is the probability of failure (PoF) threshold. Here, uncertainties from various sources are taken into account to improve and generate more accurate predictions, which aid in industry decision-making. When contrasted to the conventional fixed interval strategy, the suggested approach yields lower cost rate outcomes. Determining how ILI tool specifications affect pipeline risks and expenses is also crucial in order to suggest the best integrity assessment and risk mitigation practices.

In 2024 Chen investigated the pipelines carrying gas and oil (OGP) are essential to maintaining the economy. The supply and demand for energy are growing in tandem with the pipeline network's rapid expansion. However, many pipeline network safety operational problems occur while the transportation of oil and gas, like corrosion failure that results in leakage, which frequently causes fatalities, serious environmental harm, and financial losses. To find accident precursors and stop accidents before they happen, risk and reliability evaluations must be carried out. Additionally, it could predict the pipeline deterioration process, prevent significant failures, prioritize risk mitigation, and allocate resources as efficiently as possible. When operating, many types of OGP systems produce a lot of data. The suggested approach optimizes the weight distribution, resolves the inconsistency of current approaches to appropriately model fuzzy concepts, takes into account the uncertainty in the evaluation process, and produces an assessment outcome that is more rational and scientific. The reliability of the pipeline could be directly mapped to the magnetic flux leakage (MFL) inspection data using a residual neural network (ResNet)-based reliability prediction technique. Deep learning algorithms are successfully merged with pipeline defect-effective area models, as opposed to those based solely on depth.

In 2024, Ling et al explained a popular nondestructive testing technology for identifying and measuring flaws in pipeline inspection is magnetic flux leakage (MFL). Rebuilding flaws from MFL signals is essential for predicting failure pressure and making maintenance decisions in pipeline integrity management. In terms of modern research procedures, this reconstruction is mostly a matter of determining the dimensions of the defect which, taken together, form a rectangular parallelepiped and include length, breadth, and depth. However, this box-based approach might lead to low estimation of pipeline integrity in some cases. To further refine the reconstruction results and provide detailed defect information for integrity assessment, a 3-D reconstruction model of pipeline corrosion defects from MFL signals is provided.

In 2024, Abubakar et al states that long-distance transportation of hydrocarbon relies on pipelines, which are the backbone of the international oil and gas sector. There is need to ensure the consistency and reliability of these pipelines since their effectiveness play a major role in preserving the environment and the societies through which they pass as well as adequately satisfying the energy demands of the world. This work also posits that there is need to manage the integrity of pipeline assets in a more proactive way so as to avoid disastrous situations arising from terminal failures. Traditionally, pipeline asset management has been more of a firefighting process where issues are detected after they have become failures. These issues are compounded by aging pipeline infrastructure, which means that there is a need to develop a long-term approach that includes pipes as an element of the infrastructure throughout their life cycle. LCCA based DSS incorporates the use of sophisticated data analysis, risk evaluation, and optimization methods to support decision making that takes into account the life cycle cost of assets. In the end, establishing an LCCA-based DSS has the ability to increase pipeline infrastructure's safety, environmental preservation, and economic efficiency while providing a stable and secure future.

In 2021, Khan et al presented the energy-intensive economy, pipelines were the most crucial energy-transportation mechanism. Because major failures could have disastrous implications on the environment, society, and economy, pipeline integrity is possibly connected to continuous enhancement and resilience of modern societies. For responsible development and future prosperity, pipeline integrity and safety are therefore crucial. Pipeline integrity management has garnered interest from academics, practitioners, and regulators. The present research goals to document the evolution to risk-based techniques in integrity management, with a focus on last 20 years.

In 2023, Tu et al provided pipeline flaws utilizing the magnetic flux leakage (MFL) signal could serve as a solid benchmark and a trustworthy reference for estimating how long pipes that are still in use will last. However, the accuracy of recognition is severely hampered by the complexity of the MFL signal. The three steps of analysis for this model are feature extraction, combining features, and defect recognition. In order to eliminate duplicate features and realize information complementation within various feature sets, a multi-feature fusion technique that utilizes the Apriori algorithm and Dempster-Shafer (DS) evidence theory is developed in the second phase. Experiments demonstrate that the suggested design has a good anti-jamming capability and increases recognition accuracy.

In 2021, Wong & McCann that proposed Pipeline networks has been widely used to safely and effectively move waste items, natural gas, water, and oil over a variety of distances with little assistance from humans. Among the many state-of-the-art detection techniques which were used in different pipeline areas, this endeavour has successfully shed light on a number of unresolved research issues. Among these difficulties involve increasing a pipeline network's lifespan to lower maintenance costs and preventing disruptive pipeline failures to minimize downtime. The results of the taxonomy's examination will help researchers in the years to come to create effective, precise, and dependable failure detection systems by utilizing sensor fusion and data-centric approaches.

In 2024, Gao et al developed a technology for detecting pipeline defects is crucial to pipeline transportation and maintenance. In real-world engineering, machine learning-based defect identification has drawn a lot of interest. Due to low intra-class concentration and poor inter-class discriminability, it is still challenging to give a diagnostic and assess the severity of the defect. The DTML algorithm built on ResNet50 has the aim to learn discriminative features of the defect images acquired by vision sensors. The Gramian Angular Field (GAF) has been employed to attain the two-dimensional feature extraction for enhancing the features of MFL signals. The findings reveal which the suggested multi-modal cascade detection architecture is effective for both evaluating the degree of defects and detecting them.

In 2020, Xie et al posited that the probability of leakage due to localized defects may greatly rise when long-distance oil pipelines are near the end of their service life, hence the need for constant inspection and repair. One of the well-known NDT methods called magnetic flux leakage (MFL) inspection were employed. Due to large amount of monitoring data, the methods based on computer vision and deep learning are crucial for increasing the accuracy of detection and its efficiency. This method developed; a new cascade detection technique is proposed which integrates a new multi-input parallel convolution structure with the advanced visual recognition network YOLOv8. After performing the necessary experimental analysis, the data preprocessing technique has been found to surpass traditional approaches in terms of quantitative analysis and fault identification.

In 20222, Hosseinzadeh et al examined LHS, FEA, and ML to predict the RUL of pipelines with corrosion issues. For purposes of calculating the Failure Pressure and Failure Maximum Von-Mises Stress (MVMS) under the different circumstances of longitudinal spacing ([[EQUATION]]) and internal pressure (IP), finite element modeling is performed with ABAQUS software and with the assistance of Python programming. Internal pressure, longitudinal spacing, and other relevant variables are also in the dataset that the model generates for ML model training and evaluation. Grid search and overfitting checks are used to evaluate the model's performance. Future MVMS values and related failure probability could be predicted thanks to the dynamic updating of input data provided by a corrosion growth algorithm. To choose the most accurate model, the Probability of Failure (POF) is computed and the Probability Density Functions (PDFs) for failure pressure are examined utilizing Kolmogorov-Smirnov tests and standard distributions. By analyzing pipeline failures and probabilistic failure pressure over time, this method offers a strong foundation for predicting RUL and offers important insights into the security and reliability of pipeline systems in a range of scenarios and time periods.

In 2024, Fu et al offered the integrity of oil and gas pipelines is essential to guaranteeing the security of energy transportation, and as science and technology advance, there is a growing emphasis on the advancement and use of novel detection technologies. The history and practical significance of the chosen issue are first discussed in this study, which aims to investigate more effective pipeline inspection techniques to guarantee the steady operation of energy networks. Additionally, this method examines the benefits and drawbacks of traditional ultrasonic and magnetic particle flaw detection, as well as the new acoustic emission and fiber grating inspection methods, from the perspectives of physical principle and application practice. This method also demonstrates the use cases of each method in real-world projects. The advancement of these technologies not only increases the thoroughness and precision of inspections, but it also offers substantial assistance in achieving pipeline life cycle management.

In 2019, Tsai et al discussed the most significant problems within the petroleum sector is corrosion beneath insulation. To quantify the amount of corrosion on each pipeline section, inspectors typically replace the insulation to check for corrosion. Nevertheless, experience-based inspection might not be appropriate to each location due to the diverse conditions found there. In order to gather site data and incorporate it into a Building Information Modeling (BIM) structure, this study makes use of passive RFID sensors, that were smart sensing technologies.

In 2024, Li & Deng have explored the widely utilized NDE methods for inspecting pipelines to detect potential permanent conditions is magnetic flux leakage (MFL). This investigation assessed two basic ML-based approximation Bayesian inference methods, convolutional neural network and deep ensemble, to focus the input uncertainty resulted by MFL response data since the forward uncertainty propagation process is challenging to describe. The autoencoder models might have been further optimized with the help of prior information derived from massive simulated MFL signals. The improved autoencoder’s enhanced data is then used for classification of defects sizes by the use of machine learning. To examine the prediction performance and compare with liftoff uncertainty and prediction accuracy, the present research conducted a calibration-based prediction accuracy and uncertainty analysis. In overall, the suggested method of quantification of uncertainty helps in gathering valuable data for measuring reliability in inverse problems and decision making in MFL conditions.

In 2023, Lan et al identified that an effective monitoring system that can detect small leaks which may not be detected by several sensors and give feedback in real-time is still lacking. One significant benefit is that using DL techniques to integrate and analyze the data set by an unmanned aerial vehicle (UAV) could offer real-time feedback and forecast potential pipeline segments that might deteriorate over time. The use of this structure is anticipated to guarantee a most effective and proactive pipeline monitoring process for reducing risks and averting mishaps related to oil and gas spills or leaks.

In 2022, Mukherjee

et al investigated non-destructive evaluation (NDE) methods for inline inspection for such contemporary, massive pipe systems produce enormous amounts of data. The suggested approach gathers inline inspection data using laser profiling and is based on optical imaging. The laser-scan image's spatial and temporal characteristics were carefully considered, with special focus paid to utilizing the non-deformed laser rings' circular shape.

Table 5 represents the assessment on Integration of MFL with predictive maintenance frameworks

7. Advancements in MFL Sensor Technology

In 2024, Mukherjee et al explained a Neodymium-35 magnet to apply a powerful magnetic field to the target object, a steel plate. In the target plate structure, metal loss anomalies of varying sizes were purposefully created. The Hall magnetic sensor gathered and recorded information on both undamaged and damaged magnetic flux after scanning the target specimen at a steady pace. The raw flux leakage input was subjected to successive signal correction processes in order to improve accuracy and identify key features. The type of flux leakage in the magnetic Hall sensors was observed by analyzing the magnetic induction signal curve. To further grasp important aspects, frequency analysis and sorted amplitude analysis were performed. A low-pass filter and fast Fourier transform-based filtering were used to remove undesired flux leakage after box plot-based outlier identification. A three-step iteration-based wavelet decomposition was suggested as a defect allocation method, and it was effective in identifying the fault region.

In 2024, Li et al introduced Steel wire rope (SWR) inspection frequently uses magnetic flux leakage (MFL) technology for non-destructive testing. But in order to manage complicated noise situations and a variety of defect types, accurate defect characterisation necessitates sophisticated methods for processing signals. This method combines adaptive thresholding, discrete wavelet transforms, and multi-scale feature fusion to detect small flaws and large-area corrosion at the same time. By the median recall of 89%, precision of 91%, and an F1 score of 0.90 under high-noise settings, the suggested approach outperformed current approaches in detection performance.

In 2022, Sathappan presented the severe environmental conditions seen in refineries and thermal power plants cause oil and gas pipes to corrode. This work was spurred by intriguing issues like internal and external corrosion that have arisen from the growing need for pipeline protection. Early pipe problem diagnosis is therefore crucial to preventing catastrophic consequences. For high temperature conditions, a coil sensor (ferrite core with coil) with a magnetic circuit is designed. The resulting sensor establishes the foundation for the MFL technique's non-destructive evaluation (NDE) of pipe defects. The detection and characterization of MFL distribution brought on by metal loss in ferromagnetic steel pipes are the main objectives of the study. Deeply rusted pipe samples of various thicknesses in air are used for the first experimental verifications. The Giant Magneto Resistance (GMR) sensor (AA002-02) is utilized in conjunction with AlNiCo magnets. Using the radiofrequency identification (RFID) technology, the investigation is further replicated for saltwater conditions in connection to changing electrical conductivity. The relationship with underwater and magnetic data communication is another area of investigation. A coil sensor with its magnetic response at ambient temperature and high temperatures has been developed and experimentally evaluated as a consequence of the investigation.

In 2021, Sampath et al provided a new and very sensitive in-line inspection (ILI) technique to gas pipelines is presented in this work. The suggested approach is unique because it (1) combines two cutting-edge techniques to a more sensitive and accurate result, (2) inspects the target pipeline in real-time, (3) uses a specially made sensor array to estimate and locate defects in three dimensions, and (4) uses little power and is economically viable. To demonstrate the method's sensitivity and resilience, laboratory tests are performed on a variety of fault kinds. The present research project offers a strong foundation for a transition by a pilot study to a practical, real-time implementation of a unique pipeline inspection technique.

In 2021, Yigzew et al proposed the most popular nondestructive evaluations (NDE) techniques is the magnetic flux leakage (MFL) based methodology for the in-service assessment of pipeline abnormalities. The study is significant because it offers a trustworthy steel pipe inspection method based on MFL principles. A sensor head prototype is used in this investigation to detect and evaluate the MFL signal that leak as a result of metal loss. The steel pipeline is scanned using the specially built sensor head that has hall sensors. The targeted pipeline specimen's anomalies have been investigated using the measured MFL signals. To improve the resolution and extent for defect level, Hilbert transform-based wrapping and associated digital signal processing were carried out after the MFL signal had been obtained and evaluated. Traditional MFL signal processing has limitations that could lower the effectiveness of MFL-based steel pipe inspection since it necessitates the evaluation of substantial amounts of raw input and output data.

In 2021, Chen et al the safe transportation of pipelines is affected by a number of elements, including high pressure, an inflammable and explosive medium, a complicated and variable route environment, and others. Adopting several advanced and focused inspection techniques to find pipeline flaws, classifying various kinds of flaws, and then performing safety evaluation and maintenance is an efficient method of ensuring pipeline safety. In order to serve as a guide for advancement and implementation of in-line inspection technique on oil and gas pipeline girth welds, this article examines the primary failure aspects of girth welds and methodically compiles the information and techniques of several in-line inspection techniques on girth weld in light of such failure aspects.

In 2020, Shankar et al suggested the secure transmission of energy, pipeline operators in Canada invest around $1.5 billion annually in pipeline integrity. Pipeline integrity is most commonly achieved through the use of inline inspection (ILI) tools. Because those methods rely on human labor to complete the task, they can be expensive and have significant safety and environmental risks. An operator could maximize pump station bypassing by using this multisensor tracking technology, that boosts confidence in pig passages and flow rate calculations. Lastly, the Global System to Mobile Communications (GSM) and satellite link support IOT telemetry devices, ensuring worldwide coverage for remote tool tracking. The semi-permanent tracking solution's communication module is chosen depending on endpoints and connectivity.

In 2024, Wei et al examined the transfer of natural gas and oil beneath the sea, pipe-in-pipe systems are essential. For the security of energy transmission and environmental preservation, it is crucial to accurately identify and characterize pipe-in-pipe flaws. Even though magnetic flux leakage (MFL) testing techniques were frequently employed to identify also evaluate pipeline flaws, the outside metal pipe will always have an impact on inner pipe's detection signal throughout the testing procedure, causing the MFL signal to incorrectly represent the defect's magnitude. MFL pipe-in-pipe defect experiments were used to confirm the effectiveness of the simulation outcomes. These results are helpful for assessing MFL detection in subsea pipe-in-pipe quantitatively.

In 2019, Yang et al offered numerous local and international oil and gas pipeline leak incidents demonstrated that corrosion, cracks, weld joints, and mechanical degradation were the primary causes endangering pipeline operating safety. The most practical and widely accepted approach to guarantee the safe operation of gas and oil pipelines was to perform routine pipeline inspections. The robot's general dependability was confirmed through a traction testing conducted on pipeline by varying speeds (0.5–3 m/s).

In 2021, Zhang et al discussed the tiny leaks in oil and gas pipelines are harder to find with traditional monitoring and patrolling, they are more likely to have major repercussions than bigger leaks. Over time, a pinhole leak that goes unnoticed might cause serious contamination of the soil and groundwater. Using a pull test on a 10-inch pipe string with fabricated flaws, the usefulness and suitability of magnetic flux leakage (MFL) in describing and sizing pinhole defects are investigated. Blind scenarios were used to assess MFL technologies from five different suppliers. Additionally, the viability of detecting pinhole defects with hydrostatic testing is examined. The findings indicate that pinhole diameter, depth, position, and other factors could have an impact on the MFL signal.

In 2022, Sheikh et al explored bimorph sensors depend on the in-line inspection (ILI) technique has recently demonstrated a great deal of promise for identifying surface flaws in gas pipelines, such as corrosion. Initially, different sizes of corrosion defects were taken into account and examined utilizing piezoelectric theory. The following were the study's novel contributions: (1) To identify and measure corrosion flaws, the suggested analytical technique combines the piezoelectric effect with the vibrational mode forms of cantilever beams. (2) The present work suggested a bimorph sensor approach that could do real-time pipeline inspection at a high scanning speed (0.5 m/s). (3) Analytical and experimental studies are conducted to examine the effectiveness for suggested approach on several bimorph positions on the cantilever probe and scanning speed. (4) In intricate pipeline networks, numerous corrosion flaws and pipeline joints were found and effectively located.

In 2019, Jarram et al determined the properties and field validation of a remote sensing method designed to monitor changes in the magnetic field surrounding pipelines in order to identify localized abnormal pipe wall stress. Areas of elevated localized stress in pipes under pressure are caused by corrosion, cracks, metallurgical flaws, and external forces coming from sources like ground movement. The non-invasive technique provides a 3-dimensional map of the pipeline path, including depth of cover, variations in wall thickness and diameter, and casing placement, all with centimeter accuracy. It also provides the geometric center of areas of localized stress in Megapascals. By tracking stress without detecting changes in metal mass or pipe wall geometry, the inspection system adopts a revolutionary approach to integrity management. Making maintenance decisions no longer requires classifying the defect type, determining the defect clock position, or precisely measuring the defect shape. When combined with other technologies, this technology might effectively monitor a mixture of flaws, such as cracks and dents, at the same time and prioritize repair schedules. Along with its possible use for inspecting difficult lines, the advantages of applying this technique to both piggable and unpiggable pipelines are also discussed.

In 2021, Liang et al investigated an integral part of contemporary cities' urban infrastructure are buried pipelines. This study first examines and evaluates advancements that utilize physics, such as electromagnetic induction and electromagnetic wave techniques. After that, it concentrates on location and sound detection technologies before introducing novel innovations. The technical features of every location and detection technique were then compared, and their advantages and disadvantages have been determined. Each buried non-metallic pipeline location and detection technologically present trends and prospects have also been defined. Lastly, several recommendations are made for the advancement of underground non-metallic pipeline locating and detection technology in the coming years.

In 2021, Peng et al explained the most widely used in-line inspection methods for identifying corrosion flaws in pipelines is magnetic flux leakage (MFL). Due to their complementing measuring nature, fusing the inspection data by axial MFL (aMFL) and circumferential MFL (cMFL) is one possible method to lessen such variation. Prior to the fusion procedure, data by the multi-modal MFL must match. The following shows how the box data by the cMFL was grouped according to their location information. Next, two MFL data sets' coordinate systems were synchronized. Finally, the density-based spatial clustering of applications with noise (DBSCAN) approach is adjusted to perform many-to-many matching in the aligned coordinate system.

In 2024, Hussain

et al have explained the transformational role of artificial intelligence (AI) and machine learning (ML) in oil and gas industry. This paper also looks at how the oil and gas industry are being impacted by artificial intelligence (AI) specifically in the field of oil and gas pipelines. The study also focusses at non-technical issues with data, human aspects, and collaborative models. In order to demonstrate how artificial intelligence (AI) could be used to predict production dynamics, optimize enhancement plans, detect residual oil, detect fractures, and improve oil recovery and uses cutting-edge predictive analytics such as machine learning (ML) as well as artificial intelligence (AI) to detect corrosion flaws. The analysis on Advancements in MFL Sensor Technology has been illustrated by

Table 6.

8. Research Gaps

However, there are still research gaps in pipeline integrity management even with the improvements made. The application of new advanced hybrid models such as fuzzy surfacelet neural networks with real-world application and applicability of the developed models in real-world and large-scale applications especially in complex terrains has not been addressed adequately. Also, cross-departmental data sharing and real-time GIS integration into the urban and mountainous pipeline system need improvement. However, the practical implementation of the proposed intelligent monitoring and IDS for intrusion detection into the complicated and various pipeline systems requires extensive research and development. The existing mathematical models for quantitative analysis of MS effects on MFL signals have not received adequate experimental testing under various circumstances, thus restricting their usefulness. Hardware and testing methodologies for MFL systems in complex internal tendon configurations are still evolving and must be fine-tuned to increase the accuracy of measurements and reduce signal noise. Furthermore, the mechanical MFL inspections for thick-walled steel pipes, especially at high speeds, encounter problems of MIEC and signal distortion which requires the use of advanced techniques to ensure that signal quality and magnetization is achieved.

Although there are new improvements in inline inspection (ILI) technologies, there are still some research gaps. There is a need to study the effectiveness of passive magnetic flux density (MFD) and low-resolution techniques for detecting small defects and assessing the effects of the environment more thoroughly. Furthermore, interaction between neighboring flaws in MFL signals requires a more effective modeling and compensation technique to improve the detection performance. Finally, the application of ILI technologies like the remote field testing (RFT) for non-metallic and lined pipelines is not well optimized especially in handling problems arising from complex pipeline systems. As shown in MMHAN, there is an enhancement in accuracy when using multimodal attention mechanism, further research should focus on real-time application of the model and stability of the model when confronted with noisy data sets with dynamic defects. Liu et al.’s work reveals stress-induced MFL signal changes, however, more elaborate models that include actual environmental parameters and material inhomogeneities are required for accurate defect depth prediction under different operating conditions. Feng et al.’s framework enhances the defect signal localization in MFL heat maps, but there is a need to fine-tune it to accommodate overlapping defects and high noise levels particularly for pipelines of complex shapes.

As Chen and Tu et al. discuss deep learning and multi-model fusion for the identification of defects, future research must be conducted to incorporate these methods into real-time pipeline monitoring systems to improve operational reaction and defect position precision. A proactive approach is revealed in Abubakar et al.’s LCCA-based DSS, yet more studies are needed to incorporate predictive maintenance models based on IoT and AI for deteriorating infrastructure. Wong & McCann focus on identifying failure but fail to provide information on sensor reliability and flexibility especially in conditions that are extreme such as underwater or high-pressure pipeline conditions where cross environmental solutions are important.

Sheikh et al. designed a bimorph sensor for real-time inspection, but more research is required to enhance the sensor size and its integration into pipelines with complicated shapes and other challenging conditions. Peng et al. discussed data matching for axial and circumferential MFL, however, the future work should be directed towards the development of real-time fusion algorithms that can handle large volume of data with varying noise and resolutions. Liang and colleagues enumerated issues with non-metallic pipeline detection, however, more studies should be conducted to develop efficient and affordable devices for various pipelines and complex settings.

9. Conclusion

In conclusion, the use of the Magnetic Flux Leakage (MFL) system is a powerful and efficient approach to guaranteeing pipeline integrity through condition-based maintenance. Since MFL could detect defects including corrosion and cracks at an early stage, operators could prevent failures and thus minimize dangers to personnel, the environment, and system performance. However, when combined with such features as machine learning and IoT, it becomes an indispensable tool for managing pipelines at the present stage. For analysis, a total of 81 papers were selected from the year 2019-2024 for deliberating the techniques, performance, dataset as well as the limitations present in the existing studies. Further evolution of MFL systems will remain both key and relevant as the demand for safer and sustainable infrastructure develops in the future.

Funding

On Behalf of all authors the corresponding author states that they did not receive any funds for this project.

Data Availability Statement

All the data is collected from the simulation reports of the software and tools used by the authors. Authors are working on implementing the same using real world data with appropriate permissions.

Conflicts of Interest

The authors declare that we have no conflict of interest.

Competing Interests: The authors declare that we have no competing interest.

References

- Ma, Q.; Tian, G.; Zeng, Y.; Li, R.; Song, H.; Wang, Z.; Zeng, K. Pipeline in-line inspection method, instrumentation and data management. Sensors 2021, 21, 3862. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, B.; Gao, D.; Xu, L. Fuzzy surfacelet neural network evaluation model optimized by adaptive dragonfly algorithm for pipeline network integrity management. Applied Soft Computing 2021, 113, 107862. [Google Scholar] [CrossRef]

- Yongsheng, Z.O.U. Intelligent construction of mountainous oil and gas pipeline and its prospect. Oil & Gas Storage and Transportation 2021, 40, 1–6. [Google Scholar]

- Wang, M.; Ma, Y.; Wu, C.; Ji, M. A Data-Driven Online Model System for Urban Water Pipeline Network Based on GIS. In 2024 IEEE 14th International Conference on Electronics Information and Emergency Communication (ICEIEC) (pp. 297-301). 2024. [Google Scholar]

- Wu, T.; Chen, Y.; Deng, Z.; Shen, L.; Xie, Z.; Liu, Y.; Li, Y. Oil pipeline leakage monitoring developments in China. Journal of Pipeline Science and Engineering 2023, 3, 100129. [Google Scholar] [CrossRef]

- Chen, H.; Dai, L.; Xuan, H.; Gao, X.; Yang, K.; Wang, L.; Huo, C. Tensile Strain Capacity Prediction Model of an X80 Pipeline with Improper Transitioning and Undermatched Girth Weld. Materials 2022, 15, 7134. [Google Scholar] [CrossRef]

- Dakheel, A.H.; Dakheel, A. H.; Abbas, H. H. Intrusion detection system in gas-pipeline industry using machine learning. Periodicals of Engineering and Natural Sciences 2019, 7, 1030–1040. [Google Scholar] [CrossRef]

- Lu, J.; Fathi, A.; Yoosef-Ghodsi, N.; Tetteh-Wayoe, D.; Hill, M. A Case Study of Predicting Tensile Strain Capacity of In-Service Pipelines. In International Pipeline Conference (Vol. p. V002T06A001). American Society of Mechanical Engineers (2020, September.

- Levy, J. Smart technologies for data-driven pipeline risk assessment. Smart Technologies in Data Science and Communication: Proceedings of SMART-DSC 2020, 2019, 287–302. [Google Scholar]

- Fang, Z.; Shi, P.; Fu, J.; Song, C.; Yuan, J.; Deng, J. Research on the Prediction Method of the Areas of Fluorine Chemical Pipeline Susceptible to Erosion. Processes 2022, 10, 657. [Google Scholar] [CrossRef]

- Peng, X.; Anyaoha, U.; Liu, Z.; Tsukada, K. Analysis of magnetic-flux leakage (MFL) data for pipeline corrosion assessment. IEEE Transactions on Magnetics 2020, 56, 1–15. [Google Scholar] [CrossRef]

- Durai, M.; Lin, Z.Q.; Lan, C.W.; Chang, H.; Peng, C.C. Study of defects in the petrochemical storage tank floor using the magnetic flux leakage (MFL) technique. Journal of Failure Analysis and Prevention 2022, 22, 807–814. [Google Scholar] [CrossRef]

- Peng, Z.H.A.N.G.; Minghui, W.E.I.; Zhiyong, G.U.O.; Zhongxiang, L.I.U. Advances in magnetic flux leakage testing technology. Journal of Measurement Science & Instrumentation.

- Hao, S.; Shi, P.; Su, S.; Liang, T. A magnetic shielding strategy for magnetic sensor in magnetic flux leakage testing. Journal of Magnetism and Magnetic Materials 2022, 563, 169888. [Google Scholar] [CrossRef]

- Javed, A.; Sadeghnejad, A.; Yakel, A.; Azizinamini, A. Magnetic Flux Leakage (MFL) Method for Damage Detection in Internal Post-Tensioning Tendons (2021).

- Piao, G.; Guo, J.; Hu, T.; Leung, H. The effect of motion-induced eddy current on high-speed magnetic flux leakage (MFL) inspection for thick-wall steel pipe. Research in Nondestructive Evaluation 2020, 31, 48–67. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, F.; Chen, J. Quantitative detection of wire rope based on three-dimensional magnetic flux leakage color imaging technology. IEEE Access 2020, 8, 104165–104174. [Google Scholar] [CrossRef]

- Yousaf, J.; Harseno, R. W. , Kee, S. H., Yee, J. J. Evaluation of the size of a defect in reinforcing steel using Magnetic Flux Leakage (MFL) measurements. Sensors 2023, 23, 5374. [Google Scholar] [CrossRef]

- Wu, J.; Wu, W.; Li, E.; Kang, Y. Magnetic flux leakage course of inner defects and its detectable depth. Chinese Journal of Mechanical Engineering 2021, 34, 63. [Google Scholar] [CrossRef]

- Tang, J.; Wang, R.; Liu, B.; Kang, Y. A novel magnetic flux leakage method based on the ferromagnetic lift-off layer with through groove. Sensors and Actuators A: Physical 2021, 332, 113091. [Google Scholar] [CrossRef]