Submitted:

15 July 2025

Posted:

18 July 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Background

2.1. Overview of Broiler Weight Prediction Methods

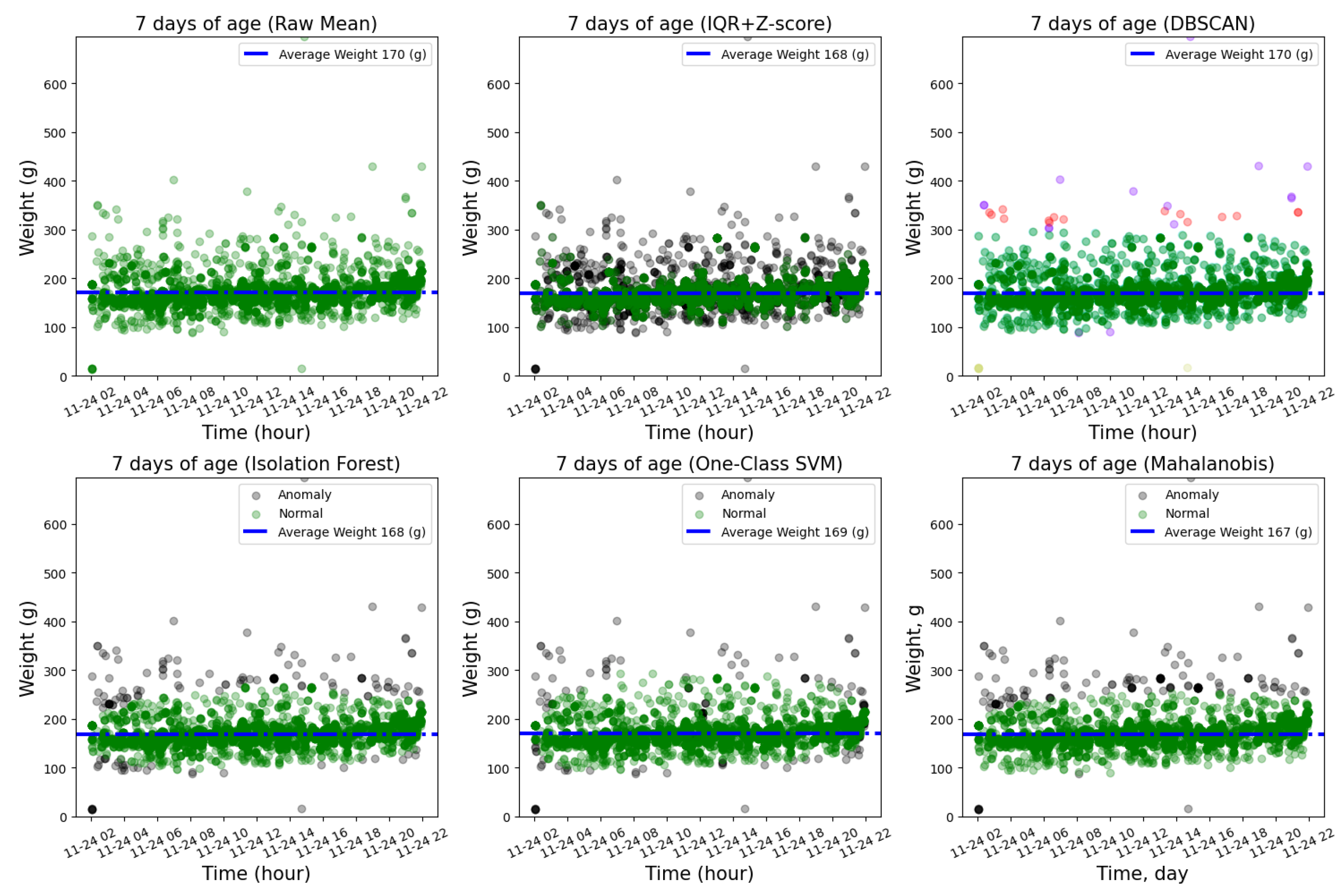

2.2. Object Detection for Broiler Counting on the Weighing Platform

2.3. Outlier Handling

2.3.1. IQR and Z-Score

2.3.2. DBSCAN

2.3.3. Isolation Forest

- Construct binary trees (Isolation Trees, iTrees) randomly from the training dataset;

- For a test sample , input it into all iTrees and record the path length required from the root node to complete isolation (reaching a leaf node) in each tree. Then calculate the average path length across all trees (Equation (3));

- The anomaly score is calculated according to Equation (4), where represents the theoretical expected path length for a sample size of , serving as a normalization factor for path lengths, as defined in Equation 5. where represents the approximation of the i-th harmonic number, with the constant being the Euler-Mascheroni constant;

- If , the sample x is highly likely to be an anomaly. If s, the sample x is generally considered normal. When all samples in the dataset yield scores close to 0.5, it indicates no significant anomalies exist in the dataset;

2.3.4. One-Class Support Vector Machines

2.3.5. Mahalanobis

3. Materials and Methods

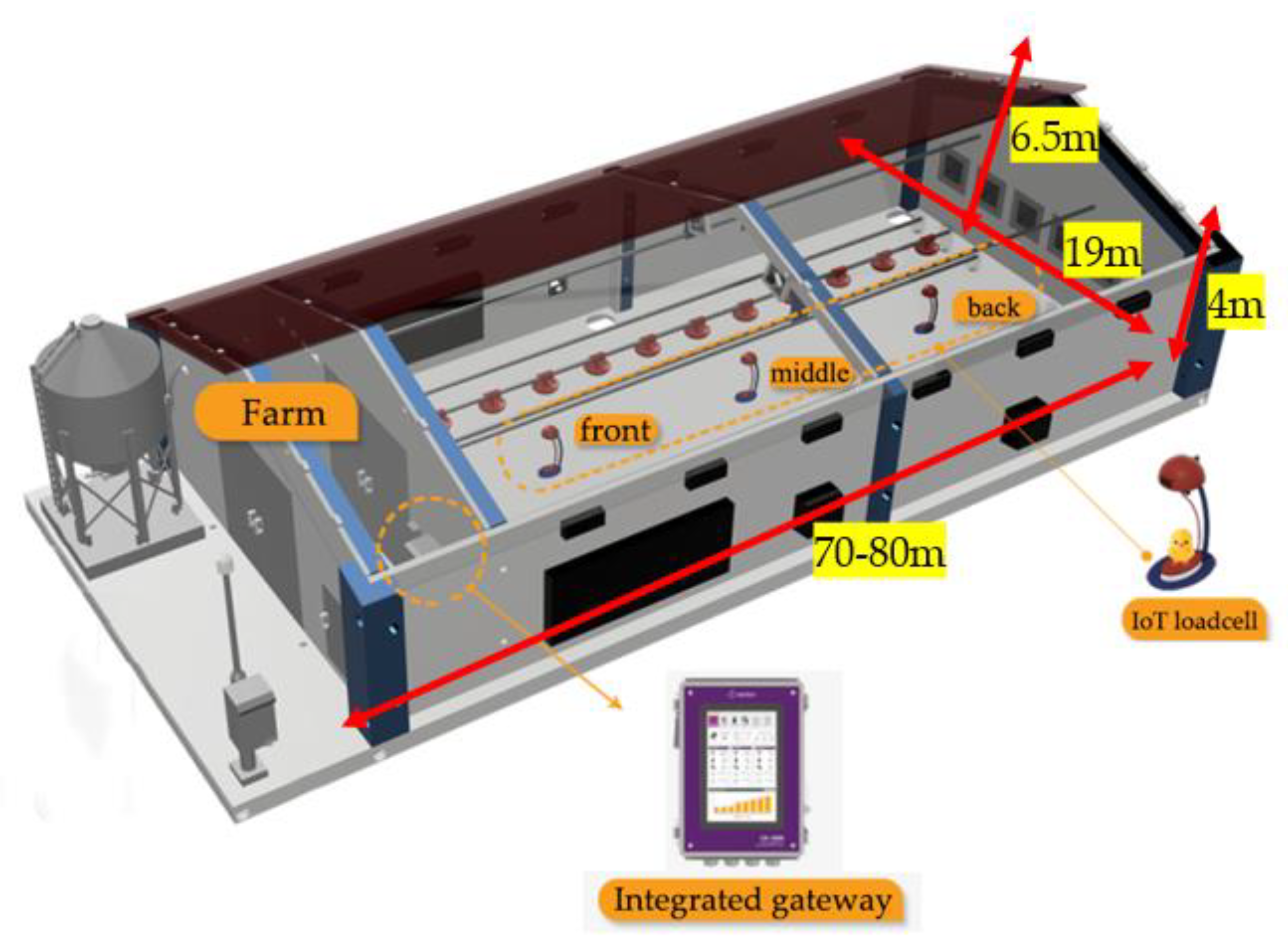

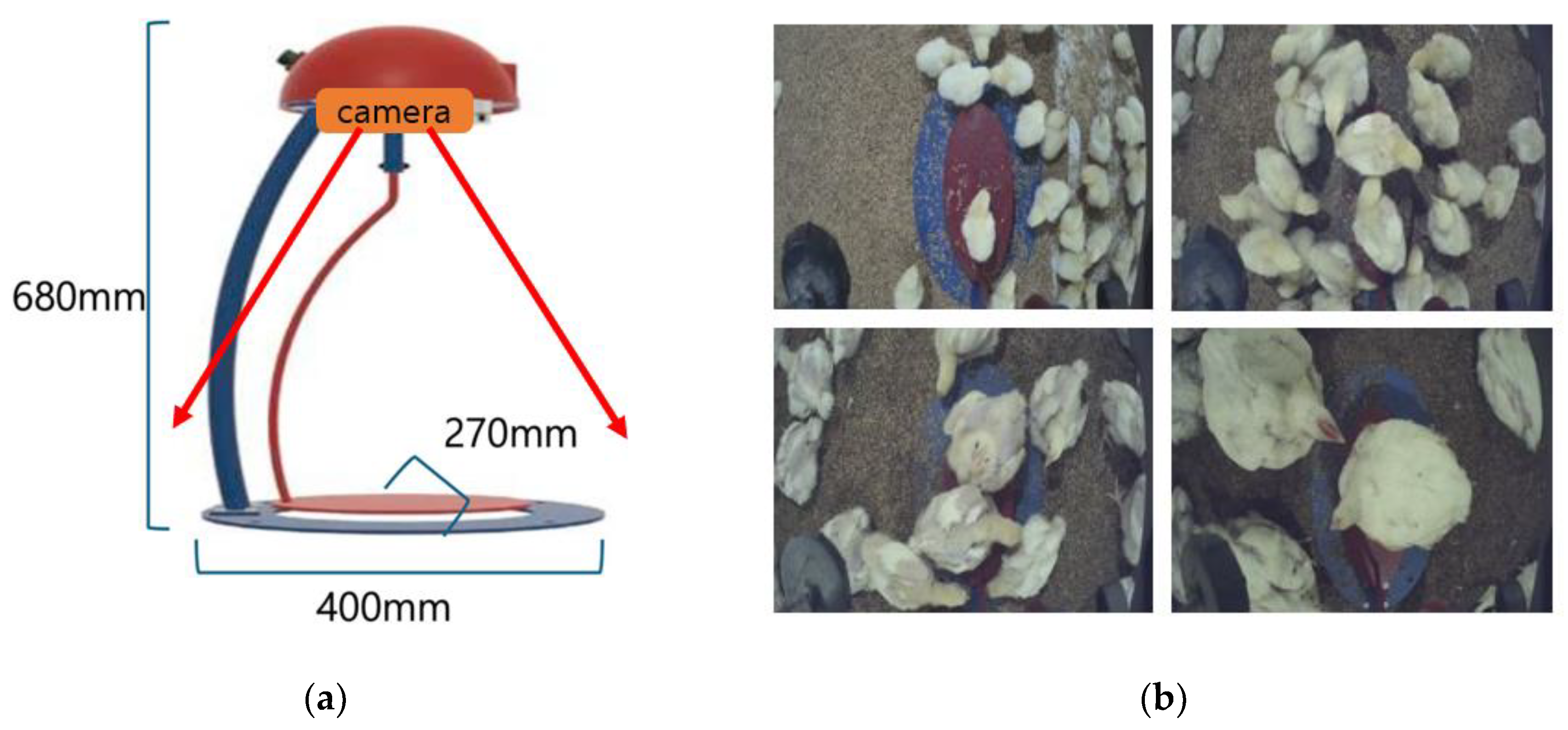

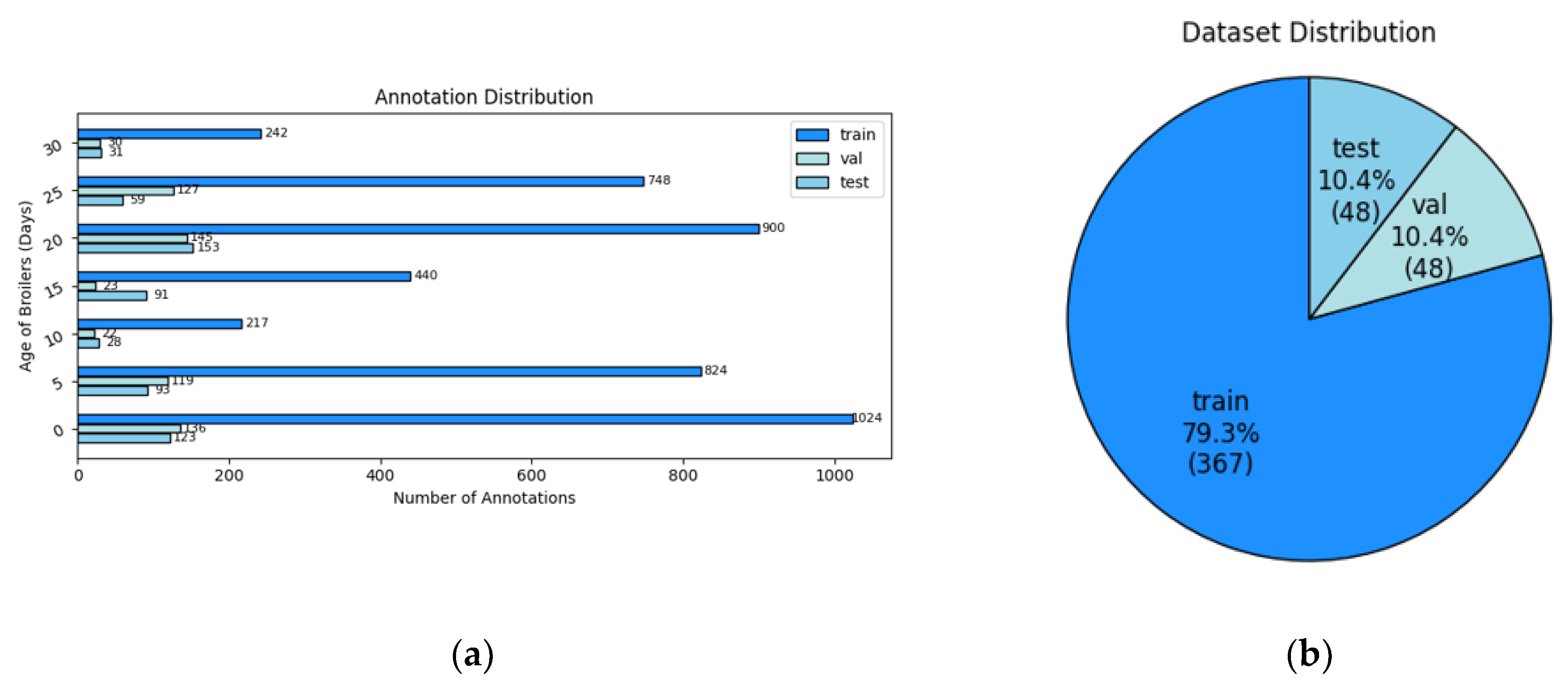

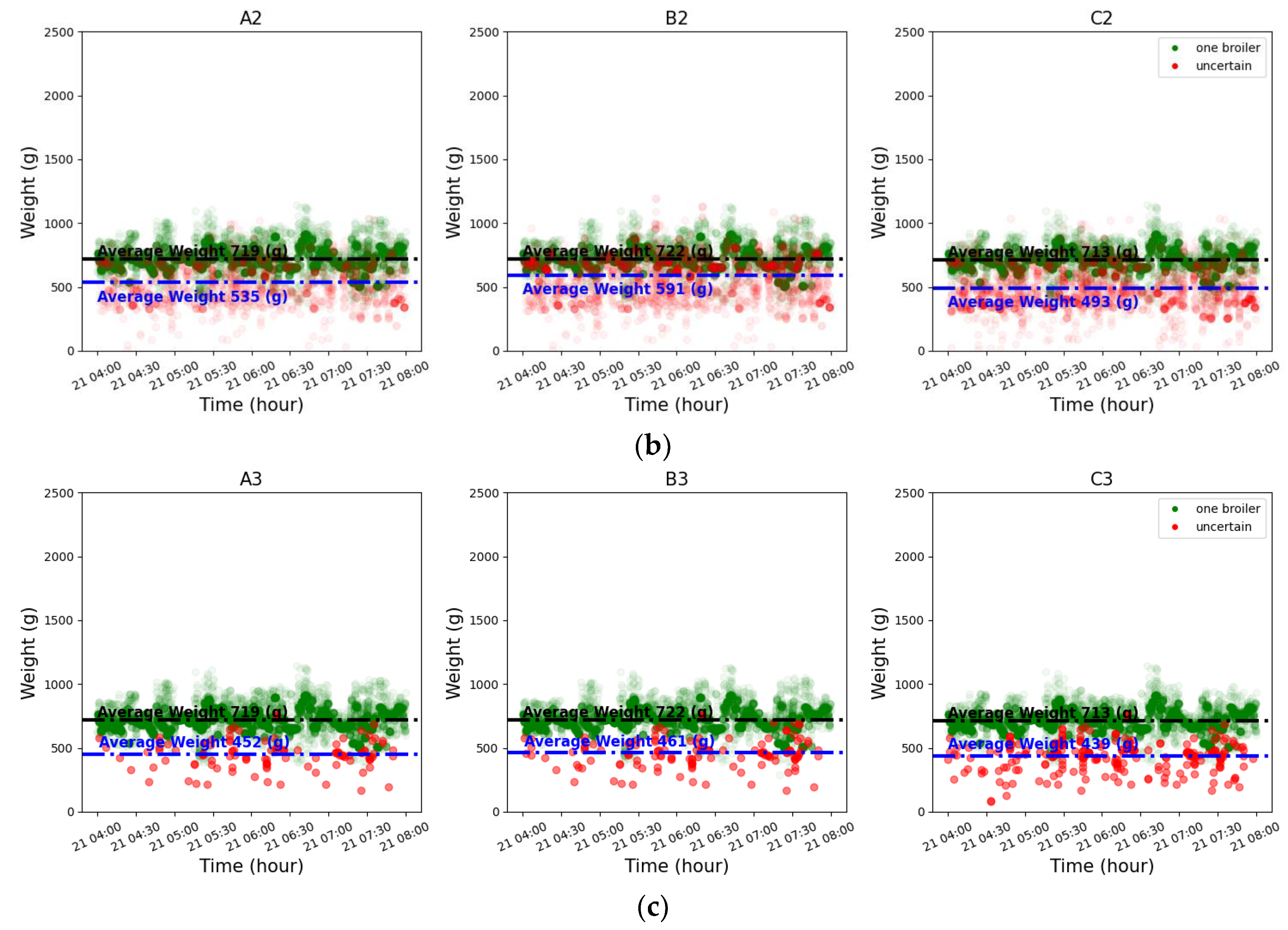

3.1. Data Collection

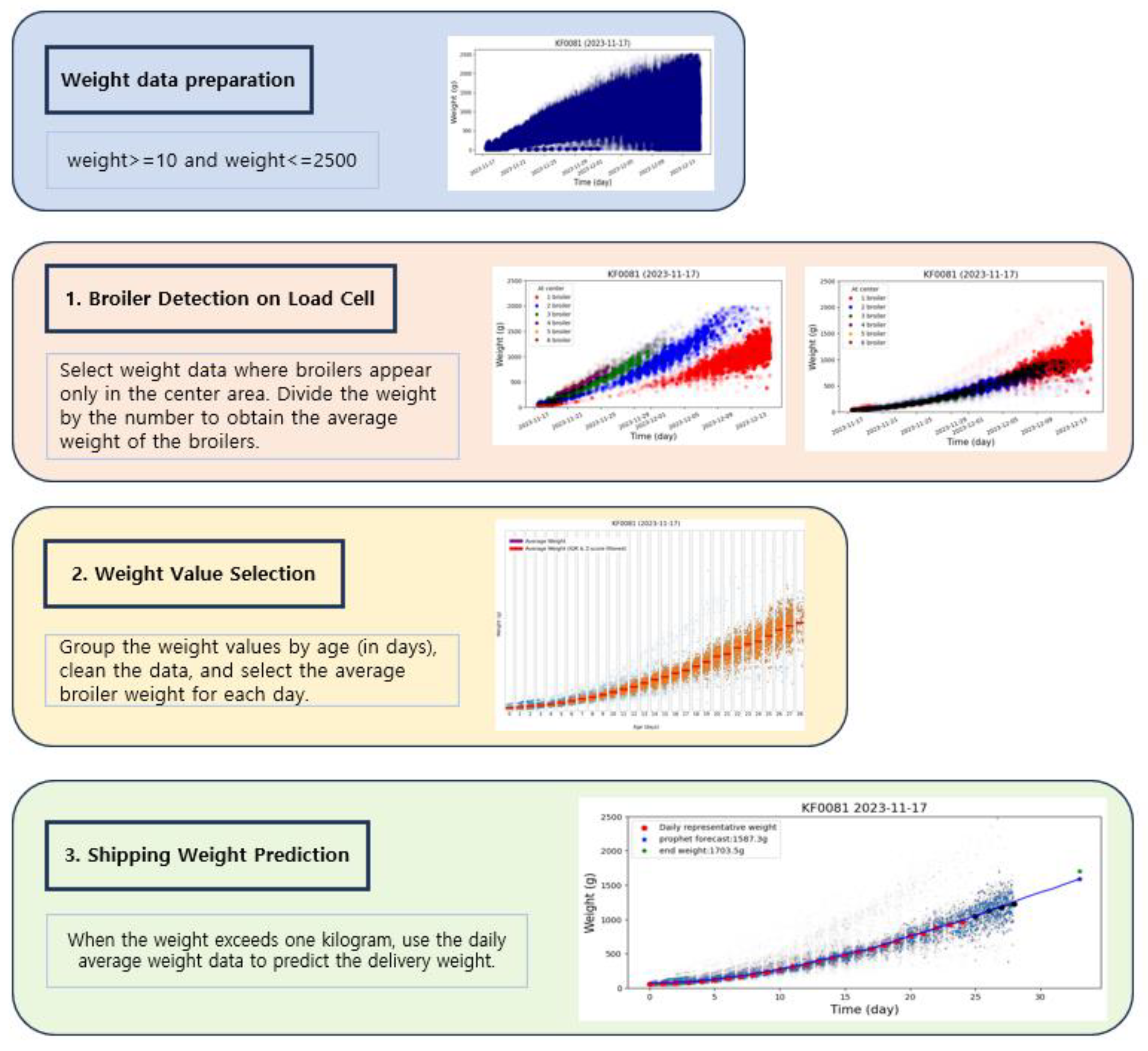

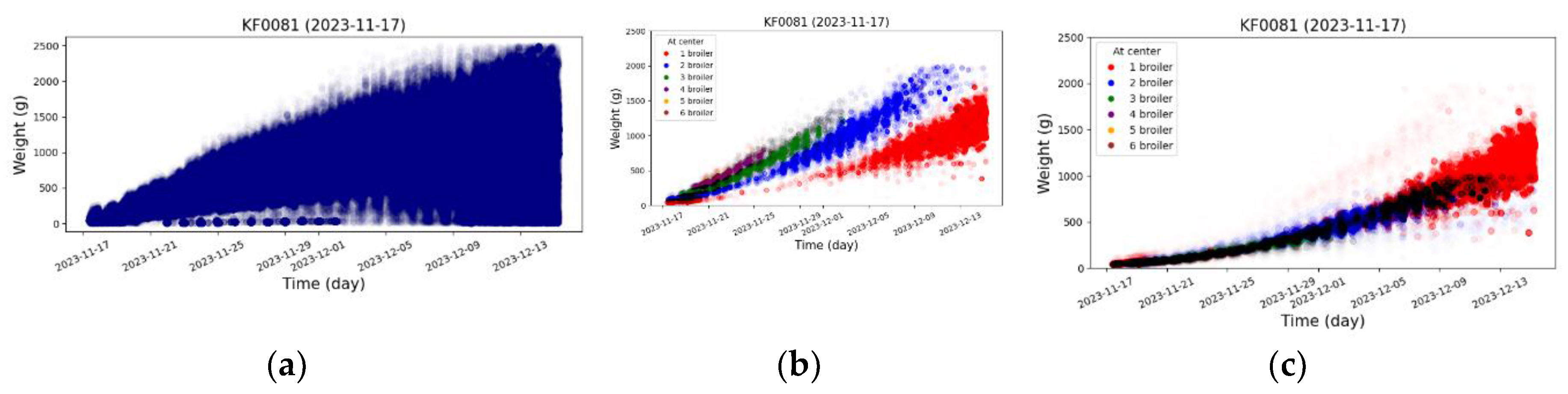

3.2. Algorithm Composition and Design

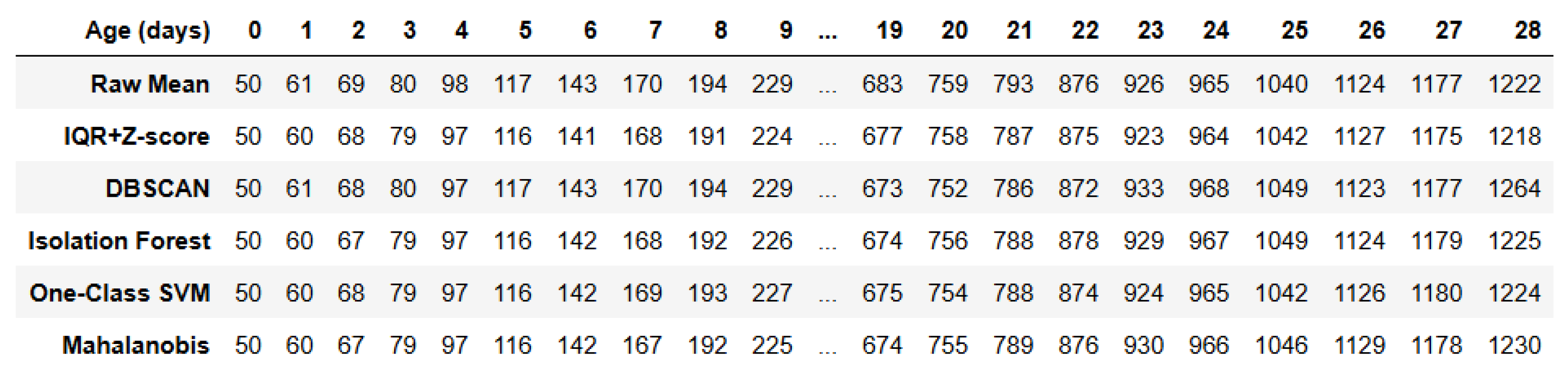

- Raw Mean: Direct calculation without any preprocessing;

- IQR + Z-score;

- DBSCAN;

- Isolation Forest;

- One-Class SVM;

- Mahalanobis.

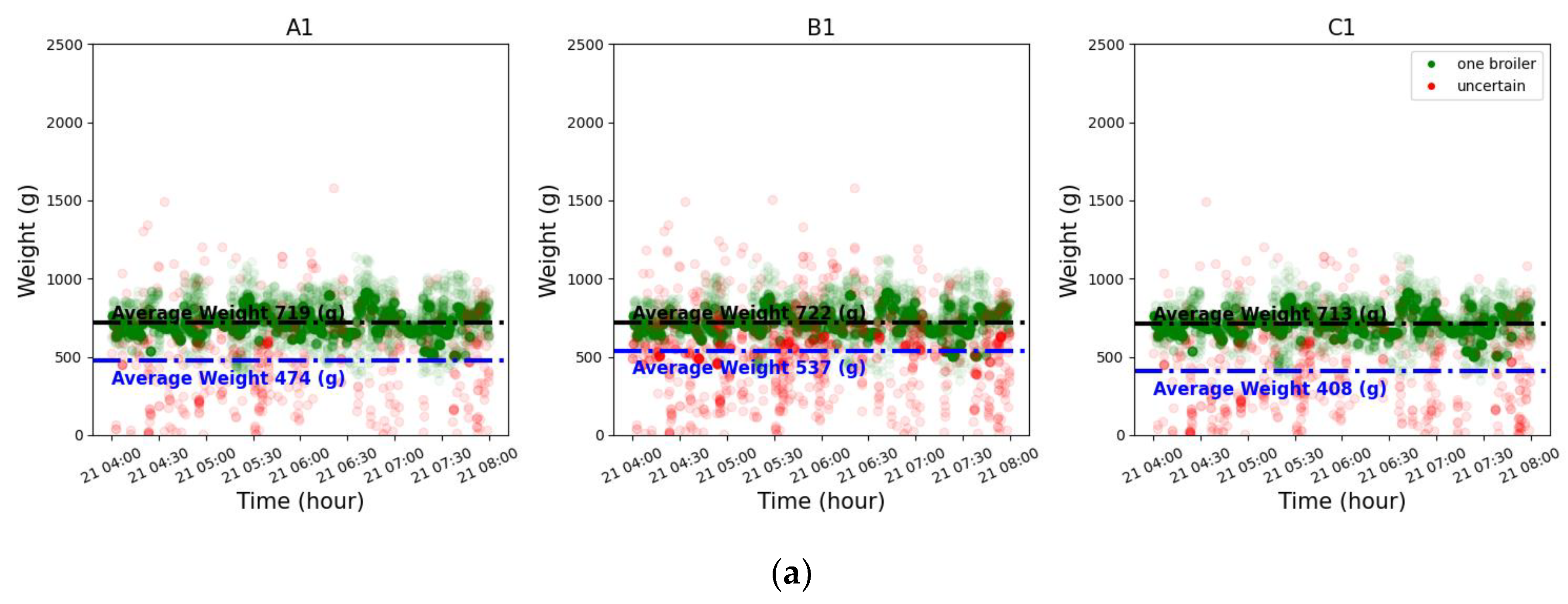

- Experiment A (Basic Configuration):

- Experiment B (Center Contraction):

- Experiment C (Edge Expansion):

3.3. Performance Evaluation of the Algorithm

4. Results

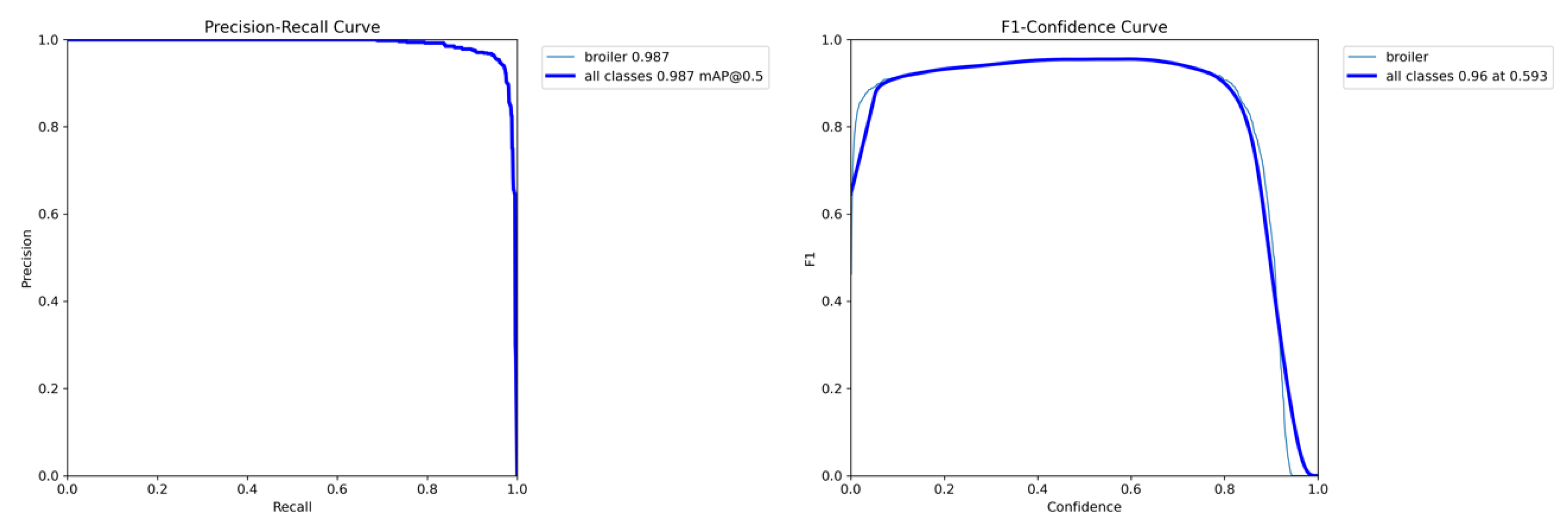

4.1. Experiments in Object Detection Evaluation

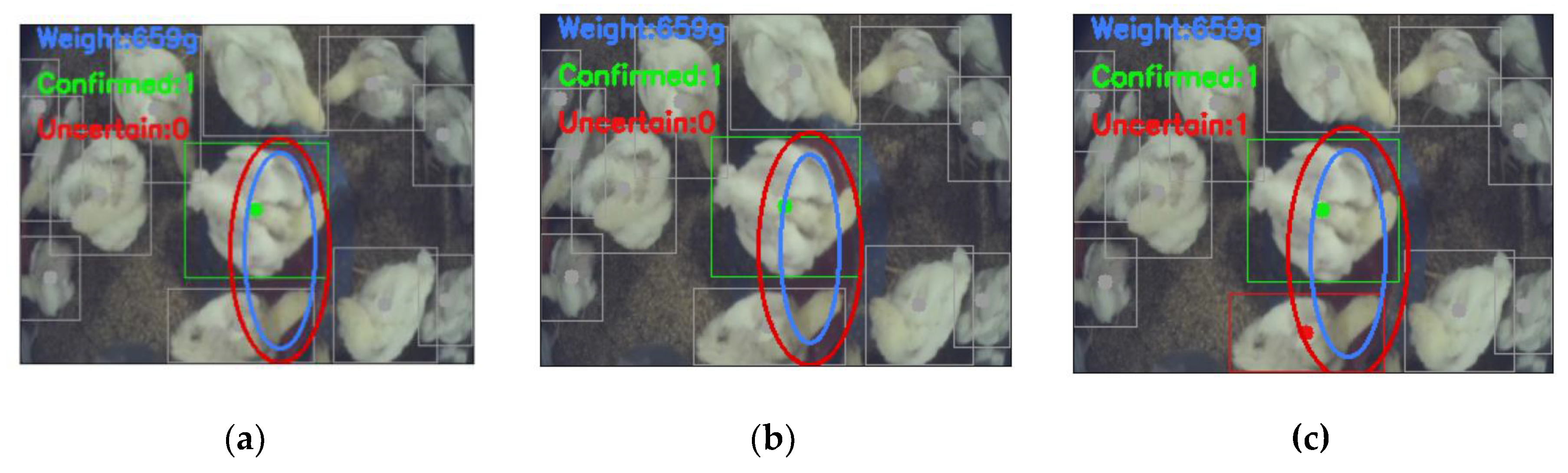

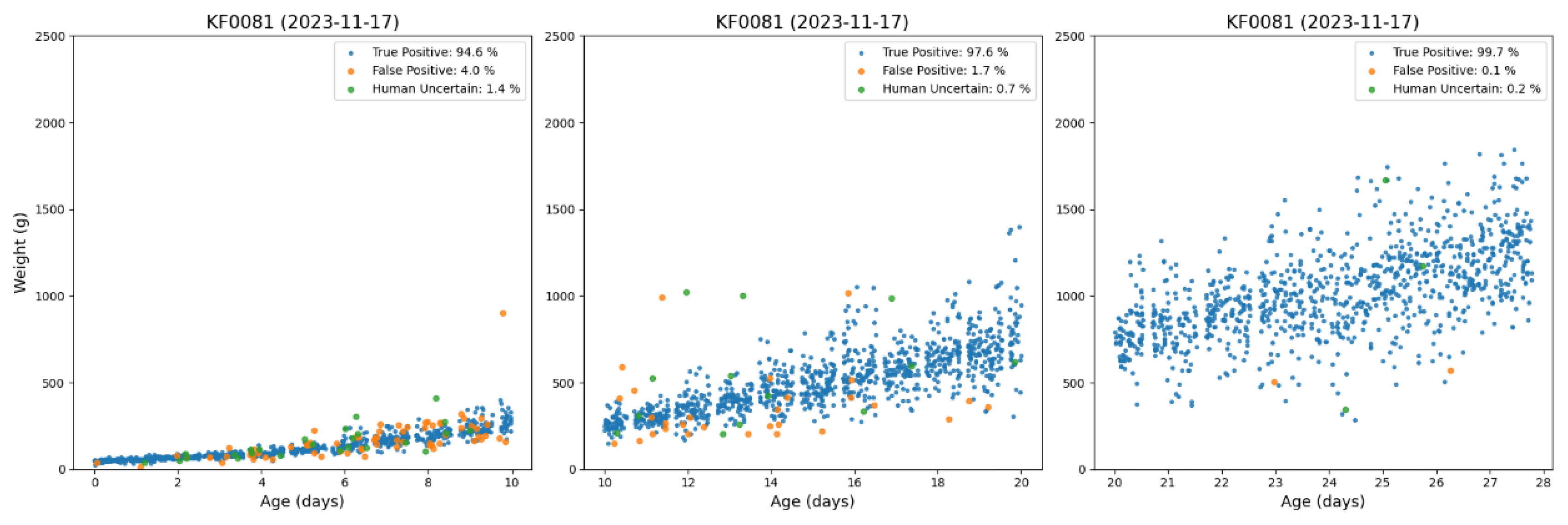

4.2. Evaluation Experiments of Edge/Center Region Strategy

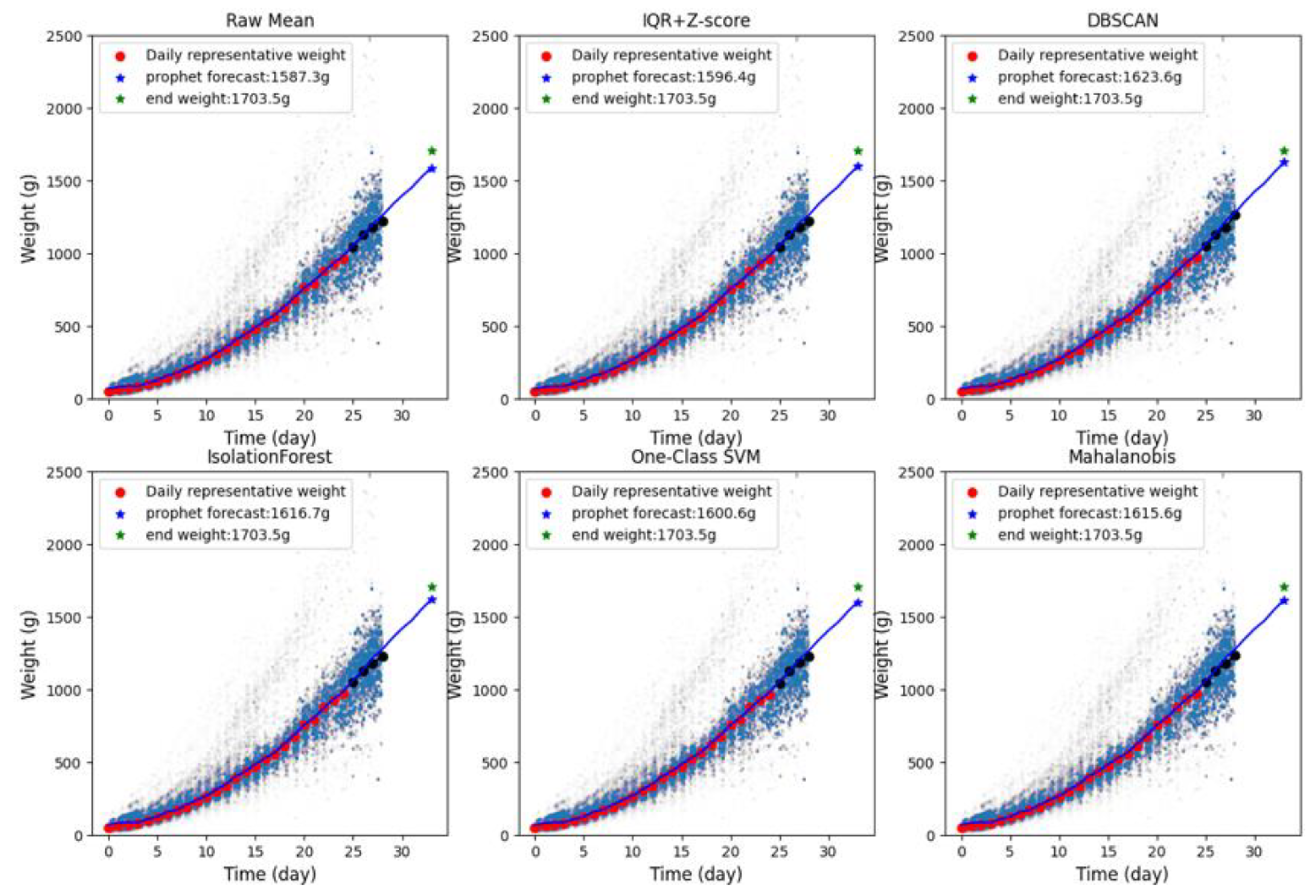

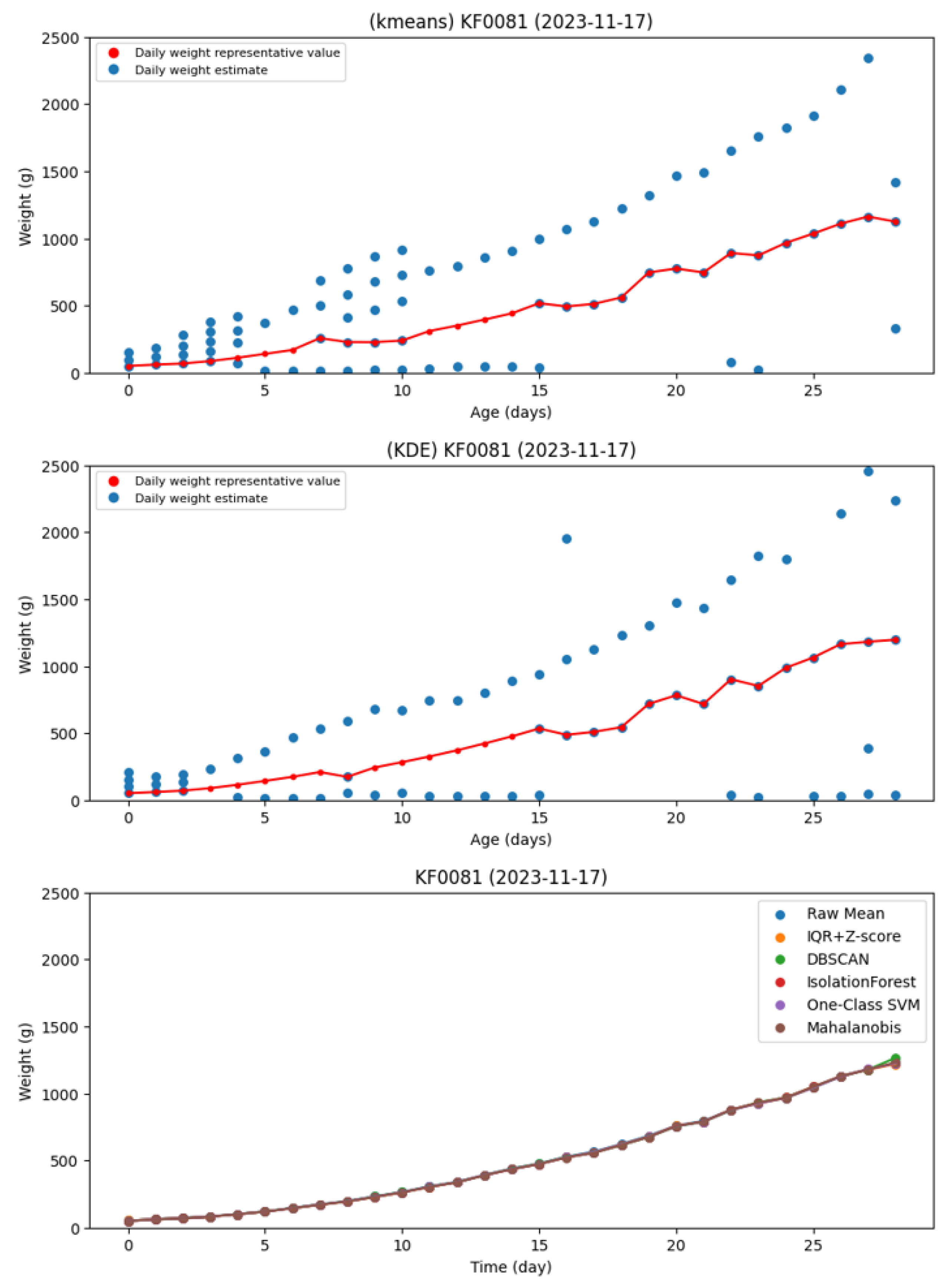

4.3. Experiments in the Shipping Weight Prediction Step

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, H.-C.; Kim, D.-H.; Kim, E.-T.; Lee, H.-J.; Park, J.-H.; Kim, J.-B.; Lee, J.-Y.; Jeon, J.-H.; Ki, K.-S.; Kwon, K.-S. Livestock Production in Korea: Recent Trend and Future Prospects of ICT Technology Livestock Production in Korea: Recent Trend and Future Prospects of ICT Technology.

- Korea Meat Distribution and Export Association Available online: http://www.kmta.or.kr/kr/data/stats_import_chicken_month.php (accessed on 7 July 2025).

- Oh, Y.; Lyu, P.; Ko, S.; Min, J.; Song, J. Enhancing Broiler Weight Estimation through Gaussian Kernel Density Estimation Modeling. Agriculture 2024, 14, 809. [CrossRef]

- Lee, B.; Song, J. Development of an Algorithm for Predicting Broiler Shipment Weight in a Smart Farm Environment. Agriculture; Basel 2025, 15. [CrossRef]

- Beiki, H.; Pakdel, A.; Moradi-Shahrbabak, M.; Mehrban, H. Evaluation of Growth Functions on Japanese Quail Lines. The Journal of Poultry Science 2013, 50, 20–27. [CrossRef]

- Al-Samarai, F.R. Growth Curve of Commercial Broiler as Predicted by Different Nonlinear Functions. American Journal of Applied Scientific Research 2015, 1, 6–9.

- Araújo, C.C.; Rodrigues, K.F.; Vaz, R.G.M.V.; Conti, A.C.M.; Amorim, A.F.; Campos, C.F.A. Analysis of Growth Curves in Different Lineages of Caipira Broiler Type. Acta Scientiarum. Animal Sciences 2018, 40. [CrossRef]

- Johansen, S.V.; Bendtsen, J.D.; Martin, R.; Mogensen, J. Broiler Weight Forecasting Using Dynamic Neural Network Models with Input Variable Selection. Computers and Electronics in Agriculture 2019, 159, 97–109. [CrossRef]

- Mouffok, C.; Semara, L.; Ghoualmi, N.; Belkasmi, F. Comparison of Some Nonlinear Functions for Describing Broiler Growth Curves of Cobb 500 Strain. Poultry Science Journal 2019, 7, 51–61.

- AA, S. Comparison of the Accuracy of Nonlinear Models and Artificial Neural Network in the Performance Prediction of Ross 308 Broiler Chickens. Poultry Science Journal 2019, 7, 151–161.

- Kucukonder, H.; Demirarslan, P.C.; Alkan, S.; Özgur, B.B. Curve Fitting with Nonlinear Regression and Grey Prediction Model of Broiler Growth in Chickens. Pakistan Journal of Zoology 2020, 52, 347. [CrossRef]

- Zuidhof, M.J. Multiphasic Poultry Growth Models: Method and Application. Poultry science 2020, 99, 5607–5614. [CrossRef]

- Yalcin, S.; Settar, P.; Ozkan, S.; Cahaner, A. Comparative Evaluation of Three Commercial Broiler Stocks in Hot versus Temperate Climates. Poultry Science 1997, 76, 921–929. [CrossRef]

- Wang, D.Q.; Lu, L.Z.; Ye, W.C.; Shen, J.D.; Tao, Z.R.; Tao, Z.L.; Ma, F.L.; Chen, Y.C.; Zhao, A.Z.; Xu, J. Study on the Growth Regularity of Jinyun Muscovy Duck. Zhejiang Journal of Animal Science and Veterinary Medicine 2004, 6, 3–5.

- Yang, Y.; Mekki, D.M.; Lv, S.J.; Wang, L.Y.; Yu, J.H.; Wang, J.Y. Analysis of Fitting Growth Models in Jinghai Mixed-Sex Yellow Chicken. International Journal of Poultry Science 2006, 5, 517–521.

- De Wet, L.; Vranken, E.; Chedad, A.; Aerts, J.-M.; Ceunen, J.; Berckmans, D. Computer-Assisted Image Analysis to Quantify Daily Growth Rates of Broiler Chickens. British poultry science 2003, 44, 524–532. [CrossRef]

- Mortensen, A.K.; Lisouski, P.; Ahrendt, P. Weight Prediction of Broiler Chickens Using 3D Computer Vision. Computers and Electronics in Agriculture 2016, 123, 319–326. [CrossRef]

- Amraei, S.; Abdanan Mehdizadeh, S.; Salari, S. Broiler Weight Estimation Based on Machine Vision and Artificial Neural Network. British poultry science 2017, 58, 200–205. [CrossRef]

- Liu, D.; Vranken, E.; Van Den Berg, G.; Carpentier, L.; Fernández, A.P.; He, D.; Norton, T. Separate Weighing of Male and Female Broiler Breeders by Electronic Platform Weigher Using Camera Technologies. Computers and Electronics in Agriculture 2021, 182, 106009. [CrossRef]

- Wang, C.-Y.; Chen, Y.-J.; Chien, C.-F. Industry 3.5 to Empower Smart Production for Poultry Farming and an Empirical Study for Broiler Live Weight Prediction. Computers & Industrial Engineering 2021, 151, 106931. [CrossRef]

- Guo, Y.; Chai, L.; Aggrey, S.E.; Oladeinde, A.; Johnson, J.; Zock, G. A Machine Vision-Based Method for Monitoring Broiler Chicken Floor Distribution. Sensors 2020, 20, 3179. [CrossRef]

- Geffen, O.; Yitzhaky, Y.; Barchilon, N.; Druyan, S.; Halachmi, I. A Machine Vision System to Detect and Count Laying Hens in Battery Cages. Animal 2020, 14, 2628–2634. [CrossRef]

- Siriani, A.L.R.; Kodaira, V.; Mehdizadeh, S.A.; de Alencar Nääs, I.; de Moura, D.J.; Pereira, D.F. Detection and Tracking of Chickens in Low-Light Images Using YOLO Network and Kalman Filter. Neural Computing and Applications 2022, 34, 21987–21997. [CrossRef]

- Cruz, E.; Hidalgo-Rodriguez, M.; Acosta-Reyes, A.M.; Rangel, J.C.; Boniche, K. AI-Based Monitoring for Enhanced Poultry Flock Management. Agriculture 2024, 14, 2187. [CrossRef]

- Ultralytics YOLOv8 Available online: https://docs.ultralytics.com/models/yolov8 (accessed on 30 June 2025).

- Chandola, V.; Banerjee, A.; Kumar, V. Anomaly Detection: A Survey. ACM computing surveys (CSUR) 2009, 41, 1–58.

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A Density-Based Algorithm for Discovering Clusters in Large Spatial Databases with Noise. In Proceedings of the kdd; 1996; Vol. 96, pp. 226–231.

- Liu, F.T.; Ting, K.M.; Zhou, Z.-H. Isolation Forest. In Proceedings of the 2008 eighth ieee international conference on data mining; IEEE, 2008; pp. 413–422.

- Schölkopf, B.; Williamson, R.C.; Smola, A.; Shawe-Taylor, J.; Platt, J. Support Vector Method for Novelty Detection. In Proceedings of the Advances in Neural Information Processing Systems; MIT Press, 1999; Vol. 12.

- McLachlan, G.J. Mahalanobis Distance. Resonance 1999, 4, 20–26.

- Satopaa, V.; Albrecht, J.; Irwin, D.; Raghavan, B. Finding a" Kneedle" in a Haystack: Detecting Knee Points in System Behavior. In Proceedings of the 2011 31st international conference on distributed computing systems workshops; IEEE, 2011; pp. 166–171.

- Schubert, E.; Sander, J.; Ester, M.; Kriegel, H.P.; Xu, X. DBSCAN Revisited, Revisited: Why and How You Should (Still) Use DBSCAN. ACM Transactions on Database Systems (TODS) 2017, 42, 1–21.

| File Name | Start Date | Delivery Date | Avg. Weight (g) | Images |

|---|---|---|---|---|

| 2023_1117_KF0081_01-Img_Data | 2023-11-17 9:13 | 2023-12-21 7:59 | 1703.5 | 2191039 |

| 2024_0105_KF0081_01-Img_Data | 2024-01-05 11:30 | 2024-02-08 3:59 | 1810 | 2745771 |

| 2024_0502_KF0081_01-Img_Data | 2024-05-02 10:09 | 2024-06-06 23:45 | 1910 | 2589510 |

| 2024_0502_KF0081_02-Img_Data | 2024-05-02 10:09 | 2024-06-06 23:45 | 1910 | 2461297 |

| 2024_1226_KF0081_01-Img_Data | 2024-12-26 11:04 | 2025-01-24 19:59 | 1366 | 2030085 |

| Age (days) | 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | 32 |

|---|---|---|---|---|---|---|---|---|---|

| train | 69 | 36 | 15 | 16 | 36 | 67 | 72 | 37 | 19 |

| val | 8 | 5 | 2 | 2 | 2 | 12 | 10 | 4 | 3 |

| test | 8 | 5 | 1 | 2 | 7 | 12 | 6 | 4 | 3 |

| Equipment | Model |

|---|---|

| Processor | Intel Xeon Gold 5218R CPU Processor NVidia a100-pcie-80gb |

| RAM | 256 GB |

| SSD | 6 TB |

| OS | Ubuntu 20.04 LTS |

| Method | MAE (g) | MAPE (%) | RMSE (g) |

|---|---|---|---|

| k-means | 94.94 | 5.25% | 154.28 |

| KDE | 117.36 | 6.66% | 152.44 |

| Raw Mean | 51.72 | 2.99% | 61.95 |

| IQR + Z-score | 50.6 | 2.92% | 58.72 |

| DBSCAN | 44.36 | 2.56% | 47.97 |

| Isolation Forest | 43.22 | 2.49% | 48.78 |

| One-Class SVM | 46.38 | 2.70% | 54.67 |

| Mahalanobis | 41.82 | 2.43% | 47.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).