Submitted:

04 July 2025

Posted:

08 July 2025

You are already at the latest version

Abstract

Keywords:

Laboratory Results

River Sand (Lorica)

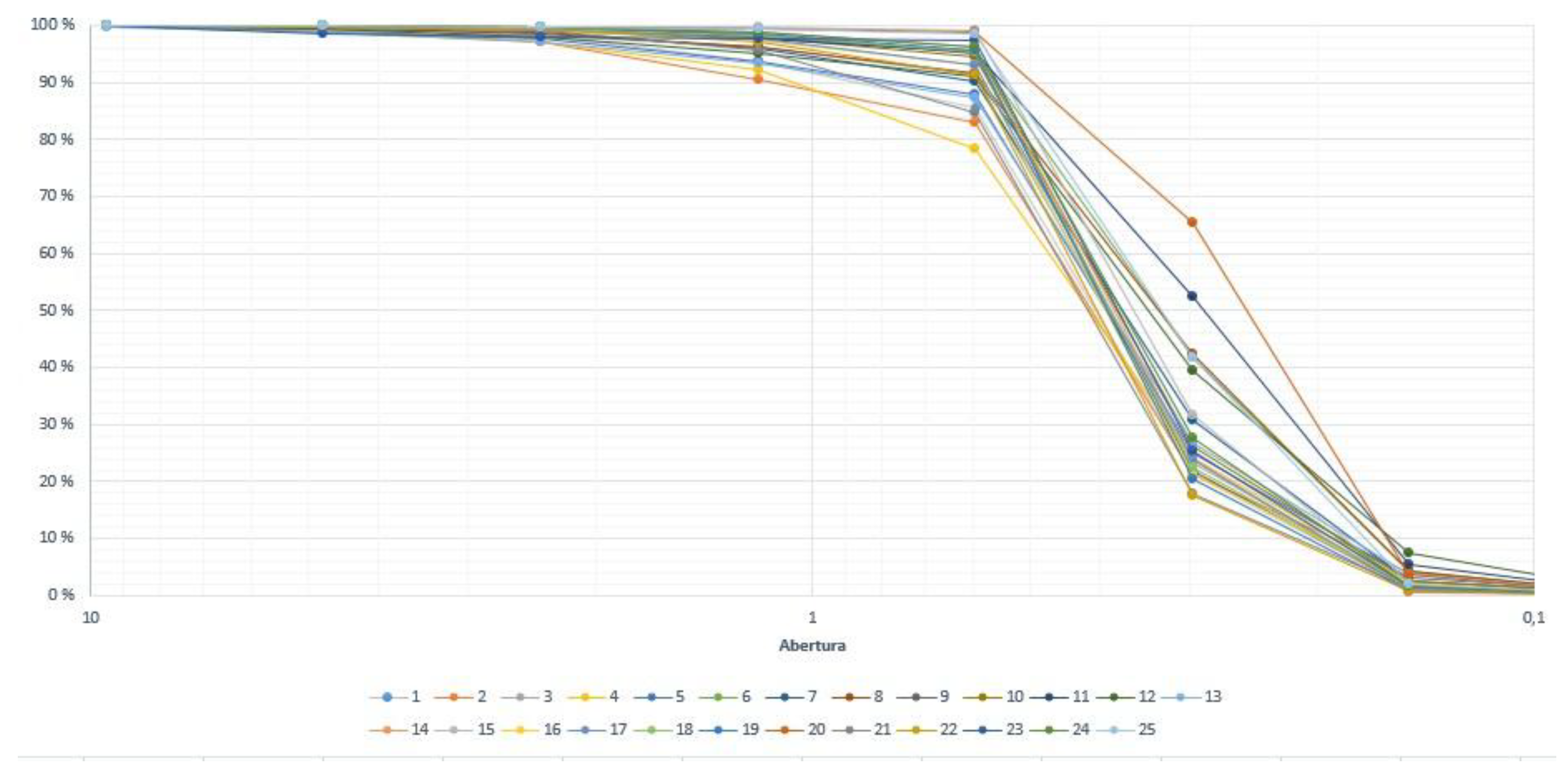

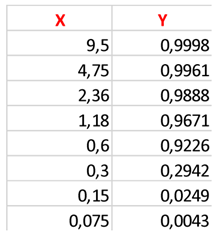

| Sieve | Opening (mm) | Average | Standard deviation |

| 3/8" | 9.5 | 99.98 | 0.079 |

| No. 4 | 4.75 | 99.61 | 0.392 |

| No. 8 | 2.36 | 98.88 | 0.916 |

| No. 16 | 1.18 | 96.71 | 2,395 |

| No. 30 | 0.6 | 92.26 | 5,313 |

| No. 50 | 0.3 | 29.42 | 11,637 |

| No. 100 |

0.15 | 2.49 | 1,612 |

| No. 200 |

0.075 | 0.43 | 0.277 |

| Rehearsal | Average | Standard deviation |

| Percentage of material finer than the 75 µm sieve | 1.44 | 0.61 |

| Apparent density (kg/m3) | 2525.36 | 32.55 |

| Surface-dry saturated density (kg/m3) | 2574.68 | 32.77 |

| Nominal Density (kg/m3) | 2656.77 | 36.38 |

| Absorption (%) | 1.95 | 0.18 |

| Organic matter content | 1 | - |

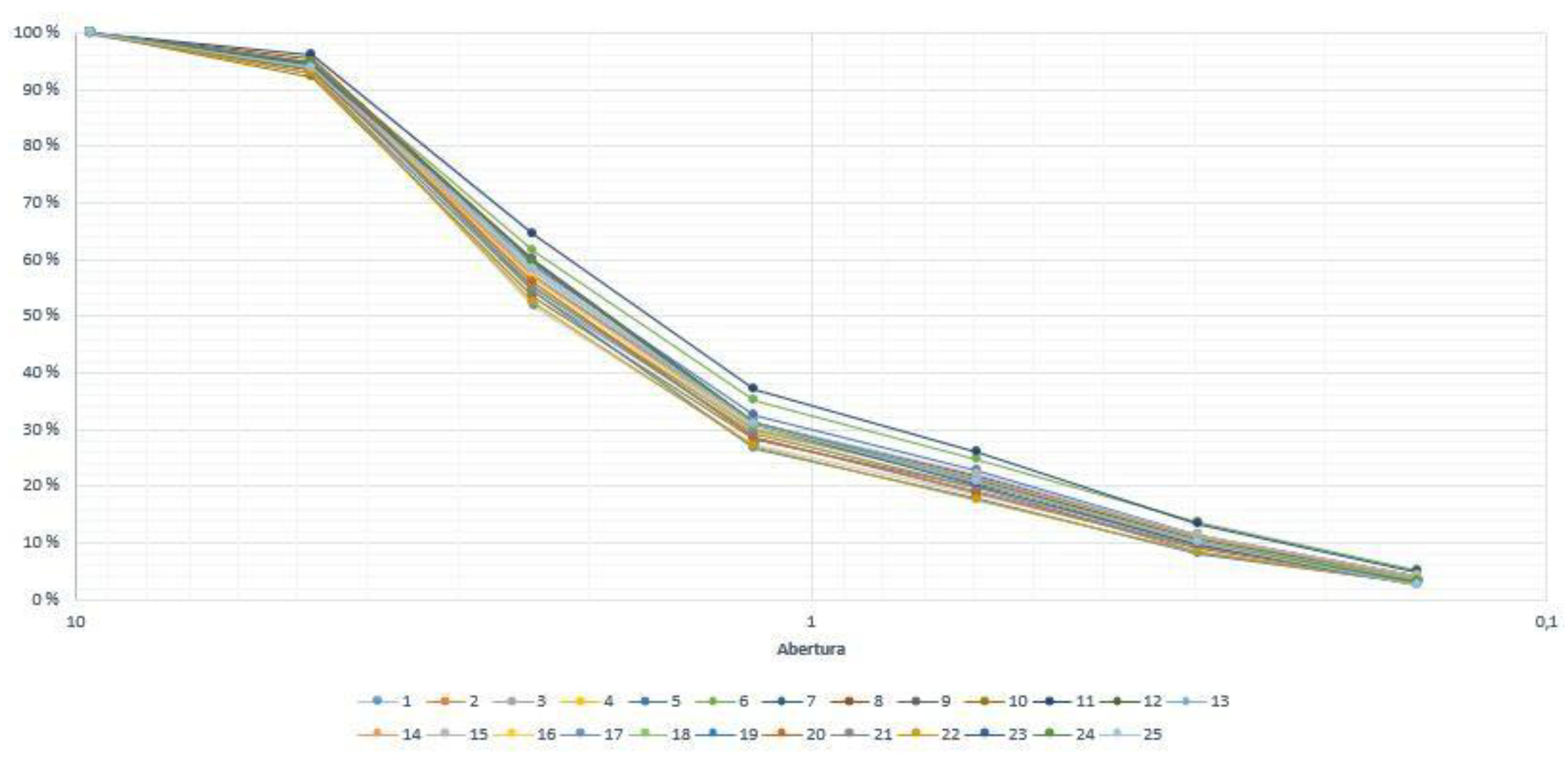

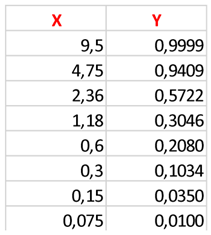

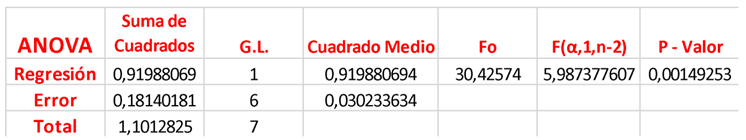

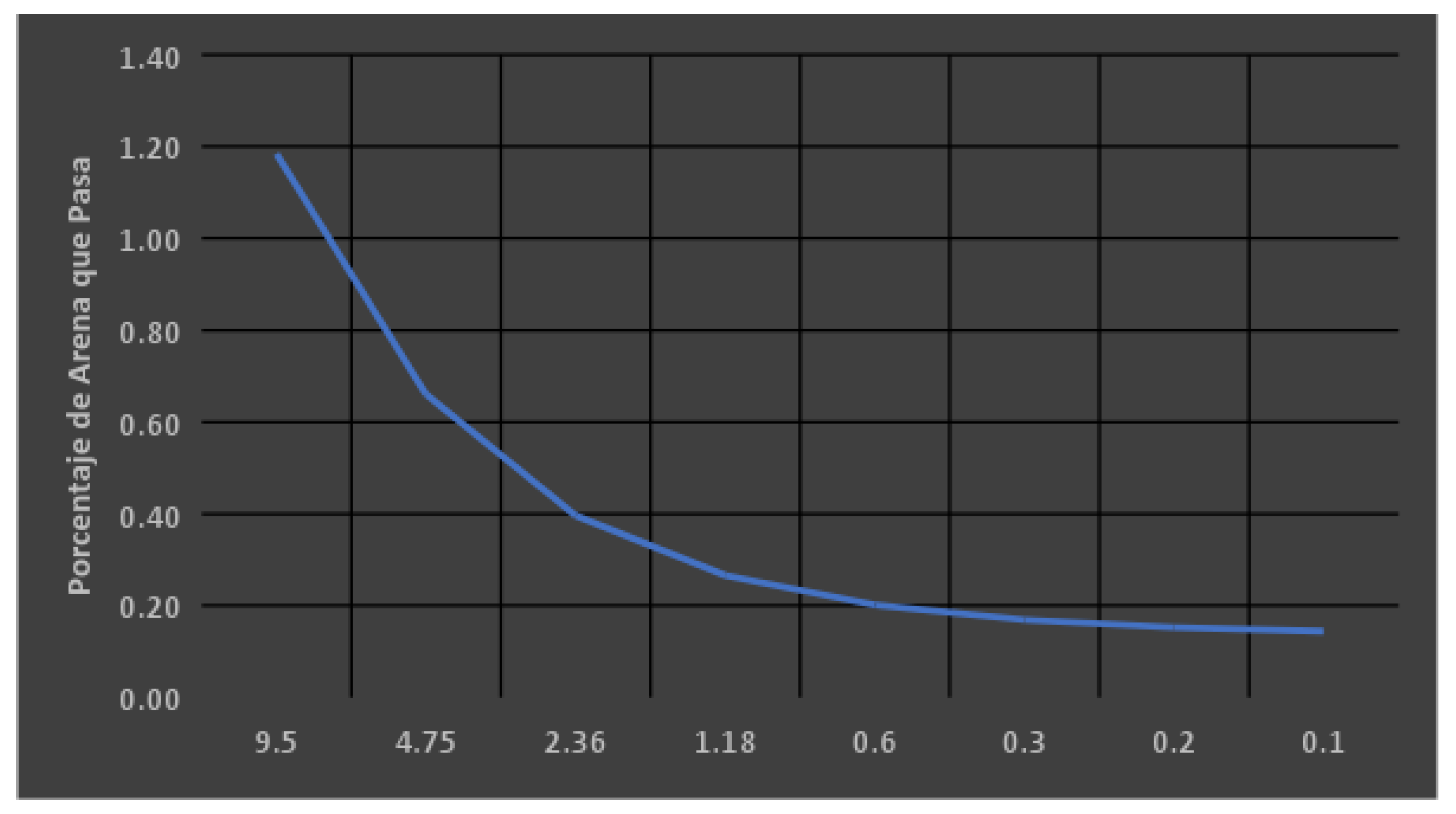

| Sieve | Opening (mm) | Average | Standard deviation |

| 3/8" | 9.5 | 99.99 | 0.073 |

| No. 4 | 4.75 | 94.09 | 0.807 |

| No. 8 | 2.36 | 57.22 | 2,920 |

| No. 16 | 1.18 | 30.46 | 2,267 |

| No. 30 | 0.6 | 20.80 | 1,921 |

| No. 50 | 0.3 | 10.34 | 1,293 |

| No. 100 |

0.15 |

3.50 |

0.701 |

| No. 200 |

0.075 |

1.00 |

0.360 |

| Rehearsal | Average | Standard deviation |

| Percentage of material finer than the 75 µm sieve | 6.59 | 0.97 |

| Apparent density (kg/m3) | 2446.46 | 21.87 |

| Surface-dry saturated density (kg/m3) | 2545.63 | 20.83 |

| Nominal Density (kg/m3) | 2716.56 | 24.07 |

| Absorption (%) | 4.05 | 0.21 |

| Organic matter content | 1 | - |

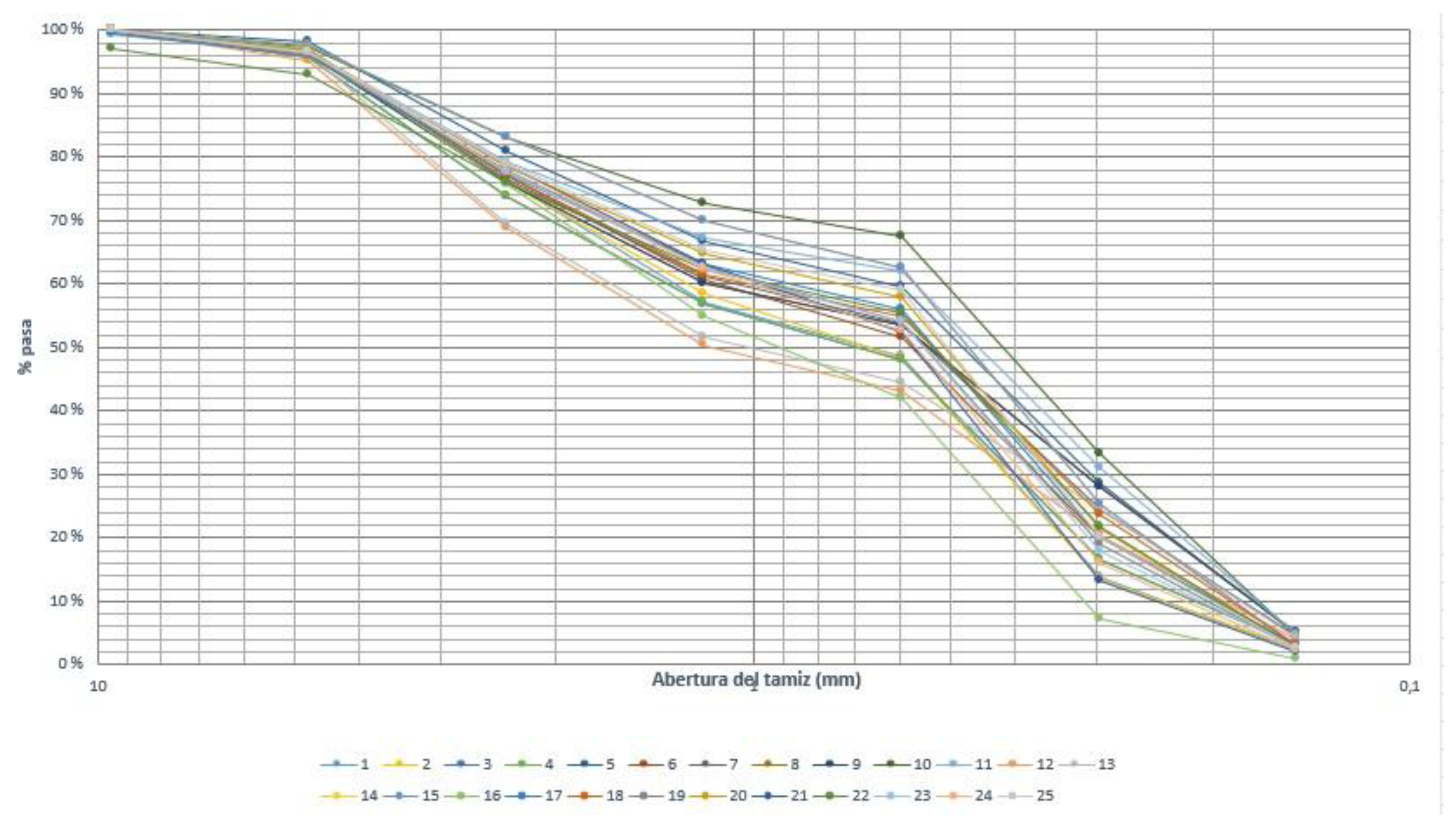

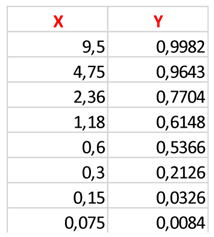

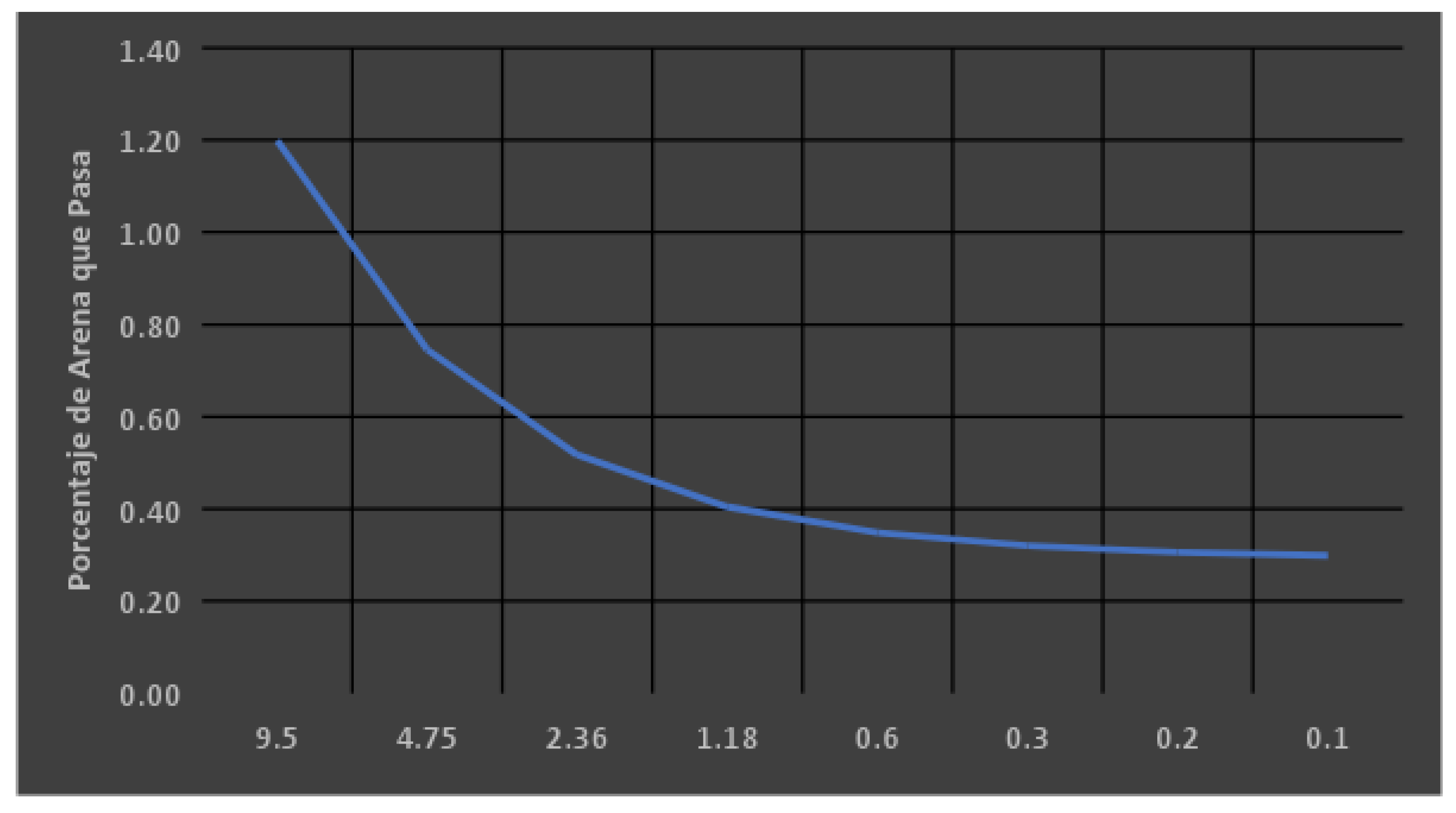

Combined Sand

| Sieve | Opening (mm) | Average | Standard deviation |

| 3/8" | 9.5 | 99.82 | 0.603 |

| No. 4 | 4.75 | 96.43 | 0.936 |

| No. 8 | 2.36 | 77.04 | 3,242 |

| No. 16 | 1.18 | 61.48 | 5,092 |

| No. 30 | 0.6 | 53.66 | 5,995 |

| No. 50 | 0.3 | 21.26 | 6,063 |

| No. 100 |

0.15 | 3.26 | 1,036 |

| No. 200 |

0.075 | 0.84 | 0.325 |

| Rehearsal | Average | Standard deviation |

| Percentage of material finer than the 75 µm sieve | 3.88 | 0.48 |

| Apparent density (kg/m3) | 2500.53 | 32.40 |

| Surface-dry saturated density (kg/m3) | 2574.68 | 32.77 |

| Nominal Density (kg/m3) | 2701.49 | 40.00 |

| Absorption (%) | 2.97 | 0.29 |

| Organic matter content | 1 | - |

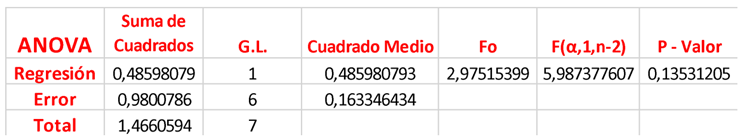

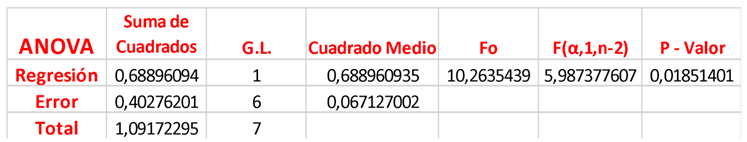

Statistical Analysis

|

|

|

|

|

|

Analysis of Results

| A/C | Age (Days) | Average strength (MPa) | Standard Deviation |

| 0.75 | 28 | 15.90 | 3.04 |

| 0.7 | 28 | 24.99 | 2.67 |

| 0.65 | 28 | 28.38 | 2.56 |

| 0.6 | 28 | 28.80 | 3.24 |

| 0.55 | 28 | 36.39 | 3.40 |

| 0.5 | 28 | 39.67 | 3.18 |

| 0.45 | 28 | 45.81 | 4.67 |

| 0.4 | 28 | 55.29 | 4.68 |

| 0.35 | 28 | 59.52 | 8.29 |

| A/C | Age (Days) | Average strength (MPa) | Standard Deviation |

| 0.75 | 7 | 14.07 | 3.46 |

| 0.7 | 7 | 19.22 | 3.88 |

| 0.65 | 7 | 22.25 | 3.23 |

| 0.6 | 7 | 24.44 | 5.23 |

| 0.55 | 7 | 31.24 | 1.56 |

| 0.5 | 7 | 33.22 | 1.78 |

| 0.45 | 7 | 41.16 | 6.52 |

| 0.4 | 7 | 51.99 | 5.47 |

| 0.35 | 7 | 55.74 | 9.69 |

| A/C | 7-day average (MPa) | Average 28 days (MPa) | Percentage Achieved 7 days (%) |

| 0.75 | 13.54 | 15.65 | 86.51 |

| 0.7 | 19.22 | 24.23 | 79.30 |

| 0.65 | 22.25 | 27.82 | 79.97 |

| 0.6 | 24.44 | 28.66 | 85.28 |

| 0.55 | 31.24 | 36.52 | 85.53 |

| 0.5 | 33.22 | 39.67 | 83.74 |

| 0.45 | 38.25 | 46.01 | 83.14 |

| 0.4 | 48.44 | 54.59 | 88.74 |

| 0.35 | 50.99 | 59.19 | 86.15 |

| Average | 84.26 |

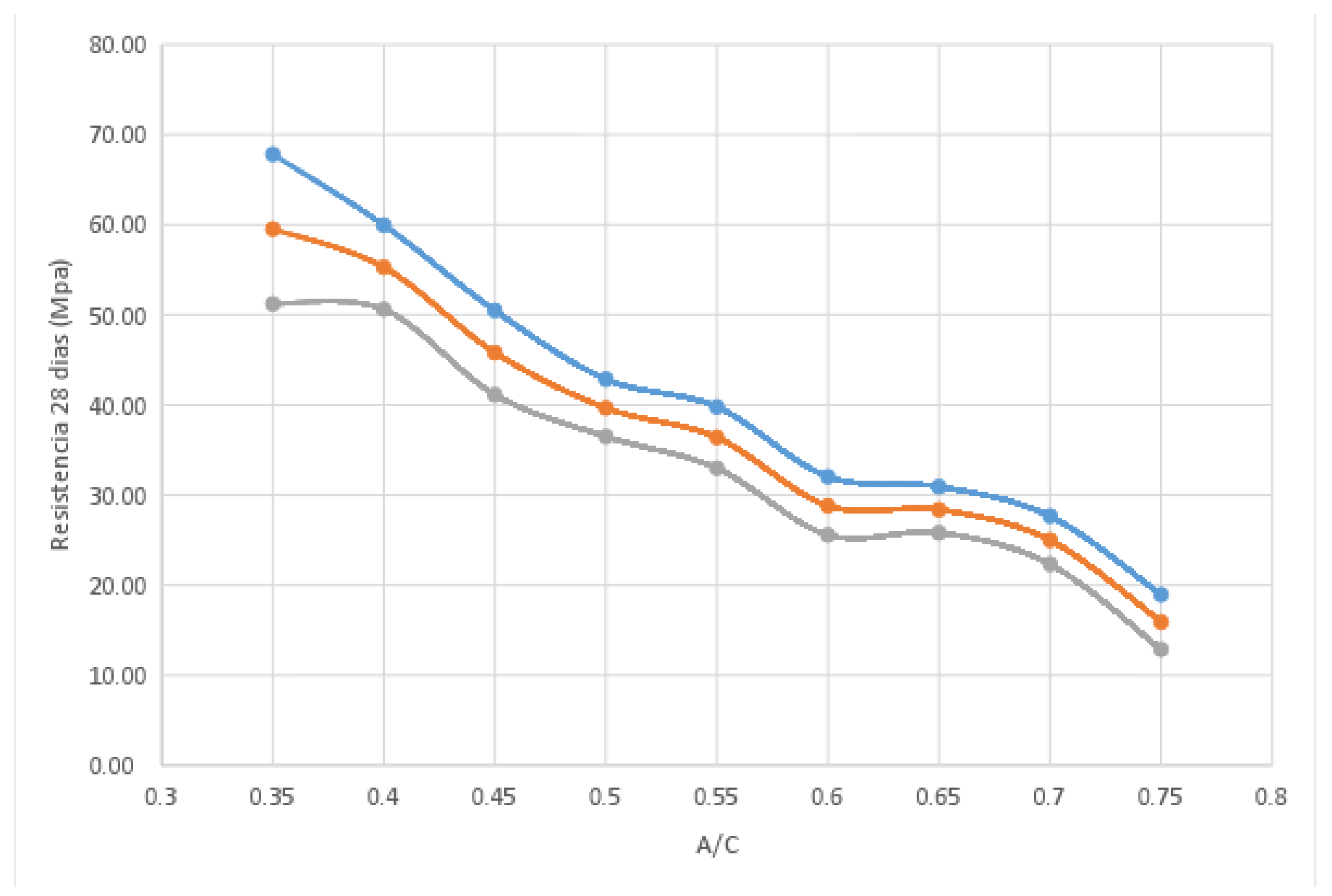

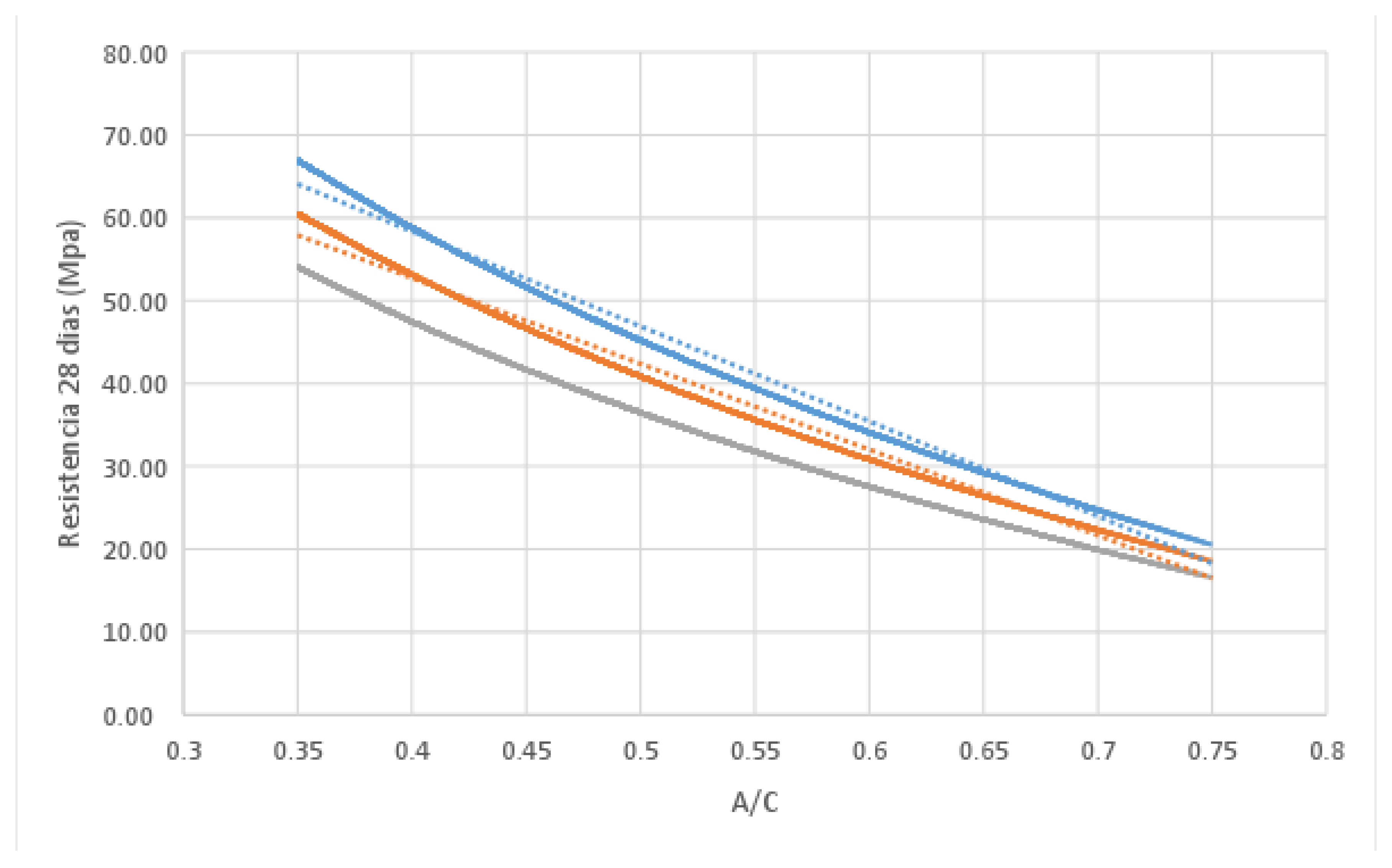

Preparation and Modeling of the A/C Curve

| A/C | Age (Days) | Average strength (MPa) | Standard Deviation |

| 0.75 | 28 | 15.90 | 3.04 |

| 0.7 | 28 | 24.99 | 2.67 |

| 0.65 | 28 | 28.38 | 2.56 |

| 0.6 | 28 | 28.80 | 3.24 |

| 0.55 | 28 | 36.39 | 3.40 |

| 0.5 | 28 | 39.67 | 3.18 |

| 0.45 | 28 | 45.81 | 4.67 |

| 0.4 | 28 | 55.29 | 4.68 |

| 0.35 | 28 | 59.52 | 8.29 |

| A/C | Average strength (Mpa) |

Deviation | upper limit (Mpa) | upper limit (Mpa) |

| 0.75 | 15.90 | 3.04 | 18.94 | 12.87 |

| 0.7 | 24.99 | 2.67 | 27.66 | 22.33 |

| 0.65 | 28.38 | 2.56 | 30.93 | 25.82 |

| 0.6 | 28.80 | 3.24 | 32.04 | 25.57 |

| 0.55 | 36.39 | 3.40 | 39.79 | 32.98 |

| 0.5 | 39.67 | 3.18 | 42.85 | 36.49 |

| 0.45 | 45.81 | 4.67 | 50.48 | 41.14 |

| 0.4 | 55.29 | 4.68 | 59.97 | 50.61 |

| 0.35 | 59.52 | 8.29 | 67.82 | 51.23 |

Conclusions

References

- Bracamonte Miranda, A. J., Vertel Morinson, M. L., & Cepeda Coronado. (2013). Caracterización Físico-mecánica de agregados peteros de la formación geológica Toluviejo (Sucre) para producción de concreto.

- Ávila Díaz, M. Á., Galviss Pizon, S., & Serna Hernández, L. F. (2015). Análisis de curvas para el diseño de mezclas de concreto con material triturado del río Magdalena en el sector de Girardot, Cundinamarca.

- Orbe Pinchao, L. V., & Zúñiga Morales, P. S. (2013). Optimización de la relación agua/cemento en el diseño de hormigones estándar establecidos en códigos ACI-ASTM.

- Sánchez, D. (1997). Tecnología de concreto – Tomo 1. Bhandar Editores Ltda.

- Valdivieso Taborda, C. E., Valdivieso Castellón, R., & Valdivieso Taborda, O. (2011).

- Determinación de muestra bajo el árbol de decisión.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). NTC 129: Ingeniería Civil y Arquitectura. Práctica para la toma de muestras de agregados.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). NTC 3674: Ingeniería civil y Arquitectura. Práctica para la reducción de las muestras de agregados, tomadas en campo para la realización de ensayos.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2000). NTC 174: Concretos: Especificaciones de los agregados para el concreto.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2007). NTC 77: Concretos: Método de ensayo para el análisis por tamizado de los agregados finos y gruesos.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). NTC 1776: Ingeniería civil y Arquitectura. Método de ensayo para determinar por secado el contenido total de humedad de los agregados.

- Instituto Nacional de Vías (INV). INV E-230: Índice de aplanamiento y alargamiento de los agregados para carreteras.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2000). NTC 176: Ingeniería Civil y Arquitectura: Método para determinar la densidad y absorción del agregado grueso.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (1995). NTC 92: Ingeniería Civil y Arquitectura: Determinación de la masa unitaria y los vacíos entre partículas de agregados.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (1995). NTC 78: Ingeniería Civil y Arquitectura: Método para determinar por lavado el material que pasa el tamiz 75 µm en agregados minerales.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2000). NTC 237: Ingeniería Civil y Arquitectura: Método para determinar la densidad y absorción del agregado fino.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2000). NTC 127: Concretos: Método de ensayo para determinar las impurezas orgánicas en agregado fino para concreto.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (1992). NTC 396: Ingeniería Civil y Arquitectura: Método de ensayo para determinar el asentamiento del concreto.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (1994). NTC 1377: Ingeniería Civil y Arquitectura: Elaboración y curado de especímenes de concreto para ensayos de laboratorio.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). NTC 3512: Cementos. Cuartos de mezclado, cámaras y cuartos húmedos y tanques para el almacenamiento de agua, empleados en los ensayos de cementos hidráulicos y concretos.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). (2010). NTC 673: Concretos: Ensayo de resistencia a la compresión de especímenes de concreto.

- American Concrete Institute (ACI). (2011). Código ACI 318-11: Requisitos de reglamento para concreto estructural.

- ASOCRETO. (s. f.). Tecnología del Concreto, Tomo 1, Cap. 8.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).