1. Introduction

Concrete is the most widely used material in the construction sector due to its compressive strength and ease of manufacture. However, it exhibits low tensile strength and tends to crack under external stresses [

1] . This limitation compromises structural durability, especially in slabs and elements exposed to differential stresses [

2]. In various countries, such as South Korea and Colombia, these cracks have been observed to affect structural performance, causing deflections and reducing the service life of structures [

3]. In Peru, the situation is worsened by the high percentage of self-built housing, many of which do not follow proper technical criteria, increasing their seismic vulnerability and leading to premature deterioration [

4]. Moreover, the production of cement—a key component of concrete—generates approximately one ton of CO₂ per ton produced, significantly contributing to climate change [

5]. Therefore, it is necessary to implement sustainable solutions, such as the partial replacement of cement with natural waste materials possessing high pozzolanic reactivity, like calcined ashes, as well as the use of plant fibers to improve the mechanical performance of concrete [

6,

7].

Previous studies have shown that the inclusion of fibers can enhance compressive, flexural, and tensile strengths, while the use of ashes as partial cement replacement improves compactness and reduces the environmental footprint of concrete [

8]. These strategies are particularly relevant in light of the growing demand for cement, which is projected to increase by 225% by 2050, potentially worsening the environmental crisis in the sector [

9]. In this context, several studies have explored the use of agro-industrial waste, such as coconut filaments and various organic ashes, in conventional concretes. For example, additions of 1% to 4% coconut fiber have been shown to yield improvements of up to 2.88% in compressive strength and 10.34% in flexural strength, although with reduced workability [

10]. Similarly, the use of coconut filament ash as a partial replacement for fine aggregate resulted in up to 22% improvement in compressive strength and 7.5% in indirect tensile strength, along with greater mix fluidity [

11]. ]. In another case, a 2% replacement of cement with coconut fiber achieved improvements of 3.6% in compressive strength and 26.6% in flexural strength [

12]. Regarding plant-based ashes, the use of cashew nutshell ash resulted in up to 15.3% increase in compressive strength, albeit with a reduction in slump and density [

13]. ]. Likewise, the incorporation of rice husk ash in geopolymer concretes has improved compressive strength by as much as 54.7% with just 2.5% addition [

14]. In Peru, studies on tara ash have reported a 17.16% increase in compressive strength and 1.78% in indirect tensile strength with an optimal dosage of 6%, although with a significant decrease in slump [

15]. The combination of 0.65% coconut fiber and 1.2% eucalyptus ash has also shown improvements of 20% in compressive strength and up to 53.7% in flexural strength [

16]. In lower-strength concrete designs (f’c), the use of 1% coconut fiber led to an 8.5% increase in compressive strength and 2% in flexural strength [

17]. Similarly, the application of combinations of corn husk and

ichu fiber resulted in 18% improvement in tensile strength and over 16% in compressive strength [

18], while other alternatives, such as coca leaf ash, yielded modest gains in compressive strength and acceptable behavior in slump and flexural performance when used in moderate doses [

19]

In this context, the present research aims to analyze the combined effect of the addition of natural ash and plant fiber on the mechanical properties of concrete, using a concrete mix design with a compressive strength of f’c = 210 kg/cm², in order to evaluate their interaction and joint performance. The goal is to contribute to the development of more sustainable concretes with greater durability and reduced environmental impact.

2. Materials and Methods

This research was based on an experimental design using a control mix with a characteristic compressive strength of f’c = 210 kg/cm², formulated according to the guidelines of ACI 211.1 [

20]. Type I Portland cement, locally sourced fine and coarse aggregates, potable water, calcined tara ash as a partial cement substitute, and plant-based fibers as additional reinforcement were used. The ash replacement levels evaluated were 0%, 6%, 12%, and 16% by cement weight, while the fiber content levels were 0%, 0.5%, 1%, and 1.5% by volume. A control mix without ash or fiber was also included.

The mixtures were prepared by first mixing all dry components following the standard dry mixing procedure, after which water was added according to the corresponding water-to-cement (w/c) ratio. Cylindrical specimens of 15 × 30 cm and beams of 15 × 15 × 50 cm were fabricated. The specimens were cured by immersion in water at ambient temperature and subsequently tested at 28 days to evaluate mechanical strength: compressive strength (ASTM C39) [

21], ], flexural strength (ASTM C78) [

22] and indirect tensile strength via diametral compression (ASTM C496) [

23]. The slump test was performed in accordance with ASTM C143 [

24].

Statistical evaluation of the results was carried out using a 4×4 factorial design, considering ash content and fiber inclusion as factors, each with four levels. An analysis of variance (ANOVA) was applied to determine the statistical significance of each variable, and the Tukey test was used to identify differences among treatments.

2.1. Preparation and Characterization of Materials

2.1.1. Procedure for Obtaining Tara Ash

The process of obtaining tara ash began with the collection of the dried husk, which was weighed prior to being subjected to a controlled combustion process. The material was incinerated in a handmade furnace at a temperature of approximately 600 °C for a period of 5 to 7 hours, until it transformed into a fine, light gray powder with a dusty texture. As a result, 7.56 kg of ash were obtained from two 50 kg sacks of husks, representing about 8% of the original material weight. This procedure is similar to those used in studies involving pozzolanic plant-based residues, such as sugarcane bagasse ash, where calcination temperatures between 600 °C and 700 °C are recommended to preserve pozzolanic activity without causing vitrification [

25].

Figure 1.

(A) Dried tara husk collected and selected as the base material for ash production. (B) Sample of tara ash obtained after calcination, ready to be sieved and used as an additive in the concrete mix design.

Figure 1.

(A) Dried tara husk collected and selected as the base material for ash production. (B) Sample of tara ash obtained after calcination, ready to be sieved and used as an additive in the concrete mix design.

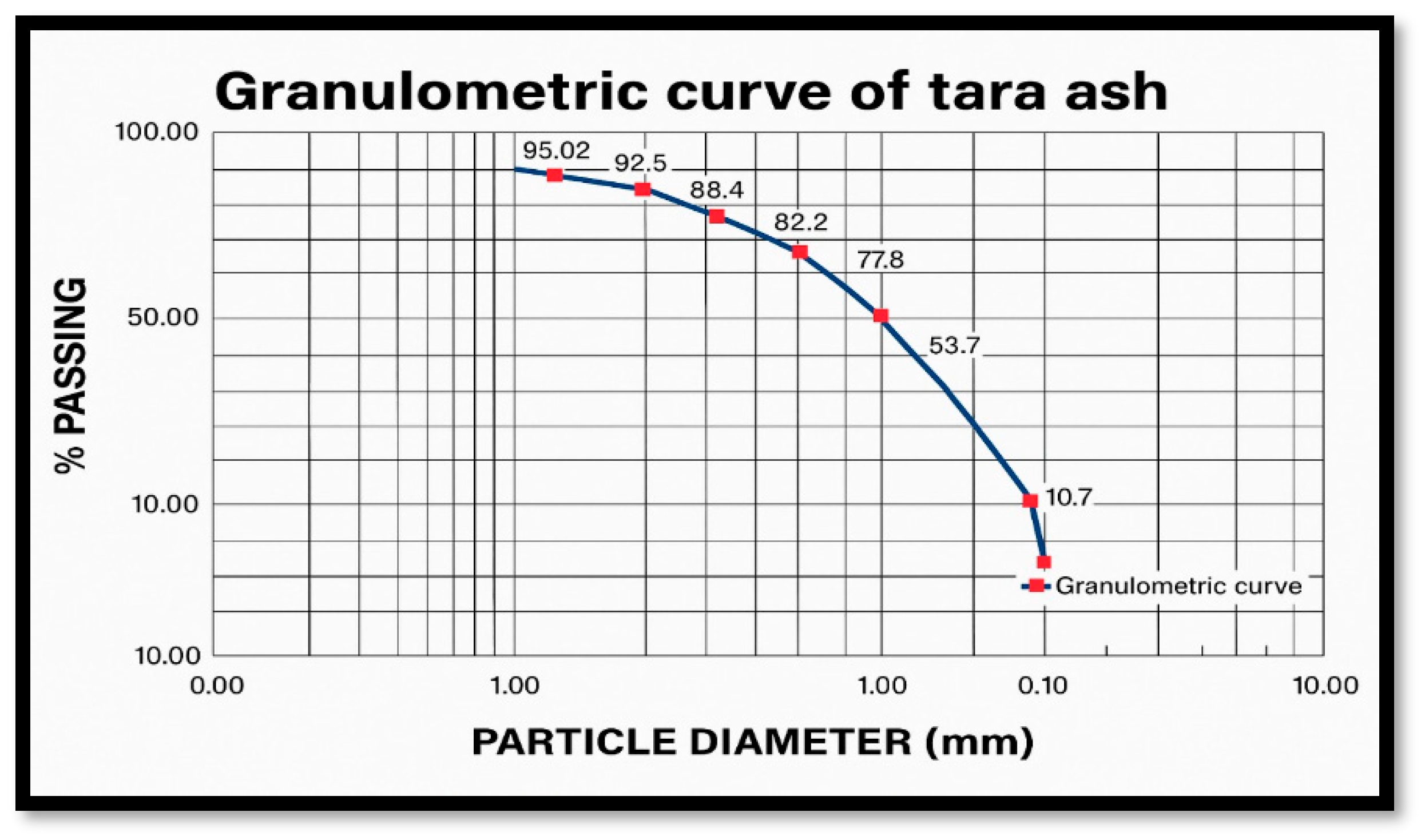

2.1.2. Particle Size Analysis of Tara Ash (ASTM C136)

The particle size analysis of tara ash shows that most of the particles are smaller than 0.85 mm, especially those retained on fine sieves such as No. 100 and No. 200, as illustrated in the figure. This distribution is crucial in applications where particle size directly influences the porosity and impermeability of concrete, since smaller particles tend to reduce voids, resulting in a denser matrix. The analysis followed the procedure established in ASTM C136, a standard widely used to determine the particle size distribution of cementitious materials [

26].

Figure 2.

Gradation curve of tara ash.

Figure 2.

Gradation curve of tara ash.

2.1.3. Specific Gravity and Water Absorption of Tara Ash

The table presents the tara ash, which has a relative specific gravity of 2.763 g/cm³—a value slightly lower than that of common mineral aggregates (2.6 to 2.9 g/cm³), making it acceptable for use as an additive or partial replacement in concrete mixtures. However, its water absorption is considerably high (28.6%), well above the typical value for conventional aggregates (less than 3%), indicating a high porosity. This characteristic can compromise the workability and durability of concrete if not properly managed, as has been reported in studies on natural ashes with similar properties [

27].

Table 1.

Specific gravity and water absorption of tara ash.

Table 1.

Specific gravity and water absorption of tara ash.

| Description |

Unit |

Data |

Relative Specific Gravity of Solids

Average at 20 °C (Gs))

|

g/cm3

|

2.763 |

| Water absorption |

% |

28.6 |

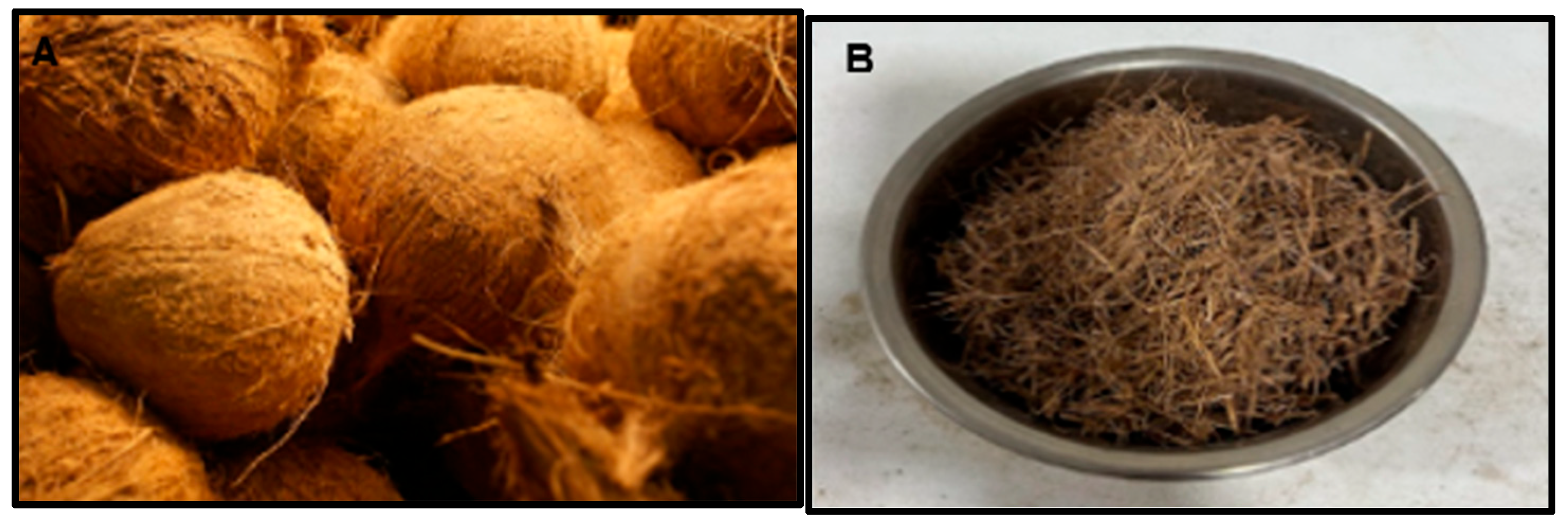

2.2. Coconut Fiber Extraction Process

The process of obtaining coconut fiber began with the collection of mature coconuts. From the husk, the fiber was separated from the hard shell using manual tools such as knives and machetes. Over an average duration of 3 to 4 hours, approximately 8 kg of fiber were obtained, with an average length of 0.03 cm, variable diameter, and a color range from light to dark brown. The natural moisture content of the fibers ranged between 10% and 20%, making it necessary to apply a drying process to reduce their water content before incorporating them into the concrete mix, as shown in the figures. Similar procedures for collecting, extracting, and conditioning plant fibers have been widely reported in the literature for their application as reinforcement in cementitious materials [

28].

Figure 3.

(A) Mature coconut fruits (Cocos nucifera L.) used as raw material for fiber extraction. (B) Plant fibers obtained through manual extraction, drying, and selection, intended for reinforcement in concrete mixtures.

Figure 3.

(A) Mature coconut fruits (Cocos nucifera L.) used as raw material for fiber extraction. (B) Plant fibers obtained through manual extraction, drying, and selection, intended for reinforcement in concrete mixtures.

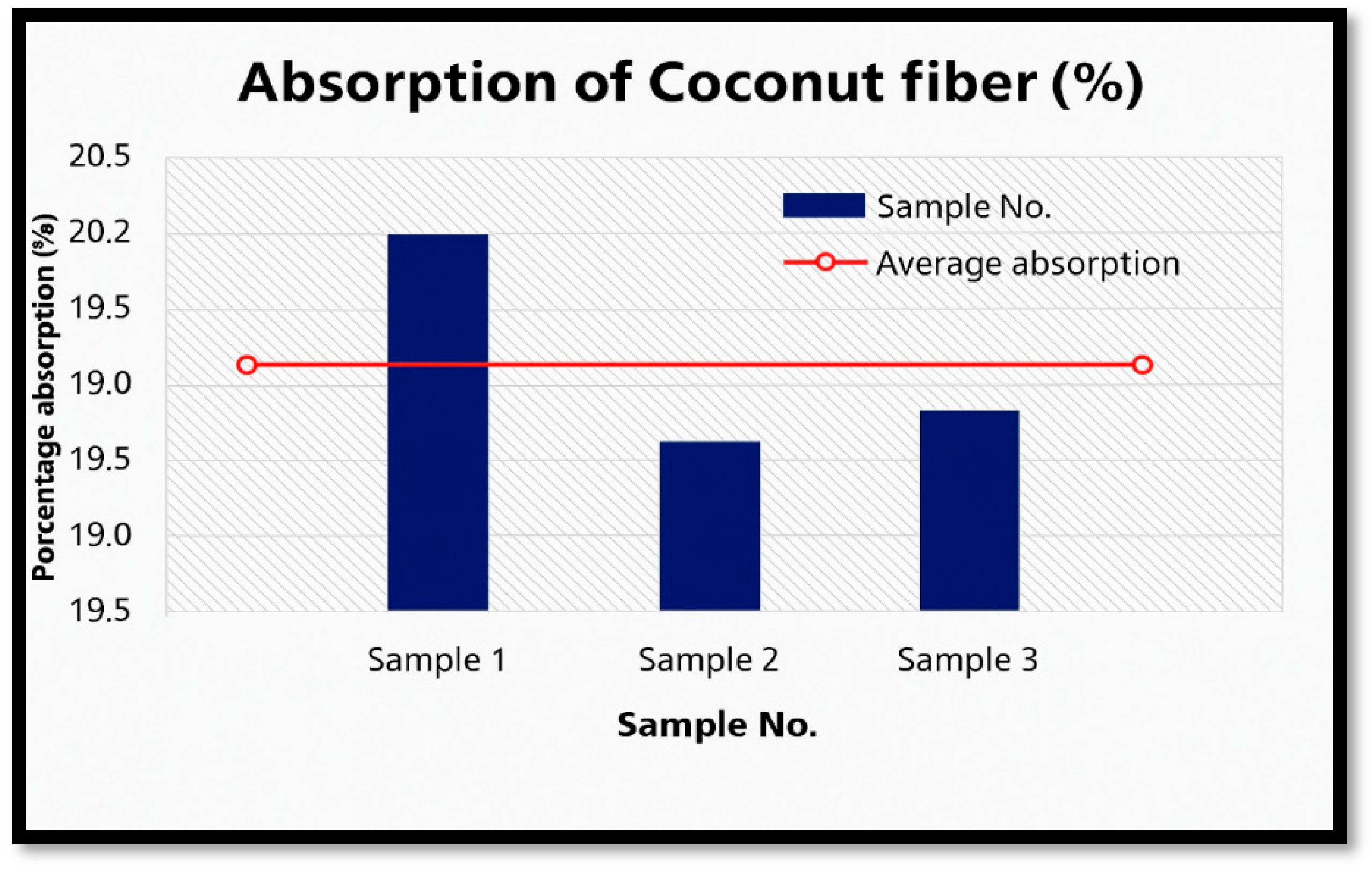

2.2.1. Water Absorption of Coconut Fiber

The following figure presents the water absorption values of three coconut fiber samples: 20.2%, 19.5%, and 19.6%, with an average of 19.8%, indicating a moderate moisture retention capacity. These data are relevant in composite material applications, as high absorption can alter the water-to-cement ratio in the mix, negatively affecting both workability and strength. Recent studies on lignocellulosic fibers in cementitious matrices have shown that high moisture absorption may induce expansion, weaken the interfacial transition zone, and reduce mechanical properties if not properly managed [

29].

Figure 4.

Water absorption of coconut fiber.

Figure 4.

Water absorption of coconut fiber.

2.2.2. Coconut Fiber Length

In this section, the length of five coconut fiber samples was analyzed, yielding values between 29 mm and 32 mm, with an average length of 30.4 mm. This moderate length suggests that the fibers can effectively act as reinforcement in concrete mixes, improving tensile strength and reducing crack formation, as shown in the figure. In line with the findings reported by Martinelli et al., the mechanical properties and durability of coconut fibers are enhanced when an optimized length (~30 mm) is maintained, contributing to better integration within the cementitious matrix and improved crack control. [

30].

Figure 5.

Length of coconut fiber.

Figure 5.

Length of coconut fiber.

3. Results

3.1. Mix Design (ACI 211.1)

To ensure the reliability of the experimental results, a concrete mix design was prepared in accordance with ACI 211.1 [

20] for a target compressive strength of f’c = 210 kg/cm². The control mix was optimized to maintain a slump between 3" and 4", using materials sourced from the Trapiche quarry, including fine aggregate, coarse aggregate, and Type I Portland cement. A water-to-cement (w/c) ratio of 0.62 was established, allowing for adequate workability without negatively affecting the mechanical strength of the concrete.

Based on this reference mix, modified mixtures were developed to evaluate the influence of tara ash (TA) and coconut fiber (CF) as natural additives in concrete. Tara ash was used as a partial cement replacement, while coconut fiber was added as a supplement to the fine aggregate, without completely replacing it. Dosages were adjusted to combine proportions of 6%, 12%, and 16% tara ash with 0.5%, 1.0%, and 1.5% coconut fiber, resulting in a total of 16 experimental variations, including the control mix (0% TA and 0% CF).

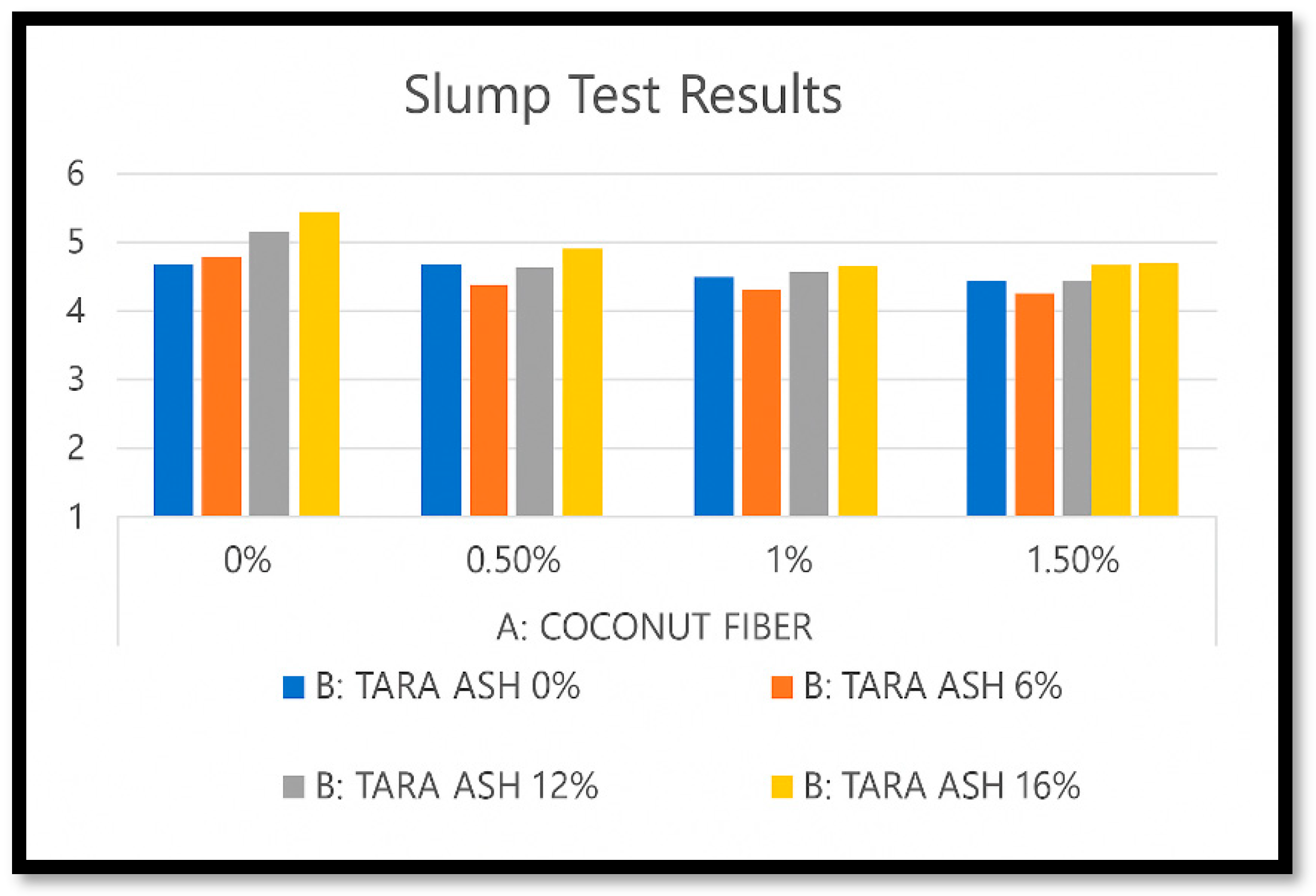

3.2. Slump Test (ASTM C143/C143M)

In this study, the slump test was conducted in accordance with ASTM C143/C143M [

24], to evaluate the workability of fresh concrete when incorporating tara ash and coconut fiber. This test is essential for assessing the behavior of modified mixes under real-world construction conditions. The control mix exhibited a slump within the target range of 3" to 4", as defined in the base design. The experimental mixes, containing high-absorption materials such as calcined ash and plant fibers, required careful control of moisture and effective water content. Despite this, the results showed stable workability across all dosages, demonstrating that the incorporation of these natural additives did not negatively affect the plastic behavior of the concrete, allowing it to retain both workability and consistency.

Table 2.

Slump Test Results for the Different Concrete Mixes Prepared.

Table 2.

Slump Test Results for the Different Concrete Mixes Prepared.

| |

|

A: COCONUT FIBER |

| |

|

0% |

0.50% |

1% |

1.50% |

| B:TARA ASH |

0% |

4" 1/4 |

4" 1/8 |

3" 3/4 |

3" 1/2 |

| 6% |

4" |

3" 3/4 |

3" 1/2 |

3" |

| 12% |

4" 1/2 |

3" 7/8 |

3" 7/8 |

3" 1/2 |

| 16% |

5" |

4" 1/4 |

3" 7/8 |

3" 5/8 |

Figure 6.

Slump Test Results.

Figure 6.

Slump Test Results.

As observed in the previous table and figure, the slump progressively decreased as the dosage of coconut fiber increased, indicating a reduction in concrete workability. As tara ash was added, the slump also tended to decrease, especially in combinations with higher fiber content. The mix with 16% tara ash and 0% fiber showed the highest slump (5"), while the mix with 6% tara ash and 1.5% fiber showed the lowest (3").

3.3. Compressive Strength

To evaluate the effect of tara ash and coconut fiber on the 28-day compressive strength of concrete, various combinations of experimental mixes were developed. The table above presents the results obtained, allowing for the observation of behavioral variations according to the percentages used. These differences will be analyzed in more detail using statistical tools to determine the significance of the evaluated factors and their interaction within the factorial model.

Table 3.

Compressive Strength Results at 28 Days.

Table 3.

Compressive Strength Results at 28 Days.

| |

|

|

|

28 DAYS |

|

|

| |

|

CONOCUT FIBER |

| |

|

0.0% |

0.5% |

1% |

1.5% |

| TARA ASH |

0.0% |

217.2 |

217.3 |

219.0 |

220.1 |

218.9 |

219.0 |

216.3 |

214.8 |

| 217.7 |

216.4 |

219.7 |

218.4 |

218.6 |

218.0 |

216.2 |

215.3 |

| 217.6 |

216.3 |

220.4 |

219.1 |

218.0 |

219.8 |

213.9 |

216.6 |

| 6% |

218.7 |

220.4 |

215.4 |

215.0 |

216.2 |

219.0 |

214.0 |

217.2 |

| 220.7 |

220.4 |

216.4 |

215.3 |

217.3 |

220.3 |

216.0 |

215.2 |

| 220.2 |

221.4 |

216.3 |

214.8 |

217.8 |

216.3 |

213.4 |

212.8 |

| 12% |

214.3 |

215.3 |

218.7 |

217.8 |

216.0 |

215.3 |

213.6 |

213.5 |

| 215.0 |

216.1 |

218.8 |

219.5 |

214.7 |

216.7 |

212.8 |

213.9 |

| 215.3 |

215.0 |

219.1 |

220.4 |

214.2 |

217.1 |

213.2 |

211.5 |

| 16% |

214.0 |

213.8 |

218.2 |

216.3 |

217.2 |

216.3 |

214.0 |

213.2 |

| 214.0 |

215.4 |

217.1 |

215.6 |

217.6 |

215.2 |

214.4 |

216.5 |

| 215.2 |

214.9 |

216.4 |

215.1 |

217.8 |

217.7 |

213.5 |

214.0 |

3.3.1. Inferential Statistics

According to the results of the normality test applied to the 96 compressive strength data at 28 days, the Kolmogorov–Smirnov test yielded a significance value of 0.081. Since this value is greater than the critical level of 0.05, it indicates that the data follow a normal distribution. Consequently, the assumption of normality required to apply parametric statistical analyses, such as ANOVA and the Tukey test, is satisfied..

Table 4.

Normality test for 28-day compressive strength.

Table 4.

Normality test for 28-day compressive strength.

| |

Kolmogórov-Smirnov |

| |

|

Statistic |

df |

Sig. |

Compressive strength,

28 days |

0,78 |

96 |

0,081 |

| |

|

|

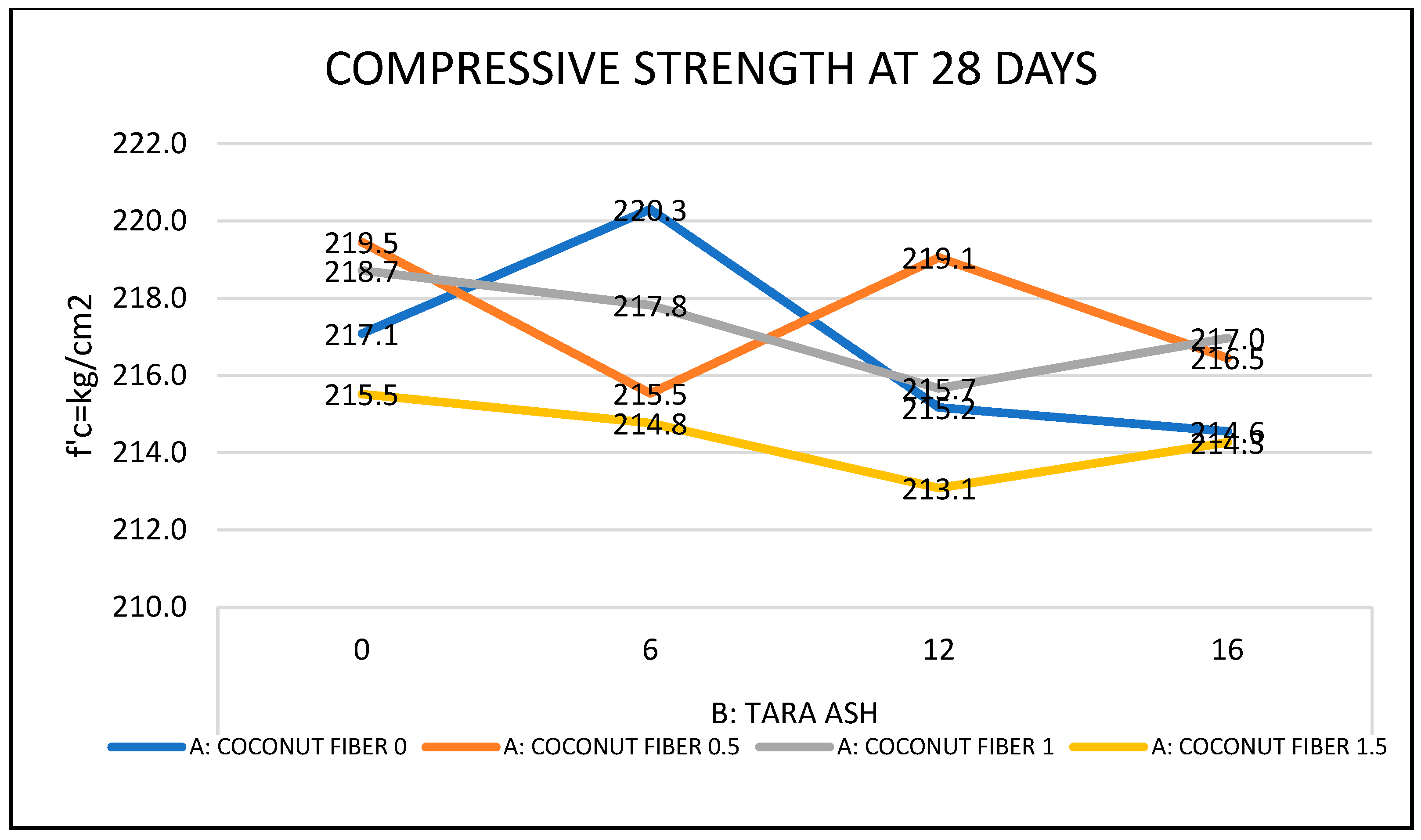

Figure 7.

Average Compressive Strength at 28 Days.

Figure 7.

Average Compressive Strength at 28 Days.

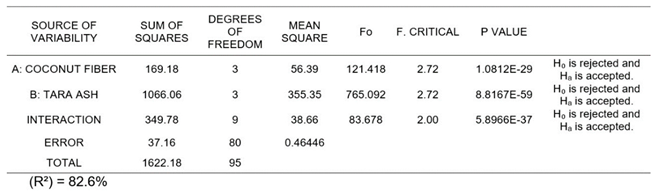

Table 5.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Compressive Strength.

Table 5.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Compressive Strength.

Table 6.

Tukey Test for Compressive Strength at 28 Days.

Table 6.

Tukey Test for Compressive Strength at 28 Days.

| |

A: CONOCUT FIBER |

|

|

|

B: TARA ASH |

|

| |

A4 |

A1 |

A2 |

A3 |

|

|

B4 |

B3 |

B1 |

B2 |

| A3 |

3.21 |

0.84 |

0.33 |

0 |

|

B2 |

2.13 |

1.95 |

0.59 |

0 |

| A2 |

2.88 |

0.51 |

0 |

0.33 |

|

B1 |

1.54 |

1.36 |

0 |

0.59 |

| A1 |

2.37 |

0 |

0.51 |

0.84 |

|

B3 |

0.18 |

0 |

1.36 |

1.95 |

| A4 |

0 |

2.37 |

2.88 |

3.21 |

|

B4 |

0 |

0.18 |

1.54 |

2.13 |

The analysis of variance (ANOVA) presented in

Table 5 shows that both coconut fiber and tara ash have a statistically significant influence on the 28-day compressive strength of concrete, as the p-values associated with each factor are extremely low (p < 0.05), and the Fo values far exceed the established critical values. The greatest effect was caused by tara ash (Fo = 765.09), followed by coconut fiber (Fo = 121.41), and the interaction between both factors (Fo = 83.67). This supports the experimental findings, which identified the best absolute result as a compressive strength of 220.3 kg/cm², corresponding to the combination of 6% tara ash and 0% fiber.

Additionally, the multiple comparisons analysis using the Tukey test confirmed significant differences among several combinations, considering a critical value of 1.7016. The most efficient interaction combination was 12% tara ash with 0.5% coconut fiber (B3–A2), reaching 219.1 kg/cm², while the least favorable was 12% ash with 1.5% fiber (B3–A4), with 213.1 kg/cm². These differences support the alternative hypothesis and demonstrate that the interaction between both additives has a significant impact on the mechanical performance of concrete. Moreover, the coefficient of determination R² = 82.6% indicates that the statistical model explains a large portion of the observed variability.

3.4. Flexural Strength

To evaluate the flexural behavior of concrete at 28 days, various combinations of coconut fiber and tara ash were analyzed. The previous table presents the average values obtained, showing how flexural strength varies with the use of these additives. At first glance, it can be observed that mixtures with higher proportions of both components tend to reduce mechanical performance, while certain moderate dosages may help maintain stable values. These results will be interpreted further through graphical analysis and statistically validated using a two-factor ANOVA model.

Table 7.

Flexural Strength Results at 28 Days.

Table 7.

Flexural Strength Results at 28 Days.

| |

|

|

|

28 DAYS |

|

|

| |

|

CONOCUT FIBER |

| |

|

0.0% |

0.5% |

1% |

1.5% |

| TARA ASH |

0.0% |

40.8 |

41.2 |

43.1 |

43.4 |

43.1 |

43.3 |

42.3 |

42.4 |

| 40.6 |

41.2 |

43.2 |

43.4 |

43.2 |

43.3 |

42.4 |

42.3 |

| 41.0 |

41.2 |

43.3 |

43.5 |

43.3 |

43.5 |

42.5 |

42.4 |

| 6% |

38.1 |

38.2 |

35.8 |

35.8 |

37.8 |

37.7 |

36.9 |

36.7 |

| 37.9 |

38.3 |

35.9 |

35.7 |

37.7 |

37.9 |

36.8 |

36.7 |

| 38.2 |

38.4 |

36.0 |

35.6 |

37.9 |

37.9 |

36.8 |

36.6 |

| 12% |

37.9 |

37.3 |

30.7 |

31.3 |

29.8 |

29.7 |

25.9 |

26.1 |

| 37.8 |

37.2 |

30.8 |

31.4 |

29.9 |

29.7 |

26.2 |

26.0 |

| 37.5 |

37.1 |

31.0 |

31.5 |

29.7 |

29.6 |

26.2 |

26.1 |

| 16% |

37.0 |

37.3 |

22.7 |

22.0 |

24.6 |

24.8 |

22.7 |

22.0 |

| 37.1 |

37.4 |

22.3 |

22.9 |

24.9 |

24.7 |

22.3 |

21.5 |

| 37.2 |

37.5 |

22.3 |

23.0 |

24.8 |

24.7 |

22.4 |

21.7 |

3.4.1. Inferential Statistics

According to the results of the normality test applied to the 96 flexural strength data at 28 days, the Kolmogorov–Smirnov test yielded a significance value of 0.086. Since this value is higher than the critical level of 0.05, the null hypothesis is not rejected, indicating that the data follow a normal distribution. Therefore, the assumption of normality required to apply parametric statistical methods such as ANOVA and the Tukey test is satisfied.

Table 8.

Normality Test for Flexural Strength at 28 Days.

Table 8.

Normality Test for Flexural Strength at 28 Days.

| |

Kolmogórov-Smirnov |

| |

|

Statistic |

df |

Sig. |

| Flexural strength, 28 days |

0,101 |

96 |

0,086 |

| |

|

|

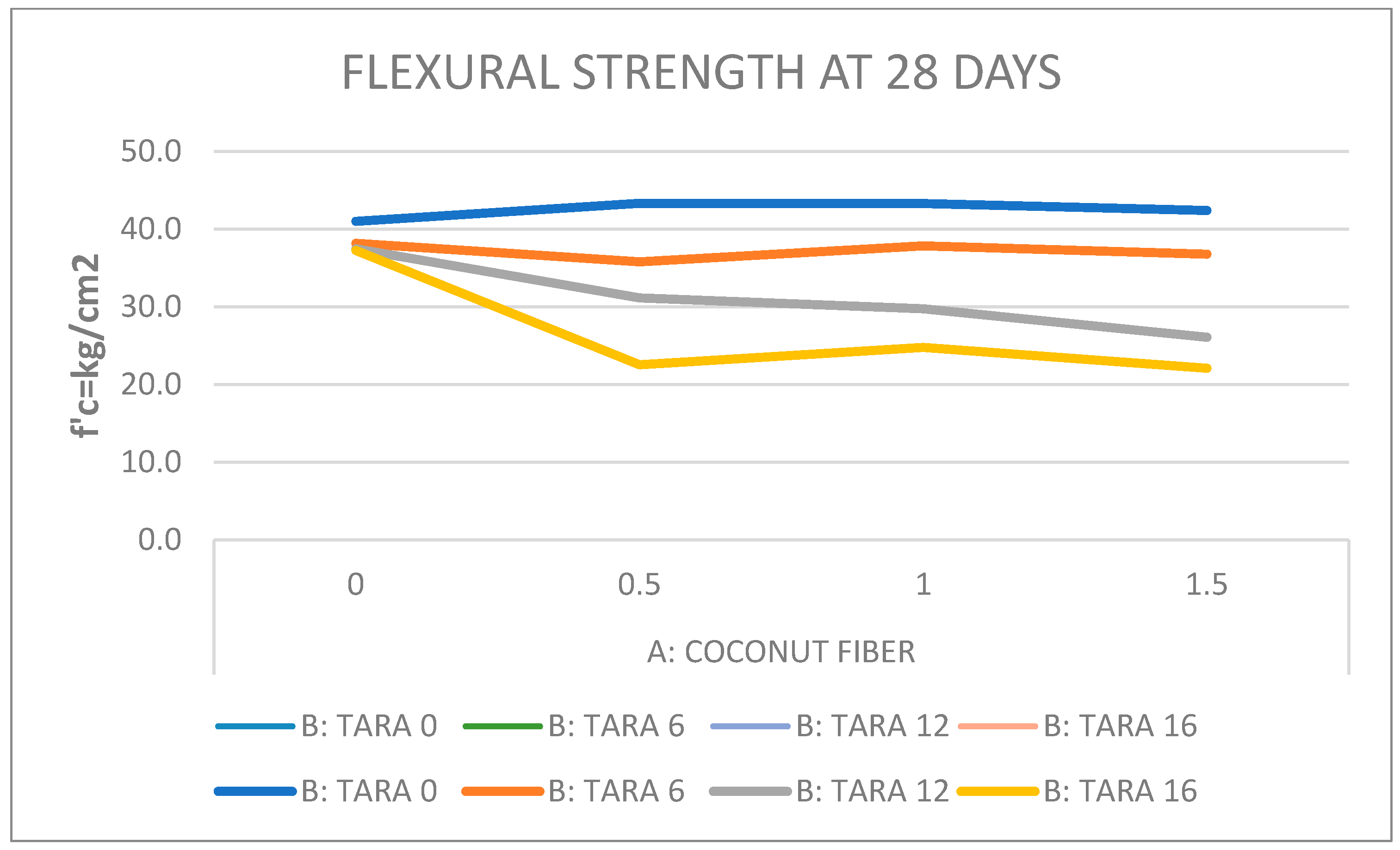

Figure 8.

Average Flexural Strength at 28 Days.

Figure 8.

Average Flexural Strength at 28 Days.

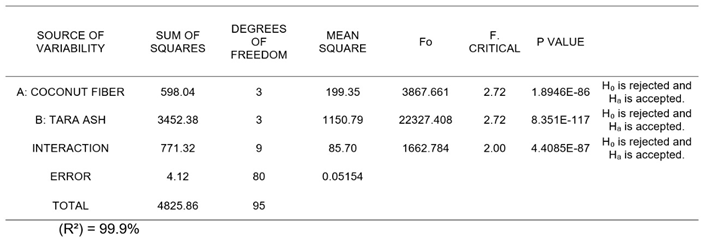

Table 9.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Flexural Strength.

Table 9.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Flexural Strength.

Table 10.

Tukey Test for Flexural Strength at 28 Days.

Table 10.

Tukey Test for Flexural Strength at 28 Days.

| |

A: CONOCUT FIBER |

|

|

|

B: TARA ASH |

|

| |

A2 |

A4 |

A3 |

A1 |

|

|

B4 |

B3 |

B2 |

B1 |

| A1 |

5.26 |

4.51 |

3.04 |

0.00 |

|

B1 |

11.20 |

10.38 |

5.03 |

0.00 |

| A3 |

2.22 |

1.47 |

0.00 |

3.04 |

|

B2 |

6.17 |

5.35 |

0.00 |

5.03 |

| A4 |

0.75 |

0.00 |

1.47 |

4.51 |

|

B3 |

0.82 |

0.00 |

5.35 |

10.38 |

| A2 |

0.00 |

0.75 |

2.22 |

5.26 |

|

B4 |

0.00 |

0.82 |

6.17 |

11.20 |

The factorial analysis of variance for 28-day flexural strength (

Table 9) shows that the statistical model has an extremely high explanatory capacity, with a coefficient of determination R² = 99.9%, indicating that virtually all observed variability is explained by the evaluated factors. Coconut fiber (Fo = 3867.661), tara ash (Fo = 22327.408), and their interaction (Fo = 1662.784) all exhibit Fo values far exceeding the critical threshold, accompanied by near-zero p-values. This allows for the rejection of the null hypothesis and confirms that all factors have a statistically significant effect on the flexural strength of concrete.

However, the analysis of mean values reveals that this effect is predominantly negative, as the simultaneous increase of both additives tends to reduce strength, as observed in the combinations with higher percentages of ash and fiber.

The Tukey test further confirms the existence of statistically significant differences between treatments, with several comparisons exceeding the critical value of 0.3827. The highest flexural strength values were recorded in the combinations with 0.5% and 1.0% coconut fiber without ash (A2–B1 and A3–B1), both reaching 43.3 kg/cm², suggesting that intermediate fiber levels can enhance flexural performance as long as no ash is used. In contrast, the least favorable combination was 1.5% fiber with 16% tara ash (A4–B4), with a strength of 22.1 kg/cm², indicating that high combined proportions of both additives significantly deteriorate the mechanical performance of concrete.

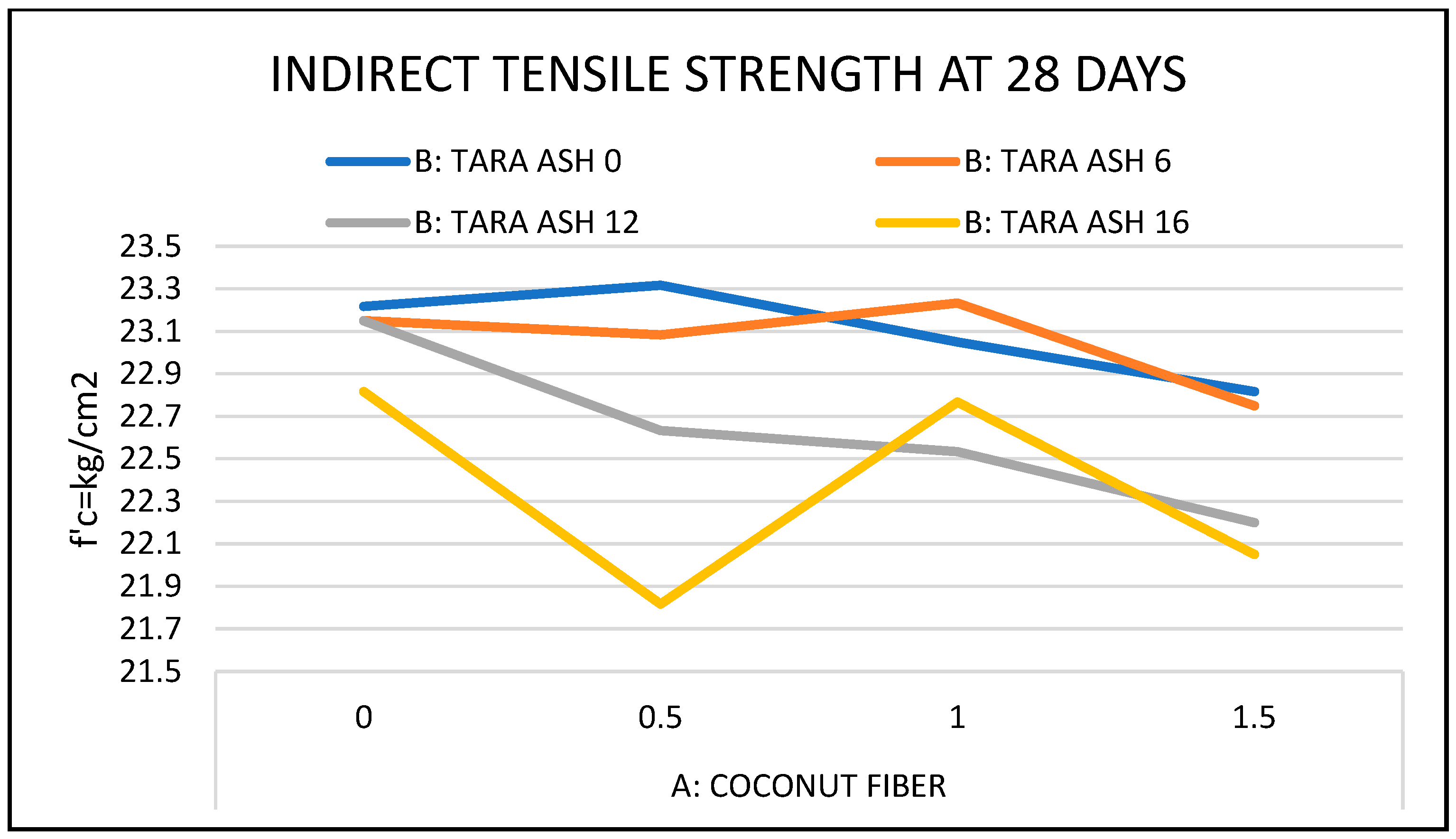

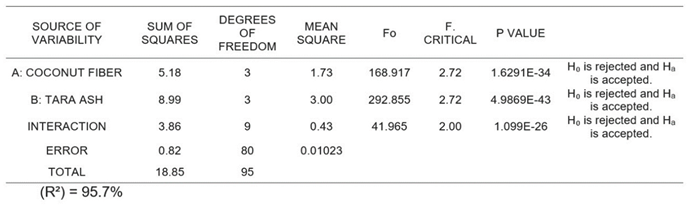

3.5. Indirect Tensile Strength

To evaluate the indirect tensile behavior of concrete at 28 days, multiple combinations of coconut fiber and tara ash were analyzed. The table above shows that the control mix (0% ash – 0% fiber) reached an average value of 23.2 kg/cm², and that combinations such as 0.5% fiber without ash (0% TA – 0.5% CF) maintained that level with 23.2 kg/cm², without significant improvements. When tara ash was incorporated at moderate proportions (6% and 12%) with low fiber levels (0.5% and 1%), similar values were preserved, ranging from 23.1 to 23.3 kg/cm², but without clearly surpassing the control mix. In contrast, the combinations with 16% ash and 1.5% fiber yielded the lowest values, dropping to 22.0 kg/cm² and 22.1 kg/cm². This suggests that, as with flexural behavior, high dosages of both additives tend to reduce mechanical performance. These results will be complemented with statistical and graphical analysis to confirm significant differences among treatments.

Table 11.

Indirect Tensile Strength Results at 28 Days.

Table 11.

Indirect Tensile Strength Results at 28 Days.

| |

|

|

|

28 DAYS |

|

|

| |

|

CONOCUT FIBER |

| |

|

0.0% |

0.5% |

1% |

1.5% |

| TARA ASH |

0.0% |

23.2 |

23.2 |

23.4 |

23.2 |

23.1 |

23.0 |

22.9 |

22.9 |

| 23.3 |

23.0 |

23.5 |

23.2 |

23.1 |

23.0 |

22.9 |

22.6 |

| 23.2 |

23.4 |

23.3 |

23.3 |

23.0 |

23.1 |

22.9 |

22.7 |

| 6% |

23.1 |

23.3 |

23.0 |

23.1 |

23.2 |

23.2 |

22.9 |

22.6 |

| 23.0 |

23.2 |

23.0 |

23.2 |

23.3 |

23.2 |

22.9 |

22.6 |

| 23.1 |

23.2 |

23.1 |

23.1 |

23.3 |

23.2 |

22.9 |

22.6 |

| 12% |

23.3 |

23.1 |

22.8 |

22.6 |

22.6 |

22.6 |

22.2 |

22.2 |

| 23.1 |

23.1 |

22.7 |

22.6 |

22.6 |

22.3 |

22.2 |

22.2 |

| 23.2 |

23.1 |

22.6 |

22.5 |

22.7 |

22.4 |

22.2 |

22.2 |

| 16% |

22.9 |

22.8 |

21.9 |

21.8 |

22.7 |

22.7 |

22.0 |

22.1 |

| 22.9 |

22.8 |

21.8 |

21.9 |

22.8 |

22.8 |

22.0 |

22.0 |

| 22.8 |

22.7 |

21.6 |

21.9 |

22.8 |

22.8 |

22.1 |

22.1 |

3.5.1. Inferential Statistics

According to the results of the normality test applied to the 96 indirect tensile strength data at 28 days, the Kolmogorov–Smirnov test yielded a significance value of 0.071. Since this value is above the critical level of 0.05, the null hypothesis is not rejected, indicating that the data are normally distributed. Therefore, the assumption of normality required to apply parametric statistical methods—such as analysis of variance (ANOVA) and the Tukey multiple comparison test—is satisfied.

Table 12.

Normality Test for Indirect Tensile Strength at 28 Days.

Table 12.

Normality Test for Indirect Tensile Strength at 28 Days.

| |

Kolmogórov-Smirnov |

| |

|

Estadístico |

gl |

Sig. |

Indirect Tensile

Strength at 28 Days |

0,142 |

96 |

0,071 |

| |

|

|

Figure 9.

Average Splitting Tensile Strength at 28 Days.

Figure 9.

Average Splitting Tensile Strength at 28 Days.

Table 13.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Indirect Tensile Strength.

Table 13.

Two-Factor ANOVA – Factorial Variance Analysis for 28-Day Indirect Tensile Strength.

Table 14.

Tukey Test for Indirect Tensile Strength at 28 Days.

Table 14.

Tukey Test for Indirect Tensile Strength at 28 Days.

| |

A: CONOCUT FIBER |

|

|

|

B: TARA ASH |

|

| |

A4 |

A3 |

A2 |

A1 |

|

|

B4 |

B3 |

B2 |

B1 |

| A1 |

0.63 |

0.37 |

0.19 |

0.00 |

|

B1 |

0.74 |

0.47 |

0.05 |

0.00 |

| A2 |

0.44 |

0.18 |

0.00 |

0.19 |

|

B2 |

0.69 |

0.42 |

0.00 |

0.05 |

| A3 |

0.26 |

0.00 |

0.18 |

0.37 |

|

B3 |

0.27 |

0.00 |

0.42 |

0.47 |

| A4 |

0.00 |

0.26 |

0.44 |

0.63 |

|

B4 |

0.00 |

0.27 |

0.69 |

0.74 |

The factorial analysis of variance for 28-day indirect tensile strength (

Table 13) demonstrates that the statistical model has a high explanatory capacity, with a coefficient of determination R² = 95.7%, indicating that more than 95% of the observed variability is explained by the evaluated factors. Both coconut fiber (Fo = 168.917) and tara ash (Fo = 292.855), as well as their interaction (Fo = 41.965), present Fo values significantly higher than the critical value (F critical = 2.72), accompanied by p-values close to zero. Consequently, the null hypothesis is rejected and the alternative hypothesis is accepted, concluding that both individual factors and their interaction have a significant effect on the tensile strength of concrete. However, the analysis of means shows that this effect is not always positive. When the proportions of ash and fiber are increased simultaneously, tensile strength tends to decrease, with the lowest values observed in combinations containing the highest levels of both additives.

The Tukey test confirms the existence of statistically significant differences between treatments, as several comparisons exceed the critical value of 0.3827 (

Table 14). The best-performing combinations were found in the pairs A2–A1 and A2–A4 for coconut fiber, and B1–B4 and B2–B4 for tara ash, indicating that intermediate fiber levels (0.5%) and low ash contents (0% to 6%) are more favorable for maintaining or improving tensile strength. In contrast, the least efficient combination was 1.5% fiber with 16% ash (A4–B4), which yielded an average strength as low as 22.1 kg/cm². These results confirm that high proportions of both additives significantly reduce the mechanical performance of concrete in terms of indirect tensile strength.

4. Discussion

The experimental results demonstrate that the addition of tara ash and coconut fiber produces differentiated effects on the mechanical behavior of concrete, depending on the proportions used and the type of mechanical stress evaluated (compression, flexural, or indirect tensile strength). For compressive strength, the use of 6% tara ash with 0% fiber achieved the best result (220.3 kg/cm²), slightly surpassing the control concrete (217.2 kg/cm²). This behavior aligns with previous studies reporting that plant-based ash can act as an effective pozzolanic additive [

11,

13,

15]. However, higher dosages combined with fiber (e.g., 12% TA and 1.5% CF) tend to reduce strength due to increased porosity and weakening of the cementitious matrix.

In terms of flexural strength, the highest values were observed in combinations with 0.5% and 1.0% coconut fiber without ash, reaching up to 43.5 kg/cm². These results reflect the fiber’s potential to absorb energy and control cracking, as documented in studies on concrete reinforced with natural fibers [

10,

12,

17,

29]. Nevertheless, when ash and fiber proportions are simultaneously increased, flexural strength significantly declines, reaching values as low as 22.1 kg/cm² with 1.5% fiber and 16% ash, due to lower cohesion and increased water demand [

18,

19].

Regarding indirect tensile strength, a similar trend was observed. The control mix reached 23.2 kg/cm², which was matched by combinations such as 0% TA – 0.5% CF or 6% TA – 1.0% CF. However, high levels of both additives (e.g., 16% TA – 1.5% CF) reduced tensile strength to 22.0 kg/cm². These findings are consistent with the reviewed literature, which warns of structural integrity loss in mixes with high fiber and ash content [

16,

18].

Overall, it can be concluded that the combined use of tara ash and coconut fiber can enhance or maintain the mechanical properties of concrete, provided they are used in moderate dosages. Their application contributes to the development of eco-efficient concrete with lower environmental impact, although careful balance of proportions and mixing conditions is required to avoid negative effects.

5. Conclusions

This research concludes that the combined use of tara ash and coconut fiber can significantly influence the mechanical properties of concrete, depending on the proportions used.

The addition of 6% tara ash as a partial replacement for cement improved compressive strength, reaching 220.3 kg/cm², which represents a 1.4% increase compared to the control mix. The highest flexural strengths (43.5 kg/cm²) were recorded with 0.5% and 1.0% coconut fiber without ash, whereas combinations containing ash significantly reduced performance. For indirect tensile strength, combinations with low levels of both additives matched the performance of the control mix, while higher dosages were less effective.

The proper combination of these natural additives allows for the production of concrete with a lower environmental impact without compromising its mechanical properties, provided that the water/cement ratio and workability are properly controlled.

It is recommended that future research assess long-term behavior, durability against aggressive agents, and structural applicability in elements subjected to real loading conditions.

References

- Mohamed Pioneering Sustainable Construction: The Breakthrough Innovations In Self-Healing Bacterial Concrete For Enhanced Durability And Eco-Friendly Infrastructure. Nanotechnol. Percept. 2024, 20. [CrossRef]

- Lopes, J.P.; Ferrari, V.J.; Camões, A.; Souza, A.; Fangueiro, R. Influência de nanotubos de carbono sobre o desempenho de concreto e de concreto reforçado com fibras (CRF). Matér. Rio Jan. 2022, 27, e13197. [Google Scholar] [CrossRef]

- Hong, S.-H.; Choi, J.-S.; Yuan, T.-F.; Yoon, Y.-S. A Review on Concrete Creep Characteristics and Its Evaluation on High-Strength Lightweight Concrete. J. Mater. Res. Technol. 2023, 22, 230–251. [Google Scholar] [CrossRef]

- Marin, V.; Carranza, M. Influence of spray curing on the compressive strength of concrete f’c=210 kg/cm2. In Proceedings of the Proceedings of the 22nd LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2024): “Sustainable Engineering for a Diverse, Equitable, and Inclusive Future at the Service of Education, Research, and Industry for a Society 5.0.”; Latin American and Caribbean Consortium of Engineering Institutions, 2024.

- Muñoz Perez, S.P.; Vallejos Peltroche, D.G.; Pérez Villanueva, J.A. Revisión sistemática de las propiedades físico-mecánicas del hormigón con incorporación de Ceniza de Madera. Ing. Compet. 2023, 25. [Google Scholar] [CrossRef]

- Neyra Torres, J.L.; Beltran Guzman, O.; Ramirez Montenegro, L. The Influence of Recycling of Concrete Waste in Construction for the Preparation of Aggregates. In Proceedings of the Proceedings of the 22nd LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2024): “Sustainable Engineering for a Diverse, Equitable, and Inclusive Future at the Service of Education, Research, and Industry for a Society 5.0.”; Latin American and Caribbean Consortium of Engineering Institutions, 2024.

- Roman Neira, A.D.; Mendoza Rojas, G. Bloques de concreto con adición de ceniza de caña de azúcar y concreto reciclado en Lambayeque, Perú. Rev. Científica Pakamuros 2023, 11, 102–120. [Google Scholar] [CrossRef]

- Escobar Jorge, E.; Meza Gala, Y.K.; Eyzaguirre Acosta, C.A. Experimental investigation of an ecological concrete developed with calcareous silica brick and basalt fibers for the reduction of CDW. In Proceedings of the Proceedings of the 22nd LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2024): “Sustainable Engineering for a Diverse, Equitable, and Inclusive Future at the Service of Education, Research, and Industry for a Society 5.0.”; Latin American and Caribbean Consortium of Engineering Institutions, 2024. [CrossRef]

- Gamboa Idrogo, O.G.; Leonardo Céspedes, J.A.; Muñoz Pérez, S.P.; Leiva Piedra, J.L.; Garcia, J.; Alvarez, J. Effect of Corn Stover Ash Reinforced with Cabuya Fiber on the Mechanical Properties of Concrete. J. Sustain. Archit. Civ. Eng. 2024, 35, 103–116. [Google Scholar] [CrossRef]

- Ibrahim, N. Concrete with Coconut Fibre Treated with Sodium Hypochlorite – Compressive and Flexural Strength. J. Mech. Eng. 2023, 20, 125–138. [Google Scholar] [CrossRef]

- Rajamanickam, G.; Ramasamy, S.; Soundararajan, E.K.; Karuppanan, K.; Arumugam, C. Influence of Presaturated Coconut Fibre Ash Pellets in Concrete. Matér. Rio Jan. 2023, 28, e20230190. [Google Scholar] [CrossRef]

- Kc, K. Potency of Concrete by Utilizing Coconut Fiber to Improve Strength of Concrete. [CrossRef]

- Oyebisi, S.; Ede, A.; Owamah, H.; Igba, T.; Mark, O.; Odetoyan, A. Optimising the Workability and Strength of Concrete Modified with Anacardium Occidentale Nutshell Ash. Fibers 2021, 9, 41. [Google Scholar] [CrossRef]

- Wardhono, A.; Law, D.W.; Sofianto, M.F.; Wulandari, M. Strength Performance of Fly Ash and Rice Husk Ash Geopolymer as Sustainable Infrastructure Green Materials in Supporting SDG 9 and SDG 13. E3S Web Conf. 2024, 568, 02003. [Google Scholar] [CrossRef]

- Incidence of Tara Ash on the Physical-Mechanical Properties of Concrete F’c = 350 Kg/Cm2. Nanotechnol. Percept. 2024, 1–25. [CrossRef]

- Romaldo Chávez, R.; Sandoval Tamariz, A.E.; Reynoso Oscanoa, J.; Perez Pereda, F.Y. Adición de Ceniza de Eucalipto y Fibra de Coco para Optimizar las Propiedades del Concreto. Cienc. Lat. Rev. Científica Multidiscip. 2024, 8, 342–358. [Google Scholar] [CrossRef]

- Mas, S. Carrera Sustainable Concrete with Coconut Fibers to Improve Its Mechanical Characteristics in Buildings. Mater. Sci. Forum 2022, 1060. [Google Scholar] [CrossRef]

- Muchotrigo Salas, K.D.; Reynoso Oscanoa, J. Adición de fibra de ichu y cenizas de capacho de maíz para optimizar las propiedades mecánicas del concreto. Cienc. Lat. Rev. Científica Multidiscip. 2024, 7, 6234–6250. [Google Scholar] [CrossRef]

- Rojas, I.M.C.; Oscanoa, J.R.; Tamariz, A.E.S.; Pereda, F.Y.P. Cinzas de folhas de coca como substituição parcial do cimento para otimizar as propriedades do concreto f’c=420 kg/cm2. Braz. J. Technol. 2024, 7, 15–29. [Google Scholar] [CrossRef]

- Dixon, D.E.; Prestrera, J.R.; Burg, G.R.U.; Abdun-Nurt, E.A.; Barringer-t, W.L.; Barton, S.G.; Bell, L.W.; Bennett, J.E.; Best, J.F.; Carrasquillo, R.L.; et al. 211.1-91 Standard Practice for Selecting Proportions for Normal Heavyweight, and Mass Concrete.

- C09 Committee ASTM International. Test Method for Compressive Strength of Cylindrical Concrete Specimens. [CrossRef]

- C09 Committee ASTM International. Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). [CrossRef]

- C09 Committee ASTM International. Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. [CrossRef]

- ASTM International Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM Int. 2020.

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine Grinding of Sugar Cane Bagasse Ash for Application as Pozzolanic Admixture in Concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- C09 Committee ASTM International. Test Method for Sieve Analysis of Fine and Coarse Aggregates. [CrossRef]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Resistance to Chloride Penetration of Blended Portland Cement Mortar Containing Palm Oil Fuel Ash, Rice Husk Ash and Fly Ash. Constr. Build. Mater. 2008, 22, 932–938. [Google Scholar] [CrossRef]

- Oraimi, A.; Seibi, A.C. Concr. Compos. 1995, pp. 229–237.

- Jamshaid, H.; Mishra, R.K.; Raza, A.; Hussain, U.; Rahman, Md.L.; Nazari, S.; Chandan, V.; Muller, M.; Choteborsky, R. Natural Cellulosic Fiber Reinforced Concrete: Influence of Fiber Type and Loading Percentage on Mechanical and Water Absorption Performance. Materials 2022, 15, 874. [Google Scholar] [CrossRef] [PubMed]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.D.C.G.; Azevedo, A.R.G.D. A Review of the Use of Coconut Fiber in Cement Composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).