1. Introduction

Additive manufacturing, especially Fused Filament Fabrication (FFF) technology, has become a key method for producing prototypes, functional parts and personalized products in areas such as industrial design, automotive industry and biomedical applications [

1,

2]. Chokshi et al. and Suteja et al. in their research emphasize that this technology enables fast and flexible processing of thermoplastics including the widely used polylactide (PLA), which is popular mainly due to its biodegradability, low processing temperature and favorable affordability [

3,

4]. PLA is considered a material suitable not only for hobby use, but also for technical applications, as long as its mechanical properties are optimized by an appropriate combination of manufacturing parameters [

5,

6].

Moradi et al. and Fekiač et al. in their studies show that the mechanical properties of FFF-produced prints are strongly influenced by a number of technological factors, such as layer height, extrusion temperature, printing speed, type and density of the infill, fiber orientation, and the number of perimeters – i.e., the peripheral walls of the print [

7,

8]. While Kartikeyan et al. and Harpool et al. point out that while most research works focus primarily on the infill geometry and its density, the perimeter as a parameter is often neglected, despite the fact that it turns out to be one of the most fundamental factors affecting the stiffness, strength, and anisotropy of prints [

9,

10]. Studies by Beníček et al. show that an increase in the number of perimeters leads to a significant increase in tensile strength, as well as a decrease in differences between directional strengths, which is especially important for loads acting off the axis of the layering [

11]. The findings of Aveen et al. and Fekiač et al., show that the perimeter plays a key role in the distribution of stress at the interface between layers and at the same time helps to strengthen the areas where the maximum stress occurs under load [

12,

13]. For example, a study by Vanaei et al. showed that optimizing perimeters can improve tensile strength by more than 30% without significantly increasing material consumption, making the perimeter an effective tool for increasing mechanical reliability while maintaining low costs [

14]. Research by Kohutiar et al. showed that the perimeter affects not only the static properties but also the viscoelastic behavior of the material, especially after the application of DCSBD plasma treatment, which significantly changes the glass transition temperature depending on the type of filler and perimeter [

15]. Other studies by Karski et al. and Kadhum et al. demonstrated a synergistic effect between the infill and the perimeter, which underlines the importance of a comprehensive approach to optimizing FFF parameters [

16,

17].

From the point of view of practical application, this knowledge is very valuable. When manufacturing functional parts that must meet specific mechanical requirements, it is appropriate to pay increased attention to the perimeters - especially in cases where it is not desirable to significantly increase the infill density, which extends the printing time and increases material consumption. The advantage of perimeters is also their direct impact on the dimensional accuracy of the parts, which is another important aspect in the production of final functional parts.

It follows from the above that the perimeter as a design and manufacturing parameter deserves systematic analysis, especially in the context of the mechanical behavior of PLA prints. The aim of this study is therefore to experimentally investigate the effect of the number of perimeters on the tensile and dynamic-mechanical properties of PLA parts manufactured using the FFF technology, while other parameters remain constant. Samples of BambuLab PLA filament (1.75 mm diameter) were used for the investigation, with a range of 1 to 10 perimeters tested. Each variant was represented by five samples. The evaluation included standard tensile tests, dynamic mechanical analysis (DMA), microscopic observation of fracture surfaces with a confocal microscope, and numerical prediction of mechanical parameters.

2. Materials and Methods

The test samples were produced using the Fused Filament Fabrication (FFF) additive technology using a Bambu Lab P1S 3D printer. PLA filament with a diameter of 1.75 mm from the manufacturer Bambu Lab was used as the input material.

The following process parameters were applied during printing: the nozzle temperature was set to 240 °C, the bed temperature to 55 °C and the nozzle diameter was 0.4 mm. The layer height was 0.2 mm and the printing was carried out at the default speed recommended for the given device. The printing was carried out with a horizontal layer orientation. The infill had a density of 20% and was carried out using a cubic infill structure.

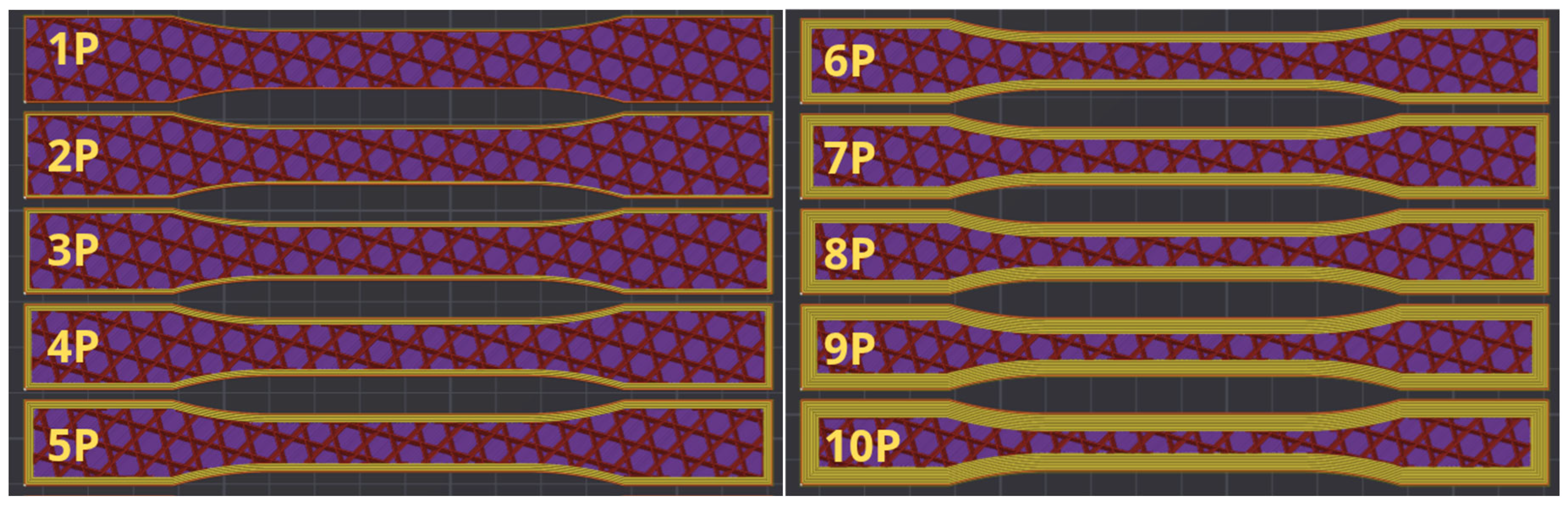

In

Figure 1, it can be seen that the investigated parameter was the number of perimeters (wrapping layers), which varied from 1 to 10. 5 samples were produced for each configuration. The geometry of the test specimens was designed in accordance with the ASTM D638 standard, intended for determining the tensile properties of plastics [

18]. The samples were subjected to a tensile test that was performed on an In-stron 5500R instrument and the evaluation program was BLUEHILL 3, in which the following mechanical characteristics were measured: tensile strength, yield strength, elastic modulus and elongation at break. The tests were performed at a speed of 5 mm/min. Analytical software suitable for the accurate determination of mechanical parameters was used to evaluate the data. Based on the experimental data, prediction models for tensile strength and elastic modulus were created, which allow estimating the behavior of the material at different numbers of perimeters using nonlinear regression.

Dynamic-mechanical analysis was performed on a Ta instrument DMA Q800 in the temperature range from 40 °C to 100 °C with a heating rate of 3 °C/min, a frequency of 10 Hz and an amplitude of 15 µm. The parameters monitored included elastic modulus (E′), loss modulus (E″) and glass transition temperature (Tg) determined based on the maximum of the loss angle tan δ. For each perimeter configuration, an average curve was constructed from five repetitions. The temperature Tg was determined as the maximum of the loss modulus and tan δ, while E′ was determined using the OnSet method.

3. Results

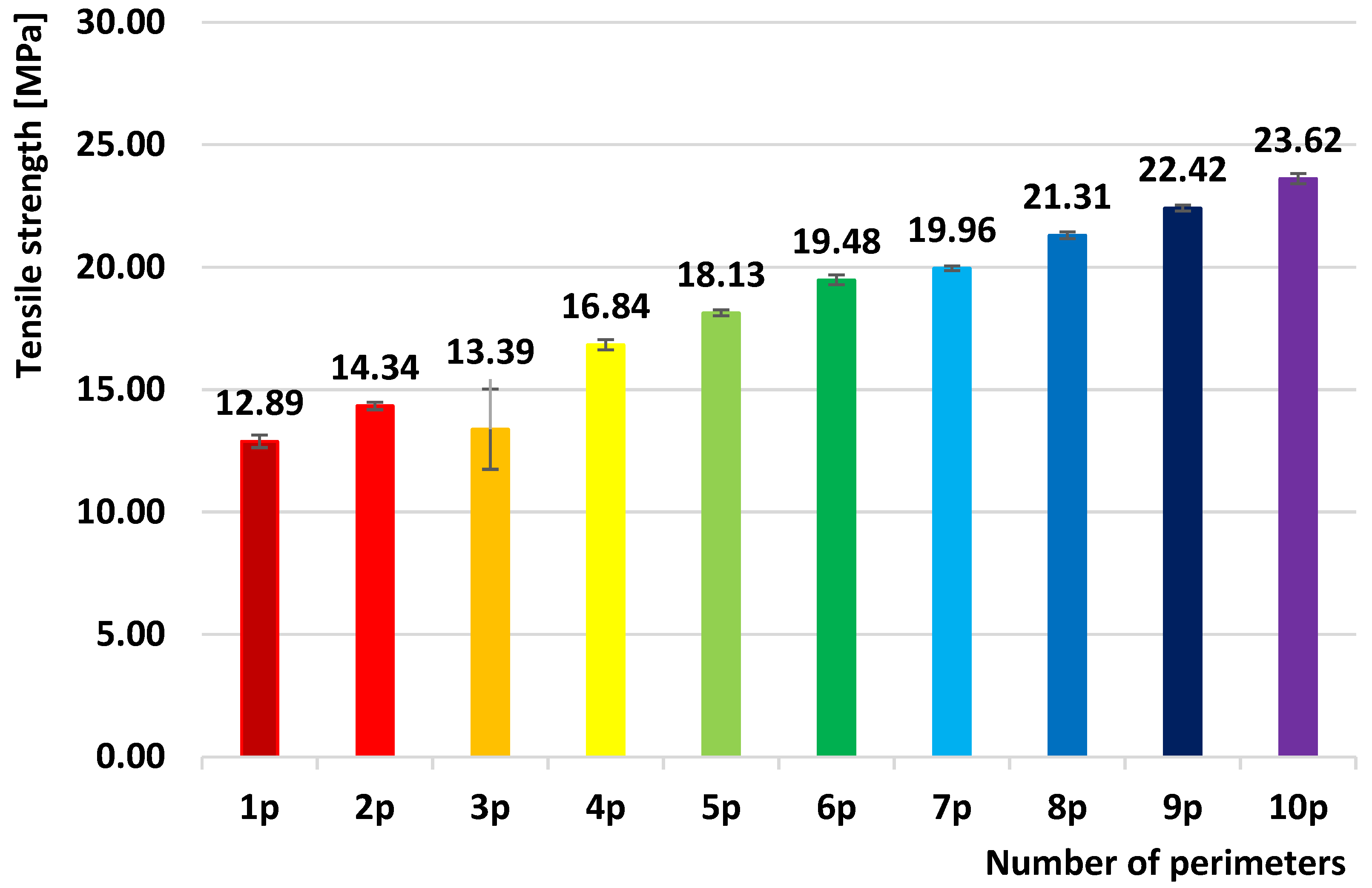

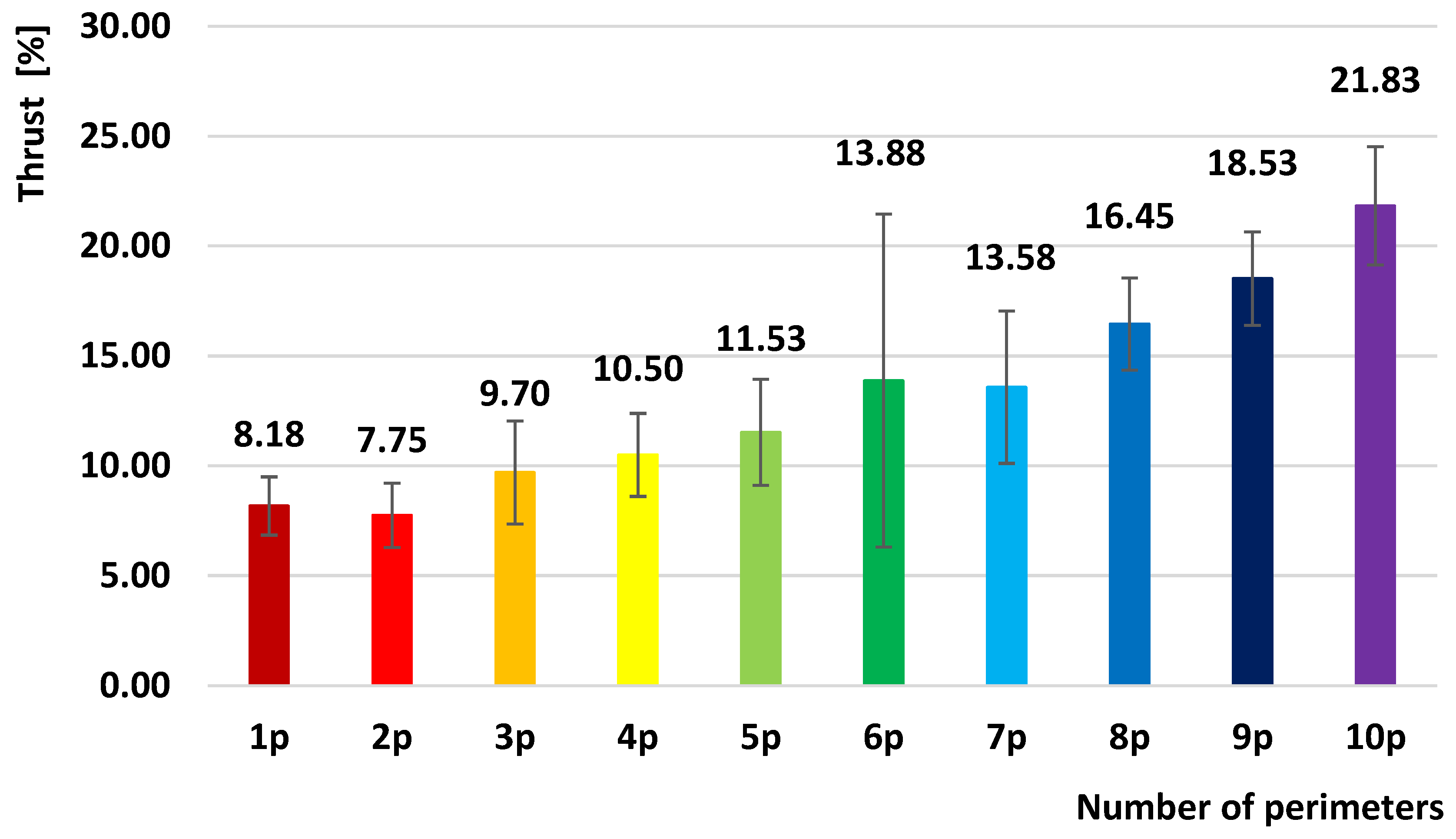

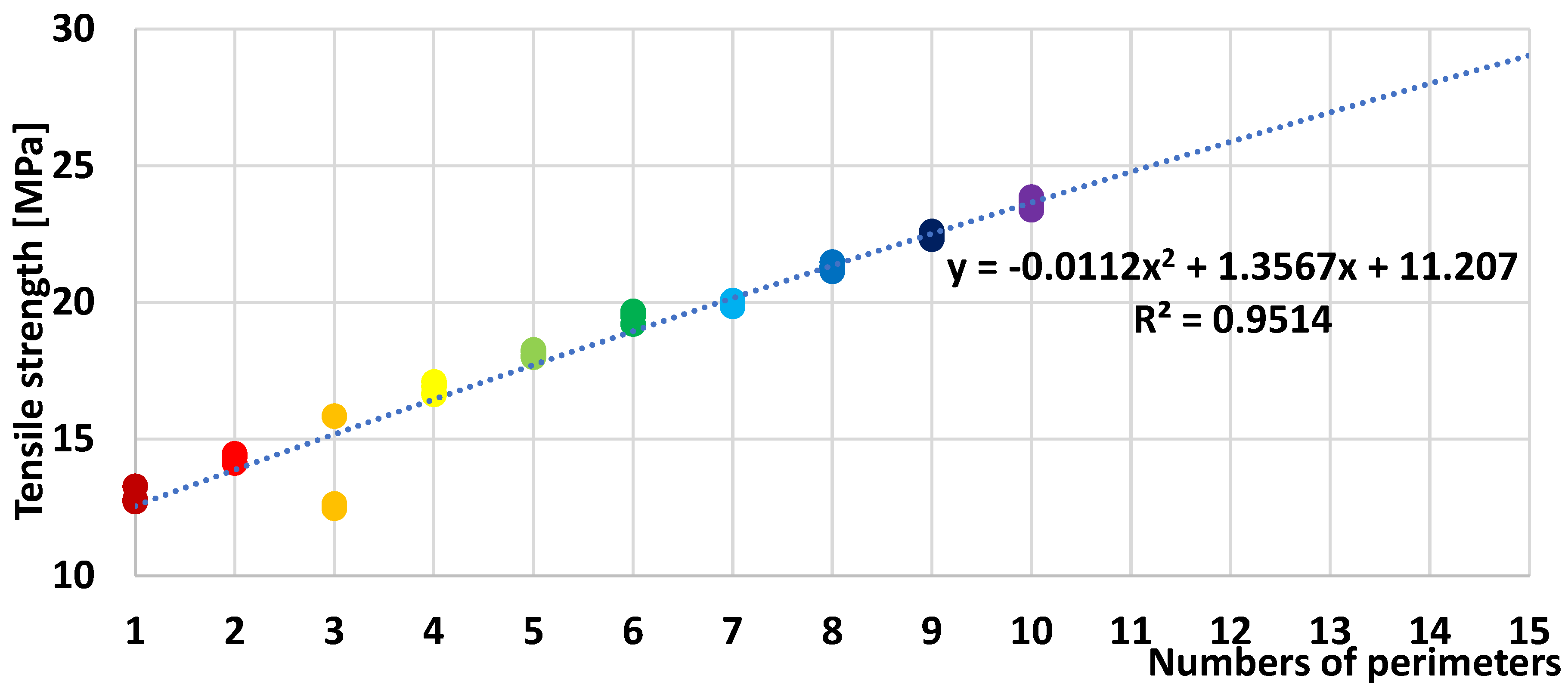

Nowadays, the number of perimeters is increasingly considered as one of the key factors in optimizing the mechanical properties of FFF-produced parts. The number of perimeters directly affects the external structural integrity and adhesion between layers, which has a significant impact on the strength, stiffness and ductility of the print. The tensile test results (

Figure 2) clearly show a progressive improvement in tensile strength with increasing number of perimeters. The lowest average tensile strength was measured with one perimeter layer (12.89 MPa), while the highest value was achieved with ten perimeters (23.62 MPa). The most significant increase was observed between three and six perimeters, indicating that the reinforcing effect of the perimeters begins to have a significant effect above a certain threshold.

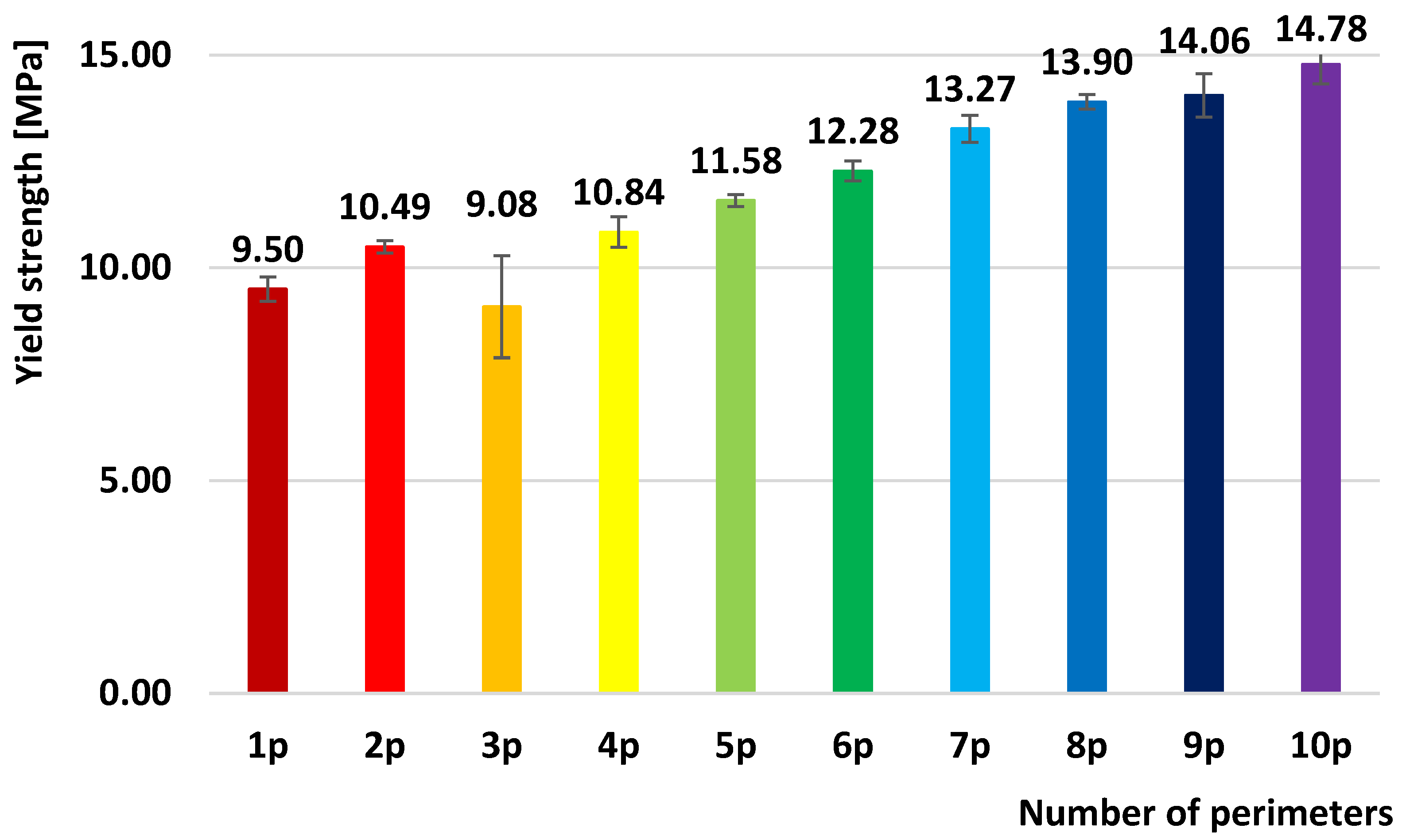

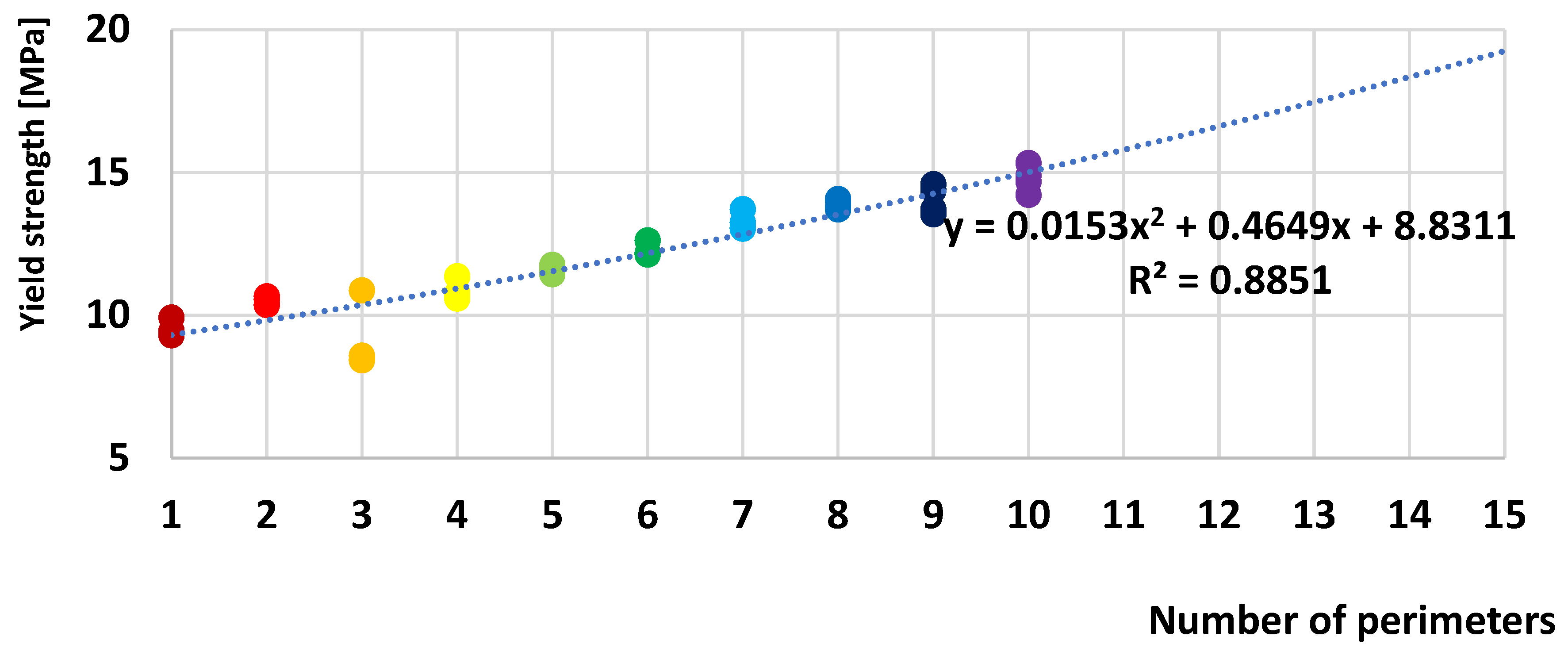

A similar trend was observed for the yield strength (

Figure 3). The specimens with one perimeter showed the lowest yield strength (9.34 MPa), while the maximum value was achieved with ten perimeters (14.72 MPa). The yield strength value increased consistently with each added perimeter, indicating better resistance to the onset of plastic deformation with a higher number of perimeters. The data indicate that increasing the number of perimeter contours strengthens the edge zones of the extrudate and reduces their susceptibility to local failure.

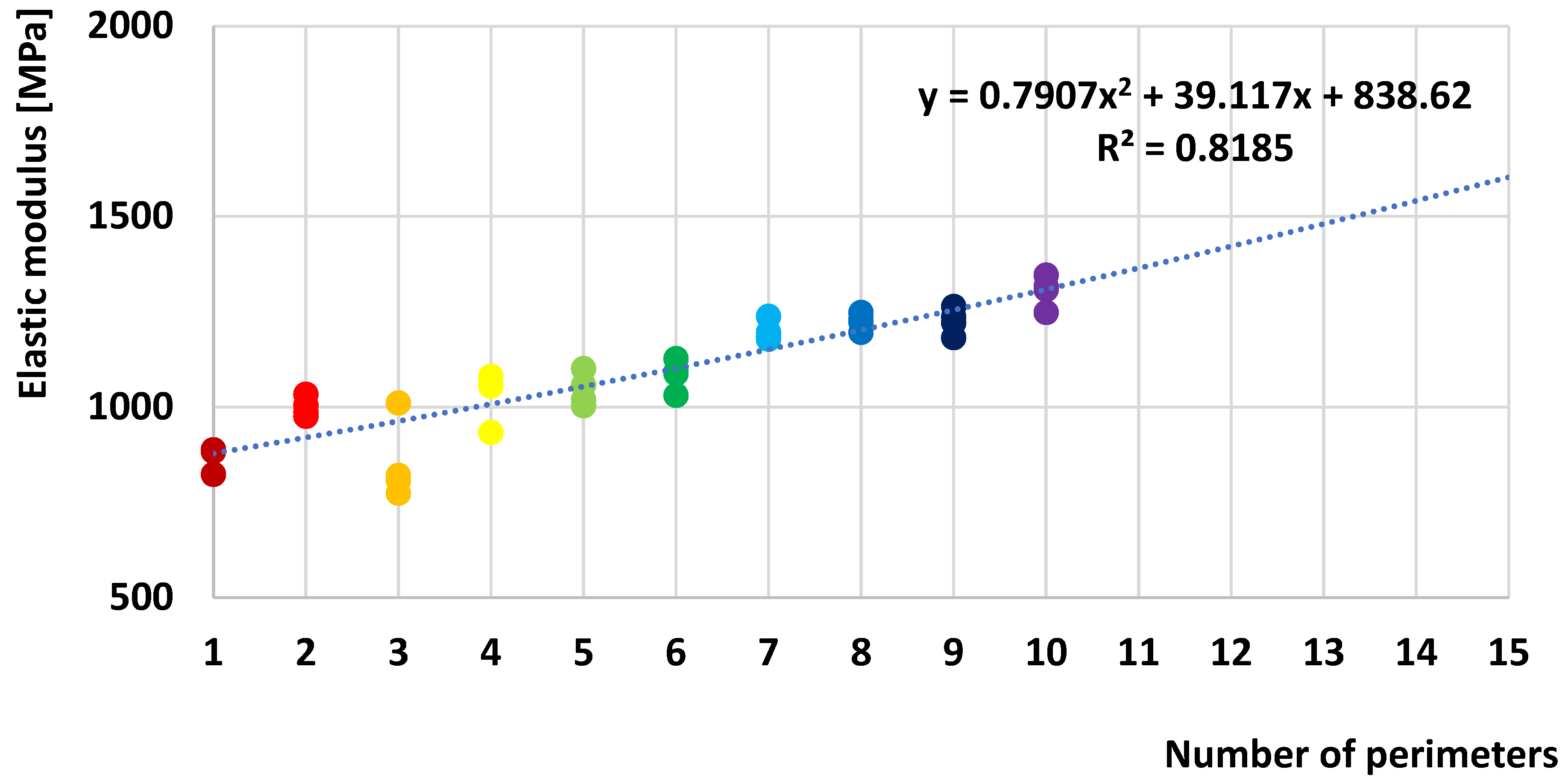

The elastic modulus (

Figure 4) also increased with increasing number of perimeters – from 861.67 MPa for one perimeter to 1345.45 MPa for ten. This smooth increase in stiffness confirms that the perimeter layers contribute significantly to the overall stiffness of the print. The improvement in elastic modulus can be attributed to more effective interconnection between layers and better alignment of the perimeter paths under tensile loading.

The ductility behavior, expressed as elongation at break (

Figure 5), showed greater variability, but also followed an overall increasing trend. While the lowest ductility was recorded for a single perimeter (7.98%), samples with ten perimeters reached the highest average value (21.40%). Despite the observed dispersion, especially for higher perimeter numbers, these results suggest that additional perimeter layers allow for greater deformation to be absorbed before failure, which is likely related to delayed crack propagation in a thicker and more cohesive perimeter structure.

The results thus confirm that the mechanical properties of PLA prints produced by FFF technology are significantly influenced by the number of perimeters. Increasing the number of perimeters leads to an improvement in tensile strength, yield strength and stiffness, while also contributing to an increase in ductility. These findings highlight the importance of optimizing perimeters in the design of 3D printed parts that are exposed to mechanical loading and where the integrity of the external structure plays a crucial role.

3.1. Prediction of Mechanical Properties

Based on the experimental results, mathematical models were created describing the dependence of selected mechanical properties on the number of perimeters. Predictions were made for tensile strength, yield strength and elastic modulus using second-degree polynomial functions that best described the trend found in the measured data.

The prediction model for tensile strength (

Figure 6) shows a strong correlation between the number of perimeters and the resulting material strength. The relationship was described by the equation

with a coefficient of determination R² = 0.9514, which indicates a high accuracy of the model. This equation allows for reliable prediction of strength values depending on the perimeter setting of the print, especially in the range up to 10 perimeters, where experimental data were obtained.

A similar approach was applied to the yield strength modeling (

Figure 7), where the dependence was described by the equation

with a value of R² = 0.8851. Although this model shows slightly lower accuracy than the previous one, it still provides a very good prediction of the yield strength evolution for different perimeter settings. The significant quadratic term component indicates that at higher perimeter numbers the increase in the value slows down, which may be related to the saturation of the reinforcing effect of the perimeter layers.

For the elastic modulus, the prediction equation y = 07907x² + 39.117x + 838.62

with a coefficient of determination R² = 0.8185 (

Figure 8). This model confirms the trend of a gradual increase in the stiffness of the material with an increasing number of perimeters. Although the R² value is lower compared to other models, the prediction model captures the main dynamics of the stiffness growth in the tested range.

The prediction models developed in this study thus provide a reliable tool for optimizing perimeter settings to achieve the desired mechanical properties of the prints. Their use is particularly beneficial in cases where it is not desirable to perform extensive testing for each combination of parameters, or where it is necessary to predict the behavior of the print outside the experimental range.

3.2. Dynamic-Mechanical Analysis

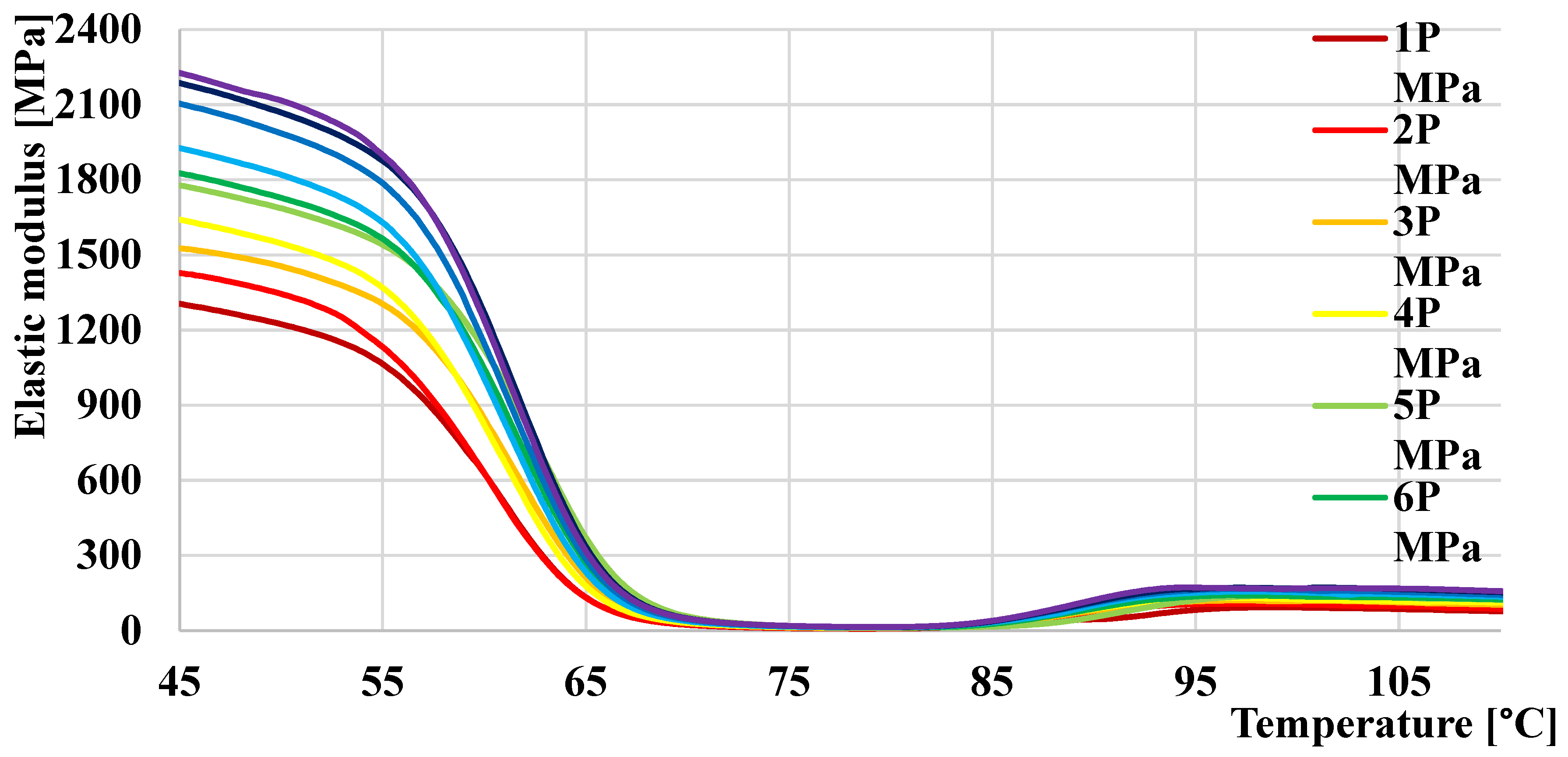

Dynamic-mechanical analysis (DMA) provided a detailed view of the viscoelastic behavior of the material depending on the number of perimeters. Measurements were performed in the temperature range from 45 °C to 105 °C, while the key parameters were monitored - elastic modulus, loss modulus and loss angle tan δ, as well as the glass transition temperature Tg derived from the maximum of the tan δ curve.

The elastic modulus curves (

Figure 9) showed that with an increasing number of perimeters, the initial stiffness values increase. With one perimeter layer, the material reached a value of approximately 1300 MPa, while with ten perimeters the value increased to over 2100 MPa. This trend confirms that the perimeter layers contribute significantly to the overall stiffness of the print, thereby increasing its resistance to elastic deformation at temperatures below Tg.

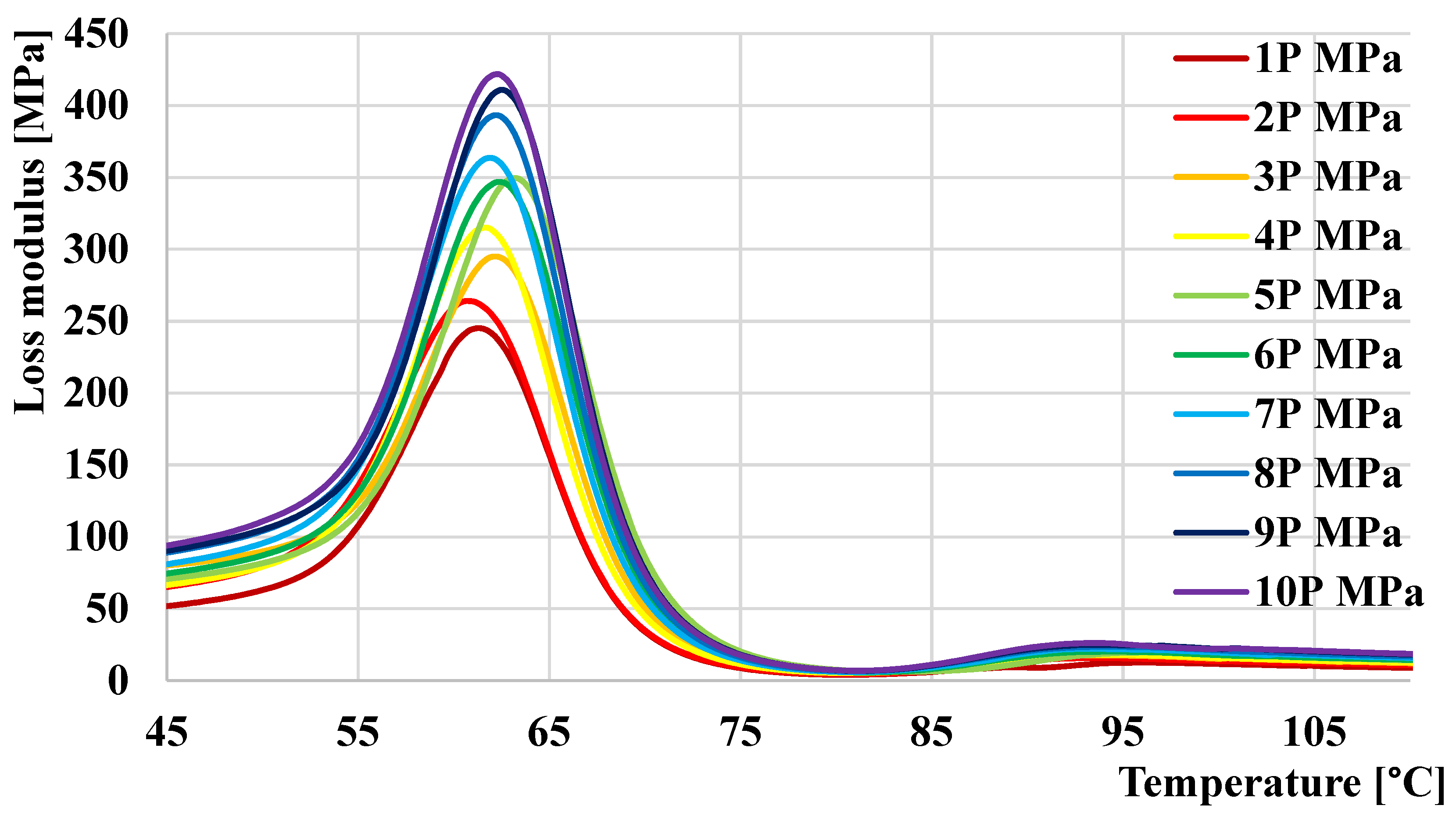

The loss modulus (

Figure 10) reached its maximum at a temperature of approximately 65–68 °C for all perimeter configurations. The significant differences in the maximum loss modulus values indicate that a higher number of perimeters improves the material’s ability to dissipate energy in the form of internal friction. The highest loss modulus values were observed for ten perimeters, indicating a better internal structure and a higher proportion of mechanically active zones.

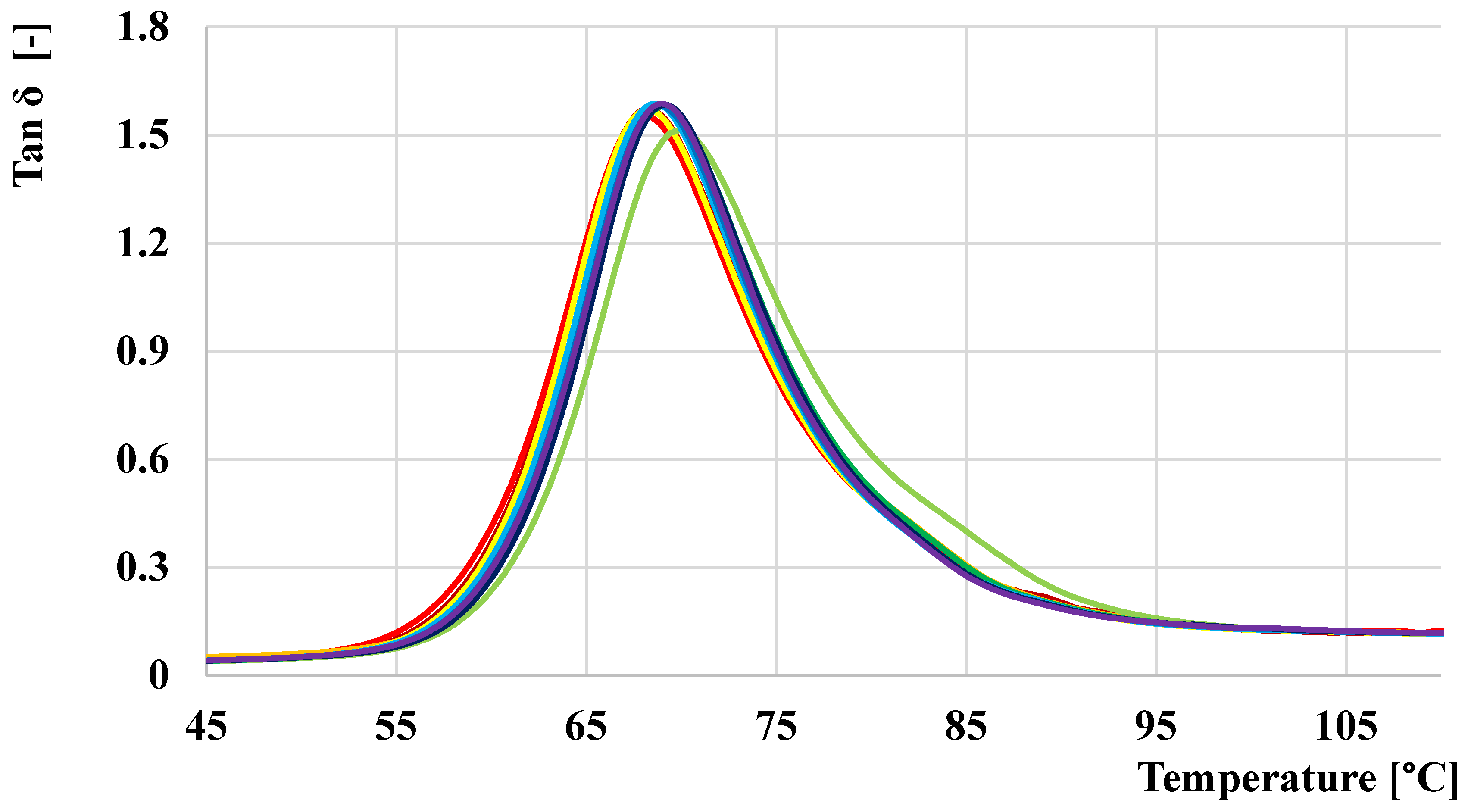

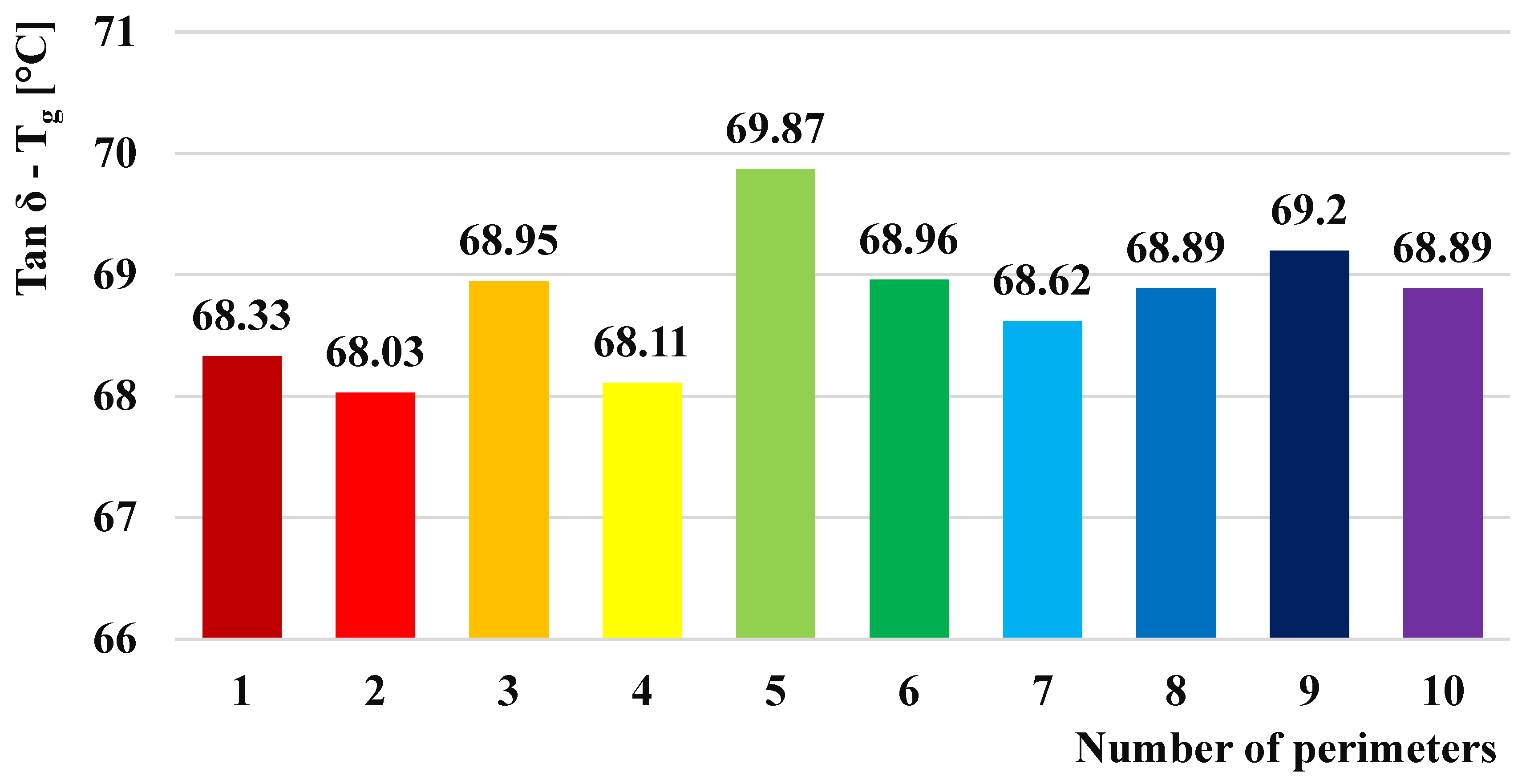

When analyzing tan δ (

Figure 11), which represents the degree of mechanical energy attenuation, all samples were characterized by a clear maximum in the range of 68–70 °C. The glass transition temperature graph (

Figure 12) shows that the Tg values ranged in a narrow range from 68.03 °C (2 perimeter) to a maximum of 69.87 °C (5 perimeter). Although the differences between individual samples appeared to be relatively small, it is clear that changes in the perimeter configuration can also affect the thermal behavior of the material.

The obtained results confirm that the perimeter layers affect not only the mechanical but also the viscoelastic and thermal properties of the prints. A higher number of perimeters increases the initial stiffness of the material, improves the loss behavior and slightly shifts the Tg towards higher values. This information is especially important in the design of components exposed to thermal stress, where it is necessary to ensure the preservation of mechanical integrity above the glass transition temperature.

3.3. Microscopic analysis

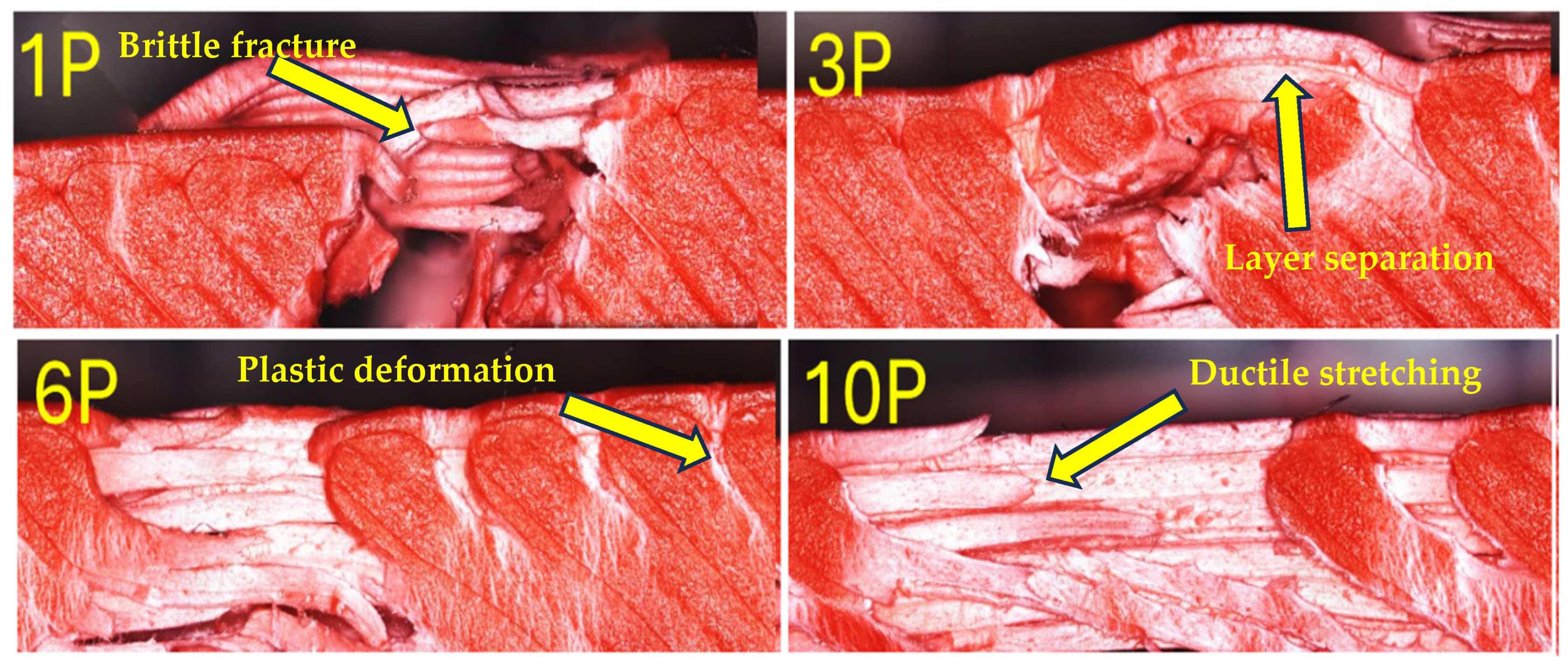

To better understand the mechanical behavior of the prints, microscopic analysis of the fracture surfaces was performed using a confocal microscope. Selected samples with different numbers of perimeters (1P, 3P, 6P and 10P) were observed after performing the tensile test, with the aim of identifying differences in the layer structure, the presence of failuresand types of failure.

Figure 13 shows significant differences between the perimeter configurations. The one-perimeter (1P) sample shows significant delamination, with clearly separated layers and a low degree of cohesion between the perimeter and infill sections. Failure occurred primarily in the interlayer bond area, which is consistent with the low strength and stiffness values measured during mechanical testing. The three-perimeter (3P) sample still exhibits significant porosity and discontinuous fractures, indicating insufficient mechanical connection of the perimeter tracks to the infill. Despite some improvement in the structure, the fracture surface remains fragmented and prone to crack initiation. Significant improvement is already visible at six perimeters (6P), where the layers appear more homogeneous and less prone to delamination. The perimeter layers are more clearly interconnected with the internal filling and the failure occurs in a continuous mass rather than along the interfaces, which contributes to higher strength and stiffness. The most compact and homogeneous structure is shown by the sample with ten perimeters (10P). The layers are tightly interconnected, the occurrence of failures is minimal and the failure has the character of a ductile fracture. Such a fracture pattern confirms a high degree of internal crosslinking and effective connection of the perimeters with the filling, which corresponds to the highest values of strength, stiffness and ductility. Thus, the microscopic analysis shows that increasing the number of perimeters directly contributes to improving the structural integrity of the print. A higher number of perimeters reduces porosity, reduces the risk of delamination and allows for more efficient transmission of mechanical loads. These visual observations thus complement and support the results of mechanical and dynamic-mechanical tests.

4. Discussion

The tensile strength measurements showed that the strength of PLA prints increases with increasing number of perimeters. The highest strength of 38.44 MPa was measured for a sample with 10 perimeters, which represents an increase of approximately 31% compared to the sample with 2 perimeters. This increase confirms the importance of perimeter layers as a significant factor contributing to the increase in the load capacity of prints. Similar findings are also reported by Khaliq et al. [

19], who identified the number of perimeters as a decisive parameter affecting the tensile strength. Similarly, Alhuzaim et al. [

20] point to the synergistic effect of perimeter layers and infill patterns, which increase the overall structural integrity of the components. These results are also complemented by the study by Eryildiz et al. [

21], according to which filling patterns such as cubic or gyroid significantly improve the strength, with the highest being achieved with cubic filling.

The yield strength increased from 16.4 MPa (at 2 perimeters) to 22.74 MPa (at 10 perimeters), which represents an increase of more than 38%. This trend indicates that the perimeter layers significantly affect the initial deformation resistance of the material. The results are in line with the observations of Habeeb et al. [

22], who demonstrated that structural modifications such as the addition of fillers (e.g., CaCO₃) increase the initial resistance to plastic deformation. This is also confirmed by Yazar et al. [

23], according to which the honeycomb filling achieves the highest tensile strength values, which indicates the significant role of the inner layers in stress redistribution.

The modulus of elasticity, as an indicator of stiffness, increased with the number of perimeters. The maximum value of 2354 MPa was achieved for the sample with 10 perimeters, which represents an increase of more than 38% compared to the sample with 2 perimeters. This result confirms that the perimeter layers significantly affect the material’s resistance to elastic deformation. Cristea et al. [

24] demonstrated that the scale of the filler has an effect on the stiffness, which is consistent with our findings - the perimeter performs a similar function to the filler geometry. Similarly, Birosz et al. [

25] state that the combination of filler and density leads to the optimization of the mechanical response of the parts.

In terms of ductility, slight deviations were observed, with the highest value (9.63%) measured at 10 perimeters. This increase indicates that the perimeter layers increase the material’s ability to absorb deformation without immediate failure. The results complement the findings of Birosz et al. [

25], who demonstrated that the choice of the filler pattern and its combination with other parameters (e.g., density) significantly affect the elasticity and toughness of the parts.

Results of dynamic mechanical analysis (DMA) showed that a higher number of perimeters leads to an increase in both the initial stiffness (storage modulus) and the loss modulus, confirming that the perimeter layers affect the material’s ability to accumulate and dissipate mechanical energy. A slight shift in the glass transition temperature was also noted, indicating a change in the mobility of the molecular chains. These observations are in line with the results of Vargas et al. [

26], who emphasize the sensitivity of the viscoelastic properties of PLA to structural parameters, as well as with the work of Habeeb et al. [

22], where structural modifications significantly changed the mechanical-thermal behavior of the material.

Microscopic analysis of fracture surfaces using a confocal microscope showed that a higher number of perimeters leads to a significantly more compact structure, a reduction in macropores and improved adhesion between layers. While significant delaminations and discontinuities occurred at a low number of perimeters, a continuous structure with homogeneous layer connection was observed at 10 perimeters. These findings are in line with the research of Mencarelli et al. [

27], who confirmed that improving structural homogeneity significantly increases the material’s resistance to impact and cyclic loading. In conclusion, it can be stated that perimeter layers play a fundamental role in influencing the mechanical and functional properties of PLA prints produced by FFF technology. The results of this work extend the knowledge of the existing literature and emphasize the importance of optimizing perimeters when designing prints for applications with high demands on strength, stiffness and reliability.

5. Conclusions

This study demonstrated that the number of perimeter layers has a significant impact on the performance characteristics of 3D printed PLA parts produced by Fused Filament Fabrication (FFF). Based on the results of mechanical tests, dynamic-mechanical analysis, and microscopic observation, it can be concluded that perimeter as a printing parameter represents one of the most effective tools for improving the mechanical and functional properties of the parts without the need for material changes or complex infill geometries.

1. Effect of the number of perimeters on mechanical properties

The mechanical tests showed that when the number of perimeters increased from 1 to 10, the average tensile strength increased from 13.01 MPa to 22.06 MPa, which represents an increase of 69.5%. Similarly, the yield strength increased from 9.34 MPa to 14.72 MPa (+57.6%) and the elastic modulus increased from 861.67 MPa to 1345.45 MPa (+56.1%). Significant progress was also recorded in the case of ductility, which increased from 7.98% to 21.40%, which represents a more than 2.5-fold improvement in the material’s ability to absorb deformation before failure. These results confirm that the perimeter layers significantly strengthen the structure of the part and at the same time contribute to increased toughness without reducing elasticity.

2. Dynamic-mechanical analysis (DMA)

The recorded increase in the initial elastic modulus from approximately 1300 MPa at one perimeter to more than 2100 MPa at ten perimeters clearly confirms the increased stiffness of the prints. The loss modulus also showed a significant improvement at higher perimeter configurations, indicating the ability of the perimeter layers to dissipate mechanical energy more efficiently. The glass transition (Tg) value ranged within a narrow range of 68–70 °C, with a slight upward shift with increasing perimeters indicating a positive effect on the thermal stability of the prints.

3. Microscopic analysis of fracture surfaces

The results of the microscopic analysis visually confirmed the structural changes inside the prints. At low perimeters, delamination and the presence of structural defects at the layer interface were evident. In contrast, samples with a higher perimeter number showed a homogeneous and cohesive microstructure, with a ductile fracture type and minimal occurrence of defects. These observations support the hypothesis that the perimeter layers act as a reinforcing frame that strengthens the edge areas of the part and improves the transfer of mechanical stress within the entire structure.

4. Predictive modeling and application potential

Based on the created mathematical models, which achieved high values of the coefficient of determination (R² > 0.8), this knowledge can be used to reliably predict the mechanical behavior of parts at various perimeter settings. These models have high application potential, especially in industrial practice, where it is necessary to quickly and efficiently design components with the desired properties without the need for repeated testing.

From a practical point of view, it turns out that increasing the number of perimeters represents a simple, economical and production-friendly tool for optimizing 3D printing. When designing functional parts that are to be exposed to static or cyclic mechanical stress, it is recommended to use perimeter configurations of at least 6 to 10 layers, which demonstrably increase strength, stiffness and resistance to delamination. New possibilities are opened for the future for research into the combined effects of perimeters and other parameters, such as layer thickness, filling pattern or layer orientation. It is also appropriate to analyze the interaction of perimeters with different types of materials and modifications, such as fillers, fibers, or chemical surface treatments. These research directions can contribute to further improving the performance of parts and expanding the application possibilities of FFF technology in industrial environments.

Author Contributions

Conceptualization, J.J.F., M.K. (Michal Krbata) and M.K. (Marcel Kohutiar); methodology, L.K. and A.D.; software, M.E. and Z.S.; validation, P.M., M.E. and L.K.; formal analysis, M.K. (Michal Krbata) and M.K. (Marcel Kohutiar); investigation, A.Ddata.; resources, Z.S. and P.M.; data curation, A.D. and L.K.; writing—original draft preparation, M.K. (Michal Krbata), J.J.F. and M.K. (Marcel Kohutiar); writing—review and editing, L.K. and M.E.; visualization, M.K. (Marcel Kohutiar) and Z.S.; supervision, M.K. (Michal Krbata) and J.J.F., P.M.; project administration, M.E., A.D. and L.K.; funding acquisition, M.K. (Michal Krbata). All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Mazlan, M.A.; Anas, M.A.; Nor Izmin, N.A.; Abdullah, A.H. Effects of Infill Density, Wall Perimeter and Layer Height in Fabricating 3D Printing Products. Materials 2023, 16, 695. [CrossRef]

- Sedlak, J.; Joska, Z.; Jansky, J.; Zouhar, J.; Kolomy, S.; Slany, M.; Svasta, A.; Jirousek, J. Analysis of the Mechanical Properties of 3D-Printed Plastic Samples Subjected to Selected Degradation Effects. Materials 2023, 16, 3268. [CrossRef]

- Chokshi, H., Shah, D. B., Patel, K. M., & Joshi, S. J. (2021). Experimental investigations of process parameters on mechanical properties for PLA during processing in FDM. Advances in Materials and Processing Technologies, 8(sup2), 696–709. [CrossRef]

- Suteja, T.J.; Soesanti, A. Mechanical Properties of 3D Printed Polylactic Acid Product for Various Infill Design Parameters: A Review. Journal of Physics: Conference Series 2020, 1569(4), 042010. [CrossRef]

- Salgueiro, M.P.; Pereira, F.A.M.; Faria, C.L.; Pereira, E.B.; Almeida, J.A.P.P.; Campos, T.D.; Fakher, C.; Zille, A.; Nguyễn, Q.; Dourado, N. Numerical and Experimental Characterisation of Polylactic Acid (PLA) Processed by Additive Manufacturing (AM): Bending and Tensile Tests. J. Compos. Sci. 2024, 8, 55. [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Salah, B.; Zimon, D. Parametric Investigation and Optimization to Study the Effect of Process Parameters on the Dimensional Deviation of Fused Deposition Modeling of 3D Printed Parts. Polymers 2022, 14, 3667. [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Hakimi, A. Experimental Investigation on Mechanical Characterization of 3D Printed PLA Produced by Fused Deposition Modeling (FDM). Materials Research Express 2021, 8(3), 035304. [CrossRef]

- Fekiač, J. J., et al. (2025). Influence of Infill Geometry and Density on the Mechanical Properties of 3D-Printed Polylactic Acid Structure. Journal of Manufacturing and Materials Processing, 9(4), 134. [CrossRef]

- Kartikeyan, B.; Ponshanmugakumar, A.; Saravanan, G.; BharathGanesh, S.; Hemamalini, V. Experimental and Theoretical Analysis of FDM AM PLA Mechanical Properties. Materials Today: Proceedings 2023. [CrossRef]

- Harpool, T.D.; Alarifi, I.M.; Alshammari, B.A.; Aabid, A.; Baig, M.; Malik, R.A.; Mohamed Sayed, A.; Asmatulu, R.; EL-Bagory, T.M.A.A. Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer. Materials 2021, 14, 2195. [CrossRef]

- Beníček, L.; Vašina, M.; Hrbáček, P. Influence of 3D Printing Conditions on Physical–Mechanical Properties of Polymer Materials. Polymers 2025, 17, 43. [CrossRef]

- Aveen, K.P.; Londe, N.V.; Vikas, K.; Lettigar, S.Y.; Kumar, K.K.; Dhananjay, J. Experimental Investigation on Comparing Mechanical Properties in 3D Printed Polymers by Varying Process Parameter. Journal of Mines, Metals and Fuels 2022, 70(8A), 128–134. [CrossRef]

- Yeoh, C.K.; Cheah, C.S.; Pushpanathan, R.; Song, C.C.; Tan, M.A.; Teh, P.L. Effect of Infill Pattern on Mechanical Properties of 3D Printed PLA and cPLA. IOP Conference Series: Materials Science and Engineering 2020, 957, 012064. [CrossRef]

- Vanaei, S.; Rastak, M.; El Magri, A.; Vanaei, H.R.; Raissi, K.; Tcharkhtchi, A. Orientation-Dependent Mechanical Behavior of 3D Printed Polylactic Acid Parts: An Experimental–Numerical Study. Machines 2023, 11, 1086. [CrossRef]

- Kohutiar, M., et al. (2025). Dynamic Mechanical Analysis of PLA Produced by FFF Additive Manufacturing Technology after DCSBD Plasma Treatment. Manufacturing Technology Journal, 25(2). [CrossRef]

- Karski, P.; Nokielski, N.; Krzykawska-Szczepańska, J.; Dziembała, R.; Dratwiński, M.; Banaszkiewicz, J.; Rudnicka, M.; Ptaszny, J.; Pawełczyk, F.; Kłusek, M.; Michczyńska, D.J.; Jędrzejowski, M. Influence of Wall Perimeters and Printing Temperature on Tensile Properties of 3D Printed PLA Test Specimens. International Students Scientific Conference, Silesian University of Technology, Gliwice, Poland, 26 January 2024.

- Kadhum, A.H.; Al-Zubaidi, S.; Abdulkareem, S.S. Effect of the Infill Patterns on the Mechanical and Surface Characteristics of 3D Printing of PLA, PLA+ and PETG Materials. ChemEngineering 2023, 7, 46. [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Khaliq, J.; Gurrapu, D.R.; Elfakhri, F. Effects of Infill Line Multiplier and Patterns on Mechanical Properties of Lightweight and Resilient Hollow Section Products Manufactured Using Fused Filament Fabrication. Polymers 2023, 15, 2585. [CrossRef]

- Alhuzaim, A. Investigation of Layer Thickness Effects on Mechanical Properties of PLA Using FDM Additive Manufacturing. Yanbu Journal of Engineering and Science 2025, 22. [CrossRef]

- M. Eryildiz, “The effects of infill patterns on the mechanical properties of 3D printed PLA parts fabricated by FDM”, Ukrainian Journal of Mechanical Engineering and Materials Science, vol. 7, no. 1-2, pp. 1-8, 2021.

- Habeeb, H.A.; Abood, A.; Mohan, A. Influence of Layer Thickness and Infill Density on the Impact Strength of Carbon Particle and Polylactic Acid (CP/PLA) Composite. Solid State Technology 2020, 63, 1064–1076.

- Yazar, A.; Top, N.; Bülbül, R.; Şahin, I. Effect of Infill Density and Infill Pattern on Mechanical Properties in Fused Deposition Modeling (FDM). 2021.

- Cristea, M.; Ionita, D.; Iftime, M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [CrossRef]

- Birosz, M.; Ando, M. Effect of Infill Pattern Scaling on Mechanical Properties of FDM-Printed PLA Specimens. Progress in Additive Manufacturing 2023, 9. [CrossRef]

- Vargas, C.P.; Aldas, M.; Samper, M.; Motoc, D.; Ferrándiz, S.; López, J. Mechanical, Dynamic-Mechanical, Thermal and Decomposition Behavior of 3D-Printed PLA Reinforced with CaCO₃ Fillers from Natural Resources. Polymers 2022, 14, 2646. [CrossRef]

- Mencarelli, M.; Sisella, M.; Puggelli, L.; Innocenti, B.; Volpe, Y. Sensitivity Analysis of 3D Printing Parameters on Mechanical Properties of Fused Deposition Modeling-Printed Polylactic Acid Parts. Appl. Mech. 2025, 6, 17. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).