2.1. Sensorless Estimation of the Relative Angular Position and Speed at Lower Speed Differences

Unlike SRMs, which are designed for the use as an independent drive and must be suitable for self-sustained start up and operation at low rotation speeds, the function of the presented actuator in rotary operation is reducing the relative rotation speed

between the gearwheel on the side

i (

i becomes

left or

right in the double-sided LRRA) and the output shaft :

where

is the rotation speed of the gearwheel and

is the rotation speed of the output shaft. In linear operation, the shift sleeve can be successfully engaged with the complementary ring at absolute values of

less than 150 rpm with a sufficient shifting comfort. Thus, a complete speed synchronization to

is not required.

However, continuous monitoring of the difference(s) between the rotation speed of the gearwheel(s) and the rotation speed of the output shaft is necessary for two reasons. Firstly, this provides information for optimal gear shifting [

5]. Secondly,

is required to start the synchronization and shift the gear properly [

4]. If the gearwheel on the opposite side (or any gearwheel in the case of gearbox with gear number higher than two) is engaged, its rotation speed is equal to

, and

can be calculated solely from the rotation speed of the countershaft

:

where

is the gear ratio between the counter shaft and the engaged gearwheel.

In neutral gear, and change independently on each other, so that can change both its absolute value and sign. For this case, we present a method of sensorless estimation of the relative angular position and speed at lower speed differences including zero-crossing detection in this chapter.

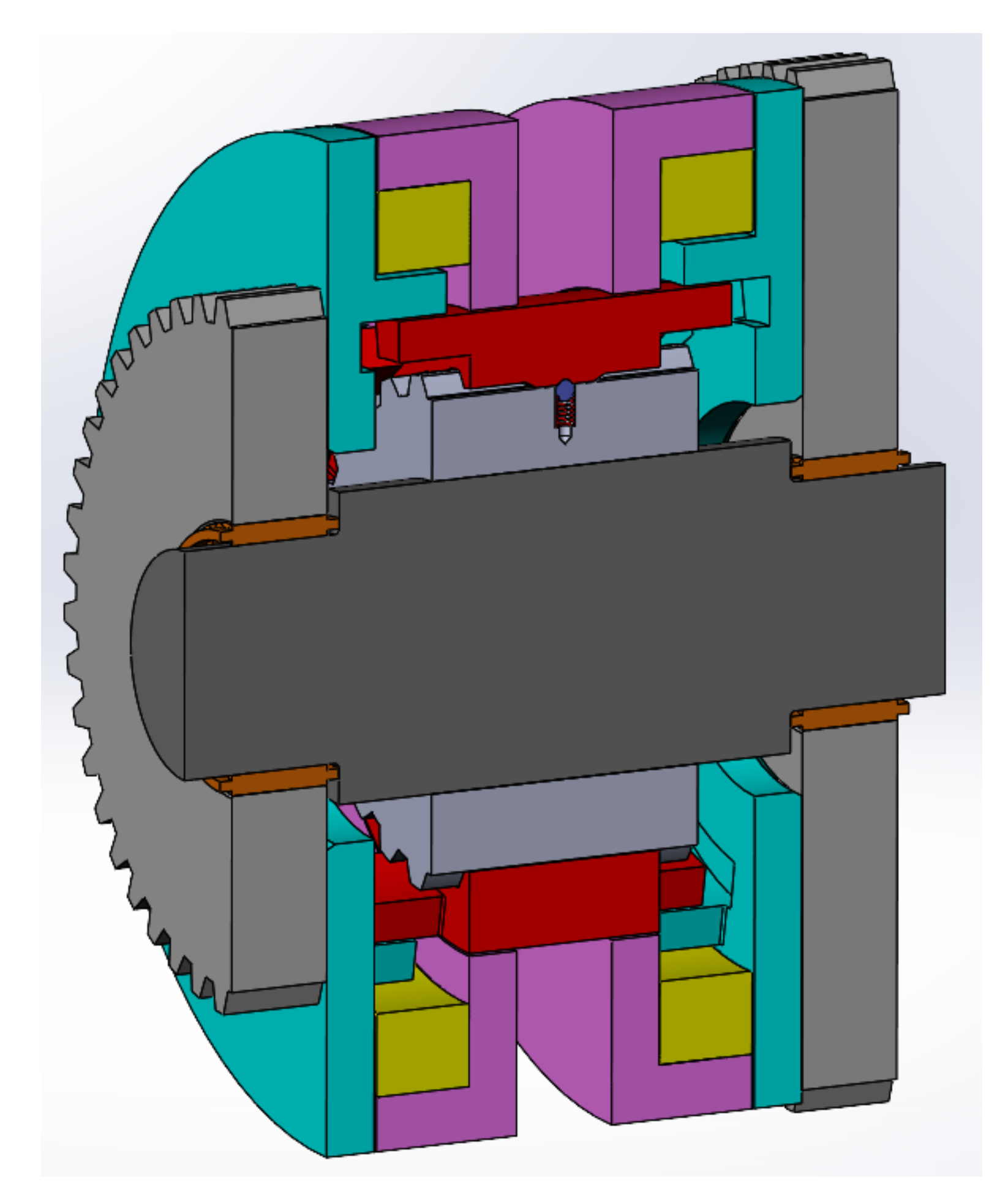

In our previous work, we developed a method for design and optimization of the actuator geometry [

3], where one of the main optimization goals is obtaining an inductance characteristic with a good suitability for sensorless estimation of the relative angular position.

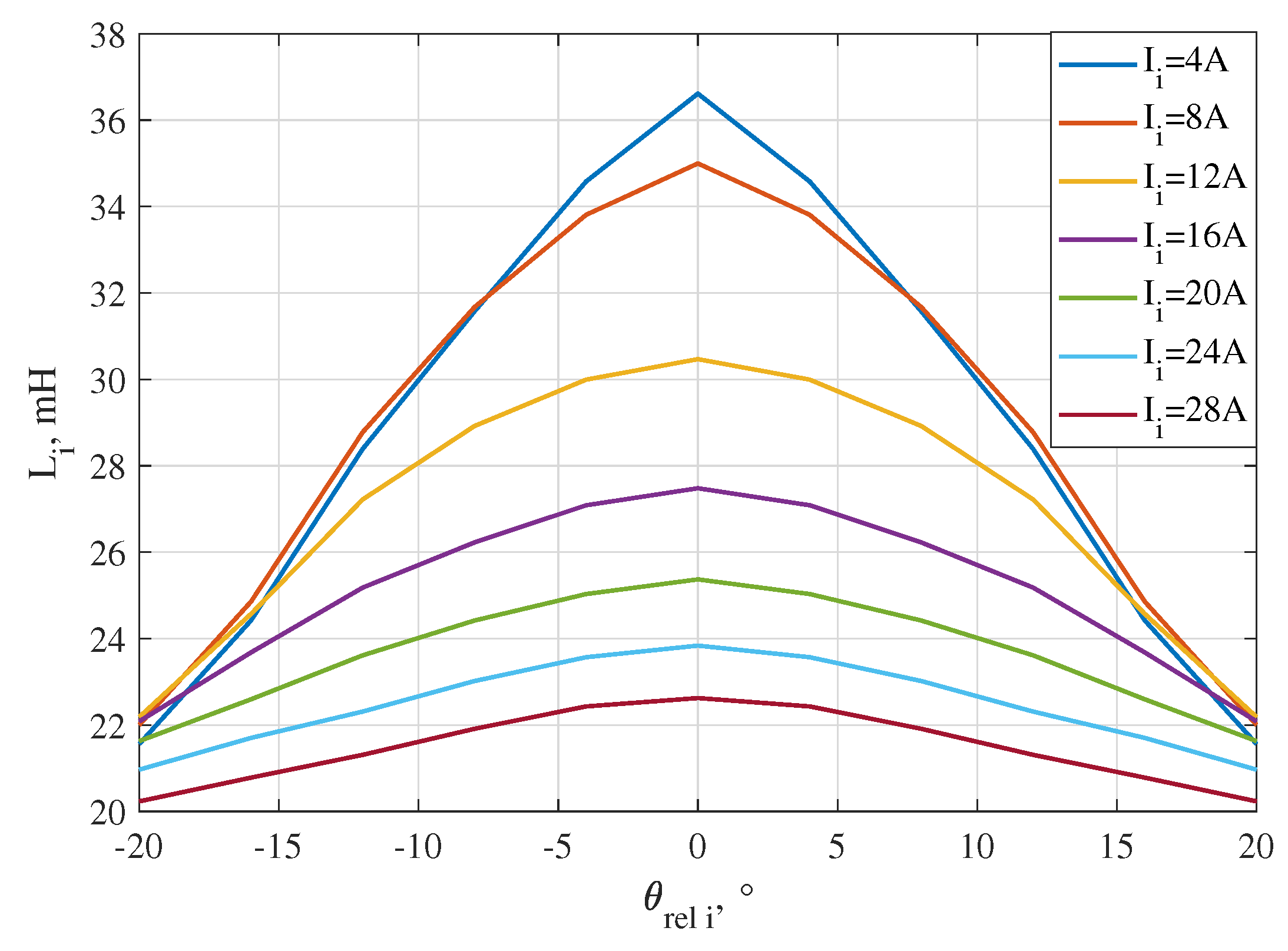

Figure 2 shows the inductance characteristic of the optimized actuator for the central axial position

x = 0 (neutral gear position), where

is the coil inductance,

is the relative angular position between the teeth [

2] and

the coil current on the side of gear

i. Since the magnetic circuits on both sides are symmetrical if

x = 0,

-characteristic is valid for both coils. Moreover, it can be seen in

Figure 2 that

always decreases with the increase of

, and

is especially explicit at lower currents.

If the coil is excited on the side

i at non-zero

, the voltage induced in the coil

can be calculated as

If the voltage applied to the coil has some constant value

and

= 0,

is zero, and the coil current

is equal to

divided by the coil resistance

. Once the gearwheel starts to rotate relatively to the shift sleeve, the change of

induces voltage in the coil (the second term in (

3)), which causes the change of

, and the voltage induced by the change of current (the first term in (

3)) also becomes nonzero. As long as the supply voltage

doesn’t change, the first and the second terms in (

3) have opposite signs, and their amplitude increases with increasing amplitude of

. Thus, the total value of

is limited, and the sign of

is always opposite to the sign of

. Since the operation principle of the proposed LRRA [

1,

2,

3,

4] is similar to that of SRMs [

10], it is enough to know the signs of

and

to detect the positions where the reluctance torque with the desired direction can be generated.

The sign of

is further named as side state. State 0 corresponds to positive

, and state 1 to negative

. The states can be estimated from

, i.e., measuring the coil current

while a constant DC-voltage is applied to the coil. In idle operation, a DC-voltage of the value

=

can be permanently applied to the coil to excite it with a low current value

that generates an insignificant reluctance torque and force but allows the estimation of the side state. During the synchronization, a DC-voltage of the value

=

is applied to the coil after the de-/magnetization is finished, where

=

at the state where no torque must be generated and

=

+

where the synchronizing torque must be generated (

is the required synchronizing current [

4]).

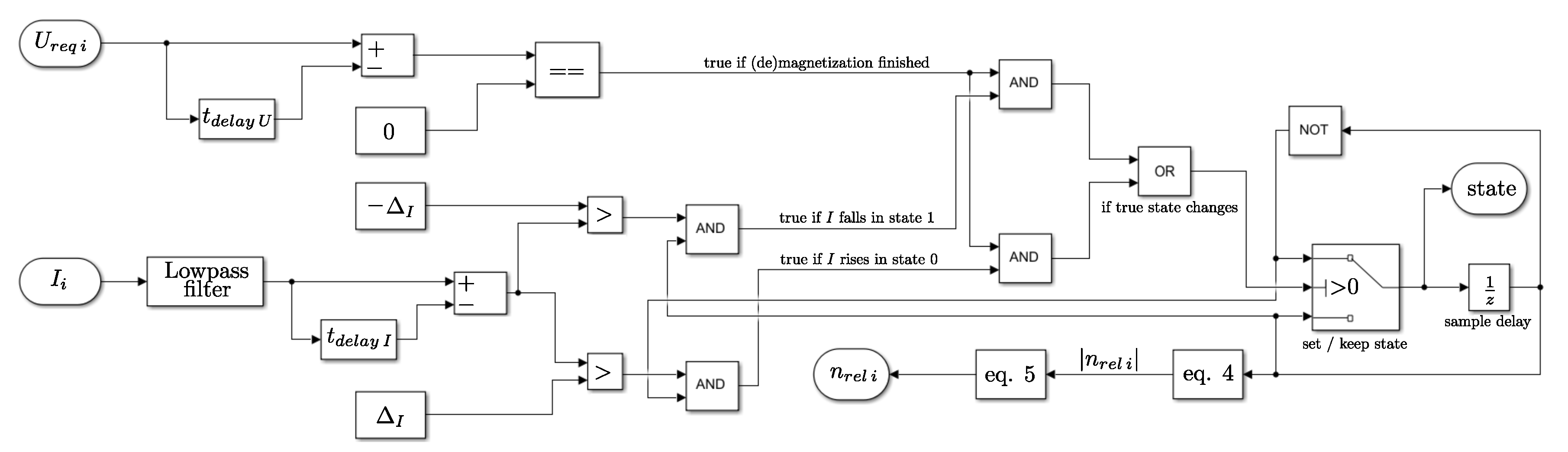

The measured value of is passed through a low-pass filter to reduce the noise influence. However, if the noise is relative strong, it can not be completely eliminated from the current signal without a significant reduction of the sensing capability. Therefore, instead to calculate directly, the actual value of the filtered current is compared with its delayed value , where the delay time is . Further, their difference is compared with the value , which must be chosen greater than the residual noise in the filtered current. Thus, the side state and the position where it changes can be easily estimated. If becomes greater than while the side state is 0, the state becomes 1. Similarly, the state is switched from 1 to 0 as soon as becomes less than . To avoid false estimation caused by the influence of eddy currents, which create some current dip after the magnetization is finished, and some current peak after the the demagnetization is finished, the state is only switched if the time passed after the de-/magnetization is greater than , i.e., the actual value of the voltage on the side and its value delayed by are same.

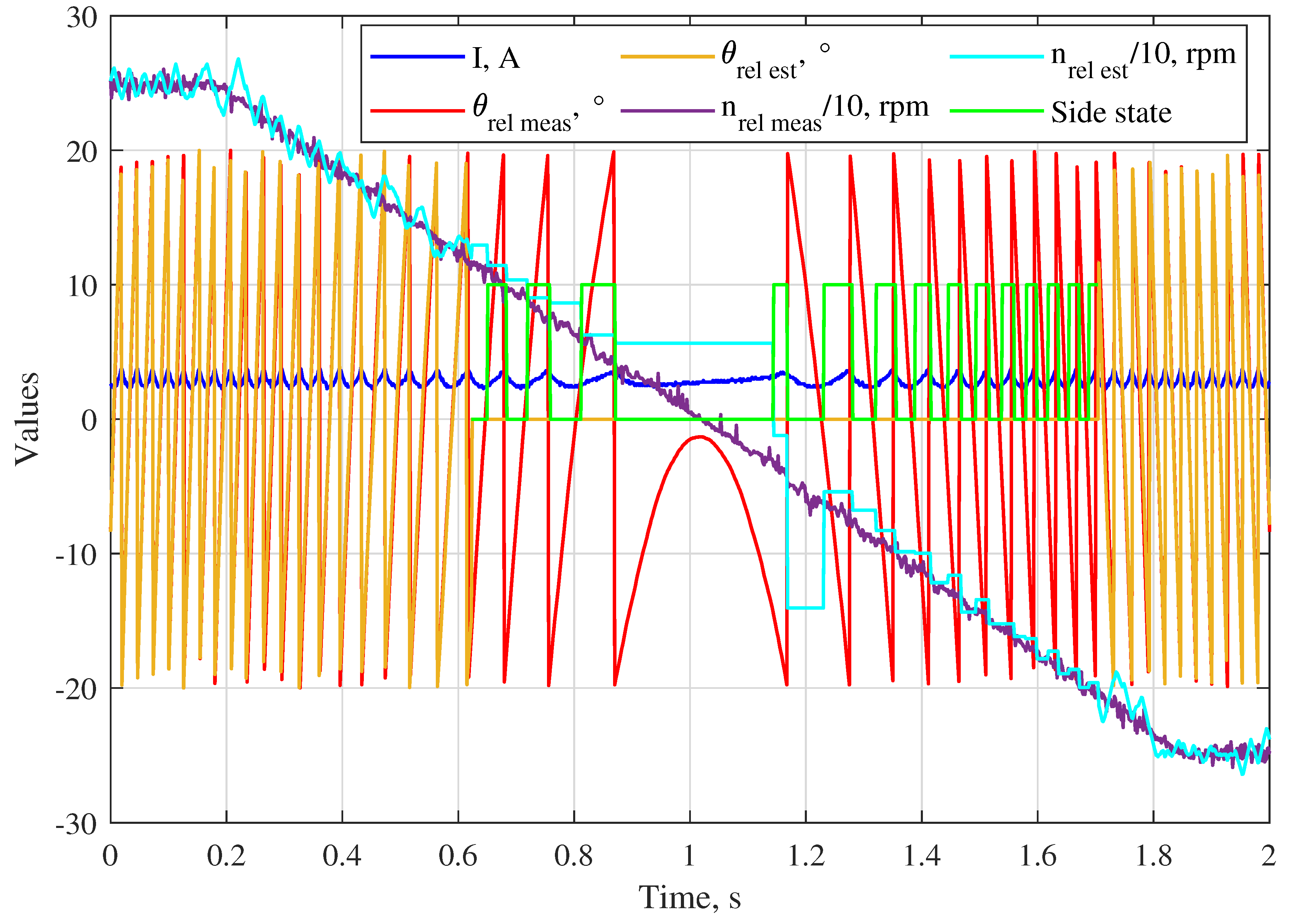

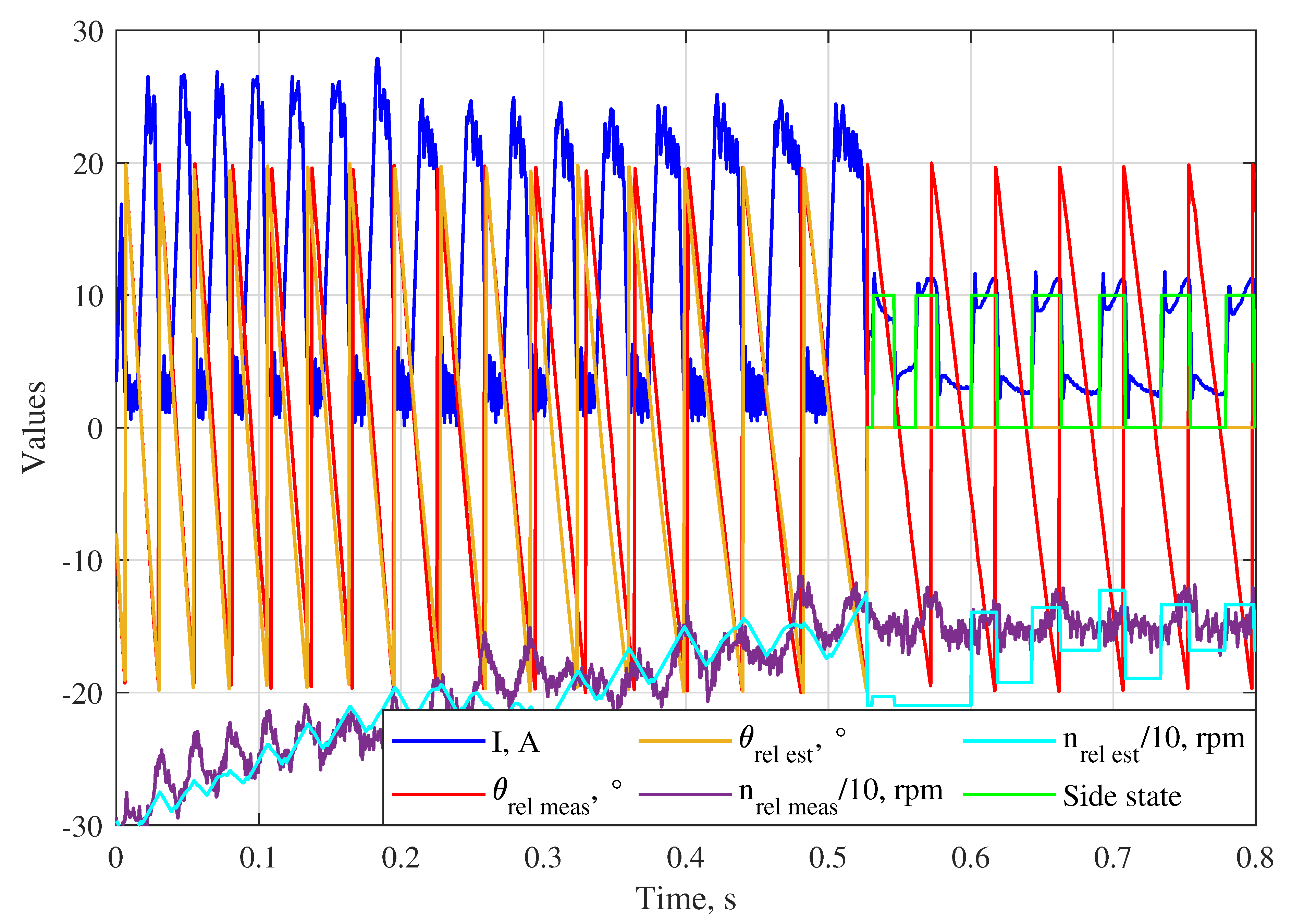

The entire algorithm for the sensorless estimation of the side state is shown in

Figure 3. The time elapsed between the state changes

corresponds to the change in

equal to 360/

degrees, where

z is the number of tooth pairs on one actuator side (9 in the considered actuator [

4]). Hence, the absolute value of the average

in the time interval

can be easily estimated as

The initial sign of

is known from (

2) or from the direction of the countershaft rotation during starting up. The direction change can be estimated sensorless based on the arithmetic mean formula: the sign of

changes if

where

and

are the absolute values of the relative speed estimated at the last state change and at the previous state change, respectively.

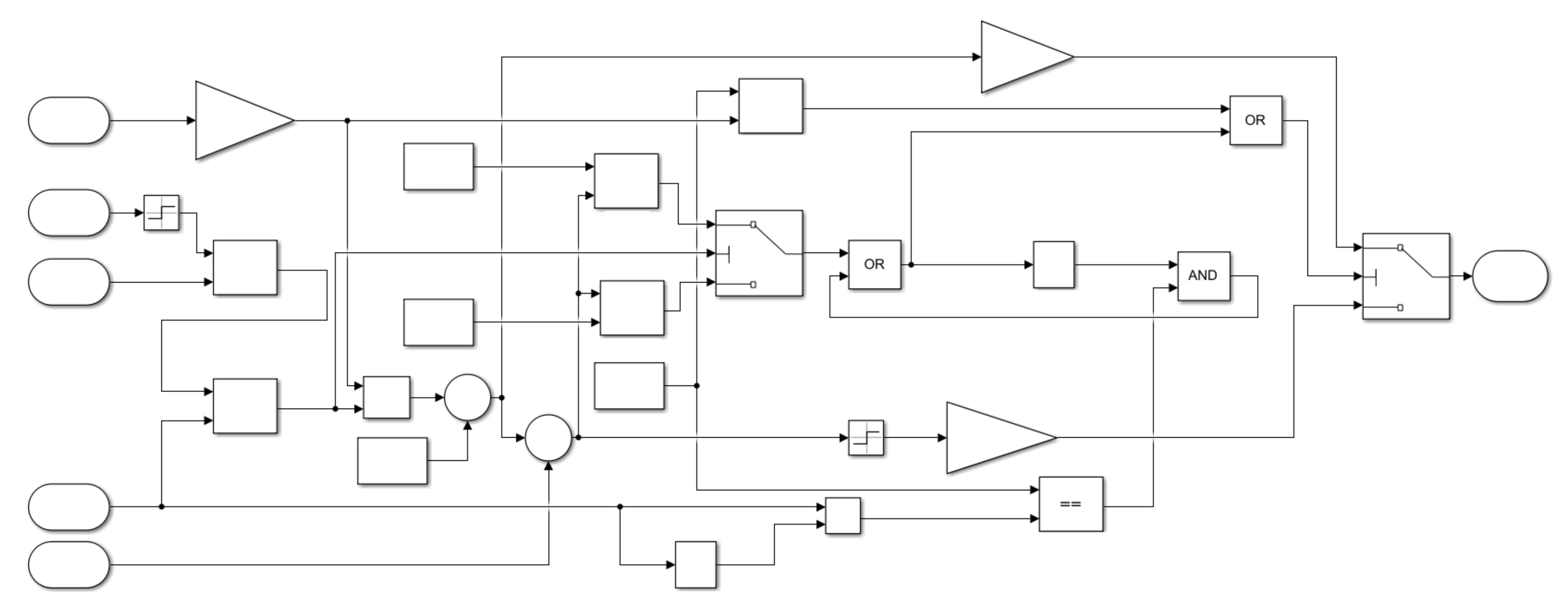

The algorithm of the voltage control based on the estimated state is shown in

Figure 4. The required coil current is estimated from the required torque (braking or accelerating) and the side state. Further, the maximum available voltage

with the corresponding sign is applied to the coil based on the difference between the required and measured current to de-/magnetize the side. To compensate the influence of the mentioned current peaks and dips, that arise under the influence of the magnetic fluxes generated by eddy currents after the de-/magnetization is finished, the coil is excited to a slightly higher current and de-excited to a slightly lower current than required. The difference between the required current value and the current value at which the de-/excitation is finished is represented by the additional term

. The value of voltage is switched from ±

to

when the coil current

becomes higher than

(excitation) or lower than

(deexcitation).

2.2. Sensorless Estimation of Relative Angular Position and Speed at Higher Speed Differences

The relative angular position

and speed

on the side

i can be estimated at higher speed differences using a sliding mode flux observer. The theory and design of the SMFO have been described in detail for SRMs in the past [

11] and can be applied for the presented LRRA. The values of the relative angular position

and relative angular speed

can be estimated at the time

t integrating the error function

, which is calculated based on the difference between the measured

and estimated

flux linkages of the coil:

where

and

are the speed gain and the position gain, respectively.

is calculated integrating the induced voltage:

In SRMs, the estimated flux linkage can be calculated simply multiplying the measured current

by the inductance

, which value is obtained from the inductance characteristic (

Figure 2) using the values of

and

. However, eddy currents, which are significant in the LRRA, are not considered in this case. Thus, the additional term

is added:

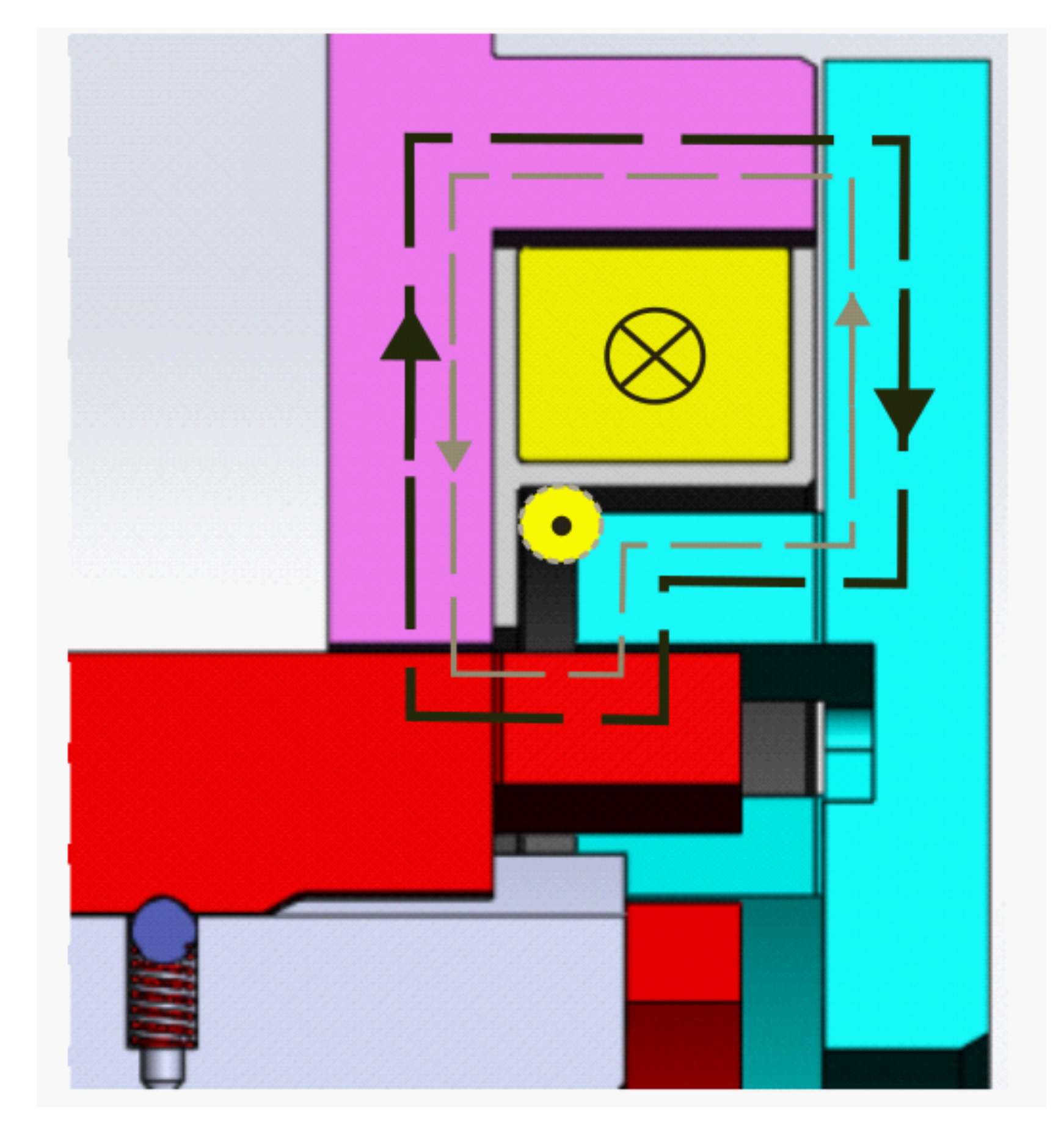

To calculate

, a simplified model of the magnetic fluxes generated by eddy currents is introduced (

Figure 5). When the coil on the side

i is being de-/excited, the magnetic flux

on this side changes (

=

divided by the number of coil turns

) and induces eddy currents in the stator, complementary ring and shift sleeve. The fluxes created by the eddy currents in each part always delay the rise of

when the coil is being excited and the fall of

when it is being de-excited. Omitting the fact that the flux propagates in the steel starting from the areas nearest to the coil, the influence of eddy currents can be modeled with a fictive turn, which has the same magnetic circuit as the coil but the opposite direction of the current. Its resistance is

, and its inductance

is equal to the coil inductance divided by

. The change of

induces the voltage

in the fictive turn, which is

times lower than

, creating the current

and magnetic flux

:

is calculated solving Equation (

11) in a loop and dividing

by

. The value of

can be determined experimentally measuring the difference between the modeled and measured flux linkages of the coil and dividing it by

. The quotient represents the measured

, and

is found iteratively comparing the values of

calculated for different

from (

11) with the measured value. Finally,

can be obtained with the known value of

as