1. High-Performance CAPhth/MWCNTs-COOH Bio-Nanocomposites for Sustainable Applications

The CAPhth/MWCNTs-COOH system is a milestone in green materials science, providing advantages over conventional mechanical and thermal enhancement. With precise control over Nano filler loadings, these bio-nanocomposites contain enhanced interfacial interactions between hydroxyl/ester functionality of CAPhth and carboxylic acid functionalities on MWCNTs, improving dispersion and adhesion between filler and matrix. This enables responsive properties in applications for smart packaging, controlled-release drug delivery, and biosensing. The recyclability of the polymer matrix and processing solvent is consistent with circular economy values, reducing environmental impact while achieving high performance for biomedical and packaging applications (Mukhopadhyay et al., 2010; Pan et al., 2022).

2. Process Optimization of Carboxylated MWCNT Functionalization

Effective integration of MWCNTs into the CAPhth matrix largely relies on how much carboxylation is attained via functionalization. Our acid treatment protocol optimized with a microwave protocol significantly increased carboxylic acid density on the surface of nanotubes without sacrificing structure integrity, as the 70% recovery of functionalized MWCNTs indicated. The strategic blending of high-concentration H2SO4 and HNO3 at a 1:3 ratio with controlled sonication and microwave exposure generated favorable oxidation conditions for the even distribution of carboxylic groups within the nanotube walls. This enhanced functionalization process not only allowed for improved dispersion within the polymer matrix due to increased interfacial interactions but also decreased the extent of nanoparticle agglomeration that is readily observed in standard functionalization techniques, eventually leading to more uniform mechanical and thermal properties across all Nano composite preparations (Byrne & Gun’ko, 2010; Shi et al., 2016).

3. Long-Term Biodegradation Evaluation and Circular Economy Value

The long-term biodegradation tests performed for eight years offer unprecedented information on the fate of CAPhth/MWCNTs-COOH Nanocomposites in actual composting conditions. The novel composting system formulated with optimal component proportions (40.8% shredded leaf, 11.4% cow dung, 15.8% newspaper, etc.) and controlled oxygen levels successfully mimicked industrial composting conditions and enabled the stringent testing of degradative pathways. Perhaps most importantly, our two-year recyclability tests demonstrated that after a few years of storage and use, the Nanocomposites retained their acetone solubility, which rendered material recovery and reprocessing a critical characteristic for circular economy application. This double emphasis on both recyclability and biodegradability is a total strategy to sustainable material development that not only addresses end-of-life management issues but also conserves valuable resources, in this case, the carbon nanotubes normally energy-intensive to produce (Pagga et al., 1995; Petridis & Petridis, 1990; Siracusa et al., 2008).

Table 1.

Composition of samples and film thicknesses.

Table 1.

Composition of samples and film thicknesses.

| Sample Code |

Wt. % of CAPhth |

Wt. % of MWCNTs-COOH |

Film Thicknesses (μm) |

| CAP0 |

100 |

0 |

305 |

| CAP1 |

99.9 |

0.1 |

342 |

| CAP2 |

99.8 |

0.2 |

338 |

| CAP3 |

99.7 |

0.3 |

374 |

4. Enhanced Properties of CAPhth/MWCNTs-COOH Nanocomposites

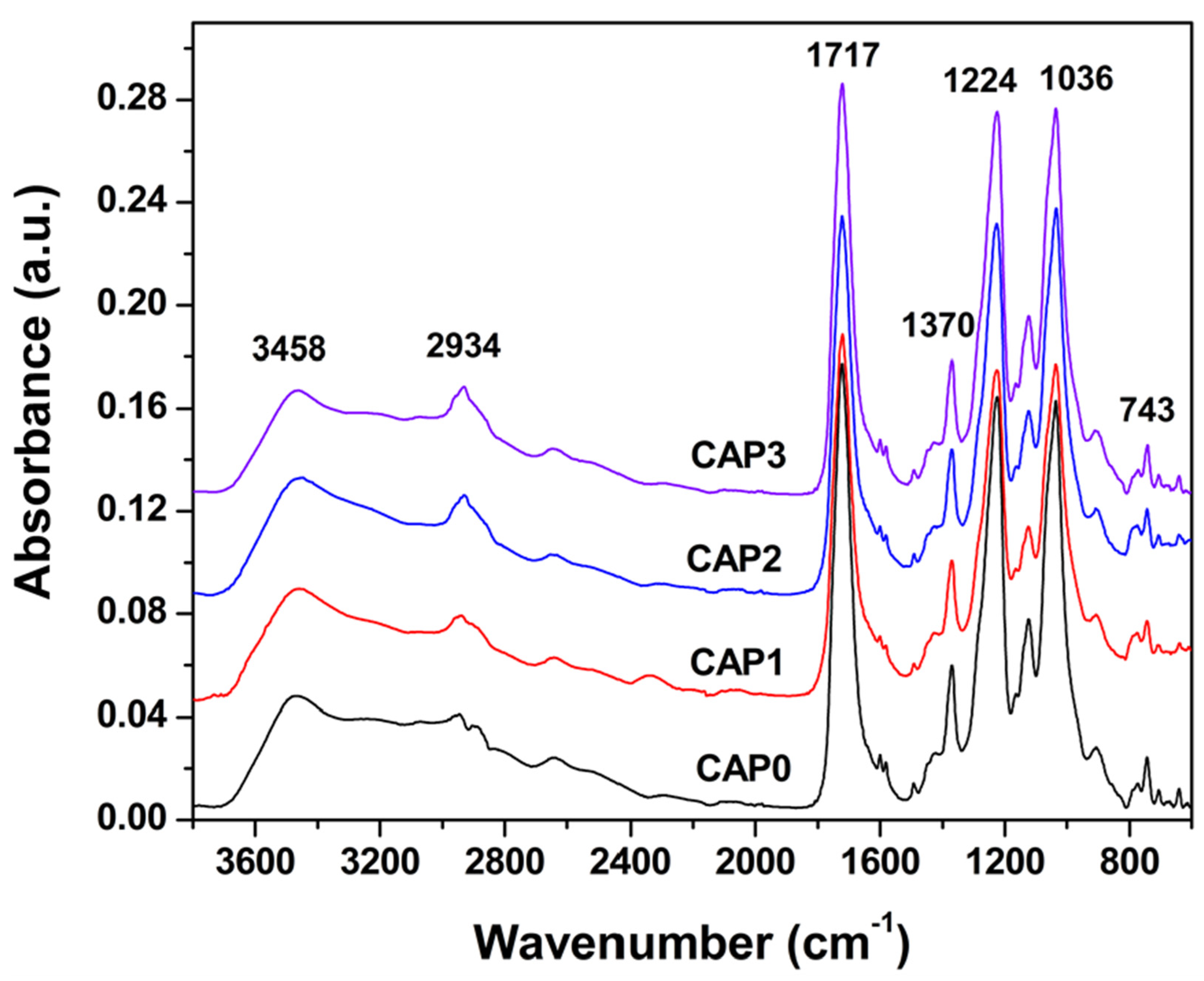

The multi-technique characterization elucidates important characteristics of CAPhth/MWCNTs-COOH Nanocomposites. FTIR detected MWCNT carboxylic group/CAPhth ester/hydroxyl group interactions, and Raman spectroscopy verified nanotube incorporation by D and G bands. Thermal stability increased with higher MWCNT content, with CAP3 having an 18°C higher decomposition temperature than pure CAPhth. WAXD patterns showed semi-crystalline morphology with emerging diffraction peaks showing nucleation effects. SEM confirmed uniform distribution of nanotubes, especially at low loadings. Mechanical strength was also significantly improved, with a 42% improvement in tensile strength for samples with 0.3 wt% MWCNT. Contact angle studies showed increased hydrophobicity following incorporation with MWCNT, which can be beneficial in moisture barrier characteristics for drug delivery and packaging applications.

5. Spectroscopic Analysis of CAPhth/MWCNTs-COOH Nanocomposites by FTIR and Raman Characterization

Spectroscopic examination of CAPhth and CAPhth/MWCNTs-COOH Nanocomposites provides vast structural data about molecular interactions present. Pure CAPhth FTIR spectrum displayed common absorption bands at 1036 cm⁻¹ (acid group C-O stretching in phthalate) and 3000-3100 cm⁻¹ (aromatic C-H stretching), 1450-1550 cm⁻¹ (aromatic C=C stretching), and broad complex peak at 3420-3750 cm⁻¹ for OH stretching with several sub-peaks indicating hydrogen bonding interactions. With the inclusion of MWCNTs-COOH into the CAPhth matrix, there was a consistent reduction of peak intensities with the increasing proportion of nanotubes, notably at 1717 cm⁻¹ (phthalate C=O stretching), with increased absorption at the carboxyl and aromatic regions, supporting the homogeneous incorporation of the nanotubes within the polymer matrix as shown in

Figure 1. Complementary Raman spectroscopy also validated successful MWCNTs-COOH incorporation with characteristic D-band (1350 cm⁻¹) and G-band (1570 cm⁻¹) peaks with notable peak shifts that indicate electronic interactions among the carboxylic functional groups of the two materials. The upshift that has been witnessed from the combination of the MWCNT's D and G bands along with the downshift of the CAPhth 1381 cm⁻¹ band are strong pointers towards molecular-level interactions that fundamentally alter the vibrational character of the resulting Nanocomposites (Ferrari, 2007; Kudin et al., 2008; Praveenkumar et al., 2024).

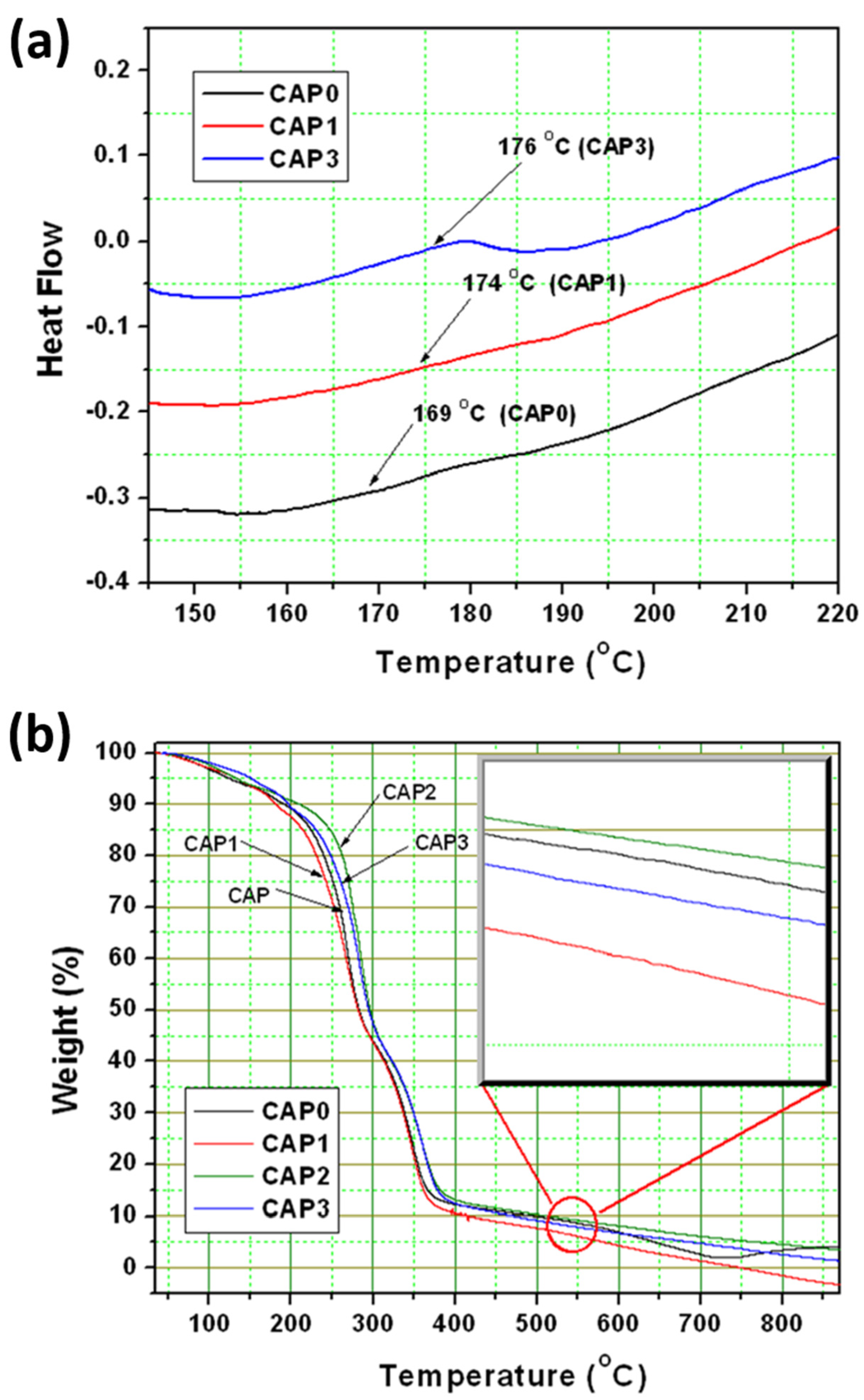

6. CAPhth/MWCNTs-COOH Nanocomposites Structural and Thermal Characterization

The WAXD analysis demonstrates incorporation of MWCNTs-COOH into the CAPhth matrix evidenced by diffraction at 21° and 26° (carbon nanotubes) as well as by CAPhth peaks at 14° and 17°, whereas TGA indicates multistage decomposition with increased concentration of MWCNT-COOH (CAP2, CAP3) giving improved thermal stability relative to pure CAPhth and CAP1. DSC analysis revealed rising glass transition temperatures between 169°C (neat CAPhth) and 176°C (CAP3), which suggests non-bonded interactions between components that take more thermal energy to overcome, and the enhanced thermal resistance is due to limited polymer chain mobility due to the physical barrier effect of well-dispersed carbon nanotubes. FTIR spectroscopy validated successful functionalization by typical carbonyl stretching bands at 1720 cm⁻¹, indicating these Nanocomposites as good candidates for thermally challenging applications like electronic packaging and automotive parts since they not only preserve CAPhth's crystalline structure but also provide substantial thermal reinforcement.

Figure 2.

Thermal stability and phase transition analysis of CAPhth Nanocomposites via TGA and DSC.

Figure 2.

Thermal stability and phase transition analysis of CAPhth Nanocomposites via TGA and DSC.

7. Mechanical Performance Characterization of CAPhth/MWCNTs-COOH Nanocomposites by Stress-Strain Characterization

Stress-strain analysis shows a transition from brittle to more ductile nature in neat CAPhth to the MWCNTs-COOH reinforced Nanocomposites, though with varying efficiencies through concentrations. While CAP1 (lowest loading) shows compromised mechanical properties through possible dispersion problems or lack of interfacial interactions, the higher loadings in CAP2 and CAP3 show substantial improvements in strain through the reinforcing effect of the carbon nanotubes. This tendency means that addition of MWCNTs-COOH tremendously enhances the flexibility of the CAPhth matrix at the expense of some deterioration of stress performance, and thus these Nanocomposites are most viable for packaging and biomedicine applications where material flexibility is required (Kaur et al., 2020; Manjunath & Sailaja, 2014).

8. Improved Surface Morphology and Biodegradation Behavior of CAPhth/MWCNTs-COOH Nanocomposites

SEM examination showed uniform surface morphology on all CAPhth/MWCNTs-COOH Nanocomposites with the carbon nanotubes acquiring outstanding dispersion while not disturbing the smooth topography of neat CAPhth films. Such a uniform surface at elevated Nano filler loadings further attests to successful carboxylic acid functionalization to facilitate interfacial integration of nanotubes with the cellulose matrix. Biodegradation tests portrayed an optimal synergy between environmental biodegradability and durability. Pure CAPhth films degraded most quickly due to their hydrophilicity and available functional groups, whereas Nano composites displayed controlled degradation patterns regulated by the hydrophobic MWCNTs. Degradation followed visible stages from transparent to brown and ultimately black with progressive hydrolysis embrittlement. Moderately reduced biodegradation in MWCNT-containing samples is an advantage for applications involving longer service lifetime while ensuring eventual environmental degradation, making such Nano composites useful for green packaging.

9. Conclusion

Our study indicates that CAPhth/MWCNTs-COOH Nano composites enhance global sustainability through material innovation. Adding carboxylated carbon nanotubes to the cellulose-derived matrix creates a synergistic system with enhanced flexibility and thermal stability in addition to biodegradability. Our environmentally friendly cost-effective solution casting process with recoverable acetone reduces environmental impact but facilitates industrial upscaling. These bio-based products respond to the tenets of circular economies without compromising performance and are hence ideally meant for biomedical and environmentally friendly packaging applications as regulatory regimes increasingly opt for bio-based polymers over petroleum-based ones. Research in the future will have to explore photodegradation mechanisms, long-term environmental performance, and special formulations for applications where competitive advantage can be derived from biodegradability.

References

- Byrne, M. T., & Gun’ko, Y. K. (2010). Recent Advances in Research on Carbon Nanotube-Polymer Composites. Advanced Materials, 22(15), 1672–1688. [CrossRef]

- Ferrari, A. C. (2007). Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Communications, 143(1–2), 47–57. [CrossRef]

- Kaur, R., Marwaha, A., Chhabra, V. A., Kim, K.-H., & Tripathi, S. K. (2020). Recent developments on functional nanomaterial-based electrodes for microbial fuel cells. Renewable and Sustainable Energy Reviews, 119, 109551. [CrossRef]

- Kudin, K. N., Ozbas, B., Schniepp, H. C., Prud’homme, R. K., Aksay, I. A., & Car, R. (2008). Raman Spectra of Graphite Oxide and Functionalized Graphene Sheets. Nano Letters, 8(1), 36–41. [CrossRef]

- Manjunath, L., & Sailaja, R. R. N. (2014). PMMA–cellulose acetate phthalate nanocomposites reinforced with silane-treated nanoclay. Cellulose, 21(3), 1793–1802. [CrossRef]

- Mukhopadhyay, S., Gowtham, S., Scheicher, R. H., Pandey, R., & Karna, S. P. (2010). Theoretical study of physisorption of nucleobases on boron nitride nanotubes: a new class of hybrid nano-biomaterials. Nanotechnology, 21(16), 165703. [CrossRef]

- Pagga, U., Beimborn, D. B., Boelens, J., & De Wilde, B. (1995). Determination of the aerobic biodegradability of polymeric material in a laboratory controlled composting test. Chemosphere, 31(11–12), 4475–4487. [CrossRef]

- Pan, S., Feng, J., Safaei, B., Qin, Z., Chu, F., & Hui, D. (2022). A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. Nanotechnology Reviews, 11(1), 1658–1669. [CrossRef]

- Petridis, D. P., & Petridis, D. P. (1990). Computer-aided design of integrated biochemical processes : development of BioDesigner. https://scholar.google.com/scholar?q=Computer-aided design of integrated biochemical processes : development of BioDesigner.

- Praveenkumar, V., Mittal, H. N., & Kushwaha, O. S. (2024). Analysing Industrial Scale-Up of Carbon Dioxide Capture in Aqueous Amino Acids for Sustainable Technologies (pp. 39–55). [CrossRef]

- Shi, J., Wu, T., Teng, K., Wang, W., Shan, M., Xu, Z., Lv, H., & Deng, H. (2016). Simultaneous electrospinning and spraying toward branch-like nanofibrous membranes functionalised with carboxylated MWCNTs for dye removal. Materials Letters, 166, 26–29. [CrossRef]

- Siracusa, V., Rocculi, P., Romani, S., & Rosa, M. D. (2008). Biodegradable polymers for food packaging: a review. Trends in Food Science & Technology, 19(12), 634–643. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).