1. Introduction

In modern conditions of mining and processing of ore materials, special attention is paid to the integrated use of raw materials and the maximum extraction of valuable components. One of the promising areas is the processing of metallurgical slags, which are man-made mineral resources containing residual amounts of non-ferrous and precious metals. Their effective extraction contributes not only to increasing the profitability of production, but also to reducing the anthropogenic impact on the environment [

1,

2,

3,

4,

5,

6].

The granulometric composition of the processed material plays a key role in the efficiency of precious metal extraction processes. The particle size determines the surface area available for interaction with reagents, and also affects the processes of flotation, leaching, and gravity enrichment. Studies show that different fractions of the material can exhibit different degrees of metal recoverability, which makes granulometric analysis an important stage in the development and optimization of slag processing technologies [

7,

8,

9,

10,

11,

12,

13].

The relevance of the study is due to the need to increase the efficiency of metallurgical waste processing and to search for new methods of their enrichment. Various approaches to slag processing are used in world practice, including X-ray fluorescence sorting, magnetic separation and hydrometallurgical methods. For example, studies have shown that X-ray fluorescence sorting makes it possible to effectively isolate non-ferrous metals from industrial waste, depending on the properties of the particle surface [

14,

15,

16,

17]. In addition, it was found that the characteristics of the granulometric composition have a significant effect on the processes of metal reduction in the peripheral zone of the blast furnace [

18,

19].

The present work is devoted to the study of the granulometric composition of slag samples and its effect on the efficiency of extraction of precious metals. In the course of the study, laboratory experiments were conducted to determine the granulometric composition of slags, analyze the effect of particle sizes on metal extraction processes, as well as a comparative analysis of various technological approaches to waste processing. The results obtained will make it possible to develop recommendations for optimizing the processing of metallurgical waste, increase the recoverability of valuable metals and minimize losses during their processing.

2. Materials and Methods

The study included sampling of slag from the slag dump of the former Shymkent lead plant (

Figure 1), grinding using a mill and then conducting a granulometric analysis using a sieve method, chemical analysis to determine the content, as well as flotation experiments [

20,

21].

A 178×356 mm “Unal” rod mill operating at 45 rpm was used for the study. The sample, pre–ground to a size of 1 mm, weighing about 1000 g, was processed at a ratio of solid: liquid = 1:1 for different times given below. The particle size distribution was recorded after each stage of using wet sieving. The results are shown in

Table 1.

3. Experimental Part

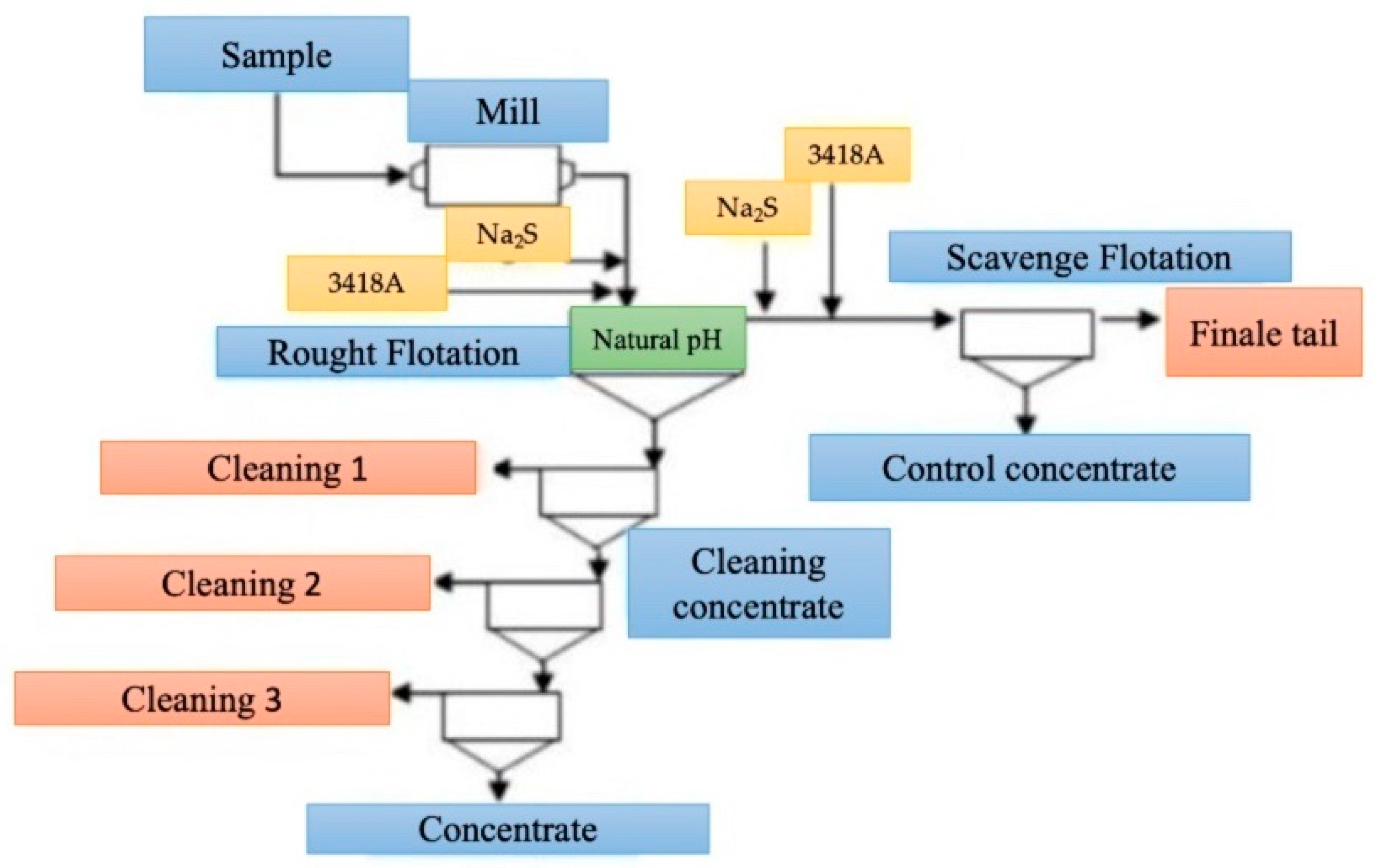

Flotation experiments with Na2S-3418A

In this series of experiments, sulfurization with various amounts of Na2S was performed before using coarse and control flotation, and then 3418A was used as a collector. Flotation tests were carried out between pH values from 9.50 and above, which constitute the natural level of the alkaline slag environment. Other variables were maintained on an ongoing basis to see the effect of pH changes, the experiment was conducted in a control flotation by lowering the pH level to 7.60.

The process of purification of coarse concentrate in the experiments was carried out in a maximum of 6 stages. With different size distributions, as shown in

Figure 2. Since the number of cleaning steps has different numbers, after cleaning they are expressed as "Residue after cleaning".

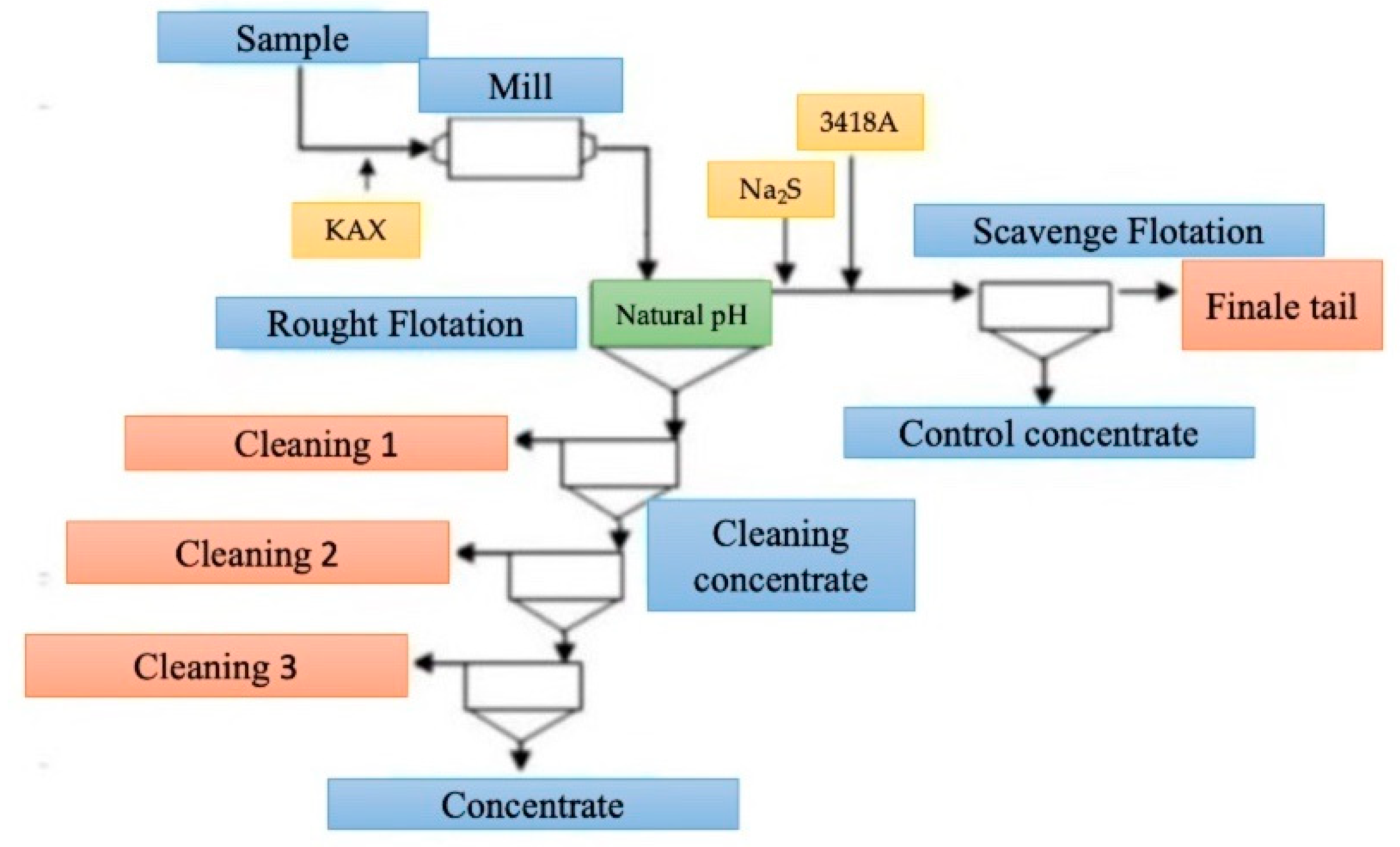

Flotation experiments with KAX-Na2S-3418A

Unlike the previous experiment, KAX was used as a collector instead of 3418 A, and AX was added directly to the mill. Na2S was added before the control flotation, the condition was created within 5 minutes, and 3418A was used as a collector. The experiments were carried out in various size distributions, according to the general flow chart of the experiments, as shown in

Figure 3.

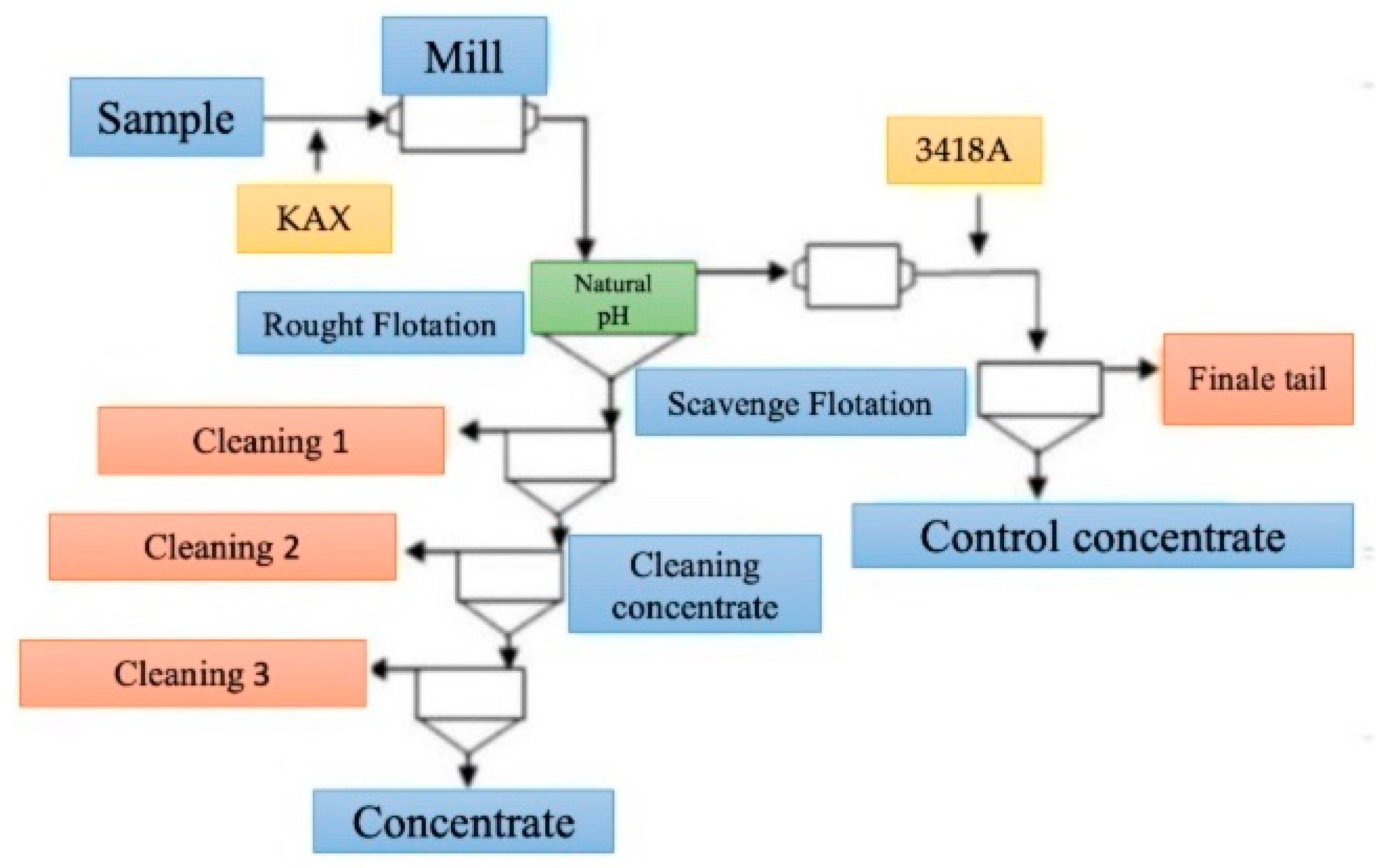

Flotation experiments with the sample after grinding of coarse residues

Unlike previous experiments, Na

2S was not used in this series. The general flow chart of the experiments is shown in

Figure 4.

4. Results and Discussion

4.1. Time of Grinding and Size Distribution of Coarse Sludge Residues

Table 1 shows the results that show the dependence of the cumulative particle size distribution on the grinding time, where the proportion of sifted particles corresponds to different time intervals.

Table 1 shows an accelerated decrease in the proportion of large particles and a gradual increase in the content of small fractions over the grinding time. The most intensive grinding takes place between 17 and 25 minutes, after which the process slows down significantly. For large particles (for example, 150 microns), the cumulative yield reaches 100% by 35 minutes of grinding. At the same time, for smaller particles (for example, 20 microns), the cumulative increase is noticeable even after 45 minutes, which indicates the continued crushing of the material.

The results show the efficiency of rod mills for grinding slag: after 35 minutes, most of the material reaches a size of less than 75 microns. When grinding for up to 60 minutes, almost all the material passes through a sieve with a mesh size of 20 microns, which significantly affects the processing steps such as flotation or hydrometallurgy. The data obtained on the particle distribution and the grinding time of coarse sludge residues are in good agreement with the literature data. For example, Liu et al. (2019) showed that increasing the grinding time of dry-granulated blast furnace slag from 10 to 20 minutes makes it possible to achieve an optimal average particle size (D50 ~16.6 microns), which has a positive effect on cement strength. With a further increase in time to 30-50 minutes, particle agglomeration and deterioration of properties were observed [

19]. Li et al. (2024) also noted that when grinding steel slag, the optimal time is about 20 minutes — during this period, the maximum specific surface area is reached, and excess time leads to clumping of particles [

21].

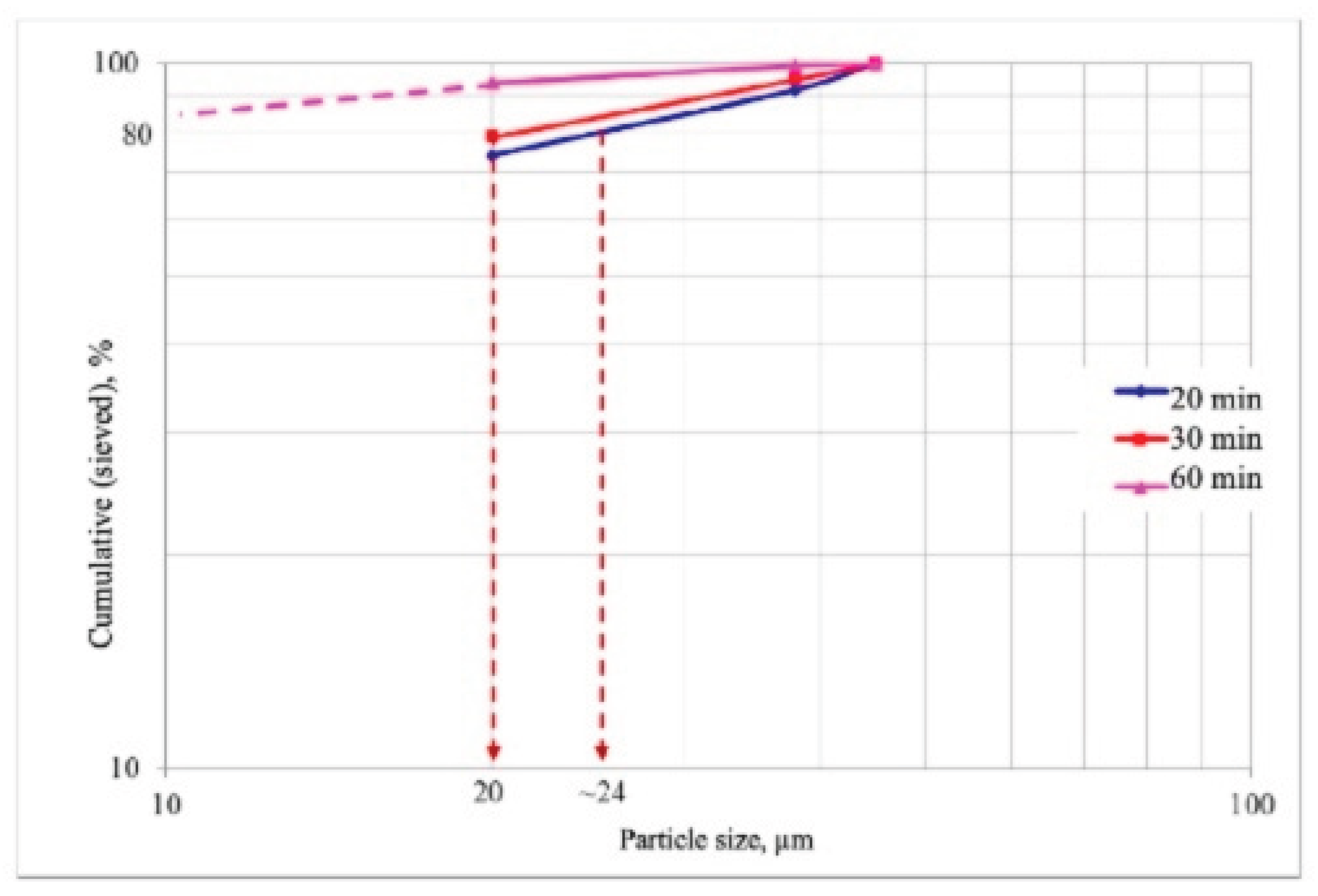

As part of the control flotation, to study the effect of the particle size (38 microns), the coarse flotation residues were subjected to repeated grinding. Experiments on control flotation were carried out with particle sizes in the following fractions: 24 microns, 20 microns and <10 microns (

Table 2).

The table shows the results of particle size distribution after grinding coarse residues in various time intervals. When analyzing the particle distribution after grinding coarse particles, the following changes are observed. For synchronization of 38 microns, the weight fraction drops from 8.37% (30 minutes) to 5.28% (60 minutes), while the cumulative value remains at 100% for the lower time intervals, which indicates the complete removal of large particles. At the same time, the mass fraction of particles with particle sizes of 20 microns varies slightly: it decreases from 17.6 at 30 minutes to 16.15% at 60 minutes, however, a cumulative increase in the proportion from 91.6 to 94.72% indicates a gradual decrease in large particles. The most noticeable increase occurs within 20 microns, where the weight fraction of fine particles increases from 74.0 (30 minutes) to 78.57% (60 minutes), and the cumulative value for this group reaches 93.72%. These results indicate the effectiveness of long-term grinding to prepare the material for further processing.

Figure 5 shows that with particle sizes of about 20 microns, the cumulative distribution increases over the grinding time, reaching about 80% after 20 minutes, slightly more than 85% after 30 minutes, and about 93% after 60 minutes. For smaller particles (<20 microns), the largest increase in cumulative mass is observed during the transition from 30 to 60 minutes of grinding. At the same time, for large particles (>24 microns), the cumulative value remains close to 100% regardless of the grinding time, which indicates the almost complete removal of large fractions. Thus, an increase in the grinding time leads to a more significant reduction in particle size and a significant increase in the proportion of small fractions.

In the work of Marwa (2023), it was found that small waste fractions (<10 mm) exhibit high values of acidity and intensive metal leaching, emphasizing the importance of fineness control to reduce environmental risks [

16]. The article by Lyalyuk et al. (2013) emphasizes the importance of coke crushing to improve the gas permeability of the blast furnace charge, where reducing large fractions (>80 mm) to 1-2% increases furnace productivity and reduces coke consumption [

18]. In addition, data from Jani et al. (2018) indicate that even for landfill waste, fine fractions (<10 mm) are of key importance for the mobility of heavy metals (Zn, Cu, Cr), which is important to consider during processing and reclamation [

13]. Pfandl et al. (2019) noted that the efficiency of X-ray fluorescence sorting of non-ferrous metals from slags strongly depends on the particle size range (optimally 10-32 mm), and smaller fractions require separate processing [

19]. Thus, our own results confirm the importance of choosing the optimal grinding time in order to maximize the release of valuable components, minimize large fractions, and improve technological performance during subsequent processing stages. This is consistent with the literature data on the need to control particle distribution at different stages of raw material preparation.

4.2. The Effect of Particle Size Distribution on the Extraction of the Studied Components from Slags

Particle size plays a key role in the efficiency of the flotation process, as it directly affects the interaction of reagents with metallurgical waste containing valuable elements.

Table 3 shows the values of the results of flotation experiments using various reagents (Na

2S-3418A, KAX-Na

2S-3418A) with different particle fractions.

The results show that nearly half of the Cu can be recovered during rougher flotation, and the Cu grade in the concentrate can reach up to 20.15% after six stages of cleaning. The use of Na

2S during coarse flotation had a positive effect, but no effect was observed during control flotation, which is consistent with the conclusions (Sajjad & Otsuki, 2022), which emphasize that the effectiveness of reagents and their interaction with minerals depend on the stages of the process and the characteristics of the suspension [

22]. Also, reducing the pH level in the control flotation proved to be insufficiently effective. An increase in flotation efficiency was achieved by regulating the particle size distribution, which fully corresponds to the conclusions Kazemi et al. [

23], where the optimal particle fraction of +40-60 microns gave the greatest Cu extraction in laboratory conditions (

Table 3) [

23,

24,

25].

The conducted studies on lead-produced slags revealed important patterns: the particle size of 38 microns turned out to be the most suitable for the initial stages of flotation, providing a sufficient contact area of the waste with flotation reagents and minimizing copper losses. This is also confirmed by studies Chi Wang et al., [

26], which show that fine particles can improve interaction with air bubbles and reagents, but their excess can negatively affect the process due to aggregation and changes in the rheological properties of the pulp [

26,

27].

Reducing the particle size to <10 microns demonstrated a positive effect on copper extraction: Cu extraction increases by about 7%, and the overall flotation efficiency reaches about 60%. This effect is associated with an increase in the available surface of minerals for interaction with reagents and air bubbles, which improves the formation of partially bubble aggregates and promotes better separation of valuable components from waste rock. Similar approaches aimed at improving the efficiency of flotation of fine particles using nanobubbles and nanoparticles are discussed in detail in [

28] (Sigauke et al., 2025), which emphasizes their role in increasing hydrophobicity, stabilizing foam, and improving separation [

28,

29,

30].

However, it is important to take into account that excessive grinding, resulting in a particle size of <10 microns, is not always the optimal solution. If the grinding is too fine, a number of negative consequences are observed, including a deterioration in pulp filtration, an increase in the viscosity of the slurry, the formation of aggregates of fine particles, as well as a significant increase in energy consumption for grinding. These problems reduce the efficiency of the subsequent stages of the process, require longer time for dehydration of concentrates and can lead to the loss of some valuable components due to non-selective capture of particles in tailings. This is confirmed in the work [

31] (Zeng et al., 2023), where the authors emphasize the importance of finding a balance between the degree of grinding and the efficiency of flotation, noting that excessive grinding contributes to the formation of aggregates ("card houses"), increased viscosity and deterioration of filtration, which is especially critical in the design and modernization of processing plants [

31,

32,

33].

It should also be noted the significant content of precious metals (Au, Ag), which showed that their magnitudes in concentrates at 38 microns reach 1.3 g/t of gold and 416 g/t of silver, although the content of these metals in the initial sample was quite low. This is due to the fact that gold and silver are often associated with finely dispersed minerals, which makes them more vulnerable to flotation extraction in fine fractions. Thus, the obtained results and literature data emphasize that achieving maximum efficiency of flotation of copper and precious metals requires an integrated approach: particle size control, optimization of grinding time, proper selection of flotation reagents, consideration of pulp rheology and, if necessary, the introduction of innovative methods — from flotation with carriers to the use of nanotechnology. All this raises the relevance of further research on optimizing the processing of metallurgical waste and improving the economic and environmental efficiency of processes [

34].

5. Conclusions

The conducted research has shown that the granulometric composition of slags significantly affects the efficiency of extraction of non-ferrous and precious metals. The optimal particle size of about 38 microns ensures the highest efficiency of copper flotation, and reducing the size to <10 microns additionally increases extraction, but is accompanied by a deterioration in filtration and an increase in energy consumption. Noble metals (Au, Ag) are concentrated mainly in fine fractions, which makes their extraction effective at the stage of copper flotation. The data obtained make it possible to recommend the optimization of grinding modes and the selection of flotation reagents to increase the profitability of metallurgical waste processing and reduce the environmental burden.

Author Contributions

Conceptualization, S.A.; Data curation, A.N.; Formal analysis, B.B.; Investigation, M.N.; Methodology, R.B.; Validation, Sh.Zh. and G.B.; writing—original draft preparation, M.N.; Supervision, S.A.; Writing—review and editing, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan, grant BR24993178 "Development of innovative technology for processing secondary resources – waste from metallurgical industries, by-products of oil refining and oil production".

Data Availability Statement

Not applicable.

Conflict of Interest

There is no conflict of interest.

References

- Maslak, O.I.; Hryshko, N.Ye.; Hlazunova, O.O.; Maslak, M.V.; Yakovenko, Ya.Yu.; Savielova, A.D. Prospects of the recycling of metallurgical waste. IOP Conf. Series: Earth and Environ. Sc. 2024, 1415, 012128. [Google Scholar] [CrossRef]

- Bulaev, A.G.; Muravyov, M.I.; Pivovarova, T.A.; Fomchenko, N.V.; Kondrat’eva, T.F. Bioprocessing of mining and metallurgical wastes containing nonferrous and precious metals. Adv. Materials Res. 2013, 825, 301–304. [Google Scholar] [CrossRef]

- Adesina, A. Performance and sustainability overview of alkali-activated self-compacting concrete. Waste Dispos. Sustain. Energy. 2020, 2, 165–175. [Google Scholar] [CrossRef]

- Muravyov, M.I.; Bulaev, A.G.; Kondrat’eva, T.F. Complex treatment of mining and metallurgical wastes for recovery of base metals. Minerals Eng. 2014, 64, 63–66. [Google Scholar] [CrossRef]

- Ban, J.; Sun, K.; Yao, J.; Sunahara, G.; Hudson-Edwards, K.; Jordan, G.; Alakangas, L.; Ni, W.; Poon, C.S. Advances in the use of recycled non-ferrous slag as a resource for non-ferrous metal mine site remediation. Environ Res. 2022, 213, 113533. [Google Scholar] [CrossRef]

- Yang, S.J.; Zhang, L.W.; Yu, D.H. Intensive development and comprehensive utilization of metallurgical slag. Adv. Building Mater. Sustain. Architecture. 2012, 174–177, 1424–1428. [Google Scholar] [CrossRef]

- Matinde, E.; Simate, G.S.; Ndlovu, S. Mining and metallurgical wastes: a review of recycling and re-use practices J. South. Afr. Inst. Mining Metallurgy. 2018, 118, 825–844. [Google Scholar] [CrossRef]

- Fomchenko, N.; Muravyov, M. Sequential Bioleaching of Pyritic Tailings and Ferric Leaching of Nonferrous Slags as a Method for Metal Recovery from Mining and Metallurgical Wastes. Minerals. 2020, 10, 1097. [Google Scholar] [CrossRef]

- Dong, K.; Wang, H.; Jiang, Z. Case Analysis of Blast Furnace Consumption Technology and Process. In: Resource Utilization of Solid Waste by Thermometallurgy in Steel Processes. 2023. Springer, Singapore. [CrossRef]

- Pfandl, K.; Küppers, B.; Scheiber, S.; Stockinger, G.; Holzer, J.; Pomberger, R.; Antrekowitsch, H.; Vollprecht, D. X-ray fluorescence sorting of non-ferrous metal fractions from municipal solid waste incineration bottom ash processing depending on particle surface properties. Waste Manage. Res. 2019, 38, 111–121. [Google Scholar] [CrossRef]

- Zhang, T.S.; Yu, Q.J.; Wei, J.X.; Zhang, P.P.; Li, S. Effect of size fraction of ground granulated blast furnace slag on its strength contribution and hydraulic activity. Adv. Sc. Letters. 2011. 4, 1286–1291. [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Bulat, I.; Popovych, V. Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Mining Miner. Dep. 2021, 15, 122–129. [Google Scholar] [CrossRef]

- Jani, Y.; Pehme, K.; Bucinskas, A.; Kriipsalu, M.; Burlakovs1, J.; Hogland, W. Speciation of Cu, Zn and Cr in Excavated Fine Fraction of Waste at two Landfills. Iranian J. Energy Environ. 2018, 9, 86–90. [Google Scholar] [CrossRef]

- Karimov, K.; Turakhodjaev, N.; Akhmedov, A.; Tashbulatov, S. A mathematical model of the technology of extraction of copper from industrial slags. E3S Web Conf. 2021, 264, 04077. [Google Scholar] [CrossRef]

- Kölking, M.; Flamme, S.; Heinrichs, S.; Schmalbein, N.; Jacob, M. More resource efficient recycling of copper and copper alloys by using X-ray fluorescence sorting systems: An investigation on the metallic fraction of mixed foundry residues. Waste Manage. Res. 2024, 42, 814–822. [Google Scholar] [CrossRef]

- Marwa, A. Effect of Particle Size on Leachate Formation Characteristics from Gold Mine Waste Rocks: At Source Acid Mine Drainage Management in Tanzania. J. Appl. Sci. Environ. Manage. 2023, 27, 2387–2392. [Google Scholar] [CrossRef]

- Pereira, G.V.d.A.; Pereira, W.V.d.S.; Ramos, S.J.; Guimarães, J.T.F.; Covre, W.P.; Dias, Y.N.; Fernandes, A.R. Bioavailable and Bioaccessible Fractions of Potentially Toxic Elements in Copper Mining Wastes in the Southeastern Amazon. Minerals 2025, 15, 140. [Google Scholar] [CrossRef]

- Lyalyuk, V.P.; Shmel’tser, E.O.; Lyakhova, I.A.; Kassim, D.A.; Tarakanov, A.K.; Otorvin, P.I. Changes in Granulometric Composition of Blast- Furnace Coke. Coke Chem. 2013, 56, 456–460. [Google Scholar] [CrossRef]

- Liu, J.; Qin, Q.; Yu, Q. The effect of size distribution of slag particles obtained in dry granulation on blast furnace slag cement strength. Powder Technol. 2020, 362, 32–36. [Google Scholar] [CrossRef]

- Buchwald, V.F.; Wivel, H. Slag analysis as a method for the characterization and provenancing of ancient iron objects. Mater. Charact. 1998, 40, 73–96. [Google Scholar] [CrossRef]

- Li, M.; Lu, Y.; Liu, Y.; Chu, J.; Zhang, T.; Wang, W. Influence of the Steel Slag Particle Size on the Mechanical Properties and Microstructure of Concrete. Sustainability. 2024, 16. [Google Scholar] [CrossRef]

- Sajjad, M. , Otsuki, A. Correlation between Flotation and Rheology of Fine Particle Suspensions. Metals. 2022, 12, 270. [Google Scholar] [CrossRef]

- Kazemi, F., Bahrami, A., Ghorbani, Y., Danesh, A., Abdollahi, M., Falah, H., Salehi, M. The interaction and synergic effect of particle size on flotation efficiency: A comparison study of recovery by size, and by liberation between lab and industrial scale data. Rudarsko-geološko-naftni zbornik (The Mining-Geology-Petroleum Engineering Bulletin) UDC: 622-699. [CrossRef]

- Hassanzadeh, A. , Safari, M. , Hoang, D.H., Khoshdast, H., Albijanic, B., Kowalczuk, P.B. Technological assessments on recent developments in fine and coarse particle flotation systems. Minerals Eng. 2022, 180, 107509. [Google Scholar] [CrossRef]

- Hassanzadeh, A. , Safari M. , Hoang, D.H. Fine, Coarse and Fine-Coarse Particle Flotation in Mineral Processing With A Particular Focus On The Technological Assessments. Minerals. 2020, 10, https. [Google Scholar] [CrossRef]

- Wang, C. , Zhang, Q. , Mao, S., Qin S. Effects of Fine Minerals on Pulp Rheology and the Flotation of Diaspore and Pyrite Mixed Ores. Minerals. 2020, 10, 60. [Google Scholar] [CrossRef]

- Wang, L. , Li, C. A Brief Review of Pulp and Froth Rheology in Mineral Flotation. Hindawi J. Chem. 2020, 16, 3894542. [Google Scholar] [CrossRef]

- Sigauke, T. , Johnson, O.T., Ndeshimona, V.L., Mashingaidze, M.M. Advancements in nanotechnology for the enhanced flotation of fine mineral particles: a review. Discover Appl. Sci. 2025, 317. [Google Scholar] [CrossRef]

- Abd El-Rahiem, F.H. Recent Trends in Flotation of Fine Particles. J. Mining World Express, 2014, 3, https. [Google Scholar] [CrossRef]

- Bilal, M. , Park, I., Hornn, V., Ito, M., Hassan, F.U., Jeon S., Hiroyoshi, N. The Challenges and Prospects of Recovering Fine CopperSulfides from Tailings Using Different Flotation Techniques: A Review. Minerals 2022, 12, 586. [Google Scholar] [CrossRef]

- Zeng, G. , Zhu, Y. , Chen, W. A Brief Review of Micro-Particle Slurry Rheological Behavior in Grinding and Flotation for Enhancing Fine Mineral Processing Efficiency. Minerals. 2023, 13, 792. [Google Scholar] [CrossRef]

- Sokolovic, J. , Miskovic, S. The effect of particle size on coal flotation kinetics: A review. Physicochem. Probl. Miner. Process. 2018, 54, 1172. [Google Scholar] [CrossRef]

- Sygusch, J. , Wilhelm, T. , Furat, O., Bachmann, K., Schmidt V., Rudolph, M. Application of Multivariate Tromp Functions for Evaluating the Joint Impact of Particle Size, Shape and Wettability on the Separation of Ultrafine Particles via Flotation. Powders. 2024, 3, 338. [Google Scholar] [CrossRef]

- Strube, F. , Guy, B.M., Pereira, L., Ebert, D., Zgheib, A., Fischer, M., Möckel, R., Schmidt A., Rudolph, M. Batch Flotation of Lithium-Bearing Slag—A Special Focus on the Phase Properties of Engineered Artificial Minerals for Enhancing the Recycling of End-of-Life Lithium-Ion Batteries. Minerals 2025, 15, 334. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).