1. Introduction

Geothermal energy harnesses the planet’s internal heat as a renewable energy source fundamentally distinct from solar, wind, or hydropower in its ability to provide continuous, dispatchable power [

1]. Emerging deep beneath the Earth’s crust through residual heat from formation and the decay of radioactive isotopes, geothermal energy manifests in hot reservoirs that can be accessed via engineered wells and advanced extraction technologies [

2]. Geothermal wells are usually exposed to high-temperature subsurface environment, requiring high-temperature resistant seals to maintain hydraulic integrity [

3,

4].

The persistence and magnitude of Earth’s heat mean this resource is inexhaustible on human timescales, capable of consistently supporting 24/7 energy production regardless of weather or time of day [

5]. In contrast to variable renewables such as wind and solar, geothermal energy functions as a firm, baseload power source, delivering reliability and high capacity factors exceeding 75% in modern installations [

6]. Geothermal plants demonstrate a compact land footprint as most core infrastructure is concealed beneath the surface, reducing land use conflicts and enabling deployment in proximity to demand centers. The lifecycle emissions of geothermal electricity are markedly low, often below those of solar PV and several orders of magnitude beneath fossil fuel sources, which positions geothermal as a pivotal player in decarbonization strategies [

1]. Furthermore, geothermal projects tend to create more jobs per megawatt than wind or solar, and contribute to local tax revenues and royalties, fostering both economic and social co-benefits [

5].

Traditional geothermal power generation, generally referred to as conventional hydrothermal systems, relies on naturally occurring reservoirs of hot water and permeable rock, a combination found in limited tectonic or volcanic settings. This geographical constraint has historically confined geothermal utilization to specific regions such as the Ring of Fire, thereby restricting its global contribution to less than 1% of electricity production [

7,

8]. To transcend these limitations, Enhanced Geothermal Systems (EGSs) have emerged as a paradigm-shifting approach to geothermal development [

9]. EGSs are engineered geothermal reservoirs created in hot, typically dry rock that lacks sufficient natural fracturing or fluid to support commercial heat extraction. By deploying techniques such as hydraulic or chemical stimulation to increase rock permeability, and then circulating water or alternative working fluids through these deep formations, EGSs can tap into an otherwise inaccessible and vast store of geothermal energy [

10]. This innovation decouples geothermal potential from rare geological circumstances, extending its applicability to regions around the globe and unlocking an energy source with theoretical potential far exceeding today’s energy demand projections.

Despite their transformative promise, EGSs face significant operational and sustainability hurdles, with thermal breakthrough standing out as a particularly critical challenge. Thermal breakthrough refers to the premature arrival of cold injected fluid at production wells via preferential or fast flow pathways, which leads to an accelerated decline in output temperature and, consequently, a sharp reduction in the reservoir’s effective lifespan and heat recovery efficiency [

11,

12]. The phenomenon is fundamentally tied to the design and dynamics of fracture networks within the EGS reservoir, as spatial heterogeneity in permeability, fracture aperture, and well configuration can create dominant channels that shortcut heat exchange. Operational parameters, such as well spacing, injection rates, and fluid properties, further influence the timing and severity of breakthrough [

13]. The occurrence of thermal breakthrough not only jeopardizes the commercial and environmental viability of EGS projects but also complicates investment and risk profiles, thus impeding widescale adoption.

Recognizing the urgency of this issue, the scientific and engineering community has proposed and evaluated a spectrum of mitigation techniques. These encompass flow management strategies to optimize fluid pathways and delay thermal drawdown [

11], advanced reservoir stimulation methods to enhance permeability distribution and minimize preferential chanelling [

13], operational protocols such as intermittent thermal extraction to enable reservoir recharge [

14], the adoption of alternative working fluids like supercritical CO₂ to exploit their improved thermal properties [

13], and the deliberate management of fracture conductivity to limit fast pathways [

15,

16]. Nevertheless, the ability to reliably predict and mitigate thermal breakthrough remains constrained by the complex interplay of geological heterogeneity, coupled thermo-hydro-mechanical-chemical processes, and limited field-scale experimental validation [

12,

13,

17].

A critical gap in the current literature is the lack of comprehensive, multidisciplinary reviews that systematically synthesize these diverse mitigation strategies, their interdependencies, and their performance under varying geological and operational conditions. Most existing studies focus on modeling single mitigation aspects or rely on simplified assumptions of reservoir behavior, thereby limiting their prescriptive value for practical EGS deployments. Furthermore, experimental studies and long-term monitoring of fracture network behavior under cyclic thermal stresses remain scant, introducing further uncertainty into predictive models and management protocols [

13]. Research into non-water working fluids such as CO₂, while promising for efficiency and carbon sequestration co-benefits, has yet to see widespread field demonstration or operational optimization.

The objective and novelty of this review paper lie in providing a holistic and integrative synthesis of thermal breakthrough mitigation in EGSs, organized around five key technological and operational domains: flow management techniques, reservoir stimulation techniques, intermittent thermal extraction, using CO₂ as working fluid, and managing fracture conductivity. By elucidating fundamental principles and critically evaluating recent advances and limitations across these domains, this paper uniquely consolidates the state-of-the-art while identifying promising directions for future research and innovation. By providing a critical and thoroughly referenced synthesis, this review intends to serve as a foundational resource for researchers, engineers, and decision-makers striving to enhance the durability, efficiency, and scalability of EGS technology through effective mitigation of thermal breakthrough.

2. Brief Introduction to Enhanced Geothermal Systems and Thermal Breakthrough

EGSs refer to artificially engineered subterranean reservoirs designed to capture and exploit thermal energy from deep rock formations that possess sufficient temperatures but lack the natural permeability or fluid content necessary for conventional geothermal energy extraction [

8]. In EGS development, permeability is intentionally created or increased—typically through stimulation techniques such as hydraulic fracturing—to form pathways for fluid circulation in otherwise impermeable or minimally permeable hot dry rocks, thereby transforming the subsurface environment into a productive thermal reservoir for sustainable energy utilization [

8]. Unlike conventional hydrothermal resources, which rely on existing fractures and natural fluid presence, EGSs enable geothermal energy access in regions previously deemed unsuitable for geothermal exploitation [

17].

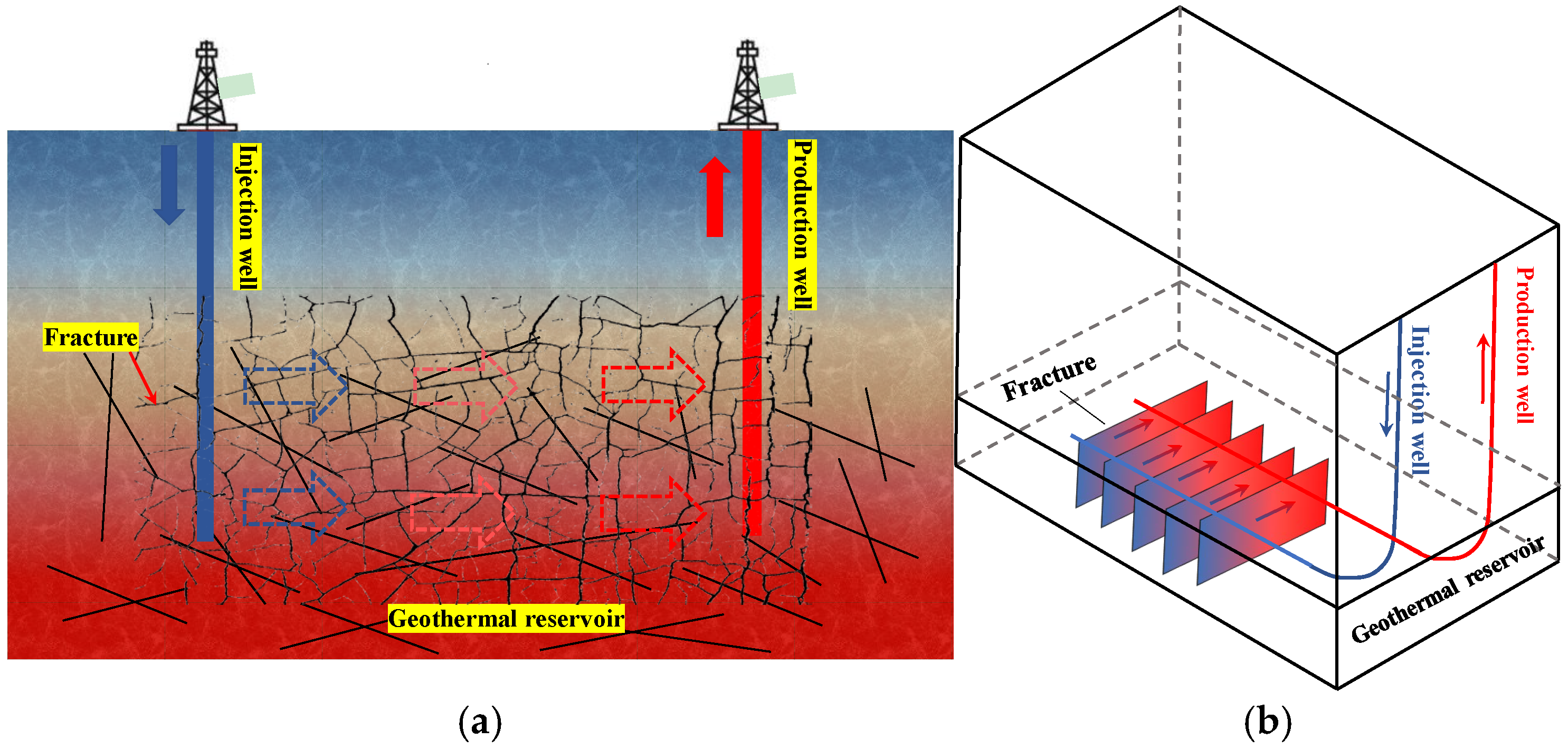

EGSs are broadly categorized based on the orientation and configuration of the wells constructed within the geothermal reservoir. The first category is the vertical well-based EGS, characterized by drilling injection and production wells in a vertical orientation that penetrates the target hot rock zones at great depths, as seen in

Figure 1a. In these systems, stimulation efforts focus on generating or enlarging fractures between the vertical injection and production wells to facilitate efficient fluid flow and heat transfer between distinct vertical boreholes. Although this approach has driven the development of EGS since the 1970s, vertical well systems can be hindered by limited fracture network surface area and suboptimal connectivity, which may result in reduced flow rates and rapid declines in extracted fluid temperatures. The second prominent category encompasses EGSs presented in

Figure 1b that are constructed using horizontal wells, leveraging advances from the oil and gas sector in horizontal drilling and multi-stage fracturing [

18]. Here, horizontal or deviated wells are drilled laterally within the geothermal formation, often intersecting multiple fracture planes or branches along the well path to maximize contact with hot rock and stimulated fracture networks. This configuration enables a larger heat exchange surface area, improved connectivity between injection and production segments, and more effective reservoir sweeping, collectively enhancing heat recovery and operational longevity compared to vertical well systems [

18].

Thermal breakthrough in the context of EGS describes the event in which the temperature of the produced fluid drops sharply because injected cooler fluid reaches the production well earlier than anticipated, resulting in a significant decrease in the temperature differential between the injection and production wells [

19]. The phenomenon occurs when the injected fluid travels along preferential and often unintended higher-permeability pathways, bypassing much of the intervening rock, thereby short-circuiting the intended heat exchange process [

20]. Operationally, thermal breakthrough is detected as a noticeable and sustained reduction in the production well’s temperature, signaling that substantial reservoir cooling has occurred, compromising the efficiency of geothermal heat extraction in that sector. Mitigating thermal breakthrough in EGS operations is crucial for maintaining the technical, economic, and environmental viability of geothermal energy production. Early or uncontrolled breakthrough limits the amount of recoverable heat by rapidly cooling local rock volumes, reducing the duration and magnitude of usable energy output and impeding the project’s economic sustainability [

13]. Without active management, premature breakthrough can also lead to greater operational costs by necessitating additional stimulation and drilling interventions to restore or relocate heat-extraction capacity in depleted zones. Research has shown that optimizing well spacing, controlling injection rates, increasing fracture network complexity, and employing advanced reservoir management techniques can delay or prevent thermal breakthrough, thereby prolonging reservoir lifespan and improving heat recovery efficiency [

15].

3. Thermal Breakthrough Mitigation Techniques

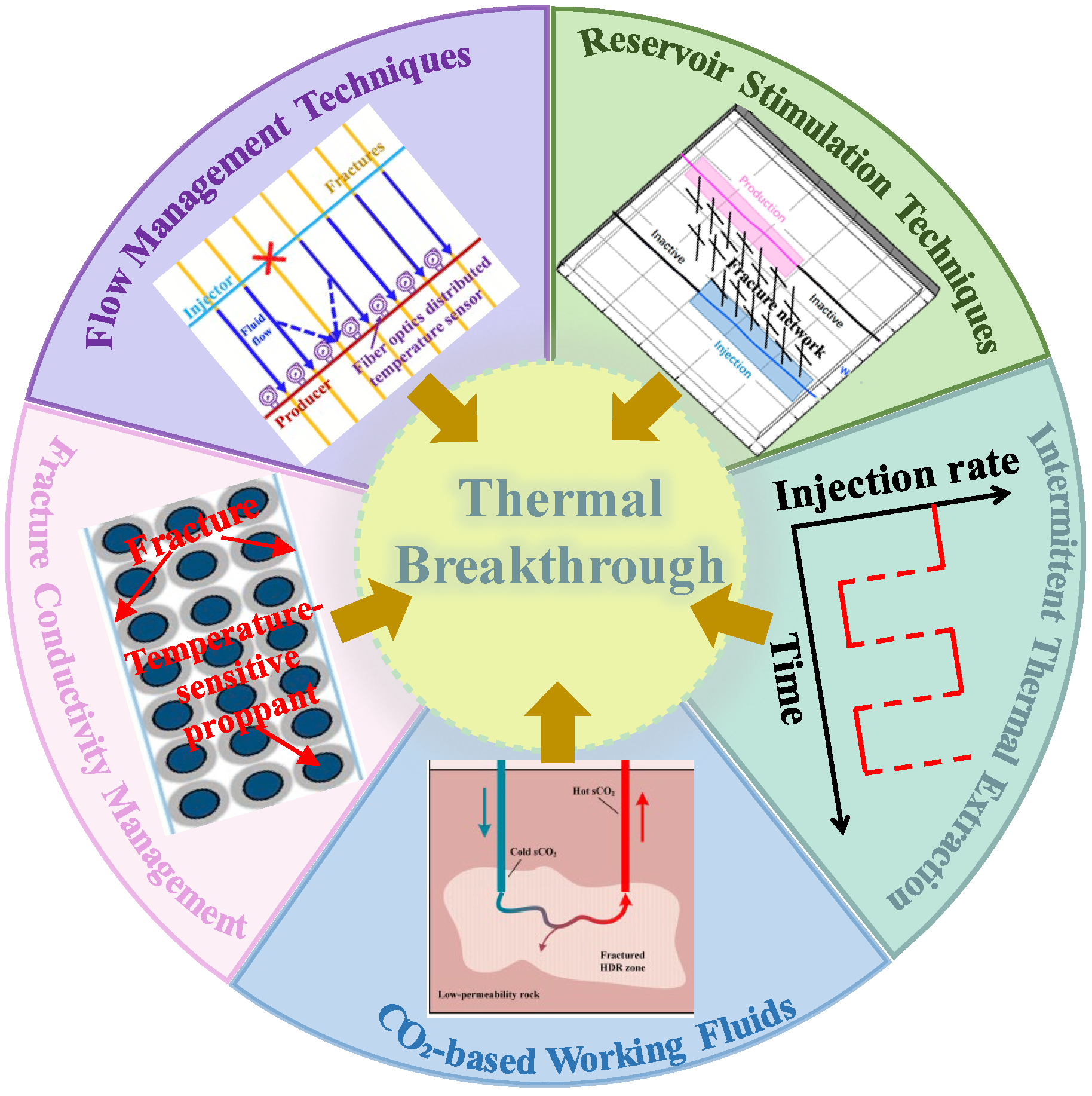

In the past years, various techniques have been proposed to delay or prevent thermal breakthrough from different perspectives. Among them, the following five latest techniques have been extensively investigated: flow management techniques, reservoir stimulation techniques, intermittent thermal extraction, using CO₂ as working fluid, and managing fracture conductivity. In this section, regarding their principles, latest key progress, and limitations, these techniques are critically assessed in a holistic and integrative way, as illustrated in

Figure 2.

3.1. Flow Management Techniques

Flow management is a critical aspect of EGS operations, focusing on optimizing the distribution of injected fluid within the reservoir to maximize heat extraction and delay thermal breakthrough. The primary goal of flow management is to prevent or minimize the formation of preferential flow paths or “short circuits,” where the injected fluid bypasses significant portions of the hot rock and reaches the production well prematurely. Two major flow management strategies have been developed in the past, including adjusting injection and production rates, and implementing real-time monitoring and control systems.

One of the primary strategies for mitigating thermal breakthrough involves carefully managing injection and production rates. This approach involves carefully controlling the volume and speed at which fluid is injected into the reservoir and extracted from it, aiming to maximize heat recovery while preventing premature cooling of the production wells [

21]. The underlying principle is to manage fluid flow paths and residence time within the fractured rock mass, ensuring efficient heat exchange and preventing short-circuiting of colder injected water directly to the production well [

22,

23]. Reducing the injection temperature can also be beneficial for fully extracting heat energy from the rock mass [

24]. Fluid injection and production rates adjustments can be based on numerical models that analyze the impact of various parameters, including formation properties, wellbore characteristics, and injected fluid properties, on heat transfer efficiency [

18]. These adjustments can significantly impact the thermal performance of an EGS. Reducing the injection rate can increase the residence time of the injected fluid within the hot reservoir rock, allowing for more efficient heat absorption. This is particularly effective in systems where the fracture network is not fully interconnected, and slower flow rates encourage the fluid to permeate a larger volume of the rock mass [

10]. Conversely, increasing the production rate, while potentially leading to higher initial heat extraction, can also accelerate thermal breakthrough if not carefully managed [

25]. A balanced approach involves dynamically adjusting both injection and production rates based on real-time temperature monitoring and reservoir modeling. This allows operators to adapt to changing reservoir conditions, mitigate thermal drawdown, and prolong the lifespan of the EGS. Multistage stimulation can enhance well flow performance, delay thermal breakthrough, and ultimately improve heat production. In this case, the optimal injection and production rates for maximizing heat production may be impacted by the well spacing and stimulation scenario. As suggested by the thermal breakthrough calculation of Li et al. [

26], when well spacing is limited and the number of stages is low, operating at a reduced fluid circulation rate is preferable to help postpone thermal breakthrough; however, with larger well spacing and a greater number of stages, thermal breakthrough occurs later, making it advantageous to circulate fluid at the maximum allowable flow rate (

Figure 3). Research also suggests that different stages of production require adjustments in the injection water temperature to adapt to reservoir changes and optimize production [

10]. The numerical study by Zhang et al. [

27] indicated that when injected fluid temperature was increased, not only was production temperature raised but also EGS longevity was elongated.

While adjusting injection and production rates offers significant benefits, it also presents certain disadvantages. One major concern is the potential for induced seismicity due to changes in pore pressure within the reservoir. Altering flow rates can destabilize existing faults and fractures, increasing the risk of minor to moderate earthquakes [

28]. Another disadvantage is the potential for thermal stress-induced damage to the reservoir rock. Rapid changes in temperature caused by fluctuating flow rates can lead to thermal fracturing and reduced permeability over time [

29]. Furthermore, the optimization of flow rates requires sophisticated reservoir modeling and monitoring, adding to the operational complexity and cost of EGS projects.

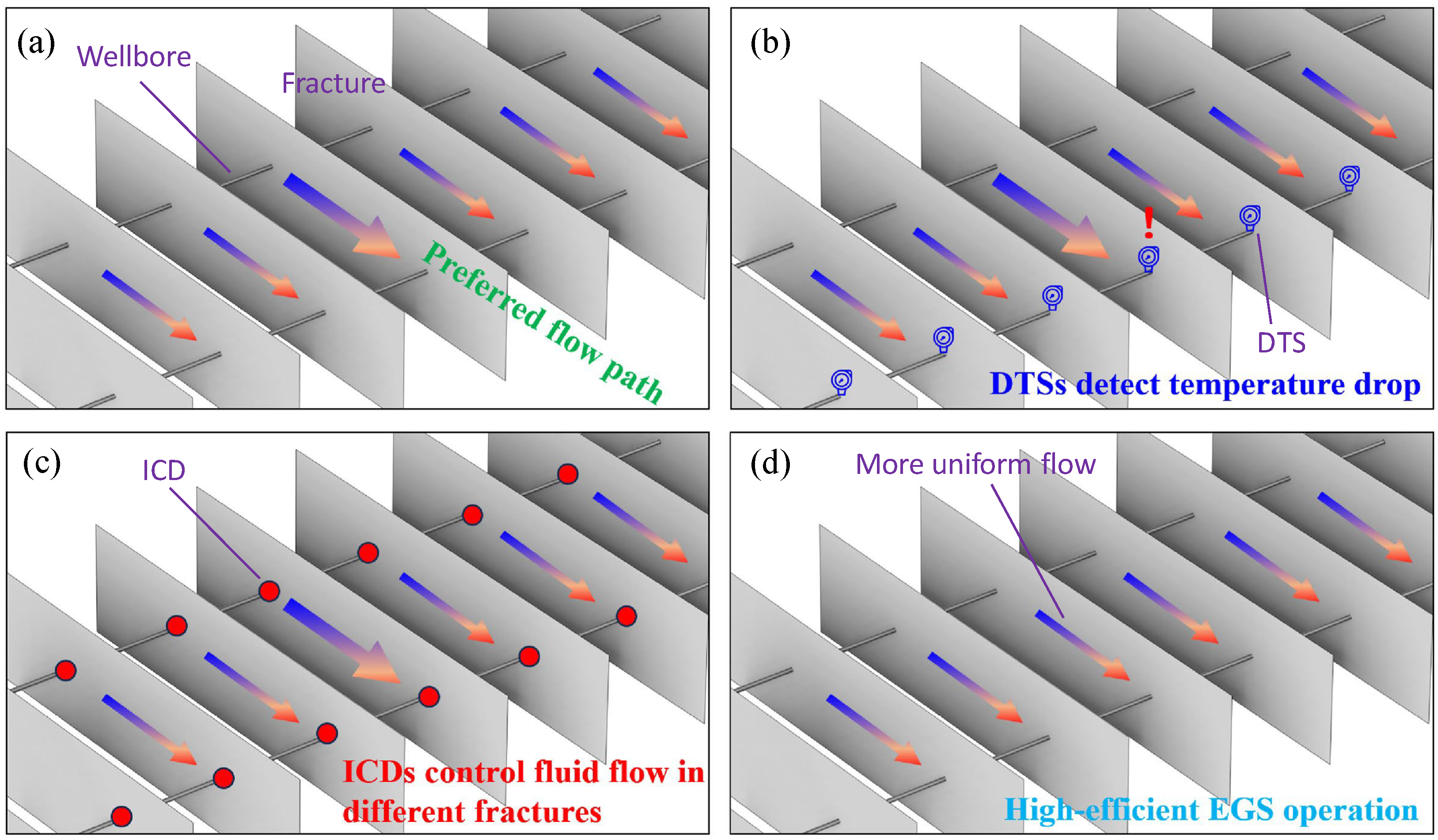

Real-time temperature monitoring and flow control systems offer a more dynamic approach to flow management. These systems utilize a network of sensors to continuously monitor temperature and pressure conditions within the reservoir. The data collected is then used to adjust injection and production rates in real-time, optimizing fluid flow and heat extraction, as illustrated in

Figure 4 [

30]. This approach allows for a more adaptive response to changing reservoir conditions, such as the development of preferential flow paths or the onset of thermal breakthrough.

Numerous studies have explored the integration of real-time temperature monitoring and flow control systems in EGSs to address challenges such as thermal breakthrough and suboptimal heat extraction efficiency. These approaches rely on strategically placed sensors that continuously record temperature and pressure within the subsurface, providing operators with immediate insight into reservoir behavior. The resulting data enable dynamic adjustments to injection and production parameters, which seek to distribute fluid more evenly across available fracture networks, thereby minimizing the risk of rapid cooling along dominant flow paths—a frequent cause of early thermal breakthrough. For instance, field-scale simulations by Zhang and Taleghani [

31] utilizing downhole temperature sensors combined with adjustable flow control devices have shown promising results, with up to a 60 K increase in production temperature and an above-48% rise in total heat extracted over long-term operation. Multi-stage fluid control, an operational protocol derived from such studies, is particularly emphasized for sustaining improved heat sweep over decades and preventing the counterproductive reopening of previously isolated injection zones [

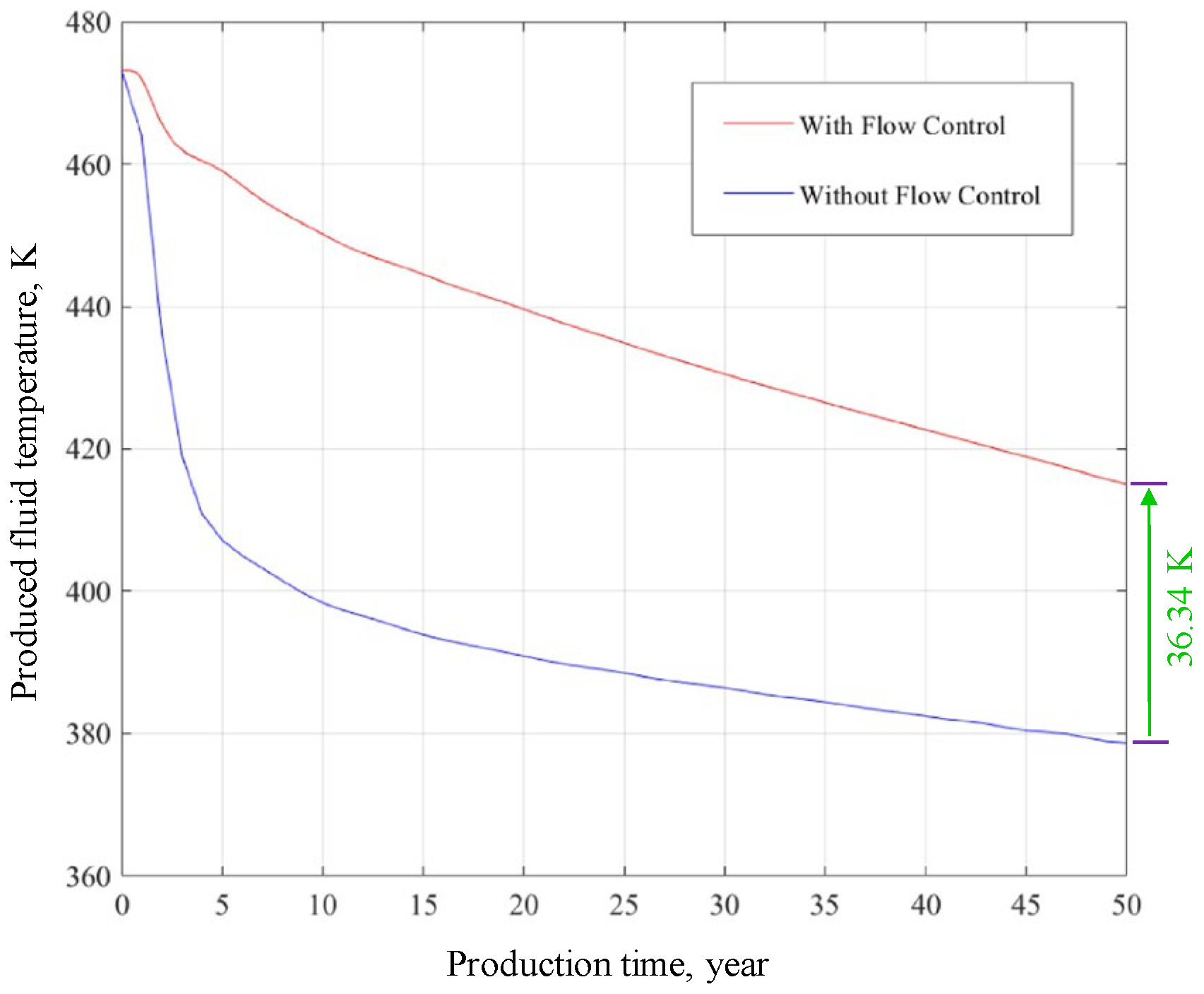

31]. Moreover, research into self-regulating flow control methods reveals that promoting circulation through hotter, lower-permeability fractures can further optimize energy recovery, raising output temperatures by over 36 K and boosting heat extraction efficiency by 60% across multiple decades, as shown in

Figure 5 [

30]. Other advancements, including distributed fiber-optic sensors and acoustic monitoring technologies, improve the spatial resolution of data, enabling rapid detection and mitigation of flow imbalances or instabilities [

32]. Machine learning has also emerged as a supportive tool, enhancing predictive modeling and facilitating more precise control algorithms [

33].

Despite their potential, these strategies are accompanied by practical limitations. Deployment of sensor networks and flow control devices in EGS reservoirs is technically challenging, often constrained by extreme temperatures, high pressures, and corrosive chemistries that limit equipment lifespan and reliability [

34]. The complexity of installation and maintenance, paired with high capital and operational costs, remains a significant barrier to widespread adoption. Furthermore, incomplete reservoir characterization and limited spatial coverage of monitoring sensor arrays can result in inadequate or misleading data, undermining real-time adjustments and diminishing overall system efficacy [

35]. The need for sophisticated operational expertise and comprehensive system integration further accentuates cost and operational hurdles. In cases of highly channelized flow or irregular fracture patterns, solely relying on flow control may be insufficient without additional reservoir stimulation techniques. In summary, while real-time monitoring and control systems for EGSs represent a substantive advancement for enhancing system longevity and efficiency, practical disadvantages in durability, deployment logistics, economic viability, and data robustness underscore the necessity for further research and innovation in this domain.

3.2. Reservoir Stimulation Techniques

EGSs represent a promising renewable energy technology that harnesses thermal energy stored in deep rock formations. A critical challenge in EGS development is the inherently low permeability of deep rocks, which necessitates enhancement through various stimulation methods [

36]. Reservoir stimulation techniques encompass hydraulic, chemical, and thermal approaches, with hydraulic stimulation being the most commonly employed technique. These stimulation operations are essential as they create pathways for fluid circulation, thereby enabling efficient heat extraction from otherwise inaccessible geothermal resources. The primary objective of these techniques is to increase both reservoir permeability and the specific area for heat exchange, which directly impacts the system’s heat extraction efficiency and its ability to mitigate thermal breakthrough.

Hydraulic stimulation involves injecting large amounts of fluid into the target reservoir through perforations of a wellbore [

37,

38,

39]. High-pressure fluid injection can induce the formation of new tensile fractures and, when natural fractures exist, can also trigger their opening or shear displacement. These mechanisms contribute to a substantial permeability enhancement, primarily through the widening of tensile fractures and shear dilation of pre-existing ones. Additionally, the process may generate fractures that extend toward and link with more distant natural fractures, greatly improving the reservoir’s hydraulic connectivity. An important outcome of this fracturing activity is the expansion of the fracture surface area, which plays a vital role in enlarging the heat exchange interface and boosting the efficiency of thermal energy extraction from the surrounding rock matrix. Hydraulic stimulation combines both hydraulic fracturing and hydroshearing mechanisms, a perspective now widely accepted in the EGS community. This combined approach has been demonstrated to be effective in enhancing reservoir performance, as confirmed by experiences from the Soultz EGS project [

29]. The process of improving permeability through hydraulic stimulation directly addresses thermal breakthrough challenges by creating a more extensive and better-connected fracture network, which allows for more uniform heat extraction across a larger rock volume.

Chemical stimulation involves injecting acidic fluids into the formation while maintaining pressure below the reservoir breakdown threshold [

40]. Permeability enhancement through this method is achieved via mineral precipitation, transport, and dissolution processes. This technique has been widely adopted for enhanced hydrocarbon recovery and has been successfully applied in various EGS projects, including those at Groß Schönebeck, Desert Peak, and Soultz. Chemical stimulation refers specifically to a reservoir permeability enhancement method that introduces chemical stimulants into fractured geothermal reservoirs to improve their performance [

41]. By dissolving minerals blocking fluid pathways, chemical stimulation can create more extensive and interconnected flow channels, which contribute to delaying thermal breakthrough by promoting more uniform fluid distribution and heat exchange throughout the reservoir [

42]. This process allows for better heat transfer between the circulating fluid and the hot rock, thereby maintaining higher production temperatures over extended operational periods [

43].

Thermal stimulation typically involves injecting cold water into the reservoir for several weeks. The large temperature contrast between the injected cold fluid and the hot reservoir rock generates thermal stresses that can deform existing natural fractures and potentially initiate the formation of new fractures within the reservoir. This method effectively utilizes thermal shock to enhance flow performance in tight porous media [

44]. The resultant thermal stresses alter the mechanical properties of the rock, promoting increased fluid mobility and creating additional pathways for heat exchange [

45]. Thermal stimulation plays a vital role in mitigating thermal breakthrough by promoting a more uniform temperature distribution within the reservoir [

46]. By strategically inducing thermal fracturing, this technique creates a network of fluid pathways that allows for more effective heat absorption from the surrounding rock [

47].

Heat extraction in EGS primarily depends on the flow characteristics through fractures and the heat exchange efficiency between circulating fluid and surrounding rocks. Water flow in EGSs is mainly controlled by fractures rather than the rock matrix, making the fracture network crucial for thermal performance. A critical challenge in EGS operation is the formation of channelized preferential flow paths due to variable permeability and heterogeneous aperture distribution in fractures. The development of preferential flow channels can result in a premature drop in production temperature, as a larger share of the circulating fluid is diverted through these high-permeability pathways, limiting interaction with the surrounding rock for heat exchange. The specific surface area of fractures, defined as the heat exchange interface per unit volume of reservoir, plays a critical role in determining thermal transfer efficiency. From a heat transfer standpoint, the rate of energy exchange is directly linked to this surface area, with higher values enabling more effective heat extraction. Therefore, creating more fractures with smaller hydraulic apertures may be more beneficial for EGS than fewer fractures with larger apertures. This approach maximizes the heat exchange area while maintaining the required permeability enhancement.

Numerous studies have investigated the effectiveness of stimulation techniques in enhancing EGS performance. Findings from the Soultz EGS project revealed that permeability improvements were significantly influenced by a combination of newly formed hydraulic fractures and the shear activation of existing natural fractures [

29]. Insights gained from the Fenton Hill EGS experiments in the United States indicated that hydraulic stimulation led to both the opening and shearing of certain natural fractures, as evidenced by the analysis of microseismic activity. Recent studies have advanced the understanding of hydraulic stimulation through multi-stage fracturing approaches. This technique involves isolating sections along horizontal boreholes using packers and injecting fluid into these sections concurrently or following a specific order. This creates several fractures along a wellbore, stimulating a greater rock volume and increasing permeability (

Figure 6a). Such an approach would increase flow rates per well and potentially double the ultimate recovery of energy by extracting heat from a larger volume of rock [

48]. Multi-stage fracturing with careful attention to stress interference (“shadow effect”) ensures that fractures are distributed more evenly in the reservoir, leveraging complex fracture geometry to maximize the heat sweep volume and postpone cold-water advancement. The analysis by Jia et al. [

29] showed that for the same permeability enhancement, scenarios with more fractures of smaller apertures deliver significantly better thermal performance than those dominated by fewer, wider fractures, as shown in

Figure 6b. Cyclic Soft Stimulation (CSS) is an emerging approach that integrates repeated fluid injection cycles with a traffic light system (TLS) designed to monitor and manage induced seismicity in real time. This method aims to enhance reservoir permeability while mitigating fluid injection-induced seismicity. Laboratory studies have demonstrated that cyclic hydraulic fracturing lowers the breakdown pressure by approximately 20% relative to traditional hydraulic stimulation methods, while also promoting the formation of more intricate and branched fracture networks [

29]. Besides, past chemical stimulation studies demonstrated significant benefits for geothermal reservoirs [

49]. Chemical stimulation is often used as an auxiliary method in EGS engineering, with chemical stimulants divided into acid stimulants and other types. Novel approaches using chelating agents have also been proposed as alternatives to traditional acidic solutions, potentially offering less environmental impact [

50]. Regarding the performance of chemical stimulation, the findings by Luo et al. [

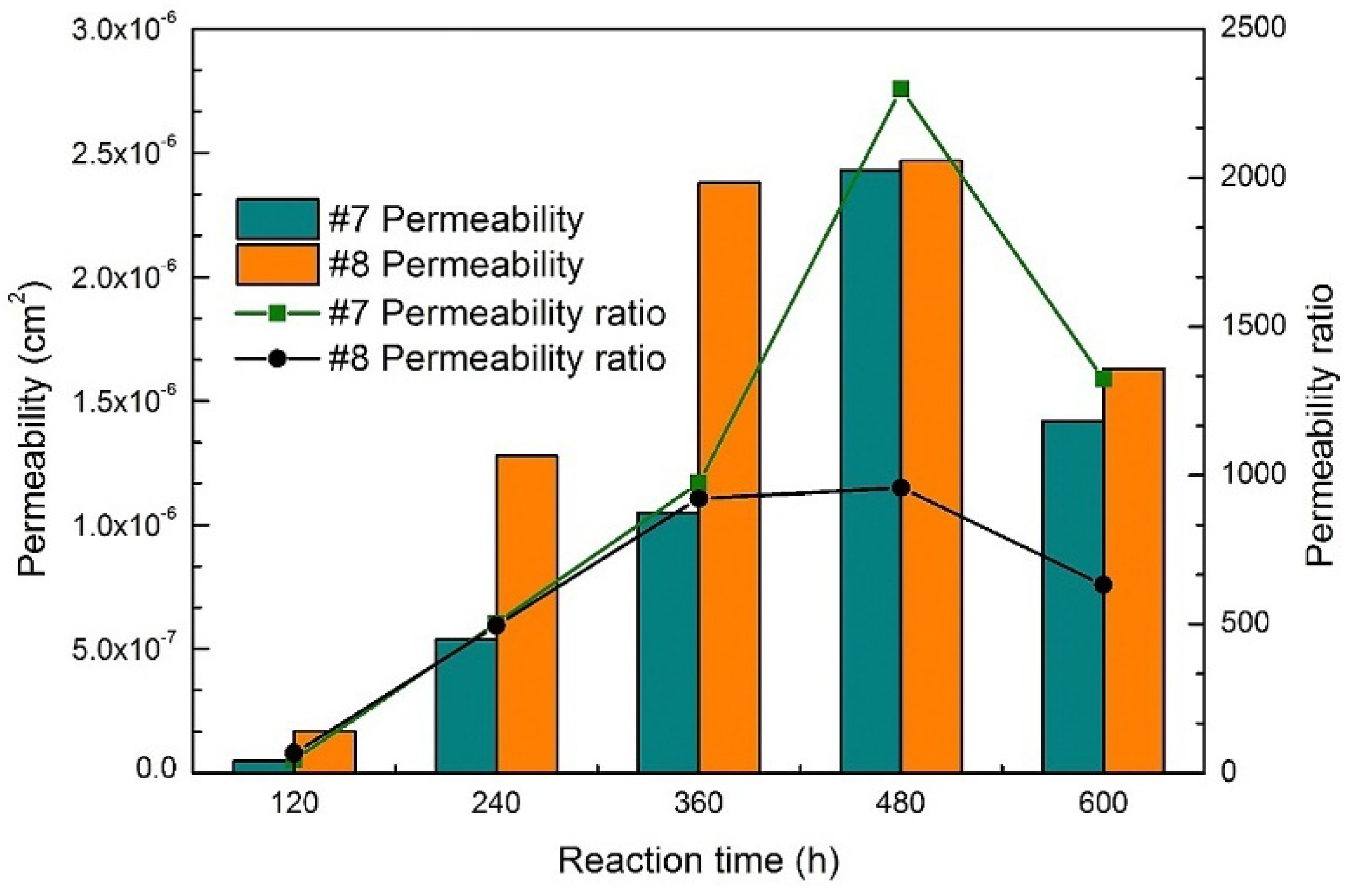

42] suggested that variation in hydraulic permeability is closely linked to chemical processes, as shown in

Figure 7; hence, the reaction duration must be carefully optimized to ensure the effective implementation of chemical stimulation in hot dry rock reservoirs.

Although stimulation methods offer notable advantages, they also come with significant challenges and constraints. One major concern is the potential for injection-induced seismicity associated with hydraulic stimulation, which can occur both during and following fluid injection. While the majority of seismic events linked to EGS projects typically register below magnitude 3.0, there have been instances where larger, damaging earthquakes have been recorded [

29]. Notable examples include earthquakes at the Basel geothermal site in Switzerland (maximal magnitude Mw 3.4) and the Pohang geothermal field in South Korea (magnitude Mw 5.5), both of which led to project suspensions [

51]. Chemical stimulation raises environmental concerns related to the potential contamination of groundwater and ecological impacts. The effectiveness of chemical treatments may also be limited by the depth of penetration, with reactions often occurring predominantly near the wellbore [

52]. Additionally, controlling reaction kinetics presents challenges, requiring careful timing and control of the injection process. Thermal stimulation requires precise management of temperature and pressure to prevent irreversible damage to the reservoir rock. Thermal breakthrough remains a main challenge for maintaining efficient heat extraction throughout an EGS project’s lifespan. Improper thermal management can lead to rapid cooling of the reservoir, reducing overall energy output and economic viability.

The effectiveness of reservoir stimulation techniques in enhancing EGS performance depends on careful design and implementation strategies. A thorough geological assessment of the natural fracture network and adjacent fault zones is essential prior to the development of an EGS. Additionally, the strategic design of well configurations for injection and production, alongside effective fluid injection protocols, are crucial for ensuring the successful deployment of EGS technology. Additional studies on the coupled thermo-hydro-mechanical-chemical interactions occurring during and after fluid injection in EGSs are essential, with a specific focus on gaining deeper insights into the mechanisms underlying induced seismicity. As EGS technology advances, optimizing stimulation techniques while minimizing environmental impacts and seismic risks will be crucial for the widespread adoption of this promising renewable energy source.

3.3. Intermittent Thermal Extraction

Intermittent thermal extraction (ITE) is another method that addresses thermal breakthrough challenges encountered during continuous thermal extraction. The core mechanism that enables ITE to mitigate thermal breakthrough lies in its operational cycling, which alternates periods of active heat extraction with shut-in or resting phases. During active extraction, the fluid draws heat from the reservoir, and without adequate intervention, this can lead to locally cooled “short-circuit” zones around the production wells where the temperature drops precipitously [

53]. By implementing scheduled pauses in the extraction process, ITE allows these cooled regions to recover thermally as heat from adjacent rock conducts into the depleted zones, thereby counteracting the establishment of persistent low-temperature channels and restoring near-wellbore temperatures [

54]. The cycling strategy of ITE, where extraction is periodically shut down for thermal soak periods, enables a more uniform redistribution of the thermal front and delays the advance of cold plumes toward the production wells [

55]. This process has been shown to compensate for localized cooling effects, destabilize short-circuit pathways, and maintain a more stable thermal gradient, collectively minimizing the decline of output temperature over time. Consequently, subsequent production cycles yield higher output temperatures and more sustainable heat extraction.

A substantive body of research underpins ITE’s efficacy in EGS. To mitigate channeling flow in EGSs, Chen and Liang [

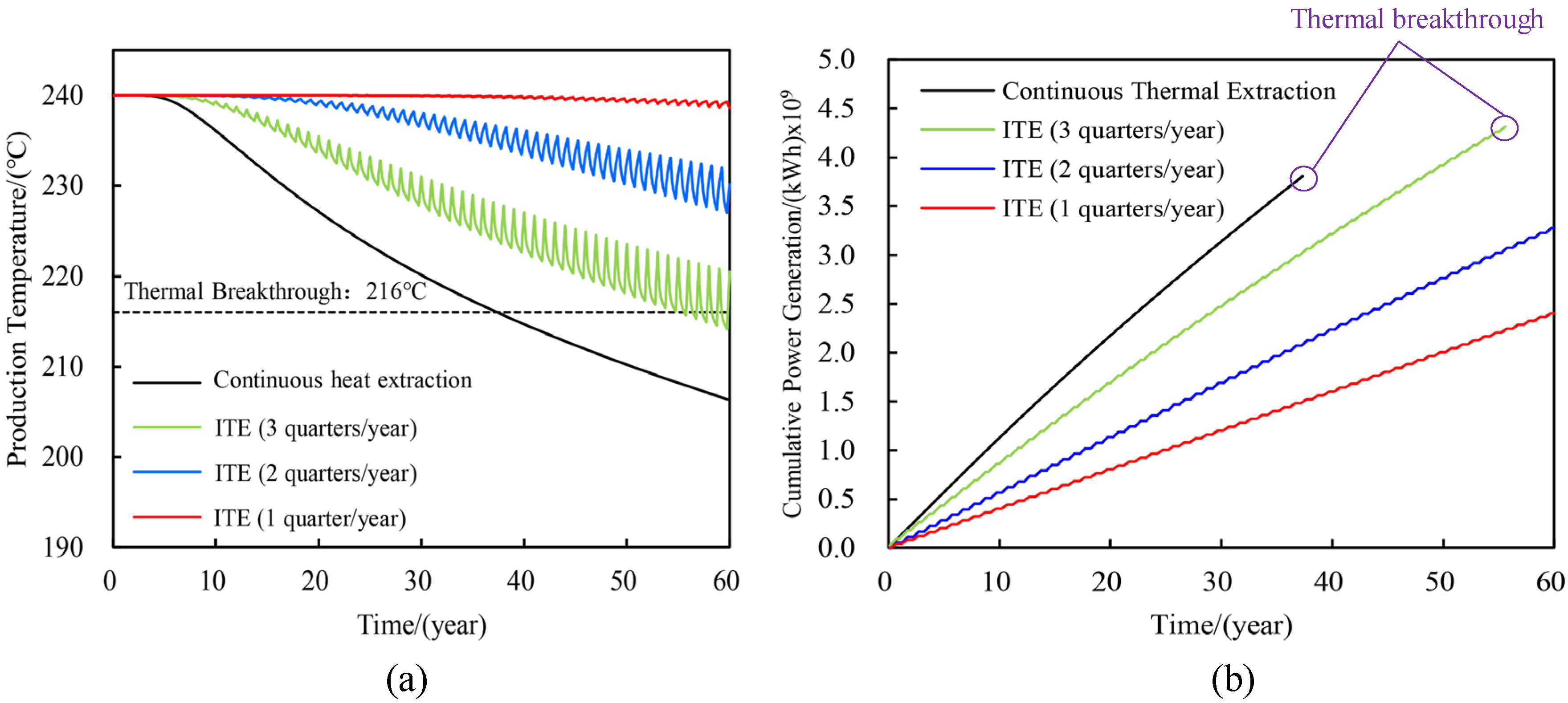

56] developed and tested unstable alternation operation (UAO) techniques, which generate unsteady water flooding by periodically switching water injection among multiple wells; their result indicated that the UAO techniques alleviated flow short-circuiting and increased heat exchange area by promoting uniform fluid flow across the entire fracture, thus leading to higher thermal output than continuous heat production. Also, numerical simulation studies, such as those that model dual-vertical or horizontal well configurations, demonstrated that intermittent extraction could extend thermal field longevity and improve cumulative heat production by over 13% compared to continuous operation, as shown in

Figure 8 [

14]. To achieve an economical thermal production scenario for abandoned well patterns, Xu et al. [

57] built an oil-water coupled model with intermittent operation considered and evaluated the efficiency of synergic oil-heat extraction, from which it was found that well spacing and production periods impacted heat production the most, and that the lifespan of intermittent operation is much longer than continuous operation. Zuo and Weijermars [

58] designed and explored the performance of a production plan alternating 8-h fluid circulation with 16-h shut-in within a day for an EGS, which showed that this production plan can maintain a quasi-steady state of production temperature that is not achievable for a continuous operation scheme. Past research revealed that optimizing the timing and duration of shut-in intervals amplifies thermal recharge and delays the onset of cold water or “thermal” breakthrough [

59,

60]. These findings are corroborated by studies that specifically analyze fracture-dominated reservoirs, where the inherent heterogeneity can cause uneven thermal depletion; ITE helps regulate temperature fields and maximizes the utilization of available thermal energy [

61,

62]. Additionally, advanced modeling incorporating thermal-hydraulic-mechanical coupling reveals that the periodic cessation of flow has potential to reduce adverse geomechanical impacts, supporting greater reservoir stability and performance [

45,

63].

Despite the significant advantages offered by ITE in managing thermal breakthrough and improving thermal recovery, the method entails several notable drawbacks and operational challenges. The foremost limitation is the reduced average instantaneous heat supply due to cycling-induced downtime; each rest period is non-productive, which may compromise the continuous delivery required for some heat or electricity demand profiles [

64]. This necessitates either the integration of energy storage technologies or hybrid systems, both of which can increase system complexity and capital costs. The cyclic thermal and pressure loads associated with ITE impose additional mechanical and thermal stresses on wells and reservoir rocks, raising the risk of geomechanical instability or infrastructure fatigue, especially in heterogeneous subsurface settings [

56]. The start-stop nature of ITE also presents practical challenges for plant operation and maintenance, requiring sophisticated control algorithms and enhanced monitoring to ensure optimal cycling schedules and to respond adaptively to subsurface feedback. Also, the effectiveness of ITE is context-dependent because improper cycle timing or reservoir mischaracterization may result in suboptimal recharge or even exacerbate cold plume migration if not carefully managed. While ITE mitigates near-wellbore cooling, it does not necessarily guarantee a dramatic extension of total system life in every geological context, especially where fracture connectivity dominates over conductive recharge dynamics. Finally, operational complexity, increased monitoring requirements, and potential economic trade-offs represent additional barriers to widespread adoption.

In summary, ITE represents a nuanced and effective approach for managing the heat recovery challenges presented by EGS, particularly concerning thermal breakthrough and reservoir sustainability. Substantial evidence has demonstrated ITE’s ability to redistribute reservoir heat, delay cold fluid intrusion, and enhance cumulative heat extraction over time. However, practical limitations, including operational interruptions, geomechanical and economic considerations, and site-specific dependencies, require thorough assessment and tailored system design before broad implementation.

3.4. CO2-Based EGSs

Injecting carbon dioxide (CO

2) as a working fluid into EGSs offers a scientifically compelling solution to address the persistent problem of thermal breakthrough. The advantage lies in the unique thermodynamic and transport properties exhibited by CO

2 compared to conventional fluids like water [

65]. Most notably, CO

2’s relatively low viscosity and enhanced thermal expansivity facilitate greater mobility and higher flow velocities in the reservoir, which improves the sweep of the rock matrix and fosters a more comprehensive heat exchange within fracture networks [

66]. Furthermore, when CO

2 is injected into the reservoir under supercritical or near-critical conditions, it experiences significant buoyancy due to density differences between the cooler injected and the warmer produced phases [

67]. This density contrast sets up a natural convection mechanism or “thermosiphon effect,” supporting more extended and uniform flow circulation for the working fluid and reducing the early breakthrough of cold front at the production well [

68]. Consequently, CO

2 molecule paths are less direct than those of water, leading to a delayed migration of the thermal front and, in turn, a more stable temperature at the production well for a longer duration [

69]. These thermophysical advantages are augmented by CO

2’s relatively minimal interaction with reservoir minerals at moderate temperatures, which lessens scaling and maintains fracture aperture [

70].

A substantial body of simulation and experimental research supports CO

2’s effectiveness in mitigating thermal breakthrough and enhancing heat recovery in EGS. Pruess [

69], among the earliest to numerically evaluate this strategy, demonstrated that CO

2 achieves higher mass flow and net heat extraction rates than water under identical operational conditions due to its favorable thermodynamic characteristics. Findings from a numerical simulation study by Pruess [

71] showed that CO

2 delays the arrival of the thermal breakthrough front, resulting in nearly constant heat output for over two decades before a gradual decline begins. A similar conclusion was echoed by Masuoka et al. [

72], whose reservoir-scale simulations revealed that CO

2-based systems both sustain higher fluid velocities and suppress the acceleration of temperature decline in continuous extraction scenarios. Experimental validation by Li et al. [

73] provided further nuance, as laboratory injection of supercritical CO

2 into fractured granite indicated that efficient heat transfer could be maintained with appropriate management of fracture permeability, and the impairment effects of mineralization could be combated through operational adjustments such as proppant usage. Starczewska et al. [

74] performed a life cycle assessment comparing water and supercritical CO

2 cycles, confirming that sCO

2-based systems achieve higher energy conversion efficiency, especially when operating at lower temperature differentials; CO

2-EGS not only improves heat recovery but also reduces overall greenhouse gas emissions by integrating geothermal extraction with CO

2 sequestration. Okoroafor et al. [

75] directly compared thermal performance with CO

2 and water as working fluids, concluding that CO

2 enhances heat production longevity and slows temperature depletion at the production well. Moreover, advanced coupled thermo-hydro-mechanical-chemical analyses by Li et al. [

73] has demonstrated that CO

2-water-rock interactions can be managed to balance mineralization for storage while maintaining permeability, further bolstering EGS sustainability. In field studies, results from the historic Ogachi project in Japan provided early but valuable real-world data on flow and borehole performance in a CO

2-using pilot EGS [

76]. The heat production performance of a CO

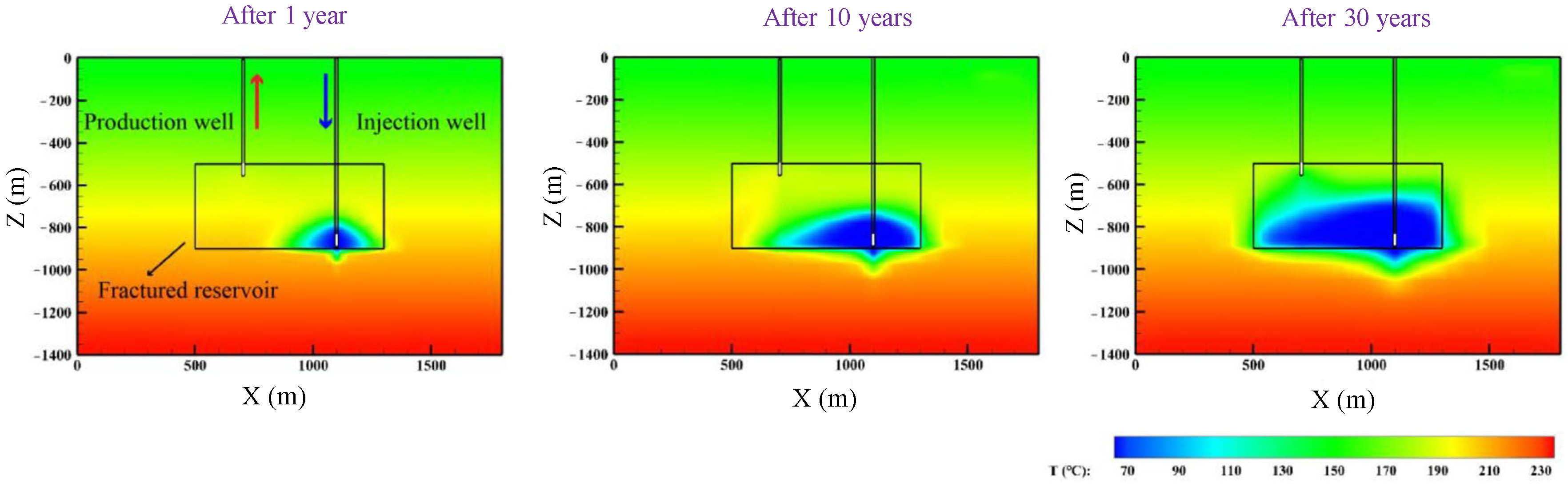

2-EGS is also impacted by well placement. For example, a dual-vertical well configuration with a vertical offset displayed in

Figure 9 has proven advantageous for geothermal systems utilizing CO₂ as the working fluid; this arrangement extends the flow path of the injected cold CO₂, allowing more time for effective heat transfer and contributing to a significant delay in thermal breakthrough [

67].

Despite CO

2’s benefits, several disadvantages accompany its use as a geothermal working fluid. The most significant technical challenge is the strong Joule-Thomson effect experienced by CO

2, which causes noticeable cooling during its depressurization in the production well; this can lead to lower wellhead temperatures and reduce the effective thermal energy available for power generation, potentially offsetting some of the inherent heat extraction efficiency gains [

77]. A second drawback is CO

2’s corrosivity, which requires upgraded materials and infrastructure to prevent well and surface facility degradation, thereby increasing capital and operational expenditures [

67]. Additional concerns originate from CO

2’s high mobility, which, if not carefully managed, can actually accelerate channeling and enable earlier than expected breakthrough if the reservoir configuration or injection parameters are suboptimal [

78]. Mineral trapping and chemical reactions with host rock can, over multiple thermal cycles, reduce fracture and matrix permeability, incrementally diminishing the system’s ability to sustain high heat extraction rates if not properly balanced through operational strategies [

73]. Finally, risks of CO

2 leakage, both through wellbores and fractures, present environmental and safety considerations that must be addressed to retain the climate benefits of co-sequestration. The limited number of long-term, large-scale commercial CO

2-EGS projects means that current conclusions are anchored primarily in laboratory, pilot-scale, and modeling studies; thus, significant technical and regulatory challenges remain before broad commercial implementation can be realized [

74].

3.5. Managing Fracture Conductivity

Actively managing fracture conductivity, a strategy that seeks to control and optimize the flow distribution within induced or natural fracture networks, has been shown to be an effective means to suppress this short-circuiting, thereby preserving higher production temperatures and sustaining heat extraction rates over extended operational periods [

15]. The essential aim of fracture conductivity management is to engineer the distribution of hydraulic conductivity in fractures so that fluid moves more uniformly through the hot reservoir formations rather than bypassing large portions of the reservoir via highly conductive, cold-dominated channels [

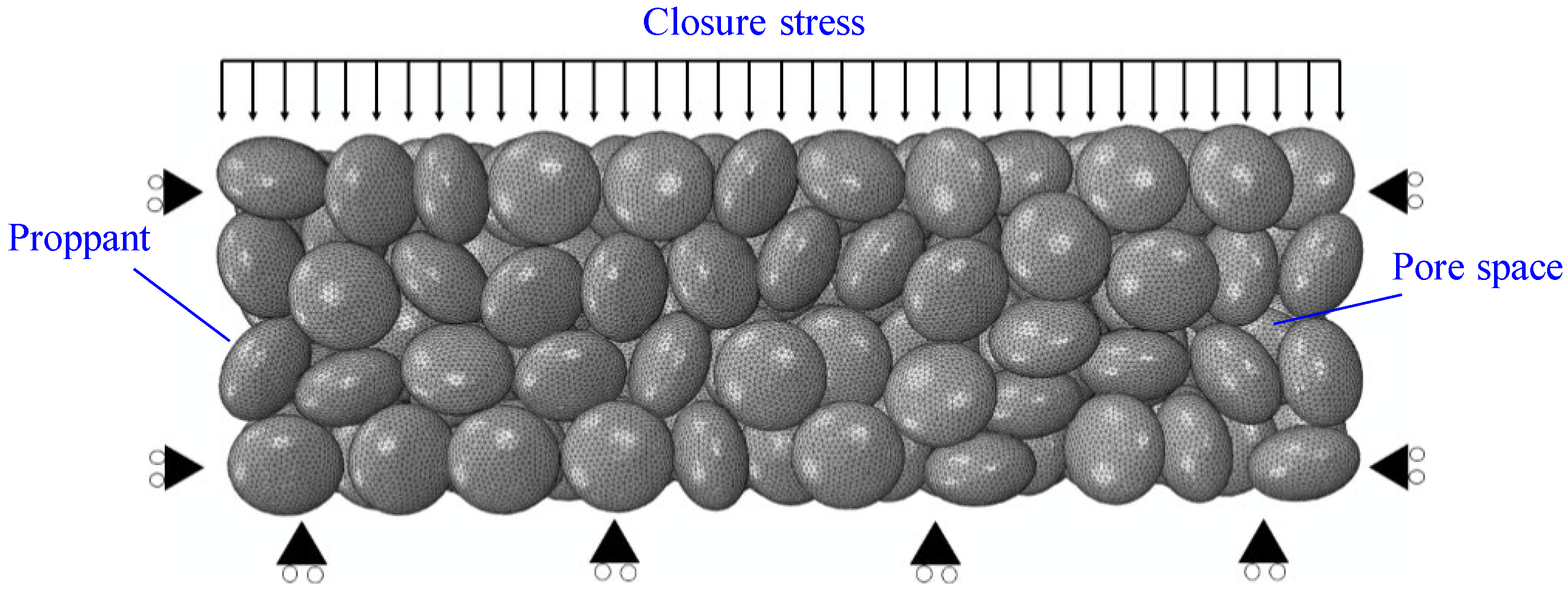

16]. By dynamically tuning fracture conductivity, for instance by increasing resistance in cooler, depleted zones and maintaining higher conductivity in as yet unexploited, high-temperature regions, the method extends the contact time between circulating fluid and hot rock. This adjustment can be realized through the use of temperature-sensitive proppants or materials with variable hydraulic responses, which autonomously modify fracture apertures in response to local thermal conditions [

15]. Advanced techniques such as the Fracture Conductivity Tuning Technique (FCTT) exploit materials that either shrink or expand with changing temperatures, effectively narrowing highly cooled, fast-flow conduits while sustaining or enhancing flow in hotter pathways [

16]. Simulation and modeling studies have confirmed that more uniform flow distribution achieved through such adaptive systems substantially increases the total available heat extraction and significantly postpones the onset of thermal breakthrough [

16]. These approaches thereby maximize the exploitation of heat stored in the reservoir and reduce the risk of local thermal depletion that would otherwise shorten the productive lifespan of the EGS facility.

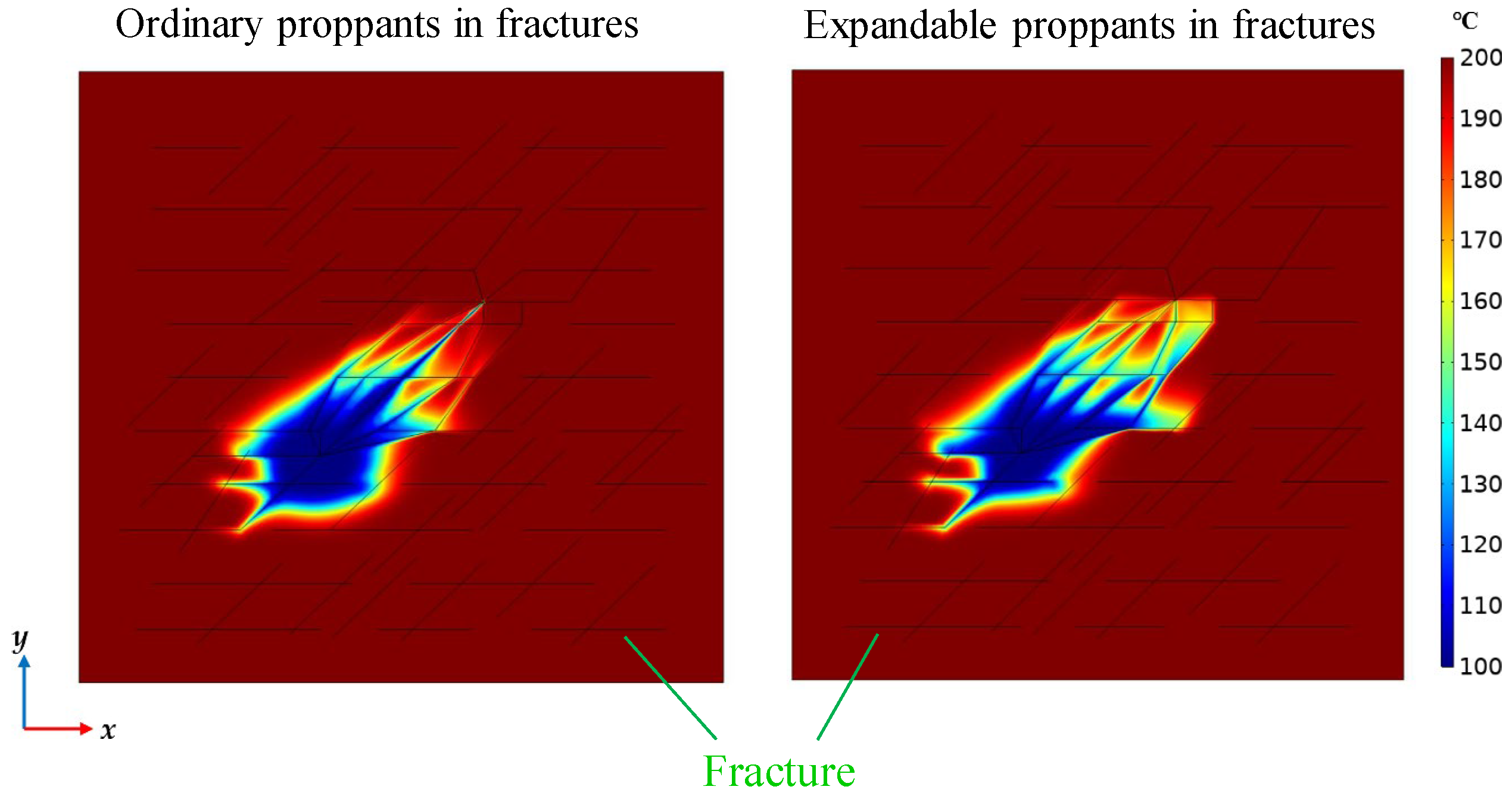

A breadth of research validates the efficacy of fracture conductivity management in EGS. Studies across modeling, laboratory, and field domains consistently highlight substantial improvements in heat extraction and operational resilience when fracture conductivity is managed with advanced techniques. For example, Zhang et al. [

16] demonstrated that tuning fracture conductivity via FCTT led to more than a 214% improvement in cumulative heat extraction over a 50-year period, relative to conventional operations. Similarly, field-scale simulations leveraging temperature-responsive proppants modeled in

Figure 10, conducted by Al Balushi et al. [

15], revealed an approximate 31% increase in extracted heat; the principle behind this increase is that expandable proppants led to more uniform fluid flow and temperature distribution among fractures by using adaptive fracture conductivity adjustment to eliminate any short-circuit flow path, as shown in

Figure 11. These gains are attributed not simply to increased initial productivity, but to the sustained and balanced utilization of the full geothermal reservoir volume. Further evidence arises from research exploring extreme channelization in real-world fracture systems; these works found that optimized well placement and orientation, combined with fracture conductivity management, could mitigate the detrimental effects of dominant flow channels, thereby preserving production temperatures and enhancing the net thermal recovery available from the resource [

11]. Laboratory experiments and coupled thermal-hydrological-mechanical-chemical models indicate that by controlling conductivity, EGS operators may both prevent unwanted channel formation and accommodate changes in fracture properties resulting from geochemical and thermal processes over time [

79,

80].

Despite the advantages, several challenges and potential drawbacks are associated with fracture conductivity management in EGS. Precisely controlling fracture conductivity across complex and heterogeneous subsurface networks is technically demanding given that fracture geometry, size, orientation, and the evolving nature of rocks under geothermal conditions are difficult to predict and manipulate [

11,

81]. Some systems may experience unexpected propagation of large fractures or dominant pathways that ultimately foster rapid channel formation and renewed short-circuiting, particularly when fracture apertures become excessively large or poorly distributed [

82]. Additional operational concerns include the possible degradation or failure of temperature-sensitive proppants over the long service life typical of EGS projects, as well as the risk of proppant embedment or chemical alteration reducing their effectiveness [

83]. Unintended side-effects from chemical interaction with reservoir fluids may result in either local precipitation or dissolution that complicates fracture permeability control. Moreover, efforts to manage conductivity may contribute to induced microseismicity or increased stress on the reservoir, which, if not closely monitored, introduce further operational risks [

84]. The complexity and cost associated with designing and deploying sophisticated fracture conductivity management systems, especially in deep and high-temperature contexts, also remain considerable barriers to universal adoption. Finally, while modeling studies provide compelling theoretical justification, additional field-scale empirical data is needed to ensure long-term reliability and optimize these approaches for widespread deployment.

To summarize, appropriately managing fracture conductivity within EGS reservoirs stands as a critical innovation for delaying thermal breakthrough, thereby extending high-efficiency heat extraction and unlocking the full potential of geothermal resources. Future research and operational advances regarding this should focus on improving in-situ monitoring, enhancing the durability and responsiveness of conductivity-modifying materials, and refining reservoir characterization to enable more effective and resilient geothermal energy production.

4. Future Research Directions

While considerable progress has been made in developing techniques to mitigate thermal breakthrough in EGSs, challenges still remain, and further research is needed to improve the efficiency, sustainability, and economic viability of EGSs. Emerging strategies for mitigating thermal breakthrough and enhancing heat extraction in EGSs are increasingly multidisciplinary, leveraging innovations in subsurface diagnostics, fluid engineering, and nanotechnology. Among these, three particularly promising avenues—reactive tracers, temperature-sensitive viscosity fluids, and nanofluids—present substantial opportunities for future breakthroughs in EGS performance optimization.

A leading research direction lies in the deployment of reactive tracers, which respond predictably to reservoir temperature or chemical conditions, as diagnostic and management tools in EGSs. Unlike conventional conservative tracers, reactive tracers offer the ability to detect incipient thermal fronts well before the arrival of significant thermal breakthrough at production wells, enabling early intervention and adaptive management of reservoir operations [

85,

86]. Recent studies have demonstrated that combining inert and reactive tracers yields high-resolution mapping of advective heat transfer processes and heat transfer surface area between wells in fracture-dominated rock environments [

85,

87]. Computational techniques integrated with tracer data can reconstruct reservoir geometry and forecast effective thermal lifetimes, supporting proactive operational adjustments designed to maximize heat extraction and delay breakthrough [

87]. The future of this approach involves refining tracer chemistries and kinetic models to increase their sensitivity and selectivity to thermal and geochemical transitions characteristic of evolving geothermal systems [

88]. Further, field-scale tracer tests, coupled to mechanistic numerical simulations, will be pivotal for validating predictive models of fracture connectivity and fluid pathways under operational EGS conditions.

Another emerging method for mitigating thermal breakthrough is the use of working fluids that possess strong temperature-sensitive viscosity characteristics. These advanced fluids are engineered to increase viscosity at lower temperatures, commonly present in cold, fast flow paths, while maintaining lower viscosity in hotter, under-swept regions of the reservoir [

19,

89]. This behavior enables redirection of injected fluids away from thermally depleted zones towards hotter rock, promoting a more uniform thermal sweep and reducing early cooling of production wells. Research teams have reported significant advances with temperature-sensitive proppants and swelling particles, including shape memory polymers that expand in cooler fractures, dynamically restricting fluid flow in short circuit pathways and prolonging thermal exchange [

90]. Computational and scaled laboratory studies suggest these materials and fluids can be tuned to specific reservoir conditions to offer reversible, site-selective moderation of flow paths [

90]. Going forward, research priorities include optimizing the thermo-rheological properties for geothermal temperatures (150—275°C and above), ensuring chemical compatibility with reservoir minerals, and verifying the long-term mechanical and transport stability of these materials under cyclic thermal loading [

90]. Moreover, the coupling of temperature-responsive fluids with adaptive reservoir management protocols and real-time analytics remains an open field, offering the possibility of robust, feedback-controlled heat extraction that dynamically responds to subsurface changes.

The adoption of nanofluids, fluids containing dispersed nanoparticles engineered for superior heat transfer, constitutes a compelling research trend in thermal breakthrough mitigation and heat recovery optimization for EGSs [

91,

92]. Nanofluids are known for significantly higher thermal conductivity relative to conventional fluids due to mechanisms such as Brownian motion, interfacial layering, and particle clustering, which facilitate rapid and uniform heat transfer throughout highly fractured reservoirs [

91,

93]. Of particular interest are shear-thickening nanofluids, which increase in viscosity under high shear conditions characteristic of fast-flowing fractures, thus enabling concurrent enhancement in heat transfer and mitigation of preferential flow short-circuiting. Despite encouraging laboratory-scale outcomes, such as up to 23% increased heat extraction versus base fluids, challenges remain in optimizing nanoparticle type, concentration, and base fluid compatibility for high-temperature geothermal applications [

93]. Future investigations must systematically examine the stability, rheological performance, and environmental impact of nanofluids under the extreme pressure, temperature, and chemical gradients found in EGS environments. Advanced modeling and field-scale testing will be crucial to validating the efficacy of these fluids in operational settings.

The convergence of these technologies, reactive tracer-based diagnostics, temperature-sensitive viscosity fluids, and nanofluid engineering, suggests that hybrid strategies may ultimately yield the most robust mitigation of thermal breakthrough in EGSs. Integrative research that harnesses real-time tracer data to modulate the deployment of adaptive fluids, possibly in concert with dynamic proppant placement and nanofluid-based heat exchangers, represents a fertile direction for future studies. Systematic cross-disciplinary investigation, involving geoscience, reservoir engineering, materials science, and nanotechnology, will be essential to design, implement, and monitor these advanced solutions at commercial scale.

In summary, the promising research directions described, reactive tracers for high-resolution reservoir mapping, working fluids with temperature-responsive viscosity, and nanofluids for both rheological control and heat transfer enhancement, each address key mechanisms underlying early thermal breakthrough and inefficient heat recovery in EGSs. Successful real-world implementation will rest on continued experimental validation, model refinement, and integrated field demonstration, ultimately enabling more resilient, productive, and sustainable geothermal energy extraction.

5. Conclusions

In this paper, a comprehensive review is presented of various techniques aimed at mitigating thermal breakthrough and improve heat production of EGSs, spanning from fluid flow management to reservoir stimulation, intermittent thermal extraction, use of CO2 as working fluid, and fracture conductivity management. Each strategy offers unique advantages and limitations, highlighting the complexity of managing heat extraction in heterogeneous subsurface environments. Critical findings achieved are the following:

Although adjusting fluid circulation rates and implementing real-time monitoring can significantly enhance thermal output from EGSs, these strategies also introduce challenges such as a heightened risk of induced seismicity, increased operational complexity, and higher costs. Multi-stage fracturing offers a means to generate well-distributed fractures throughout the reservoir, promoting the development of complex fracture networks that expand the thermal sweep area and delay the arrival of cold water. Chemical stimulation, which enhances flow paths by dissolving minerals along fluid routes, can improve reservoir connectivity and postpone thermal breakthrough, though it requires careful management of potential environmental impacts. Additionally, intermittent heat extraction, alternating between active production and shut-in periods, allows for thermal recovery of the surrounding rock, thereby helping to sustain outlet temperatures over extended periods.

CO2’s unique thermophysical characteristics enhance reservoir coverage and promote more effective heat exchange throughout fracture networks, contributing to improved thermal energy recovery. However, its inherent corrosive nature necessitates the use of corrosion-resistant materials and advanced infrastructure to protect wells and surface systems, thereby raising both initial investment and ongoing operational costs. Meanwhile, temperature-responsive proppants offer the potential to extend long-term heat production in EGS by dynamically regulating fluid flow through fractures, which helps delay thermal breakthrough. Despite this promise, challenges such as subsurface heterogeneity and the potential degradation or failure of the proppants pose significant barriers to the practical and economic implementation of this technology.

An integrated approach that leverages a suite of complementary technologies is essential to optimizing heat extraction and enhance the overall feasibility of EGSs. Emerging avenues of research include the use of reactive tracers for precise reservoir characterization, the development of smart working fluids whose viscosity adapts to temperature changes, and the application of nanofluids to improve both flow behavior and thermal conductivity. These innovations target critical challenges such as premature thermal breakthrough and suboptimal heat recovery. By highlighting these developments, this review serves as a valuable resource for scientists, engineers, and policymakers committed to driving forward the evolution of EGS toward a reliable and sustainable energy solution.

References

- Geothermal Basics | Department of Energy. (2022). https://www.energy.gov/eere/geothermal/geothermal-basics.

- Liu, S., Al Balushi, F., & Taleghani, A. D. (2023). Heat extraction through conductive proppants. Sustainable Energy Technologies and Assessments, 60, 103514.

- Liu, S., Taleghani, A. D., & Tabatabaei, M. (2024). Graphite reinforced polymers for sealing geothermal wells. Composites Part B: Engineering, 270, 111121. [CrossRef]

- Liu, S., Taleghani, A. D., & Tabatabaei, M. (2024). Surface-modified graphite based polymer nanocomposites for high-temperature geothermal applications. Polymer Composites, 45(16), 14715-14730. [CrossRef]

- Jones, B., Pedersen, A., Richardson, J. (Oct 17, 2023). All the Advantages of Geothermal. https://geothermal.org/our-impact/blog/all-advantages-geothermal.

- Betanabhatla, V. (2024). Beyond levelized cost: What’s the true value of geothermal energy? https://www.slb.com/resource-library/insights-articles/beyond-lcoe-what’s-the-true-value-of-geothermal-energy.

- Seligman, A. (March 24, 2025). An introduction to the next clean energy frontier: Superhot rock and the future of geothermal. https://www.catf.us/2025/03/introduction-next-clean-energy-frontier-superhot-rock-future-geothermal/.

- Horne, R., Genter, A., McClure, M., Ellsworth, W., Norbeck, J., & Schill, E. (2025). Enhanced geothermal systems for clean firm energy generation. Nature Reviews Clean Technology, 1-13. [CrossRef]

- Sharmin, T., Khan, N. R., Akram, M. S., & Ehsan, M. M. (2023). A state-of-the-art review on geothermal energy extraction, utilization, and improvement strategies: conventional, hybridized, and enhanced geothermal systems. International Journal of Thermofluids, 18, 100323. [CrossRef]

- Wang, L., Liang, X., Shi, X., Han, J., Chen, Y., & Zhang, W. (2023). Heat Transfer Analysis of Enhanced Geothermal System Based on Heat-Fluid-Structure Coupling Model. Geofluids, 2023(1), 8840352. [CrossRef]

- Rangel-Jurado, N., Hawkins, A. J., & Fulton, P. M. (2023). Influence of extreme fracture flow channels on the thermal performance of open-loop geothermal systems at commercial scale. Geothermal Energy, 11(1), 19. [CrossRef]

- Frash, L. P., Carey, J. W., Ahmmed, B., Sweeney, M., Meng, M., Li, W., ... & Iyare, U. (2023). A proposal for safe and profitable enhanced geothermal systems in hot dry rock. In 48th Workshop on Geothermal Reservoir Engineering, Stanford University.

- Li, D., Li, N., Jia, J., Yu, H., Fan, Q., Wang, L., & Mohsen, A. (2024). Development status and research recommendations for thermal extraction technology in deep hot dry rock reservoirs. Deep Underground Science and Engineering, 3(3), 317-325. [CrossRef]

- Liu, Z., Wu, M., Zhou, H., Chen, L., & Wang, X. (2024). Performance evaluation of enhanced geothermal systems with intermittent thermal extraction for sustainable energy production. Journal of Cleaner Production, 434, 139954. [CrossRef]

- Al Balushi, F., Zhang, Q., & Dahi Taleghani, A. (2023). Autonomous fracture conductivity using expandable proppants in enhanced geothermal systems. SPE Journal, 28(05), 2660-2674. [CrossRef]

- Zhang, Q., Taleghani, A. D., & Li, G. (2024). Fracture conductivity management to improve heat extraction in enhanced geothermal systems. International Journal of Heat and Mass Transfer, 218, 124725. [CrossRef]

- Liu, J., Shao, C., Yang, B., Ngata, M. R., Mwangomba, M., Josephat, S., & Aminu, M. D. (2024). Advances in enhanced geothermal systems: Integrating laboratory, numerical and field insights. Applied Thermal Engineering, 249, 123350. [CrossRef]

- Wang, H., Tie, Y., Liu, H., Zhang, L., Wu, H., Xiong, X., ... & Hu, L. (2025). Numerical investigations on the performance analysis of multiple fracturing horizontal wells in enhanced geothermal system. Geothermal Energy, 13(1), 12. [CrossRef]

- Shi, H., Wang, G., & Lu, C. (2023). Numerical investigation on delaying thermal breakthrough by regulating reinjection fluid path in multi-aquifer geothermal system. Applied Thermal Engineering, 221, 119692. [CrossRef]

- Williams, C. F. (2010, February). Thermal energy recovery from enhanced geothermal systems—evaluating the potential from deep, high-temperature resources. In Proceedings, thirty-fifth workshop on geothermal reservoir engineering. Stanford University, Stanford, California.

- Dehdouh, A., Mellal, I., Bettir, N., Abdelhamid, C., Allam, L., Rasouli, V., & Gyimah, E. (2024, June). Key Design Parameters for Enhanced Geothermal System (EGS). In ARMA US Rock Mechanics/Geomechanics Symposium (p. D022S021R012). ARMA.

- Huang, Y., Zhang, Y., Hu, Z., Lei, H., Wang, C., & Ma, J. (2019). Economic analysis of heating for an enhanced geothermal system based on a simplified model in Yitong Basin, China. Energy Science & Engineering, 7(6), 2658-2674. [CrossRef]

- Zinsalo, J. M., Lamarche, L., & Raymond, J. (2020). Injection strategies in an enhanced geothermal system based on discrete fractures model. Applied Thermal Engineering, 169, 114812. [CrossRef]

- Zhang, L., Hu, Z., Ma, Y., Ding, H., Li, Q., & Song, Y. (2024). Study on optimization of thermal injection parameters in fractured reservoirs of HDR. Geosystem Engineering, 1-12. [CrossRef]

- McLean, M. L., & Espinoza, D. N. (2023). Thermal destressing: Implications for short-circuiting in enhanced geothermal systems. Renewable Energy, 202, 736-755. [CrossRef]

- Li, T., Shiozawa, S., & McClure, M. W. (2016). Thermal breakthrough calculations to optimize design of a multiple-stage Enhanced Geothermal System. Geothermics, 64, 455-465. [CrossRef]

- Zhang, J., Zhao, M., Wang, G., & Ma, P. (2022). Evaluation of heat extraction performance of multi-well injection enhanced geothermal system. Applied Thermal Engineering, 201, 117808. [CrossRef]

- Mukuhira, Y., Yang, M., Ishibashi, T., Okamoto, K., Moriya, H., Kumano, Y., ... & Zuo, Y. (2023). Scaling microseismic cloud shape during hydraulic stimulation using in situ stress and permeability. Journal of Geophysical Research: Solid Earth, 128(8), e2023JB026839. [CrossRef]

- Jia, Y., Tsang, C. F., Hammar, A., & Niemi, A. (2022). Hydraulic stimulation strategies in enhanced geothermal systems (EGS): a review. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 8(6), 211. [CrossRef]

- Zhang, Q., & Taleghani, A. D. (2025). Real-time temperature monitoring and flow control for improved heat extraction in enhanced geothermal systems. Energy, 314, 134274. [CrossRef]

- Zhang, Q., & Taleghani, A. D. (2024). Downhole flow control: A key for developing enhanced geothermal systems in horizontal wells. Renewable Energy, 237, 121578. [CrossRef]

- Khankishiyev, O., Salehi, S., Hasanov, G., & Hu, Z. (2024). Application of Distributed Temperature Sensing (DTS) in Geothermal Wells. In PROCEEDINGS, 49th Workshop on Geothermal Reservoir Engineering (Vol. 49).

- Al-Fakih, A., Abdulraheem, A., & Kaka, S. (2024). Application of machine learning and deep learning in geothermal resource development: Trends and perspectives. Deep Underground Science and Engineering, 3(3), 286-301. [CrossRef]

- Curkan, B., DePencier, J., & Klaczek, W. (2019). An Introduction to Flow Control Devices and the Potential Benefits to Geothermal Applications. GRC Transactions, 43.

- Prauzek, M., Kucova, T., Konecny, J., Adamikova, M., Gaiova, K., Mikus, M., ... & Koziorek, J. (2023). Iot sensor challenges for geothermal energy installations monitoring: a survey. Sensors, 23(12), 5577. [CrossRef]

- Zhang, Y., Zhang, Y., Zhou, L., Lei, Z., Guo, L., & Zhou, J. (2022). Reservoir stimulation design and evaluation of heat exploitation of a two-horizontal-well enhanced geothermal system (EGS) in the Zhacang geothermal field, Northwest China. Renewable Energy, 183, 330-350. [CrossRef]

- Liu, S., Zhang, Z., & Huang, Z. (2021). Three-Dimensional hydraulic fracture simulation with hydromechanical coupled-element partition method. International Journal of Geomechanics, 21(9), 04021162. [CrossRef]

- Liu, S., Liu, Z., & Zhang, Z. (2022). Numerical study on hydraulic fracture-cavity interaction in fractured-vuggy carbonate reservoir. Journal of Petroleum Science and Engineering, 213, 110426. [CrossRef]

- Yang, Y., Shao, Z., Wu, K., & Wang, Y. (2024). A plastic Stillinger-Weber potential-based discretized virtual internal bond approach for modeling soft rock fracture and its application in tunnel failure. Engineering Fracture Mechanics, 301, 110056. [CrossRef]

- Zhu, T., Wei, X., & Zhang, Z. (2023). Numerical simulation of hydraulic-mechanical-chemical field coupled acid fracturing in complex carbonate reservoir. Computers and Geotechnics, 156, 105277. [CrossRef]

- Ma, L., Cui, Z., Feng, B., Qi, X., Zhao, Y., & Zhang, C. (2023). Reactive Transport Modeling of Chemical Stimulation Processes for an Enhanced Geothermal System (EGS). Energies, 16(17), 6229. [CrossRef]

- Luo, J., Zhu, Y., Guo, Q., Tan, L., Zhuang, Y., Liu, M., ... & Xiang, W. (2018). Chemical stimulation on the hydraulic properties of artificially fractured granite for enhanced geothermal system. Energy, 142, 754-764. [CrossRef]

- Portier, S., Vuataz, F. D., Nami, P., Sanjuan, B., & Gérard, A. (2009). Chemical stimulation techniques for geothermal wells: experiments on the three-well EGS system at Soultz-sous-Forêts, France. Geothermics, 38(4), 349-359. [CrossRef]

- Kumari, W. G. P., Ranjith, P. G., Perera, M. S. A., & Chen, B. K. (2018). Experimental investigation of quenching effect on mechanical, microstructural and flow characteristics of reservoir rocks: Thermal stimulation method for geothermal energy extraction. Journal of Petroleum Science and Engineering, 162, 419-433. [CrossRef]

- Ngoma, M. C., Kolawole, O., & Olorode, O. (2024). Geothermo-mechanical alterations due to heat energy extraction in enhanced geothermal systems: Overview and prospective directions. Deep Underground Science and Engineering, 3(3), 256-268. [CrossRef]

- Wang, Z., Zhang, B., Zhu, X., Yang, L., Fan, Y., Yin, H., ... & Liu, J. (2024). How does the space of production wells influence the heat extraction efficiency?–defined by a 3D modeling work in enhanced geothermal system (EGS). Frontiers in Energy Research, 12, 1361290.

- Liang, Yanzhong, et al. “Study of the Heat Extraction Performance of Integrated Enhanced Geothermal Systems Based on a Novel Semi-Analytical Model.” SPE Journal (2025): 1-20. [CrossRef]

- Mark McClure. Why Multistage Stimulation is the Most Exciting Idea in Geothermal. ResFrac May 16, 2021.

- Liu, C., Feng, G., & Wang, J. (2022). Research Frontiers of Enhanced Geothermal System Thermal Reservoir Stimulation. Examines in Marine Biology & Oceanography. [CrossRef]

- Watanabe, N., Takahashi, K., Takahashi, R., Nakamura, K., Kumano, Y., Akaku, K., ... & Komai, T. (2021). Novel chemical stimulation for geothermal reservoirs by chelating agent driven selective mineral dissolution in fractured rocks. Scientific reports, 11(1), 19994. [CrossRef]

- Grigoli F, Cesca S, Rinaldi AP, Manconi A, Lopez-Comino JA, Clinton JF et al. (2018) The November 2017 Mw 5.5 Pohang earthquake: A possible case of induced seismicity in South Korea. Science 360(6392):1003–1006. [CrossRef]

- C-FER Technologies. Enhanced Geothermal Systems Promise and Challenges. https://www.cfertech.com/insights/enhanced_geothermal-promise-challenge/.

- McClure, M. (2023). Thermoelastic fracturing and buoyancy-driven convection: Surprising sources of longevity for EGS circulation. arXiv preprint arXiv:2308.02761.

- Lei, Z., Zhang, Q., Lin, X., & Li, Y. (2025). Intermittent Thermal Extraction Optimization in Geothermal Heating Systems: A Case Study of Pei County, Jiangsu Province, China. Energy Exploration & Exploitation, 01445987241305155.

- Jin, G., Zhang, X., Guo, S., Wu, X., & Bi, W. (2017). Evaluation and analysis of thermal short-circuiting in borehole heat exchangers. Energy Procedia, 105, 1677-1682. [CrossRef]

- Chen, Y., & Liang, W. (2024). The assessment of geothermal extraction efficiency for unstable alternation operation through thermal-hydro mechanical coupling simulations. Renewable Energy, 232, 121032. [CrossRef]

- Xu, F., Song, X., Song, G., Ji, J., Song, Z., Shi, Y., & Lv, Z. (2023). Numerical studies on heat extraction evaluation and multi-objective optimization of abandoned oil well patterns in intermittent operation mode. Energy, 269, 126777. [CrossRef]

- Zuo, L., & Weijermars, R. (2019). Longevity of enhanced geothermal systems with brine circulation in hydraulically fractured hydrocarbon wells. Fluids, 4(2), 63. [CrossRef]

- McSpadden, A. R., Coker, O. D., & Bohlander, S. (2022, September). Closed-Loop Geothermal Well Design with Optimization of Intermittent Circulation and Thermal Soak Times. In SPE Annual Technical Conference and Exhibition? (p. D031S054R004). SPE. [CrossRef]

- Wu, X., Li, Y., & Tang, C. A. (2023). Comparative study on heat extraction performance of three enhanced geothermal systems. Rock Mechanics Bulletin, 2(2), 100041. [CrossRef]

- Huang, Q., Guo, N., Huang, H., Yu, J., Pei, G., & Hu, M. (2025). Method to Improve Heat Extraction in Enhanced Geothermal Systems with Heterogeneous Fracture Network. [CrossRef]

- Wang, Z., Zhang, B., Yin, L., Yang, L., Fan, Y., Yin, H., ... & Liu, J. (2023). The number of production wells affects the heat extraction performance of an enhanced geothermal system: insights from engineering-scale 3D THM coupling numerical simulations. Frontiers in Earth Science, 11, 1185936. [CrossRef]

- Sun, Z. X., Zhang, X., Xu, Y., Yao, J., Wang, H. X., Lv, S., ... & Huang, X. (2017). Numerical simulation of the heat extraction in EGS with thermal-hydraulic-mechanical coupling method based on discrete fractures model. Energy, 120, 20-33. [CrossRef]

- Gong, F., Guo, T., Sun, W., Li, Z., Yang, B., Chen, Y., & Qu, Z. (2020). Evaluation of geothermal energy extraction in Enhanced Geothermal System (EGS) with multiple fracturing horizontal wells (MFHW). Renewable Energy, 151, 1339-1351. [CrossRef]

- Esteves, A. F., Santos, F. M., & Pires, J. C. M. (2019). Carbon dioxide as geothermal working fluid: An overview. Renewable and Sustainable Energy Reviews, 114, 109331. [CrossRef]

- Cong, L., Lu, S., Jiang, P., Zheng, T., Yu, Z., & Lü, X. (2024). Research Progress on CO2 as Geothermal Working Fluid: A Review. Energies, 17(21), 5415. [CrossRef]

- Zhao, W., Yuan, Y., Jing, T., Zhong, C., Wei, S., Yin, Y., ... & Wang, S. (2023). Heat production performance from an enhanced geothermal system (EGS) using CO2 as the working fluid. Energies, 16(20), 7202. [CrossRef]

- Evangeline, S. I., & Darwin, S. (2025). The role of carbon dioxide in enhancing geothermal energy: A review of current developments and future potential. Renewable and Sustainable Energy Reviews, 214, 115525. [CrossRef]

- Pruess, K. (2006). Enhanced geothermal systems (EGS) using CO2 as working fluid—A novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics, 35(4), 351-367. [CrossRef]

- Wu, Y., & Li, P. (2020). The potential of coupled carbon storage and geothermal extraction in a CO2-enhanced geothermal system: a review. Geothermal Energy, 8(1), 19. [CrossRef]

- Pruess, K. (2010). Enhanced geothermal systems (EGS) with CO2 as heat transmission fluid--A scheme for combining recovery of renewable energy with geologic storage of CO2.

- Masuoka, K., Yamamoto, H., & Kumamoto, S. (2023). Simulation Study on Heat Extraction Efficiency and CO2 Recovery Rate for CO2-EGS in Hydrothermal Reservoirs. In Proceedings, 48th Workshop on Geothermal Reservoir Engineering.

- Li, P., Hao, Y., Wu, Y., Wanniarachchi, A., Zhang, H., & Cui, Z. (2023). Experimental study on the effect of CO2 storage on the reservoir permeability in a CO2-based enhanced geothermal system. Geothermal Energy, 11(1), 24. [CrossRef]

- Starczewska, M., Strojny, M., Sowiżdżał, A., Gładysz, P., & Pająk, L. (2024). Life cycle assessment of enhanced geothermal systems with CO2 as a working fluid—polish case study. Clean Technologies and Environmental Policy, 1-13. [CrossRef]

- Okoroafor, E. R., Williams, M. J., Gossuin, J., Jimoh-Kenshiro, O., Horne, R. N., Rita, E., ... & Horne, R. N. (2021, February). Comparison of EGS Thermal Performance with CO2 and Water as Working Fluids. In PROCEEDINGS, 46th Workshop on Geothermal Reservoir Engineering, Stanford University Stanford, California (p. 10).

- Kaieda H, Ito H, Kiho K002C Suzuki K, Suenaga H, Shin K (2005) Review of the Ogachi HDR Project in Japan. In Proceedings of the Proceedings World Geothermal Congress, Antalya, Turkey, 24–29.

- Pruess, K. (2007). Enhanced Geothermal Systems (EGS) comparing water with CO2 as heat transmission fluids.

- Lei, H. (2022). Performance comparison of H2O and CO2 as the working fluid in coupled wellbore/reservoir systems for geothermal heat extraction. Frontiers in Earth Science, 10, 819778. [CrossRef]

- Zhang, W., Wang, D., Wang, Z., Guo, T., Wang, C., He, J., ... & Qu, Z. (2023). Study on permeability evolution and damage mechanism along the EGS fracture in heat mining stage under thermal stress/cracking. Geothermal Energy, 11(1), 31. [CrossRef]

- Dobson, P. F., Kneafsey, T. J., Nakagawa, S., Sonnenthal, E. L., Voltolini, M., Smith, J. T., & Borglin, S. E. (2021). Fracture sustainability in Enhanced Geothermal Systems: Experimental and modeling constraints. Journal of Energy Resources Technology, 143(10), 100901. [CrossRef]

- Rashid, H. U., & Olorode, O. (2024). Use of controlled fractures in enhanced geothermal systems. Advances in Geo-Energy Research, 12(1), 35-51. [CrossRef]

- Li, L., Guo, X., Zhou, M., Xiang, G., Zhang, N., Wang, Y., ... & Landjobo Pagou, A. (2021). The Investigation of Fracture Networks on Heat Extraction Performance for an Enhanced Geothermal System. Energies, 14(6), 1635. [CrossRef]

- Mattson, E. D., Neupane, G., Plummer, M., Jones, C., & Moore, J. (2016). Long-term sustainability of fracture conductivity in geothermal systems using proppants (No. INL/CON-15-37080). Idaho National Lab.(INL), Idaho Falls, ID (United States).

- Xie, Z., Han, D., Li, J., & Li, K. (2024). A State-of-the-Art Review of Hydraulic Fracturing in Geothermal Systems. Sustainability, 16(24), 11087. [CrossRef]

- Plummer, M. A., Palmer, C. D., Mattson, E. D., Redden, G. D., & Hull, L. C. (2010). Advancing reactive tracer methods for monitoring thermal drawdown in geothermal enhanced geothermal reservoirs (No. INL/CON-10-18881). Idaho National Lab.(INL), Idaho Falls, ID (United States).

- Redden, G., Stone, M., Wright, K. E., Mattson, E., Palmer, C. D., Rollins, H., ... & Hull, L. C. (2010, February). Tracers for characterizing enhanced geothermal systems. In Proceedings, 35th Workshop on Geothermal Reservoir Engineering Stanford University, Stanford, California, February (pp. 1-3).

- Tester, J. W., & Hawkins, A. J. (2023). A reactive tracer method for predicting EGS reservoir geometry and thermal lifetime: development and field validation (No. A reactive tracer method for predicting EGS reservoir geometry and thermal lifetime: development and field validation). Cornell Univ., Ithaca, NY (United States).

- Spitzmüller, M. S. L. (2025). Development of functionalized silica-based nanoparticle tracers for geo-reservoirs.

- Liu, Y., Wu, H., Taleghani, A. D., Zhang, K., Zhang, J., Yang, M., & Zhang, B. (2024). Effects of temperature-dependent viscosity on thermal drawdown-induced fracture flow channeling in enhanced geothermal systems. Renewable Energy, 235, 121274. [CrossRef]

- Hydraulic Properties | Department of Energy. (2025). https://www.energy.gov/eere/geothermal/hydraulic-properties.