1. Introduction

Urban mining, conceived as a circular economy strategy, encompasses various concepts that complement each other by aiming to transform waste into valuable secondary resources. Attention towards this type of mining has been growing in discussions about secondary raw materials, although its application in developing countries is often limited by local resources, technology, and ineffective legislation on electronic waste (e-waste) [

1].

Kazançoglu et al. [

2] describe urban mining as a management approach that aids the supply of secondary raw materials through the recycling of precious metals, contributing to improved consumption patterns and decreased resource use. Ghisellini et al. [

3] expand on this idea, defining urban mining as a process (encompassing collection, separation, sorting, and processing) at the city level for waste streams such as Construction and Demolition Waste (CDW) and Waste Electrical and Electronic Equipment (WEEE), aiming for their return to a new production cycle.

These concepts complement each other by highlighting that urban mining is an activity embedded within the context of the circular economy, with the main objective of recovering resources from waste, thereby decreasing the reliance on virgin raw materials. They differ, on the other hand, in the scope of the waste considered and the level of detail of the process. While some authors focus primarily on e-waste, others include a broader range of urban waste, such as CDW.

In the context of the circular economy, urban mining operationalizes the principle of material circulation, transforming what would be discarded into a new source of resources. Fatimah et al. [

4] state that efforts to overcome the e-waste problem exist, and urban mining is an essential component of these efforts. Ouro-Salim [

5] also emphasizes the synergy between urban mining and the circular economy, highlighting that the former serves as a critical mechanism to realize the principles of the latter and minimize environmental impacts.

In the realm of sustainability, urban mining presents itself as a practice with the potential to generate positive impacts in various dimensions. Environmentally, it contributes to the reduction of pollution associated with the inadequate disposal of hazardous waste, such as those present in e-waste [

1,

5,

6,

7,

8]. Economically, it can generate new business opportunities and green jobs, in addition to reducing costs for industries by providing secondary raw materials [

1,

9,

10]. Socially, it can promote the formalization of the informal recycling sector and improve the working conditions of those involved [

3,

10].

Urban mining of e-waste is a new frontier to be explored in Brazil, with the potential for economic valorization and waste minimization [

9]. Its successful implementation can play important roles in promoting several Sustainable Development Goals (SDGs), including sustainable cities and communities (SDG 11) and responsible consumption and production (SDG 12) [

4].

When contrasting the approaches to urban mining in Europe and Brazil, it is noticeable that, although both share a common goal of sustainability, the urgency and motivators manifest in distinct ways. Europe, driven by the scarcity of natural resources, strong environmental regulations, and the ambition to lead the transition to a circular economy, directs its efforts towards urban mining as a central strategy to ensure access to essential materials and reduce dependence on imports. The growing consumer awareness and the pressure for responsible business practices also drive this activity as a strategic priority for the competitiveness of European industry and security of supply.

On the other hand, Brazil, possessing vast mineral reserves, faces the challenge of reconciling economic development with the effective application of its environmental legislation, which often presents gaps and enforcement challenges. Although the country has abundant mineral resources, the uncontrolled exploitation and environmental impacts associated with conventional mining generate considerable social and environmental costs. In this context, urban mining in Brazil reveals itself as a necessity to promote sustainable development, reduce social inequalities, and protect its vast natural heritage.

A critical analysis reveals that the different socioeconomic and regulatory contexts shape the implementation of urban mining in Europe and Brazil. While Europe invests in advanced recycling technologies and the creation of value chains for recovered materials, aiming to strengthen its strategic autonomy and reduce its ecological footprint, Brazil still faces significant challenges. Among these challenges are the public's lack of knowledge about the correct destination of WEEE, the informality in the recycling chain, the lack of an official database on the generation and flows of WEEE, and the difficulties related to the traceability of this waste [

10].

Additionally, Brazil's continental dimensions and the concentration of recyclers in the South and Southeast regions of the country, coupled with the scarcity of processing units for precious metals, increase logistical costs and may increase greenhouse gas emissions resulting from transportation, including for export. The lack of a specific and unified taxation policy for the sector also generates legal uncertainty and can discourage urban mining entrepreneurs. In contrast, Europe, with its more developed infrastructure and more cohesive policies regarding the circular economy and waste management, presents a more favorable scenario for the expansion of urban mining on a large scale.

Considering the presented panorama, this article proposes to analyze the challenges and opportunities for the development of urban mining in Brazil, focusing on the dimensions of knowledge production, technological appropriation, and the effectiveness of current and necessary legislation to drive this activity. Through the investigation of these pillars, this analysis seeks to contribute scientifically to a deeper understanding of Brazil's specific conditions, offering subsidies for future research and for the formulation of public policies that can effectively promote urban mining as a strategy for sustainability and the utilization of secondary resources in the country.

2. Methodology

This review set out to analyze the challenges and opportunities for the development of urban mining in Brazil, focusing on the dimensions of knowledge production, technological appropriation, and the effectiveness of legislation. To this end, it concentrated on the search and critical analysis of original research articles, including other reviews, available on the Web of Science platform. Priority was given to the inclusion of current references, with an emphasis on the last 5 years, encompassing, however, materials up to 10 years old, in order to ensure the relevance and robustness of the presented panorama, also aiming to identify research gaps and avoid duplications.

The literature search strategy involved the use of specific terms related to the central themes of the article. For the analysis of the processes and technologies employed in urban mining (

Section 4), combined searches were performed for the term "urban mining" with the main chemical recovery processes: "hydrometallurgy", retrieving a total of 27 articles; "pyrometallurgy", with 9 articles retrieved; and "biohydrometallurgy", resulting in 10 articles.

To examine knowledge production and technological appropriation in Brazil (

Section 6), the term "urban mining" was used, filtering the results by country ("Brazil"), totaling 41 articles. It is important to note that the number of articles found for each combination of terms influenced the depth and format of the corresponding discussions. Furthermore, recognizing the multidisciplinary nature of the theme, some works may have coincided in different searches. Extra sources, in addition to those initially identified by the term combinations, were included whenever they were considered relevant to enrich the discussion.

The methodological approach for the analysis of the legal dimension (

Section 7) focused on providing an overview of the evolution of legislation on solid waste, with a comparison between Brazil [

11,

12,

13,

14] and the European Union [

15,

16,

17,

18,

19], dedicating special attention to Waste Electrical and Electronic Equipment (WEEE) as a central raw material for urban mining. The National Solid Waste Policy [

20] and its subsequent decrees [

21,

22,

23,

24] were detailed, explaining concepts such as shared responsibility and reverse logistics.

Additionally, the methodology incorporated the Critical Discourse Analysis (CDA) of Brazilian policies related to WEEE. This qualitative analysis transcends the mere description of legislation, seeking to identify the existing gaps between the official discourse and the operational reality, the lack of clarity and ambiguities in the definition of responsibilities, as well as the practical difficulties in the implementation of legal guidelines. The application of CDA, based mainly on the theoretical-methodological proposal of Norman Fairclough [

25], allowed a more in-depth evaluation of the effectiveness of the current legislation, highlighting challenges such as the informality of the sector, the insufficient awareness of the population, and the need for investment in infrastructure, contributing directly to the analysis proposed in the article.

3. Fundamentals of Urban Mining

Urban mining, which consists of the recovery of valuable materials and the coordination of materials, information, and services that enable the recovery of value from industrial and urban activities, can be understood as the set of processes and activities related to the production of secondary raw materials from Urban Solid Waste (USW) [

26]. The term is applied exclusively to the recovery of secondary raw materials from waste under the concept of the 3Rs (reduce, reuse, and recycle), with the premise that valuable materials can be recovered from waste in a manner analogous to traditional mining, producing high-value and sustainable secondary raw materials [

9].

The main components of urban mining involve the collection and dismantling of waste; pre-treatment, which includes steps such as size reduction, grinding, and separation of metallic and non-metallic fractions; and processing for the recovery of valuable materials, using physical, chemical, or biological methods [

27].

Various types of urban waste can be used as raw materials in urban mining, including: Waste Electrical and Electronic Equipment (WEEE) or e-waste, which has high potential due to its diversity and concentration of metals – this waste contains precious metals (Au, Ag), base metals (Cu, Al), and critical metals (Li, Co); Construction and Demolition Waste (CDW), from which recycled aggregates and other materials can be recovered; Urban Solid Waste (USW), including plastics, metals, and even incineration ash; industrial waste, such as electrical and non-electrical equipment, and infrastructure waste, such as pavement; end-of-life vehicles (ELV); landfill mining waste, with the potential for the recovery of plastics and metals [

27].

Urban mining presents significant pros, encompassing the conservation of natural resources through the use of secondary sources [

10], the mitigation of environmental impacts associated with traditional mining, such as lower energy and water consumption, and a reduction in waste generation and pollution [

9,

10]. This activity also promotes the economic valorization of waste, transforming discarded materials into valuable raw materials, and drives the circular economy, reintegrating materials into the production cycle and extending the lifespan of resources [

9,

10]. Other advantages include the reduction of dependence on primary raw materials and the risks in their supply chain, as well as the potential for job creation in the sectors of collection, processing, and material recovery [

9,

27].

However, there are challenges associated with urban mining that need to be recognized: the complexity of reverse logistics due to the variety of waste with different compositions, which hinders collection, transportation, and sorting; the costs involved in reverse logistics and recovery processes are also a challenge, which may question the economic viability of the activity in the context of the circular economy, with viability dependent on the quality and volume of the material; the need for specific technologies and technical knowledge for the processing and recovery of materials can be a barrier due to their limited availability or accessibility [

10,

27].

In addition, the presence of hazardous substances in some waste, such as in WEEE, requires special care in handling and processing to avoid contamination and health risks [

27]. The informal recycling market, operating without adequate standards, hinders the formalization and control of the value chain [

10]. The lack of specific regulations and economic incentives for the formal chain discourages urban mining compared to virgin raw materials, with the taxation of WEEE being a possible disincentive [

10,

27]. The need for correct waste disposal by consumers is essential to feed the chain, just as the scale of production and the diversity of electronic products impact the generation and treatment of WEEE [

10].

4. Processes Used in Urban Mining

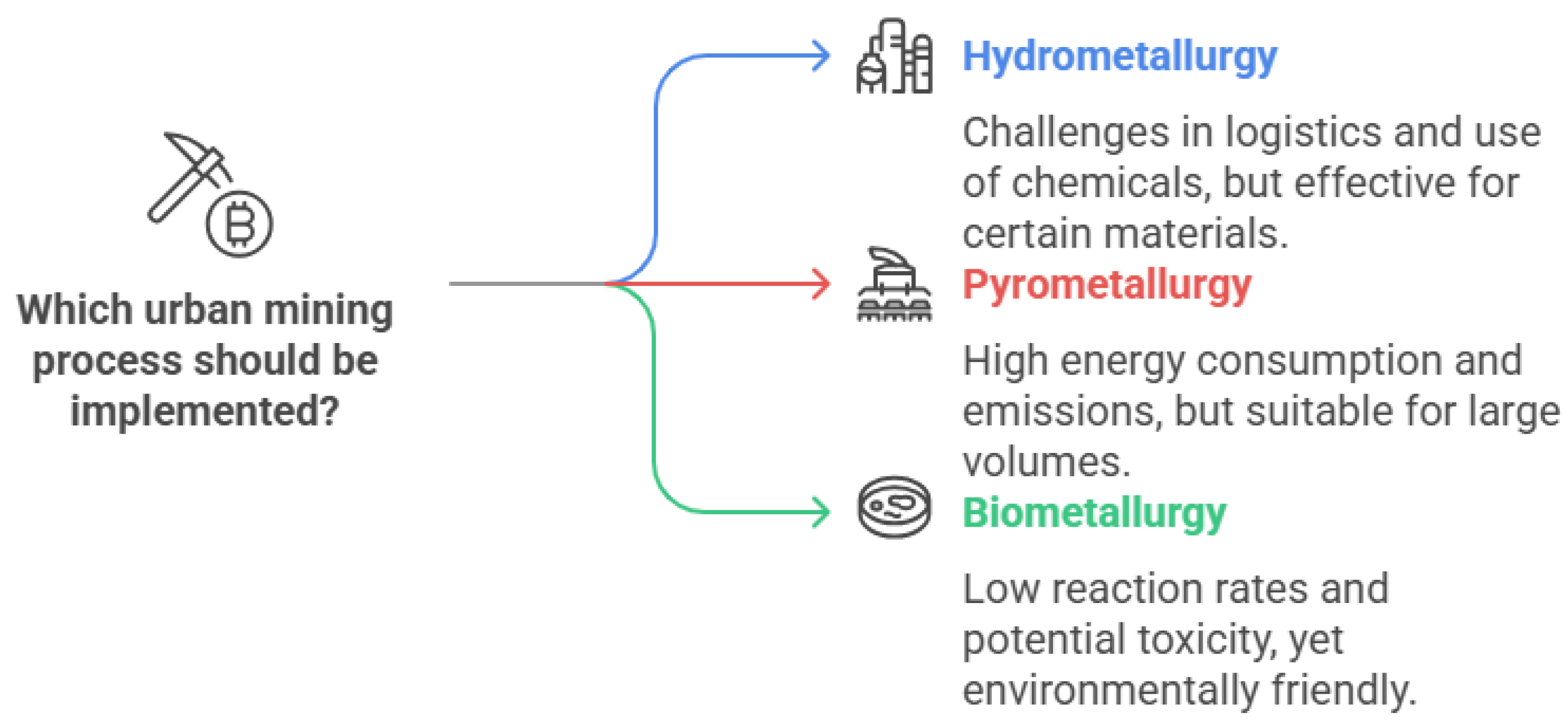

This section presents the main processes (

Figure 1) employed in the recovery of valuable metals from urban waste: Hydrometallurgy (processing in aqueous solutions), Pyrometallurgy (processing at high temperatures), and Biometallurgy (use of microorganisms). Various technologies, both traditional and emerging such as electrochemistry and supercritical fluids, can be applied in the scenario of Rare and Precious Metal (RPM) recovery as presented by Wang et al. [

28], while Xavier et al. [

27] offer a comprehensive review on key concepts and treatment methods for materials in urban waste. Additionally, Firmansyah et al. [

29] reviews technological advances focused on the recycling potential of electronic waste.

Recently, Kankanamge et al. [

30] investigated the factors that influence the design and adoption of technologies to make urban mining of electronic waste more sustainable, proposing a taxonomy that groups these factors into four categories: the device cluster, referring to the intrinsic characteristics of the technologies; the process cluster, which encompasses variables such as efficiency and cost; the organizational cluster, relating to the structure and policies of the entities involved; and the macro cluster, which includes external influences such as data security and intellectual property. In the following subsections, we will assess the efficiency, environmental impact, and economic viability of each process, conducting a comparative analysis of their advantages and disadvantages, aiming to identify future perspectives for metal recovery in the context of a circular economy.

4.1. Hydrometallurgy

Hydrometallurgy, which extracts metals through chemical reactions with acidic or basic solutions, typically comprises steps such as leaching, precipitation, solvent extraction, and electrodeposition. According to Tunsu et al. [

31], the advantages of applying hydrometallurgical methods for the urban mining of Rare Earth Elements (REEs) include the ability to process low-quality and complex materials, obtain products of higher purity, generate less gaseous pollution compared to pyrometallurgy, reduce dependence on primary mining, and enable the recycling of materials. However, it faces significant challenges such as the complex logistics of collection and sorting, the heterogeneity of materials that require flexible processes, the need for efficient separation methods for materials with low REE content, the intensive use of chemicals with the potential generation of secondary waste, and the costs of development and industrial implementation.

4.1.1. Leaching

Leaching consists of the selective dissolution of metals from solid waste using acidic or alkaline solutions, being applied in the recovery of valuable metals from electronic waste and spent catalysts. Gomes et al. [

32] reviewed the acid leaching of REEs from WEEE, pointing to urban mining as a promising strategy. Anwer et al. [

33] compared different acids in the extraction of metals from printed circuit boards (PCBs), highlighting organic acids (such as citric acid) as a more sustainable alternative. Alternatively to the traditional process, Prodius et al. [

34] demonstrated a hydrometallurgical route using copper salts to recover REEs and cobalt from magnetic and electronic waste, with subsequent precipitation of the REEs for reuse as oxides.

Arya et al. [

35] used chemical leaching to recover copper (Cu) and lead (Pb) from WPCBs (Waste Printed Circuit Boards), warning about the need for proper management of the waste generated. Acid leaching is also fundamental in the recovery of cobalt in lithium-ion batteries, using acids such as hydrochloric and sulfuric acid, to dissolve the components, followed by techniques such as solvent extraction, ion exchange, or precipitation to separate the cobalt, as highlighted by Botelho Júnior et al. [

36]. Rocchetti et al. [

37] proposed multi-stage countercurrent leaching as an innovative solution to recover indium from discarded Liquid Crystal Display (LCD) screens. This approach consists of using the same acid solution to treat several stages of LCD waste, concentrating the metal in the leaching solution. Oliveira et al. [

38] suggested acid leaching as the most suitable method for recovering gallium and REEs from LEDs (Light Emitting Diodes).

Martins et al. [

39] explored a three-stage sulfuric leaching to recover metals from WPCBs, especially in motherboard and memory board: the first stage focuses on the recovery of iron (Fe), aluminum (Al), and tin (Sn); the second, in an oxidizing medium, selectively recovers copper (Cu), silver (Ag), nickel (Ni), and zinc (Zn); and the third, with nitric acid, solubilizes the remaining metals, with the extraction efficiency dependent on the metal/acid ratio. Agrawal et al. [

40] developed an eco-friendly hydrometallurgical route to recover manganese (Mn) and nickel (Ni) from discarded tantalum capacitors, using selective leaching with hydrochloric acid that dissolves Mn (99.9%) and Ni (98.9%) while isolating tantalum (Ta), followed by solvent extraction. Finally, Tran et al. [

41] reviewed leaching with thiosulfate as a benign alternative to cyanidation for recovering gold (Au) and silver (Ag) from WPCBs, addressing the specific challenges of its application in urban mining, such as reagent consumption and reaction complexity.

4.1.2. Precipitation

Precipitation separates dissolved metals by adding reagents that form poorly soluble compounds. In contrast to traditional and energy-intensive thermal treatments for dismantling PCBs, Yang et al. [

42] proposed a green alternative that involves immersing PCBs in spent tin stripping solution (TSS) at room temperature, followed by the recovery of leached metals by chemical precipitation by adjusting the pH in different stages, achieving approximately 99% recovery of Sn, Pb, Fe, Cu, and Zn. This process offers advantages such as energy efficiency, waste reuse, and efficient metal recovery.

Caldas et al. [

43] explored methods for selective silver recovery, proposing an effective route with two stages of sulfuric leaching, with 100% of the silver recovered, followed by silver purification by precipitation as AgCl with NaCl and the production of silver nanoparticles (AgNPs) by the Turkevich method. Lima et al. [

44] used chemical precipitation as an initial step to recover aluminum from NCA (Nickel-Cobalt-Aluminum) batteries, a challenge due to the presence of aluminum in the cathode, then proceeding with the recovery of cobalt by solvent extraction and nickel/lithium by precipitation.

4.1.3. Solvent Extraction

This process involves the selective transfer of metals from an aqueous solution to an organic solvent, being applied in the recovery of precious metals and REEs from electronic waste. Tunsu et al. [

45] tested different extractants (acidic, solvating and mixed extractant systems) for REEs in simulated acidic solutions and identified that the blended DEHPA–Cyanex 923 is effective in minimizing the co-extraction of iron. The use of Ionic Liquids (ILs) and Deep Eutectic Solvents (DESs) as alternatives to conventional REE recovery processes was explored by Quijada-Maldonado et al. [

46] and Arrachart et al. [

47], respectively. Alguacil e Robla [

48] conducted a comprehensive review showing the potential of solvent extraction to recover various metals (rare earths, copper, lithium, gold, silver, palladium, platinum, etc.) from various sources using different types of extractants, discussing challenges and the future of the technique.

Zhang et al. [

49] employed supercritical fluid extraction (SCFE) using supercritical carbon dioxide and a tributylphosphate–nitric acid adduct (TBP–HNO

3) to recover REEs, such as terbium (Tb), europium (Eu) and yttrium (Y), from fluorescent lamp waste, achieving extraction rates greater than 70% for yttrium and europium, and 50% for terbium. Castillo-Ramírez and Janssen [

50] explored Pseudo-Protic Ionic Liquids (PPILs) for the extraction of metals relevant in urban mining. The authors tested four different PPILs for the extraction of indium, neodymium, yttrium, and lanthanum, with tri-hexylammonium octanoate showing high efficiency for all. And that indium was particularly well extracted by all PPILs tested. The authors reported the recyclability of most of the PPILs tested and the relative ease of yttrium and neodymium recovery.

4.1.4. Electrodeposition

Electrodeposition recovers metals in elemental form by applying electric current to an ionic solution, being used to obtain high-purity metals, such as copper, gold, and silver. Reyes-Valderrama et al. [

51] combined acid leaching with selective electrochemical recovery, demonstrating the recovery of Cu by electrodeposition at pH 1.5 and of Zn at pH 5, although nickel did not show relevant deposition under the tested conditions. Recently, Son et al. [

52] developed a gold electrodeposition process using a thiourea-based electrolyte, a less toxic alternative to cyanide, achieving 97% gold recovery with drastically reduced energy consumption (0.129 kWh/kg Au), attributed to the oxidation of thiourea at the anode. Although thiourea decomposes, electrodeposition slightly slows down this degradation compared to chemical deposition, possibly due to its regeneration at the cathode.

4.2. Pyrometallurgy

Pyrometallurgy [

53,

54,

55,

56,

57] is a non-ferrous metal extraction process that uses high temperatures and consumes a lot of energy. It involves enrichment steps by smelting, conversion, and refining, being considered the most traditional and industrially used treatment. Its advantages include the ability to treat large volumes of waste, recover metals in high concentration, and process complex materials [

58]. Application examples include the recovery of copper (Cu) [

53], gold (Au) [

59], zinc (Zn) and indium (In) [

60], gallium (Ga) [

61], among others. The key step is smelting (melting to separate metals by melting points), which can be performed by flash smelting processes, which use oxygenated gas for autogenous conditions, or by bath smelting, where the reaction occurs in a melt pool.

However, pyrometallurgy inevitably generates slag, soot, and toxic gases, requiring strict environmental controls, such as filters and gas treatment, to minimize pollution and ensure sustainability. The equipment is expensive, and energy consumption is high, making it unsuitable for small and medium-sized enterprises. Furthermore, it lacks selectivity for rare and precious metals and presents complexity in the recovery of pure metals [

58]. The choice between hydrometallurgy and pyrometallurgy depends on the characteristics of the waste, the target metals, and environmental and economic factors, and in many cases, the combination of both may be the most efficient and sustainable solution. Therefore, future research is needed to optimize pyrometallurgical processes, reduce their impacts, and develop integrated technologies.

4.3. Biohydrometallurgy

Emerging as a promising, ecological, and economic alternative for the treatment of electronic waste, biohydrometallurgy uses microorganisms to extract and recover metals. Its main process, bioleaching, employs microorganisms such as bacteria (

Acidithiobacillus ferrooxidans and

Thiooxidans), fungi (

Penicillium, Aspergillus, Fusarium, Alternaria, Candida), and their metabolites. Efficiency is demonstrated by works such as that of Madhavan et al. [

62], who recovered copper (Cu) and gold (Au) from PCBs using

Alcaligenes aquatilis; Rodrigues et al. [

63] who demonstrated high efficiency of the fungus

Aspergillus niger in the bioleaching of copper and gold and Thakur e Kumar [

64] who used the bacterial strain

Bacillus sporothermodurans ISO1 for copper and silver recovery. Other biohydrometallurgical processes include bioaccumulation (adsorption of metals in microbial cells) [

65] and bioreduction (reduction of metal ions to the elemental form) [

66]. The biorecovery of critical metals, such as from lamp phosphor powder, exemplifies the transition to a biologically based circular economy [

67].

The advantages of biohydrometallurgy include being a sustainable process (minimizes hazardous waste and emissions, reduces energy/chemical consumption), efficient (selective recovery even at low concentrations), and flexible (adaptable and integrable with other technologies) [

53]. Despite this, it has limitations such as low reaction rates, the possibility of metal precipitation, long process times, and potential toxicity of metals to microorganisms. Factors such as microorganism choice, surface area, pulp density, precursor, temperature, and pH are essential for success [

53]. Although it still faces optimization and industrial scalability challenges, continuous development indicates a promising future for its application in waste recovery, contributing to sustainability and the circular economy.

5. Perspectives of Urban Mining in Brazil and Europe

Since the main objective of urban mining is to extract precious metals, base metals, plastics, glass, and other reusable components, transforming what was previously considered waste into economic resources for some productive chain, the inputs produced compete with the extraction of virgin natural resources, and may, in principle, reduce the environmental impacts associated with conventional mining.

Many studies address the opportunities offered for the recycling of composite materials from different waste streams [

68] and few contemplate the barriers and challenges faced by urban mining [

1,

2]. Its development faces challenges as complex as those of conventional mining, although of different natures.

While traditional mining deals with resource depletion, large-scale environmental impacts, and social conflicts related to land ownership [

69], urban mining stumbles upon issues such as the complexity of waste composition, the presence of hazardous substances, the lack of adequate collection and processing infrastructure, the informality of the sector, the need for efficient and economically viable separation technologies, and the implementation of public policies that encourage recycling and extended producer responsibility.

Table 1 presents a comparison between conventional and urban mining.

In the global scenario, Brazil and Europe contrast in their approaches to mining, both conventional and urban. Brazil, possessing vast mineral reserves and marked by social inequalities that have historically sustained the workforce in conventional mining, faces the challenge of reconciling economic development with the effective application of its environmental legislation, often permeated by gaps and enforcement challenges [

69]. Europe, on the other hand, driven by resource scarcity and growing environmental awareness, as evidenced by the European Commission's policies on critical raw materials, directs its efforts toward urban mining as a central strategy to ensure access to essential materials, reduce dependence on imports, and promote a circular economy [

70,

71]. In addition, the mastery of specific technologies applicable in urban mining allows the establishment of virtuous partnerships to the capital and geopolitics of selling technologies or services and acquiring products thus mined at a low price and without pollution in European countries.

In view of this, while Brazil seeks to optimize the management of its natural resources and mitigate the socio-environmental impacts of traditional mining, Europe invests in advanced recycling technologies and in the creation of value chains for recovered materials, with the aim of strengthening its strategic autonomy and reducing its ecological footprint [

1,

5]. Therefore, the transposition of successful models in European countries to Brazil requires a critical analysis, considering the socioeconomic, environmental, technological, and regulatory specificities of the country.

The direct application of European models to the Brazilian context ignores the profound existing differences. Brazil, although a country rich in mineral resources, faces complex challenges to ensure that conventional mining is conducted sustainably. Institutional fragility, precarious enforcement, and the prevalence of negligent practices have resulted in serious environmental and social disasters, such as the collapse of the Barragem do Fundão em Mariana (Minas Gerais) [

72], a tragic landmark that exposed the flaws in the licensing system and the lack of socio-environmental responsibility of mining companies in this country.

The Mariana disaster, a tragic landmark of Brazilian conventional mining, serves as a stark warning: negligence and precarious enforcement cannot be repeated in the implementation of urban mining. Although promising, this modality, if conducted improperly, can replicate negative environmental and social impacts [

73,

74,

75,

76], such as soil and water contamination by heavy metals present in electronic waste, the exposure of workers to toxic substances during sorting and processing, and the creation of environmental liabilities resulting from the inadequate disposal of non-recoverable waste.

To avoid repeating the mistakes of conventional mining, urban mining must be guided by rigorous control and prevention measures. This includes conducting detailed and comprehensive environmental impact studies, adopting clean and innovative technologies for the separation and processing of materials, and guaranteeing the active participation of civil society in the planning and oversight of activities. Furthermore, it is essential that mining companies assume extended responsibility [

77,

78,

79] for the management of waste generated at all stages of the process, from selective collection to environmentally sound final disposal, prioritizing the traceability of materials and the implementation of circular economy practices.

Even so, the urgency of urban mining manifests itself differently in the Brazilian and European contexts, although they share a common goal of sustainability. In Europe, the scarcity of natural resources, strong environmental regulations, and the ambition to lead the transition to a circular economy drive a pressing need to implement urban mining on a large scale. Dependence on imports of critical raw materials, coupled with growing consumer awareness and pressure for responsible business practices, makes urban mining a strategic priority to ensure the competitiveness of European industry and security of supply.

From a geopolitical and economic point of view, security of supply for items that Europe does not produce can be achieved through diversified partnerships in Asia, Africa, and Latin America with contributions of technology and capital sufficient to transform their strategic needs into commodities. This strategy has been used by several economic and technological powers throughout recent history, marking a kind of neocolonialism.

Furthermore, while Europe stands out for its selective collection and recycling infrastructure, Brazil still faces significant challenges in the management of urban solid waste. Informality in collection, lack of adequate infrastructure, and low public awareness hinder the separation and routing of waste to urban mining. Also, some situations related to conventional mining demonstrate that Brazilian environmental legislation, although advanced in some aspects, lacks effective mechanisms to guarantee the accountability of companies and the reparation of damages caused by their activities [

69,

80,

81]. Therefore, urban mining in Brazil cannot be presented as an environmental merit in itself without a set of guarantees of its efficacy, efficiency, and effectiveness.

Another point that deserves highlighting is the social issue. The experience of the city of Trento, in Italy, illustrates the implementation of a program coordinated by local recycling companies. Collaboration with entities specialized in waste management suggests a more formalized approach through selective collection [

79,

82,

83]. In Brazil, informality and the presence of recyclable material collectors in situations of social vulnerability require a differentiated approach, which promotes social inclusion and income generation for this population.

In Brazil, the urgency of urban mining is revealed in a less immediate, but equally relevant way. Although the country has abundant mineral resources, conventional mining is only considered an effective social function at the beginning of the undertaking, after which it responds to the demands of the national and international market by lowering its costs, increasing its production without assuming all the environmental and social externalities it generates in the process and in the increase in the scale of production [

69,

80,

81]. Therefore, unbridled conventional mining brings significant environmental impacts and social and environmental costs. Urban mining emerges as an alternative to diversify sources of raw materials, reduce pressure on fragile ecosystems, and promote social inclusion through the generation of green jobs and the formalization of the sector [

84,

85,

86].

In addition, the increasing production of electronic waste and other complex waste streams requires urgent solutions to prevent soil and water contamination, protect public health, and recover valuable materials that can be reintroduced into the production chain. Thus, while Europe sees urban mining as a matter of economic security and environmental leadership, Brazil needs to adopt it as a strategy to promote sustainable development, reduce social inequalities, and protect its vast natural heritage.

The news from the National Electric Energy Agency [

87] about the expressive growth of 8.84 GW in micro and mini-distributed generation of electricity, in 2024, highlights a critical point for the sustainability of the Brazilian energy sector: the urgent need to prepare the country for the management of the life cycle of the equipment used in these facilities. As in the case of large solar plants, the expansion of micro and mini-distributed generation, driven by photovoltaic solar panels installed in homes, businesses, and rural properties, will inevitably lead to a significant increase in the volume of electronic waste (e-waste) containing valuable and potentially hazardous materials [

88].

In this scenario, urban mining becomes a key piece to ensure the environmental and economic sustainability of micro and mini-distributed generation. By recovering materials such as silicon, silver, copper, and aluminum present in end-of-life solar panels, urban mining can reduce the demand for virgin raw materials, reduce the environmental impacts of ore extraction and processing, and create new business opportunities and green jobs. However, the implementation of urban mining on a large scale in the context of micro and mini-distributed generation presents specific challenges. The geographical dispersion of facilities, the lack of adequate collection and sorting infrastructure, and the absence of specific regulations for the management of solar panel waste hinder reverse logistics and efficient material recovery.

To overcome these challenges, it is essential that the Brazilian government, in partnership with the private sector and civil society, develops public policies that encourage selective collection, the creation of specialized recycling centers, the promotion of extended producer responsibility, and the awareness of consumers about the importance of the correct disposal of end-of-life solar panels. In addition, it is necessary to invest in research and development of innovative recycling technologies, which allow the efficient recovery of materials present in solar panels, minimizing the costs and environmental impacts of the process.

By embracing urban mining as an integral part of the strategy to expand micro and mini-distributed generation, Brazil will be able to ensure that the energy sector becomes not only cleaner and more decentralized, but also more circular and sustainable. Thus, the role of the government is, first and foremost, to regulate the market so that it is virtuous by imposing on the private sector and, indirectly, on photovoltaic generators, the environmental costs of this technology. In this way, whoever profits and whoever benefits must internalize the environmental costs of the activity within a long-term vision that goes from production to decommissioning.

6. Knowledge Production and Technological Appropriation on Urban Mining in Brazil

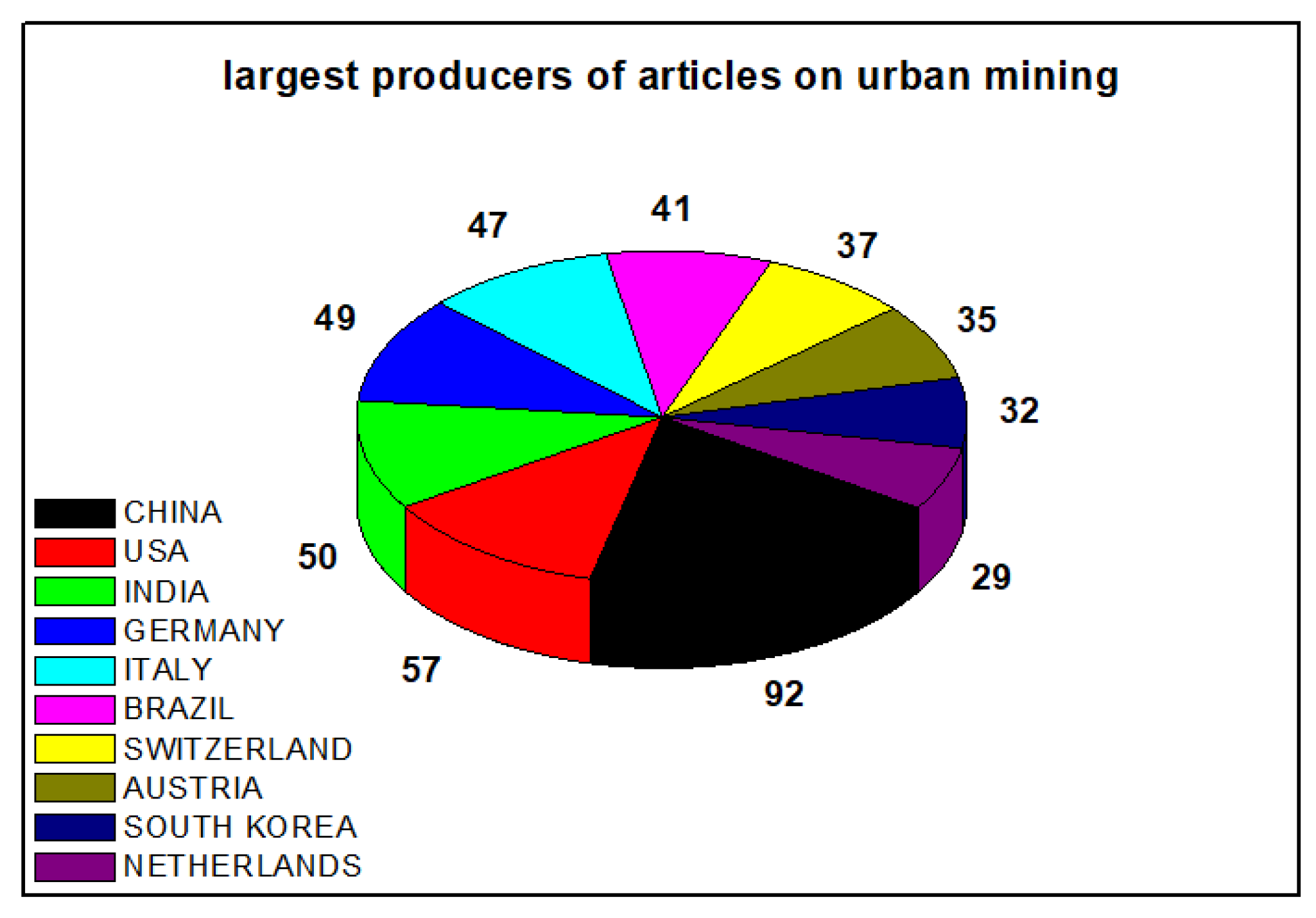

The mapping of Brazilian scientific production on urban mining reveals a field of investigation that, although it demonstrates a recent growing interest, is still in a phase of development compared to other environmental areas or international production, especially European. A search carried out in March/2025 on the Web of Science resulted in 633 documents found for the term "urban mining," of which 573 are articles, with 75 being reviews. Brazil ranks 6th among the countries that have produced the most articles on the topic,

Figure 2.

The existing literature, dispersed in journals of various areas (engineering, chemistry, environmental sciences, management), conference proceedings, and, expressively, in theses and dissertations, tends to concentrate on specific thematic niches. Studies dedicated to the quantitative and qualitative characterization of flows such as Waste Electrical and Electronic Equipment (WEEE), in which it seeks to identify precious and critical metals, and Construction and Demolition Waste (CDW), whose focus lies on the potential for reuse of aggregates, predominate.

Investigations on technological routes for the processing of these wastes were also recovered, ranging from physical pre-treatments to metallurgical processes on a laboratory or pilot scale, often adapting technologies or seeking lower-cost alternatives. An analysis of this corpus suggests a preference for applied technical approaches, whose central objective seems to be the establishment of the technical-economic feasibility of material recovery, precluding discussions about the social, political contexts and the broader implications of urban mining in Brazil to a secondary plane.

Considering the growing challenge of managing WEEE in Brazil, whose generation exceeds population growth and which stand out for their complexity, potential hazard, and for containing valuable materials, the National Solid Waste Policy instituted Reverse Logistics Systems (RLS) as fundamental instruments for the transition to the circular economy [

10,

20]. In this context, urban mining emerges as a strategy fostered by RLS, although the effectiveness of both approaches faces significant paradoxes. High costs, logistical challenges, the informality of the recycling chain, public ignorance, the lack of adequate infrastructure and specific tax policies are bottlenecks that question the real contribution of these approaches to sustainability and emissions reduction, demanding the recognition of these obstacles to drive technological and regulatory solutions [

10]. The lack of formal RLS, especially in metropolitan regions, contributes to a recycling rate estimated at only 2%, also influenced by the lack of reliable data, the significant role of the informal sector, and the continental dimensions of the country [

89].

Aiming to improve urban mining, studies have focused on the detailed characterization of waste and the development of processing routes. Castro e Pereira-Filho [

90], for example, carried out an exploratory study of the chemical composition of Printed Circuit Boards (PCBs) from hard drives, where it was possible to identify about twenty chemical elements through Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) and Flame Atomic Absorption Spectrometry (FAAS). Using exploratory data analyses such as Principal Component Analysis (PCA) and correlation maps, it was also possible to make significant associations, demonstrating that the direct analysis of fragments combined with chemometrics is promising for the characterization and planning of recycling routes.

In a complementary way, Castro et al. [

91] proposed the combined use of Laser-Induced Breakdown Spectroscopy (LIBS) and Parallel Factor Analysis (PARAFAC) to characterize PCBs, improving the identification of interferents and the accuracy in the classification of elements such as Au and Ag. The characterization of other WEEE, such as Light-Emitting Diodes (LEDs) and lithium-ion batteries, reveals not only the presence of valuable and critical materials (Cu, Ga, Y, In, Au, Ag in LEDs and Co, Ni, Li in lithium-ion batteries), but also toxic elements (such as Pb and As in LEDs) and a compositional heterogeneity that challenges recycling processes [

92,

93].

Overcoming technological barriers is identified as a critical factor in Brazil, which, despite being the largest generator of e-waste in South America, only performs the initial processing stage locally [

94]. Using the DEMATEL (Decision Making Trial and Evaluation Laboratory) method based on expert opinion, the authors pointed out technology as the only primary and causal barrier, directly influencing others such as technical knowledge, pollution control, costs, and consumer. This lack of advanced technologies and specialized knowledge, added to the low collection flow (~2%), makes it impossible to install sophisticated recovery plants in the country, resulting in the export of components rich in noble materials [

94]. In view of this, several processing approaches have been investigated. Hydrometallurgy is frequently cited as a promising route [

27,

44,

54], with studies focusing on the optimization of parameters such as acid leaching (e.g., H

2SO4, HNO

3, aqua regia), solid/liquid ratio, pH, and redox potential to recover metals such as Cu, Ag, Fe, Au, Ga and Rare Earth Elements (REE) from PCBs, LEDs, and other sources. Separation techniques such as selective precipitation, solvent extraction, ion exchange, and membrane separation (nanofiltration, reverse osmosis) are explored for the purification and concentration of metals and recovery of reactants [

44,

95].

Alternatives and emerging technologies are also highlighted in the search for sustainability. Bioleaching using fungi such as

Aspergillus niger has proven efficient in the recovery of Cu and Au from PCBs, also enabling the synthesis of metallic nanoparticles [

96]. Bio-hydrometallurgy in general is pointed out as a promising innovation, especially for critical raw materials [

27,

36,

67]. Biphasic Aqueous Systems (BAS) emerge as a "green" alternative for the recovery of bismuth and gold, minimizing the use of organic solvents and operating under mild conditions [

97,

98]. Magnetic Nanohydrometallurgy (MNHM) is presented as an innovative nanotechnological approach for the selective separation of lanthanides [

99].

Other techniques such as gravity concentration [

100], hybrid (mechanical-thermal) approaches for photovoltaic panels [

101] and supercritical water (SCW) technology for simultaneous recycling of solar panels and effluent treatment [

102] também são investigadas. are also investigated. The recovery of REE, given their technological importance and supply risk, is a particular focus, although acid leaching still predominates and recovery from PCBs remains a challenge [

103,

104]. Similarly, the recovery of indium from LCDs faces analytical and market challenges in Brazil [

105].

As already mentioned, urban mining is not restricted to WEEE, also covering CDW, where the concept of buildings as material banks proposes to treat buildings as recoverable sources [

106]. Although Brazil has research in the area, it contrasts with European countries due to the lack of robust public policies, with systematized data and incentive policies being necessary to overcome the competitiveness of virgin materials. The incorporation of waste such as milled asphalt pavement [

107] and polyethylene [

108] in asphalt mixtures also demonstrates potential, although the environmental benefits depend on the technologies and energy matrices employed and more Life Cycle Assessment (LCA) studies are needed. The recovery of lead from motorcycle batteries also presents economic and environmental relevance, with significant forecasts of obtaining it via urban mining, but faces capacity and illegal recycling challenges [

109].

The spatial and social perspective of urban mining reveals additional complexities. A study in the Metropolitan Region of Rio de Janeiro (MRRJ) identified significant potential, but also a concentration of recyclers that leaves areas of high generation isolated, reinforcing the need to optimize routes and improve data management and collection [

78]. Universities emerge as promising sources of WEEE ("urban mines"), however, even in higher education communities, there is ignorance about proper disposal and reverse logistics, with the lack of infrastructure and information being significant barriers [

110]. Urban mining is strongly connected to Sustainable Development Goals (SDGs) such as industry/innovation (SDG 9) and responsible consumption/production (SDG 12), but presents social trade-offs, especially linked to informality and precarious working conditions of waste pickers, demanding ethical and inclusive approaches [

26].

The geography of urban mining is uneven, shaped by the local political economy, resulting in disparities in practices and technologies between different urban contexts. For example, while the London Larger Urban Zone (LLUZ) and Sao Paulo Macrometropolis (SPMM) stand out for the predominance of formal companies and advanced recycling technologies, the Greater Accra Region (GAR) faces significant challenges with informal collection and rudimentary techniques that generate environmental and health impacts [

111]. In addition, the mining activity itself, even urban, can entail socio-environmental risks, such as subsidence in Maceió, requiring tools such as Geographic Information System (GIS) and Multi-Criteria Decision Aid (MCDA) for mapping vulnerabilities and supporting urban planning [

112]. The lack of standardization in sustainability reports on waste management also hinders a complete view of flows and the advancement of the circular economy [

113].

In summary, urban mining, aligned with the principles of the circular economy, is presented as an important strategy in the face of pressure on primary resources and the increase in waste generation in Brazil. Although it represents an opportunity to recover valuable and critical materials from various anthropogenic sources, such as WEEE and CDW, its consolidation depends on overcoming technological, logistical, economic, informational, and socio-political barriers. The development and implementation of characterization and processing technologies, combined with effective public policies, functional reverse logistics systems, greater public awareness, and socially inclusive approaches, are fundamental for urban mining to reach its potential to contribute to sustainability and the efficient management of resources in the country.

7. Legal Dimension of Urban Mining: Effectiveness of Brazilian Legislation and Obstacles to Overcome

Regarding the legal dimension, urban mining, particularly with regard to the utilization of WEEE, is intrinsically linked to the normative framework that regulates the management of solid waste in the country. The evolution of this legislation, from the establishment of the National Solid Waste Policy (NSWP) [

20], in 2010 to the most recent decrees [

21,

22,

23,

24] that improve the regulation of WEEE management, demonstrates a normative progress towards shared responsibility and reverse logistics. However, the mere existence of a set of laws and regulations does not guarantee its effectiveness.

This section proposes to deepen the critical analysis of Brazilian legislation applicable to urban mining, examining to what extent the current legal framework is effective in driving this activity, as well as the main persistent challenges in its practical implementation and enforcement. From an assessment of the normative scenario and the obstacles encountered in its application, it will be possible to identify the gaps and the needs for legislative improvement for the full development of urban mining as a strategy for sustainability and the utilization of secondary resources in Brazil.

The trajectory of waste management in the European Union [

15,

16,

17,

18,

19], with its progressive legislative sophistication guided by the search for sustainable practices and the principles of the circular economy, serves as an important benchmark for the analysis of policies in other regions. Although Brazil has its particularities and challenges inherent to international experiences, such as the European one, often influence the adoption of models and the normative evolution in developing countries. In this context, the understanding of international approaches and the principles that govern the management of WEEE helps to examine the effectiveness of Brazilian legislation applicable to urban mining.

The evolution of waste management in the European Union (

Table 2) demonstrates a progressive legislative sophistication, guided by the search for sustainable practices. The

Table 2 shows that, in the 1970s, Europe adopted Directive 75/442/CEE [

15], which prioritized the elimination of waste, with the aim of mitigating the environmental impacts associated with final disposal. Although this approach was fundamental, it focused on solving the problem in a reactive way, that is, after the generation of waste.

Directive 91/156/CEE [

16], in the 1990s, introduced the paradigm of integrated management, shifting the focus to prevention at the source and the valorization of waste. This change represented a significant conceptual advance, promoting the hierarchization of management strategies. Concomitantly, specific directives for waste streams, such as 94/62/CE for packaging, were promulgated, complementing the framework legislation and establishing specific requirements for each type of waste.

The period between 2006 and 2008 was characterized by the consolidation and improvement of the legal framework. Directive 2006/12/CE [

17] codified the pre-existing legislation, while the Waste Framework Directive (2008/98/CE) [

18] consolidated the management hierarchy, with emphasis on prevention, reuse, recycling, and valorization, and strengthened producer responsibility.

From 2008 onwards, the legislation incorporated the principles of the circular economy. The 2018 Circular Economy Package, for example, established ambitious targets for recycling and reducing final disposal, aiming for a transition to a more sustainable production and consumption model. This trajectory demonstrates the EU's commitment to sustainability in waste management, continuously seeking to optimize policies and internalize the principles of circularity.

The European directives on WEEE are well-formulated, with a focus on Extended Producer Responsibility, which seeks to involve manufacturers in the product life cycle. In contrast, its effectiveness depends on factors such as efficient enforcement, public awareness, and adequate infrastructure for collection and recycling. For WEEE policies to be successful, it is necessary to invest in these areas and ensure coordination between legislation, companies, consumers, and government agencies.

Although Brazil is independent, some practices of European companies (and those of other countries) influence the use of some models already adopted by other countries. The search for sustainable practices in waste management has driven legislative evolution in various regions of the world, Brazil has demonstrated a progressive development of its normative structure for the governance of WEEE, consolidating a comprehensive legal framework that encompasses laws, decrees, normative instructions, and technical standards. This normative set aims not only to minimize the negative impacts of improper disposal but also to promote the transition to a circular economy model, promoting the use of resources present in WEEE.

The National Solid Waste Policy (Law nº 12.305/2010) [

20] bases the management of Waste Electrical and Electronic Equipment (WEEE) on shared responsibility and reverse logistics. Distributing responsibilities among manufacturers, importers, distributors, merchants, consumers, and the government, the NSWP integrates management, aiming at proper disposal. The policy aims to assign manufacturers the responsibility for the environmental costs of the production, use, and disposal of WEEE (such as pollution and resource depletion), encouraging these costs to be reflected in the final price of the products. This encourages the prevention of waste generation, through the development of more durable and less polluting products.

In addition, the NSWP prioritizes the reuse of equipment, the recycling of its components, and the recovery of valuable materials, thus minimizing the amount of waste that reaches landfills and the associated environmental impact. Co-responsibility encourages sustainable practices, from product design to its disposal, closing the life cycle and promoting the circular economy. The aforementioned Policy thus seeks to mitigate waste generation, conserve natural resources, and reduce pollution, contributing to sustainable development. Reverse logistics operationalizes the manufacturer's responsibility, ensuring the collection and proper processing of WEEE, while consumer participation is fundamental for the success of the system.

Complementing the NSWP, recent decrees have improved the regulation of WEEE management, with emphasis on Decree nº 10.240/2020 [

21], which establishes goals and deadlines for the implementation of reverse logistics; Decree nº 10.657/2021 [

22], which, by promoting the Pro-minerals Policy and defining criteria for strategic minerals, indirectly drives urban mining of WEEE; and Decrees nº 10.936/2022 [

23] and nº 11.413/2023 [

24], which promote improvements in the regulation of the PNRS and institute the Reverse Logistics Recycling Credit Certificate, the Structuring and Recycling Certificate of General Packaging, and the Future Mass Credit Certificate, within the scope of reverse logistics systems, respectively. The convergence of these legal instruments strengthens the regulatory structure and creates an environment conducive to the development of urban mining, a practice that aims at the recovery of metals and other valuable materials from WEEE, aligning with the principles of the circular economy.

The standardization of processes and the guarantee of safety and efficiency in the management of WEEE are ensured by technical standards of the Brazilian Association of Technical Standards. Brazilian Standard - NBR 10.004:2004 [

11] establishes the classification of solid waste according to its risks, providing guidelines for the proper handling of WEEE. Standards NBR 16.156:2013 [

12] and NBR 15.833:2018 [

13] specify the requirements for the reverse manufacturing of electro-electronics and refrigeration appliances, respectively, promoting recycling and material recovery. Additionally, NBR IEC 63.000:2019 [

14], harmonized with the European RoHS (Restriction of Hazardous Substances) Directive, regulates the restriction of hazardous substances in electrical and electronic equipment, contributing to the protection of human health and the environment.

Although the normative advance is remarkable, the full implementation of WEEE management in Brazil still faces significant challenges. The complexity of the production chain, the high informality in the recycling sector, the insufficient awareness of the population about the correct disposal, and the need for greater investments in collection and processing infrastructure represent obstacles to be overcome.

To achieve the sustainability objectives outlined in the NSWP, the intensification of enforcement of compliance with the legislation, the stimulation of technological innovation in recycling processes, the strengthening of articulation between the different levels of government (municipal, state, and federal), and the promotion of environmental education campaigns become essential. Future research should prioritize the evaluation of the impact of current legislation, the identification of bottlenecks in the implementation, and the proposition of solutions for the improvement of the system, aiming at a more efficient and fully aligned WEEE management with the principles of the circular economy.

In Brazil, many practices are still in initial stages or are adopted incompletely. This difference can be explained by the variation in environmental regulations and the level of social and economic pressure that motivates companies to adopt more sustainable practices. In developed countries, stricter environmental legislation and the growing consumer demand for sustainable practices contribute to greater adherence to these initiatives.

7.1. Critical Discourse Analysis

Critical Discourse Analysis (CDA) is a valuable theoretical-methodological approach for critical organizational studies, as it contributes to the reflection on contemporary social issues and seeks to denaturalize beliefs that sustain structures of domination. Although the use of CDA in Administration is not recent, its application is still limited, and the analysis of the textual dimension is not always explored in depth. Our article relies on the theoretical and methodological assumptions of CDA, as proposed by Norman Fairclough (2010) [

25], and we offer subsidies for the analysis of the representational dimension, illustrating its operationalization. Our objective is to clarify aspects related to the linguistic analysis of normative texts between Brazil and Europe.

Applying Norman Fairclough's CDA to Brazilian solid waste policies, a profound disconnect between the official discourse and the operational reality is observed, resulting in low effectiveness. Textually, the use of specific technical jargon hinders the understanding of the lay public, limiting citizen participation in social control and the appropriation of policy guidelines. The lack of clarity in the definition of responsibilities of each actor involved - government, companies, citizens - generates ambiguities and overlaps of competences, hindering the practical implementation of actions. In addition, the emphasis on an imposing discursive modality, centered on obligations and punishments, to the detriment of incentives and mechanisms of voluntary adherence, can generate resistance and hinder the internalization of appropriate waste management practices.

Discursively, adherence to the legal-administrative genre, with its formality and impersonality, creates a distance between the official discourse and the concrete needs of the population. The complex network of intertextual references to other norms and regulations makes it difficult to access complete information and build a comprehensive understanding of the policy. The representation of waste generators as passive agents, subject only to legal impositions, ignores the fundamental role of education and awareness in promoting effective behavioral changes.

Socio-historically, the policy reflects the ideology of ecological modernization, which seeks to reconcile economic development and environmental preservation. However, this ideology can be used to justify greenwashing practices, masking the maintenance of unsustainable patterns of production and consumption. The power relations inherent in the process of formulation and implementation of the policy often marginalize vulnerable groups, such as recyclable material collectors, whose informal waste management practices are often disregarded.

The search for a hegemonic vision, which imposes a single management model, disregards the diversity of contexts and social perspectives, hindering the construction of a consensus and the effective implementation of actions. As a consequence, the legislation, although potentially robust, is not effective in practice, perpetuating the fragility of shared responsibility and problems such as the inadequate disposal of waste in dumps, with its negative impacts on the environment and public health.

The adoption of circular business models, the strategic use of technology, and the strengthening of Extended Producer Responsibility are essential factors for the construction of a more efficient, fair, and sustainable system. In addition, CDA emerges as a crucial tool to deconstruct dominant discourses and reveal the power relations that influence WEEE management policies.

8. Conclusions

Urban mining in Brazil presents a unique configuration that notably differentiates it from the models observed in other regions, such as Europe. While the latter is primarily driven by the scarcity of critical metals, the Brazilian context directs the focus to reducing the volume of waste discarded in landfills and to the opportunity to integrate the vast existing informal workforce. This duality between waste management and social inclusion sets up a challenging scenario for the creation of an effective productive and value chain but highlights the strategic importance of this activity for the country's sustainable development.

Regarding knowledge production and technological appropriation, Brazil still faces significant gaps. The recovery of critical metals from WEEE requires sophisticated technologies, whose research and development need greater incentives. It is essential that specific public policies be created to promote technological advancement in the sector, accompanied by regulations that encourage reverse logistics and traceability of waste, as well as subsidies or tax credits that make the recycling of strategic metals economically attractive. The integration of recycling cooperatives into industrial processes, with due technical training, emerges as a promising way to reconcile technological innovation with social inclusion. The adoption of a hybrid model, which combines the general recovery of materials with extraction focused on critical metals, and the implementation of a national urban mining program, could optimize the flow of waste and integrate the sector into circular economy and energy transition plans.

The legal dimension of urban mining in Brazil, although it has evolved with the National Solid Waste Policy and subsequent decrees, still demonstrates challenges in its effectiveness. The critical analysis of the legislation reveals a disconnection between the regulatory framework and its practical implementation, marked by a lack of clarity in responsibilities, ambiguities, and enforcement difficulties. The informality of the recycling sector and low public awareness are additional obstacles that contrast with the more consolidated infrastructure and formalization in European countries. For the legislation to fulfill its guiding role, it is imperative to strengthen control mechanisms, promote coordination between government entities, and implement effective educational campaigns.

In light of the foregoing, urban mining in Brazil is configured as a strategic opportunity to build a differentiated model that combines sustainability, innovation, and social inclusion. Overcoming the challenges identified in the areas of knowledge production, technological appropriation, and legislative effectiveness will require coordinated efforts and integrated policies. Future research is essential to assess the real impact of current legislation, identify specific bottlenecks in the implementation of reverse logistics systems, deepen the study of technological solutions adapted to the Brazilian reality, and investigate models of social inclusion that guarantee decent and fair working conditions for the actors involved in the urban mining chain.

Use of Artificial Intelligence

In accordance with the guidelines for the ethical and responsible use of Generative Artificial Intelligence (AI), the production of this article was aided by AI tools at various stages of the research and writing process. It is essential to emphasize that all outputs generated by AI tools were subjected to rigorous curation and validation by the authors, ensuring the scientific accuracy and integrity of the final content.

Author Contributions

Writing—original draft preparation, J.M.M.N., R.C.L., N.L.S.A., E.A.S.; writing—review and editing, J.M.M.N., R.C.L., N.L.S.A., E.A.S. All authors have read and agreed to the published version of the manuscript.”

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed at the corresponding author.

Acknowledgments

One of the authors (JMMN) acknowledges CNPq and FAPEPI for research support (PDCTR - Process 301246/2022-0).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AgNPs |

Silver Nanoparticles |

| ATPS |

Aqueous Two-Phase Systems |

| CDA |

Critical Discourse Analysis |

| CDW |

Construction and Demolition Waste |

| CE |

European Conformity |

| DEMATEL |

Decision Making Trial and Evaluation Laboratory |

| DESs |

Deep Eutectic Solvents |

| EEC |

European Economic Community |

| ELV |

End-of-Life Vehicles |

| EU |

European Union |

| FAAS |

Flame Atomic Absorption Spectroscopy |

| GIS |

Geographic Information System |

| ICP-OES |

Inductively Coupled Plasma - Optical Emission Spectroscopy |

| IEC |

International Electrotechnical Commission |

| ILs |

Ionic Liquids |

| LCA |

Life Cycle Assessment |

| LCD |

Liquid Crystal Display |

| LEDs |

Light Emitting Diodes |

| LIBS |

Laser-Induced Breakdown Spectroscopy |

| MCDA |

Multi-Criteria Decision Aid |

| MNHM |

Magnetic Nanohydrometallurgy |

| MRRJ |

Metropolitan Region of Rio de Janeiro |

| NCA |

Nickel-Cobalt-Aluminum |

| PARAFAC |

Parallel Factor Analysis |

| PCBs |

Printed Circuit Boards |

| NSWP |

National Solid Waste Policy |

| PPILs |

Pseudo-Protic Ionic Liquids |

| REEs |

Rare Earth Elements |

| RLSs |

Reverse Logistics Systems |

| RoHS |

Restriction of Hazardous Substances |

| RPMs |

Rare and Precious Metals |

| SCFE |

Supercritical Fluid Extraction |

| SDGs |

Sustainable Development Goals |

| SWT |

Supercritical Water Technology |

| TSS |

Tin Stripping Solution |

| USW |

Urban Solid Waste |

| WEEE |

Waste Electrical and Electronic Equipment |

| WPCBs |

Waste Printed Circuit Boards |

References

- Erdiaw-Kwasie, M.O.; Abunyewah, M.; Baah, C. A systematic review of the factors – Barriers, drivers, and technologies – Affecting e-waste urban mining: On the circular economy future of developing countries. J. Clean. Prod. 2024, 436, 140645. [Google Scholar] [CrossRef]

- Kazançoglu, Y.; Ada, E.; Ozturkoglu, Y.; Ozbiltekin, M. Analysis of the barriers to urban mining for resource melioration in emerging economies. Resour. Pol. 2020, 68, 101768. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ncube, A.; Casazza, M.; Passaro, R. Toward circular and socially just urban mining in global societies and cities: Present state and future perspectives. Front. Sustain. Cities 2022, 4, 930061. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Govindan, K.; Sasongko, N.A.; Hasibuan, Z.A. The critical success factors for sustainable resource management in circular economy: Assessment of urban mining maturity level. J. Clean. Prod. 2024, 469, 143084. [Google Scholar] [CrossRef]

- Ouro-Salim, O. Urban mining of e-waste management globally: Literature review. Clean. Waste Syst. 2024, 9, 100162. [Google Scholar] [CrossRef]

- Udage Kankanamge, A.K.S.; Erdiaw-Kwasie, M.O.; Abunyewah, M. Towards a Taxonomy of E-Waste Urban Mining Technology Design and Adoption: A Systematic Literature Review. Sustainability 2024, 16, 6389. [Google Scholar] [CrossRef]

- Ogunseitan, O.A.; Schoenung, J.M.; Saphores, J.D.M.; Shapiro, A.A. The electronics revolution: from e-wonderland to e-wasteland. Science 2009, 326, 670–671. [Google Scholar] [CrossRef] [PubMed]

- Arora, R.; Paterok, K.; Banerjee, A.; Saluja, M.S. Potential and relevance of urban mining in the context of sustainable cities. IIMB Manag. Rev. 2017, 29, 210–224. [Google Scholar] [CrossRef]

- Xavier, L.H.; Giese, E.C.; Ribeiro-Duthie, A.C.; Lins, F.A.F. Sustainability and the circular economy: A theoretical approach focused on e-waste urban mining. Resour. Policy 2021, 74, 101467. [Google Scholar] [CrossRef]

- Contador, L.S.; Freire, L.S.; Xavier, L.H. Paradoxos da logística reversa de resíduos eletroeletrônicos e a mineração urbana no Brasil. Rev. Tecnol. Soc. 2022, 18, 141–153. [Google Scholar] [CrossRef]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS - ABNT. NBR 10004: Resíduos sólidos – Classificação. Rio de Janeiro, 2004.

- ABNT. NBR 16156: Resíduos de equipamentos eletroeletrônicos — Requisitos para atividade de manufatura reversa. Rio de Janeiro, 2013.

- ABNT. NBR 15833: Manufatura reversa — Aparelhos de refrigeração. Rio de Janeiro, 2018.

- ABNT. NBR IEC 63000: Documentação técnica para a avaliação de produtos elétricos e eletrônicos com relação à restrição de substâncias perigosas (RoHS). Rio de Janeiro, 2019.

- UNIÃO EUROPEIA. Conselho. Diretiva 75/442/CEE, de 15 de julho de 1975, relativa aos resíduos. Jornal Oficial das Comunidades Europeias, L 194, 25 jul. 1975.

- UNIÃO EUROPEIA. Conselho. Diretiva 91/156/CEE, de 18 de março de 1991, que altera a Diretiva 75/442/CEE relativa aos resíduos. Jornal Oficial das Comunidades Europeias, L 78, 26 mar. 1991.

- UNIÃO EUROPEIA. Parlamento Europeu. Conselho. Diretiva 2006/12/CE, de 5 de abril de 2006, relativa aos resíduos. Jornal Oficial da União Europeia, L 114, 27 abr. 2006.

- UNIÃO EUROPEIA. Parlamento Europeu. Conselho. Diretiva 2008/98/CE, de 19 de novembro de 2008, relativa aos resíduos e que revoga certas Diretivas. Jornal Oficial da União Europeia, L 312, 22 nov. 2008.

- UNIÃO EUROPEIA. Parlamento Europeu. Conselho. Diretiva 2012/19/UE, de 4 de julho de 2012, relativa a resíduos de equipamentos elétricos e eletrónicos (REEE). Jornal Oficial da União Europeia, L 197, 24 jul. 2012.

- BRASIL. Lei nº 12.305, de 2 de agosto de 2010. Institui a Política Nacional de Resíduos Sólidos; altera a Lei no 9.605, de 12 de fevereiro de 1998; e dá outras providências. Diário Oficial da União, Brasília, DF, 03 ago. 2010. Available online: https://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 20 April 2025).

- BRASIL. Decreto nº 10.240, de 12 de fevereiro de 2020. Acordo Setorial para implementação de Sistema de Logística Reversa de Produtos Eletroeletrônicos e seus componentes de Uso Doméstico. Available online: http://www.planalto.gov.br/ccivil_03/_ato2019-2022/2020/decreto/D10240.htm (accessed on 6 April 2025).

- BRASIL. Decreto nº 10.657, de 24 de março de 2021. Institui a Política de Apoio ao Licenciamento Ambiental de Projetos de Investimentos para a Produção de Minerais Estratégicos - Pró-Minerais Estratégicos, dispõe sobre sua qualificação no âmbito do Programa de Parcerias de Investimentos da Presidência da República e institui o Comitê Interministerial de Análise de Projetos de Minerais Estratégicos. Available online: https://www.planalto.gov.br/ccivil_03/_Ato2019-2022/2021/Decreto/D10657.htm (accessed on 20 April 2025).

- BRASIL. Decreto nº 10.936, de 12 de janeiro de 2022. Regulamenta dispositivos da Lei nº 12.305, de 2 de agosto de 2010, que institui a Política Nacional de Resíduos Sólidos. Available online: https://www.planalto.gov.br/ccivil_03/_ato2019-2022/2022/decreto/d10936.htm (accessed on 20 April 2025).

- BRASIL. Decreto nº 11.413, de 13 de fevereiro de 2023. Institui o Certificado de Crédito de Reciclagem de Logística Reversa, o Certificado de Estruturação e Reciclagem de Embalagens em Geral e o Certificado de Crédito de Massa Futura, no âmbito dos sistemas de logística reversa de que trata o art. 33 da Lei nº 12.305, de 2 de agosto de 2010. Available online: https://www.planalto.gov.br/ccivil_03/_Ato2023-2026/2023/Decreto/D11413.htm (accessed on 20 April 2025).

- Fairclough, N. Critical discourse analysis: The critical study of language. Longman: London, 2010.

- Botelho Junior, A.B.; Martins, F.P.; Cezarino, L.O.; Liboni, L.B.; Tenório, J.A.S.; Espinosa, D.C.R. The sustainable development goals, urban mining, and the circular economy. Extr. Ind. Soc. 2023, 16, 101367. [Google Scholar] [CrossRef]

- Xavier, L.H.; Ottoni, M.; Abreu, L.P.P. A comprehensive review of urban mining and the value recovery from e-waste materials. Resour. Conserv. Recycl. 2023, 190, 106840. [Google Scholar] [CrossRef]

- Wang, M.; Tan, Q.; Chiang, J.F.; Li, J. Recovery of rare and precious metals from urban mines—A review. Front. Environ. Sci. Eng. 2017, 11, 1. [Google Scholar] [CrossRef]

- Firmansyah, M.L.; Rizki, I.N.; Ullah, N. Recent advances in urban mining technology: A focus on electronic waste recycling potential in Indonesia. Clean. Waste Syst. 2025, 10, 100239. [Google Scholar] [CrossRef]

- Udage Kankanamge, A.K.S.; Erdiaw-Kwasie, M.O.; Abunyewah, M. Towards a Taxonomy of E-Waste Urban Mining Technology Design and Adoption: A Systematic Literature Review. Sustainability 2024, 16, 6389. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergorić, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239–258. [Google Scholar] [CrossRef]

- Gomes, R.F.; Pereira, M.M.; Leão, V.A. Acid Leaching of Rare Earth Elements Present in Waste Electrical and Electronic Equipment: A Brief Review. Rev. Virtual Quim. 2022, 14, 319–328. [Google Scholar] [CrossRef]

- Anwer, S.; Panghal, A.; Majid, I.; Mallick, S. Urban mining: recovery of metals from printed circuit boards. Int. J. Environ. Sci. Technol. 2022, 19, 9731–9740. [Google Scholar] [CrossRef]

- Prodius, D.; Gandha, K.; Mudring, A.V.; Nlebedim, I.C. Sustainable Urban Mining of Critical Elements from Magnet and Electronic Wastes. ACS Sustainable Chem. Eng. 2020, 8, 1455–1463. [Google Scholar] [CrossRef]

- Arya, S.; Patel, A.; Kumar, S.; Pau-Loke, S. Urban mining of obsolete computers by manual dismantling and waste printed circuit boards by chemical leaching and toxicity assessment of its waste residues. Environ. Pollut. 2021, 283, 117033. [Google Scholar] [CrossRef]

- Botelho Junior, A. B.; Stopic, S.; Friedrich, B.; Tenório, J. A. S.; Espinosa, D.C.R. Cobalt Recovery from Li-Ion Battery Recycling: A Critical Review. Metals 2021, 11, 1999. [Google Scholar] [CrossRef]

- Rocchetti, L.; Amato, A.; Fonti, V.; Ubaldini, S.; De Michelis, I.; Kopacek, B.; Vegliò, F.; Beolchini, F. Cross-current leaching of indium from end-of-life LCD panels. Waste Manag. 2015, 42, 180–187. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, R.P.; Benvenuti, J.; Espinosa, D.C.R. A review of the current progress in recycling technologies for gallium and rare earth elements from light-emitting diodes. Renew. Sustain. Energy Rev. 2021, 145, 111090. [Google Scholar] [CrossRef]

- Martins, T.A.G.; Caldas, M.P.K.; Moraes, V.T.; Tenório, J.A.S.; Espinosa, D.C.R. Recovering metals from motherboard and memory board waste through sulfuric leaching. J. Environ. Chem. Eng. 2021, 9, 106789. [Google Scholar] [CrossRef]

- Agrawal, M.; Singh, K.K.; Singh, R. Hydrometallurgical recovery of manganese and nickel and isolation of tantalum from obsolete tantalum capacitor. J. Environ. Chem. Eng. 2022, 10, 108887. [Google Scholar] [CrossRef]