Submitted:

15 April 2025

Posted:

17 April 2025

You are already at the latest version

Abstract

Keywords:

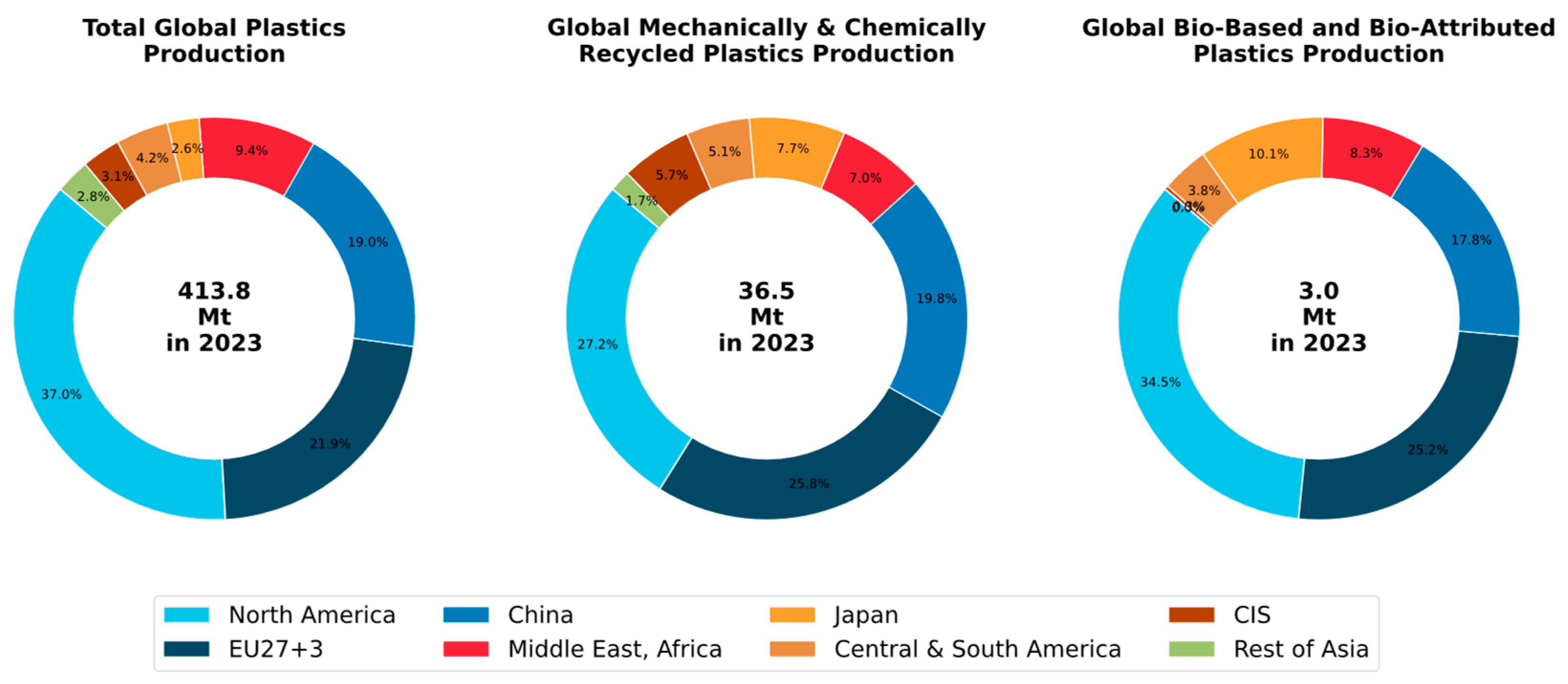

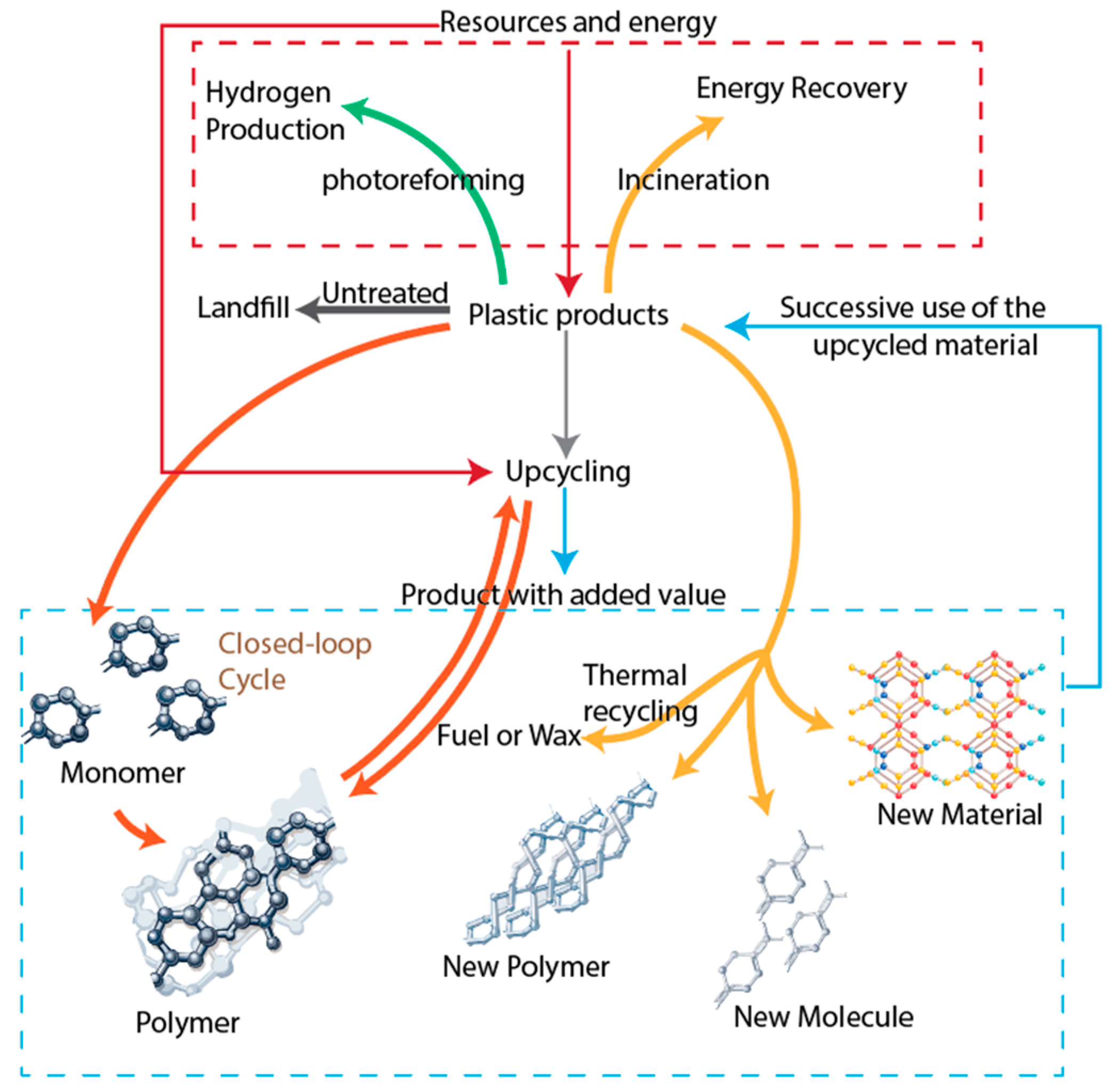

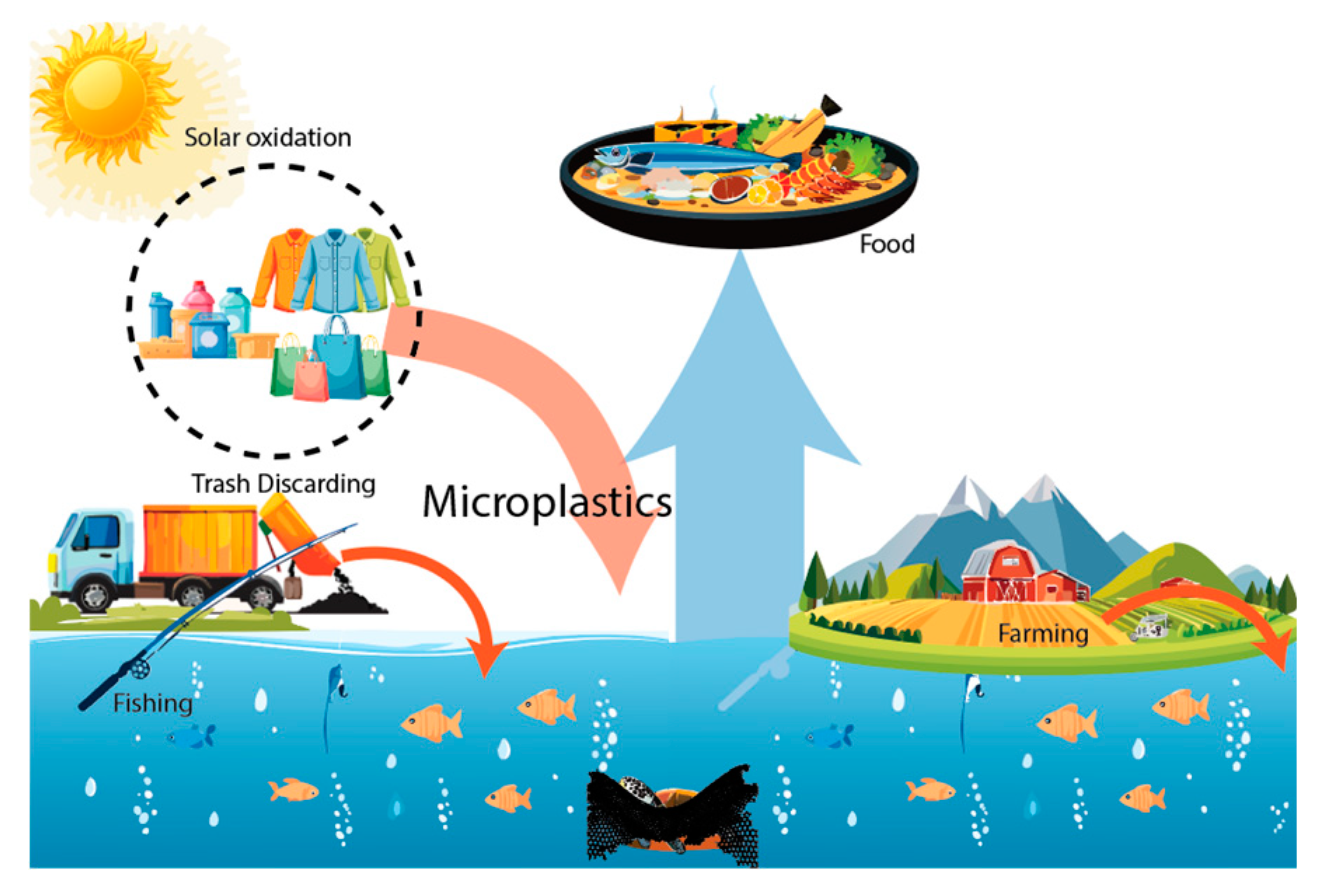

1. Introduction

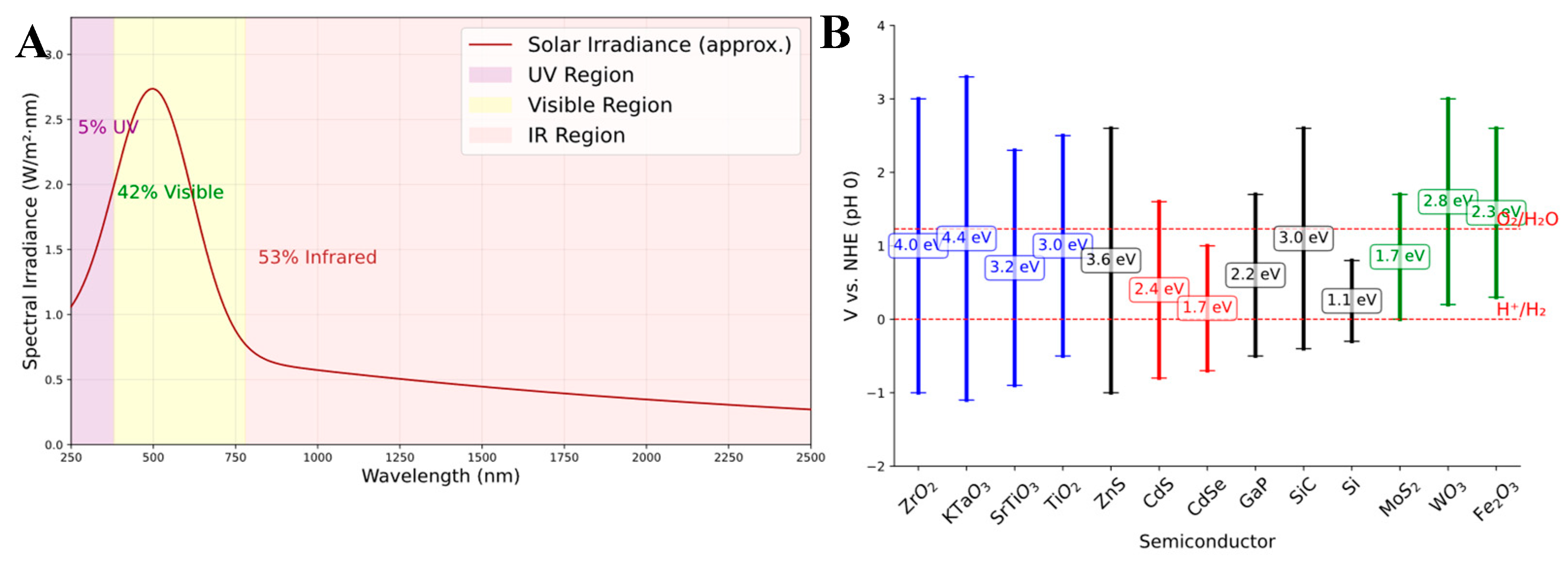

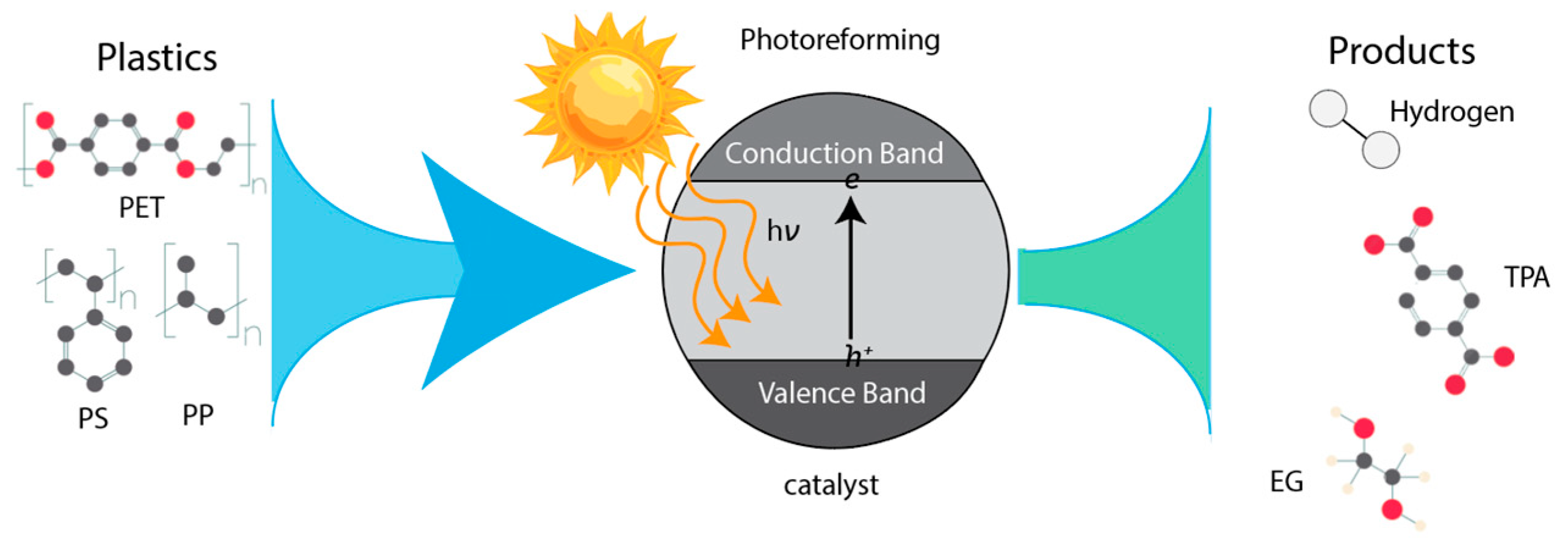

2. Fundamentals of Plastic Photoreforming

2.1. Overview of Photoreforming

- The catalyst absorbs photons, exciting electrons from the highest occupied molecular orbital to the lowest unoccupied molecular orbital, resulting in an activated catalyst.

- The excited catalyst interacts with reactants, generating active intermediates through H2 atom transfer or electron transfer, thereby selectively facilitating plastic conversion.

2.2. Reaction Pathways and Mechanisms

2.3. Thermodynamic and Kinetic Considerations

3. Types of Plastics and Their Suitability for Photoreforming

3.1. Common Plastics

3.2. Characteristics Affecting Photoreforming

4. Photocatalysts and Catalyst Engineering

4.1. Semiconductor Photocatalysts

4.2. Metal-Organic Frameworks (MOFs) and Carbon-Based Composites

4.3. Noble Metal and Transition Metal Co-catalysts

| Category | Noble Metal Co-Catalysts (Pt, Pd, Au) | Non-Noble Metal Co-Catalysts (Ni, Co, Fe, Cu, Mo, etc.) |

| Hydrogen Evolution Efficiency | High activity, excellent electron trapping, and fast proton reduction. | Moderate to high activity dependent on material engineering (doping, alloying, or structuring). |

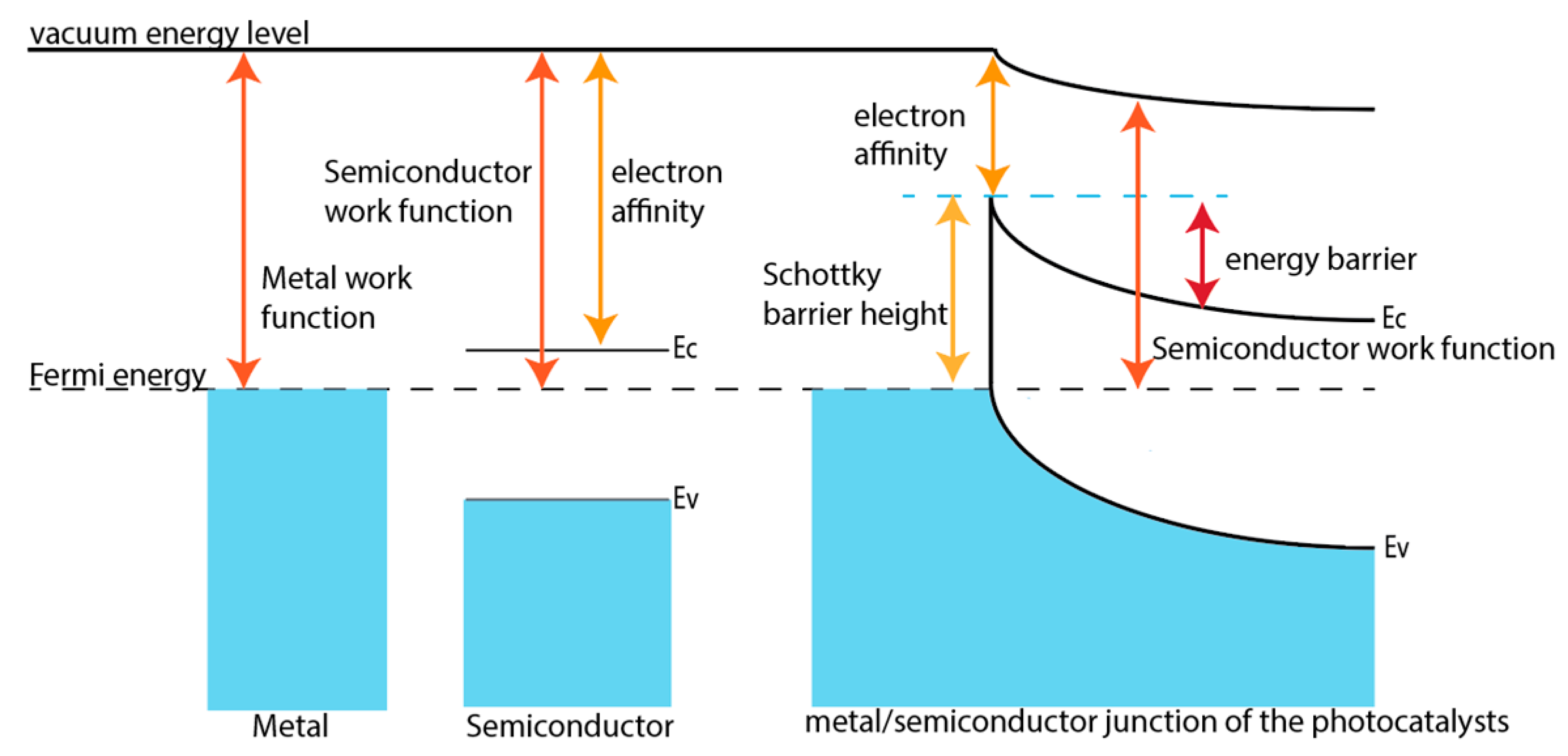

| Charge Separation | Forms Schottky junctions, effectively suppressing electron-hole recombination. | Requires heterojunctions or defect engineering to achieve similar charge separation efficiency. |

| Stability and Durability | Chemically stable under reaction conditions, low corrosion rate. | Some non-noble metals (e.g., Fe) can corrode or deactivate over time unless properly stabilized. |

| Cost and Scalability | Very expensive and scarce, limiting large-scale applications. | Earth-abundant and low-cost, catalysts are highly scalable for industrial use. |

| Environmental Impact | Mining and refining noble metals have significant environmental impacts. | More sustainable, widely available, and eco-friendly. |

| Versatility | Effective across a range of photocatalytic systems (e.g., plastic reforming, water splitting). | Catalysts can be engineered into various alloys and oxides to enhance versatility and selectivity. |

| Activation Energy and Reaction Kinetics | Low activation energy, enabling rapid reaction kinetics. | Requires co-doping (e.g., Ni₂P, CoP, MoS2) to reduce activation energy for HER. |

| Long-Term Performance | Maintains high catalytic performance over extended use. | Some non-noble metals may degrade or lose efficiency over prolonged cycles. |

| Engineering Potential | Limited modification potential due to intrinsic properties of noble metals. | High tunability is achieved through the capabilities of doping, alloying, or nanostructuring for enhanced photocatalytic properties. |

4.4. Design and Fabrication Strategies

4.5. Catalyst Characterization Techniques

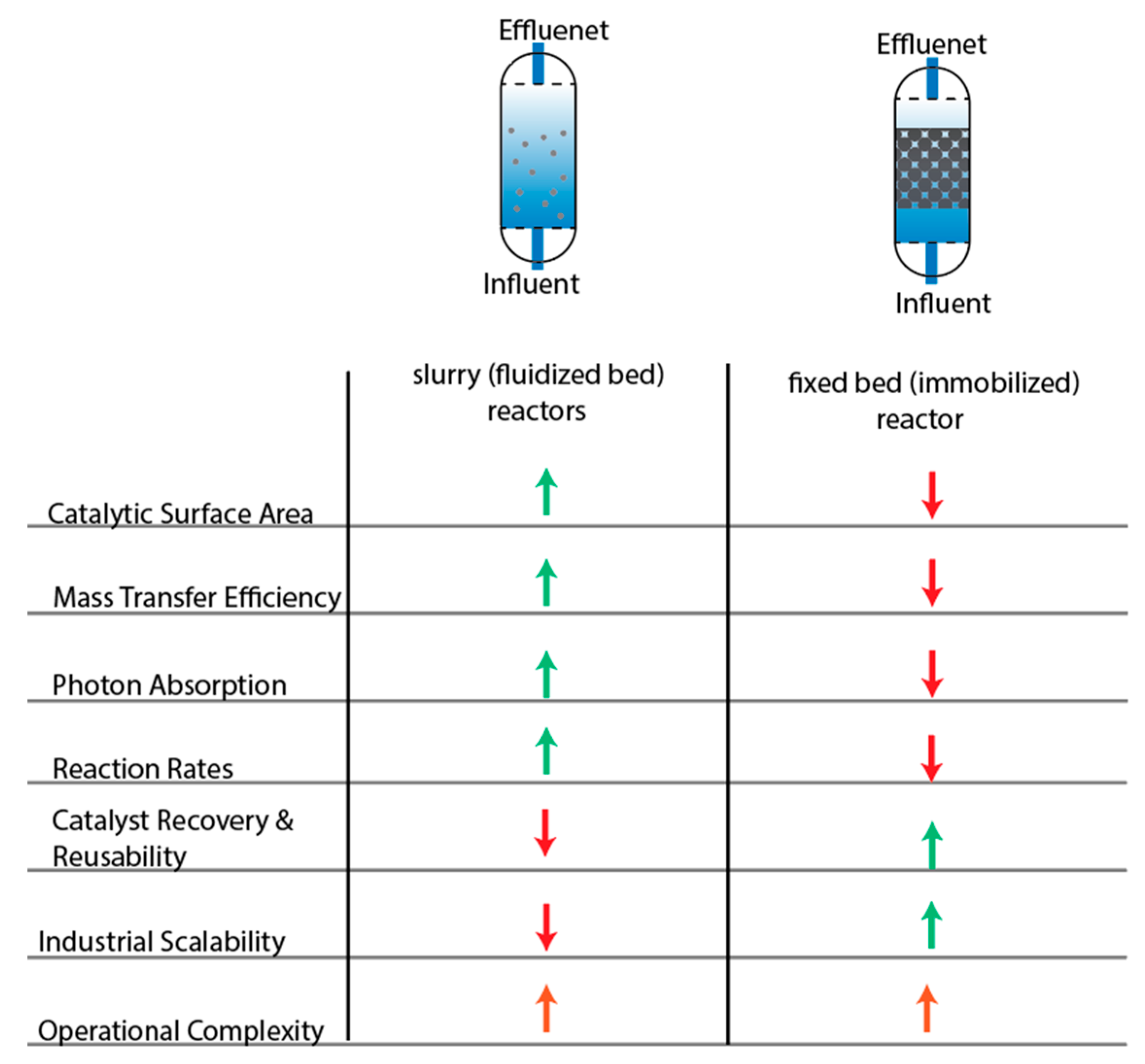

5. Reactor Configurations and Photoreforming Conditions

5.1. Bench-Scale Reactors and Scale-Up Challenges

5.2. Light Sources and Illumination Strategies

5.3. Operational Parameters

6. Performance Metrics and Process Evaluation

6.1. Hydrogen Yield and Production Rates

| Catalyst | experimental conditions | Hydrogen yield (µmol g-1 h-1) | Reference |

| Pt/TiO2 | 500 W Xe lamp, 5M NaOH, PET | 1130 | [125] |

| CNx|Ni2P | AM 1.5 sunlight, ambient temperature, PET | 82 | [56] |

| CNx|Ni2P | AM 1.5 sunlight, ambient temperature, PLA | 178 | |

| Zn|n2S4 (mesoporous) | Simulated sunlight, PET | 23.6 | [130] |

| Zn|n2S4 (conventional) | Simulated sunlight, PET | 8.9 | |

| CdS/CdOx | Simulated sunlight, PET | 6.6 | [131] |

| NiCr2O4/TiO2-Zn0.5Cd0.5S | Visible light, mixed plastics | 81.4 × 103 | [132] |

| NiPS3/CdS | Solar-driven, PET | 31.4 × 103 | [133] |

| NiPS3/CdS | Solar-driven, PLA | 39.8 × 103 | |

| g-C3N4/Pt | With NaOH pretreatment, PET | 533 | [127] |

| Au0.28Pd0.72/TiO2 HS | 5M NaOH, 300 W Xe, PET | 0.85 × 103 | [125] |

| MoS2/CdS | 300 W Xe lamp AM 1.5, 10M KOH | PLA: 6.68 × 103 PET: 3.90 × 103 PE: 1.13 × 103 |

|

| Co–Ga2O3 | 300 W Xe lamp, AM 1.5, 10M KOH, PE | 692 | [134] |

| d-NiPS3/CdS | 43× and 1.5× 300 W xenon lamp (PLS-SXE 300), λ > 400 nm, 2M KOH, PLA | 39.76 × 103 | [128] |

6.2. Selectivity and Byproduct Formation

6.2.1. Liquid-Phase Organics

6.2.2. Gas-Phase Organics

6.2.3. Solid Residues

6.2.4. Treatment and Opportunities with Byproducts

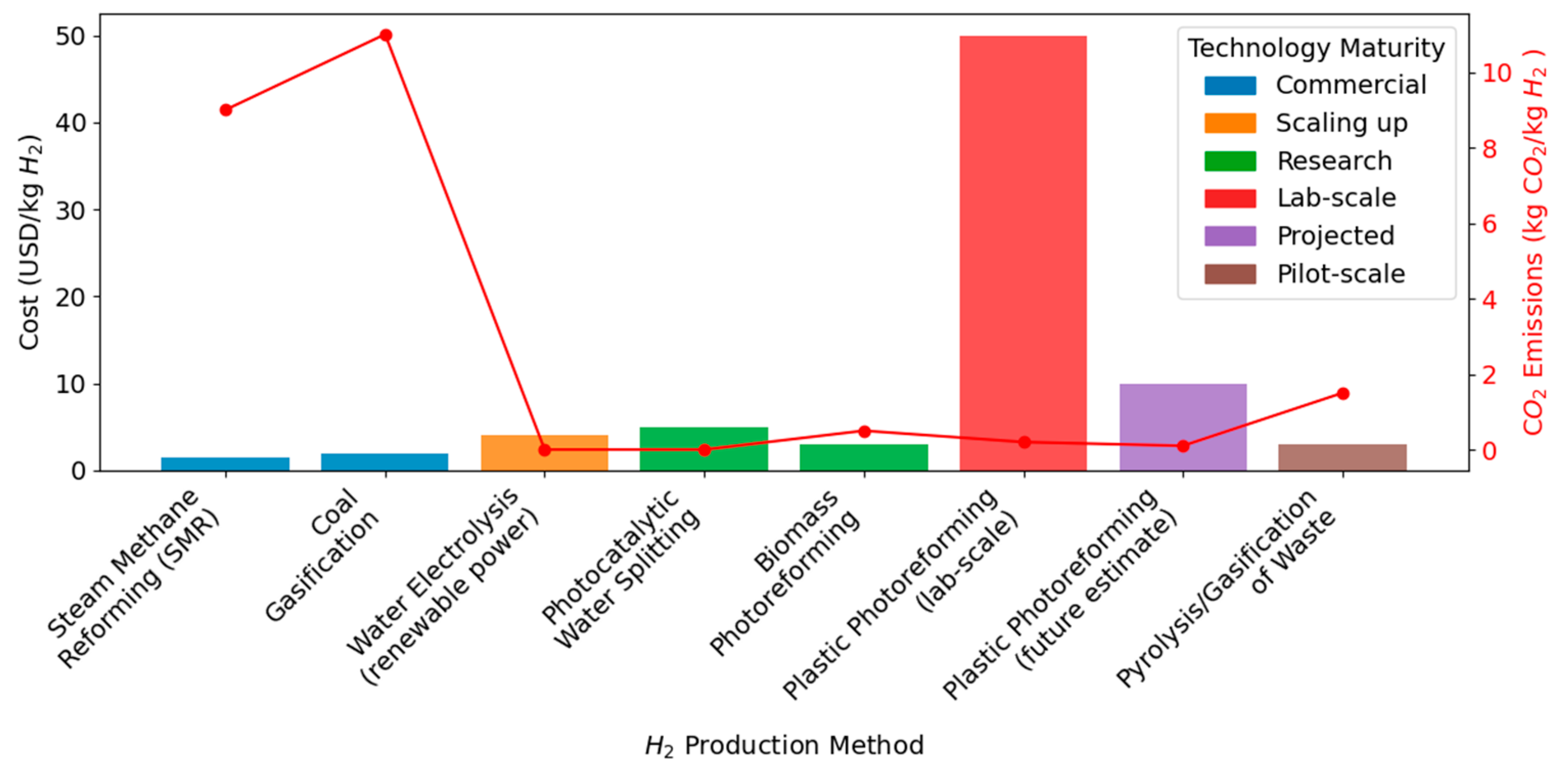

6.3. Life-Cycle Assessment (LCA) and Techno-Economic Analyses (TEA)

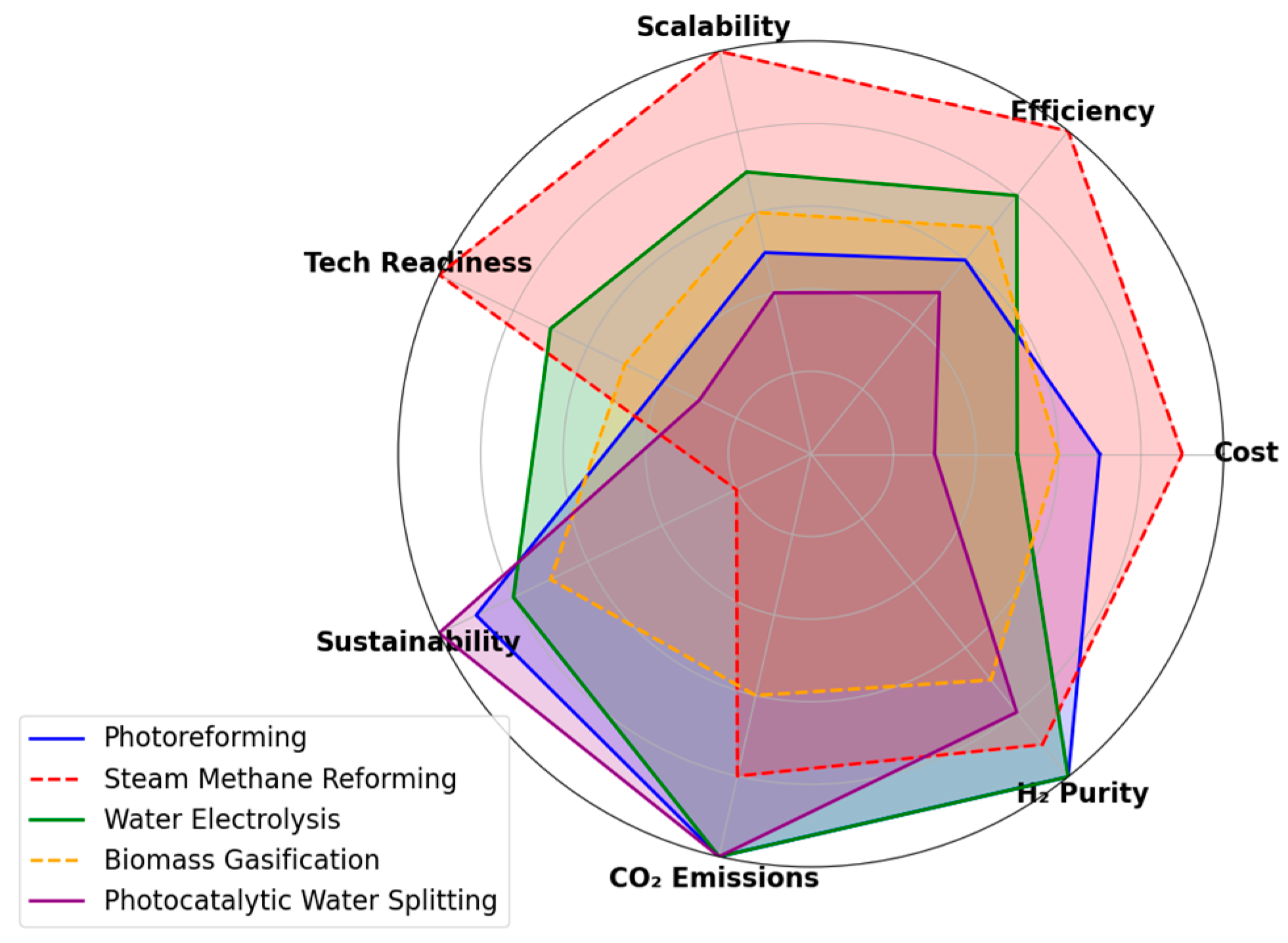

6.4. Comparative Benchmarking

7. Environmental and Sustainability Perspectives

7.1. Waste Management and the Circular Economy Context

7.2. Waste Management and the Circular Economy Context

7.3. Policy and Regulatory Landscape

- Increased R&D Funding: Governments could allocate research grants to accelerate the development of high efficiency photocatalysts and scalable reactor designs.

- Market-Based Incentives: Carbon credits or renewable energy credits could be extended to photoreforming projects.

- Mandated Recycled Content: Setting minimum thresholds for recycled plastic usage in industrial applications could further drive investment in advanced recycling technologies.

8. Challenges and Future Directions

8.1. Technical Hurdles

8.2. Materials Innovation

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- B. Research, "Market Trends in the Plastics Industry: An Analysis of Developments by Key Plastics Manufacturers," Sep 2023 2023. [Online]. Available: https://www.bccresearch.com/market-research/plastics/plastic-industry-market-trends.html.

- G. E. Network. "Plastic Production and Industry | Plastics and the Environment Series." https://www.genevaenvironmentnetwork.org/resources/updates/plastic-production-and-industry/ (accessed.

- M. Kumar et al., "Current research trends on micro-and nano-plastics as an emerging threat to global environment: A review," Journal of Hazardous Materials, vol. 409, p. 124967, 2021. [CrossRef]

- P. Europe. Plastics – the fast Facts 2024. (2024). [Online]. Available: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2024/.

- "Department of Energy Hydrogen Program Plan," U.S. Department of Energy 2024. [Online]. Available: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/hydrogen-program-plan-2024.pdf?sfvrsn=bfc739dd_1.

- K. Lan and Y. Yao, "Feasibility of gasifying mixed plastic waste for hydrogen production and carbon capture and storage," Communications Earth & Environment, vol. 3, no. 1, p. 300, 2022. [CrossRef]

- C. Jehanno et al., "Critical advances and future opportunities in upcycling commodity polymers," Nature, vol. 603, no. 7903, pp. 803-814, 2022/03/01 2022. [CrossRef]

- U. EPA. "National Overview: Facts and Figures on Materials, Wastes and Recycling." https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials#Recycling/Composting (accessed.

- T. K. Anh Nguyen, T. Trần-Phú, R. Daiyan, X. Minh Chau Ta, R. Amal, and A. Tricoli, "From Plastic Waste to Green Hydrogen and Valuable Chemicals Using Sunlight and Water," Angewandte Chemie International Edition, vol. 63, no. 32, p. e202401746, 2024. [CrossRef]

- E. M. N. T. Edirisooriya, P. S. Senanayake, H. B. Wang, M. R. Talipov, P. Xu, and H. Wang, "Photo-reforming and degradation of waste plastics under UV and visible light for H2 production using nanocomposite photocatalysts," Journal of Environmental Chemical Engineering, vol. 11, no. 2, p. 109580, 2023/04/01/ 2023. [CrossRef]

- H. T. N. Hai, T. T. Nguyen, M. Nishibori, T. Ishihara, and K. Edalati, "Photoreforming of plastic waste into valuable products and hydrogen using a high-entropy oxynitride with distorted atomic-scale structure," Applied Catalysis B: Environment and Energy, vol. 365, p. 124968, 2025/05/15/ 2025. [CrossRef]

- M. Ashraf, N. Ullah, I. Khan, W. Tremel, S. Ahmad, and M. N. Tahir, "Photoreforming of Waste Polymers for Sustainable Hydrogen Fuel and Chemicals Feedstock: Waste to Energy," Chemical Reviews, vol. 123, no. 8, pp. 4443-4509, 2023/04/26 2023. [CrossRef]

- A. Mehtab et al., "Hydrogen Energy as Sustainable Energy Resource for Carbon-Neutrality Realization," ACS Sustainable Resource Management, vol. 1, no. 4, pp. 604-620, 2024/04/25 2024. [CrossRef]

- L.-H. Chang, S.-T. Yong, S. P. Chai, L. K. Putri, L. L. Tan, and A. R. Mohamed, "A review of methanol photoreforming: elucidating the mechanisms, photocatalysts and recent advancement strategies," Materials Today Chemistry, 2023. [CrossRef]

- X. Tang, X. Han, N. H. M. Sulaiman, L. He, and X. Zhou, "Recent Advances in the Photoreforming of Plastic Waste: Principles, Challenges, and Perspectives," Industrial & Engineering Chemistry Research, vol. 62, no. 23, pp. 9032-9045, 2023/06/14 2023. [CrossRef]

- C. Y. Toe et al., "Advancing photoreforming of organics: highlights on photocatalyst and system designs for selective oxidation reactions," Energy & Environmental Science, vol. 14, no. 3, pp. 1140-1175, 2021. [CrossRef]

- S. P. Shelake, D. N. Sutar, B. M. Abraham, T. Banerjee, A. V. S. Sainath, and U. Pal, "Emerging Photoreforming Process to Hydrogen Production: A Future Energy," Advanced Functional Materials, vol. 34, no. 40, p. 2403795, 2024. [CrossRef]

- E. M. N. Thiloka Edirisooriya, P. S. Senanayake, P. Xu, and H. Wang, "Hydrogen production and value-added chemical recovery from the photo-reforming process using waste plastics," Journal of Environmental Chemical Engineering, vol. 11, no. 6, p. 111429, 2023/12/01/ 2023. [CrossRef]

- P. Praus, "Photoreforming for microplastics recycling: A critical review," Journal of Environmental Chemical Engineering, vol. 12, no. 3, p. 112525, 2024/06/01/ 2024. [CrossRef]

- T. K. A. Nguyen et al., "Understanding Structure-Activity Relationship in Pt-loaded g-C3N4 for Efficient Solar- Photoreforming of Polyethylene Terephthalate Plastic and Hydrogen Production," Small Methods, vol. 8, no. 2, p. 2300427, 2024. [CrossRef]

- X. Li, Q. Wang, Y. Sun, S. Sun, and L. Ge, "Photogenerated charge carriers’ regulation strategies: Structure design, mechanism, and characterization technology," International Journal of Hydrogen Energy, vol. 69, pp. 1341-1365, 2024/06/05/ 2024. [CrossRef]

- A. S. Morshedy, E. M. El-Fawal, T. Zaki, A. A. El-Zahhar, M. M. Alghamdi, and A. M. A. El Naggar, "A review on heterogeneous photocatalytic materials: Mechanism, perspectives, and environmental and energy sustainability applications," Inorganic Chemistry Communications, vol. 163, p. 112307, 2024/05/01/ 2024. [CrossRef]

- N. Goodarzi, Z. Ashrafi-Peyman, E. Khani, and A. Z. Moshfegh, "Recent Progress on Semiconductor Heterogeneous Photocatalysts in Clean Energy Production and Environmental Remediation," Catalysts, vol. 13, no. 7, p. 1102, 2023. [Online]. Available: https://www.mdpi.com/2073-4344/13/7/1102. [CrossRef]

- M. B. Tahir and K. N. Riaz, "Fundamentals of Photocatalysis for Environmental Remediation," in Nanomaterials and Photocatalysis in Chemistry: Mechanistic and Experimental Approaches, M. B. Tahir and K. N. Riaz Eds. Singapore: Springer Singapore, 2021, pp. 19-41.

- M. M. Khan, "Chapter 4 - Semiconductors as photocatalysts: visible-light active materials," in Theoretical Concepts of Photocatalysis, M. Mansoob Khan Ed.: Elsevier, 2023, pp. 53-75.

- K. Huang et al., "Interface-induced charge transfer pathway switching of a Cu2O-TiO2 photocatalyst from p-n to S-scheme heterojunction for effective photocatalytic H2 evolution," Journal of Materials Science & Technology, vol. 193, pp. 98-106, 2024/09/10/ 2024. [CrossRef]

- Y. Liu et al., "Bandgap engineering control bifunctional MnxCd1-xS photocatalysts selectively reforming xylose to C3 organic acids and efficient hydrogen production," Journal of Colloid and Interface Science, vol. 652, pp. 2066-2075, 2023/12/15/ 2023. [CrossRef]

- V. S. Mothika, P. Sutar, P. Verma, S. Das, S. K. Pati, and T. K. Maji, "Regulating Charge-Transfer in Conjugated Microporous Polymers for Photocatalytic Hydrogen Evolution," Chemistry – A European Journal, vol. 25, no. 15, pp. 3867-3874, 2019. [CrossRef]

- T. Li and Y. Jing, "Band Structure Engineering of 2D Heterotriangulene Polymers by Incorporating Acetylenic Linkages for Photocatalytic Hydrogen Production," The Journal of Physical Chemistry C, vol. 126, no. 42, pp. 17836-17843, 2022/10/27 2022. [CrossRef]

- N. Tuan Van, T. Mahider, L. Quyet Van, T. Chau Van, A. Sang Hyun, and K. Soo Young, "Recent progress and strategies of non-noble metal electrocatalysts based on MoS2/MOF for the hydrogen evolution reaction in water electrolysis: an overview," Microstructures, vol. 4, no. 4, p. 2024046, 2024. [CrossRef]

- X. Wang, M. Yu, and X. Feng, "Electronic structure regulation of noble metal-free materials toward alkaline oxygen electrocatalysis," eScience, vol. 3, no. 4, p. 100141, 2023/08/01/ 2023. [CrossRef]

- J. Ni et al., "Development of noble metal-free electrocatalysts towards acidic water oxidation: From fundamental understanding to state-of-the-art catalysts," eScience, vol. 5, no. 2, p. 100295, 2025/03/01/ 2025. [CrossRef]

- Y. Lin, Y. Cao, Q. Yao, O. J. H. Chai, and J. Xie, "Engineering Noble Metal Nanomaterials for Pollutant Decomposition," Industrial & Engineering Chemistry Research, vol. 59, no. 47, pp. 20561-20581, 2020/11/25 2020. [CrossRef]

- E. M. N. T. Edirisooriya, P. S. Senanayake, P. Xu, and H. Wang, "Enhanced H2 Production Efficiency in Photo-Reforming of PET Waste Plastic Using Dark-Deposited Atom/Nanocomposite Pt/TiO2 Photocatalysts," Catalysts, vol. 15, no. 4, p. 334, 2025. [Online]. Available: https://www.mdpi.com/2073-4344/15/4/334. [CrossRef]

- J. Wang, P. Kumar, H. Zhao, M. G. Kibria, and J. Hu, "Polymeric carbon nitride-based photocatalysts for photoreforming of biomass derivatives," Green Chemistry, 10.1039/D1GC02307A vol. 23, no. 19, pp. 7435-7457, 2021. [CrossRef]

- S. Yue, Z. Zhao, T. Zhang, F. Li, P. Wang, and S. Zhan, "Photoreforming of Plastic Waste to Sustainable Fuels and Chemicals: Waste to Energy," Environmental Science & Technology, vol. 58, no. 52, pp. 22865-22879, 2024. [CrossRef]

- A. Gautam, S. Das, and M. I. Ahmad, "Band gap engineering through calcium addition in (Mg, Co, Ni, Cu, Zn)O high entropy oxide for efficient photocatalysis," Surfaces and Interfaces, vol. 46, p. 104054, 2024/03/01/ 2024. [CrossRef]

- Y. Yu, Z. Zhu, and H. Huang, "Surface engineered single-atom systems for energy conversion," Advanced Materials, vol. 36, no. 16, p. 2311148, 2024. [CrossRef]

- X. Liang et al., "Photoreforming of poly(ethylene-terephthalate) plastic into valuable chemicals and hydrogen over BiVO4/MoOx: Synergistic promotion of oxidation and reduction processes," Applied Catalysis B: Environment and Energy, vol. 357, p. 124326, 2024/11/15/ 2024. [CrossRef]

- X. Zhang, W. Zu, and L. Y. S. Lee, "Crucial role of pre-treatment in plastic photoreforming for precision upcycling," npj Materials Sustainability, vol. 3, no. 1, p. 3, 2025/01/16 2025. [CrossRef]

- J. Xiao, "Catalyzing photo-degradation of waste plastics with a uranium complex," Science Bulletin, vol. 68, no. 21, pp. 2498-2499, 2023. [CrossRef]

- B. Gewert, M. M. Plassmann, and M. MacLeod, "Pathways for degradation of plastic polymers floating in the marine environment," Environmental Science: Processes & Impacts, vol. 17, no. 9, pp. 1513-1521, 2015. [CrossRef]

- G. Scott, Degradable Polymers: Principles and Applications. 2002.

- G. Pritchard, Plastics Additives. Springer Dordrecht, 1998.

- L. H. Sperling, Introduction to Physical Polymer Science. Hoboken, New Jersey: John Wiley & Sons, Inc. , 2006.

- S. A. Norman, E. Michael, M. Mehrdad, and J. Ken, "Hydrolytic degradation of poly(ethylene terephthalate): Importance of chain scission versus crystallinity," European Polymer Journal, vol. 27, no. 12, pp. 1373-1378, 1991. [CrossRef]

- J. K. Fink, Thomas, S., Visakh, P. M., Handbook of Engineering and Specialty Thermoplastics. WILEY, 2011.

- T. Uekert, M. F. Kuehnel, D. W. Wakerley, and E. Reisner, "Plastic waste as a feedstock for solar-driven H2 generation," Energy & Environmental Science, vol. 11, no. 10, pp. 2853-2857, 2018. [CrossRef]

- E. M. N. T. Edirisooriya, S. S. Punhasa, X. Pei, and W. Huiyao, "Hydrogen production and value-added chemical recovery from the photo-reforming process using waste plastics," Journal of Environmental Chemical Engineering, vol. 11, no. 6, p. 111429, 2023. [CrossRef]

- X. Jiao, K. Zheng, Z. Hu, S. Zhu, Y. Sun, and Y. Xie, "Conversion of waste plastics into value-added carbonaceous fuels under mild conditions," Advanced Materials, vol. 33, no. 50, p. 2005192, 2021. [CrossRef]

- X. Jiao, K. Zheng, Z. Hu, S. Zhu, Y. Sun, and Y. Xie, "Conversion of Waste Plastics into Value-Added Carbonaceous Fuels under Mild Conditions," Advanced Materials, vol. 33, no. 50, p. 2005192, 2021. [CrossRef]

- S. Bhattacharjee, V. Andrei, C. Pornrungroj, M. Rahaman, C. M. Pichler, and E. Reisner, "Reforming of Soluble Biomass and Plastic Derived Waste Using a Bias-Free Cu30Pd70|Perovskite|Pt Photoelectrochemical Device," Advanced Functional Materials, vol. 32, no. 7, p. 2109313, 2022. [CrossRef]

- M. Rakowski DuBois and D. L. DuBois, "Development of molecular electrocatalysts for CO2 reduction and H2 production/oxidation," (in eng), Acc Chem Res, vol. 42, no. 12, pp. 1974-82, Dec 21 2009. [CrossRef]

- X. Zhang, W. Zu, and L. Y. S. Lee, "Crucial role of pre-treatment in plastic photoreforming for precision upcycling," npj Materials Sustainability, vol. 3, no. 1, 2025. [CrossRef]

- S. Yue, Z. Zhao, T. Zhang, F. Li, P. Wang, and S. Zhan, "Photoreforming of Plastic Waste to Sustainable Fuels and Chemicals: Waste to Energy," Environ Sci Technol, vol. 58, no. 52, pp. 22865-22879, Dec 31 2024. [CrossRef]

- T. Uekert, H. Kasap, and E. Reisner, "Photoreforming of Nonrecyclable Plastic Waste over a Carbon Nitride/Nickel Phosphide Catalyst," Journal of the American Chemical Society, vol. 141, no. 38, pp. 15201-15210, 2019/09/25 2019. [CrossRef]

- Y. Wan et al., "Enhanced degradation of polyethylene terephthalate plastics by CdS/CeO2 heterojunction photocatalyst activated peroxymonosulfate," Journal of Hazardous Materials, vol. 452, p. 131375, 2023/06/15/ 2023. [CrossRef]

- F. Ippolito, G. Hübner, T. Claypole, and P. Gane, "Calcium Carbonate as Functional Filler in Polyamide 12-Manipulation of the Thermal and Mechanical Properties," Processes, vol. 9, no. 6, p. 937, 2021. [Online]. Available: https://www.mdpi.com/2227-9717/9/6/937. [CrossRef]

- S. Siraj, A. H. Al-Marzouqi, M. Z. Iqbal, and W. Ahmed, "Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material," (in eng), Polymers (Basel), vol. 14, no. 22, Nov 9 2022. [CrossRef]

- C. Cazan, A. Enesca, and L. Andronic, "Synergic Effect of TiO(2) Filler on the Mechanical Properties of Polymer Nanocomposites," (in eng), Polymers (Basel), vol. 13, no. 12, Jun 20 2021. [CrossRef]

- G. L. Chiarello, A. Di Paola, L. Palmisano, and E. Selli, "Effect of titanium dioxide crystalline structure on the photocatalytic production of hydrogen," Photochemical & Photobiological Sciences, 10.1039/C0PP00154F vol. 10, no. 3, pp. 355-360, 2011. [CrossRef]

- Y. Miao, Y. Zhao, J. Gao, J. Wang, and T. Zhang, "Direct Photoreforming of Real-World Polylactic Acid Plastics into Highly Selective Value-Added Pyruvic Acid under Visible Light," Journal of the American Chemical Society, vol. 146, no. 7, pp. 4842-4850, 2024/02/21 2024. [CrossRef]

- H. Li, B. Cheng, J. Xu, J. Yu, and S. Cao, "Crystalline carbon nitrides for photocatalysis," EES Catalysis, vol. 2, no. 2, pp. 411-447, 2024. [CrossRef]

- T. K. Anh Nguyen, T. Tran-Phu, R. Daiyan, X. Minh Chau Ta, R. Amal, and A. Tricoli, "From Plastic Waste to Green Hydrogen and Valuable Chemicals Using Sunlight and Water," Angew Chem Int Ed Engl, vol. 63, no. 32, p. e202401746, Aug 5 2024. [CrossRef]

- H. Nagakawa and M. Nagata, "Photoreforming of Organic Waste into Hydrogen Using a Thermally Radiative CdO(x)/CdS/SiC Photocatalyst," ACS Appl Mater Interfaces, vol. 13, no. 40, pp. 47511-47519, Oct 13 2021. [CrossRef]

- E. M. N. T. Edirisooriya, P. S. Senanayake, P. Xu, M. R. Talipov, and H. Wang, "Optimization of green hydrogen evolution from low-density plastics using TiO2-based nano-photocatalysts with techno-economic and carbon footprint assessment," Nanotechnology for Environmental Engineering, vol. 9, no. 4, pp. 817-832, 2024/12/01 2024. [CrossRef]

- H. Pan, J. Li, Y. Wang, Q. Xia, L. Qiu, and B. Zhou, "Solar-Driven Biomass Reforming for Hydrogen Generation: Principles, Advances, and Challenges," (in eng), Adv Sci (Weinh), vol. 11, no. 29, p. e2402651, Aug 2024. [CrossRef]

- D. N. Sutar, S. P. Shelake, N. R. Indla, S. Varangane, A. V. Sesha Sainath, and U. Pal, "Visible light-driven photoreforming of polystyrene segmented glycopolymer architectures for enhanced hydrogen generation," Materials Today Energy, vol. 45, p. 101667, 2024/10/01/ 2024. [CrossRef]

- J. He et al., "Efficient photodegradation of polystyrene microplastics integrated with hydrogen evolution: Uncovering degradation pathways," iScience, vol. 26, no. 6, p. 106833, 2023/06/16/ 2023. [CrossRef]

- L. Lan et al., "Effect of Ball-Milling Pretreatment of Cellulose on Its Photoreforming for H(2) Production," (in eng), ACS Sustain Chem Eng, vol. 10, no. 15, pp. 4862-4871, Apr 18 2022. [CrossRef]

- M. Samadi, M. Zirak, A. Naseri, E. Khorashadizade, and A. Z. Moshfegh, "Recent progress on doped ZnO nanostructures for visible-light photocatalysis," Thin Solid Films, vol. 605, pp. 2-19, 2016/04/30/ 2016. [CrossRef]

- M. A. Khan, S. Mutahir, I. Shaheen, Y. Qunhui, M. Bououdina, and M. Humayun, "Recent advances over the doped g-C3N4 in photocatalysis: A review," Coordination Chemistry Reviews, vol. 522, p. 216227, 2025/01/01/ 2025. [CrossRef]

- J. R. Wang et al., "Robust links in photoactive covalent organic frameworks enable effective photocatalytic reactions under harsh conditions," Nat Commun, vol. 15, no. 1, p. 1267, Feb 10 2024. [CrossRef]

- N. Sun, X. Si, L. He, J. Zhang, and Y. Sun, "Strategies for enhancing the photocatalytic activity of semiconductors," International Journal of Hydrogen Energy, vol. 58, pp. 1249-1265, 2024/03/08/ 2024. [CrossRef]

- H. M. Rasheed, K. Aroosh, D. Meng, X. Ruan, M. Akhter, and X. Cui, "A review on modified ZnO to address environmental challenges through photocatalysis: Photodegradation of organic pollutants," Materials Today Energy, vol. 48, p. 101774, 2025/03/01/ 2025. [CrossRef]

- J. Jeyavani, K. A. Al-Ghanim, M. Govindarajan, G. Malafaia, and B. Vaseeharan, "A convenient strategy for mitigating microplastics in wastewater treatment using natural light and ZnO nanoparticles as photocatalysts: A mechanistic study," Journal of Contaminant Hydrology, vol. 267, p. 104436, 2024/11/01/ 2024. [CrossRef]

- Y. Ma, G. Hai, J. Liu, J. Bao, Y. Li, and G. Wang, "Enhanced visible light photocatalytic hydrogen evolution by intimately contacted Ni2P decorated Ni-doped CdS nanospheres," Chemical Engineering Journal, vol. 441, p. 136002, 2022/08/01/ 2022. [CrossRef]

- N. Downs, Parisi, A.V., Galligan, L., Turner, J., Amar, A., King, R., Ultra, F., & Butler, H., "Solar radiation and the UV index: An application of numerical integration, trigonometric functions, online education and the modelling process," International Journal of Research in Education and Science, vol. 2, no. 1, pp. 179-189, 2016.

- J. D. Graham and N. I. Hammer, "Photocatalytic Water Splitting and Carbon Dioxide Reduction," in Handbook of Climate Change Mitigation, W.-Y. Chen, J. Seiner, T. Suzuki, and M. Lackner Eds. New York, NY: Springer US, 2012, pp. 1755-1780.

- W. Ma, L. Yu, P. Kang, Z. Chu, and Y. Li, "Modifications and Applications of Metal-Organic-Framework-Based Materials for Photocatalysis," Molecules, vol. 29, no. 24, Dec 11 2024. [CrossRef]

- H. Zhang, C. Li, Y. Li, J. Pang, and X. Bu, "The Advanced Synthesis of MOFs-Based Materials in Photocatalytic HER in Recent Three Years," Catalysts, vol. 12, no. 11, 2022. [CrossRef]

- Q. Wang et al., "Recent Advances in g-C(3)N(4)-Based Materials and Their Application in Energy and Environmental Sustainability," Molecules, vol. 28, no. 1, Jan 3 2023. [CrossRef]

- J. Y. Kim and D. H. Youn, "Nanomaterials for Advanced Photocatalytic Plastic Conversion," Molecules, vol. 28, no. 18, Sep 7 2023. [CrossRef]

- T. T. Nguyen, J. Hidalgo-Jiménez, X. Sauvage, K. Saito, Q. Guo, and K. Edalati, "Phase and sulfur vacancy engineering in cadmium sulfide for boosting hydrogen production from catalytic plastic waste photoconversion," Chemical Engineering Journal, vol. 504, p. 158730, 2025/01/15/ 2025. [CrossRef]

- M. A. Ahmed, S. A. Mahmoud, and A. A. Mohamed, "Unveiling the photocatalytic potential of graphitic carbon nitride (g-C(3)N(4)): a state-of-the-art review," RSC Adv, vol. 14, no. 35, pp. 25629-25662, Aug 12 2024. [CrossRef]

- L. T. Zongyang Ya, Dong Xu, Hua Wang, Shengbo Zhang, "Photoreforming of waste plastic by B-doped carbon nitride nanotube: Atomic-level modulation and mechanism insights," American Institute of Chemical Engineers, 2025. [CrossRef]

- J.-Q. Yan, D.-W. Sun, and J.-H. Huang, "Synergistic poly(lactic acid) photoreforming and H2 generation over ternary NixCo1-xP/reduced graphene oxide/g-C3N4 composite," Chemosphere, vol. 286, p. 131905, 2022/01/01/ 2022. [CrossRef]

- D. Liu, J. Yao, S. Chen, J. Zhang, R. Li, and T. Peng, "Construction of rGO-coupled C3N4/C3N5 2D/2D Z-scheme heterojunction to accelerate charge separation for efficient visible light H2 evolution," Applied Catalysis B: Environmental, vol. 318, p. 121822, 2022/12/05/ 2022. [CrossRef]

- S. Chen, T. Takata, and K. Domen, "Particulate photocatalysts for overall water splitting," Nature Reviews Materials, vol. 2, no. 10, p. 17050, 2017/08/01 2017. [CrossRef]

- Z. Xi, "Nanostructures Design: the Role of Cocatalysts for Hydrogen and Oxygen Generation in Photocatalytic Water Splitting," arXiv: Chemical Physics, 2021.

- O. Al-Madanat, Y. AlSalka, W. Ramadan, and D. W. Bahnemann, "TiO2 Photocatalysis for the Transformation of Aromatic Water Pollutants into Fuels," Catalysts, vol. 11, no. 3, 2021. [CrossRef]

- K. S. Exner, "On the optimum binding energy for the hydrogen evolution reaction: How do experiments contribute?," Electrochemical Science Advances, vol. 2, no. 4, 2021. [CrossRef]

- G. Cha et al., "As a single atom Pd outperforms Pt as the most active co-catalyst for photocatalytic H2 evolution," iScience, vol. 24, no. 8, p. 102938, 2021/08/20/ 2021. [CrossRef]

- A. Chen, M.-Q. Yang, S. Wang, and Q. Qian, "Recent Advancements in Photocatalytic Valorization of Plastic Waste to Chemicals and Fuels," Frontiers in Nanotechnology, vol. 3, 2021. [CrossRef]

- Y. Chen, L. Bai, D. Peng, X. Wang, M. Wu, and Z. Bian, "Advancements in catalysis for plastic resource utilization," Environmental Science: Advances, vol. 2, no. 9, pp. 1151-1166, 2023. [CrossRef]

- Y. Pan, Y. Lin, Y. Chen, Y. Liu, and C. Liu, "Cobalt phosphide-based electrocatalysts: synthesis and phase catalytic activity comparison for hydrogen evolution," Journal of Materials Chemistry A, vol. 4, no. 13, pp. 4745-4754, 2016. [CrossRef]

- S. Chu et al., "Photocatalytic Conversion of Plastic Waste: From Photodegradation to Photosynthesis," Advanced Energy Materials, vol. 12, no. 22, 2022. [CrossRef]

- B. Mokhtar, M. G. Ahmed, H. S. Alqahtani, and T. A. Kandiel, "Biomass and Plastic Photoreforming for Hydrogen and Valuable Chemicals Production." Berlin, Heidelberg: Springer Berlin Heidelberg, pp. 1-31.

- M. T. Islam et al., "Selectivity of Sol-Gel and Hydrothermal TiO(2) Nanoparticles towards Photocatalytic Degradation of Cationic and Anionic Dyes," Molecules, vol. 28, no. 19, Sep 27 2023. [CrossRef]

- A. B. Quispe Cohaila et al., "Improving Photocatalytic Hydrogen Production with Sol–Gel Prepared NiTiO₃/TiO₂ Composite," Energies, vol. 17, no. 23, 2024. [CrossRef]

- N. Kadiyala et al., "Ionic Liquid Mediated Sol Gel Method for Fabrication of Nanostructured Cerium and Phosphorus Doped TiO(2) - A Benign Photocatalyst: Diversified Applications in Degradation of Dyes and Microbes," (in eng), ACS Omega, vol. 10, no. 3, pp. 2658-2678, Jan 28 2025. [CrossRef]

- M. T. Islam et al., "Selectivity of Sol-Gel and Hydrothermal TiO2 Nanoparticles towards Photocatalytic Degradation of Cationic and Anionic Dyes," Molecules, vol. 28, no. 19, p. 6834, 2023. [Online]. Available: https://www.mdpi.com/1420-3049/28/19/6834. [CrossRef]

- F. Xu et al., "One-Step Hydrothermal Synthesis of Nanostructured MgBi(2)O(6)/TiO(2) Composites for Enhanced Hydrogen Production," (in eng), Nanomaterials (Basel), vol. 12, no. 8, Apr 11 2022. [CrossRef]

- A. Zindrou, P. Psathas, and Y. Deligiannakis, "Flame Spray Pyrolysis Synthesis of Vo-Rich Nano-SrTiO3-x," Nanomaterials, vol. 14, no. 4, p. 346, 2024. [Online]. Available: https://www.mdpi.com/2079-4991/14/4/346. [CrossRef]

- S. K. Nayak et al., "Metal–Organic Framework-Derived Hierarchical Ag/Sr6Bi2O9-α-Bi2O3 Ternary Photocatalyst for Micropollutant Remediation and Bacterial Photoinactivation," ACS Applied Engineering Materials, vol. 2, no. 1, pp. 179-194, 2024/01/26 2024. [CrossRef]

- C. Wang and M. N. Ghazzal, "Nanostructured TiO2for improving the solar-to-hydrogen conversion efficiency," Energy Advances, vol. 2, no. 7, pp. 965-979, 2023. [CrossRef]

- Y. Abdel-Maksoud, E. Imam, and A. Ramadan, "TiO2 Solar Photocatalytic Reactor Systems: Selection of Reactor Design for Scale-up and Commercialization—Analytical Review," Catalysts, vol. 6, no. 9, 2016. [CrossRef]

- R. A. Damodar, S.-J. You, and S.-H. Ou, "Coupling of membrane separation with photocatalytic slurry reactor for advanced dye wastewater treatment," Separation and Purification Technology, vol. 76, no. 1, pp. 64-71, 2010. [CrossRef]

- W. Xi and S.-u. Geissen, "Separation of titanium dioxide from photocatalytically treated water by cross-flow microfiltration," Water Research, vol. 35, no. 5, pp. 1256-1262, 2001/04/01/ 2001. [CrossRef]

- H. Jiang, G. Zhang, T. Huang, J. Chen, Q. Wang, and Q. Meng, "Photocatalytic membrane reactor for degradation of acid red B wastewater," Chemical Engineering Journal, vol. 156, no. 3, pp. 571-577, 2010/02/01/ 2010. [CrossRef]

- R. Yang, J. Xu, J. Wu, D. Lu, F. Wang, and K. Nie, "Enzyme Immobilization on Stainless Steel Fleece and Its Mass Transfer Enhancement of Enzymatic Catalysis in a Rotating Packed Bed Reactor," Catalysts, vol. 13, no. 12, 2023. [CrossRef]

- S. E. Kudaibergenov and G. I. Dzhardimalieva, "Flow-Through Catalytic Reactors Based on Metal Nanoparticles Immobilized within Porous Polymeric Gels and Surfaces/Hollows of Polymeric Membranes," Polymers (Basel), vol. 12, no. 3, Mar 4 2020. [CrossRef]

- F. Khodadadian, "Optimizing photon utilization in LED-based photocatalytic reactors," PhD, Delft University of Technology, Dissertation (TU Delft), Delft University of Technology, 2019. [Online]. Available: https://resolver.tudelft.nl/uuid:68bc7aa0-914c-4d2d-8e32-9d0ef996fdcc.

- H. Fu et al., "Green hydrogen production via a photocatalyst-enabled optical fiber system: A promising route to net-zero emissions," Energy and Climate Change, vol. 6, p. 100175, 2025/12/01/ 2025. [CrossRef]

- P. P. Kant, "Optimizing photocatalysts and photoreactors for solar fuel synthesis," PhD, Faculty of Chemical and Process Engineering Institute of Micro Process Engineering 2023. [Online]. Available: https://publikationen.bibliothek.kit.edu/1000162170.

- S. N. Degerli, A. Gramegna, M. Tommasi, G. Ramis, and I. Rossetti, "Reactor and Plant Designs for the Solar Photosynthesis of Fuels," Energies, vol. 17, no. 13, p. 3112, 2024. [Online]. Available: https://www.mdpi.com/1996-1073/17/13/3112. [CrossRef]

- G. B. Ramis, E.; Rossetti, I, "Photoreactors Design for Hydrogen Production," Chem. Eng. Trans., vol. 74, pp. 481–486, 2019. [CrossRef]

- N. F. Jaafar, Jalil, A. A., Triwahyono, S., & Ripin, A. , "Significant Effect of pH on Photocatalytic Degradation of Organic Pollutants Using Semiconductor Catalysts.," Jurnal Teknologi, vol. 78, pp. 7-12, 2016. [CrossRef]

- F. Azeez et al., "The effect of surface charge on photocatalytic degradation of methylene blue dye using chargeable titania nanoparticles," (in eng), Sci Rep, vol. 8, no. 1, p. 7104, May 8 2018. [CrossRef]

- J. Wenk, C. Graf, M. Aeschbacher, M. Sander, and S. Canonica, "Effect of Solution pH on the Dual Role of Dissolved Organic Matter in Sensitized Pollutant Photooxidation," Environmental Science & Technology, vol. 55, no. 22, pp. 15110-15122, 2021/11/16 2021. [CrossRef]

- A. Chaudhuri, S. D. A. Zondag, J. H. A. Schuurmans, J. van der Schaaf, and T. Noël, "Scale-Up of a Heterogeneous Photocatalytic Degradation Using a Photochemical Rotor–Stator Spinning Disk Reactor," Organic Process Research & Development, vol. 26, no. 4, pp. 1279-1288, 2022/04/15 2022. [CrossRef]

- J. C. García-Prieto, L. A. González-Burciaga, J. B. Proal-Nájera, and M. García-Roig, "Study of Influence Factors in the Evaluation of the Performance of a Photocatalytic Fibre Reactor (TiO2/SiO2) for the Removal of Organic Pollutants from Water," Catalysts, vol. 12, no. 2, p. 122, 2022. [Online]. Available: https://www.mdpi.com/2073-4344/12/2/122. [CrossRef]

- J. Akach, J. Kabuba, and A. Ochieng, "Simulation of the Light Distribution in a Solar Photocatalytic Bubble Column Reactor Using the Monte Carlo Method," Industrial & Engineering Chemistry Research, vol. 59, no. 40, pp. 17708-17719, 2020/10/07 2020. [CrossRef]

- Q. Jamil, B. Žener, U. Putar, and L. Matoh, "Continuous flow photocatalytic reactor for degradation of selected pollutants: Modeling, kinetics, mineralization rate, and toxicity assessment," Heliyon, vol. 10, no. 21, 2024. [CrossRef]

- N. H. M. Sulaiman, S. Wang, H. Yue, J. Wei, P. Schmuki, and X. Zhou, "Hydrogen evolution using alloyed AuPd/TiO2 hollow spheres by photoreforming of polyethylene terephthalate waste," Journal of Materials Chemistry A, 10.1039/D5TA00189G 2025. [CrossRef]

- Y. Zheng et al., "Visible light driven reform of wasted plastics to generate green hydrogen over mesoporous ZnIn(2)S(4)," RSC Adv, vol. 13, no. 19, pp. 12663-12669, Apr 24 2023. [CrossRef]

- Q. Zhang et al., "Accelerating photocatalytic hydrogen production by anchoring Pt single atoms on few-layer g-C3N4 nanosheets with Pt–N coordination," Journal of Materials Chemistry C, 10.1039/D3TC04673G vol. 12, no. 10, pp. 3437-3449, 2024. [CrossRef]

- J. Ran et al., "NiPS(3) ultrathin nanosheets as versatile platform advancing highly active photocatalytic H(2) production," Nat Commun, vol. 13, no. 1, p. 4600, Aug 6 2022. [CrossRef]

- J. Li, H.-P. Ma, G. Zhao, G. Huang, W. Sun, and C. Peng, "Plastic Waste Conversion by Leveraging Renewable Photo/Electro-Catalytic Technologies," ChemSusChem, vol. 17, no. 10, p. e202301352, 2024. [CrossRef]

- Y. Zheng et al., "Visible light driven reform of wasted plastics to generate green hydrogen over mesoporous ZnIn2S4," RSC Advances, 10.1039/D3RA02279J vol. 13, no. 19, pp. 12663-12669, 2023. [CrossRef]

- Y. Wan, H. Wang, and P. Huo, "Plastic Degradation and Conversion by Photocatalysis," in Plastic Degradation and Conversion by Photocatalysis (Volume 2): From Waste to Wealth, vol. 1490, (ACS Symposium Series, no. 1490): American Chemical Society, 2024, ch. 1, pp. 1-22.

- N. Qin, A. Mao, J. Zou, L. Mi, and L. Wu, "Visible-light-driven H2 production from heterostructured Zn0.5Cd0.5S–TiO2 photocatalysts modified with reduced graphene oxides," New Journal of Chemistry, 10.1039/D1NJ04195A vol. 45, no. 45, pp. 21415-21422, 2021. [CrossRef]

- S. Zhang et al., "Boosted Photoreforming of Plastic Waste via Defect-Rich NiPS3 Nanosheets," Journal of the American Chemical Society, vol. 145, no. 11, pp. 6410-6419, 2023/03/22 2023. [CrossRef]

- J. Xu et al., "Plastics-to-syngas photocatalysed by Co–Ga2O3 nanosheets," National Science Review, vol. 9, no. 9, p. nwac011, 2022. [CrossRef]

- M. Nees, M. Adeel, L. Pazdur, M. Porters, C. M. L. Vande Velde, and P. Billen, "Polyurethane Waste Recycling: Thermolysis of the Carbamate Fraction," (in eng), ACS Omega, vol. 9, no. 43, pp. 43438-43446, Oct 29 2024. [CrossRef]

- S. Fawzi, E. Yousif, K. Zainulabdeen, M. Bufaroosha, and D. Ahmed, "Highly effective photostabilization of polyvinyl chloride films using omeprazole-tin additive complexes," Journal of Umm Al-Qura University for Applied Sciences, 2025/01/11 2025. [CrossRef]

- R. Yang, H. Cao, H. Dong, and X. Wang, "The mechanism of UV accelerated aging of polyvinyl chloride in marine environment: The role of free radicals," Marine Pollution Bulletin, vol. 207, p. 116736, 2024/10/01/ 2024. [CrossRef]

- D. Zhang, C. Zhang, G. Zhao, Y. Gao, T. Zhuang, and Z. Lv, "Single-atom Pt supported on defective graphitic carbon nitride for efficient photocatalytic hydrogen production," Chemical Engineering Journal, vol. 505, p. 159567, 2025/02/01/ 2025. [CrossRef]

- Y. Jiang et al., "An Integrated Plasma–Photocatalytic System for Upcycling of Polyolefin Plastics," ChemSusChem, vol. 16, no. 14, p. e202300106, 2023. [CrossRef]

- S. Bhattacharjee et al., "Chemoenzymatic Photoreforming: A Sustainable Approach for Solar Fuel Generation from Plastic Feedstocks," Journal of the American Chemical Society, vol. 145, no. 37, pp. 20355-20364, 2023/09/20 2023. [CrossRef]

- K. S. Ng and A. N. Phan, "Evaluating the Techno-economic Potential of an Integrated Material Recovery and Waste-to-Hydrogen System," Resources, Conservation and Recycling, vol. 167, p. 105392, 2021/04/01/ 2021. [CrossRef]

- Z. Chen, W. Wei, X. Chen, Y. Liu, Y. Shen, and B.-J. Ni, "Upcycling of plastic wastes for hydrogen production: Advances and perspectives," Renewable and Sustainable Energy Reviews, vol. 195, p. 114333, 2024/05/01/ 2024. [CrossRef]

- D. Gunawan et al., "Materials Advances in Photocatalytic Solar Hydrogen Production: Integrating Systems and Economics for a Sustainable Future," Advanced Materials, vol. 36, no. 42, p. 2404618, 2024. [CrossRef]

- D. Ouyang et al., "Light-driven lignocellulosic biomass conversion for production of energy and chemicals," (in eng), iScience, vol. 25, no. 10, p. 105221, Oct 21 2022. [CrossRef]

- J. Tian, C. Guan, H. Hu, E. Liu, and D. Yang, "Waste plastics promoted photocatalytic H2 evolution over S-scheme NiCr2O4/twinned-Cd0.5Zn0.5S homo-heterojunction," Acta Physico-Chimica Sinica, vol. 41, no. 6, p. 100068, 2025/06/01/ 2025. [CrossRef]

- R. Balu, N. K. Dutta, and N. Roy Choudhury, "Plastic Waste Upcycling: A Sustainable Solution for Waste Management, Product Development, and Circular Economy," (in eng), Polymers (Basel), vol. 14, no. 22, Nov 8 2022. [CrossRef]

- A. Bratovcic, "Photocatalytic Degradation of Plastic Waste: Recent Progress and Future Perspectives," Advances in Nanoparticles, vol. 13, no. 03, pp. 61-78, 2024. [CrossRef]

- G. Biale et al., "A Systematic Study on the Degradation Products Generated from Artificially Aged Microplastics," Polymers, vol. 13, no. 12, p. 1997, 2021. [Online]. Available: https://www.mdpi.com/2073-4360/13/12/1997. [CrossRef]

- T. Li, A. Vijeta, C. Casadevall, A. S. Gentleman, T. Euser, and E. Reisner, "Bridging Plastic Recycling and Organic Catalysis: Photocatalytic Deconstruction of Polystyrene via a C–H Oxidation Pathway," ACS Catalysis, vol. 12, no. 14, pp. 8155-8163, 2022/07/15 2022. [CrossRef]

- D. Chu et al., "Photocatalytic Oxidation of Polyethylene to Dicarboxylic Acid over BiOI/BiVO4 p–n Heterojunction Under Visible Light," CCS Chemistry, vol. 0, no. 0, pp. 1-11. [CrossRef]

- J. P. d. Costa, A. Avellan, C. Mouneyrac, A. Duarte, and T. Rocha-Santos, "Plastic additives and microplastics as emerging contaminants: Mechanisms and analytical assessment," TrAC Trends in Analytical Chemistry, vol. 158, p. 116898, 2023/01/01/ 2023. [CrossRef]

- X. Zhang, M. Jun, W. Zu, M. Kim, K. Lee, and L. Y. S. Lee, "Photoreforming of Microplastics: Challenges and Opportunities for Sustainable Environmental Remediation," Small, vol. 20, no. 46, p. e2403347, Nov 2024. [CrossRef]

- M. V. S. Maria Vittoria Diamanti, MariaPia Pedeferri, and R. R. Anna Maria Ferrari, *and Daniela Meroni, "Toward Sustainable Photocatalysis: Addressing Deactivation and Environmental Impact of Anodized and Sol–Gel Photocatalysts," 2025. [CrossRef]

- Y. He, A. U. Rehman, M. Xu, C. A. Not, A. M. C. Ng, and A. B. Djurišić, "Photocatalytic degradation of different types of microplastics by TiO(x)/ZnO tetrapod photocatalysts," (in eng), Heliyon, vol. 9, no. 11, p. e22562, Nov 2023. [CrossRef]

- L. V. Bora, M. Bhatt, A. Patel, and N. V. Bora, "Plastic Degradation by Photocatalysis: Basic Concepts and General Mechanisms," in Plastic Degradation and Conversion by Photocatalysis (Volume 1): A Sustainable Approach, vol. 1489, (ACS Symposium Series, no. 1489): American Chemical Society, 2024, ch. 1, pp. 1-22.

- J. Zhao et al., "Highly selective upcycling of plastic mixture waste by microwave-assisted catalysis over Zn/b-ZnO," Nat Commun, vol. 16, no. 1, p. 1726, Feb 18 202. [CrossRef]

- H. Du, Y. Xie, and J. Wang, "Microplastic degradation methods and corresponding degradation mechanism: Research status and future perspectives," Journal of Hazardous Materials, vol. 418, p. 126377, 2021/09/15/ 2021. [CrossRef]

- D. T. Li, H. Yu, and Y. Huang, "Facile H(2)PdCl(4)-induced photoreforming of insoluble PET waste for C1-C3 compound production," Front Chem, vol. 11, p. 1265556, 2023. [CrossRef]

- K. Bule Možar et al., "Evaluation of Fenton, Photo-Fenton and Fenton-like Processes in Degradation of PE, PP, and PVC Microplastics," Water, vol. 16, no. 5, p. 673, 2024. [Online]. Available: https://www.mdpi.com/2073-4441/16/5/673. [CrossRef]

- M. Surana, D. S. Pattanayak, V. Yadav, V. K. Singh, and D. Pal, "An insight decipher on photocatalytic degradation of microplastics: Mechanism, limitations, and future outlook," Environmental Research, vol. 247, p. 118268, 2024/04/15/ 2024. [CrossRef]

- Y. Pan et al., "Removing microplastics from aquatic environments: A critical review," (in eng), Environ Sci Ecotechnol, vol. 13, p. 100222, Jan 2023. [CrossRef]

- A. Xie, M. Jin, J. Zhu, Q. Zhou, L. Fu, and W. Wu, "Photocatalytic Technologies for Transformation and Degradation of Microplastics in the Environment: Current Achievements and Future Prospects," Catalysts, vol. 13, no. 5, p. 846, 2023. [Online]. Available: https://www.mdpi.com/2073-4344/13/5/846. [CrossRef]

- P. Chattopadhyay, M. C. Ariza-Tarazona, E. I. Cedillo-Gonzalez, C. Siligardi, and J. Simmchen, "Combining photocatalytic collection and degradation of microplastics using self-asymmetric Pac-Man TiO(2)," Nanoscale, vol. 15, no. 36, pp. 14774-14781, Sep 21 2023. [CrossRef]

- B. E. Llorente-García, J. M. Hernández-López, A. A. Zaldívar-Cadena, C. Siligardi, and E. I. Cedillo-González, "First Insights into Photocatalytic Degradation of HDPE and LDPE Microplastics by a Mesoporous N–TiO2 Coating: Effect of Size and Shape of Microplastics," Coatings, vol. 10, no. 7, p. 658, 2020. [Online]. Available: https://www.mdpi.com/2079-6412/10/7/658. [CrossRef]

- B. Ramasubramanian, J. Tan, V. Chellappan, and S. Ramakrishna, "Recent Advances in Extended Producer Responsibility Initiatives for Plastic Waste Management in Germany and UK," Materials Circular Economy, vol. 5, no. 1, 2023. [CrossRef]

- U. S. D. o. Energy. "Hydrogen Laws and Incentives in Federal." (accessed.

- T. Uekert, M. A. Bajada, T. Schubert, C. M. Pichler, and E. Reisner, "Scalable Photocatalyst Panels for Photoreforming of Plastic, Biomass and Mixed Waste in Flow," (in eng), ChemSusChem, vol. 14, no. 19, pp. 4190-4197, Oct 5 2021. [CrossRef]

- J. Ran, A. Talebian-Kiakalaieh, S. Zhang, E. M. Hashem, M. Guo, and S. Z. Qiao, "Recent advancement on photocatalytic plastic upcycling," Chem Sci, vol. 15, no. 5, pp. 1611-1637, Jan 31 2024. [CrossRef]

- T. K. A. Nguyen et al., "Understanding Structure-Activity Relationship in Pt-loaded g-C(3) N(4) for Efficient Solar- Photoreforming of Polyethylene Terephthalate Plastic and Hydrogen Production," (in eng), Small Methods, vol. 8, no. 2, p. e2300427, Feb 2024. [CrossRef]

- R. Wei et al., "Photocatalytic Upgrading of Plastic Waste into High-Value-Added Chemicals and Fuels: Advances and Perspectives," ACS Sustainable Chemistry & Engineering, vol. 13, no. 7, pp. 2615-2632, 2025/02/24 2025. [CrossRef]

- J. M. Carceller, K. S. Arias, M. J. Climent, S. Iborra, and A. Corma, "One-pot chemo- and photo-enzymatic linear cascade processes," Chem Soc Rev, vol. 53, no. 15, pp. 7875-7938, Jul 29 2024. [CrossRef]

- M. Daboczi, "Virtually free clean hydrogen generation by photoelectrochemical devices?," Matter, vol. 6, no. 8, pp. 2594-2596, 2023. [CrossRef]

- Q. Li, L.-G. Wang, and J.-B. Wu, "Recent advances in dual-atom catalysts for energy catalysis," Rare Metals, vol. 44, no. 2, pp. 841-867, 2025/02/01 2025. [CrossRef]

- X. Wang et al., "Developing a class of dual atom materials for multifunctional catalytic reactions," Nature Communications, vol. 14, no. 1, p. 7210, 2023/11/08 2023. [CrossRef]

- E. Wang, M. Guo, J. Zhou, and Z. Sun, "Reasonable Design of MXene-Supported Dual-Atom Catalysts with High Catalytic Activity for Hydrogen Evolution and Oxygen Evolution Reaction: A First-Principles Investigation," Materials, vol. 16, no. 4, p. 1457, 2023. [Online]. Available: https://www.mdpi.com/1996-1944/16/4/1457. [CrossRef]

- E. M. N. T. Edirisooriya, P. S. Senanayake, P. Xu, and H. Wang, "Recyclability and regeneration of Au/TiO2 nanocomposite and Pt/TiO2 atom-nano composite catalysts in photo-reforming plastics for hydrogen production," Journal of Environmental Chemical Engineering, vol. 13, no. 3, p. 116467, 2025/06/01/ 2025. [CrossRef]

- M. M. Khan, A. Rahman, and S. N. Matussin, "Recent Progress of Metal-Organic Frameworks and Metal-Organic Frameworks-Based Heterostructures as Photocatalysts," (in eng), Nanomaterials (Basel), vol. 12, no. 16, Aug 17 2022. [CrossRef]

- H. Yang, J. Xu, H. Cao, J. Wu, and D. Zhao, "Recovery of homogeneous photocatalysts by covalent organic framework membranes," Nature Communications, vol. 14, no. 1, p. 2726, 2023/05/11 2023. [CrossRef]

- S. R. Kavanagh, "Accurately Modelling Point Defects in Semiconductors: The Case of CdTe," Doctor of Computational Materials Science, Department of Chemistry (UCL) & Department of Materials (ICL), University College London & Imperial College London, 2024.

- F. Frieden and J. Leker, "Future costs of hydrogen: a quantitative review," Sustainable Energy & Fuels, vol. 8, no. 9, pp. 1806-1822, 2024. [CrossRef]

- T. Ahasan, E. M. N. T. Edirisooriya, P. S. Senanayake, P. Xu, and H. Wang, "Advanced TiO2-Based Photocatalytic Systems for Water Splitting: Comprehensive Review from Fundamentals to Manufacturing," Molecules, vol. 30, no. 5, 2025. [CrossRef]

| Characterization Technique | Key Findings | Advantages | Limitation |

| X-ray Diffraction (XRD) | Determines the crystalline structure and phase composition of catalysts. | Identifies crystalline phases. | Limited to crystalline materials. |

| X-ray Absorption Spectroscopy (XAS) | Probes local electronic and structural environment of specific elements. | Elucidates oxidation states, coordination numbers, and bond distances. | Requires synchrotron radiation sources. |

| Electron Microscopy (SEM and TEM) | Provides high-resolution images of catalyst morphology and nanostructure. | Observes particle size, shape, and dispersion. | Sample preparation can be intricate. |

| Surface Area and Porosity Analysis (BET Method) | Assesses surface area and porosity of catalysts. | Determines the availability of active sites. | Assumes idealized models that may not fit all materials. |

| UV-Vis Diffuse Reflectance Spectroscopy (DRS) | Investigates optical properties and bandgap energies. | Assesses light absorption capabilities. | Interpretation can be challenging for complex materials. |

| Photoluminescence (PL) Spectroscopy | Measures recombination rate of photogenerated electron-hole pairs. | Indicates efficiency of charge separation. | PL signals can be weak and require sensitive detection. |

| Fourier-Transform Infrared (FTIR) Spectroscopy | Identifies functional groups and chemical bonds on catalyst surfaces. | Provides insights into surface modifications and interactions with reactants. | Surface sensitivity can be limited. |

| Raman Spectroscopy | Offers information about molecular vibrations and crystal structures. | Identifies structural defects and phase compositions. | Fluorescence interference can obscure Raman signals. |

| X-ray Photoelectron Spectroscopy (XPS) | Provides information on elemental composition and chemical states of surface elements. | Surface-sensitive technique. | Limited to surface analysis (typically 1–10 nm depth). |

| Mass Spectrometry (MS) | Analyze reaction intermediates and products. | Offers insights into catalytic processes and efficiency. | Requires coupling with other techniques for comprehensive analysis. |

| Cost Factor | Key Points |

| Catalyst Synthesis | - Noble metals improve H2 yield; however, the materials are costly - Even base-metal systems (Ni, Fe) have synthesis costs - Earth-abundant alternatives (g-C3N4 mineral oxides) under study - Catalyst longevity helps spread the cost - Some metal-free systems show multi-day stability |

| Photoreactor Setup | - Light delivery requires transparent materials, large surface areas - Commercial setups: panels, troughs, floating systems - High capital cost due to quartz/glass, mirrors, CPCs - The modular scale-up appears feasible (2 mL → 120 mL) - Full-scale systems need thousands of liters, adding complexity |

| Operational Costs | - Low cost under sunlight, minimal energy input - Operational needs: pumping, stirring, catalyst replacement - Artificial light (UV/LED) increases cost dramatically - Conventional steps (shredding, washing) are low cost - Advanced pretreatments (plasma, enzymes) raise OPEX |

| Feedstock Pretreatment | - NaOH/KOH hydrolysis is common but adds chemical cost - Base recovery adds complexity - Enzymatic routes are mild but expensive - LCOH ~ $50.70/kg H2 (base pretreatment) - Cost reduction is possible via cheaper methods or active catalysts |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).